Probabilistic Analysis of Mechanical Properties and Dimensional Stability of Bamboo Scrimber

Abstract

1. Introduction

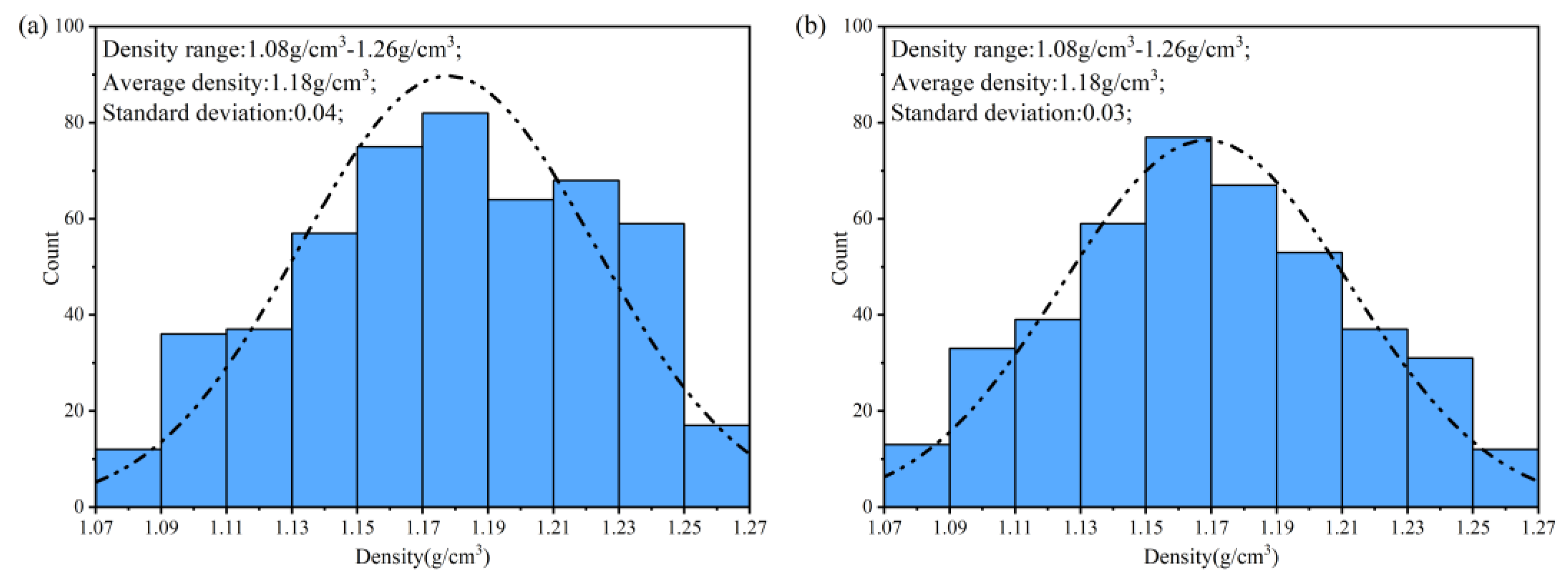

2. Materials and Methods

2.1. Materials

2.2. Pretreatment of OBFM

2.3. Preparation of Bamboo Scrimber

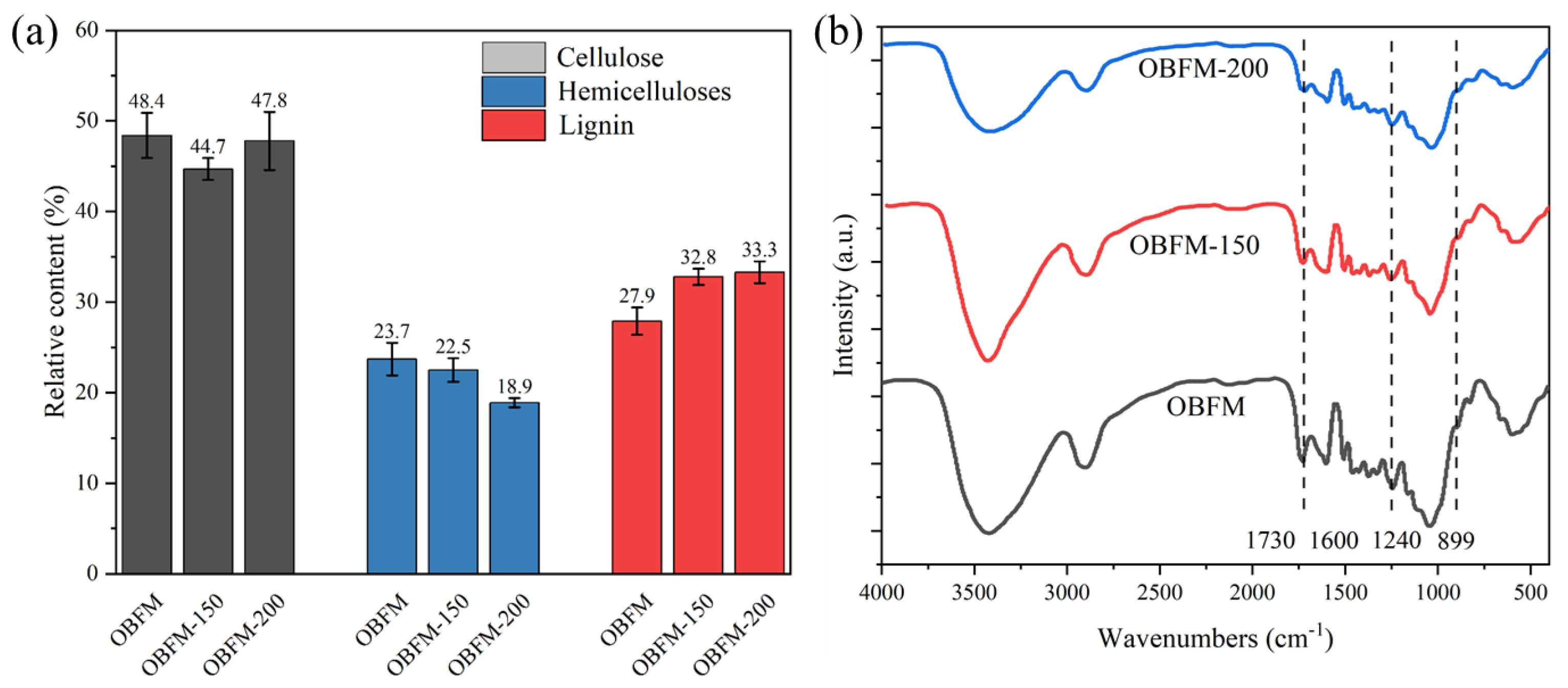

2.4. Chemical Compositions

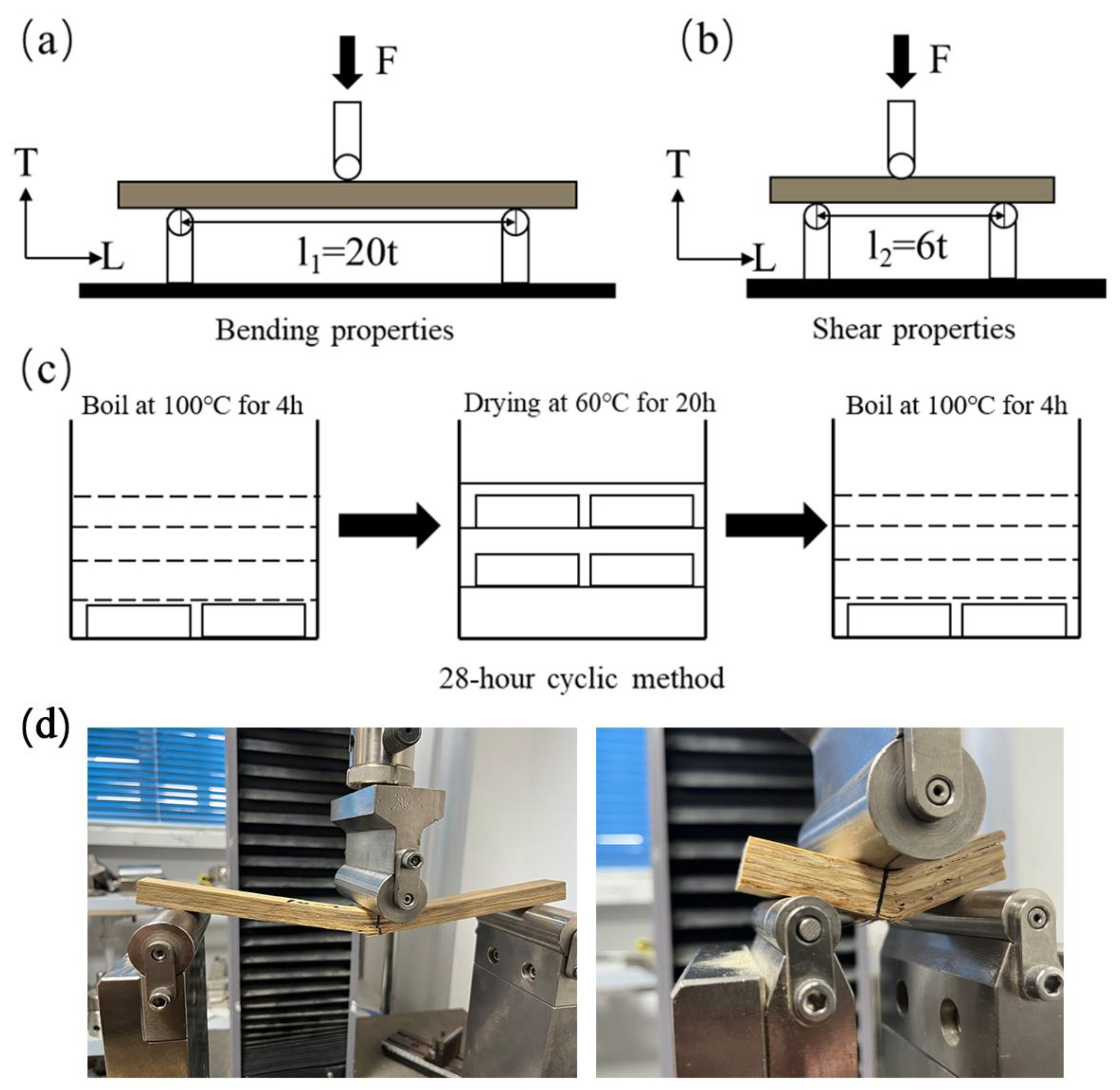

2.5. Mechanical Properties and Dimensional Stability Test

2.6. Probabilistic Analysis

3. Results and Discussion

3.1. Chemical Composition

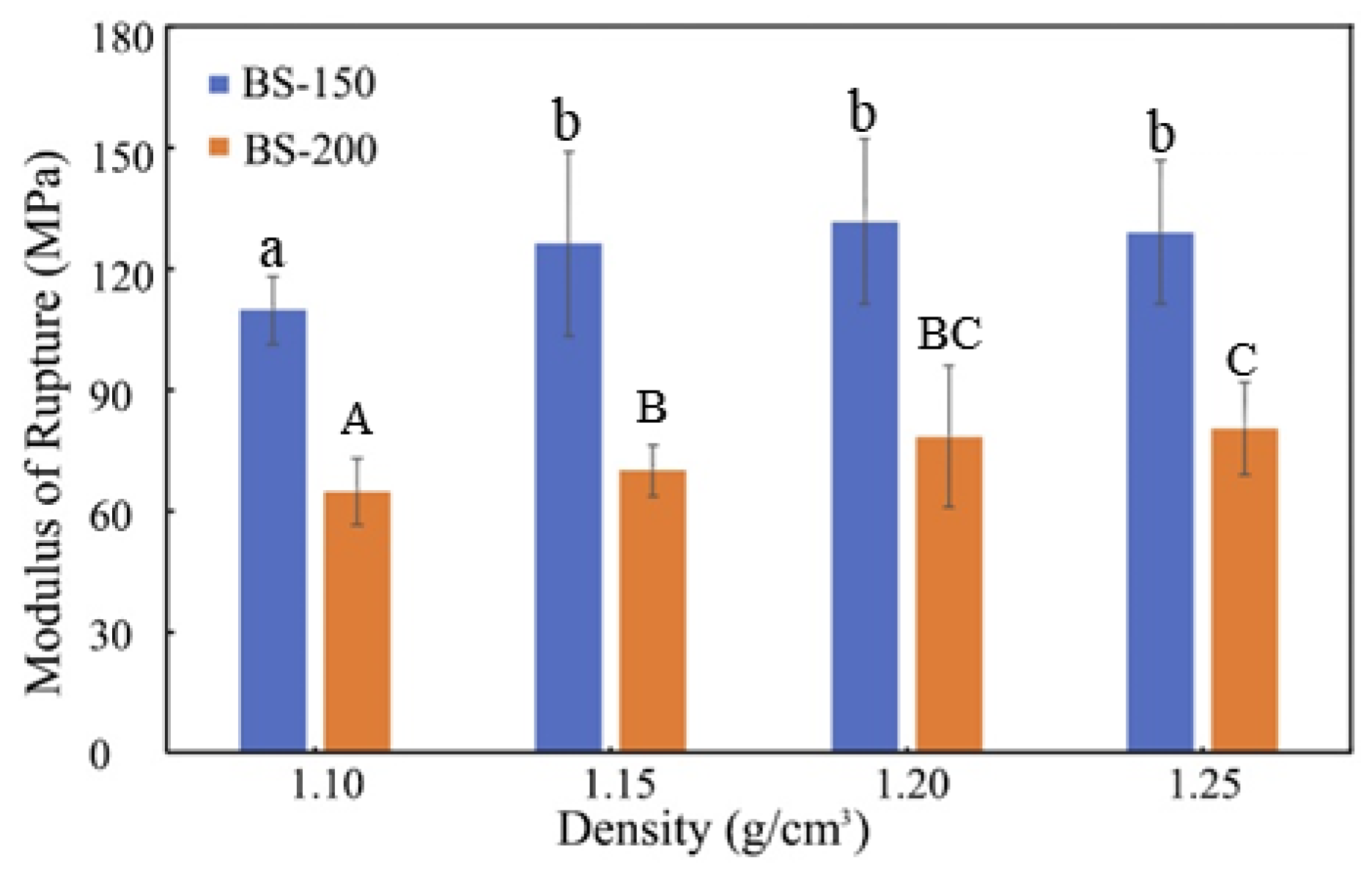

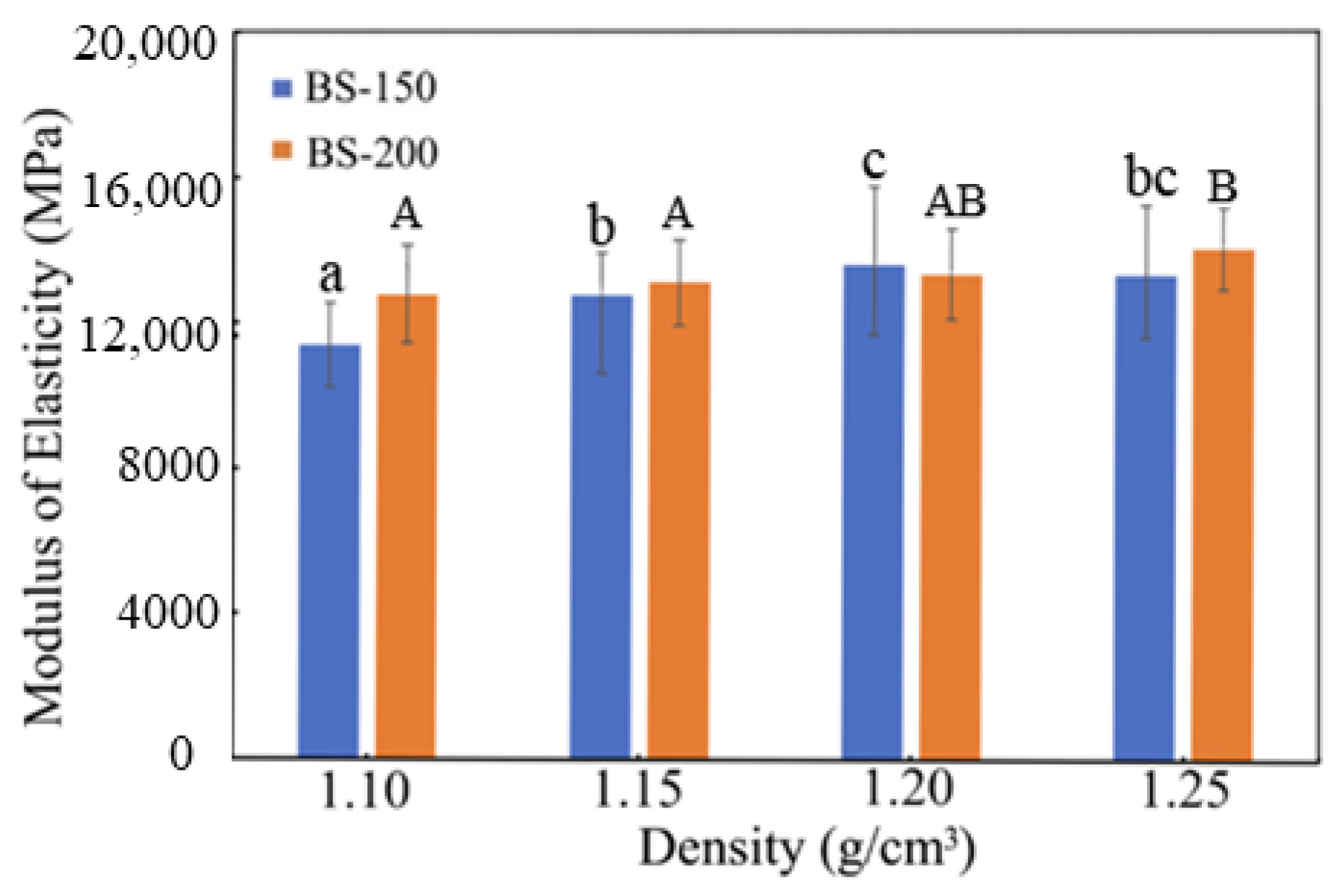

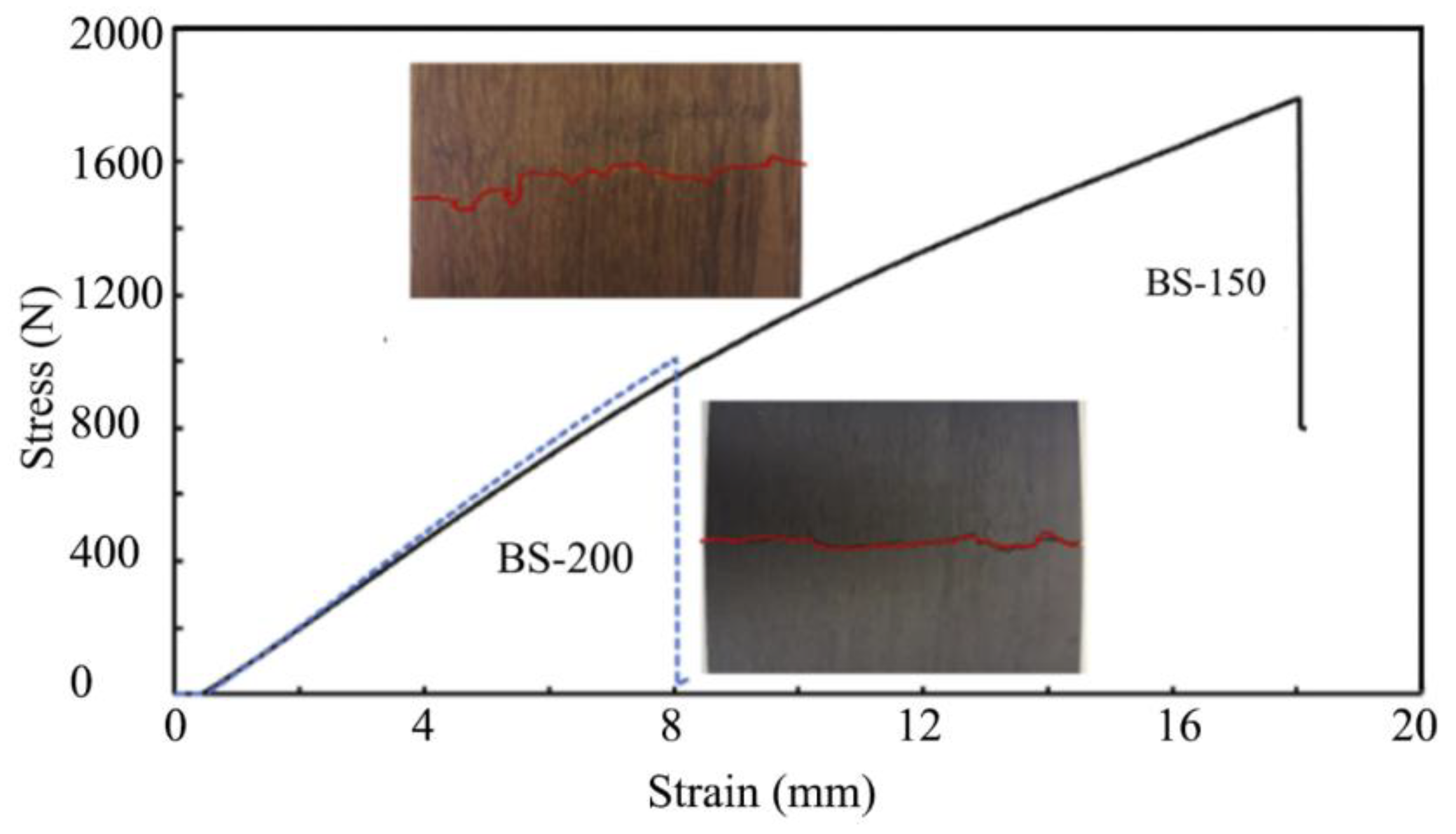

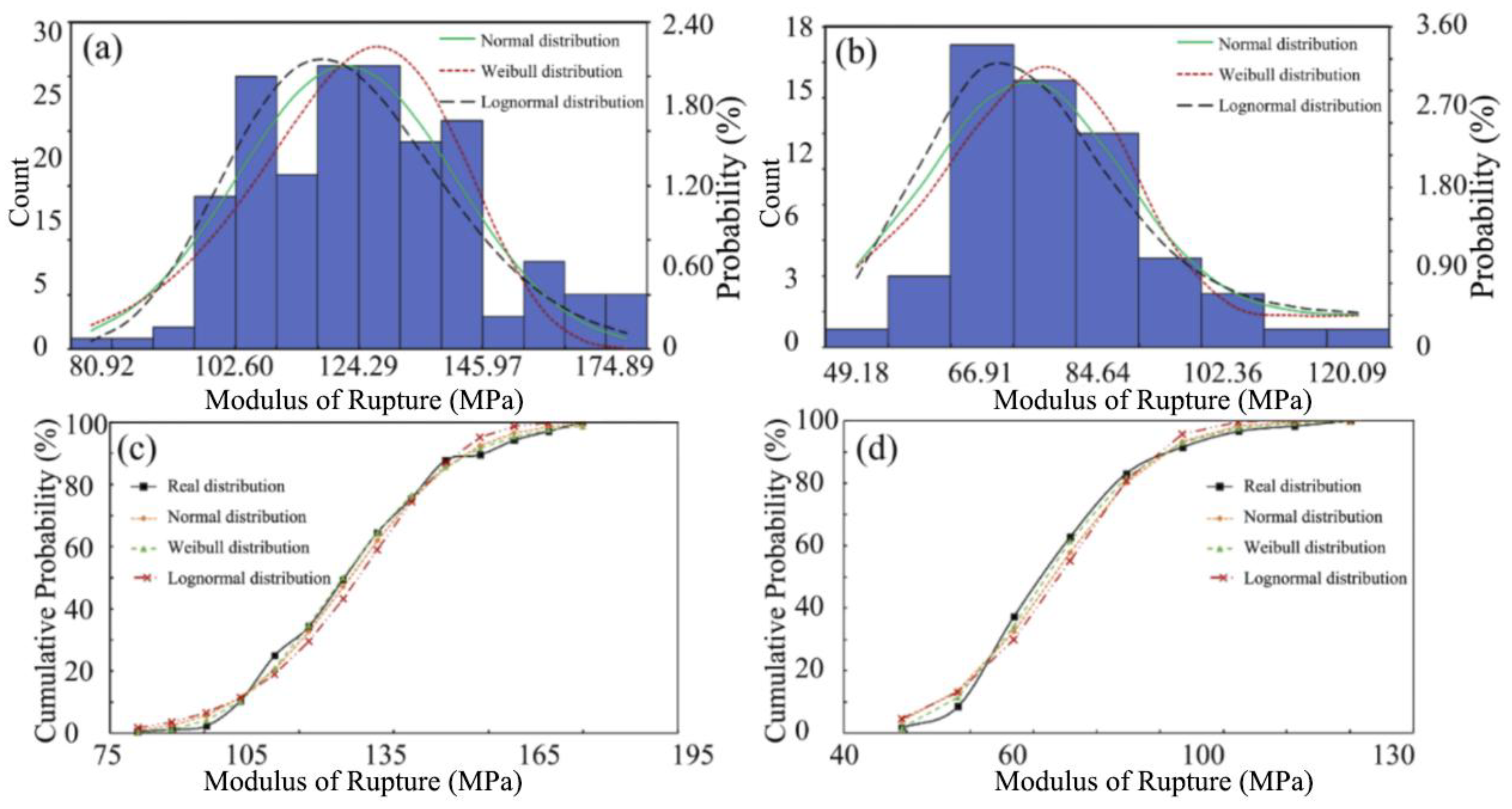

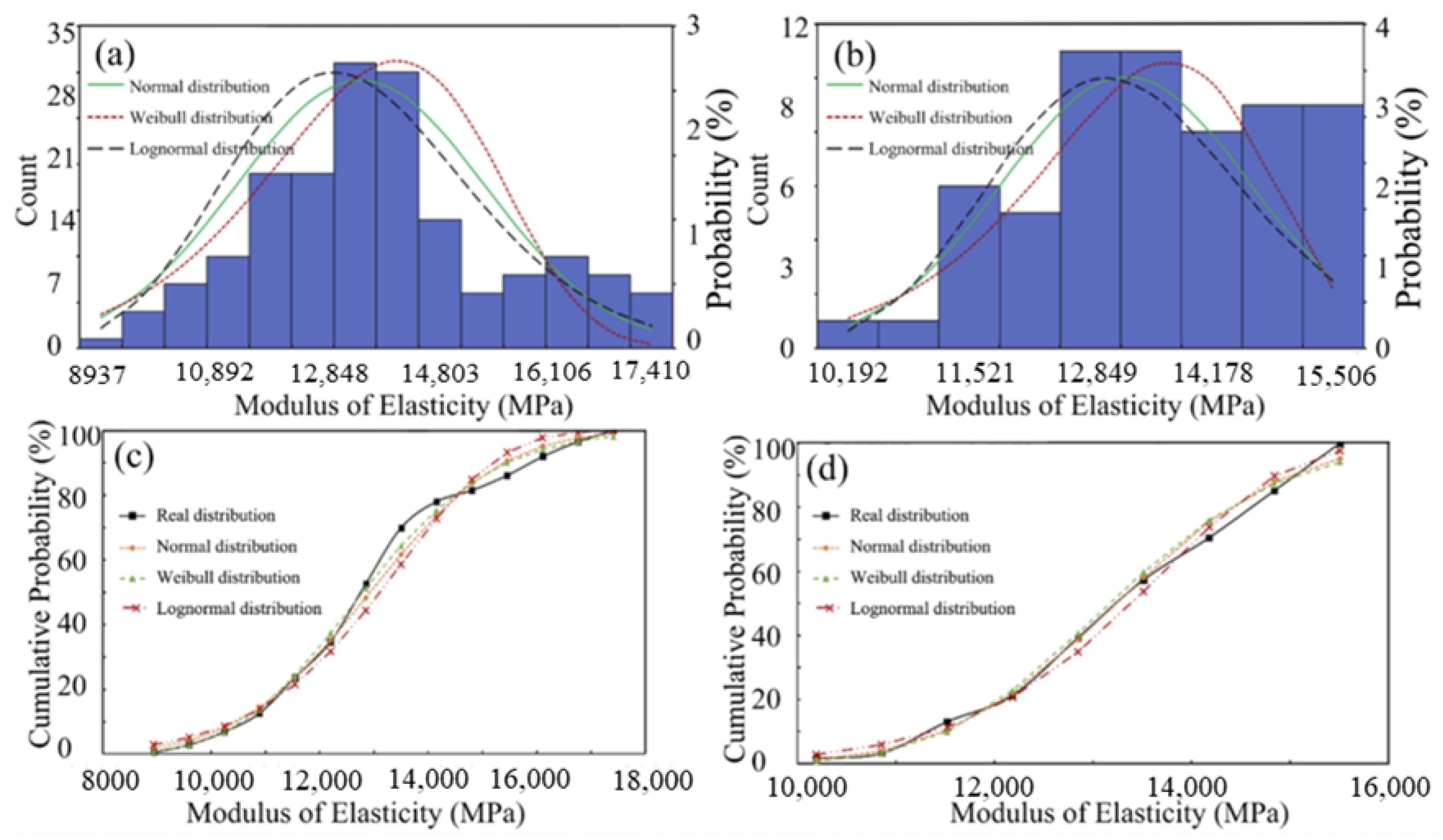

3.2. Bending Properties

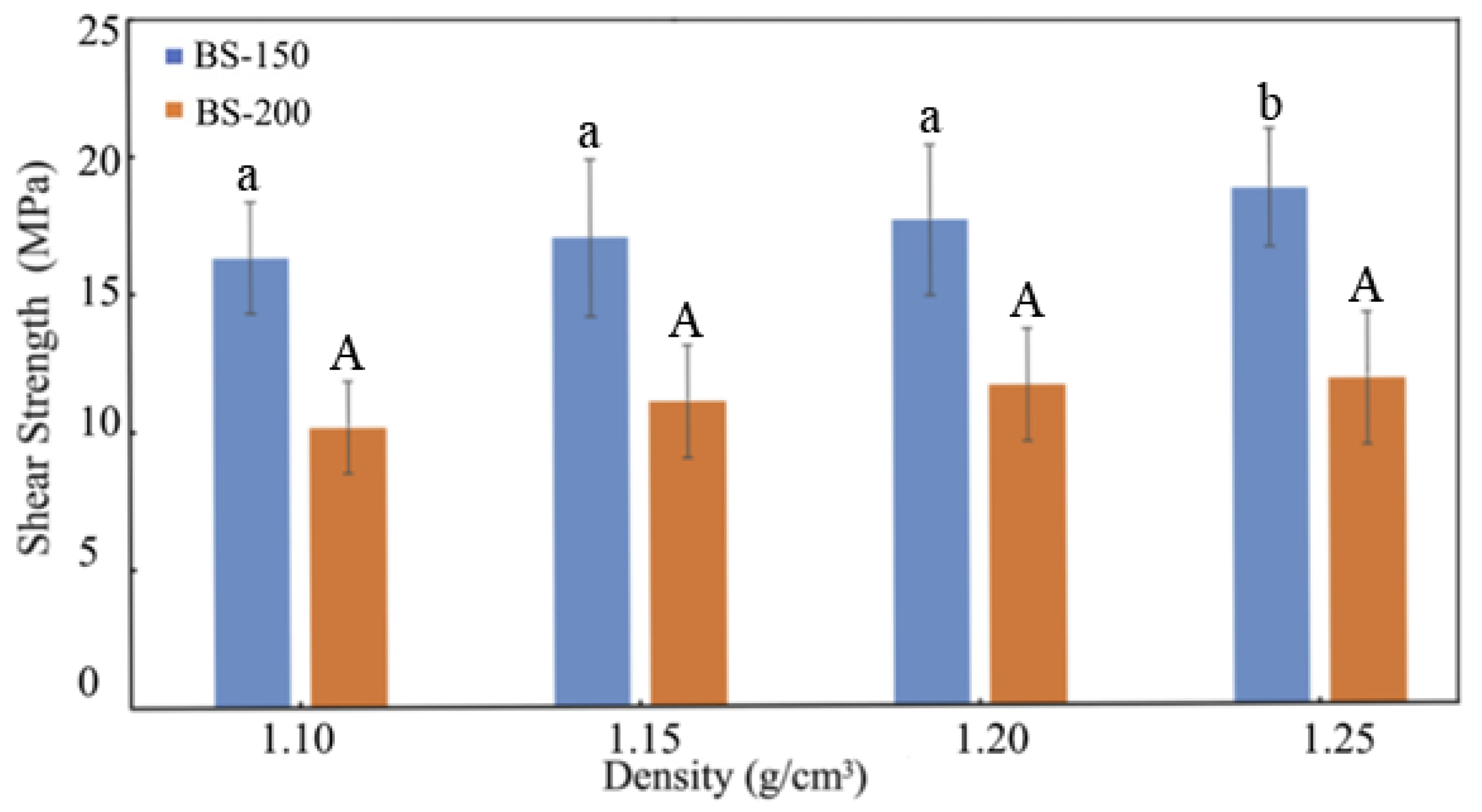

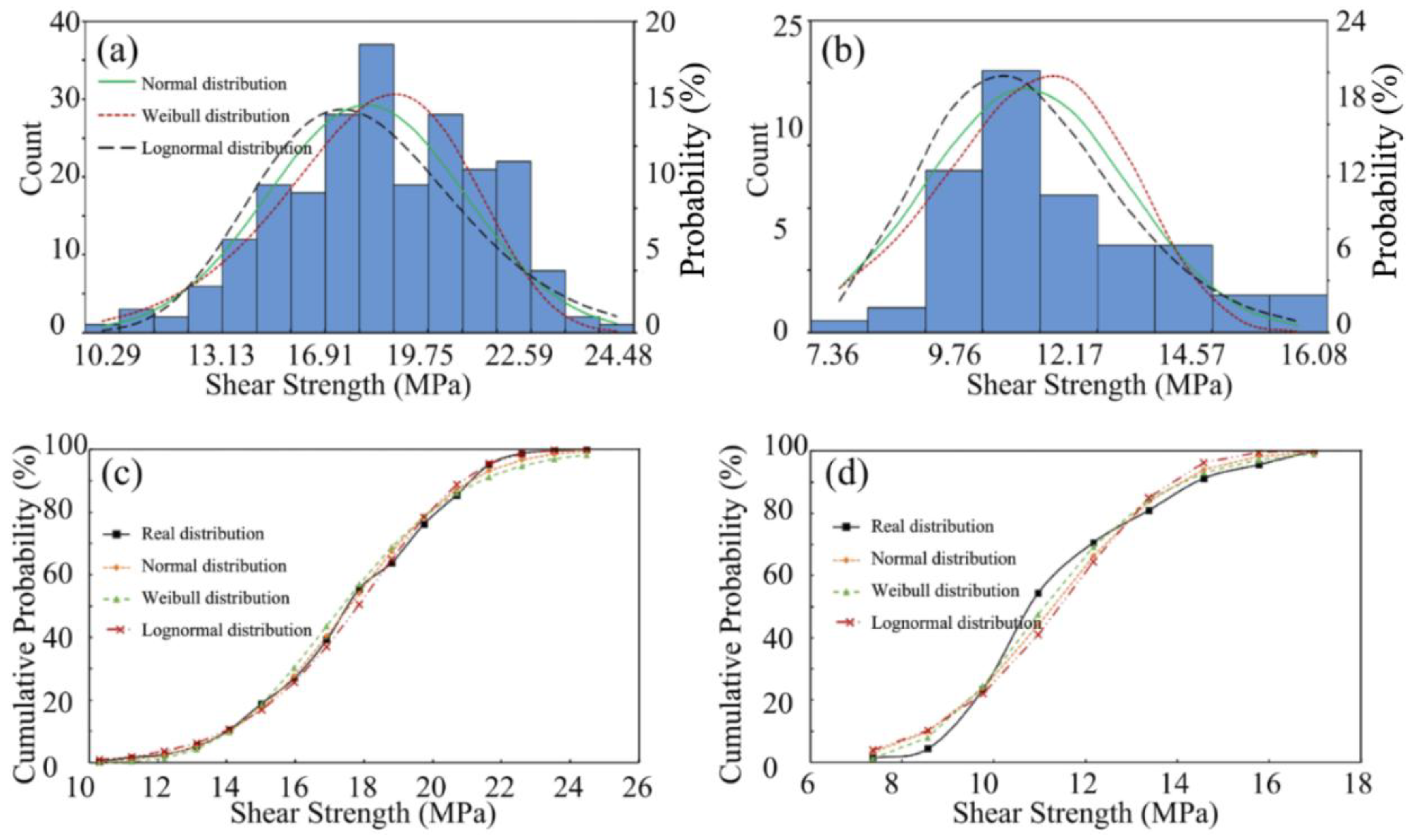

3.3. Shear Strength

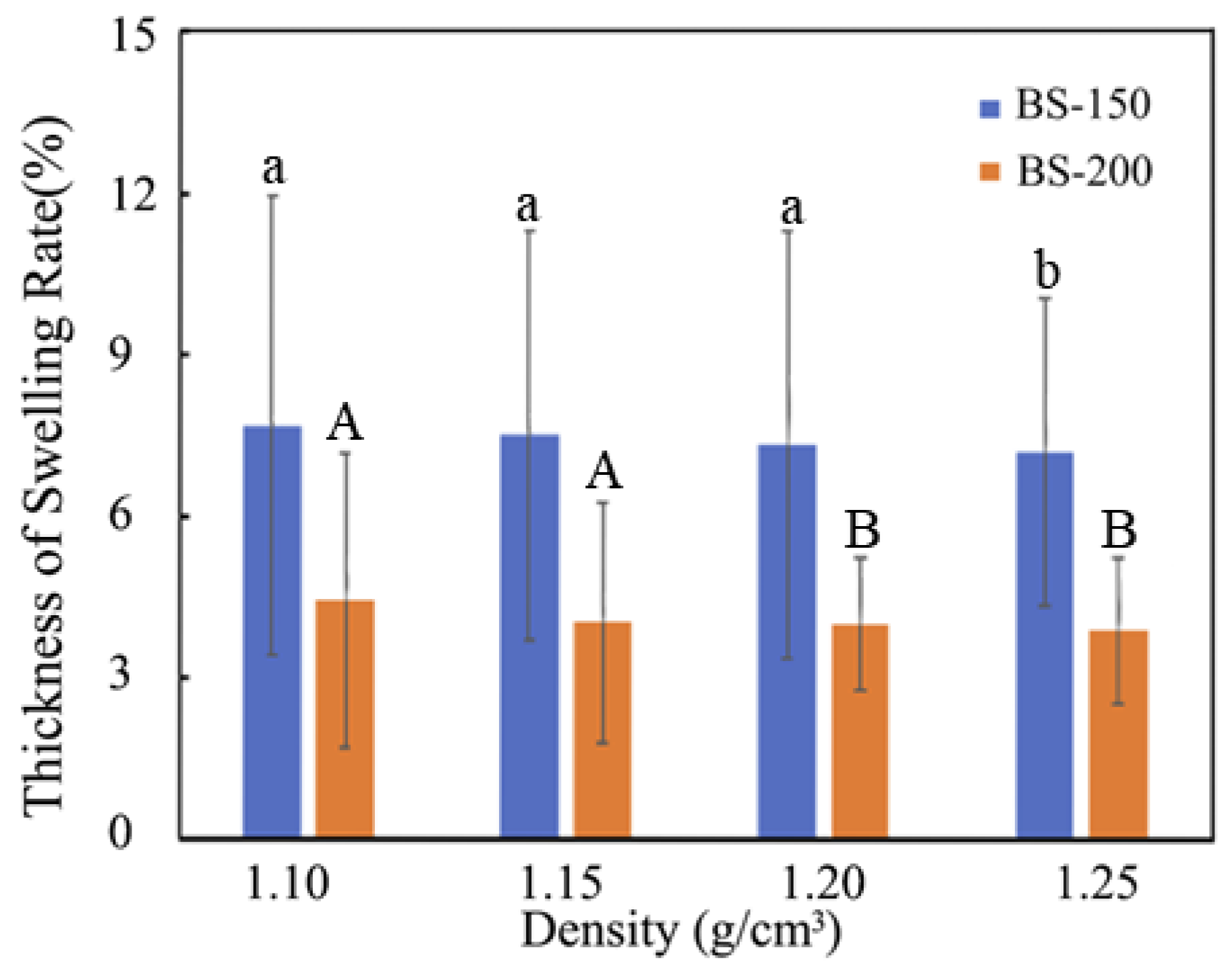

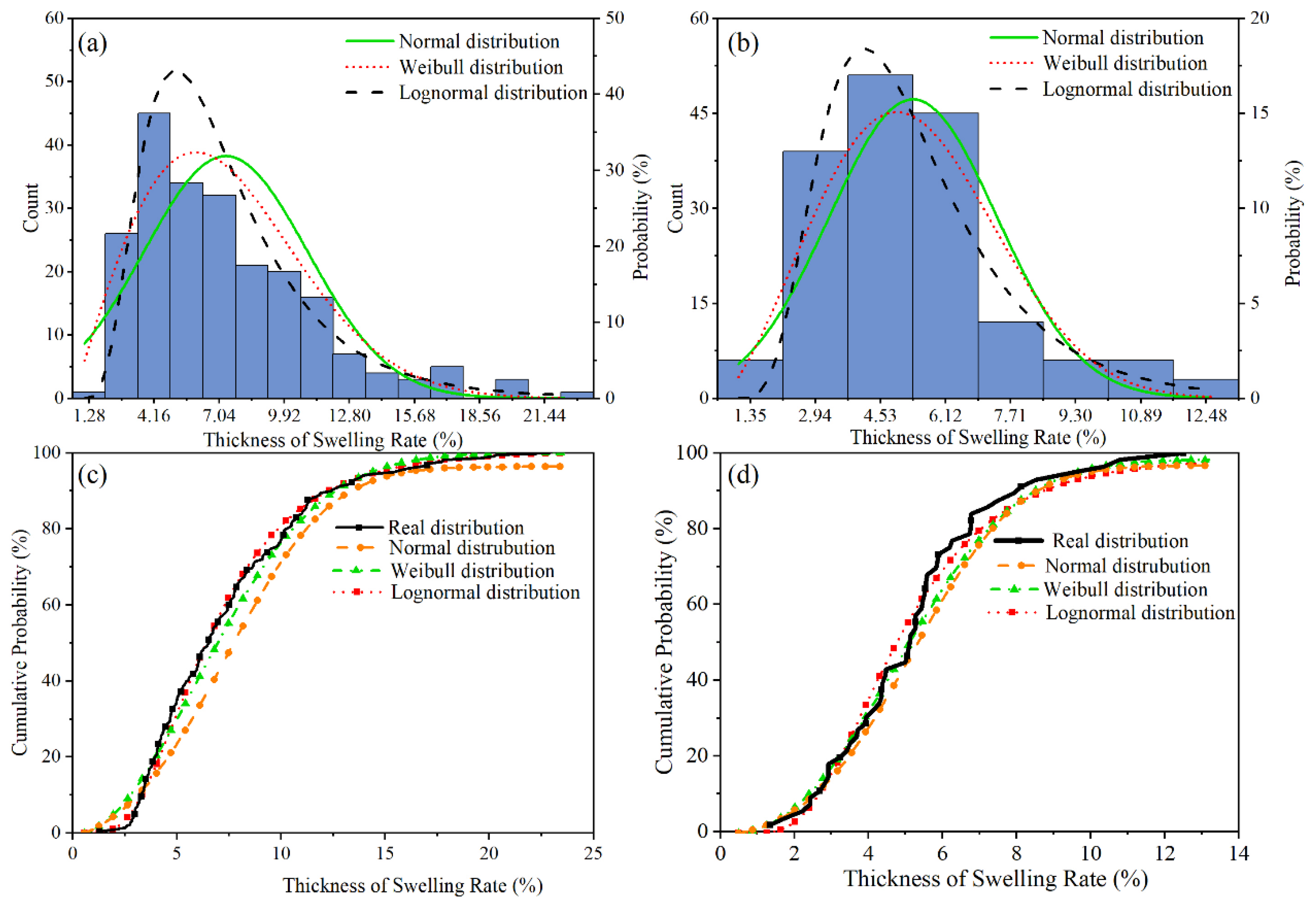

3.4. Dimensional Stability

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Hamilton, I.; Kennard, H.; Rapf, O.; Amorocho, J.; Steuwer, S.; Kockat, J.; Toth, Z. 2023 Global Status Report for Buildings and Construction: Beyond Foundations—Mainstreaming Sustainable Solutions to Cut Emissions from the Buildings Sector; United Nations Environment Programme: Washington, DC, USA, 2024; ISBN 9789280741315. [Google Scholar]

- Huang, Y.; Jiang, K.; He, Y.; Hu, J.; Dyer, K.; Chen, S.; Akinlabi, E.; Zhang, D.; Zhang, X.; Yu, Y.; et al. A Natural Lignification Inspired Super-Hard Wood-Based Composites with Extreme Resilience. Adv. Mater. 2025, 37, e2502266. [Google Scholar] [CrossRef] [PubMed]

- Gao, Q.; Gan, J.; Wang, P.; Huang, Y.; Zhang, D.; Yu, W. Bio-Inspired Hierarchical Bamboo-Based Air Filters for Efficient Removal of Particulate Matter and Toxic Gases. Exploration 2024, 5, 20240012. [Google Scholar] [CrossRef] [PubMed]

- Li, Z.; Chen, C.; Xie, H.; Yao, Y.; Zhang, X.; Brozena, A.; Li, J.; Ding, Y.; Zhao, X.; Hong, M.; et al. Sustainable High-Strength Macrofibres Extracted from Natural Bamboo. Nat. Sustain. 2022, 5, 235–244. [Google Scholar] [CrossRef]

- Shu, B.; Xiao, Z.; Hong, L.; Zhang, S.; Li, C.; Fu, N.; Nan, X. Review on the Application of Bamboo-Based Materials in Construction Engineering. J. Renew. Mater. 2020, 8, 1215–1242. [Google Scholar] [CrossRef]

- Sharma, B.; Gatoo, A.; Bock, M.; Mulligan, H.; Ramage, M. Engineered Bamboo: State of the Art. Proc. Inst. Civ. Eng-Co. 2015, 168, 56–67. [Google Scholar] [CrossRef]

- Gu, L.; Zhou, Y.; Mei, T.; Zhou, G.; Xu, L. Carbon Footprint Analysis of Bamboo Scrimber Flooring—Implications for Carbon Sequestration of Bamboo Forests and Its Products. Forests 2019, 10, 51. [Google Scholar] [CrossRef]

- Kumar, A.; Vlach, T.; Laiblova, L.; Hrouda, M.; Kasal, B.; Tywoniak, J.; Hajek, P. Engineered Bamboo Scrimber: Influence of Density on the Mechanical and Water Absorption Properties. Constr. Build. Mater. 2016, 127, 815–827. [Google Scholar] [CrossRef]

- Zhu, J.; Tan, Y.; Chen, K.; Peng, H.; Li, Z.; Jiang, J.; Lyu, J.; Zhan, T. Evaluation of Transverse Shrinking and Swelling of Bamboo Using Digital Image Correlation Technique. Ind. Crops Prod. 2024, 211, 118274. [Google Scholar] [CrossRef]

- Wang, Y.; Zhang, R.; Kong, L.; Che, H.; Peng, Y.; Cao, J. Bamboo Durability: Understanding the Combined Effect of Weathering and Mildew Infection. Ind. Crops Prod. 2024, 222, 119612. [Google Scholar] [CrossRef]

- Zhao, X.; Zhang, S.; Zhang, M.; Zhang, Z.; Zhou, M.; Cao, J. Antifungal Performance and Mechanisms of Carbon Quantum Dots in Cellulosic Materials. ACS Nano 2025, 19, 14121–14136. [Google Scholar] [CrossRef]

- Gao, Y.; Fu, Z.; Fu, F.; Zhou, Y.; Gao, X.; Zhou, F. The Formation Mechanism of Microcracks and Fracture Morphology of Wood during Drying. Dry. Technol. 2023, 41, 1268–1277. [Google Scholar] [CrossRef]

- Li, X.; Ji, S.; Li, T.; Liu, Z.; Hao, X.; Chen, Z.; Zhong, Y.; Li, X. The physical, mechanical and fire performance of bamboo scrimber processed with thermal-treated bamboo bundles. Ind. Crop. Prod. 2023, 205, 117549. [Google Scholar] [CrossRef]

- Shangguan, W.; Gong, Y.; Zhao, R.; Ren, H. Effects of Heat Treatment on the Properties of Bamboo Scrimber. J. Wood Sci. 2016, 62, 383–391. [Google Scholar] [CrossRef]

- Yuan, Z.; Wu, X.; Wang, X.; Zhang, X.; Yuan, T.; Liu, X.; Li, Y. Effects of One-Step Hot Oil Treatment on the Physical, Mechanical, and Surface Properties of Bamboo Scrimber. Molecules 2020, 25, 4488. [Google Scholar] [CrossRef]

- Lee, C.-H.; Yang, T.-H.; Cheng, Y.-W.; Lee, C.-J. Effects of Thermal Modification on the Surface and Chemical Properties of Moso Bamboo. Constr. Build. Mater. 2018, 178, 59–71. [Google Scholar] [CrossRef]

- Kamperidou, V. Chemical and structural characterization of poplar and black pine wood exposed to short thermal modification. Drv. Ind. 2021, 72, 155–167. [Google Scholar] [CrossRef]

- Feng, Q.M.; Huang, Y.H.; Ye, C.Y.; Fei, B.H.; Yang, S.M. Impact of hygrothermal treatment on the physical properties and chemical composition of Moso bamboo (Phyllostachys edulis). Holzforschung 2021, 75, 614–625. [Google Scholar] [CrossRef]

- Lalaymia, I.; Belaadi, A.; Boumaaza, M.; Alshahrani, H.; Khan, M.K.A.; Dib, A. Weibull Statistic and Artificial Neural Network Analysis of the Mechanical Performances of Fibers from the Flower Agave Plant for Eco-Friendly Green Composites. J. Nat. Fibers 2024, 21, 2305228. [Google Scholar] [CrossRef]

- Lekou, D.J.; Philippidis, T.P. Mechanical Property Variability in FRP Laminates and Its Effect on Failure Prediction. Compos. Part B Eng. 2008, 39, 1247–1256. [Google Scholar] [CrossRef]

- Hasilová, K.; Vališ, D. Composite Laminates Reliability Assessment Using Diffusion Process Backed up by Perspective Forms of Non-Parametric Kernel Estimators. Eng. Fail. Anal. 2022, 138, 106326. [Google Scholar] [CrossRef]

- Yang, H.; Qiao, P.; Wolcott, M.P. Fatigue Characterization and Reliability Analysis of Wood Flour Filled Polypropylene Composites. Polym. Compos. 2010, 31, 553–560. [Google Scholar] [CrossRef]

- Guan, S.; Zong, X.; Zhao, J.; Tian, L.; Wang, S.; Wang, Z.; Ai, Y.; Zhang, S.; Zhao, H. Effects of Thermal Treatment and Hot Pressing on Internal Pores, Micro- and Macro-Mechanical Properties of Bamboo Scrimber. Constr. Build. Mater. 2025, 458, 139461. [Google Scholar] [CrossRef]

- Schmidt, G.; Stute, T.; Lenz, M.T.; Melcher, E.; Ressel, J.B. Fungal Deterioration of a Novel Scrimber Composite Made from Industrially Heat Treated African Highland Bamboo. Ind. Crops Prod. 2020, 147, 112225. [Google Scholar] [CrossRef]

- Wang, Y.; Huang, Y.; Xue, J.; Peng, Y.; Cao, J. Effects of heat treatment temperatures on the photostability of Moso bamboo during accelerated UV weathering. Wood Mat. Sci. Eng. 2022, 17, 823–833. [Google Scholar] [CrossRef]

- Van Soest, P.J. Development of a Comprehensive System of Feed Analyses and its Application to Forages. J. Anim. Sci. 1967, 26, 119–128. [Google Scholar] [CrossRef]

- GB/T 17657-2022; Test Methods of Evaluating the Properties of Wood-Based Panels and Surface Decorated Wood-Based Panels. National Standardization Administration: Beijing, China, 2022.

- Qi, Y.; Jiang, B.; Lei, W.; Zhang, Y.; Yu, W. Reliability Analysis of Normal, Lognormal, and Weibull Distributions on Mechanical Behavior of Wood Scrimber. Forests 2024, 15, 1674. [Google Scholar] [CrossRef]

- Wu, J.; Zhong, T.; Zhang, W.; Shi, J.; Fei, B.; Chen, H. Comparison of Colors, Microstructure, Chemical Composition and Thermal Properties of Bamboo Fibers and Parenchyma Cells with Heat Treatment. J. Wood Sci. 2021, 67, 56. [Google Scholar] [CrossRef]

- Meng, F.; Yu, Y.; Zhang, Y.; Yu, W.; Gao, J. Surface Chemical Composition Analysis of Heat-Treated Bamboo. App. Surf. Sci. 2016, 371, 383–390. [Google Scholar] [CrossRef]

- Hill, C.; Altgen, M.; Rautkari, L. Thermal Modification of Wood—A Review: Chemical Changes and Hygroscopicity. J. Mater. Sci. 2021, 56, 6581–6614. [Google Scholar] [CrossRef]

- Li, X.L.; Wei, Y.Z.; Xu, J.; Xu, N.; He, Y. Quantitative Visualization of Lignocellulose Components in Transverse Sections of Moso Bamboo Based on FTIR Macro- and Micro-spectroscopy Soupled with Chemometrics. Biotechnol. Biofuels 2018, 11, 263. [Google Scholar] [CrossRef]

- Esteves, B.; Videira, R.; Pereira, H. Chemistry and Eecotoxicity of Heat-Treated Ppine Wood Extractives. Wood Sci. Technol. 2011, 45, 661–676. [Google Scholar] [CrossRef]

- Li, M.; Cheng, S.; Li, D.; Wang, S.; Huang, A.; Sun, S. Structural Characterization of steam-heat treated Tectona grandis wood analyzed by FT-IR and 2D-IR correlation spectroscopy. Chinese Chem. Lett. 2015, 26, 221–225. [Google Scholar] [CrossRef]

- Sikora, A.; Kačík, F.; Gaff, M.; Vondrová, V.; Bubeníková, T.; Kubovský, I. Impact of Thermal Modification on Color and Chemical Changes of Spruce and Oak Wood. J. Wood Sci. 2018, 64, 406–416. [Google Scholar] [CrossRef]

- Xie, J.; Qi, J.; Hu, T.; De Hoop, C.; Hse, Y.C.; Shupe, T. Effect of Fabricated Density and Bamboo Species on Physical–Mechanical Properties of Bamboo Fiber Bundle Reinforced Composites. J. Mater. Sci. 2016, 51, 7480–7490. [Google Scholar] [CrossRef]

- Phuong, L.; Shida, S.; Saito, Y. Effects of Heat Treatment on Brittleness of Styrax tonkinensis Wood. J. Wood Sci. 2007, 53, 181–186. [Google Scholar] [CrossRef]

- Ringman, R.; Pilgård, A.; Kölle, M.; Brischke, C.; Richter, K. Effects of Thermal Modification on Postia Placenta Wood Degradation Dynamics: Measurements of Mass Loss, Structural Integrity and Gene Expression. Wood Sci. Technol. 2016, 50, 385–397. [Google Scholar] [CrossRef]

- Azadeh, A.; Quiroga Flores, A.; Ghavami, K.; Barbosa, N.P.; Tolêdo Filho, R.D.; Savastano Junior, H. An Investigation of Bamboo Shear Test Methods and the Influence of Heat on Bamboo Shear Strength. Constr. Build. Mater. 2023, 399, 132586. [Google Scholar] [CrossRef]

- Guo, F.; Zhang, X.; Yang, R.; Salmén, L.; Yu, Y. Hygroscopicity, Degradation and Thermal Stability of Isolated Bamboo Fibers and Parenchyma Cells upon Moderate Heat Treatment. Cellulose 2021, 28, 8867–8876. [Google Scholar] [CrossRef]

- Wang, X.; Yao, Y.; Xie, X.; Yuan, Z.; Li, W.; Yuan, T.; Huang, Y.; Li, Y. Investigation of the Microstructure, Chemical Structure, and Bonding Interfacial Properties of Thermal-Treated Bamboo. Int. J. Adhes. Adhes. 2023, 125, 103400. [Google Scholar] [CrossRef]

- Olek, W.; Majka, J.; Czajkowski, Ł. Sorption Isotherms of Thermally Modified Wood. Holzforschung 2013, 67, 183–191. [Google Scholar] [CrossRef]

- Shinde, S.D.; Meng, X.; Kumar, R.; Ragauskas, A.J. Recent Advances in Understanding the Pseudo-Lignin Formation in a Lignocellulosic Biorefinery. Green Chem. 2018, 20, 2192–2205. [Google Scholar] [CrossRef]

| Time (h) | Dry Bulb Temperature (°C) | Oxygen Content (%) |

|---|---|---|

| 0.5 | 60 | 21 |

| 0.5 | 90 | 15 |

| 1 | 120 | 15 |

| 5 | 150 | 2 |

| 1 | 100 | 15 |

| Time (h) | Dry Bulb Temperature (°C) | Oxygen Content (%) |

|---|---|---|

| 0.5 | 80 | 15 |

| 0.5 | 120 | 15 |

| 0.5 | 150 | 2 |

| 0.5 | 180 | 2 |

| 5 | 200 | 2 |

| 1 | 100 | 15 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lei, W.; Zhou, C.; Zhu, Y.; Wang, S.; Xia, Y.; Yang, Y.; Zhang, Y.; Zhang, S.; Yu, W. Probabilistic Analysis of Mechanical Properties and Dimensional Stability of Bamboo Scrimber. Forests 2025, 16, 916. https://doi.org/10.3390/f16060916

Lei W, Zhou C, Zhu Y, Wang S, Xia Y, Yang Y, Zhang Y, Zhang S, Yu W. Probabilistic Analysis of Mechanical Properties and Dimensional Stability of Bamboo Scrimber. Forests. 2025; 16(6):916. https://doi.org/10.3390/f16060916

Chicago/Turabian StyleLei, Wencheng, Changping Zhou, Yulan Zhu, Sidong Wang, Yao Xia, Yuxin Yang, Yahui Zhang, Shaodi Zhang, and Wenji Yu. 2025. "Probabilistic Analysis of Mechanical Properties and Dimensional Stability of Bamboo Scrimber" Forests 16, no. 6: 916. https://doi.org/10.3390/f16060916

APA StyleLei, W., Zhou, C., Zhu, Y., Wang, S., Xia, Y., Yang, Y., Zhang, Y., Zhang, S., & Yu, W. (2025). Probabilistic Analysis of Mechanical Properties and Dimensional Stability of Bamboo Scrimber. Forests, 16(6), 916. https://doi.org/10.3390/f16060916