Precision Modeling of Fuel Consumption to Select the Most Efficient Logging Method for Cut-to-Length Timber Harvesting

Abstract

1. Introduction

1.1. Background

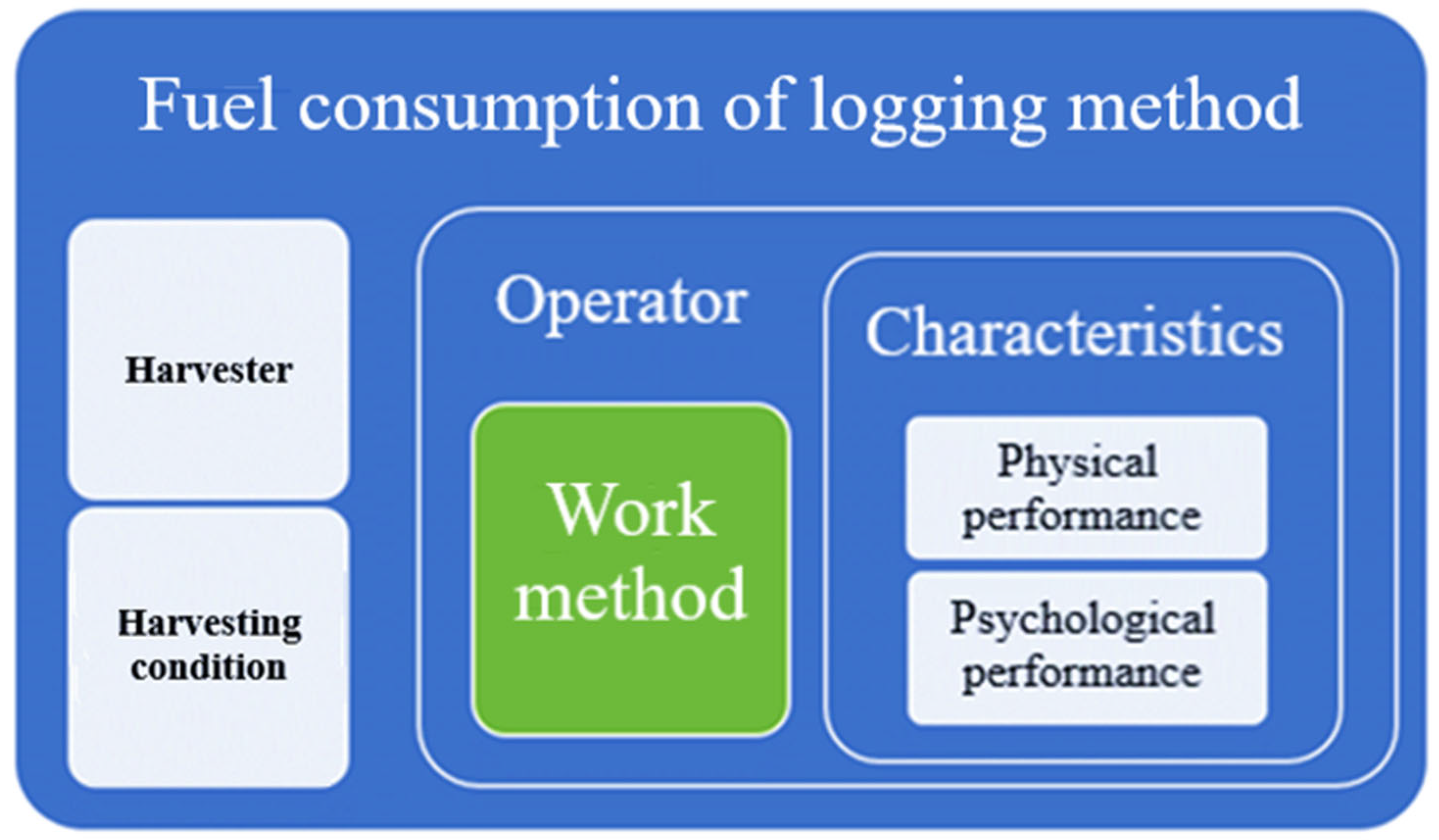

1.2. Fuel Consumption

2. Materials and Methods

2.1. Harvester

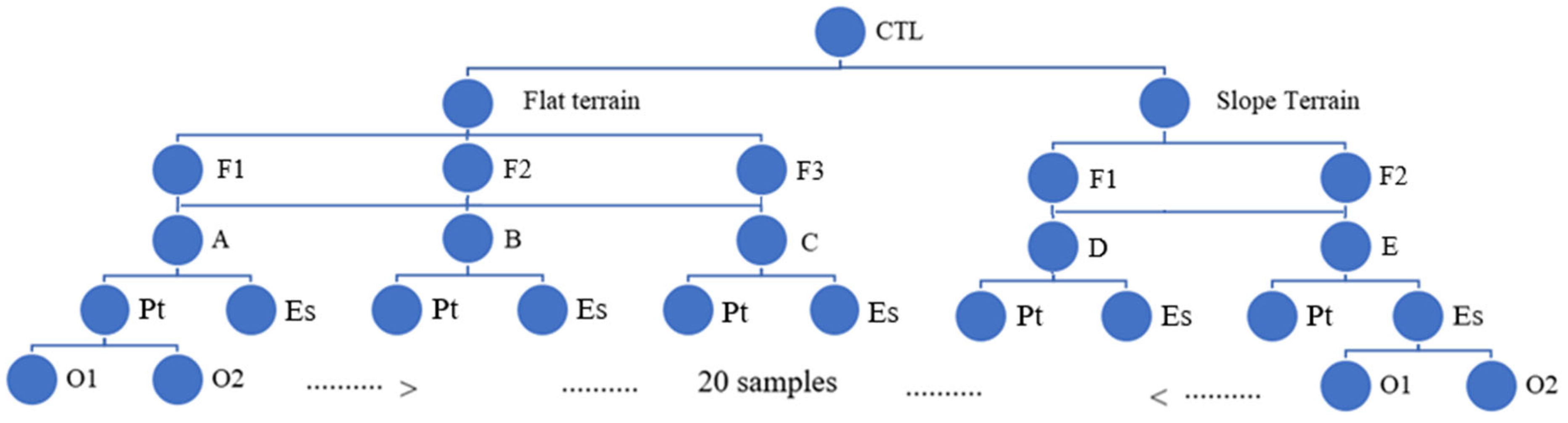

2.2. Study Design of the Logging Experiments

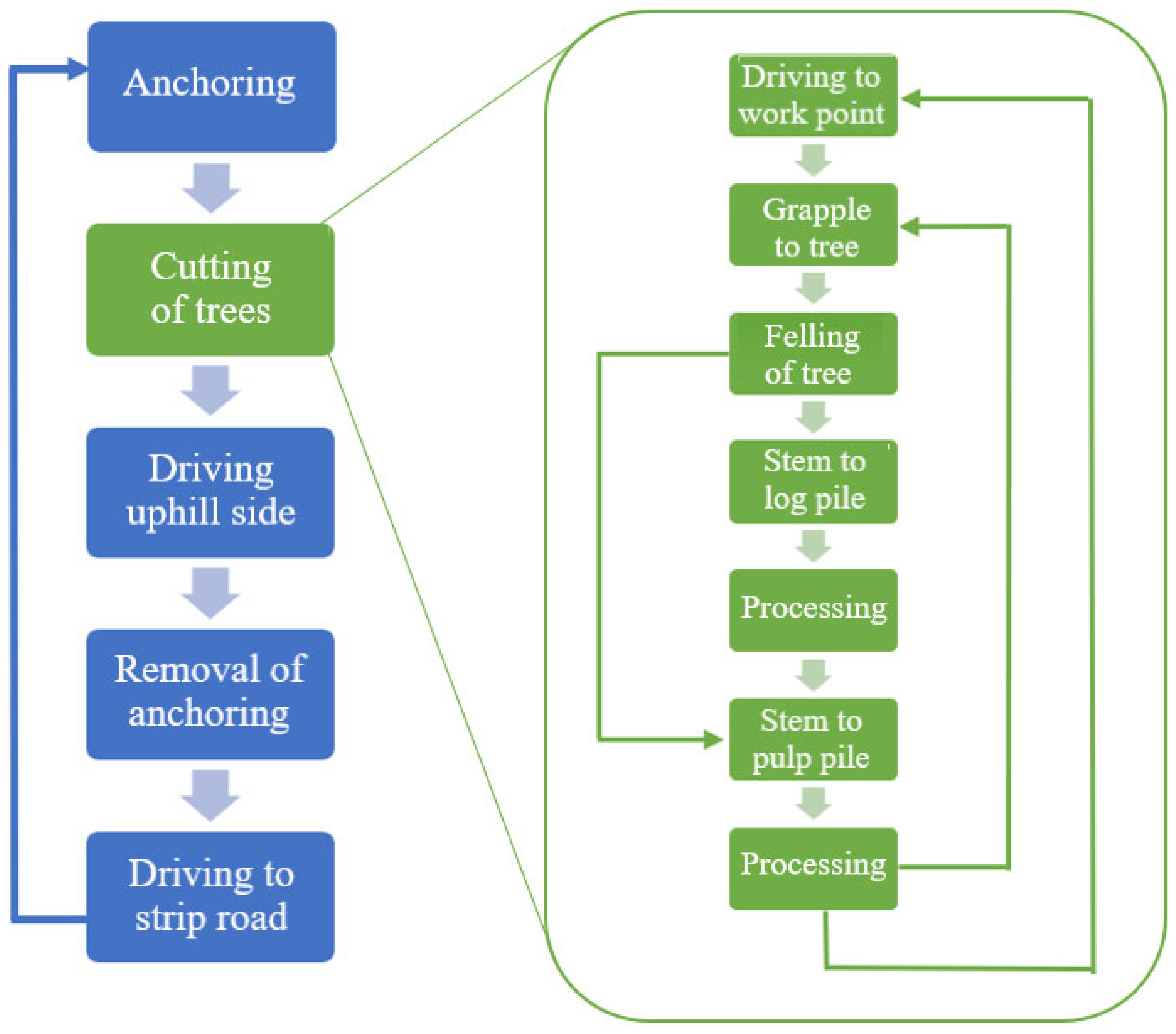

2.3. Time and Motion Study

2.4. Fuel Consumption of the Harvester–Operator System

2.5. Operators

2.6. Statistical Analysis

3. Results

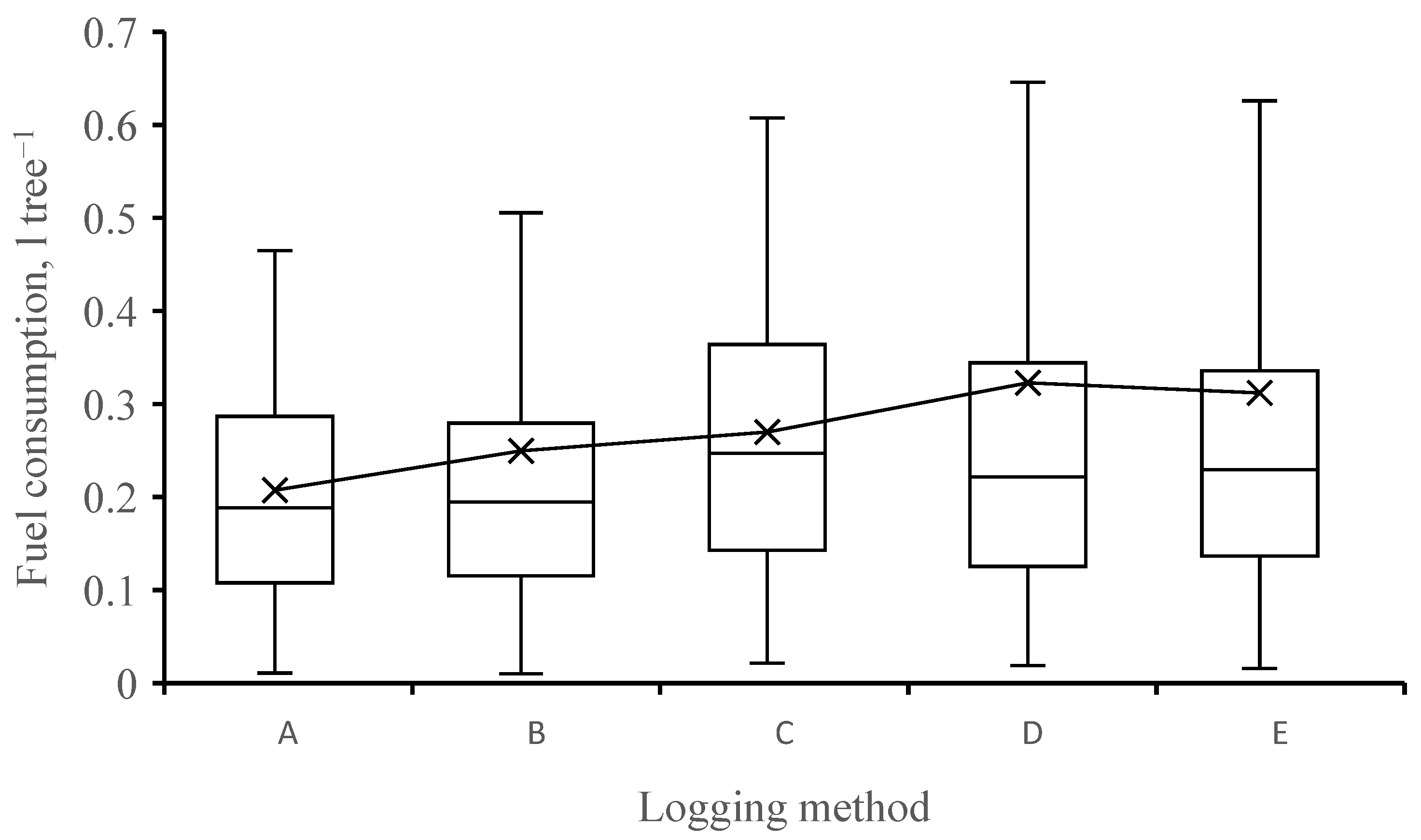

3.1. Fuel Consumption in the Tree Logging Cycle Process

3.2. Hourly and Cubic-Meter-Based Fuel Consumption

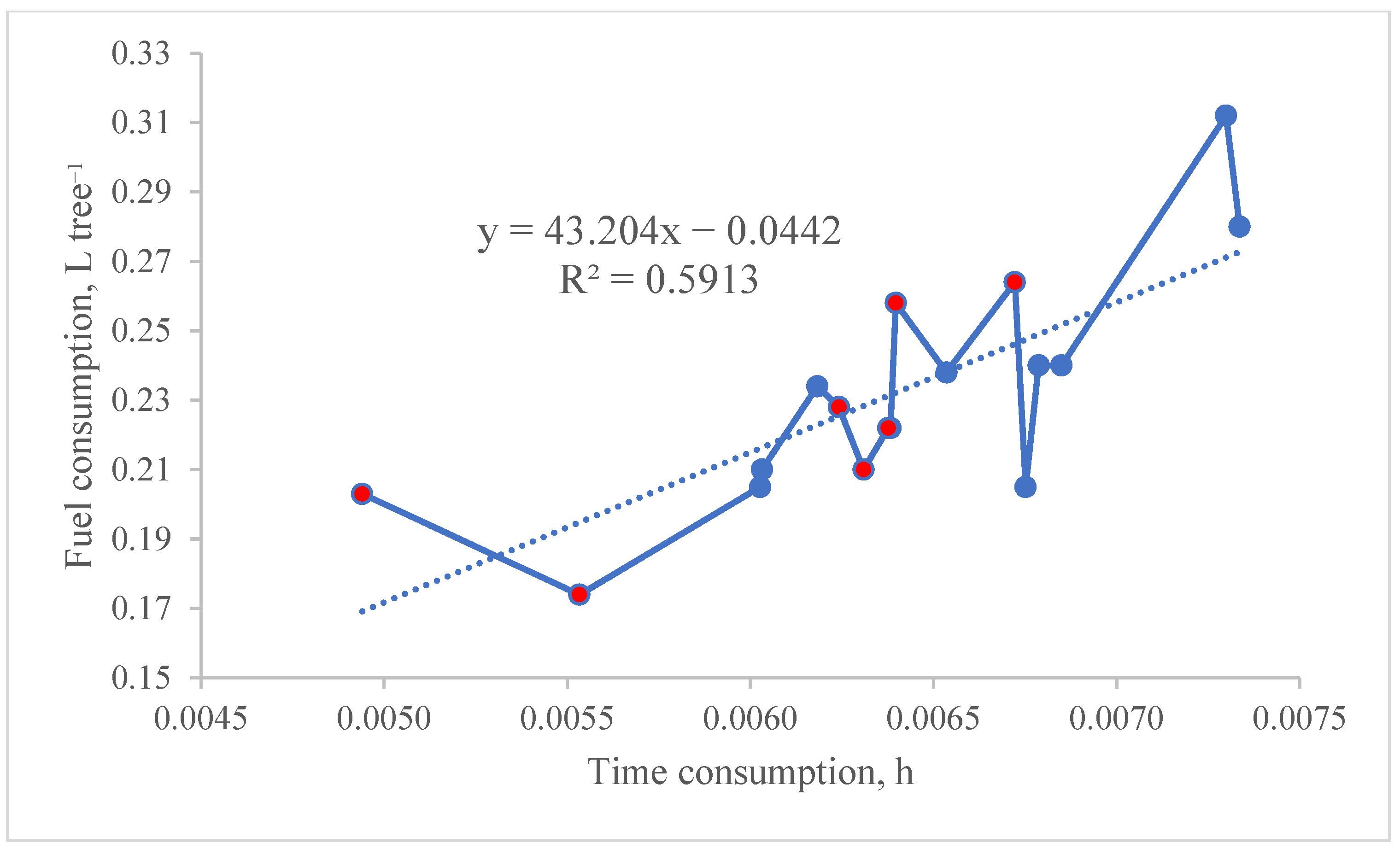

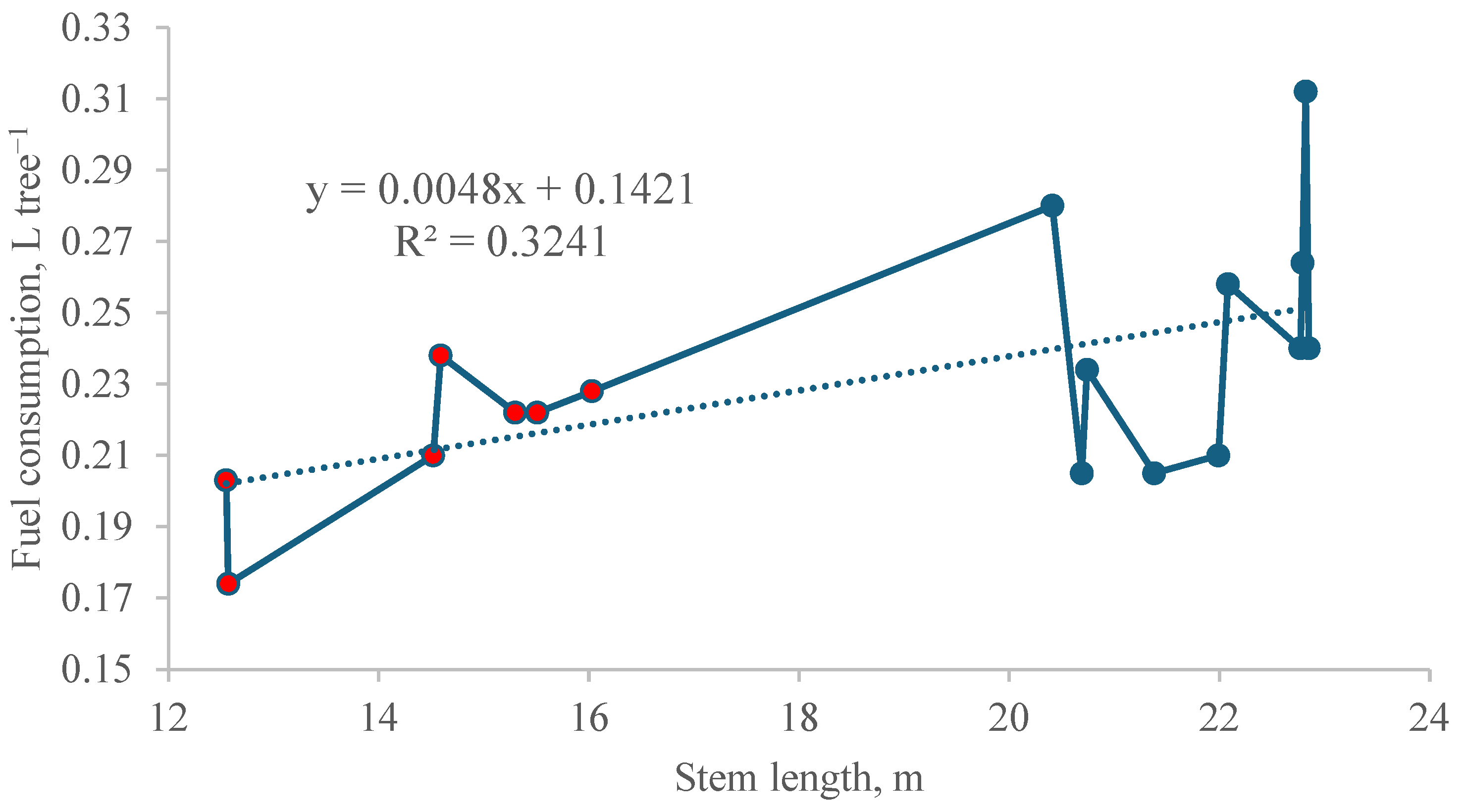

3.3. Explanatory Variables in the Logging Cycle Process

3.4. Precision Modeling of Fuel Consumption

- is fuel consumption (L) during the logging cycle process of tree i;

- is the length of the stem (m) of tree i;

- is the time consumption of the logging cycle process of the stem (E0h) of tree i;

- is the processing speed of the stem (m E0h−1) of tree i;

- is the constant term;

- , , and are the regression parameters for the predictor variables , , and

- is the residual value.

4. Discussion

4.1. Evaluation of the Study Data and the Methods

4.2. Fuel Consumption of the Logging Methods

4.3. Modeling of Fuel Consumption

4.4. Improving Environmental Efficiency

5. Conclusions

Funding

Data Availability Statement

Conflicts of Interest

References

- Palander, T. Outsourcing Issues of Wood Supply Chain Management in the Forest Industry. For. Sci. 2022, 68, 521–532. [Google Scholar] [CrossRef]

- Purfürst, T.; Erler, J. The Human Influence on Productivity in Harvester Operations. Int. J. For. Eng. 2011, 22, 15–22. [Google Scholar] [CrossRef]

- Palander, T.; Ovaskainen, H.; Tikkanen, L. An Adaptive Work Study Method for Identifying the Human Factors that Influence the Performance of a Human-Machine System. For. Sci. 2012, 58, 377–389. [Google Scholar] [CrossRef]

- Ovaskainen, H. Timber harvester operators’ working technique in first thinning and the importance of cognitive abilities on work productivity. Diss. For. 2009, 79, 62. [Google Scholar] [CrossRef]

- Ovaskainen, H.; Uusitalo, J.; Sassi, T. Effect of edge trees on harvester positioning in thinning. For. Sci. 2006, 52, 659–669. [Google Scholar] [CrossRef]

- Niebel, B. Motion and Time Study; Richard d Irwin: Homewood, IL, USA, 1993. [Google Scholar]

- Rieppo, K.; Örn, J. Measuring the Fuel Consumption of Forest Machines. Preliminary Study; Report 148; Metsäteho: Vantaa, Finland, 2003. [Google Scholar]

- Holzleitner, F.; Stampfer, K.; Visser, R. Utilization rates and cost factors in timber harvesting based on long-term machine data. Croat. J. For. Eng. 2011, 32, 501–508. [Google Scholar]

- Brunberg, T. Fuel Consumption in Forest Machines in 2012; Skogforsk: Uppsala, Sweden, 2013. [Google Scholar]

- Kenney, J.; Galagher, T.; Smidt, M.; Mitchel, D.; McDonald, T. Factors that affect fuel consumption in logging systems. In Proceeding of the Conference of the 37th Council on Forest Engineering (COFE) Annual Meeting, Moline, IL, USA, 22–25 June 2014. [Google Scholar]

- Ghaffariyan, M.R.; Apolit, R.; Kuehmaier, M. A short review of fuel consumption rates of whole tree and cut-to-length timber harvesting methods. Curr. Investig. Agri. Curr. Res. 2018, 5, 651–653. [Google Scholar] [CrossRef]

- Magagnotti, N.; Pari, L.; Spinelli, R. Use, utilization, productivity and fuel consumption of purpose-built and excavator-based harvesters and processors in Italy. Forests 2017, 8, 485. [Google Scholar] [CrossRef]

- Prinz, R.; Spinelli, R.; Magagnotti, N.; Routa, J.; Asikainen, A. Modifying the settings of CTL timber harvesting machines to reduce fuel consumption and CO2 emissions. J. Clean. Prod. 2018, 197, 208–217. [Google Scholar] [CrossRef]

- Jylhä, P.; Jounela, P.; Koistinen, M.; Korpunen, H. Mechanized Cutting: Follow-Up Study; Natural Resources and Bioeconomy Studies 11; Natural Resources Institute: Helsinki, Finland, 2019. [Google Scholar]

- Spinelli, R.; de Arruda Moura, A.C. Decreasing the Fuel Consumption and CO2 Emissions of Excavator-Based Harvesters with a Machine Control System. Forests 2019, 10, 43. [Google Scholar] [CrossRef]

- Kärhä, K.; Haavikko, H.; Kääriäinen, H.; Palander, T.; Eliasson, L.; Roininen, K. Fossil-fuel consumption and CO2eq emissions of cut-to-length industrial roundwood logging operations in Finland. Eur. J. For. Res. 2023, 142, 547–563. [Google Scholar] [CrossRef]

- Ackerman, P.; Williams, C.; Ackerman, S.; Nati, C. Diesel Consumption and Carbon Balance in South African Pine Clear-Felling CTL Operations: A Preliminary Case Study. Croat. J. For. Eng. 2017, 38, 65–72. [Google Scholar]

- Klvac, R.; Skoupy, A. Characteristic fuel consumption and exhaust emissions in fully mechanized logging operations. J. For. Res. 2009, 14, 328–334. [Google Scholar] [CrossRef]

- Lijewski, P.; Merkisz, J.; Fuć, P.; Ziółkowski, A.; Rymaniak, Ł.; Kusiak, W. Fuel consumption and exhaust emissions in the process of mechanized timber extraction and transport. Eur. J. For. Res. 2017, 136, 153–160. [Google Scholar] [CrossRef]

- Eliasson, L. New Method for Estimating Fuel Consumption in Logging Operations. Skogforsk, Kunskap 4. 2022. Available online: https://www.skogforsk.se/kunskap/kunskapsbanken/2022/ny-metod-for-skattning-av-bransleforbrukning-vid-drivningsarbete (accessed on 10 January 2025).

- Tikkanen, L.; Ovaskainen, H.; Palander, T.; Vesa, L. TimberLink as a tool for measuring the fuel consumption of a harvester. In The Nordic-Baltic Conference on Forest Operations; Suadicani, K., Ed.; Forest & Landscape Denmark University of Copenhagen Hørsholm Kongevej: Copenhagen, Denmark, 2008; pp. 70–71. [Google Scholar]

- Olivera, A.; Visser, R.; Acuna, M.; Morgenroth, J. Automatic GNSS-enabled harvester data collection as a tool to evaluate factors affecting harvester productivity in a Eucalyptus spp. harvesting operation in Uruguay. Int. J. For. Eng. 2016, 27, 15–28. [Google Scholar] [CrossRef]

- Palander, T.; Nuutinen, Y.; Kariniemi, A.; Väätäinen, K. Automatic time study method for recording work phase times of timber harvesting. For. Sci. 2013, 59, 472–483. [Google Scholar] [CrossRef]

- Hollander, M.; Wolfe, D.A. Nonparametric Statistical Methods; John Wiley and Sons: New York, NY, USA, 1973. [Google Scholar]

- Schober, P.; Boer, C.; Schwarte, L. Correlation Coefficients: Appropriate Use and Interpretation. Anesth. Analg. 2018, 126, 1763–1768. [Google Scholar] [CrossRef] [PubMed]

- Heikkilä, T. Statistical Research, 3rd ed.; Oy Edita Ab: Helsinki, Finland, 2001. [Google Scholar]

- Henley, S.; Golden, R.; Kashner, T. Statistical modeling methods: Challenges and strategies. Biostat. Epidemiol. 2020, 4, 105–139. [Google Scholar] [CrossRef]

- SPSS Inc. Version 28. SPSS-X User’s Guide, 3rd ed.; SPSS Inc.: Chicago, IL, USA, 1988. [Google Scholar]

- Ovaskainen, H. Work Models in Mechanized Logging. Metsäteho, Finland, Report 22. 2012. Available online: https://metsateho.fi/wp-content/uploads/2015/02/Raportti_221_Ty%C3%B6mallit_koneellisessa_puunkorjuussa_ho.pdf (accessed on 10 January 2025).

| Characteristic | 1 | 2 | 3 | 4 |

|---|---|---|---|---|

| The main tree species | Eucalyptus saligna | Pinus taeda | Eucalyptus saligna | Pinus taeda |

| Slope of terrain, % | 17.5 | 22.5 | 7.5 | 7.5 |

| Age of trees, years | 7 | 7 | 7 | 7 |

| Planting geometry, m × m | 3.0 × 2.0 | 3.5 × 2.0 | 3.0 × 2.0 | 3.5 × 2.0 |

| Trees’ number per ha | 1650 | 1350 | 1650 | 1350 |

| Diameter at d1.3, mm | 184 | 205 | 178 | 210 |

| Stems’ length, m | 21.3 | 13.3 | 22.1 | 15.1 |

| Trees’ size, m3 | 0.416 | 0.315 | 0.386 | 0.366 |

| Stand | Terrain | Species | Felling Technique | Logging Method | Operator | Stem Size m3 | Stem Length m | Work Time E0h | Stem Speed m h−1 | Productivity m3 E0h−1 |

|---|---|---|---|---|---|---|---|---|---|---|

| 1 | S | Es | F1 | D | O1 | 0.35 | 20.41 | 0.00734 | 2776.20 | 43.87 |

| 1 | S | Es | F1 | D | O2 | 0.40 | 22.77 | 0.00679 | 3442.79 | 56.62 |

| 1 | S | Es | F2 | E | O1 | 0.39 | 22.82 | 0.00730 | 3138.74 | 51.46 |

| 1 | S | Es | F2 | E | O2 | 0.40 | 22.85 | 0.00685 | 3391.81 | 54.50 |

| 2 | S | Ps | F1 | D | O1 | 0.34 | 14.59 | 0.00654 | 2272.77 | 50.85 |

| 2 | S | Ps | F1 | D | O2 | 0.37 | 15.51 | 0.00638 | 2462.98 | 54.19 |

| 2 | S | Ps | F2 | E | O1 | 0.38 | 16.03 | 0.00624 | 2402.60 | 54.84 |

| 2 | S | Ps | F2 | E | O2 | 0.37 | 15.30 | 0.00638 | 2487.73 | 58.12 |

| 3 | F | Es | F1 | A | O1 | 0.41 | 20.69 | 0.00675 | 2980.47 | 55.73 |

| 3 | F | Es | F1 | A | O2 | 0.41 | 21.38 | 0.00603 | 3569.78 | 65.49 |

| 3 | F | Es | F2 | B | O1 | 0.39 | 20.74 | 0.00618 | 3251.94 | 58.83 |

| 3 | F | Es | F2 | B | O2 | 0.42 | 21.99 | 0.00603 | 3346.35 | 63.51 |

| 3 | F | Es | F3 | C | O1 | 0.44 | 22.79 | 0.00672 | 3265.07 | 59.69 |

| 3 | F | Es | F3 | C | O2 | 0.43 | 22.08 | 0.00640 | 3454.09 | 63.29 |

| 4 | F | Ps | F1 | A | O2 | 0.29 | 12.55 | 0.00494 | 1887.93 | 49.67 |

| 4 | F | Ps | F2 | B | O2 | 0.29 | 12.57 | 0.00553 | 2409.16 | 52.94 |

| 4 | F | Ps | F3 | C | O2 | 0.35 | 14.52 | 0.00631 | 2327.63 | 51.69 |

| Stand | Species | Felling Technique | Logging Method | Operator | Fuel Consumption (L Tree−1) | Fuel Consumption (L E0h−1) | Fuel Consumption (L m−3) | Fuel Consumption (L m−1) |

|---|---|---|---|---|---|---|---|---|

| 1 | Es | F1 | D | O1 | 0.2800 | 35.10 | 0.8 | 0.0137 |

| 1 | Es | F1 | D | O2 | 0.2400 | 33.97 | 0.6 | 0.0105 |

| 1 | Es | F2 | E | O1 | 0.3120 | 41.17 | 0.8 | 0.0137 |

| 1 | Es | F2 | E | O2 | 0.2400 | 32.70 | 0.6 | 0.0105 |

| 2 | Ps | F1 | D | O1 | 0.2380 | 35.60 | 0.7 | 0.0163 |

| 2 | Ps | F1 | D | O2 | 0.2220 | 32.52 | 0.6 | 0.0143 |

| 2 | Ps | F2 | E | O1 | 0.2280 | 32.90 | 0.6 | 0.0142 |

| 2 | Ps | F2 | E | O2 | 0.2220 | 34.87 | 0.6 | 0.0145 |

| Stand | Species | Felling Technique | Logging Method | Operator | Fuel Consumption (L Tree−1) | Fuel Consumption (L E0h−1) | Fuel Consumption (L m−3) | Fuel Consumption (L m−1) |

|---|---|---|---|---|---|---|---|---|

| 3 | Es | F1 | A | O1 | 0.2050 | 27.87 | 0.5 | 0.0099 |

| 3 | Es | F1 | A | O2 | 0.2050 | 32.75 | 0.5 | 0.0096 |

| 3 | Es | F2 | B | O1 | 0.2340 | 35.30 | 0.6 | 0.0113 |

| 3 | Es | F2 | B | O2 | 0.2100 | 31.76 | 0.5 | 0.0095 |

| 3 | Es | F3 | C | O1 | 0.2640 | 35.81 | 0.6 | 0.0116 |

| 3 | Es | F3 | C | O2 | 0.2580 | 37.97 | 0.6 | 0.0117 |

| 4 | Ps | F1 | A | O2 | 0.2030 | 34.77 | 0.7 | 0.0162 |

| 4 | Ps | F2 | B | O2 | 0.1740 | 31.76 | 0.6 | 0.0138 |

| 4 | Ps | F3 | C | O2 | 0.2100 | 31.01 | 0.6 | 0.0145 |

| Methods | Test Statistic | Std. Error | Std. Test Statistic | Significance |

|---|---|---|---|---|

| A–B | −40.520 | 44.214 | −0.916 | 0.359 |

| A–D | −175.034 | 41.709 | −4.197 | <0.001 |

| A–E | −205.113 | 41.727 | −4.916 | <0.001 |

| A–C | −251042 | 44.631 | −5.625 | <0.001 |

| B–D | −134.514 | 41.830 | −3.216 | 0.001 |

| B–E | −164.593 | 41.848 | −3.933 | <0.001 |

| B–C | −210.522 | 44.744 | −4.705 | <0.001 |

| D–E | −30.078 | 39.192 | −0.767 | 0.443 |

| D–C | 76.008 | 42.270 | 1.798 | 0.072 |

| E–C | 45.929 | 42.289 | 1.086 | 0.277 |

| Variables | S | L | T | P | F |

|---|---|---|---|---|---|

| Correlation, rs | |||||

| S | 1.000 | 0.851 ** | 0.505 * | 0.836 ** | 0.387 |

| L | 0.851 ** | 1.000 | 0.618 * | 0.937 ** | 0.569 * |

| T | 0.505 * | 0.618 * | 1.000 | 0.435 | 0.769 ** |

| P | 0.836 ** | 0.937 ** | 0.435 | 1.000 | 0.344 |

| F | 0.387 | 0.569 * | 0.769 ** | 0.344 | 1.000 |

| Number of Trees | Parameter | Estimate | t-Value | p-Value | R2 |

|---|---|---|---|---|---|

| 2130 | 0.869 | 0.401 | 0.703 ** | ||

| 0.430 | 1.908 | 0.079 | |||

| −1.052 | −2.068 | 0.059 | |||

| 1.289 | 2.215 | 0.045 * |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Palander, T. Precision Modeling of Fuel Consumption to Select the Most Efficient Logging Method for Cut-to-Length Timber Harvesting. Forests 2025, 16, 294. https://doi.org/10.3390/f16020294

Palander T. Precision Modeling of Fuel Consumption to Select the Most Efficient Logging Method for Cut-to-Length Timber Harvesting. Forests. 2025; 16(2):294. https://doi.org/10.3390/f16020294

Chicago/Turabian StylePalander, Teijo. 2025. "Precision Modeling of Fuel Consumption to Select the Most Efficient Logging Method for Cut-to-Length Timber Harvesting" Forests 16, no. 2: 294. https://doi.org/10.3390/f16020294

APA StylePalander, T. (2025). Precision Modeling of Fuel Consumption to Select the Most Efficient Logging Method for Cut-to-Length Timber Harvesting. Forests, 16(2), 294. https://doi.org/10.3390/f16020294