Abstract

Mechanization in timber harvesting has improved the comfort and safety of operator workstations. However, there is an imminent ergonomic risk in relation to the repetition of movements, which can cause musculoskeletal injuries. The aim of this study was to apply infrared thermography to identify musculoskeletal overload in the hand region of harvester operators. This study was conducted on wood harvesting of homogeneous Eucalyptus urophylla × Eucalyptus grandis stands using a forestry harvester tractor. Thermographic images were taken of seven operators at the beginning and end of the working day during six days of the shift. The maximum, average, and minimum temperatures were measured in 14 hand regions of interest (ROI), verifying the existence of a difference between the beginning and the end of work (p-value < 5%) by using the Mann–Whitney test. The operators presented hyperradiant temperature variation in the hand region after work, with a variation above 2.5 °C, indicating a high degree of abnormality. There was greater temperature variation in the right hand (3.7 °C) due to the greater concentration of commands on the machine’s right joystick. Infrared thermography has proven to be an important tool for functional imaging diagnosis, contributing to the reduction in risks of developing Repetitive Strain Injury/Work-Related Musculoskeletal Disorder (RSI-WMSD).

1. Introduction

Advanced mechanization in timber harvesting operations worldwide has led to significant changes in the methods and ways of performing work by eliminating physically demanding work [1,2,3]. The introduction of technologies embedded in machines through air-conditioned cabins and joystick-controlled operations has significantly contributed to increasing production capacity, reducing costs, and improving operator comfort, safety, and health conditions [4]. The operator is the main component of the man–machine system and is able to use the full production capacity of forestry machines through their skills [5,6]. However, despite the improvements and numerous ergonomic resources in terms of comfort and safety in current forestry machines, especially in the harvester used to cut wood in homogeneous forests, the activity is still characterized by repetitive upper limb movements, which can lead to developing Repetitive Strain Injury (RSI) and Work-Related Musculoskeletal Disorder (WMSD) [7,8].

These musculoskeletal injuries and disorders are a consequence of highly repetitive tasks [9] and are related to different exposure factors of the operator at work, such as whole-body vibrations, application of excessive forces, and inadequate body postures. This is an increasingly worrying problem for workers, companies, and health institutions in many countries due to the increase in absenteeism rates, job turnover, and high economic and social costs [10]. In this context, performing complementary diagnosis through infrared thermography becomes of great relevance to provide detailed analysis of the different body parts of the worker, aiming at identifying possible occurrence risks of RSI/WMSDs.

Infrared thermography is a non-invasive, painless technique, without contact with the patient and without the use of contrast, which measures the infrared radiation emitted by the human body to determine the skin temperature from a photographic record made by a thermal transducer [9,11,12,13]. This is a functional examination that enables assessing the extent of tissue perfusion through the amount of blood circulating in the injured tissue, producing images (thermograms) that represent the temperature distribution on the skin surface, thereby enabling early identification of signs of muscle stress and inflammation for interventions before developing more serious conditions in various activities [14,15,16].

As reported in the literature [17], there is moderate correlation between blood flow volume and mean skin temperature during a typing task. In studies on prolonged manual work [18], an experimental test was applied in repetitive operation in the textile industry for three days in two healthy people for a certain period of time, in which the results showed that the maximum temperature obtained was 35.078 °C in the right wrist and 34.663 °C in the left wrist, with discomfort being identified in the time range where the temperatures were highest. When evaluating the thermal behavior in different regions of interest (ROIs) in parts of the hands and fingers in male and female people in repetitive work, the authors [9] found that all fingers showed the same temperature increase and recovery behavior; however, the thumb, index finger, and middle finger presented the greatest risk of injury, with temperature recovery reached after 10 min of rest.

Therefore, considering the large number of machines used in timber harvesting operations in homogeneous forests and the cyclical and repetitive nature of mechanized timber cutting activities, infrared thermography can be an efficient technique to ergonomically assess operators subjected to conditions that favor the emergence of musculoskeletal diseases, in turn contributing to establishing preventive health actions. Thus, the objective of this study was to apply the infrared thermography technique to identify the hand regions of harvester operators that are experiencing musculoskeletal overload.

2. Materials and Methods

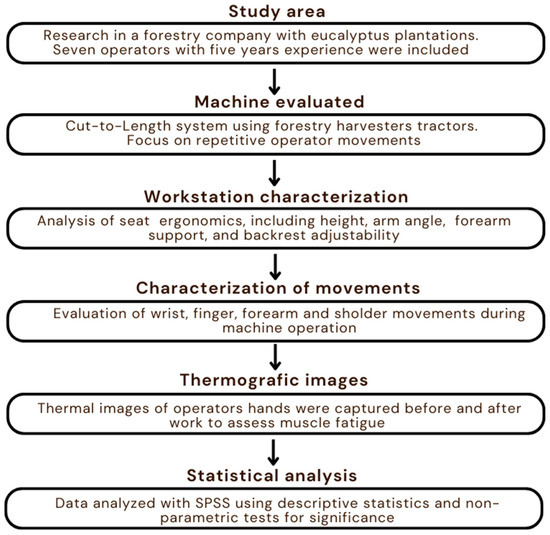

This study was conducted with the aim of evaluating the ergonomic conditions and physiological effects associated with operating forestry machinery in a company located in the Midwest region of Brazil. To ensure the robustness and reproducibility of the results, the methodology adopted was structured in sequential stages, ranging from the description of the study area and selection of participants to data collection and analysis. Below, we detail the procedures adopted to characterize the working environment, evaluate the machines used, record thermographic images, and statistically analyze the results obtained (Figure 1).

Figure 1.

Flowchart of the methodology.

2.1. Study Area and Sample

This study was conducted at a forestry company in the Central-West region of Brazil, in clonal Eucalyptus urophylla × Eucalyptus grandis stands under a clear-cutting regime at seven years of age. The average terrain slope varied from 0° to 10° and the mean tree volume was 0.30 m3. The region’s climate is defined as tropical according to the Köppen–Geiger climate classification, with a rainy season in summer and a dry season in winter, along with flat to gently undulating relief and soils such as Dark Red Latosol. This study included seven operators with five years of experience and in full health conditions, according to the Occupational Health Certificate (Atestado de Saúde Ocupacional—ASO) provided by the forestry company. The participants signed an Informed Consent Form (ICF), and this study was approved by the Research Ethics Committee according to the Certificate of Presentation of Ethical Assessment (CAAE: 71389623.1.0000.8967).

2.2. Machines Evaluated

Timber harvesting was performed using the cut-to-length system with forestry harvester and forwarder tractors. This study included harvester operators due to the cyclical nature and repetitive movements performed by the operator when felling trees and processing the timber into 7.0 m long logs. The models and technical specifications of the machines and the age of the operators are described in Table 1.

Table 1.

Characteristics of the harvester models evaluated in this study.

2.3. Workstation Characterization

The seat, in terms of height and arm angle, which directly affects executing the operator’s movements when performing the work, was characterized in both harvester models (Figure 2). The seat configuration featured anatomically adherent upholstery and easy-to-use adjustments for proximity and distance. The seat had forearm support with independent horizontal and vertical adjustment, allowing various adjustments to meet the different anthropometric standards of the operators and with anatomical accommodation respecting the forearm muscle structure. The backrest enabled adapting posture according to variation in the operator’s lumbar curvature in relation to accommodating their hips and glutes. Wrist positioning when handling the joystick used half of the pronation and supination range and had a cylindrical handle for gripping. The buttons were activated with appropriate use of the forearm support, which was properly adjusted for distributed weight discharge in order to reduce overload on the wrist.

Figure 2.

Characterization of the workstation.

2.4. Characterization of Movements

The operators performed several dynamic and repetitive movements during the tree cutting and wood processing operation with joysticks, including:

- Wrist and finger movements: The operators used their first and second fingers to make fine adjustments to the joystick, applying pressure to move the controls in different directions (forward, backward, and laterally). Although these movements are small, they require precision and could result in repetitive effort when performed for long periods.

- Forearm movements: Forearm rotation was often necessary to adjust the joystick to larger angles or to perform longer-range movements. This movement involved flexing and extending the elbow, which could overload the forearm and upper arm muscles, especially when performed with the hand in suboptimal positions.

- Shoulder movements: Positioning the joystick required the operator to move their shoulder, especially when the device was positioned at a height or at non-ergonomic angles. Repetitive shoulder abduction or rotation movements can cause muscle overload and fatigue.

- Body and neck movements: Operators adopted non-ideal positions in some situations, such as twisting their torso or tilting their head to improve their view of the device. The additional strain on the neck and spine due to these postural adjustments can contribute to increased muscle overload and to developing cervical and back pain.

2.5. Obtaining Thermographic Images

The operators were previously instructed not to consume alcoholic beverages or caffeine, not to use body moisturizer, and not to engage in high-intensity physical exercise for a minimum period of 24 h prior to obtaining the thermographic images [11]. A FLIR C2 transducer with medical calibration was used to obtain the images and configured with the following parameters: resolution of 640 × 480 pixels; emissivity of 0.98; reflected temperature of 20.0 °C; relative humidity of 50.0%; and atmospheric temperature of 23.0 °C.

The thermal images were obtained in the field in a previously prepared room and air-conditioned at 23.0 ± 1.0 °C, where the operator remained at rest for 10 min to stabilize their body temperature. An IBUTG Highmed TGD-1800 thermometer was used in order to control the environmental conditions of the room in terms of ambient temperature and relative humidity during the thermal measurements for strict control over the environmental variables that may influence the thermal response.

Thermal images of the hands were recorded and divided into Regions of Interest (ROI), as described in Table 2, following the criteria established in the Medical Thermography Manual [11], and maintaining the standard distance and inclination of the transducer in relation to the operator’s body. The thermal images were obtained in the period before (7:00 a.m.) and after (5:00 p.m.) the workday for six consecutive days of the work schedule. The company adopted a six-day work and three-day rest regime for operators, and the evaluation was then performed without interruption for 72 h of the specific task.

Table 2.

Regions of interest of the studied hands and fingers.

The ROIs in the different parts of the operators’ hands and fingers were defined based on their anatomical and physiological relevance, as well as the direct relationship with the muscular overload induced by repetitive work using joysticks, offering a solid basis for analyzing thermal and muscular impacts.

From an anatomical point of view, the hands have a dense network of thermoreceptors, which are sensitive to temperature variations and therefore accurately reflect thermal changes. In addition, the hands are composed of a combination of skeletal muscles, tendons, and ligaments, in which repetitive contractions during activities can lead to an increase in muscle energy consumption and, consequently, in the heat generated in peripheral areas. From a physiological point of view, the hands are the part of the body most exposed to repetitive physical effort, receiving the greatest workload. The thermal increase in these regions is directly related to intensified muscle metabolism, resulting in greater heat production (Table 3).

Table 3.

Temperature variation analysis criteria (∆t).

2.6. Statistical Analysis

Data were analyzed using IBM SPSS Statistics for Windows, version 25.0 194 (IBM Corporation, Armonk, NY, USA), using data frequency and descriptive measures such as mean, standard deviation, minimum, and maximum. The Kolmogorov–Smirnov test was applied to compare the data distribution and check whether the dataset followed a normal distribution. It was found that none of the variables evaluated followed a normal distribution; in turn, non-parametric tests were carried out to compare the means and check for significant differences between the periods before and after the work schedule at a significance level of p-value < 5%.

3. Results

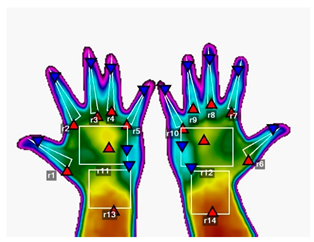

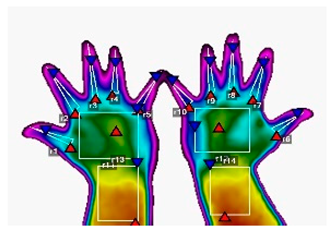

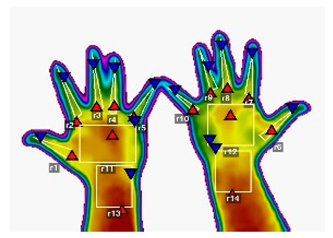

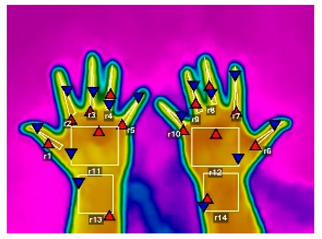

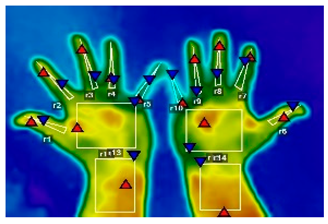

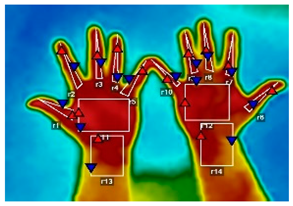

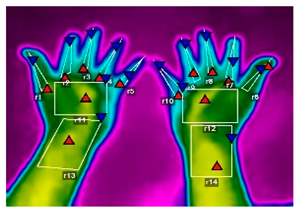

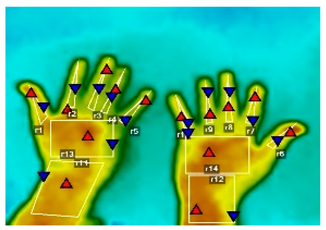

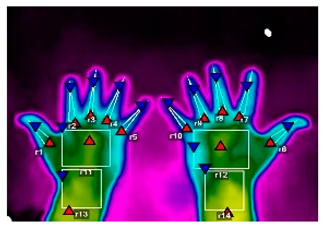

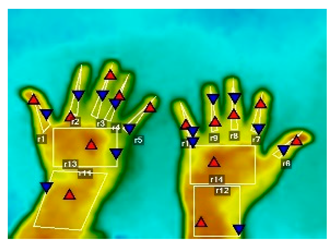

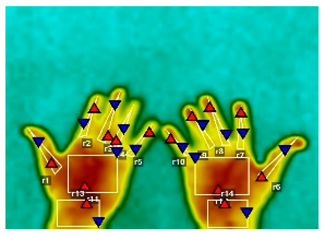

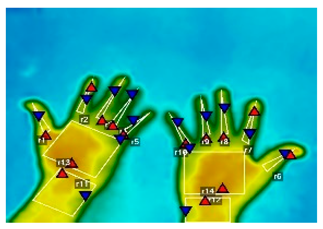

For visual representation purposes, Table 4 illustrates the thermal profile results for the hand region of two tire (HV2) and track harvester (HV1, HV3, HV4, HV5, HV6, and HV7) operators before and after the three-day work shift. This selection does not reflect all operators, all of whom are included in the minimum, mean, and maximum temperature graphs. On a visual scale, it was possible to identify a hyperradiant thermal variation after the work shift, indicating that the mechanized forest cutting activity performed by the operators influenced the increase in temperature in the hand region. It is also observed that the occurrence of thermal variation in the finger, palmar, and carpal regions indicates that the joystick handling activity during the work shift requires effort in these regions. In addition, it is noted that there was variability in the thermal profiles among the operators, and therefore it was possible to infer different muscular responses among the operators.

Table 4.

Representative illustration of the thermal profile of the hands of two operators over three work shifts.

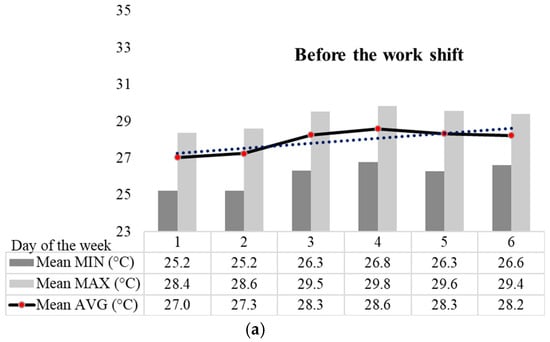

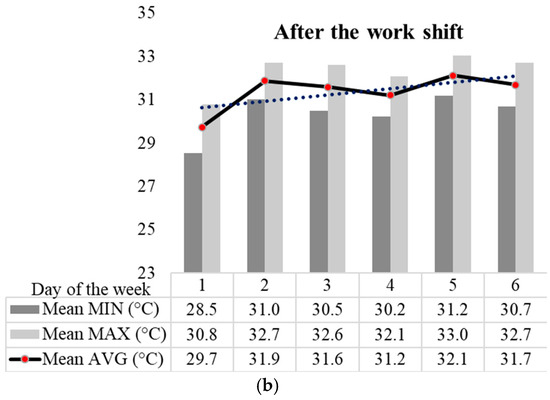

A histogram representing the mean minimum, average, and maximum temperature values of the ROIs in the operators’ hands before and after the workday over the six days of the work shift is presented in Figure 3. An increasing trend in temperature was observed in the period prior to the start of the workday until the fourth day. The mean temperature values were 28.0 °C ± 0.6, with a thermal peak of 28.6 °C on the fourth day, while an increasing trend was observed after the workday over the six days, with a peak temperature on the second day of 31.9 °C. The thermal variation was classified as hyperradiant on all workdays, with an average of 3.4 °C, indicating a high degree of abnormality. The variation on the fourth day of work was the smallest found (2.6 °C), with peak temperature occurring before the workday and a reduction after the workday. However, it should be considered that the mean temperature variation between operators on all working days remained hyperradiant, above 2.5 °C, therefore indicating significant abnormality.

Figure 3.

Histograms representing the mean minimum, average, and maximum temperatures in the region of the operators’ hands before and after their work shifts. Legend: The light and dark grey bars represent the mean minimum (Mean MIN), mean maximum (Mean MAX) and mean average (Mean AVG) temperatures before and after the shift, respectively.

It is important to note that the average minimum temperature varied the most during the six days of the work shift (4.3 °C), peaking after the shift on the second day (31.0 °C) and causing the greatest variation on that day (5 °C). On the fifth day there was another peak in the average minimum temperature (31.2 °C), but with less variation (4.9 °C) after the working day. It was also observed that the minimum temperature in the period before the working shift increased until the fourth day, with a similar behavior to the maximum temperature.

The minimum temperature showed greater variation during the six days of the scale (3.4 °C), reaching its peak after the workday on the second day of work (31.2 °C), resulting in greater variation on this day (5.1 °C). The minimum temperature in the previous workday period increased until the fourth day, with the same behavior for the maximum temperature, and therefore suggesting that the minimum and maximum temperatures tended to increasingly oscillate in the hand region until the fourth day (Table 5). It was possible to verify that the temperature at the end of the afternoon was consistently higher on all workdays, with a difference between the medians ranging from 4 °C to 6 °C, suggesting that the activity of cutting wood with the harvester causes a significant increase in hand temperature, which can cause injuries in the future. In turn, a significant difference was found when comparing the means between the images from before and after the workday between the evaluated periods using the Mann–Whitney test, and consequently the existence of a thermal hyperradiant condition in the harvester operators.

Table 5.

Minimum, maximum, and average temperatures before and after the shift and variation in the region of the operators’ hands.

The results by ROI indicated that there was a predominance of the hyperradiant condition in the 14 hand and finger regions on all workdays, indicating significant abnormality (Table 6). Greater thermal variation was observed in the right hand (3.7 °C) compared to the left hand (3.2 °C) when comparing the average results between the operators’ hands, indicating a greater concentration of joystick machine commands on the right side. The palmar and carpal regions (ROIs 11, 12, 13, and 14) showed an increase in temperature before the workday until the fourth day, reaching an average of 31.3 °C. The trend increased after the workday, reaching a temperature of 33.1 °C on the last day of the work shift.

Table 6.

Thermal variation in the hand region in different operator ROIs.

4. Discussion

Infrared thermography in measuring skin temperature using a protocol that outlined multispectral images in ROIs made it possible to verify the existence of significant thermal variations in the hand regions of harvester operators when cutting trees, highlighting the muscular overload imposed by handling the machine controls. This finding suggests that high movement repetition and possible force application when handling the controls lead to an increase in temperature due to intense muscular activity, with the potential for inflammation and injuries in the future [11]. This result demonstrated the existence of a relationship between repetitive hand movements and the development of injuries, such as tendonitis and carpal tunnel syndrome, as also reported in several studies [9,19,20].

The temperature variation in the operators’ hands suggests that the harvester’s manual controls may have contributed to the occurrence of muscle load. This result shows the need for ergonomic reviews in designing forestry machine controls through adjustments to reduce the applied force and minimize movement repetition. Introducing adjustable controls and automation through grouping some functions may contribute to this reduction in repetitive movements and physical stress on operators [21].

From a clinical perspective, the thermal variations observed in different regions of the operators’ hands may be associated with occurrences of inflammation of muscle and tendon tissues, a common precursor of chronic injuries such as tendonitis and carpal tunnel syndrome. Therefore, continuous thermal monitoring in the hand regions of forestry machine operators, especially in those characterized by short-term cyclical activities with high repetition, could be used in the diagnosis to evaluate the effectiveness of different ergonomic interventions and injury prevention programs to be implemented by companies [11]. In addition, introducing prevention programs, including the establishment of regular breaks, stretching exercises, task rotation, and awareness of operators about adopting appropriate postures, are essential to reduce muscle load and mitigate potential risks of RSI-WMSDs [22].

An analysis of the operators’ wrist is also essential, since disorders in this region are associated with the occurrence of tendonitis, tenosynovitis, and carpal tunnel syndrome caused by tension overload or tissue friction, being characterized as inflammation in the tendons due to movements of the wrist and fingers [23]. The flexor tendons of the fingers on the palmar surface also share a common tunnel, called the carpal tunnel, which is filled with a thin layer of lubricant (synovial fluid) that is important for tendon sliding [24]. The tendon properties are modified in repetitive activities due to constant tension, affecting the structure, chemical composition, and mechanical characteristics. When collagen is subjected to continuous tension, it undergoes changes in its molecular structure, resulting in loss of resistance, and excessive and repetitive use of the joint and tendons can trigger inflammatory processes [25]. Thermal behavior in repetitive activities that involve all fingers tends to be different, with [9] finding higher temperatures in the thumb, index finger, and middle finger with a variation of 1.87 °C, which is similar to that obtained in this study.

In a study on the optimization process of a hydraulic boom in a forestry machine using Intelligent Boom Control (IBC), it was possible to reduce the operating cycle time and consequently increase productivity. This cited study showed that optimizing controls can be achieved with less demand from operators, i.e., reducing the number of repetitive movements and muscle load, without compromising productivity [21]. Therefore, it is essential that new studies in this research line be conducted seeking to optimize the process and reduce repetitive work, as well as periodic monitoring of forestry machine operators, since they are subject to excessive repetitive loads in the hand region. In this context, several studies have been developed seeking to consolidate thermography as an important tool for validating work-related occupational problems as a complementary method in evaluating musculoskeletal diseases, which are scarce in forestry work.

It is clear that the technology involved in infrared image-generating equipment has significantly advanced over time while maintaining the safety of the method, which has increased sensitivity and widened its employability in various medical specialties. Thermography has high sensitivity, and according to the studies listed, it is increasingly gaining ground in the diagnostic support, monitoring, and evaluation of musculoskeletal symptoms, especially in pathologies of the hands and wrists, elbows, and shoulders, as well as in musculoskeletal pathologies related or not to work [9,17,19,26]. It is also worth noting that thermography is viable for use in diagnosis in proven cases of musculoskeletal diseases such as tendonitis. The main findings are changes in the variation rates and mean temperature difference, as well as in the sensitivity and specificity values, with significant results indicating that thermography is capable of detecting wrist tendonitis [20].

There are no published studies in the forestry context with regard to mechanized operations; therefore, some limitations imposed on this study should be highlighted with a view to new approaches to this topic in the future. One limitation refers to the cross-sectional design, which, although useful for identifying associations between muscle overload and work with the harvester, did not enable observing thermal variations over time or determining causal relationships. The cross-sectional design provided a momentary analysis of muscle conditions, limiting capture of the evolution of muscle wear associated with continuous exposure to this type of work activity, meaning that it is not possible to infer the cumulative nature and long-term effects of muscle overload in work with the harvester. As a result, it is suggested that future studies adopt a longitudinal design which enables monitoring individuals for a prolonged period, allowing an analysis of progressive changes in muscle conditions and providing a more comprehensive view of the chronic effects of physical overload; this in turn will allow us to develop more effective interventions for preventing injuries and musculoskeletal disorders in workers exposed to repetitive tasks.

Another limitation in this study is the lack of control for factors that may influence thermal results, such as pre-existing health conditions, physical fitness level, and occupational stress [11]. These factors may interfere with the physiological response of individuals working with forestry machines, resulting in variations that are not exclusively attributable to the type of work activity analyzed. Poor health conditions or low physical fitness levels may predispose workers to alter thermal responses, while occupational stress may increase the perception of thermal discomfort. Thus, it is suggested that a health screening or initial medical and physical fitness level evaluation of operators be included to mitigate this bias in future studies, which will enable more accurate analysis of the specific effects of the work, isolating the impact of thermal overload from other contextual factors. It is also important to highlight that this study did not address the impact of occupational stress and cognitive load on muscle overload, constituting factors that are frequently present in repetitive and physically demanding tasks. Stress and cognitive load can affect muscle response, exacerbating the sensation of fatigue and the perception of thermal discomfort. The interaction between physical and mental stress can alter the physiological response of forestry machine operators, increasing their vulnerability to musculoskeletal disorders and increasing the impact of heat overload. Including this discussion will broaden the scope of new studies, integrating psychophysiological aspects into the analysis of muscle overload and stimulating future research that considers both physical and psychological factors in the work environment.

Another aspect concerns the variability in thermal response among different individuals, since basal metabolism, peripheral circulation, physical activity level, and individual environmental conditions can significantly impact how individuals respond to physical effort and heat generated during work with joysticks. Such variabilities can influence local heat production, dissipation capacity, and therefore thermal results. Although the sample was composed of operators with similar characteristics, it was not possible to rigorously control individual differences in metabolic and physiological responses to heat stress. Individuals with less efficient peripheral circulation or faster metabolism may have a different thermal response compared to those with different physiological characteristics. Therefore, future studies should consider implementing individualized reference measures to improve interpretation of results and reduce the impact of these individual variabilities, such as assessing basal metabolism and peripheral circulation or using control methods that adjust the results based on the physiological characteristics of each forestry machine operator.

5. Conclusions

There was a tendency for temperatures to increase in different regions of the operators’ hands between the beginning and the end of the workday, with an increasing temperature trend throughout the work shift, and a peak temperature reached on the second day of work, thereby indicating a possible occurrence of muscle overload caused by work with the harvester.

The regions that suffered the greatest impact were the palmar and carpal regions, which showed a significant increase in temperature over the course of the working days.

This increase is possibly related to the intensive use of the joystick to control the harvester head. It is recommended that future studies further detail the relationship between the type of control and the thermal impact, as well as investigate ergonomic interventions, such as adjustments to the design of the controls and the use of protective equipment, expand the number of operators assessed, and adopt longitudinal monitoring to better understand the effects.

The harvester operators presented hyperradiant temperature variation after the workday and throughout the work shift, with a variation above 1.0 °C, indicating a high degree of abnormality for the regions of the hands, and a greater occurrence of thermal occurrence was also observed in the right hand due to a greater concentration of machine head controls on the right joystick of the machine.

Infrared thermography has proven to be a promising tool for measuring maximum, mean, and minimum temperatures, enabling practical and non-invasive image diagnosis, and may contribute to reducing possible risks of injuries and the number of absences from work. However, future studies should focus on a larger number of operators, carry out monitoring over time to assess the impact of ergonomic interventions, implement an individual baseline, use a longitudinal design, and assess the impact of stress and cognitive load in order to provide a more comprehensive and integrated understanding of the effects of repetitive work on the muscular health of forestry machine operators.

Author Contributions

Conceptualization, A.B.M. and E.d.S.L.; methodology, A.B.M., M.L.B. and E.d.S.L.; software, A.B.M. and M.L.B.; validation, M.L.B., C.K.R. and E.d.S.L.; formal analysis, A.B.M. and M.L.B.; investigation, A.B.M. and E.d.S.L.; resources, A.B.M., M.L.B. and E.d.S.L.; data curation, M.L.B., C.K.R. and E.d.S.L.; writing—original draft preparation, A.B.M. and E.d.S.L.; writing—review and editing, A.B.M., M.L.B., C.K.R. and E.d.S.L.; visualization, A.B.M., M.L.B., C.K.R. and E.d.S.L.; supervision, A.B.M., M.L.B., C.K.R. and E.d.S.L.; project administration, A.B.M., M.L.B. and E.d.S.L.; funding acquisition, M.L.B. and E.d.S.L. All authors have read and agreed to the published version of the manuscript.

Funding

This study was financed in part by the Coordination of Superior Level Staff Improvement—Brazil (CAPES)—Finance Code 001 and by the National Council for Scientific and Technological Development—Brazil (CNPq)—Finance Code 405189/2023-0.

Data Availability Statement

The raw data are available upon request to the authors. Please contact Alysson Braun Martins (alyssonbmartins@gmail.com) to access the data of this study.

Acknowledgments

The authors thank the Brazilian forest company for their support during the data collection and the National Council for Scientific and Technological Development—CNPq, Brazil, for support funds.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Oliveira, F.M.; Lopes, E.S.; Koehler, H.S.; Behling, A. Application of an Integrated Ergonomic Indicator (IEI) in evaluating forest machines. Int. J. For. Eng. 2021, 32, 256–265. [Google Scholar] [CrossRef]

- Sláma, D.; Mergl, V.; Pavlíková, E.A. Analysis of the heart rate of operators of forwarding machines during work activities. Forests 2023, 14, 1348. [Google Scholar] [CrossRef]

- Diniz, C.C.; Timofeiczyk Junior, R.; Garzel, J.C.; Robert, R.C.G.; Sessions, J.; Lopes, E.S. Comparing different replacement policies for logging machines in Brazil. Croat. J. Eng. 2024, 45, 57–70. [Google Scholar] [CrossRef]

- Holzfeind, T.; Visser, R.; Chung, W.; Holzleitner, F.; Erber, G. Development and benefits of winch-assist harvesting. Curr. For. Rep. 2020, 6, 201–209. [Google Scholar] [CrossRef]

- Pagnussat, M.B.; Lopes, E.S.; Robert, R.C.G. Machine availability and productivity during timber harvester machine operator training. Can. J. Res. 2021, 51, 433–438. [Google Scholar] [CrossRef]

- Malinen, J.; Taskinen, J.; Tolppa, T. Productivity of cut-to-length harvesting by operators’ age and experience. Croat. J. For. Eng. 2018, 39, 15–22. [Google Scholar]

- Martins, A.B.; Lopes, E.S.; Pagnussat, M.B.; Fiedler, N.C.; Oliveira, F.M. Upper limb posture and movement during tracked versus wheeled harvester operation on pinus thinning. Inter. J. Eng. 2020, 31, 263–271. [Google Scholar] [CrossRef]

- Synwoldt, U.; Gellerstedt, S. Ergonomic initiatives for machine operators by the Swedish logging industry. Appl. Erg. 2003, 34, 49–156. [Google Scholar] [CrossRef] [PubMed]

- Becerra, A.G.; Olguín-Tiznado, J.E.; Alcaraz, J.L.G.; Wilson, C.C.; Garcia-Rivera, B.R.; Vardasca, R.; López-Barreras, J.A. Infrared thermal imaging monitoring on hands when performing repetitive tasks: An experimental study. PLoS ONE 2021, 16, e0250733. [Google Scholar] [CrossRef] [PubMed]

- Muggleton, J.; Allen, R.; Chappell, P. Hand and arm injuries associated with repetitive manual work in industry: A review of disorders, risk factors and preventive measures. Ergonomics 1999, 42, 714–739. [Google Scholar] [CrossRef]

- Brioschi, M.L.; Teixeira, M.J.; Yeng, L.T.; Silva, F.M.R.M. Manual de Termografia Médica (Based of the International Consensus and Guidelines For Medical Thermography), 1st ed.; Andreoli: São Paulo, Brazil, 2012; 239p. [Google Scholar]

- Lubkowska, A.; Pluta, W. Infrared thermography as a non-invasive tool in musculoskeletal disease rehabilitation—The control variables in applicability—A systematic review. Appl. Sci. 2022, 12, 4302. [Google Scholar] [CrossRef]

- Kawasaki, R.; Sakata, A.; Hosoda, C.; Harada, S.; Soeda, T.; Nishida, Y.; Matsumoto, N.; Tatsumi, K.; Nogami, K.; Yoshimura, Y.; et al. The Use of infrared thermography for non-invasive detection of bleeding and musculoskeletal abnormalities in patients with hemophilia: An observational study. Thromb. J. 2023, 21, 70. [Google Scholar] [CrossRef] [PubMed]

- Vaz, R.; Andreoli, C.V.; Bittencourt, N.F.N.; Lasmar, R.C.P.; Kanope, T.; Silva, R.P.; Assis, M.G. The Integrated Use of Thermography and Ultrasonography as Predictive Load Control Model of Muscle Injuries in Soccer Athletes. J. Clin. Med. Image 2022, 6, 1–8. [Google Scholar]

- Côrte, A.C.; Pedrinelli, A.; Marttos, A.; Souza, I.F.G.; Grava, J.; Hernandez, A.J. Infrared thermography study as a complementary method of screening and prevention of muscle injuries: Pilot study. BMJ Open Sport. Exerc. Med. 2019, 5, e000431. [Google Scholar] [CrossRef]

- Dindorf, C.; Bartaguiz, E.; Janowicz, E.; Fröhlich, M.; Ludwig, O. Effects of unilateral muscle fatigue on thermographic skin surface temperature of back and abdominal muscles—A pilot study. Sports 2022, 10, 41. [Google Scholar] [CrossRef]

- Gold, J.E.; Cherniack, M.; Hanlon, A.; Soller, B. Skin temperature and muscle blood volume chances in the hand after typing. Inter. J. Ind. Erg. 2010, 40, 161–174. [Google Scholar] [CrossRef]

- Camargo, C.; Ordorica, J.; De La Vega, E.; Olguín, J.; López, O.; López, J. Analysis of temperature on the surface of the wrist due to repetitive movements using sensory thermography. Work 2012, 41 (Suppl. S1), 2569–2575. [Google Scholar] [CrossRef] [PubMed]

- Gold, J.E.; Cherniack, M.; Buchholz, B. Infrared thermography for examination of skin temperature in the dorsal hand of office workers. Eur. J. Appl. Physiol. 2004, 93, 45–251. [Google Scholar] [CrossRef]

- Magas, V.; Neves, E.B.; Moura, M.A.M.; Nohama, P. Avaliação da aplicação da termografia no diagnóstico de tendinite de punho por Ler/Dort. In Proceedings of the XXIII Brazilian Congress on Biomedical Engineering, Porto de Galinhas, PE, Brazil, 1–5 October 2012. [Google Scholar]

- Sokolov, A.; Seliverstov, A.; Sukhanov, Y. Forest machine automation and ergonomics. E3s Web Conf. 2023, 389, 03002. [Google Scholar] [CrossRef]

- Bandeira, F.; Neves, E.B.; Moura, M.A.M.; Nohama, P. A termografia no apoio ao diagnóstico de lesão muscular no esporte. Rev. Bras. Med. Esporte 2014, 20, 59–64. [Google Scholar] [CrossRef]

- Assunção, A.A. Sistema Musculoesquelético: Lesões por esforços repetitivos (LER). In Patologia do Trabalho; Mendes, R., Ed.; Atheneu: Rio de Janeiro, Brazil, 1997. [Google Scholar]

- Bastos, D.; Silva, G.; Teixeira, L.; Lustosa, M.; Borda, M.; Couto, S.E.; Vicente, T. Dor. Rev. SBPH 2007, 10, 86–96. [Google Scholar] [CrossRef]

- Waersted, M.; Hanvold, T.N.; Veiersted, K.B. Computer work and musculoskeletal disorders of the neck and upper extremity: A systematic review. BMC Musculoskelet. Disord. 2010, 11, 79. [Google Scholar] [CrossRef] [PubMed]

- Trotta, J.; Ulbricht, L. Termografia no diagnóstico complementar de doenças músculo esqueléticas. Pan Am. J. Med. Thermol. 2015, 2, 7–13. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).