Abstract

The aim of this study was to evaluate the suitability of eight softwood species most commonly used by Greek timber industries, including furniture manufacturers and companies producing roundwood, sawn timber, and plywood. The analysis was based on integrated Multi-Criteria Decision Analysis (MCDA), using a combined approach of the PROMETHEE method and the Analytical Hierarchy Process (AHP), taking into consideration some important criteria that affect timber quality. According to the PROMETHEE complete ranking, Aleppo pine (Pinus halepensis Mill.) achieved the best performance under the selected criteria among the examined softwood species, underlying the importance of Aleppo pine to the Greek timber industry. Our findings could be highly beneficial to the wood industry, promoting the recovery and advancement of the forest sector in general, taking into account that sustainable wood supply is lower than the total biomass available in Europe. Policymakers should prioritize the selection of conifer tree species that can strengthen Greece’s forestry sector, promote sustainable management practices, and increase the economic value derived from the country’s diverse forest resources.

Keywords:

timber industry; wood production; PROMETHEE; AHP; sustainable forest management; softwoods 1. Introduction

Mediterranean areas are highly susceptible to species reduction because of the frequent and extensive periods of drought [1]. The forests of Southern Europe suffer from long dry periods and other climatic factors that affect their viability and existence [2,3]. On the other hand, the economic importance of trees has been widely highlighted, with timber being at the core of this importance. Timber trees are used for many purposes, such as furniture, boat and shipbuilding, carts and carriages, barrel making, matches and matchboxes, musical instruments, boxes, pencils, railway carriage sleepers, toys, etc. [4].

Greece has been characterized as a hotspot for climate change, with an average temperature increase of approximately 0.05 °C per year and a total rise of 1.5 °C over the period from 1991 to 2020 across the entire country. However, there are regional variations in the rate of temperature increase [5]. These climatic changes, particularly during the tree growth season, influence forest growth, wood formation, and ultimately, timber quality. Given these environmental shifts, the forestry sector faces challenges in maintaining high-quality timber production. Nevertheless, the demand for quality wood from consumers remains, except for periods of economic crisis, underlying the need for sustainable forest management strategies that balance climate adaptation with market expectations.

The main concern in Greece is the crucial issue of forest fires, which are expected to be more severe in the future. Forest managers are adapting to climate change by combining practical fuel management with time-tested ecological principles. A study by Mitsopoulos et al. [6] found that professionals working in fir forests see thinning, pruning, and removing leftover branches after logging as the most important ways to reduce fire risk—especially as wildfires become more intense and frequent. These treatments help reshape forest structure, making it more resilient to wild forest fires and improving trees’ ability to withstand drought and insect or pathogen attacks as secondary infestations. Other steps, like clearing dry understory—where applicable—removing dense understory, and encouraging a mix of tree species, were also seen as valuable in making forests more resilient [7,8].

At a broader level of sustainable forest management (SFM), many of these ideas are not new to Greek forestry [9]. For more than seventy years, forest management in Greece has followed ecological silviculture principles that are now very close to modern climate adaptation strategies [10,11]. These include the critical protection of forest resources, the systematic rehabilitation of degraded forests (e.g., conversion of coppices to high forest), the promotion of tree species mixture, the improvement of the horizontal and vertical structure of all forest ecosystems, the exclusive use of species natural regeneration, the application of selective felling prohibiting any clear-cutting, the extensive use of low-impact harvesting practices, the retention of a few old trees for promoting biodiversity, the protection of all rare and endangered flora and fauna species, and finally, the establishment of forest protected areas [9].

Greece’s trade patterns in wood and wood products reflect broader Mediterranean trade dynamics, where imports dominate due to a persistent decline in the availability of certain wood products in short supply [12,13]. The Greek forest sector faces several key challenges, including the natural characteristics of Greek forests, restrictive policies on timber production investments, especially in state-owned industries, a lack of market research, inefficient wood sales procedures, low product quality, high production costs, and periods of economic recession [14]. Expanding domestic production across various product categories and strengthening marketing efforts would gradually reduce reliance on imports, but the country is not there yet [14].

The general decrease in wood supply makes the forest management sustainability assessment process a necessity, even though it is a complex task since it combines multiple environmental and socio-economic management factors to be taken into account for implementation in different forest areas [15].

Even though forest practices that implement short rotation crops to produce wood and somehow reach international demands have been applied over the years, these forest management practices often lead to a decline in both the quality and quantity of wood [16]. It is important to underline here that the term “wood quality” expresses the quality condition of wood in any stage of the production process, from its formation in the forest and its harvesting to the processing, the formation into final products, and its use. More specifically, it refers to desirable features and properties that best meet the requirements of specific uses [17].

Rapid-grown trees usually consist of narrower growth rings, which can affect the overall volume of wood produced. Furthermore, young trees consist of juvenile wood, which has properties that differ from older (mature) wood [18]. Short rotation plantations of conifer species tend to have a negative impact on various quality parameters, such as wood density, lignin content, and mechanical properties. Fertilization has been proven to contribute to the production of high-quality mature wood. Additionally, thinning, pruning, and control of weeds can lead to better productivity. In each case, the correct selection of the site with the appropriate soil constitution and levels of nutrients is crucial for the yield outcome [19,20].

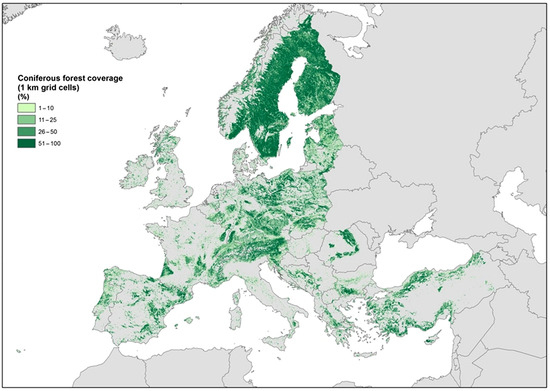

The goal should be to optimize the use of raw materials so as to maximize their value, ensuring efficient processing and high-quality end products. This factor plays a crucial role in the global timber industry, influencing both softwood and hardwood production as well. Focusing primarily on softwood, large-scale conifer plantations, particularly in temperate and boreal regions, often prioritize fast growth to meet high demand. However, this can result in lower wood density and reduced structural quality [18]. As Greece faces challenges related to forest management, softwood plantations can offer a sustainable and efficient solution. Softwood trees, which grow relatively faster, can be managed through short rotation cycles, providing a renewable source of timber. The higher-altitude zones, characterized by cooler temperatures and more consistent precipitation, support the growth of species such as the Greek fir and black pine. In contrast, lower-altitude areas with warmer, drier climates are more suited to species like the Aleppo pine (Figure 1). By focusing on softwood production in these regions, Greece can capitalize on the natural advantages of its vegetation zones, optimizing timber yields while maintaining sustainable forest management practices. Moreover, the distinction between Greece’s vegetation zones underscores the potential for selective management and the targeted planting of specific softwood species, which can enhance both the efficiency of timber production and the quality of forest products. Balancing the trade-offs between growth rate, wood quality, and production efficiency in these regions is essential for sustainable forestry management and the long-term stability of global timber markets [13].

Figure 1.

Conifer forest cover map of Europe [21].

The main aim of the current study was to evaluate the suitability of the softwood species most commonly used by Greek timber industries, including furniture manufacturers and companies producing roundwood, sawn timber, and plywood. The assessment was conducted using a combined Multi-Criteria Decision Analysis (MCDA) approach, considering specific criteria that impact wood quality. The innovation of this study is the application of MCDA methods to the creation of an assessment tool evaluating wood quality for the optimization of wood utilization. Except for two other studies [22,23], which evaluated wood quality of hardwood species based on specific traits with the application of the Preference Ranking Organization Method for Enrichment Evaluation (PROMETHEE) method, no other research is available. The present study combines the Analytical Hierarchy Process (AHP) and the PROMETHEE methods to evaluate the suitability of softwood species to the wood industry. No other relevant papers in the bibliography use an integrated MCDA approach in softwood species.

Multi-Criteria Decision Analysis (MCDA) methods are frequently used in forestry, especially in forest management planning [24]. The Preference Ranking Organization Method for Enrichment Evaluation (PROMETHEE) and the Analytic Hierarchy Process (AHP) are two of the most common MCDA methods, with broad applications in forestry [25]. According to the same authors, AHP is the most utilized method in forest management planning, mainly because of its advantage in pairwise recalibration. In the broader field of forestry, the combination of AHP and PROMETHEE has been used in several cases, e.g., for measuring performance in occupational health and safety in forest fires [26], for the evaluation of sustainable management of forest ecosystems [25], in forest road determination [27], and the mapping of declining lowland forests [28].

Focusing on applications of PROMETHEE in the timber industry, a recent study in Greece examined the suitability of ten common species of hardwood used in the Greek timber industry with the PROMETHEE method analysis, taking into consideration ten selected criteria that affect the wood quality and determine the final uses of timber [22]. Furthermore, a study conducted in the Czech Republic assessed the suitability of four hardwood species for use in construction, employing the PROMETHEE method. The authors considered criteria such as density, elasticity, workability, shrinkage, and bending strength [23].

2. Materials and Methods

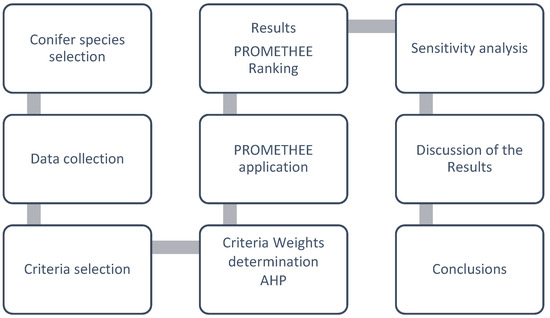

In the present paper, a combined Multi-Criteria Decision Analysis approach was conducted using the Analytical Hierarchy Process (AHP) and the Preference Ranking Organization Method for Enrichment Evaluation (PROMETHEE) to evaluate eight (8) conifer species under nine (9) criteria that affect wood quality. Figure 2 presents the workflow of the paper.

Figure 2.

Visual presentation of the research structure (workflow).

2.1. Analytic Hierarchy Process (AHP)

For the needs of the current research, the Analytical Hierarchy Process (AHP) [29] was properly implemented through a survey-based approach. The AHP is a widely used Multi-Criteria Decision Analysis (MCDA) method for assigning weights to specific criteria/factors and transforming complex decisions into a structured hierarchy. It is based on an eigenvalue-based approach to pairwise comparisons, providing a methodology to calibrate the numeric scale for the measurement of quantitative and qualitative performances [30]. Each comparison represents the relative importance of a factor, with values ranging from 1 to 9. It introduces the consistency ratio (CR) as a measure of the consistency of the final ratings [31], while a revision of the preference matrix is recommended in cases where the CR is higher than 10%. A CR value of less than or even equal to 0.10 indicates acceptable consistency, showing valid and reliable results [32]. The mathematical expression of the CR value is provided through the following equation:

where RI is the Random Index, expressing the consistency of random judgments. The following equation calculates the Consistency Index (CI):

The λmax value is the maximum eigenvalue of the pairwise comparison vector [33]. In the current study, an online questionnaire (survey) was set into operation for the pairwise comparison of each wood criterion. Seven wood technology experts were surveyed, following Saaty and Özdemir’s [34] suggestions that a sample size of three (3) to seven (7) experts is usually sufficient to obtain valid and consistent judgments. Özcan et al. [32] also limited the number of judges to no more than seven (7) or eight (8). A group consensus was achieved by aggregating the individual priority vectors of all experts based on the arithmetic mean to derive the final preference weights. All of the selected experts are PhD holders in Wood Science (wood structure and properties, wood technology, wood chemistry, and wood utilization), with more than 10 years of experience in the field, most of them (5) with an academic position (professor, assistant professor, or teaching staff) at two universities in Greece. A potential limitation of this study is the fact that all of the experts came from the academic sector, so their opinions are from a scientific perspective. However, it should be noted that all of the experts have worked with wood machinery and know about wood properties and behavior in practice.

Before this, a transformation method, as suggested by Harker [35], was employed in cases of inconsistent or missing judgments. For this purpose, the ahpsurvey library [36] in the open-source environment of R (CRAN) was implemented and used.

2.2. Preference Ranking Organization Method for Enrichment Evaluation (PROMETHEE)

The PROMETHEE II method (complete ranking) was developed by Brans in 1982 [37] and evolved by Brans and Mareschal [38,39] and Brans et al. [40] in the following years. The PROMETHEE II procedure is based on a pairwise comparison of the alternatives along the selected criteria, and these criteria need to be maximized or minimized.

According to Brans and Mareschal [38], each alternative α faces (n − 1) other alternatives in A. The following equations define the outranking flows:

Positive outranking flow

Negative outranking flow

Brans and Mareschal [40] state that φ+(α) shows the outranking character (the power) of the alternative, while φ−(α) indicates the weakness of the alternative (the outranked character).

The following equation provides the complete ranking of the alternatives:

where φ(α) is the net outranking flow, φ+(α) is the positive outranking flow (Phi+), and φ−(α) is the negative outranking flow (Phi−) of the alternatives.

Higher values of net outranking flow suggest a better ranking for the alternative. When the net outranking flow is positive [φ(α) > 0], the alternative α is more outranking than all the alternatives on all the criteria, while when the net outranking flow is negative [φ(α) < 0], the alternative α is more outranked by all the alternatives on all the criteria [41].

Preference function. A preference function has to be associated with each criterion when using the PROMETHEE II method. The preference function defines how pairwise evaluation differences are translated into degrees of preference. It reflects the perception of the criterion scale by the decision maker [42]. The preference function is a function of pairwise differences, taking into consideration the data of the problem, such as minimum, maximum, and average value, standard deviation, etc. [42].

The q indifference threshold is the largest deviation, which is considered as negligible by the decision maker, while the p preference threshold is the smallest deviation, which is considered sufficient to generate a full preference [41].

2.3. Description of the Methodology

In the present research, eight (8) conifer species were evaluated by employing nine (9) criteria, which determine wood quality and play a crucial role selecting wood’s final use. The criteria were (1) dry density, (2) modulus of rupture, (3) elasticity, (4) toughness (impact bending), (5) shrinkage, (6) splitting (resistance to cleavage), (7) resistance/durability, (8) workability, and (9) permeability.

The criteria were selected based on key wood traits identified about established wood quality standards [23,43,44]. The examined studied species were (1) fir (Abies sp.), (2) Italian cypress (Cupressus sempervirens), (3) Norway spruce (Picea abies), (4) Calabrian pine (Pinus brutia), (5) Aleppo pine (Pinus halepensis), (6) European black pine (Pinus nigra), (7) Stone pine (Pinus pinea), and (8) Scots pine (Pinus sylvestris). Together, these species reflect the variety of softwoods utilized by the Greek forest sector, offering a comprehensive overview of the growth habits and wood properties essential for different timber products. Italian cypress is valued for its durability and resistance [45]. Norway spruce is a major European softwood species with a vast distribution and various applications [46]. Calabrian pine, common in southern Greece, plays a significant role in timber production, since—along with Aleppo pine—it is recognized for its fast growth and adaptability to dry, rocky soils, contributing to timber and resin production [47,48]. European black pine is a highly adaptive species used for reforestations [49]. Stone pine and Scots pine are widely distributed across Europe and extensively used in construction [50,51,52]. Fir is known for its extended suitability for construction and fine wood products, as well as Christmas trees [53].

The collected data were derived from related studies, research, and databases [17,43,54]. The data used in the paper (Table 1) were analyzed using the Visual PROMETHEE Academic Edition software version 1.4.0.0 [42].

Criteria such as resistance/durability, workability, and permeability were described using a 5-point Likert scale (Table 2), with scoring values of 5 = very good, 4 = good, 3 = average, 2 = bad, and 1 = very bad [42].

The preference functions and the thresholds of indifference (q) and preference (p) were calculated using the “Help me” wizard of Visual PROMETHEE Academic Edition [42]. For criteria with quantitative data, the “Help me” wizard suggested the linear preference function type, while for criteria with qualitative data (resistance/durability, workability, and permeability), the suggestion was the usual preference function type (Table 2). Regarding the threshold type, the “Help me” wizard suggested the “Absolute” threshold type, based on the data of the study.

The selected criteria represent basic wood properties that define the quality of the timber and its suitability for the production of various products and services, and thus they determine its value [11]. Table 3 presents the uses and applications of the examined species.

The Analytic Hierarchy Process (AHP) method was additionally used to calculate the criteria weights (Table 4). The PROMETHEE method does not provide specific guidelines to determine the weights of the criteria [55], and the choice is made by the user, which is a weakness of the method, because it is affected by the bias of the user. Therefore, the authors used the AHP method to calculate the weights of the criteria with the aid of seven experts in the field of wood industry, based on the methodology developed by Saaty [29] in order to increase the credibility of the results.

Table 1.

The values of the selected wood criteria of the conifer species from examined databases [43,54,56].

Table 1.

The values of the selected wood criteria of the conifer species from examined databases [43,54,56].

| Evaluations | Dry Density (g/cm3) | Modulus of Rupture (MPa) | Elasticity (GPa) | Toughness (Impact Bending, Nmm/mm2) | Shrinkage T/R Ratio (Coefficient of Anisotropy) | Splitting (Resistance to Cleavage) (N/mm Width) | Resistance/Durability | Workability (5-Point) | Permeability (5-Point) |

|---|---|---|---|---|---|---|---|---|---|

| Abies sp. | 0.41 | 66.1 | 1789 | 38.8 | 2.2 | 11 | 2 | 5 | 3 |

| Cupressus sempervirens | 0.55 | 44.6 | 3468 | 43.4 | 1.4 | 15.3 | 1 | 5 | 3 |

| Picea abies | 0.41 | 63 | 1426 | 28 | 2.1 | 9.2 | 2 | 5 | 2 |

| Pinus brutia | 0.57 | 104 | 3128 | 37 | 1.5 | 14 | 2 | 5 | 2 |

| Pinus halepensis | 0.71 | 119 | 3748 | 46.3 | 1.44 | 15.1 | 4 | 5 | 2 |

| Pinus nigra | 0.52 | 64.4 | 2210 | 40.3 | 1.8 | 12.9 | 5 | 4 | 2 |

| Pinus pinea | 0.52 | 56 | 3397 | 40.5 | 1.6 | 15.3 | 5 | 4 | 2 |

| Pinus sylvestris | 0.49 | 83.3 | 1717 | 31.4 | 1.6 | 10.6 | 5 | 4 | 2 |

Table 2.

Preference parameters of the study.

Table 2.

Preference parameters of the study.

| Criteria | Density | Rupture | Elasticity | Toughness | Shrinkage | Permeability | Workability | Resistance | Splitting |

|---|---|---|---|---|---|---|---|---|---|

| (g/cm3) | (MPa) | (GPa) | (Nmm/mm2) | (T/R Ratio) | 5-Point | 5-Point | 5-Point | N/mm | |

| Min/Max | Max | Max | Max | Max | Min | Max | Max | Max | Max |

| Weight | 0.16 | 0.11 | 0.11 | 0.09 | 0.10 | 0.08 | 0.11 | 0.16 | 0.08 |

| Preference function | Linear | Linear | Linear | Linear | Linear | Usual | Usual | Usual | Linear |

| Thresholds | Absolute | Absolute | Absolute | Absolute | Absolute | Absolute | Absolute | Absolute | Absolute |

| q: Indifference | 0.08 | 20.3 | 703 | 4.6 | 0.24 | n/a | n/a | n/a | 1.8 |

| p: Preference | 0.19 | 49.7 | 1.801 | 11.8 | 0.59 | n/a | n/a | n/a | 4.7 |

Table 3.

Uses and applications of the studied species [17,43,54,56].

Table 3.

Uses and applications of the studied species [17,43,54,56].

| Species | Picea abies (Norway Spruce) | Abies sp. (Fir) | Pinus nigra (Austrian pine, European Black Pine) | Pinus sylvestris (Scotch Pine) | Cupressus sempervirens (Mediterranean Cypress, Italian Cypress | Pinus brutia (Calabrian Pine) | Pinus halepenisis (Aleppo Pine) | Pinus pinea (Stone Pine) |

|---|---|---|---|---|---|---|---|---|

| Paper (pulpwood) | * | * | * | * | ||||

| Construction/mine lumber | * | * | * | * | * | * | * | * |

| Veneer, plywood | * | |||||||

| Christmas trees | * | |||||||

| Musical instruments | * | * | ||||||

| Boxes/crates | * | * | * | * | * | * | ||

| Poles/ posts | * | * | * | * | ||||

| Flooring | * | * | ||||||

| Furniture | * | * | * | |||||

| Boat building | * | * | * | * |

* refers to the production of the specific product for each species.

Table 4.

Estimated weight of each criterion, as determined by AHP.

Table 4.

Estimated weight of each criterion, as determined by AHP.

| Criteria | Weight |

|---|---|

| 1. Dry density | 0.16323912 |

| 2. Modulus of rupture | 0.11093987 |

| 3. Elasticity | 0.10850402 |

| 4. Toughness | 0.08668352 |

| 5. Shrinkage | 0.09771894 |

| 6. Splitting | 0.07778059 |

| 7. Resistance/durability | 0.16325611 |

| 8. Workability | 0.10903984 |

| 9. Permeability | 0.08283799 |

Dry density (r0) represents the ratio of the dry mass of a given (dry) volume to that volume (r0 = M0/V0) and needs to be maximized as a criterion, since the resilience of various products and constructions is strongly related to it. Density is the best indicator of the mechanical strength of wood [44,56,57]. Furthermore, density is strongly related to mechanical properties, which define the final uses of wood. Since wood shows differentiation in the three dimensions, axially, radially, and tangentially, mechanical properties show different values at each case. Modulus of rupture, modulus of elasticity, hardness, and toughness are criteria taken into account when solid construction is needed. The stability of timber constructions is strongly affected by bending strength, elasticity, and wood density. Moreover, dimensional stability is closely related to wood density [44,56,58,59]. Thus, the criteria of mechanical properties should be maximized.

Shrinkage and swelling of wood, due to its hygroscopicity, may lead to uneven shape changes, since wood is an anisotropic material, as well as warping or cracking and even collapse of the construction [56]. So, the ratio of tangential/radial shrinkage should be minimized.

Natural durability is connected to the presence of extractives in wood, which are chemical organic compounds located inside wood cells and empty intercellular spaces of wood. A high concentration of extracts leads to greater natural endurance and less shrinkage and swelling [56,59,60]. High physical durability as a criterion needs to be maximized, since it contributes to the extension of the product’s life cycle.

Workability and permeability of wood are two factors affecting its production process and are connected to the time and effort that need to be consumed in order to form a product. Easy workable woods can reduce the time and damage to the tools and machines used for their manufacturing. High permeability is important in timber species that show low natural durability and must be impregnated with various solutions that protect them from environmental conditions or insect and fungi attack [17,54]. Both criteria should also be maximized.

3. Results

The estimated weights of each criterion, as determined through the AHP, are presented in Table 4.

Table 5 presents the PROMETHEE flow table with the ranking of the softwood species according to their net outranking flows (Phi).

Table 5.

PROMETHEE flow table.

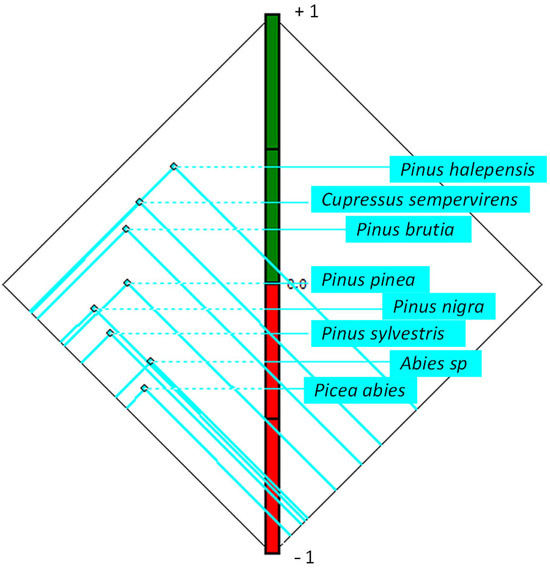

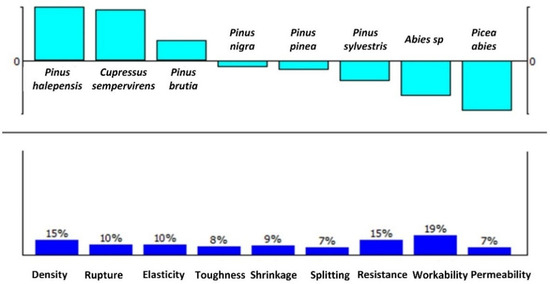

According to the PROMETHEE complete ranking, Aleppo pine (Pinus halepensis) achieved the best performance under the selected criteria, with the highest net outranking flow (Phi = 0.4351) among the examined softwood species. Cypress (Cupressus sempervirens) also achieved a very high Phi (0.3024) and is ranked in second place. Pinus brutia takes third place, presenting a high value of Phi (0.2061), while Pinus pinea achieves a marginally positive Phi (0.0051) and is therefore considered as an acceptable alternative. On the other hand, the remaining four softwood species achieved negative outranking flows and are classified as non-acceptable alternatives. More specifically, Pinus nigra’s net outranking flow was −0.0928 and was placed fifth. Pinus sylvestris and Abies sp. were placed in the sixth and seventh position of the ranking, with net outranking flows of −0.1819 and −0.2859, respectively. Finally, Picea abies achieved the lowest net outranking flow (Phi = −0.3882) and took last place among the eight softwood species. We observe that Abies sp. has achieved a higher positive outranking flow (Phi+ = 0.1324, column 4 of Table 5) compared with Pinus nigra (0.1230) and Pinus sylvestris (0.1085). However, it is ranked after these two species, because its negative outranking flow (Phi− = 0.4183) is much bigger, and therefore its net outranking flow (Phi) is −0.2859 and takes the seventh place in the ranking. Figure 3 presents the ranking of the conifer species. The vertical dimension (green-red axis) corresponds to the Phi net flow. The acceptable alternatives with positive outranking flow (Phi) are placed on the green bar, and the non-acceptable alternatives with negative outranking flow are placed on the red bar.

Figure 3.

PROMETHEE II complete ranking (diamond). (Source: produced by Visual PROMETHEE).

3.1. Sensitivity Analysis

A sensitivity analysis was conducted to assess the robustness of the results. The analysis was performed using Visual Stability Intervals, a feature of the Visual PROMETHEE software. Visual Stability Intervals show how the Phi multicriteria net flow scores and the PROMETHEE II ranking vary as a function of a criterion’s weight and identify the stability interval of the top-ranked actions. Big Weight Stability Intervals (WSI) indicate more robust results. Table 6 shows the Weight Stability Intervals for the selected criteria of the study.

Table 6.

Walking Stability Intervals (WSIs) for the criteria of the study (ST).

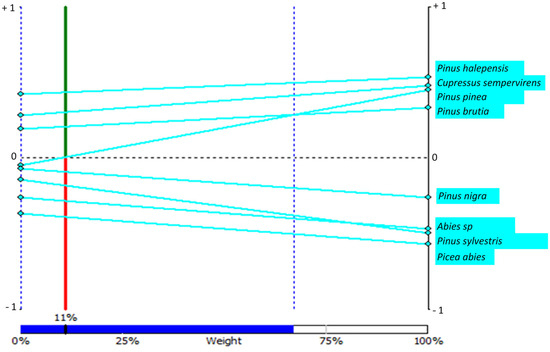

The most considerable Weight Stability Intervals were observed in the criteria of elasticity, density, splitting, shrinkage, and resistance. For these criteria, the ranking of all alternatives remains unchanged for the specific WSI. For example, for the criterion elasticity, the ranking of the alternatives remains the same if the weight is between 0.0 and 67.11 (Figure 4).

Figure 4.

Weight Stability Interval (WSI) for the criterion elasticity.

On the other hand, the least extensive Weight Stability Intervals are observed for the criteria workability (WSI: 2.81%–18.02%) and permeability (WSI: 0.00%–15.67%).

3.2. Sensitivity Analysis for the Criterion Workability

For the criterion workability, the ranking of the alternatives remains unchanged within a Weight Stability Interval (WSI) range of 2.81% to 18.02% (Table 6). This means that if the criterion weight for the workability is modified from 0.11 to 0.19 in our study, the ranking of the alternatives will change. In this scenario, the new weights for all criteria are adjusted using the Walking Weights tool provided by Visual PROMETHEE.

Figure 5 presents the new ranking of the alternatives based on the weights that were automatically calculated by the Walking Weights tool. We observe that in the new ranking, only three alternatives have positive Phi and are acceptable solutions, instead of four in the initial ranking (Table 5 and Figure 3). The only change in the ranking is that Pinus nigra is now placed fourth (instead of fifth in the initial ranking), while Pinus pinea is placed fifth (instead of fourth in the initial ranking). All other alternatives have maintained their positions as in the ranking presented in Figure 3.

Figure 5.

The new ranking of the alternatives based on the weights calculated by the Walking Weights tool of the Visual PROMETHEE Academic Edition (workability weight = 0.19).

3.3. Sensitivity Analysis for the Criterion Permeability

For the criterion permeability, the ranking of the alternatives remains unchanged within a Weight Stability Interval (WSI) range of 0.00% to 15.67% (Table 6). This means that if the criterion weight for permeability is modified from 0.08 to 0.16 in our study, the ranking of the alternatives will change. In this scenario, the new weights for all criteria are adjusted using the Walking Weights tool provided by Visual PROMETHEE.

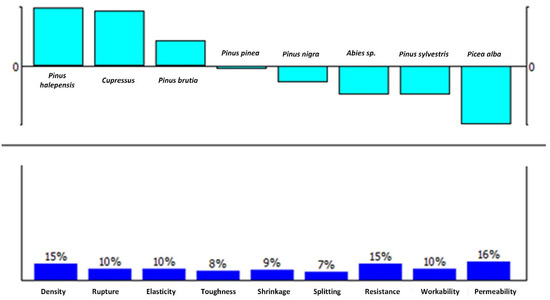

Figure 6 presents the new ranking of the alternatives based on the weights that were automatically calculated by the Walking Weights tool. We observe that in the new ranking, only three alternatives have positive Phi and are acceptable solutions, instead of four in the initial ranking (Table 5 and Figure 3). The only change in the ranking is that Abies sp. is now placed sixth (instead of seventh in the initial ranking), while Pinus sylvestris is placed seventh (instead of sixth). All other alternatives have maintained their positions as in the ranking presented in Figure 3.

Figure 6.

The new ranking of the alternatives based on the weights calculated by the Walking Weights tool of the Visual PROMETHEE Academic Edition (permeability weight = 0.16).

4. Discussion

Numerous studies have documented a strong and positive correlation between wood density and various mechanical properties such as modulus of elasticity, modulus of rupture, and compressive strength [17,56,61,62]. Based on these studies, wood density is the most important characteristic affecting wood toughness and strength, and it is strongly and positively correlated with most mechanical properties [61,62]. This documentation is in line with the results of the present study where the ranking of the studied species is primarily according to density, since density was the criterion with the most considerable weight (Table 2), according to the experts’ opinions and Analytic Hierarchy Process (AHP) results. However, it should be noted that there are some limitations to this research, since it depends on secondary data and the experts’ opinions might be subjective, even though they are prominent scientists with wood specialization. Another possible limitation of the study is the number of species and the number of the selected criteria. Future studies could include more species, such as conifers imported from other countries in the timber industry of Greece, and more criteria, such as pricing.

Unfortunately, no other studies implementing MCDA methods on the evaluation of wood quality are available, especially on softwoods, so the comparison of our results with other researchers is not possible.

The high ranking of Pinus halepensis is attributed to its high density, as well as to its good properties and behavior during processing. Pinus halepensis is a species well adapted to dry environmental conditions, since it is resistant to drought, but continuous drought stress negatively affects its wood formation, especially of earlywood. A reduction in tracheid formation has been observed as well. However, Pinus halepensis wood is widely used for various purposes due to its large availability, mainly in the Mediterranean region, and good wood quality. Moreover, other non-wood products, such as resin and seeds, are obtained from Aleppo pine [17,47,48].

The quality of wood from Pinus halepensis and Pinus brutia is generally considered to be similar to that of other pines. Nevertheless, some researchers consider Pinus brutia wood to be of higher quality than Pinus halepensis, due to its superior stem and branching formation. In addition, its quality is strongly influenced by site conditions [48].

Extractive content, particularly in the heartwood, is correlated to wood’s resistance to fungal attack. In the case of cypress, a significant correlation was observed in some cases between extractive content and natural durability. Cupressus sempervirens has a high concentration of extractives, compared to other conifers [63,64], a fact that contributes to its high ranking. Moreover, a relation between density and strength has been found, giving cypress high hardness and durability as well as an extensive range of uses and applications [45].

Physical properties of P. pinea, like high adsorption and water permeability, are considered limiting factors to its potential uses. Extractive content, such as lipophilic and phenolic compounds, gives higher durability to the heartwood, which is ranked as class 5, whereas sapwood durability is very low (class 2). Furthermore, the lowest concentration of extractives in sapwood results in greater water adsorption and leads to higher swelling of wood, factors contributing to its comparatively lower quality than the previous ones [50].

Pinus nigra is commonly used in reforestation plantations, as seen in Portugal, where it demonstrated properties similar to Pinus pinaster. In general, Pinus nigra appeared to have average values of lignin and extractive content, and its modulus of rupture and elasticity was average as well. Due to the lack of wood in the Mediterranean region because of repeated forest fires, Pinus nigra is chosen for reforestation, since it is well adapted to the local climatic conditions and its wood can be used by the forest industries, as reported in Portugal [49].

Pinus sylvestris is studied for the same reasons mentioned above, even though it shows a significant intra-population anatomical variation when grown in areas with different environmental conditions, in an effort to adjust to each case [65]. Although Pinus sylvestris demonstrated high toughness in some cases, the rest of its properties show average values, showing an impact of altitude on its wood quality. However, it is a softwood with a wide range of applications, especially nowadays, given the constraints of the wood supply [51].

Abies species in the Mediterranean region have a limited distribution, mainly in the eastern area and the Black Sea. Their wood is considered to have lower technical value compared to pines, which explains Abies’s lower ranking in our study. However, it is used in carpentry due to its softness and good workability. Moreover, fir wood is utilized in various applications, such as paper production, veneer, composite, and glued wood products, panels, and poles. Furthermore, extractives of fir contain turpentine oil, which possesses pharmaceutical properties and is used in medicinal and aromatic applications. Due to their good form, odor, and color, they are grown in plantations as ornamental and Christmas trees as well [53,66].

Picea abies takes the last position in the species ranking, probably because of its low density and physical-mechanical properties. Nevertheless, owing to its broad geographic distribution, it is widely used in the European wood industry for a wide range of products, including construction materials, furniture, paper, and other composite products [62]. It is widely cultivated in plantations for wood production; however, when the primary management objective is to maximize growth and timber volume, this often negatively affects its density and other wood traits and properties [46,67].

According to the latest national forest inventory data and the merchantable volume in industrial forests per conifer species, Abies species and Picea abies together account for approximately 32% of total conifer production. Pinus nigra and Pinus brutia contribute 24% to the latter production. The remaining production, approximately 44%, is covered by hardwood species, mainly beech (Fagus sp.), oak (Quercus sp.), and chestnut (Castanea sp.) [68].

Considering that pines and cypress are strongly recommended by our analysis, forest managers should prioritize species with high wood density and favorable mechanical properties, given their great availability and distribution in Greece and in the Mediterranean region.

For example, to our knowledge, there is currently no emphasis on the cultivation and production of cypress at the national level. This particular species could be prioritized in mixed stands which generally offer more options than monoculture without losing productivity. Moreover, recent studies suggest that diverse stands have great potential to mitigate future increases in production risks [69,70].

In contrast, although Picea abies and Abies sp. ranked lower due to their limited suitability for high-demand applications requiring strong wood characteristics, they currently represent the largest share of wood production in Greece. Therefore, where feasible, priorities in species selection and forest management should be reconsidered and adjusted accordingly. Choosing between different forest management practices or different species is always an option. With attention to biogeographically determined site limitations, this could be a crucial step in short-, medium-, and long-term decision making in forestry and when setting up measures to support a regional or national forest policy [71]. Supporting initiatives that improve the market competitiveness of Greece’s forestry sector by promoting the superior qualities of preferred species for both domestic and international markets seems to be crucial.

5. Conclusions

The present study aimed to evaluate the wood quality of eight softwood species utilized in Greek industries and having a great distribution in Greece. The evaluation took place using quality criteria rated with the AHP method, which assessed the knowledge of seven experts from the academic sector of Greece, and the species ranking was implemented with the PROMETHEE method. According to the results, Pinus halepensis was the most optimal species compared to the rest, with the highest net outranking flow (Phi = 0.4351), followed by Cupressus sempervirens, which also achieved a very high Phi (0.3024) and is ranked in second place. The lowest quality was demonstrated by Picea abies (Phi = −0.3882), followed by Abies sp. with a net outranking flow of −0.2859. However, it should be noted that due to the lack of wood supply in Greece, all selected species are widely used, since they can have various applications, are easily adapted to the Mediterranean environment, and demonstrate good growth even in plantations and deforestation.

Our findings could be highly beneficial to the wood industry, promoting the recovery and advancement of the forest sector in general, considering that sustainable wood supply is lower than the total biomass available in Europe. A potential limitation of this study is the fact that all of the experts came from the academic sector, so their opinions are from a scientific perspective. In the future, an extended expert sample including representatives from wood industries might amplify the robustness of the research results. Moreover, no other studies implementing MCDA methods on the evaluation of wood quality, especially of softwoods, are available, so the comparison of our results with other researchers is not possible.

Policymakers should prioritize the selection of conifer tree species that can strengthen Greece’s forestry sector, promote sustainable management practices, and increase the economic value derived from the country’s diverse forest resources.

To conclude, it is essential to consider each species’ quality characteristics to more effectively use raw materials. Thus, for future studies, it is suggested that each species’ wood quality be investigated to better exploit wood.

Author Contributions

Conceptualization, M.C. and S.T.; methodology, M.C., S.T. and D.I.R.; software, S.T. and D.I.R.; validation, M.C. and P.P.K.; formal analysis, S.T., D.I.R. and P.P.K.; investigation, M.C. and S.T.; resources, M.C. and S.T.; data curation, M.C. and S.T.; writing—original draft preparation, M.C., S.T., D.I.R. and P.P.K.; writing—review and editing M.C., S.T., D.I.R. and P.P.K.; visualization, M.C. and S.T.; supervision, M.C.; project administration, M.C. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

Data available under request.

Acknowledgments

The authors would like to thank Dionisios Georgiou, ICT Administrator, a member of the support staff at the Institute of Mediterranean Forest Ecosystems, for his assistance with the graphic editing of this work.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Tramblay, Y.; Koutroulis, A.; Samaniego, L.; Vicente-Serrano, S.M.; Volaire, F.; Boone, A.; Le Page, M.; Llasat, M.C.; Albergel, C.; Burak, S.; et al. Challenges for drought assessment in the Mediterranean region under future climate scenarios. Earth-Sci. Rev. 2020, 210, 103348. [Google Scholar] [CrossRef]

- Allen, C.D.; Macalady, A.K.; Chenchouni, H.; Bachelet, D.; McDowell, N.; Vennetier, M.; Kitzberger, T.; Rigling, A.; Breshears, D.D.; Hogg, E.T. A global overview of drought and heat-induced tree mortality reveals emerging climate change risks for forests. For. Ecol. Manag. 2010, 259, 660–684. [Google Scholar] [CrossRef]

- McDowell, N.; Pockman, W.T.; Allen, C.D.; Breshears, D.D.; Cobb, N.; Kolb, T.; Plaut, J.; Sperry, J.; West, A.; Williams, D.G. Mechanisms of plant survival and mortality during drought: Why do some plants survive while others succumb to drought? New Phytol. 2008, 178, 719–739. [Google Scholar] [CrossRef]

- Seth, M.K. Trees and their economic importance. Bot. Rev. 2003, 69, 321–376. [Google Scholar] [CrossRef]

- Lagouvardos, K.; Dafis, S.; Kotroni, V.; Kyros, G.; Giannaros, C. Exploring recent (1991–2020) trends of essential climate variables in Greece. Atmosphere 2024, 15, 1104. [Google Scholar] [CrossRef]

- Mitsopoulos, I.; Raftoyannis, Y.; Bakaloudis, D. Climate change, wildfires and fir forests in Greece: Perceptions of forest managers. SEEFOR 2015, 6, 143–157. [Google Scholar] [CrossRef]

- Stephens, S. Evaluation of the effects of silvicultural and fuels treatments on potential fire behavior in Sierra Nevada mixed conifer forests. For. Ecol. Manag. 1998, 105, 21–35. [Google Scholar] [CrossRef]

- Dale, V.H.; Joyce, L.A.; McNulty, S.; Neilson, R.P.; Ayres, M.P.; Flannigan, M.D.; Hanson, P.J.; Irland, L.C.; Lugo, A.E.; Peterson, C.J.; et al. Climate change and forest disturbances. BioScience 2001, 51, 723–734. [Google Scholar] [CrossRef]

- Tsakaldimi, M.; Ganatsas, P. Forest land management and the role of ecological silviculture on the sustainability of Greek forests. J. Degrad. Min. Lands Manag. 2024, 11, 5307–5317. [Google Scholar] [CrossRef]

- D’Amato, A.W. and Palik. B.J. Building on the last “new” thing: Exploring the compatibility of ecological and adaptation silviculture. Can. J. For. Res. 2020, 51, 172–180. [Google Scholar] [CrossRef]

- Palik, B.J.; D’Amato, A.W.; Franklin, J.F.; Johnson, K.N. Ecological Silviculture: Foundations and Applications; Waveland Press: Long Grove, IL, USA, 2020. [Google Scholar]

- Koulelis, P.; Fassouli, V.; Petrakis, P.; Ioannidis, K.; Alexandris, S. The impact of selected climatic factors on the growth of Greek fir on Mount Giona in mainland Greece based on tree ring analysis. Austrian J. For. Sci. 2022, 139, 1–30. [Google Scholar]

- Koulelis, P.P.; Tsiaras, S.; Andreopoulou, Z.S. Greece’s forest sector from the perspective of timber production: Evolution or decline? Forests 2023, 14, 2331. [Google Scholar] [CrossRef]

- Koulelis, P. Greek timber industries and wood product markets over the last century. Development constraints and future directions. Ann. For. Res. 2011, 54, 229–240. [Google Scholar]

- Kazana, V.; Kazaklis, A.; Raptis, D.; Stamatiou, C. A combined multi-criteria approach to assess forest management sustainability: An application to the forests of Eastern Macedonia & Thrace Region in Greece. Ann. Oper. Res. 2020, 294, 321–343. [Google Scholar]

- Civitarese, V.; Faugno, S.; Picchio, R.; Assirelli, A.; Sperandio, G.; Saulino, L.; Crimaldi, M.; Sannino, M. Production of selected short-rotation wood crop species and quality of obtained biomass. Eur. J. For. Res. 2018, 137, 541–552. [Google Scholar] [CrossRef]

- Voulgaridis, H. Quality and Uses of Wood; Kallipos, Open Academic Editions: Athens, Greece, 2015. (In Greek) [Google Scholar]

- Barrette, J.; Achim, A.; Auty, D. Impact of intensive forest management practices on wood quality from conifers: Literature review and reflection on future challenges. Curr. For. Rep. 2023, 9, 101–130. [Google Scholar] [CrossRef]

- Kennedy, R.W. Coniferous wood quality in the future: Concerns and strategies. Wood Sci. Technol. 1995, 29, 321–338. [Google Scholar] [CrossRef]

- Campion, J.M. The effects of mid- and late-rotation fertiliser application on tree growth and wood quality in softwood saw-timber stands: A critical review. South. For. 2009, 70, 7–17. [Google Scholar] [CrossRef]

- EFSA Panel on Plant Health (PLH); Jeger, M.; Bragard, C.; Caffier, D.; Candresse, T.; Chatzivassiliou, E.; Dehnen-Schmutz, K.; Gilioli, G.; Miret, J.A.J.; MacLeod, A.; et al. Pest categorisation of Dendrolimus sibiricus. EFSA J. 2018, 16, e05301. [Google Scholar]

- Tsiaras, S.; Chavenetidou, M.; Koulelis, P.P. A multiple criteria decision analysis approach for assessing the quality of hardwood species used by Greek timber industries. Fol. Oecol. 2024, 51, 109–119. [Google Scholar] [CrossRef]

- Šuhajdová, E.; Novotný, M.; Pěnčík, J.; Šuhajda, K.; Schmid, P.; Straka, B. Evaluation of suitability of selected hardwood in civil engineering. Build. Mater. Struct. 2018, 61, 73–82. [Google Scholar] [CrossRef]

- Uhde, B.; Hahn, W.A.; Griess, V.C.; Knoke, T. Hybrid MCDA methods to integrate multiple ecosystem services in forest management planning: A critical review. Environ. Manag. 2015, 56, 373–388. [Google Scholar] [CrossRef]

- Kpadé, C.P.; Tamini, L.D.; Pepin, S.; Khasa, D.P.; Abbas, Y.; Lamhamedi, M.S. Evaluating multi-criteria decision-making methods for sustainable management of forest ecosystems: A systematic review. Forests 2024, 15, 1728. [Google Scholar] [CrossRef]

- Küçükarslan, A.B.; Köksal, M.; Ekmekci, I. A model proposal for measuring performance in occupational health and safety in forest fires. Sustainability 2023, 15, 14729. [Google Scholar] [CrossRef]

- Çalişkan, E.; Bediroglu, Ş.; Yildirim, V. Determination forest road routes via GIS-based spatial multi-criterion decision methods. Appl. Ecol. Environ. Res. 2019, 17, 759–779. [Google Scholar] [CrossRef]

- Nikolić Jokanović, V.; Vulević, T.; Lazarević, K. Risk assessment of forest decline by application of geostatistics and multi-criteria analysis. J. Hydrol. Hydromech. 2020, 68, 285–292. [Google Scholar] [CrossRef]

- Saaty, T.L. The Analytic Hierarchy Process; McGraw Hill: New York, NY, USA, 1980. [Google Scholar]

- Vaidya, O.S.; Kumar, S. Analytic Hierarchy Process, an overview of applications. Eur. J. Oper. Res. 2006, 169, 1–29. [Google Scholar] [CrossRef]

- Odu, G.O. Weighting methods for multi-criteria decision making technique. J. Appl. Sci. Environ. Manag. 2019, 23, 1449–1457. [Google Scholar] [CrossRef]

- Özcan, Z.; Caglayan, İ.; Kabak, Ö.; Kılıç Gül, F. Integrated risk mapping for forest fire management using the analytical hierarchy process and ordered weighted average: A case study in southern Turkey. Nat. Hazards 2025, 121, 959–1001. [Google Scholar] [CrossRef]

- Saaty, T.L.; Vargas, L.G. Models, Methods, Concepts & Applications of the Analytic Hierarchy Process; Springer: New York, NY, USA, 2012. [Google Scholar]

- Saaty, T.L.; Özdemir, M.S. How many judges should there be in a group? Ann. Data Sci. 2014, 1, 359–368. [Google Scholar] [CrossRef]

- Harker, P.T. Alternative modes of questioning in the analytic hierarchy process. Math. Model. 1987, 9, 353–360. [Google Scholar] [CrossRef]

- Cho, F. ahpsurvey: Analytic Hierarchy Process for Survey Data in R, version 0.4.0; R Foundation for Statistical Computing: Vienna, Austria, 2019. [Google Scholar]

- Brans, J.-P. L’ingénierie de la décision: L’élaboration d’instruments d’aide a la décision. In L’aide à la Décision; Presses de l’Université Laval: Québec, QC, Canada, 1982; pp. 183–213. [Google Scholar]

- Brans, J.P.; Mareschal, B. Promethee V: MCDM problems with segmentation constraints. INFOR Inf. Sys. Oper. Res. 1992, 30, 85–96. [Google Scholar] [CrossRef]

- Brans, J.P.; Mareschal, B. The PROMCALC & GAIA decision support system for multicriteria decision aid. Decis. Support Syst. 1994, 12, 297–310. [Google Scholar]

- Brans, J.P.; Vincke, P.; Mareschal, B. How to select and how to rank projects: The Promethee method. Eur. J. Oper. Res. 1986, 24, 228–238. [Google Scholar] [CrossRef]

- Brans, J.P.; Mareschal, B. PROMETHEE methods. In Multiple Criteria Decision Analysis: State of the Art Surveys; Figueira, J., Greco, S., Ehrgott, M., Eds.; Springer: Boston, MA, USA, 2005; pp. 163–196. [Google Scholar]

- Mareschal, B. Visual PROMETHEE 1.4 Manual; VPSolutions: Brussels, Belgium, 2013. [Google Scholar]

- Meier, E.W. Wood! Identifying and Using Hundreds of Woods Worldwide; The Wood Database: Madison, WI, USA, 2015. [Google Scholar]

- Niemz, P.; Teischinger, A.; Sandberg, D. Springer Handbook of Wood Science and Technology; Springer: Heidelberg, Germany, 2023. [Google Scholar]

- Bektaş, İ.; Ramazan, K. Principal mechanical properties of cypress wood (Cupressus Sempervirens L.) naturally grown in (Kahramanmaraş) Eastern Mediterranean of Turkey. Gazi Univ. J. Sci. 2010, 23, 357–362. [Google Scholar]

- Steffenrem, A.; Kvaalen, H.; Høibø, O.A.; Edvardsen, Ø.M.; Skrøppa, T. Genetic variation of wood quality traits and relationships with growth in Picea abies. Scand. J. For. Res. 2009, 24, 15–27. [Google Scholar] [CrossRef]

- Pasho, E.; Camarero, J.J.; Vicente-Serrano, S.M. Climatic impacts and drought control of radial growth and seasonal wood formation in Pinus halepensis. Trees Struct. Funct. 2012, 26, 1875–1886. [Google Scholar] [CrossRef]

- Chambel, M.R.; Climent, J.; Pichot, C.; Ducci, F. Mediterranean pines (Pinus halepensis Mill. and brutia Ten.). In Forest Tree Breeding in Europe; Managing Forest Ecosystems 25; Springer: Dordrecht, The Netherlands, 2013; pp. 229–265. [Google Scholar]

- Dias, A.; Carvalho, A.; Silva, M.E.; Lima-Brito, J.; Gaspar, M.J.; Alves, A.; Rodrigues, J.C.; Pereira, F.; Morais, J.; Lousada, J.L. Physical, chemical and mechanical wood properties of Pinus nigra growing in Portugal. Ann. For. Sci. 2020, 77, 72. [Google Scholar] [CrossRef]

- De Angelis, M.; Romagnoli, M.; Vek, V.; Poljanšek, I.; Oven, P.; Thaler, N.; Lesar, B.; Kržišnik, D.; Humar, M. Chemical composition and resistance of Italian stone pine (Pinus pinea L.) wood against fungal decay and wetting. Ind. Crop. Prod. 2018, 117, 187–196. [Google Scholar] [CrossRef]

- Fernandes, C.; Gaspar, M.J.; Pires, J.; Alves, A.; Simões, R.; Rodrigues, J.C.; Silva, M.E.; Carvalho, A.; Brito, J.E.; Lousada, J.L. Physical, chemical and mechanical properties of Pinus sylvestris wood at five sites in Portugal. iForest 2017, 10, 669–679. [Google Scholar] [CrossRef]

- Raptis, D.I.; Papadopoulou, D.; Psarra, A.; Fallias, A.A.; Tsitsanis, A.G.; Kazana, V. Height-diameter models for King Boris fir (Abies borisii regis Mattf.) and Scots pine (Pinus sylvestris L.) in Olympus and Pieria Mountains, Greece. J. Mt. Sci. 2024, 21, 1475–1490. [Google Scholar] [CrossRef]

- Alizoti, P.G.; Fady, B.; Prada, M.A.; Vendramin, G.G. EUFORGEN Technical Guidelines for Genetic Conservation and Use of Mediterranean firs (Abies spp.); Biodiversity International: Rome, Italy, 2011. [Google Scholar]

- Kakaras, I. Wood as Raw Material. Types of Wood Properties; Applications; University of Thessaly: Karditsa, Greece, 2008. (In Greek) [Google Scholar]

- Macharis, C.; Springael, J.; de Brucker, K.; Verbeke, A. PROMETHEE and AHP: The design of operational synergies in multicriteria analysis. Eur. J. Oper. Res. 2004, 153, 307–317. [Google Scholar] [CrossRef]

- Tsoumis, G. Science and Technology of Wood: Structure, Properties, Utilization; Van Nostrand Reinhold: New York, NY, USA, 1991. [Google Scholar]

- Larjavaara, M.; Muller-Landau, H.C. Rethinking the value of high wood density. Funct. Ecol. 2010, 24, 701–705. [Google Scholar] [CrossRef]

- Kretschmann, D.E. Mechanical properties of wood. In Wood Handbook: Wood as an Engineering Material; General Technical Report FPL, GTR–190; USDA Forest Service, Forest Products Laboratory: Madison, WI, USA, 2010; pp. 5-1–5-46. [Google Scholar]

- Rohanová, A.; Nunez, E. Prediction models of Slovakian structural timber. Wood Res. 2014, 59, 757–767. [Google Scholar]

- Grigoriou, A. Chemistry and Chemical Technology of Wood. Teaching Material; Publications Office of Aristotle University of Thessaloniki: Thessaloniki, Greece, 1992. (In Greek) [Google Scholar]

- Zobel, B.; van Buijtenen, J.P. Wood Variation: Its Causes and Control; Springer: Berlin, Germany, 1989. [Google Scholar]

- Steffenrem, A.; Saranpää, P.; Lundqvist, S.-O.; Skrøppa, T. Variation in wood properties among five full-sib families of Norway spruce (Picea abies). Ann. For. Sci. 2007, 64, 799–806. [Google Scholar] [CrossRef]

- Palanti, S.; Alves, A.; Rodrigues, J.; Danti, R. Determination of extractive content in Cupressus sempervirens wood through a NIRS-PLSR model and its correlation with durability. Int. Biodeterior. Biodegrad. 2021, 162, 105247. [Google Scholar] [CrossRef]

- Chavenetidou, M.; Pantazi, C.; Parasoglou, S.; Tsioras, P.; Ganatsas, P. Quantitative determination of extractives, inorganic ingredients and pH of cypress trees (Cupressus sempervirens L.) from different provenances. Agric. For. 2023, 69, 19–29. [Google Scholar] [CrossRef]

- Martín, J.A.; Esteban, L.G.; de Palacios, P.; García Fernández, F. Variation in wood anatomical traits of Pinus sylvestris L. between Spanish regions of provenance. Trees 2010, 24, 1017–1028. [Google Scholar] [CrossRef]

- Aussenac, G. Ecology and ecophysiology of circum-Mediterranean firs in the context of climate change. Ann. For. Sci. 2002, 59, 823–832. [Google Scholar] [CrossRef]

- Hannrup, B.; Cahalan, C.; Chantre, G.; Grabner, M.; Karlsson, B.; Bayon, I.L.; Jones, G.L.; Müller, U.; Pereira, H.; Rodrigues, J.C. Genetic parameters of growth and wood quality traits in Picea abies. Scand. J. For. Res. 2004, 19, 14–29. [Google Scholar] [CrossRef]

- Hellenic Ministry of Agriculture, General Secretariat for Forest and the Natural Environment. The Results of the First National Forest Inventory (NFI) of Greece; Hellenic Ministry of Agriculture: Athens, Greece, 1992. (In Greek) [Google Scholar]

- Ammer, C. Diversity and forest productivity in a changing climate. New Phytol. 2019, 221, 50–66. [Google Scholar] [CrossRef] [PubMed]

- Dieler, J.; Uhl, E.; Bieber, P.; Müller, J.; Rötzer, T.; Pretzsch, H. Effect of forest stand management on species composition, structural diversity, and productivity in the temperate zone of Europe. Eur. J. For. Res. 2017, 136, 739–766. [Google Scholar] [CrossRef]

- Duncker, P.S.; Barreiro, S.M.; Hengeveld, G.M.; Lind, T.; Mason, W.L.; Ambrozy, S.; Spiecker, H. Classification of forest management approaches: A new conceptual framework and its applicability to European forestry. Ecol. Soc. 2012, 17, 51. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).