The Circular Economy: A Lever for the Sustainable Development of the Wood and Forestry Sector in West Africa

Abstract

1. Introduction

2. Overview of the Wood and Forestry Sector in Benin

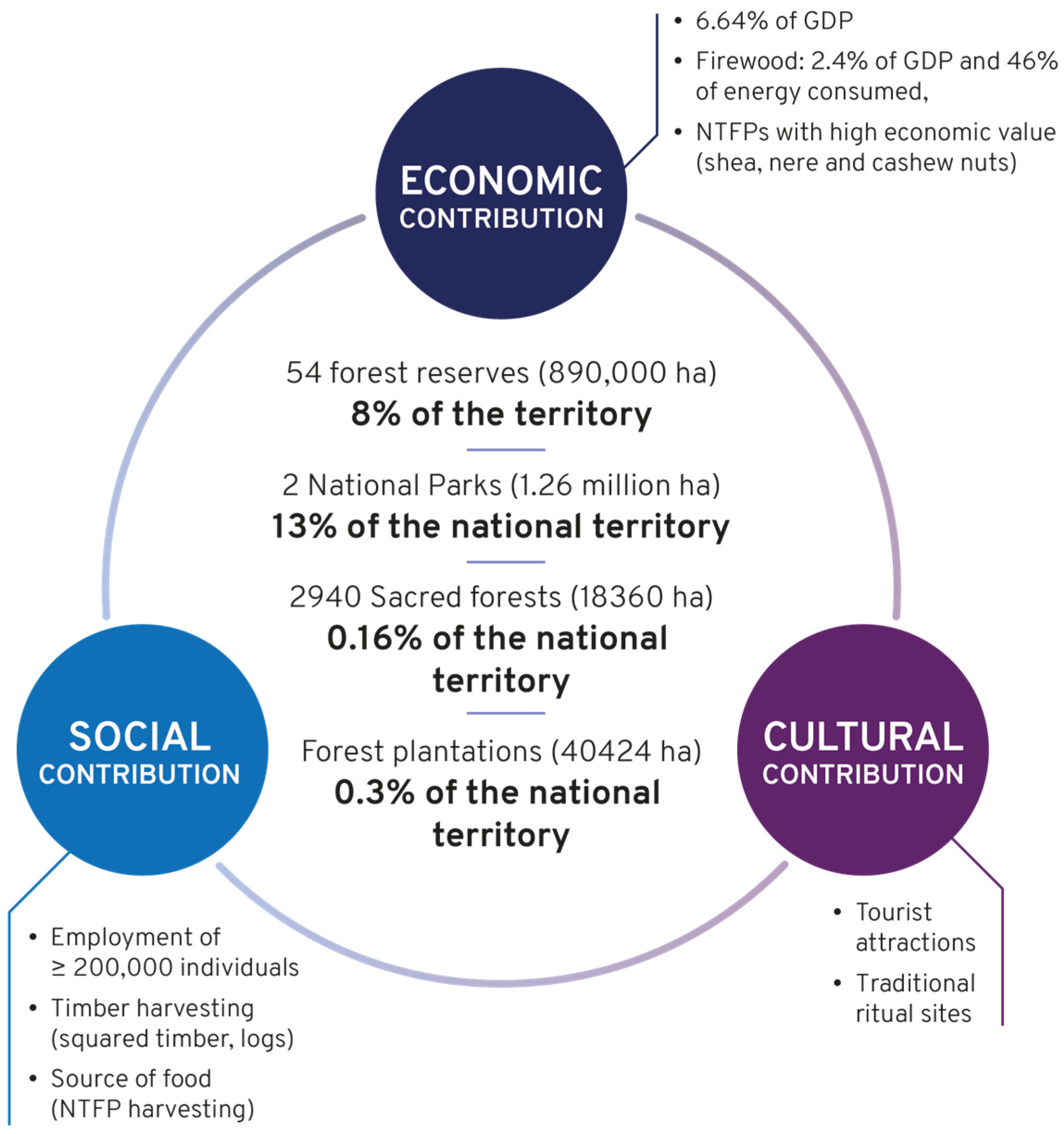

2.1. Importance of Forests and the Forestry Sector in the Beninese Economy

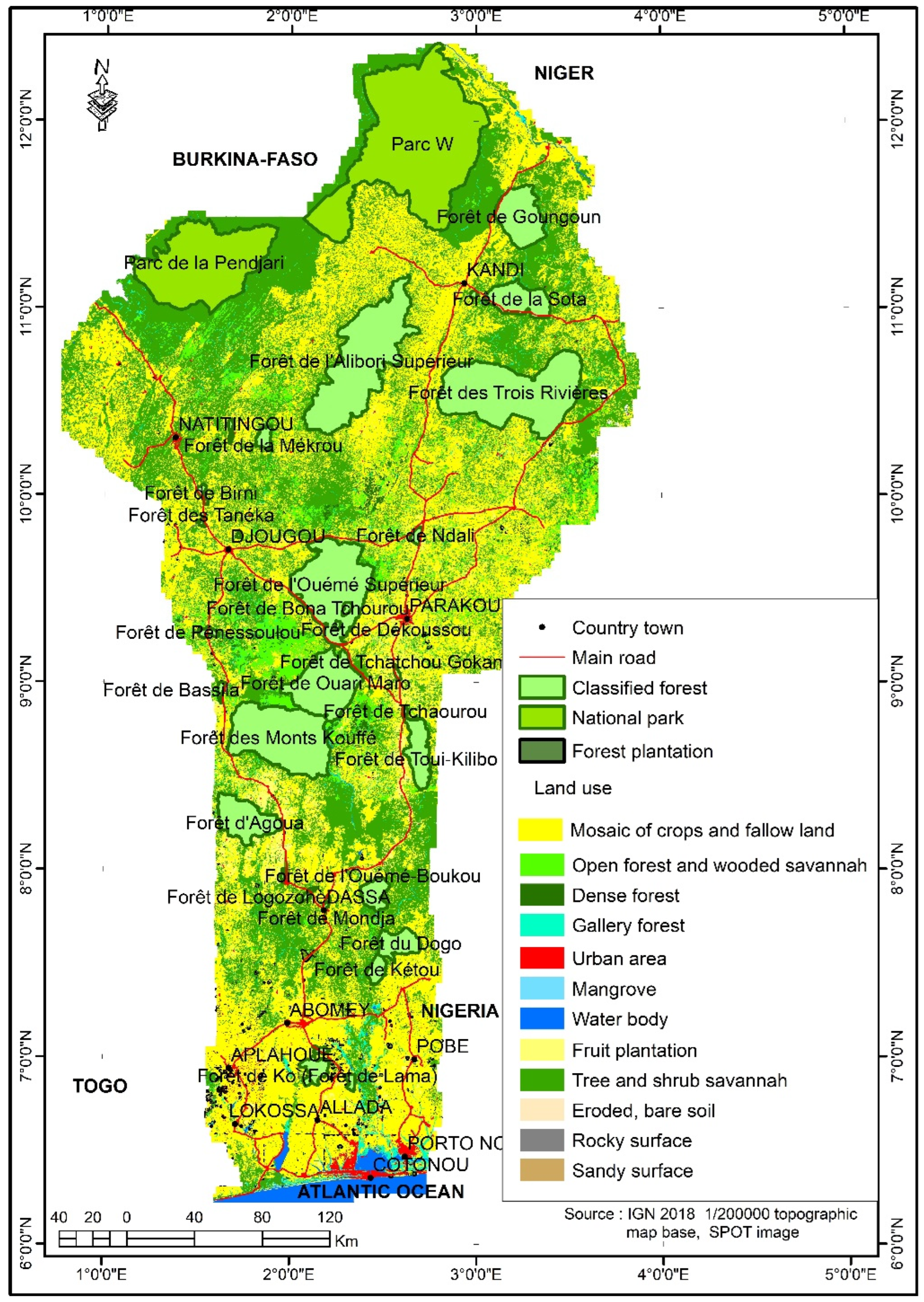

2.1.1. Forest Resources in Benin

2.1.2. Socio-Economic Role of Forests in Benin

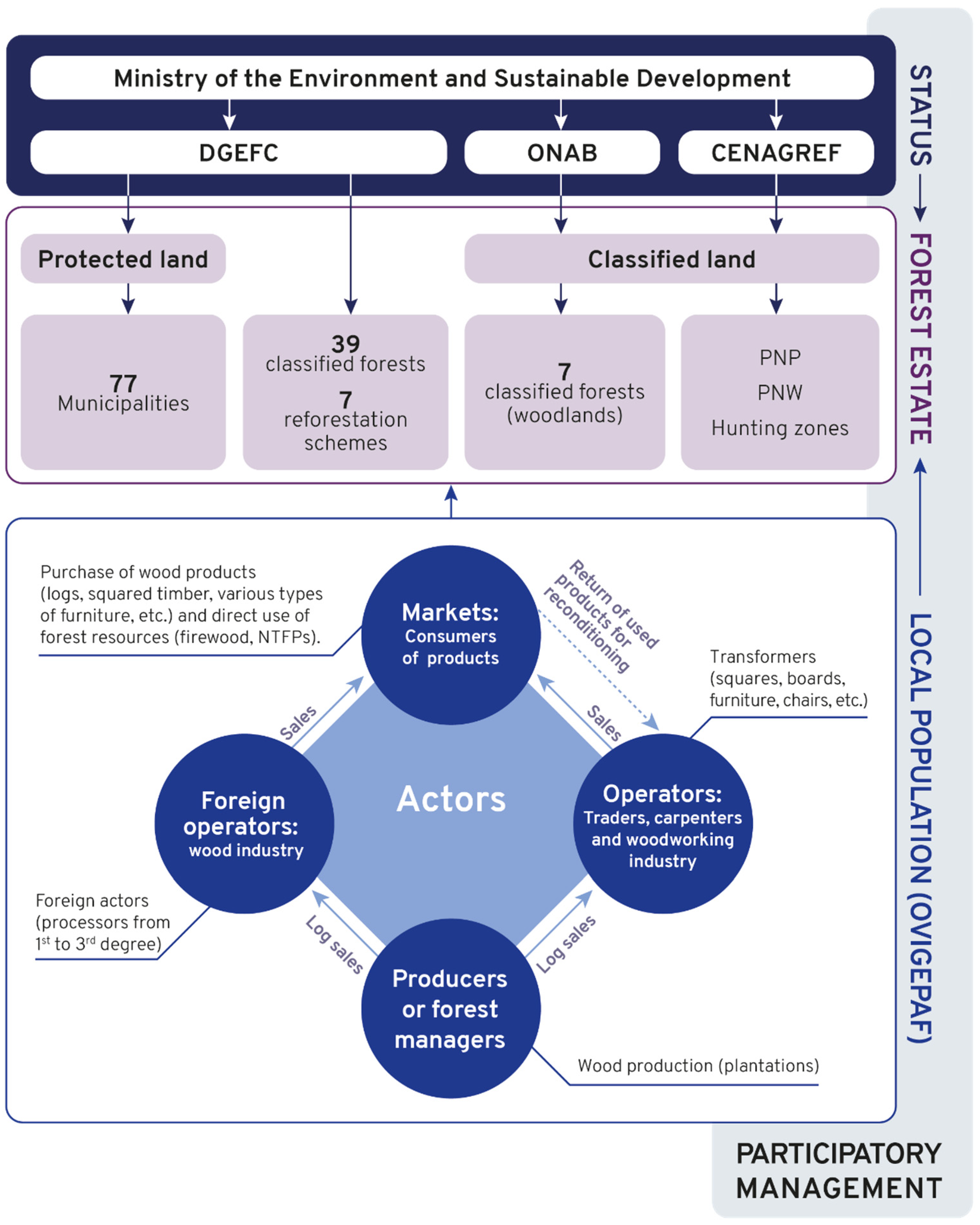

2.2. The Wood-Forestry Sector in Benin: Actors, Structures, and Dynamics

2.2.1. Management and Regulation Structures

2.2.2. Roles and Implications of Local Communities

3. Methodology

3.1. Study Area

3.2. Sampling

3.3. Data Collected and Collection Tools

3.4. Analysis Method

4. Results

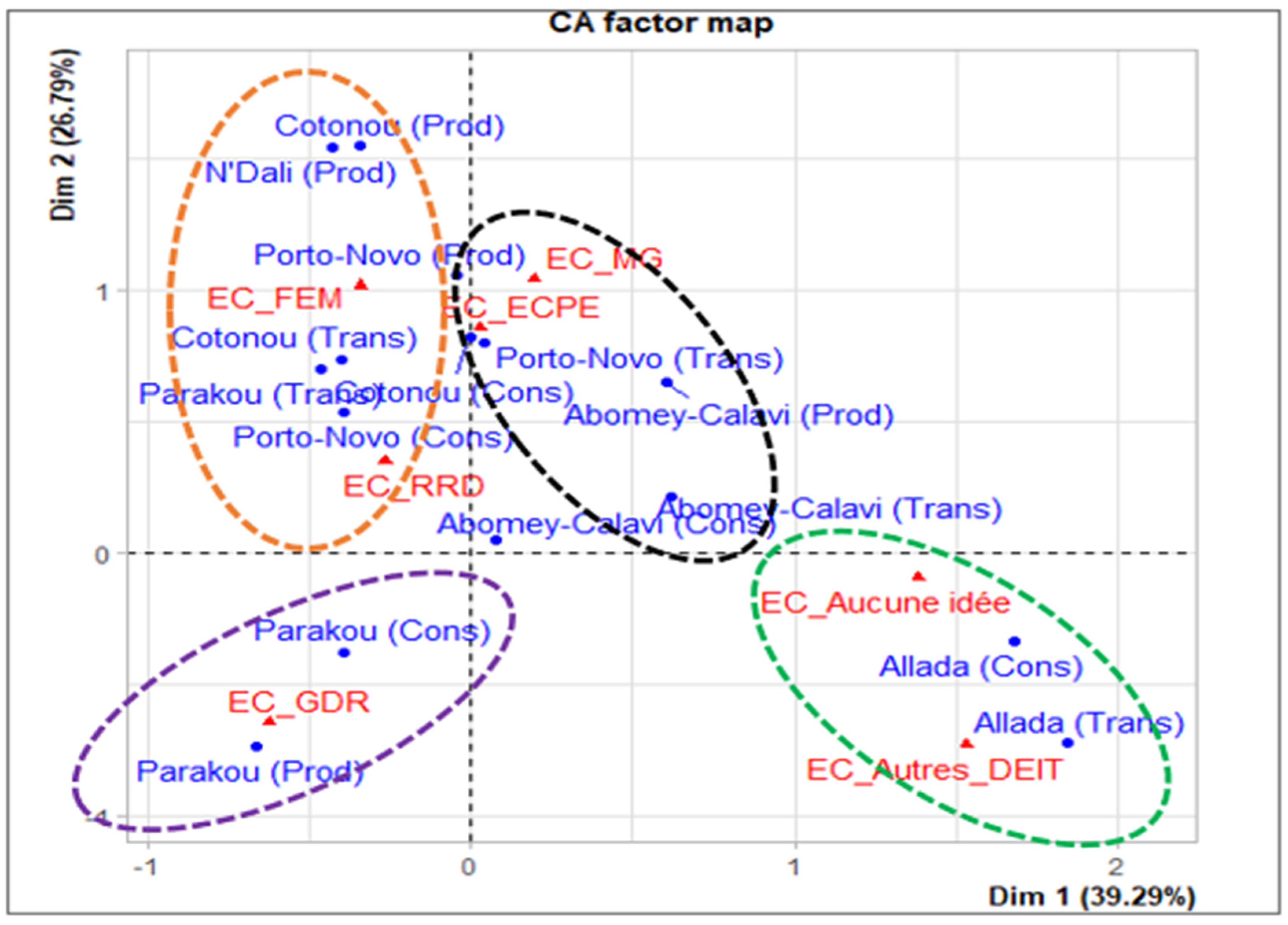

4.1. Knowledge of the Concept of Circular Economy by Stakeholders

4.1.1. Knowledge of Direct Actors

- Understanding of Direct Actors on the Concept of EC

- Global Analysis of the Knowledge of Direct Actors

4.1.2. Perception of Indirect Actors

4.2. Overview of Practices and Strategies Used by Actors

Direct Actors

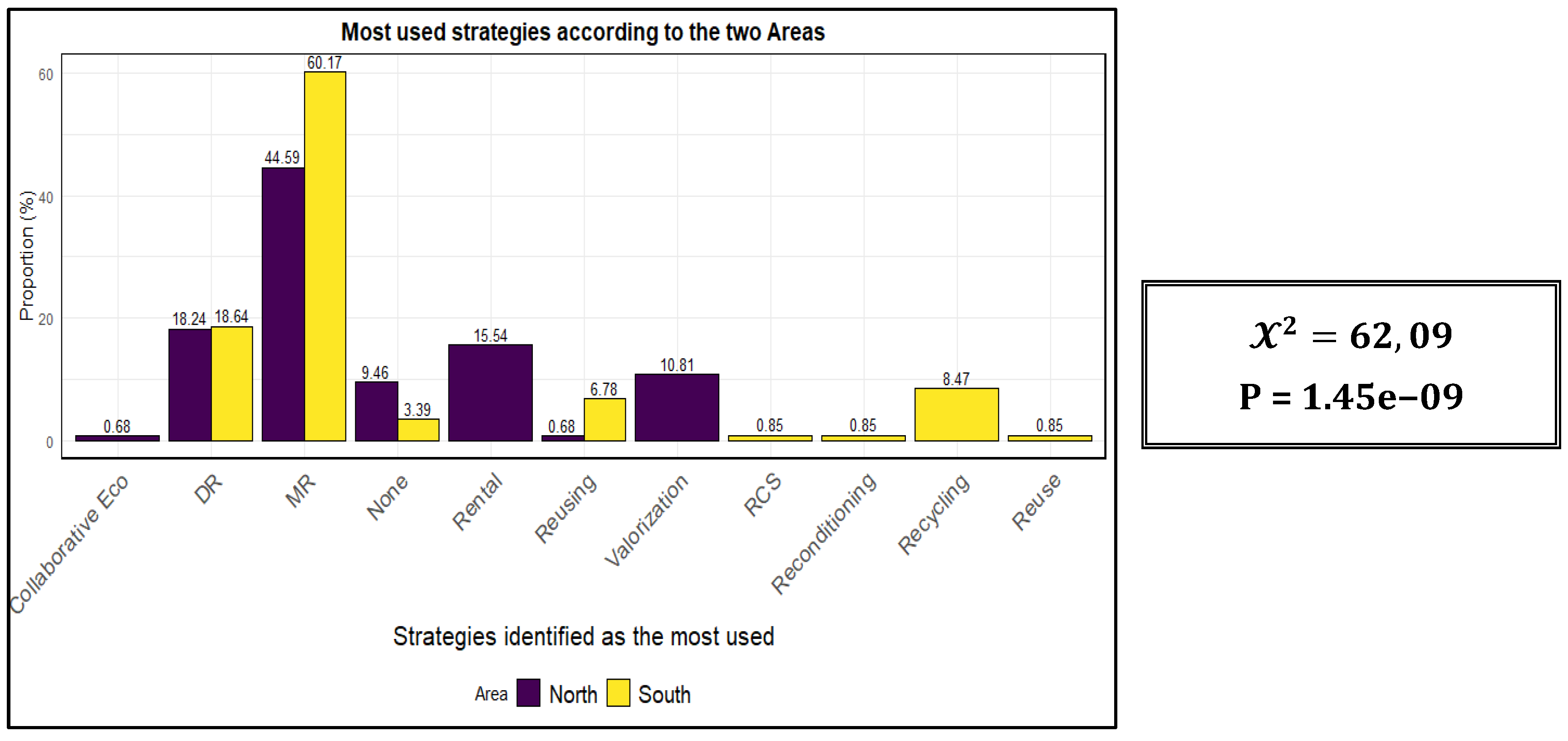

- Strategies Developed by Direct Actors

- Most used strategies in the North

- Most used strategies in the South

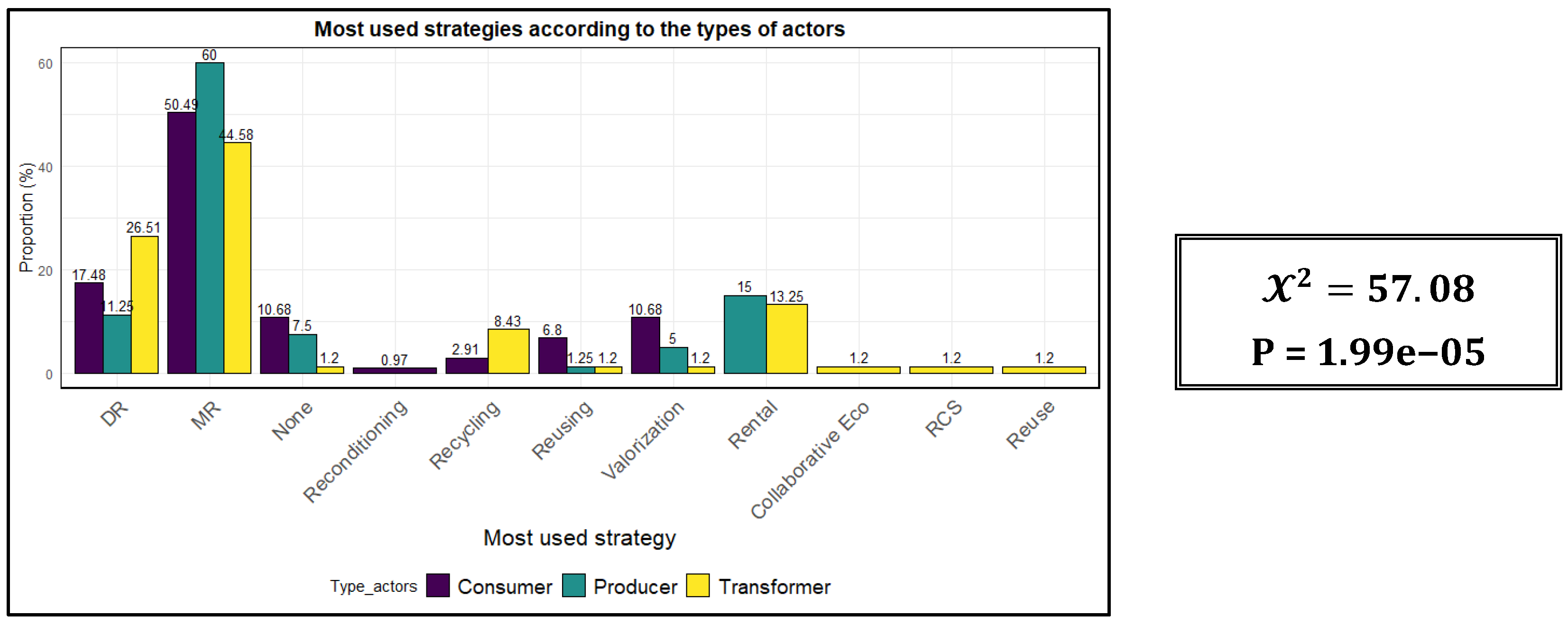

- Comparative analysis of the most used strategies according to the types of actors

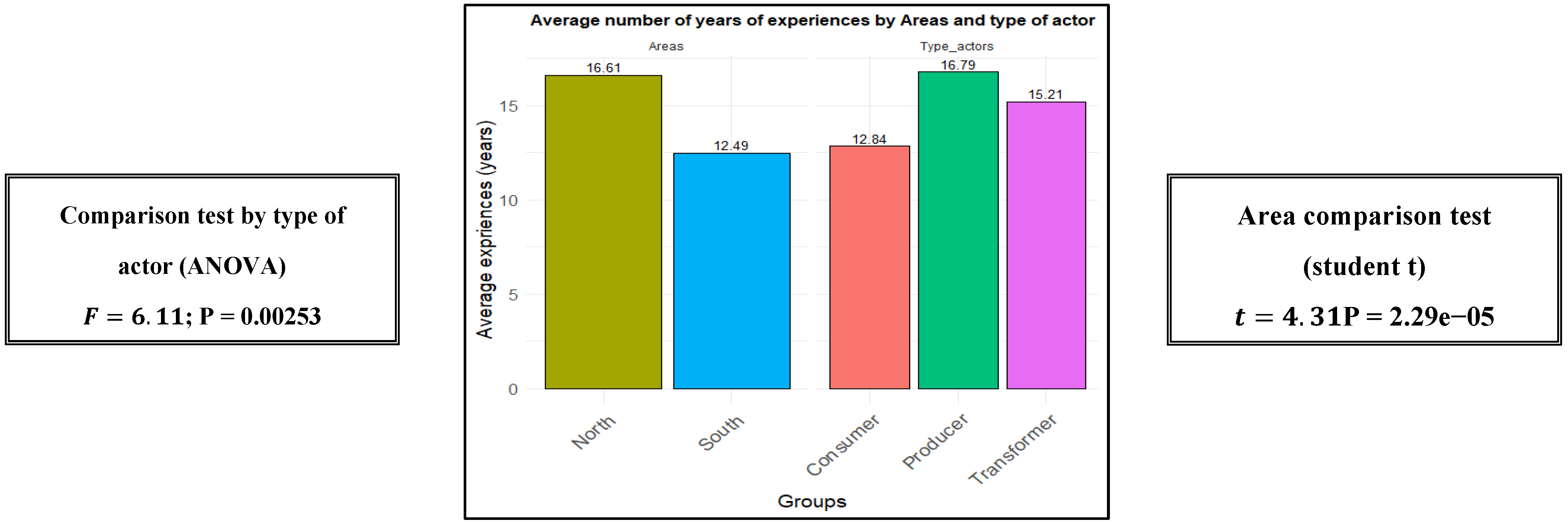

- Seniority in the strategies developed by direct actors

- Seniority according to the types of actors

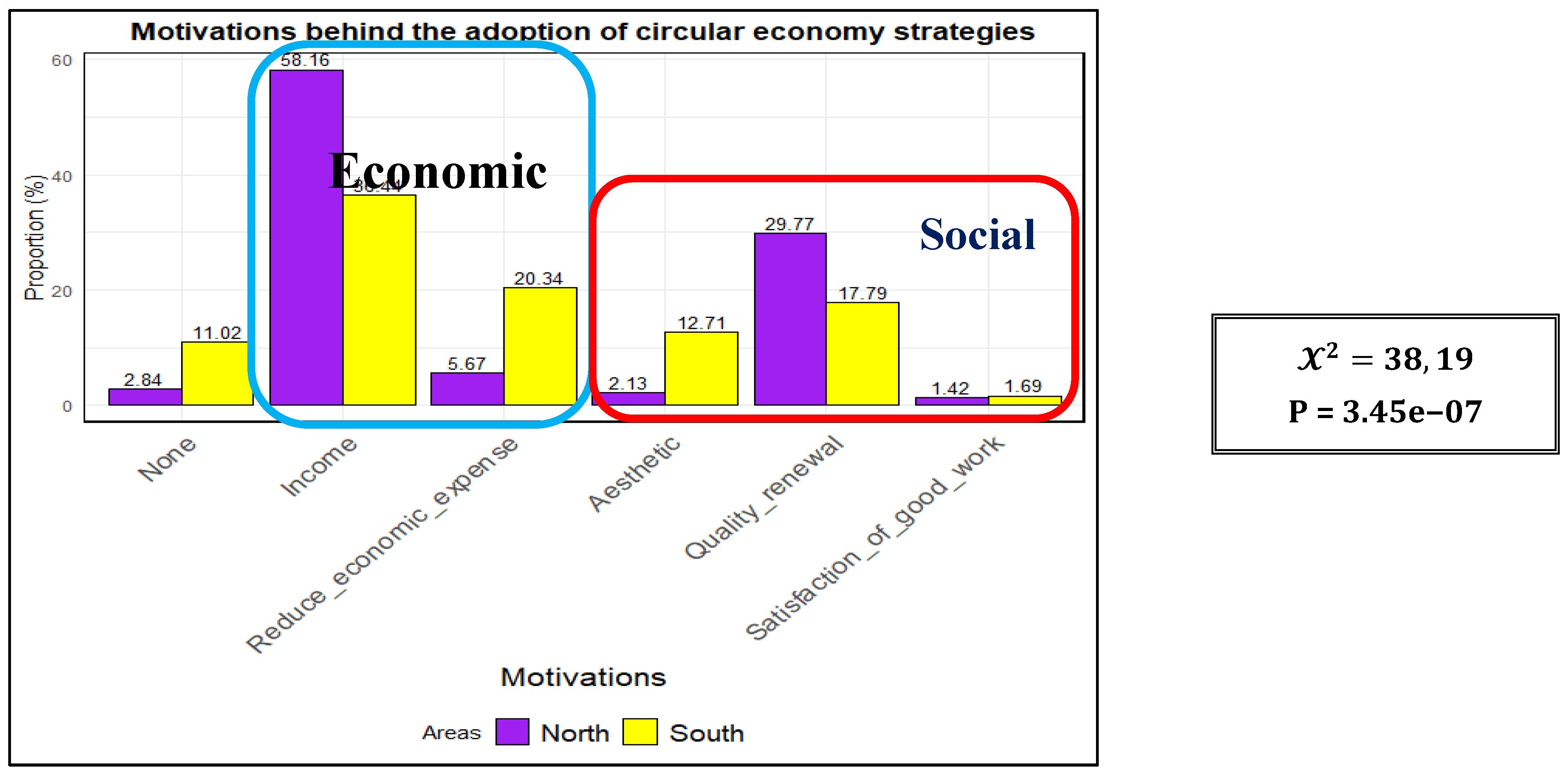

- Motivations for the strategies developed

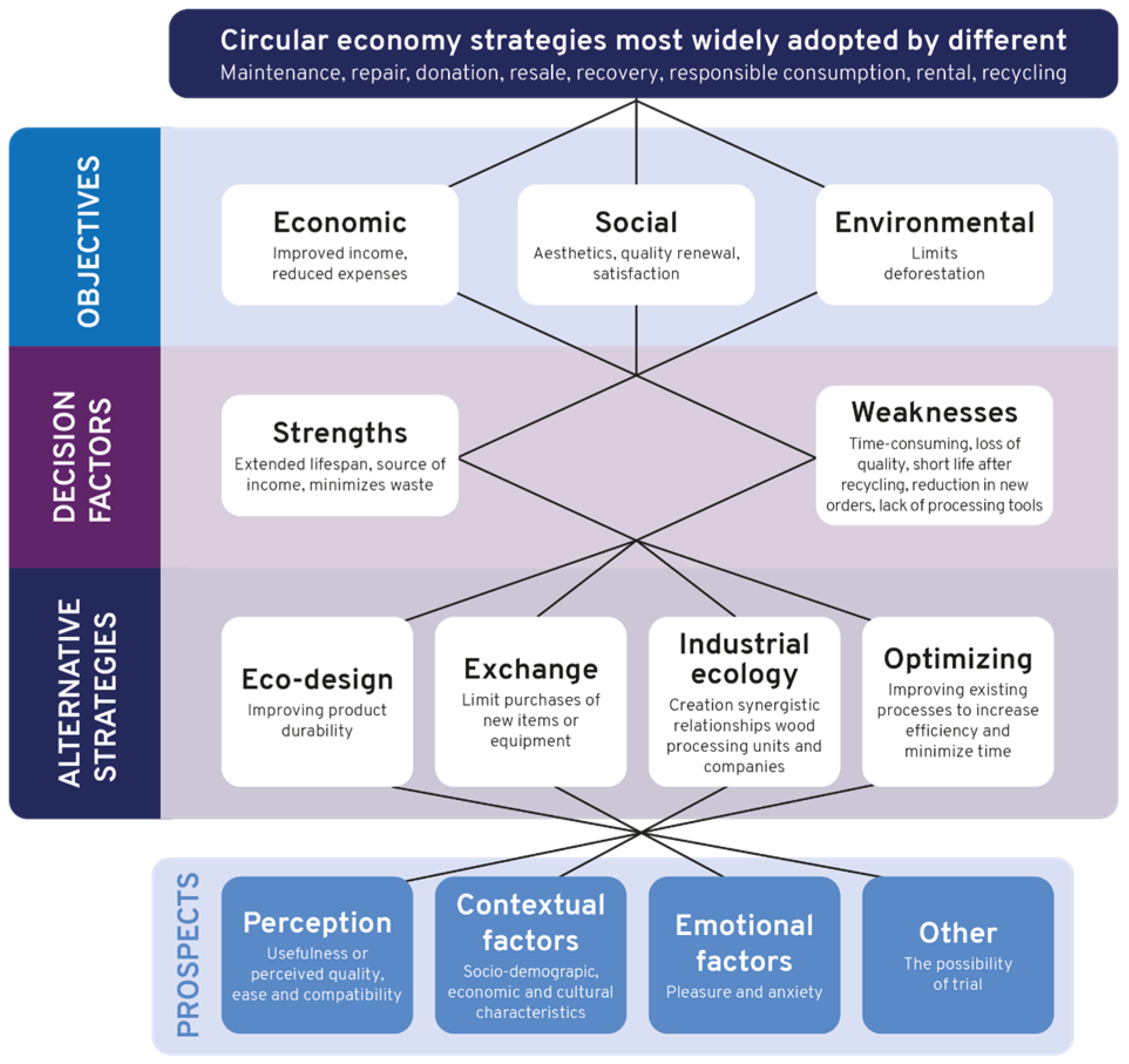

4.3. Analysis of the Strengths and Weaknesses of the Strategies Developed

4.4. Proposals for Alternative Strategies

4.5. DGEFC Position on Strategies to Promote

5. Discussion

6. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Madi, A. Analyse des Filières de Production Agricole: Fondements Théoriques et Démarches Méthodologiques; L’Harmattan: Paris, France, 2010; ISBN 9782296241336. Available online: http://digital.casalini.it/9782296241336 (accessed on 12 January 2025).

- Insee. Définition Filière. Available online: https://www.insee.fr/fr/metadonnees/definition/c1734 (accessed on 2 August 2024).

- Bazire, P.; Gadant, J. La forêt en France; La Documentation Française: Paris, France, 1991; 142p. [Google Scholar]

- Institut National de l’Économie Circulaire (INEC). La Filière Foret-Bois, au Prisme de L’économie Circulaire; INEC: Paris, France, 2022. [Google Scholar]

- Akognongbe, A.; Abdoulaye, D.; Vissin, E.W.; Boko, M. Dynamique de l’occupation du sol dans le bassin versant de l’Oueme à l’exutoire de Bétérou (Bénin). Afr. Sci. Rev. Int. Des. Sci. Technol. 2014, 10, 222–244. [Google Scholar]

- Campos, P.; Mesa, B.; Álvarez, A. Uncovering the hidden numbers of nature in the standard accounts of society: Application to a case study of oak woodland dehesa and conifer forest farms in Andalusia-Spain. Forests 2021, 12, 638. [Google Scholar] [CrossRef]

- FAO. La Situation des Forêts du Monde 2020: Forêts, Biodiversité et Activité Humaine; Food and Agriculture Organization: Rome, Italy, 2020; 78p. [Google Scholar]

- Wobeng, N.B.M.; Banfield, C.C.; Megueni, C.; Mapongmetsem, P.M.; Dippold, M.A. Impact of legumes on soil microbial activity and C cycle functions in two contrasting Cameroonian agro-ecological zones. Pedobiologia 2020, 81–82, 150662. [Google Scholar] [CrossRef]

- Alassane, I.; Agassounon, M.B.; Wedjangnon, A.A.; Akin, Y.Y.; Ouinsavi, C.A.I.N. Dynamiques de l’occupation du sol des forêts classées et forêts sacrées de la Commune de Djougou au nord-ouest du Bénin de 2002 à 2022. Mars 2023, 33, 85–102. [Google Scholar]

- Biaou, S.; Gouwakinnou, G.N.; Biaou, H.S.S.; Tovihessi, M.S.; Awessou, B.K.; Ahononga, F.C.; Houéto, F.O. Identifying the land use and land cover change drivers: Methods and case studies of two forest reserves in Northern Benin. Environ. Dev. Sustain. 2022, 24, 9885–9905. [Google Scholar] [CrossRef]

- Ali, R.K.F. Impacts Socio-économiques et Environnementaux de l’Exploitation des Ressources Ligneuses dans la Commune de Kétou au Sud–est du Benin. Eur. Sci. J. ESJ 2023, 16, 51. [Google Scholar]

- Fournier, A. Consequences of wooded hrinerituals on vegetation conservation in West Africa: A case study from the Bwaba cultural area (West Burkina Faso). Biodivers. Conserv. 2011, 20, 1895–1910. [Google Scholar] [CrossRef]

- Miassi, Y.E.; Dossa, K.F. Circular economy initiatives for forest-based bioeconomy: Harnessing the potential of non-wood biomaterials. Waste Manag. Bull. 2024, 2, 270–278. [Google Scholar] [CrossRef]

- Kalioujny, B. Le Modèle de L’économie Circulaire Dans les Systèmes Socio-Economiques de la Filière Bois: Le Cas de L’oblast de Tomsk. Economies et finances, Université Bourgogne Franche-Comté; Université Polytechnique de Tomsk (Russie), 2021. Français. ffNNT: 2021UBFCG007ff. fftel-03681274. Available online: https://theses.hal.science/tel-03681274 (accessed on 13 October 2024).

- Agence de L’environnement et de la Maîtrise de L’énergie (ADEME) Economie Circulaire: Notions, Fiche Technique, Angers, ADEME. 2014, p. 10. Available online: https://www.ademe.fr/sites/default/files/assets/documents/fiche-technique-economie-circulaire-oct-2014.pdf (accessed on 12 November 2024).

- Kalioujny, B.; Ermushko, J. Could RRI approach play key role in establishment of circular economy? Eur. Proc. Soc. Behav. Sci. (EpSBS) 2017, 26, 341–348. [Google Scholar]

- Winans, K.; Kendall, A.; Deng, H. The history and current applications of the circular economy concept. Renew. Sustain. Energy Rev. 2017, 68, 825–833. [Google Scholar] [CrossRef]

- Amadji, T.A.; Adjovi, E.C.; Gérard, J.; Barés, J.; Huon, V. Étude des propriétés technologiques d’un composite bois-plastique élaboré au Bénin. Bois For. Trop. 2021, 348, 49–63. [Google Scholar] [CrossRef]

- Chanhoun, M.; Padonou, S.; Adjovi, E.C.; Olodo, E.; Doko, V. Study of the implementation of waste wood, plastics and polystyrenes for various applications in the building industry. Constr. Build. Mater. 2018, 167, 936–941. [Google Scholar] [CrossRef]

- Niang, N.; Bourdin, S.; Torre, A. L’économie Circulaire, Quels Enjeux de Développement Pour les Territoires? Dév. Durable Territ. 2020, 11, 1–16. Available online: http://journals.openedition.org/ (accessed on 10 June 2023). [CrossRef]

- Esparon, S. La communauté de communes comme système pilote pour l’étude d’un réseau de création de valeurs forestier élargi. Écon. Rég. Urbaine 2017, 5, 837–856. [Google Scholar] [CrossRef]

- Allam, Z.; Jones, D.S. Towards a circular economy: A case study of waste conversion into housing units in Cotonou, Benin. Urban Sci. 2018, 2, 118. [Google Scholar] [CrossRef]

- Gangnibo, C.N.; Cheng, S.; Huang, L.; Sambou, A. Sustainable agriculture in Benin: Strategies for applying the Chinese circular agriculture model. J. Sustain. Dev. 2010, 3, 69. [Google Scholar] [CrossRef]

- United Nations. Convention-Cadre des Nations Unies sur les Changements Climatiques; United Nations: New York, NY, USA, 1992; p. 9.

- Banque mondiale. Note Sur Les Forêts du Bénin. Banque Internationale Pour la Reconstruction et le Développement/World Bank. 2020, pp. 1–84. Available online: https://documents1.worldbank.org/curated/en/438941599117826833/pdf/Benin-Country-Forest-Note.pdf (accessed on 20 June 2024).

- Miassi, Y.E.; Dossa, F.K.; Akdemir, Ş.; Gültekin, U. Economics of Teak. In The Teak Genome; Compendium of Plant Genomes; Ramasamy, Y., Galeano, E., Win, T.T., Eds.; Springer: Cham, Switzerland, 2021. [Google Scholar] [CrossRef]

- Gouvernement du Bénin. Gouvernement du Bénin. Politique Forestier du Bénin. Ministère du Cadre de Vie et du Développement Durable (Draft). 2019. Available online: https://sgg.gouv.bj/doc/decret-2019547 (accessed on 7 July 2023).

- Mere, S.; Yabi, J.A. Déterminants de la rentabilité économique des activités de l’artisanat du bois au Nord-Est du Bénin. Afrique Sci. 2024, 24, 87–105. [Google Scholar]

- World Bank. Benin Evaluation des Forêts Classées, Rapport Final. 2018. Available online: https://documents1.worldbank.org/curated/en/956601552544423168/pdf/Benin-GFM-Project-CGES.pdf (accessed on 7 July 2023).

- Gandonou, M.B. Étude de Faisabilité de la Certification des Plantations Domaniales de L’onab, PPD 167/13 Rev.1 (M): Analyse du Marché de Bois de L’onab en vue de la Certification. Available online: http://www.itto.int/files/itto_project_db_input/3064/Technical/PPD-167-13-R1-M-Technical%20Report.pdf (accessed on 17 November 2024).

- Afoudah, O.A.C. Circuit de Commercialisation et Rentabilité des Plantations de Teck de L’office National du Bois (ONAB): Cas de la Lama, Sud Bénin. Master’s Thesis, Université de Laval, Quebec, QC, Canada, 2018; pp. 1–59. [Google Scholar]

- Institut de l’Environnement, du Développement Durable et de l’Économie Circulaire (EDDEC). Économie Circulaire au Québec. Rapport de L’étape 4: Conclusions et Recommandations. Projet Réalisé par l’Institut EDDEC et ses Partenaires Institutionnels et Financé par le Ministère de l’Énergie et des Ressources Naturelles. 2018. 96p. Available online: https://www.google.com/url?sa=t&source=web&rct=j&opi=89978449&url=https://mrnf.gouv.qc.ca/wp-content/uploads/Rapport-final-Conclusionsrecommandations.pdf&ved=2ahUKEwi1hIuYsYWMAxWL_rsIHTegEhsQFnoECBQQAQ&usg=AOvVaw1vaU7MRV06sn0bLF2JHTSu (accessed on 3 January 2025).

- Johanson, N.; Henriksson, M. Circular economy running in circles? A discourse analysis of shifts in ideas of circularity in Swedish environmental policy. Sustain. Prod. Consum. 2020, 23, 148–156. [Google Scholar] [CrossRef]

- Leipold, S.; Feindt, P.H.; Winkel, G.; Keller, R. Discourse analysis of environmental policy revisited: Traditions, trends, perspectives. J. Environ. Policy Plan. 2019, 21, 445–463. [Google Scholar] [CrossRef]

- Papaspyropoulos, K.G.; Liakou, H.; Dimopoulos, P. Climate Change in the Biodiversity and Forest Strategies in Greece Using Discourse Analysis and Text Mining: Is an Integration into a Cost-Efficient Natural Resources Policy Feasible? Sustainability 2023, 15, 6127. [Google Scholar] [CrossRef]

- Bahers, J.-B.; Durand, M.; Beraud, H. Quelle territorialité pour l’EC? Interprétation des typologies de proximité dans la gestion des déchets. Flux 2017, 3, 129–141. [Google Scholar] [CrossRef]

- Gallaud, D.; Laperche, B. Économie Circulaire et Développement Durable: Ecologie Industrielle et Circuits Courts; Coll. Innovation, Entrepreneuriat et Gestion; ISTE Editions Ltd.: London, UK, 2016; Volume 5. [Google Scholar]

- Morfin, L.; Monteil, A. Eco-Conception et Sûreté de Fonctionnement, Quels Points Communs? Congrès Lambda Mu 22 “Les Risques au Cœur des Transitions” (e-Congrès)–22e Congrès de Maîtrise des Risques et de Sûreté de Fonctionnement, Institut Pour la Maîtrise des Risques, October 2020, Le Havre (e-Congrès), France. hal-03347877. Available online: https://hal.science/hal-03347877v1/document (accessed on 3 January 2025).

- Esseghaier, L. Interrelation de L’écologie Industrielle et de L’économie Circulaire–Etude du Parc Industriel et Portuaire de Bécancour; Centre Universitaire de Formation en Environnement et Développement Durable: Sherbrooke, QC, Canada, 2016; pp. 1–140. [Google Scholar]

- Venkatesh, V.; Thong, J.Y.; Xu, X. Unified theory of acceptance and use of technology: A synthesis and the road ahead. J. Assoc. Inf. Syst. 2016, 17, 328–376. Available online: https://ssrn.com/abstract=2800121 (accessed on 26 May 2024). [CrossRef]

- Zhu, S.J.; Li, X.; Zheng, X.; Wang, H. Understanding mobile technology adoption in a Chinese cultural context: A revised UTAUT model. Int. J. Inf. Manag. 2019. Available online: https://www.google.com/url?sa=t&source=web&rct=j&opi=89978449&url=https://instad.bj/images/docs/insae-statistiques/enquetesrecensements/EHCVM/EHCVM_Document%2520des%2520principaux%2520indicateurs.pdf&ved=2ahUKEwj6o9eBsoWMAxWKUEEAHXHfAB4QFnoECBQQAQ&usg=AOvVaw39jIdKotC1CGuUnt0hiBzX (accessed on 27 May 2024).

- Geme, T.; Nijman, E.; Ntawuhiganayo, E.B.; Negesa, D. Stakeholder knowledge and perceptions of the circular economy in Ugandan cities. Front. Sustain. 2023, 4, 1117814. [Google Scholar] [CrossRef]

- Gladek, E. The Seven Pillars of the Circular Economy, Metabolic. Available online: https://www.metabolic.nl/news/the-seven-pillars-of-the-circular-economy/ (accessed on 4 March 2025).

- Kirchherr, J.; Reike, D.; Hekkert, M. Conceptualizing the circular economy: An analysis of 114 definitions. Resour. Conserv. Recycl. 2017, 127, 221–232. [Google Scholar] [CrossRef]

- Blomsma, F.; Brennan, G. The emergence of circular economy: A new framing around prolonging resource productivity. J. Ind. Ecol. 2017, 21, 603–614. [Google Scholar] [CrossRef]

- Enquête Harmonisée sur les Conditions de Vie des Ménages (EHCVM). Première Edition de L’enquête Harmonisée sur les Conditions de vie des Ménages (EHCVM1, Bénin 2018–2019) Principaux Indicateurs; Direction Des Statistiques Démographiques Et Sociales Mars: Cotonou, Benin, 2023. [Google Scholar]

- Stahel, W.R. The circular economy. Nature 2016, 531, 435–438. [Google Scholar] [CrossRef]

- Geissdoerfer, M.; Pieroni, M.P.; Pigosso, D.C.; Soufani, K. Circular business models: A review. J. Clean. Prod. 2020, 277, 123741. [Google Scholar] [CrossRef]

- Ferronato, N.; Rada, E.C.; Portillo, M.A.; Cioca, L.; Ragazzi, M.; Torretta, V. Introduction of the circular economy within developing regions: A comparative analysis of advantages and opportunities for waste valorization. J. Environ. Manag. 2019, 230, 366–378. [Google Scholar] [CrossRef]

- Andrews, D. The circular economy, design thinking and education for sustainability. Local Econ. 2015, 30, 305–315. [Google Scholar] [CrossRef]

- Tambovceva, T.T.; Melnyk, L.H.; Dehtyarova, I.B.; Nikolaev, S.O. Circular economy: Tendencies and development perspectives. J. Clean. Prod. 2021, 178, 618–643. [Google Scholar] [CrossRef]

- Sharma, N.K.; Govindan, K.; Lai, K.K.; Chen, W.K.; Kumar, V. The transition from linear economy to circular economy for sustainability among SMEs: A study on prospects, impediments, and prerequisites. Bus. Strategy Environ. 2021, 30, 1803–1822. [Google Scholar] [CrossRef]

- Ali, Q.; Parveen, S.; Yaacob, H.; Rani, A.N.; Zaini, Z. Environmental beliefs and the adoption of circular economy among bank managers: Do gender, age and knowledge act as the moderators? J. Clean. Prod. 2022, 361, 132276. [Google Scholar] [CrossRef]

- Corvellec, H.; Stowell, A.F.; Johansson, N. Critiques of the circular economy. J. Ind. Ecol. 2022, 26, 421–432. [Google Scholar] [CrossRef]

- Velis, C.A.; Vrancken, K.C. Which material ownership and responsibility in a circular economy? Waste Manag. Res. 2015, 33, 773–774. [Google Scholar] [CrossRef] [PubMed]

- MacArthur, E. Financing the Circular Economy—Capturing the Opportunity; Ellen MacArthur Foundation Publishing: Cowes, UK, 2020. [Google Scholar]

- Soh, K.L.; Wong, W.P. Circular economy transition: Exploiting innovative eco-design capabilities and customer involvement. J. Clean. Prod. 2021, 320, 128858. [Google Scholar] [CrossRef]

- Perret, B. Les enjeux de l’économie collaborative. Rev. Cult. Contemp. 2019, 394, 29–38. [Google Scholar] [CrossRef]

- Erkman, S. L’écologie Industrielle: Une Stratégie Pour l’éco-Restructuration du Système Industriel. Ph.D. Thesis, École Doctorale Sciences pour l’Ingénieur (Troyes, Aube), Troyes, France, 2004. [Google Scholar]

- Rogers, E. Network Analysis of the Diffusion of Innovations; Mimeo: New York, NY, USA, 1975. [Google Scholar]

- Dubois, M.; Bobillier-Chaumon, M.-E. L’acceptabilité des technologies: Bilans et nouvelles perspectives. Le Travail Humain 2009, 72, 305–310. [Google Scholar] [CrossRef]

| Areas | Direct Actors | Total | ||

|---|---|---|---|---|

| Producers | Processors | Consumers | ||

| North | 51 | 41 | 58 | 150 |

| South | 30 | 43 | 61 | 134 |

| Total | 81 | 84 | 119 | 284 |

| Strengths/Weaknesses | South (%) | North (%) | Total (%) | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| C | P | T | C | P | T | C | P | T | Average | |

| Strengths (Advantages) | ||||||||||

| Indifferent | 20.45 | 0.0 | 6.82 | 12.90 | 2.82 | 0.0 | 17.33 | 1.98 | 3.61 | 6.95 |

| Limits deforestation | 4.54 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 2.66 | 0.0 | 0.0 | 0.77 |

| Extended life span | 22.73 | 0.0 | 4.54 | 29.03 | 0.0 | 2.56 | 25.33 | 0.0 | 3.61 | 8.49 |

| A real source of income | 4.54 | 66.67 | 65.91 | 0.0 | 22.53 | 69.23 | 2.67 | 35.64 | 67.46 | 36.29 |

| Minimize waste | 0.0 | 0.0 | 2.27 | 16.13 | 2.82 | 10.25 | 30.66 | 1.98 | 6.02 | 11.58 |

| Quality renewal | 2.27 | 3.33 | 0.0 | 12.9 | 66.19 | 10.26 | 6.66 | 47.52 | 4.82 | 22.01 |

| Weaknesses (Limits) | ||||||||||

| No | 88.64 | 93.33 | 88.64 | 61.29 | 14.08 | 15.38 | 77.33 | 37.62 | 54.22 | 54.44 |

| Requires more time | 0.0 | 0.0 | 0.0 | 0.0 | 59.15 | 23.07 | 0.0 | 41.58 | 10.84 | 19.69 |

| Loss of some of the quality of recycled materials | 0.0 | 0.0 | 0.0 | 6.45 | 23.94 | 53.85 | 2.66 | 16.83 | 25.3 | 15.44 |

| Reduction | 0.0 | 4.54 | 6.82 | 0.0 | 0.0 | 0.0 | 0.0 | 2.66 | 3.61 | 1.93 |

| Lack of processing tools | 0.0 | 0.0 | 0.0 | 6.45 | 1.41 | 0.0 | 2.66 | 0.99 | 0.0 | 1.16 |

| Short product life | 0.0 | 0.0 | 0.0 | 19.35 | 0.0 | 0.0 | 8.0 | 0.0 | 0.0 | 2.32 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Miassi, Y.E.; Gélinas, N.; Dossa, K.F. The Circular Economy: A Lever for the Sustainable Development of the Wood and Forestry Sector in West Africa. Forests 2025, 16, 508. https://doi.org/10.3390/f16030508

Miassi YE, Gélinas N, Dossa KF. The Circular Economy: A Lever for the Sustainable Development of the Wood and Forestry Sector in West Africa. Forests. 2025; 16(3):508. https://doi.org/10.3390/f16030508

Chicago/Turabian StyleMiassi, Yann Emmanuel, Nancy Gélinas, and Kossivi Fabrice Dossa. 2025. "The Circular Economy: A Lever for the Sustainable Development of the Wood and Forestry Sector in West Africa" Forests 16, no. 3: 508. https://doi.org/10.3390/f16030508

APA StyleMiassi, Y. E., Gélinas, N., & Dossa, K. F. (2025). The Circular Economy: A Lever for the Sustainable Development of the Wood and Forestry Sector in West Africa. Forests, 16(3), 508. https://doi.org/10.3390/f16030508