1. Introduction

The wood of black alder (Alnus glutinosa) is used in the production of furniture, plywood, and interior finishing panels due to its reddish hue, which is aesthetically appealing and easy to process. However, it is also relatively brittle. Black alder is additionally utilized for the production of charcoal and its derivatives, as well as for packaging materials and as a source of firewood. Owing to its resistance to prolonged moisture exposure, black alder wood is suitable for manufacturing items such as barrels, wooden utensils, and spoons. Nevertheless, its broader application in outdoor environments is limited by its low resistance to biological degradation. There is a fair amount of information on black alder (Alnus glutinosa) wood and how it responds to thermal modification (TM) or other heat treatments. It is not as abundant as for some very popular hardwoods (aspen, beech, birch, oak, poplar), but in-depth studies cover color changes, durability, mechanical/physical property shifts, weathering, etc. There is limited research available on TM of black alder wood in a nitrogen atmosphere.

Black alder (

Alnus glutinosa) wood was treated in a pressure autoclave with saturated steam (or a saturated steam-/air mixture) at temperatures of 95–125 °C for varying durations (3, 6, 9, 12 h). The study concluded that saturated steam TM can significantly modify the aesthetic, physical, and chemical properties of alder wood, making it suitable for applications requiring color enhancement and reduced hygroscopicity, while acknowledging minor trade-offs in density and acidity [

1]. Douglas fir (

Pseudotsuga menziesii Franco) and alder (

Alnus glutinosa) were heat-treated in an air atmosphere at 165 °C and in continuous flow steam atmosphere at 210 °C. Heat treatment in steam atmosphere significantly reduced strength and toughness of wood, especially for alder. Because alder has a higher content of hemicelluloses (which are more heat-labile), its mechanical properties degraded more at higher heat treatment compared to softwood (

Douglas fir) [

2]. Black locust (

Robinia pseudoacacia), black alder (

Alnus glutinosa), western prickly juniper (

Juniperus oxycedrus), and plum (

Prunus domestica) wood samples were subjected to heat treatment at temperatures of 130 °C and 160 °C for durations of 3 and 7 h. TM significantly improved the dimensional stability and surface quality of all four wood species, as evidenced by reduced swelling and smoother surfaces observed post treatment. The hardness decreased for all tested species at all tested treatments [

3]. Black alder (

Alnus glutinosa), red oak (

Quercus falcata), southern pine (

Pinus taeda), and yellow poplar (

Liriodendron tulipifera) were heat treated in a laboratory oven at 120 and 190 °C for 3 or 6 h. The hardness of all tested wood species dropped after treatment, but black alder was less severely affected than more porous hardwoods under tested treatment regimes. Heat treatment improved surface quality, making wood smoother, which is beneficial for applications where finish is important (furniture, veneers, etc.) [

4].

TM was applied to black alder wood (

Alnus glutinosa) stakes at three temperatures: 150 °C, 180 °C, and 200 °C, each for 2, 6, or 10 h. The stakes were placed in a field test in contact with the ground and exposed to natural weathering and decay for 3 years. TM at elevated temperatures and for longer periods increased black alder durability in ground contact. Despite improvements, TM did not fully protect wood in ground contact; protective coatings or finishes are still recommended for structurally demanding/durable uses [

5]. Alder (

Alnus cordata) wood was treated using a thermo-vacuum process at a temperature of 200 °C for 4 h and then coated with commercial coatings to investigate color stability and chemical changes in artificial weathering conditions. The thermo-vacuum treatment did not lead to an improvement in the color stability of alder wood. The treated wood exhibited significant color variation when compared to the untreated control, indicating that the treatment was ineffective in preventing UV-induced degradation [

6]. Thermo-vacuum treatment demonstrated a notably positive effect during machining with dull tools, resulting in a significant improvement in the final surface smoothness. Nevertheless, the surface quality of TM alder (

Alnus cordata) was the lowest among all tested wood species, despite its classification as a wood with generally good machinability [

7].

There are a few studies on the thermo-mechanical densification and TM of black alder veneers. Black alder (

Alnus glutinosa), beech (

Fagus sylvatica), birch (

Betula verrucosa), and pine (

Pinus sylvestris) veneers were hot-pressed under combinations of temperature (100, 150, 200 °C) and pressure (4, 8, 12 MPa) for 4 min. All species showed a strong increase in gloss after densification. The greatest gloss values were achieved at 200 °C and 12 MPa for all species and all angles of measurement [

8]. Thin veneers of black alder (

Alnus glutinosa) and beech (

Fagus sylvatica) were heat treated at 190 °C for 5, 10, 20, 40 min to quantify color changes. Because alder discolors more under the same treatment, it may be particularly useful when a strong color change is desired. Spectral changes indicated the degradation of hemicelluloses (especially) and some changes in lignin, but cellulose was less affected [

9].

Other research investigated the impact of incorporating TM black alder (

Alnus glutinosa) wood flour into high density polyethylene (HDPE) wood plastic composites. Incorporating TM alder wood flour into HDPE matrix modestly improved thermal stability and reduced water absorption compared to untreated wood flour, though at the expense of some loss in mechanical strength when filler content is high [

10]. American alder (

Alnus rubra) wood was TM at 140 °C for 4, 8 and 13 h. Moderate TM for longer durations (especially 13 h) significantly improved dimensional stability and reduced moisture uptake, internal stresses without major losses in mechanical strength [

11].

Alder wood (

Alnus cordata) was modified using double treatment—TM at 200 °C for 4 h in a thermo vacuum cylinder and impregnation with 0.1%, 0.5% and 10% alkyl ketene dimer (AKD) solution to improve surface hydrophobicity and wetting behavior. Both treatments individually improved water-related properties of alder wood, but the combination resulted in the greatest water resistance, making wood suitable for outdoor applications such as furniture, construction, or packaging [

12]. Red alder (

Alnus rubra), western hemlock (

Tsuga heterophylla), Douglas-fir (

Pseudotsuga menziesii), red cedar (

Thuja plicata), and paper birch (

Betula papyrifera) were TM in a continuous steam flow at 190 and 212 °C with total processing time of 48 h. After treatment, longitudinal and transverse hardness of red alder dropped. TM red alder displayed lowest dynamic modulus of elasticity among tested species [

13].

This research focused on exploring how the moisture content, water uptake, mechanical strength and chemical composition of European black alder (Alnus glutinosa) wood are influenced by thermal treatment carried out in a pressurized nitrogen environment. While earlier work by our team has dealt with determining suitable treatment conditions and analyzing property changes in European aspen, silver birch and Scots pine wood, comparable insights into black alder are still limited. Specifically, there is a shortage of studies examining how this species responds to thermal processing in nitrogen atmospheres, whether under open or closed systems and at standard or elevated pressures.

2. Materials and Methods

2.1. Materials

European black alder (

Alnus glutinosa) timber utilized in this study was procured from the local wood processing company Ošukalns Ltd. (Jēkabpils, Latvia), with raw material originating from forest stands located in central and eastern Latvia. For each thermal modification (TM) regime, eighteen black alder boards were employed, each with nominal dimensions of 1000 × 100 × 32 mm (longitudinal × tangential × radial). All boards selected for testing were visually inspected and confirmed to be free of macroscopic defects such as knots, fiber deviation, bark inclusions, wane, blue stain, fungal decay, insect damage, checks, or dimensional distortion. Prior to thermal treatment, the specimens were conditioned under controlled environmental conditions of 20 ± 2 °C and 65 ± 5% relative humidity until reaching equilibrium moisture content. Boards with an average air-dry density of 510 ± 10 kg/m

3 were randomly selected for TM procedures. Moisture content and density measurements were carried out in accordance with ISO 13061-1:2014 [

14] and ISO 13061-2:2014 [

15] standards, respectively.

2.2. Thermal Modification Process

TM was carried out using a 340-L pilot-scale treatment chamber, engineered by Wood Treatment Technology (Grinsted, Denmark) and fabricated from stainless steel to ensure high corrosion resistance under elevated temperatures and pressures. The chamber featured a thermally regulated jacket system, where hot mineral oil was continuously circulated to maintain a stable process temperature. Prior to thermal ramp-up, wood specimens underwent a 30 min vacuum pre-conditioning phase at 0.2 bar to evacuate residual oxygen from the system and reduce oxidative degradation during processing. Following vacuum application, nitrogen gas was introduced into the chamber from a high-pressure cylinder to raise the internal pressure to the required initial setpoint of 4 bar.

To initiate hemicellulose hydrolysis and facilitate steam phase reactions, 1 to 1.5 L of tap water were added directly into the chamber prior to heating. The system remained hermetically sealed throughout the thermal cycle, with no active agitation or mixing implemented during the process. The chamber was kept in a static, closed loop state until pressure was released in the final stage. The specific parameters applied during the TM of European black alder wood are detailed in

Table 1.

The TM parameters were selected with reference to prior nitrogen-based modification trials conducted on European aspen, silver birch, and Scots pine species [

16,

17,

18]. Upon completion of the process, any boards exhibiting significant post-treatment deformations such as surface checking, swelling, or warping were documented to assess the impact of the thermal regime on material integrity. Warping was observed in only a few samples following TM, while the majority exhibited no visible defects. Under the same TM parameters, European aspen (

Populus tremula) wood previously showed a higher incidence and diversity of defects [

16]. The total duration of the thermal cycle ranged from 16 to 18 h at 160 °C and from 18 to 19 h at 170 °C. This time frame encompassed all phases of the process: heat-up, isothermal exposure, and controlled cooling.

2.3. Physical Properties

Mass loss and volumetric changes resulting from TM were evaluated in accordance with procedures detailed in earlier research on TM hardwood and softwood species (e.g., European aspen, silver birch, and Scots pine) [

16,

17].

2.4. Dimensional Stability

The anti-swelling efficiency (ASE) and cell wall total water capacity (CWTWC) were assessed under cyclic treatment conditions using fifteen cubic specimens (20 × 20 × 20 mm3). Prior to each treatment cycle, samples were equilibrated in a controlled climate chamber at 20 ± 2 °C and 65 ± 5% relative humidity to ensure uniform initial moisture conditions. The cyclic protocol consisted of seven repetitions of water saturation and drying. The soaking phase involved vacuum-assisted impregnation (0.2 bar for 120 min), followed by water storage at 22 °C for 24 h to achieve full cell saturation. The subsequent drying sequence was staged across multiple temperature regimes: 72 h at 20 °C, followed by sequential heating at 45 °C, 60 °C, 80 °C, and 103 °C, each for 8 h.

Swelling measurements were recorded in the longitudinal, tangential, and radial directions. These dimensional changes were used to calculate ASE and CWTWC values, based on the average swelling response observed across the tested specimens. Comprehensive methodologies for calculating ASE and CWTWC are thoroughly described in our prior work [

16,

17].

2.5. Moisture Uptake

Fifteen TM wood specimens (20 × 20 × 20 mm

3) were evaluated for moisture sorption behavior under controlled relative humidity (RH) conditions of 65%, 75%, and 98% at a constant temperature of 20 ± 2 °C. Initially, the specimens were dried to a constant weight and conditioned in a climate-controlled chamber at 65% RH. Subsequently, samples were equilibrated at elevated humidity levels by placing them in desiccators over saturated solutions of NaCl (75% RH) and CuSO

4·5H

2O (98% RH) to achieve the desired moisture environments. The specimens were sequentially exposed to increasing RH levels of 65%, 75%, and 98%. Equilibrium was considered reached when sample masses remained stable over three consecutive weighings at 48 h intervals, with conditioning periods extending up to 30 days. Upon attainment of equilibrium moisture content (EMC), dimensional changes were measured following the protocols established in our previous investigations [

16,

17].

2.6. Mechanical Performance Evaluations

Prior to mechanical testing, all specimens underwent equilibration under controlled ambient conditions maintained at 20 ± 2 °C and 65 ± 5% relative humidity. Mechanical performance was evaluated by determining the modulus of rupture (MOR) and modulus of elasticity (MOE) in compliance with ISO 13061-3:2014 [

19] and ISO 13061-4:2014 [

20] standards, respectively. Static bending strength was measured through a three-point flexural test on thirty samples sized 360 × 20 × 20 mm

3, utilizing a Zwick Roell Z010 testing machine (Zwick Roell Group, Ulm, Germany). For hardness assessment, ten specimens per treatment group, each measuring 360 × 50 × 20 mm

3 (length × tangential × radial), were subjected to Brinell hardness testing following the EN 1534:2000 [

21] protocol, conducted with a Zwick Roell Z100 apparatus. The indentation process employed a hardened steel ball indenter of 10 ± 0.01 mm diameter, producing five impressions on both tangential and radial surfaces per specimen. After a minimum dwell time of three minutes post indentation, the diameters of the impressions were measured with ±0.2 mm precision in directions parallel and perpendicular to the grain. The Brinell hardness values were then calculated as the average of these measurements.

2.7. Chemical Analysis

Air-dried wood sawdust, sieved to particles smaller than 0.50 mm, was collected from each sample in quantities ranging between 24 and 43 g. Extraction was performed using acetone (99.8%, Acros Organics, Geel, Belgium) within a Soxhlet extraction system over a period of 8 to 10 h. Quantification of extractive substances was conducted following the analytical protocol established in our prior investigations.

Once extractives were removed from the biomass, the remaining solid material was analyzed to determine its content of structural polysaccharide-derived sugars (glucose, xylose, galactose, arabinose, and mannose), acetyl functionalities (estimated from the acetic acid concentration), and lignin (distinguished as acid-soluble and acid-insoluble fractions). Quantification of structural carbohydrates followed a two-stage acid hydrolysis procedure aligned with the standard TP-510-42618 [

22].

In the first stage of hydrolysis, the sample was treated with concentrated sulfuric acid (72%

v/

v) at 30 °C for 1 h inside sealed pressure resistant vessels. The slurry was periodically agitated using a teflon stirrer to ensure uniform acid exposure. In the second stage, the reaction mixture was diluted with deionized water to reach a sulfuric acid concentration of 4%, followed by autoclaving at 121 °C for 60 min to complete hydrolysis of the polysaccharides. The residual solid fraction (representing acid-insoluble material) was separated from the liquid hydrolysate using a filter crucible with pore size less than 8 µm. Sugar monomers released during hydrolysis were quantified using high-performance liquid chromatography (HPLC) on a Shimadzu LC-20AD (Shimadzu, Kyoto, Japan) system coupled with a refractive index detector (Shimadzu RID-10A) and a Thermo Scientific HyperREZ XP Carbohydrate Pb

2+ column (Thermo Fisher Scientific, Waltham, MA, USA). The chromatographic separation was performed at 70 °C using Milli-Q-grade water as the eluent at a flow rate of 0.6 mL/min, with a total runtime of 35 min. Prior to injection, the hydrolysate was neutralized using high-purity barium carbonate (99%–101%). To assess degradation by-products formed during acid hydrolysis specifically formic acid, acetic acid, levulinic acid, 5-hydroxymethylfurfural (HMF), and furfural an additional HPLC analysis was conducted on unneutralized hydrolysate samples. For this analysis, a Shodex Sugar SH-1821 column (Resonac Corporation, Tokyo, Japan) was used, maintained at 50 °C, with 0.005 M sulfuric acid as the mobile phase flowing at 0.6 mL/min. Each run lasted 55 min. Reference standards used in the quantification included high-purity compounds (≥95%–99%) such as cellobiose, individual monosaccharides (glucose, xylose, galactose, arabinose, mannose), and hydrolysis by-products (formic acid, acetic acid, levulinic acid, HMF, and furfural). All standards and reagents were obtained from Merck (Darmstadt, Germany) and used as received, without further purification. The Klason method, as detailed in standard TP-510-42618 [

22], was employed to quantify acid-insoluble lignin, while acid-soluble lignin was measured spectrophotometrically using a PerkinElmer Lambda 650 UV-Vis instrument (PerkinElmer, Waltham, MA, USA) at 203 nm. Ash content in the extractive free biomass was determined according to TP-510-42622 standard [

23].

2.8. Statistical Analysis

Data were subjected to statistical evaluation using Microsoft Excel 2016 software. Statistical significance was established at a probability level of p < 0.05. Variations among experimental treatments were assessed by one-way analysis of variance (ANOVA), and, where applicable, differences between individual group means were further examined using Fisher’s Least Significant Difference (LSD) test.

3. Results and Discussion

3.1. Physical Parameter Changes

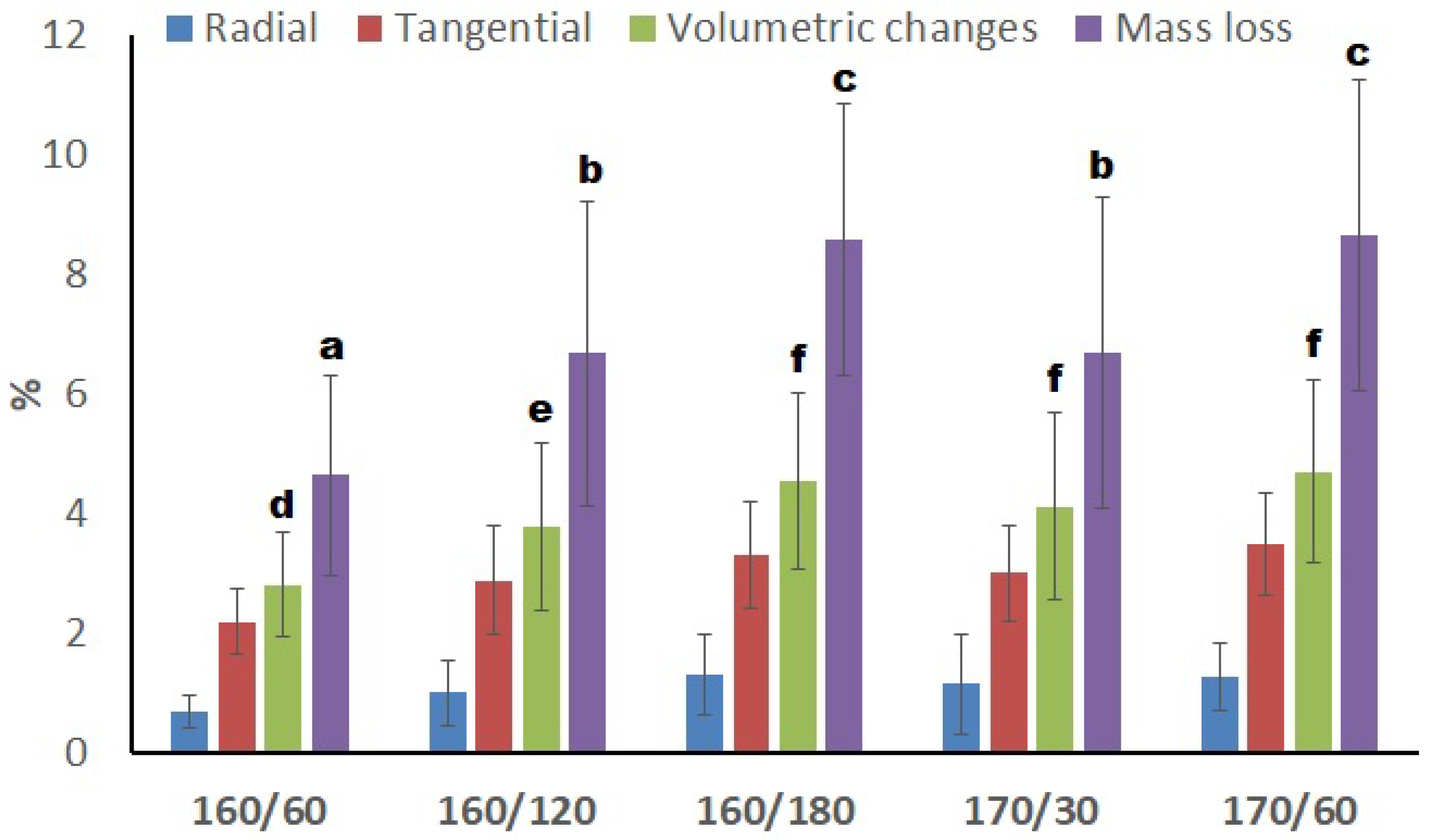

Exposure to elevated temperatures during TM can cause dimensional reduction in wood, potentially lowering material yield and diminishing the overall value of the final products. The findings suggest that this shrinkage is predominantly associated with the breakdown of structural polymers within the cell walls as a result of heat treatment. After undergoing TM, black alder wood boards exhibited a noticeable reduction in size, particularly across the tangential and radial planes (

Figure 1). Dimensional changes were more pronounced tangentially, ranging from 2.2% to 3.5%, while radial shrinkage was comparatively lower, between 0.7% and 1.3%. Overall, the combined shrinkage along these two directions led to a volumetric decrease of approximately 2.8% to 4.7%. The dimensional outcomes observed under the 160/120 regime and both treatments at 170 °C did not show meaningful statistical differences. Earlier investigations using identical TM conditions revealed that silver birch (

Betula pendula) and European aspen (

Populus tremula) experienced comparatively smaller reductions in volume, typically ranging between 6.2% and 10.2%. Pine, on the other hand, exhibited the least volume change, with values falling within the 4.4% to 6.9% interval [

16,

17]. The mass loss (ML) of black alder wood following TM ranged from 4.6% to 8.6%, depending on the applied treatment conditions. Based on the ML values, three distinct treatment intensity groups can be identified. The lowest ML was observed under the mildest regime (160/60). Intermediate regimes (160/120 and 170/30) and the more intensive treatments (160/180 and 170/60) yielded comparable results, with no statistically significant differences between them. When compared to data from previous studies [

16,

17], European aspen and silver birch wood showed greater ML under the same modification parameters (ranging from 5.4% to 12%). These findings indicate that, under pressurized and closed TM conditions, black alder exhibits superior resistance to thermal decomposition and structural change in comparison with other hardwood species.

3.2. Anti-Swelling Efficiency and Cell Wall Water Capacity

TM wood is intended for use in outdoor environments, where it is routinely exposed to ambient humidity and direct contact with water. Therefore, its ability to maintain dimensional stability under cyclic conditions alternating between wetting and complete drying caused by sunlight and wind is of particular importance. Dimensional stability in TM wood helps reduce the risk of surface cracking under moisture stress. Cracks are critical pathways for water ingress and act as initial sites for microbial colonization. In addition, dimensional fluctuations and surface fissures can compromise protective coatings applied to the wood, potentially leading to their deterioration and eventual detachment from the surface.

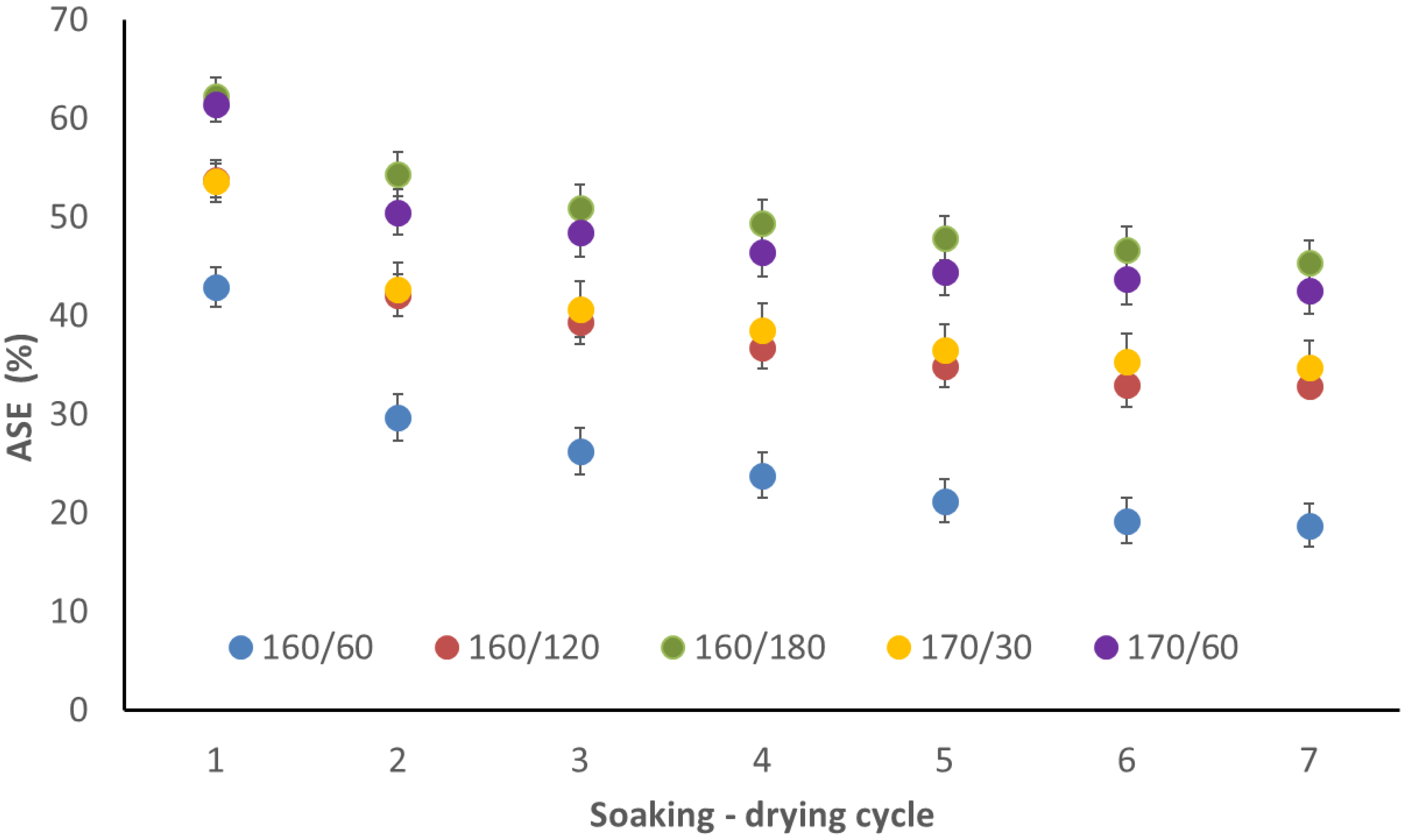

After the first soaking–drying cycle, the ASE of TM black alder wood ranged between 43% and 62% (

Figure 2). With each subsequent cycle, ASE values showed a clear downward trend dropping to 29%–54% after the second and further to 26%–50% after the third cycle. This decline continued steadily across the following cycles, reaching 18%–45% by the seventh. The progressive reduction in ASE is likely linked to increased water access within the wood structure, resulting from the leaching of degradation by-products formed during heat treatment (

Figure 3). Based on the ASE values, three distinct treatment groups can be distinguished. The lowest ASE (43% decreasing to 19%) was observed in the 160/60 regime. Treatments 160/120 and 170/30 yielded nearly identical outcomes, with ASE values ranging from 53% to 33%. Similarly, regimes 160/180 and 170/60 produced statistically comparable ASE results, from 62% down to 42%. Previous findings have shown that under comparable TM conditions using a closed, pressurized nitrogen environment, the ASE values for European aspen (

Populus tremula) and silver birch (

Betula pendula) after the fifth soaking–drying cycle ranged from 22% to 63%. This suggests that various decidous species exhibit broadly comparable trends in dimensional stability when subjected to such treatment regimes [

16,

17].

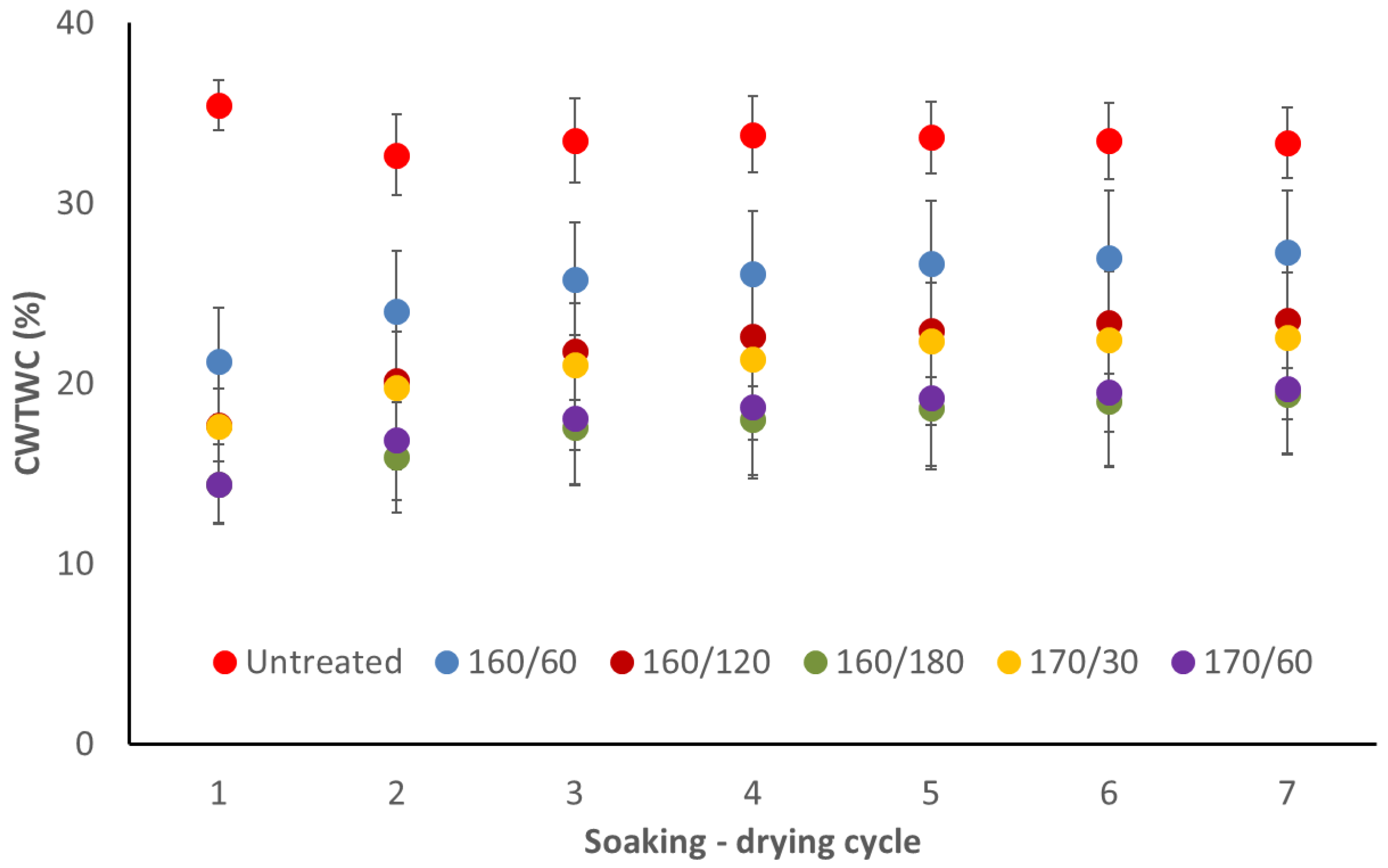

The total water capacity of cell walls (CWTWC) in TM black alder wood was reduced to a range of 19%–27% (

Figure 3), compared to 33%–35% observed in untreated samples. Throughout seven successive soaking–drying cycles, a gradual increase in CWTWC was noted across all TM specimens. Similar to the patterns observed for ASE, CWTWC results allowed for classification into three distinct groups. The mildest treatment (160/60) yielded the highest CWTWC values, ranging from 21% to 27%. Intermediate regimes (160/120 and 170/30) produced statistically comparable values between 17% and 23%, while the most intensive treatments (160/180 and 170/60) resulted in similar CWTWC values within 14% to 19%. These trends can be attributed to the progressive leaching of thermal degradation products from the wood matrix. After the fourth cycle, changes in CWTWC were minimal, indicating that most extractives were removed during the initial three cycles. Comparable CWTWC values and dynamics have been reported for other deciduous species such as European aspen and silver birch [

16,

17]. Previous investigations also demonstrated analogous behavior in European aspen (

Populus tremula), silver birch (

Betula pendula), and grey alder (

Alnus incana) subjected to TM at 160–180 °C in saturated steam within a closed pressurized system [

24].

3.3. Equilibrium Moisture Content

Equilibrium moisture content (EMC) constitutes a fundamental parameter impacting the mechanical integrity, dimensional stability, and biological durability of wood. Lower EMC levels correlate with diminished hygroscopic behavior, thereby mitigating the extent of moisture induced volumetric variations including swelling and shrinkage triggered by fluctuations in the surrounding relative humidity (RH).

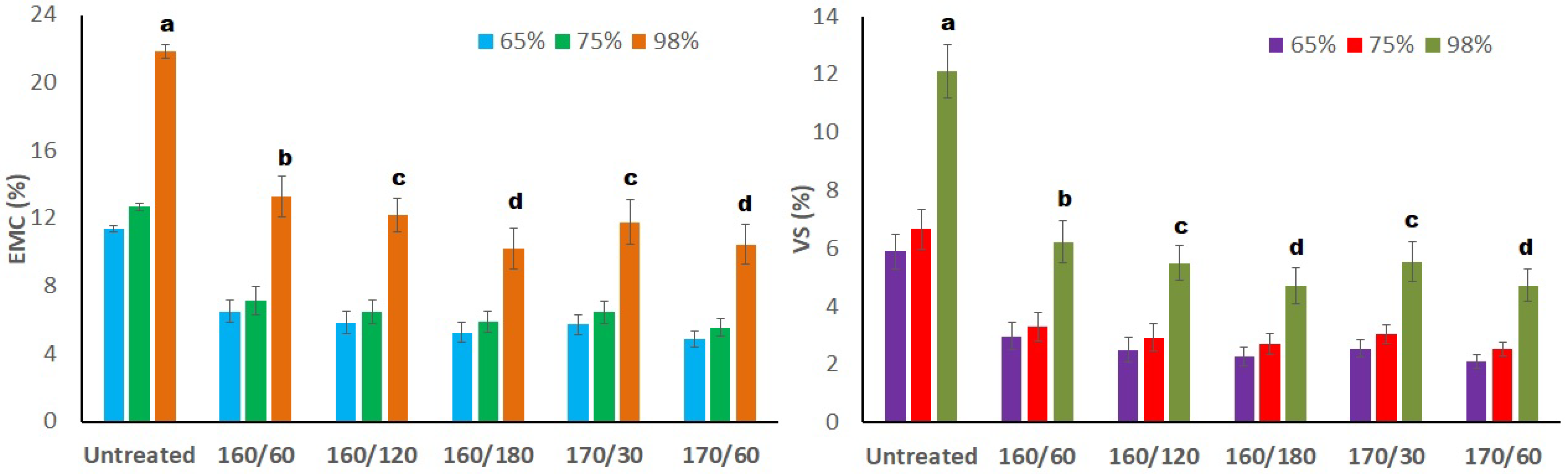

At relative humidity (RH) levels of 65%, 75%, and 98%, the EMC of untreated black alder wood was 11.4%, 12.6%, and 21.9%, respectively (

Figure 4). TM reduced EMC to ranges of 4.8%–6.5%, 5.5%–7.1%, and 10.2%–13.3% at the corresponding RH levels, reflecting a 37%–57% decrease compared to untreated samples. Similar EMC reductions have been reported for TM European aspen, silver birch, and Scots pine under a nitrogen atmosphere, with decreases of 44%–65%, 51%–64%, and 29%–56%, respectively, across identical RH conditions [

16,

17]. The EMC results for the TM wood were clustered into three groups based on treatment intensity: the mildest regime (160/60) showed the highest EMC values (6.5%–13.3%), intermediate regimes (160/120 and 170/30) exhibited statistically indistinguishable EMC between 5.7% and 12.2%, and the most severe regimes (160/180 and 170/60) had the lowest EMC values, ranging from 4.9% to 10.4%.

The volumetric swelling (VS) of unmodified black alder wood was found to be 5.9%, 6.7%, and 12.1% at RH levels of 65%, 75%, and 98%, respectively (

Figure 4). In contrast, TM samples exhibited substantially lower VS values, ranging from 2.1%–3.0% at 65% RH, 2.5%–3.3% at 75% RH, and 4.7%–6.2% at 98% RH. This indicates that TM reduces VS by approximately 48%–64%, regardless of ambient humidity. Similar swelling reducing effects of TM have been observed in previous studies involving other species such as European aspen (44%–65%), silver birch (48%–67%), and Scots pine (29%–61%) [

16,

17]. The VS values of TM wood also varied depending on the applied treatment conditions and can be grouped accordingly. The mildest treatment regime (160/60) resulted in the highest VS values among the treated samples, ranging from 3.0% to 6.2%. Treatments at 160/120 and 170/30 yielded intermediate VS levels between 2.5% and 5.5%, with no statistically significant difference between them. The most severe regimes, 160/180 and 170/60, produced the lowest VS values, falling within the range of 2.1% to 4.7%.

TM of American alder (

Alnus rubra) was performed at 140 °C for durations of 4, 8, and 13 h. The treated wood exhibited a marked reduction in both EMC and water uptake when compared to untreated controls. A clear inverse relationship was observed between EMC and treatment time, with longer exposure resulting in lower EMC values. In contrast, water uptake did not follow a consistent or linear trend in response to increasing treatment duration. Dimensional stability, as assessed by swelling behavior, improved notably in samples treated for 13 h. Tangential and radial swelling were reduced by approximately 24.2% and 16.0%, respectively, relative to the untreated material. In comparison, shorter treatments (4 or 8 h) produced either minimal or statistically insignificant changes in swelling behaviour [

11]. Although TM in a nitrogen atmosphere demonstrated a significantly greater reduction in EMC and VS, a direct comparison between the two treatment methods is not entirely objective, as the maximum temperature applied in that case (140 °C) was substantially lower than in our study (160–170 °C).

3.4. Brinell Hardness

Surface hardness is a critical property for wood products used in flooring applications, where high loads are regularly applied to a small surface area. TM wood is widely used in the construction of terrace decking and walkway elements; therefore, it is essential to determine its surface hardness to assess whether a particular modification provides sufficient durability.

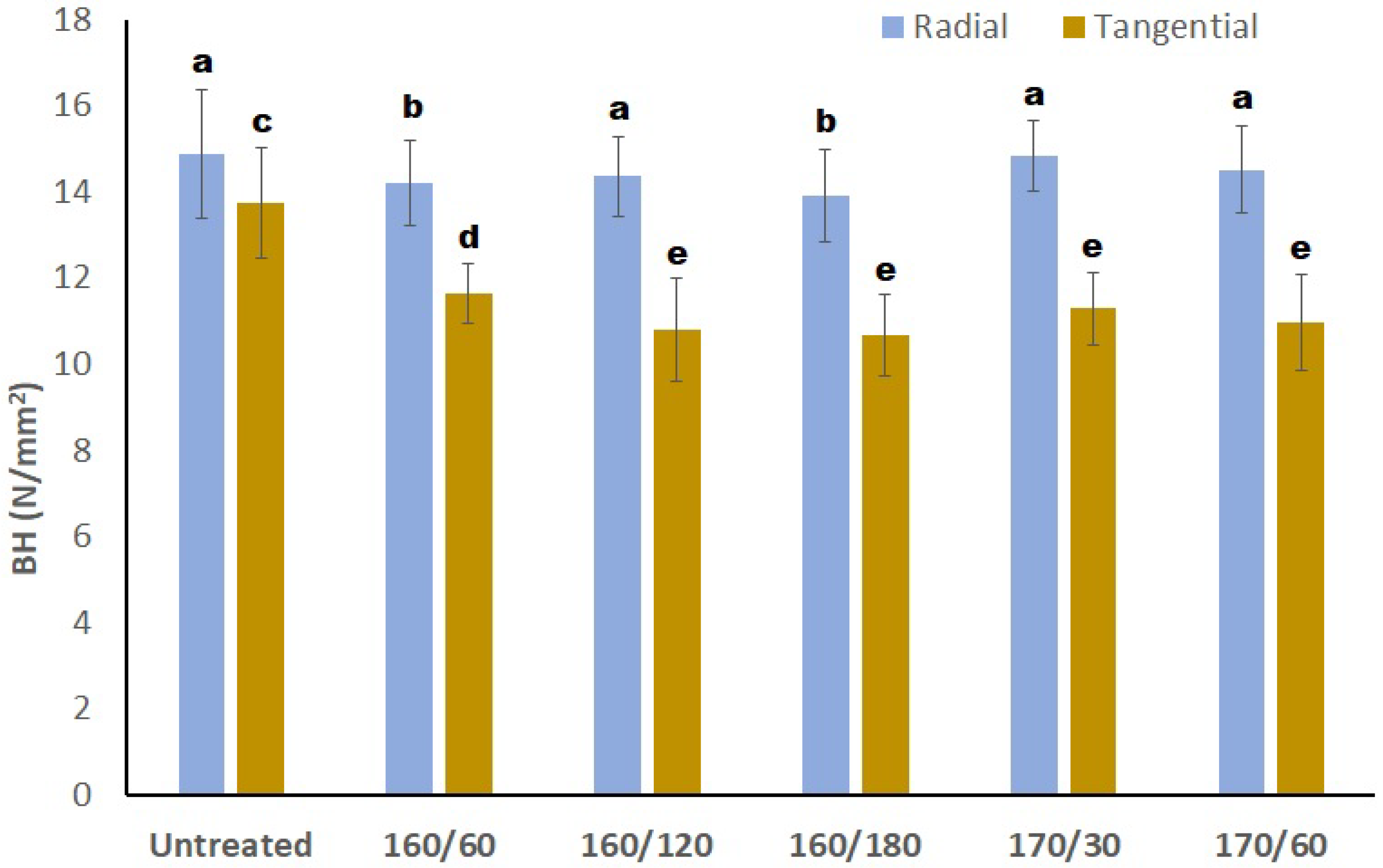

The Brinell hardness (BH) of TM black alder wood exhibited notable anisotropy, with consistently higher values measured on the radial surface compared to the tangential surface (

Figure 5). In the unmodified state, both anatomical orientations showed comparable BH values, ranging from 13.8 to 14.9 N·mm

−2. TM had minimal impact on the radial surface hardness, with only the 160/60 and 160/180 treatment regimes resulting in statistically significant reductions. In contrast, all thermal treatments led to a marked decline in BH on the tangential surface. The least severe regime (160/60) produced the smallest decrease, yielding a BH of 11.6 N·mm

−2, relative to the untreated value of 13.8 N·mm

−2. Other treatment conditions resulted in similar levels of hardness reduction, with BH values clustering between 10.8 and 11.3 N·mm

−2. In TM silver birch wood, the tangential surface exhibited substantially higher BH compared to the radial surface, whereas the opposite pattern was observed in Scots pine. This contrasting behavior can be attributed to species specific microstructural transformations induced by TM in a nitrogen atmosphere [

25]. European aspen wood, following TM, displayed a pattern of variation in both modulus of rupture (MOR) and BH across anatomical directions that closely resembled that of pine, suggesting similar underlying mechanisms in their structural response to heat treatment [

16]. Thus, black alder, aspen, and pine wood exhibit similar trends in BH variation across both anatomical directions, whereas birch wood displays an opposite pattern.

To investigate thermal treatment effects on surface hardness and roughness, specimens of black alder (

Alnus glutinosa), red oak (

Quercus falcata), Southern pine (

Pinus taeda), and yellow poplar (

Liriodendron tulipifera) were exposed to controlled heating at 120 °C and 190 °C for durations of 3 and 6 h. In black alder, Janka hardness showed a moderate decline of approximately 7.9% when treatment was extended from 3 to 6 h at 190 °C. At the lower temperature of 120 °C (6 h), the reduction was more modest, around 4.3%, relative to untreated wood. In contrast, red oak subjected to identical high temperature conditions experienced a markedly greater hardness reduction of roughly 41.7%. These results highlight the relatively higher thermal stability of black alder in terms of mechanical surface resistance, especially when compared to more porous hardwoods such as red oak under equivalent treatment intensities [

4].

Black alder (

Alnus glutinosa) wood was TM at 130 °C and 160 °C for 3 and 7 h, respectively. The treatment resulted in a reduction in surface hardness by approximately 10%–15%, with more pronounced decreases observed under higher temperatures and extended exposure. This reduction is primarily attributed to the thermal breakdown of hemicelluloses and subsequent modifications in the cell wall architecture, which compromise the material’s resistance to indentation [

3]. In a separate study, red alder (

Alnus rubra), western hemlock (

Tsuga heterophylla), Douglas fir (

Pseudotsuga menziesii), red cedar (

Thuja plicata), and paper birch (

Betula papyrifera) underwent TM in a continuous steam flow at 190 °C and 212 °C. For red alder, longitudinal hardness measured 4.5 kN, while transverse hardness reached 3.5 kN. Treatments conducted at 190 °C caused relatively minor changes in hardness across anatomical directions, whereas exposure to 212 °C significantly reduced hardness values for all tested species, indicating a threshold beyond which mechanical degradation becomes substantial [

13]. These studies cannot be directly compared with our results, as they do not specify surface hardness along individual anatomical directions, employ a different method for determining surface hardness (Janka) or use different measurement units. However, a general trend can be observed—surface hardness of alder wood tends to decrease following various thermal treatments. Similarly, increasing the treatment intensity results in a further reduction in surface hardness of TM wood.

3.5. Bending Strength

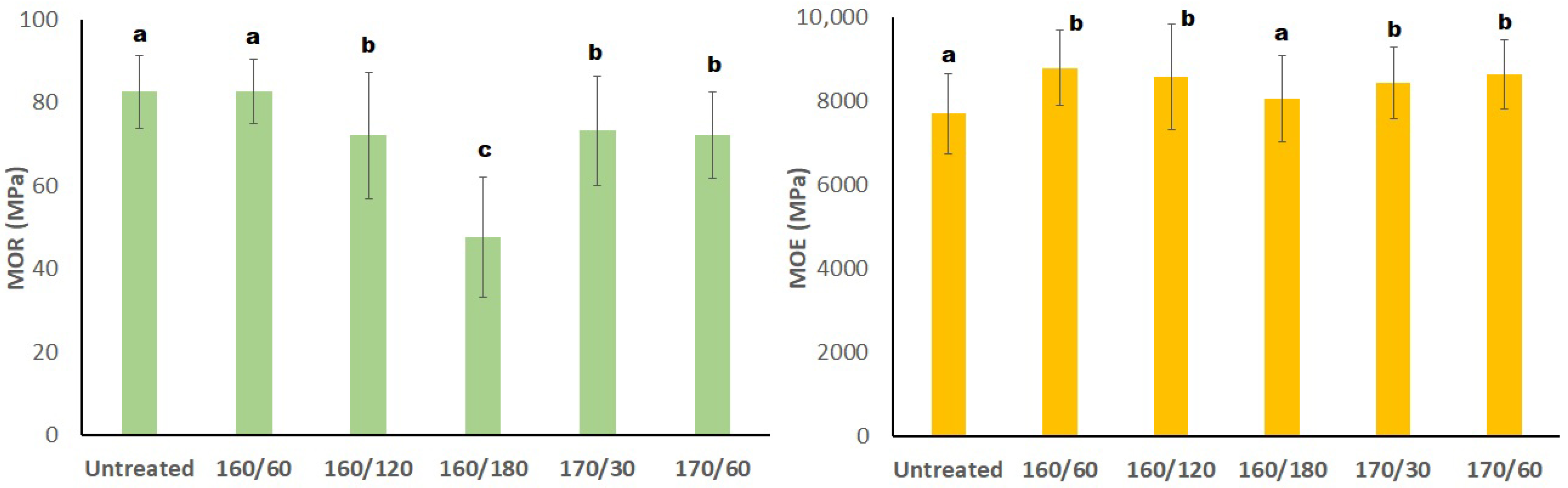

Black alder wood is considered soft and easy to machine, but also mechanically brittle, which limits its range of applications. Therefore, any wood modification process should aim to maintain or even enhance its mechanical strength. Unfortunately, most TM processes result in a reduction in mechanical strength. Consequently, it is crucial to select modification parameters that do not compromise the wood’s structural integrity to the extent that it becomes excessively brittle. Our previous experience with various wood species and different TM processes conducted in pressurized steam or nitrogen atmospheres indicates that bending strength can decrease by as much as 50%–60%, depending on the process parameters. From a practical application standpoint, a reduction in bending strength of up to 30% is considered acceptable, which we established as the maximum permissible threshold.

The modulus of rupture (MOR) for unmodified black alder was measured at 83 MPa. TM led to reductions in MOR ranging from 11% to 43%, depending on the treatment parameters. Notably, the 160/60 regime maintained a MOR statistically comparable to that of the untreated material (

Figure 6). In contrast, the most severe reduction was observed under the 160/180 regime, where MOR declined to 47 MPa (−43%). Thus, this TM regime is not suitable for black alder wood, as it results in an excessive loss of mechanical strength. Other treatment conditions (160/120, 170/30, and 170/60) yielded MOR values within a narrow and statistically equivalent range of 72–73 MPa (−12% to 13%).

TM resulted in an overall increase in the modulus of elasticity (MOE) of black alder compared to the untreated reference value of 7700 MPa. Among the tested regimes, only the 160/180 condition produced MOE values (8100 MPa) that were not statistically different from the control. All other treatment combinations led to a notable enhancement in stiffness, with MOE ranging between 8400 and 8800 MPa.

Black alder (

Alnus glutinosa) and Douglas fir (

Pseudotsuga menziesii) were TM under two distinct conditions: in ambient air at 165 °C and in an open process steam atmosphere at 210 °C. At the higher treatment temperature, black alder exhibited a pronounced decline in mechanical performance. Impact toughness was reduced by approximately 63%, and bending strength decreased by around 45% relative to untreated samples. In contrast, the MOE showed only a minor reduction from 8000 MPa in untreated wood to 7700 MPa after exposure to 210 °C. The pronounced sensitivity of black alder to elevated thermal conditions is likely related to its higher hemicellulose content, which renders it more susceptible to thermal degradation than softwoods such as Douglas fir [

2].

American alder (

Alnus rubra) was TM at 140 °C for durations of 4, 8, and 13 h. Interestingly, the 8 h treatment resulted in a noticeable improvement in bending strength, with MOR increasing by approximately 14.5%. While MOE fluctuated slightly across treatment durations, overall stiffness remained largely unaffected. These observations indicate that mild thermal exposure at 140 °C even up to 13 h does not impair, and may even enhance, the mechanical performance of alder in terms of flexural properties [

11]. Black alder (

Alnus glutinosa) wood underwent TM at 150 °C, 180 °C, and 200 °C for durations of 2, 6, and 10 h. Following treatment, the samples were installed in ground contact and subjected to natural outdoor weathering for a period of three years. In certain high-severity regimes, heat treatment alone led to a reduction in MOR by up to 50%. Subsequent environmental exposure caused further mechanical degradation across all treatment groups. Nevertheless, TM specimens consistently exhibited higher residual MOR compared to their untreated counterparts, suggesting improved structural retention under long term outdoor conditions [

5]. Red alder (

Alnus rubra), western hemlock (

Tsuga heterophylla), Douglas fir (

Pseudotsuga menziesii), red cedar (

Thuja plicata), and paper birch (

Betula papyrifera) were subjected to TM in a continuous steam flow system at 190 °C and 212 °C. Among all species evaluated, red alder exhibited the lowest dynamic MOE, measuring 9.17 GPa. A moderate thermal regime at 190 °C led to a modest 4.9% reduction in dynamic MOE for red alder, whereas exposure to 212 °C resulted in a much steeper decline ~19%. These findings point to a clear sensitivity of red alder’s stiffness to higher intensity thermal processing [

13]. Our previous studies have shown that MOR of European aspen and Scots pine wood decreases by 2%–32% following TM in a nitrogen atmosphere, while silver birch wood exhibits a slightly higher reduction ranging from 15%–42% [

16,

25]. Overall, it can be concluded that TM in a steam environment at temperatures of 160–210 °C tends to result in a somewhat greater reduction in MOR compared to TM in a nitrogen atmosphere under pressure at 160–170 °C.

3.6. Chemical Composition

TM altered the relative distribution of primary constituents in black alder wood, triggering structural adjustments within the cell wall matrix as both peak temperature (T

max) and duration at T

max increased. In contrast, black alder exhibited ML, primarily driven by the thermally induced degradation of key structural polymers specifically xylan and associated acetyl functionalities culminating in a measurable rise in extractive content (see

Table 2). The most pronounced changes resulting from TM were observed in the levels of acetone soluble extractives, as well as in the contents of glucan, xylan, and acetyl groups. In contrast, alterations in lignin and mannan content were comparatively minor. The concentration of acetone extractives in TM black alder wood increased substantially, reaching values between 4.9% and 8.9%, which represents a 2–3 fold increase compared to unmodified wood (2.6%). A comparable trend was identified in silver birch (

Betula pendula) and Scots pine (

Pinus sylvestris) wood subjected to analogous TM conditions. Notably, TM pine exhibited considerably lower levels of total extractives (1.8%–4.7%) relative to birch (4.0%–12.6%). Furthermore, the xylan content in hardwoods was markedly higher 21.4% in birch and 16.8% in grey alder compared to the 6.3% found in pine, a representative softwood species. Xylan in hardwoods undergoes significant thermal degradation during treatment, and a portion of its degradation products are removed as part of the extractive fraction [

25]. Variations in TM conditions can result in differing chemical responses among hardwood species. When black alder (

Alnus glutinosa) was subjected to controlled heating in a laboratory oven at 120 °C and 190 °C for durations of 3 or 6 h, signs of cell wall alteration were observed. However, the extent of structural damage was less pronounced than that reported for red oak (

Quercus falcata) under comparable conditions [

4].

Lignin levels in TM black alder wood showed a marked increase following most treatment conditions, with the exception of the 160/120 regime, where no significant change was observed. Across the different treatment regimes, the relative proportion of lignin remained generally consistent. Since thermal degradation primarily affects the amorphous regions of cellulose, the modified wood exhibits a higher relative amount of crystalline cellulose. This selective degradation of amorphous polysaccharides results in a relative enrichment of lignin. Nevertheless, even as lignin concentration rises, it undergoes notable chemical transformations during TM, including both depolymerization and subsequent repolymerization processes [

26]. Black alder (

Alnus glutinosa) wood was TM at 150 °C, 180 °C, and 200 °C for periods of 2, 6, or 10 h, then exposed to outdoor weathering conditions in direct contact with the ground. This study revealed a substantial degradation of hemicelluloses as a result of TM, with further breakdown occurring during environmental exposure. Alterations in lignin-associated absorption bands were also detected, suggesting structural changes in the lignin polymer. The extent of chemical deterioration correlated positively with both the treatment temperature and the duration of exposure [

5].

Following TM in a nitrogen atmosphere, the relative glucan content in black alder wood increased noticeably, with rises ranging from 1.7% to 3.5%. The highest glucan concentrations between 46.7% and 47.4% were recorded under the most intensive treatment conditions (160/180 and 170/60). This apparent increase in glucan proportion is largely attributed to the ML of wood components and removal of acetone soluble extractives, which reduces the overall mass of the sample while leaving glucan relatively enriched. In contrast, arabinan content declined from 0.4% in untreated samples to 0.2%–0.3% in TM wood. No statistically significant differences or trends were found among the various TM regimes for these components; therefore, detailed comparative data are not presented. Ash wood (

Fraxinus excelsior L.) was subjected to TM at 190 °C for 2, 6, and 10 h under three atmospheric conditions: nitrogen, steam, and air. The surrounding atmosphere had a notable impact on the degree of cellulose polymerization. Among the tested environments, nitrogen preserved the polymer structure most effectively, followed by steam, while air led to the greatest reduction in polymerization. A consistent pattern was observed in relation to treatment duration: the shortest exposure (2 h) maintained the highest degree of polymerization, which gradually declined with longer treatment times. These findings indicate that cellulose degradation is less pronounced when TM is carried out in an inert nitrogen atmosphere compared to oxidative or hydrothermal conditions [

27].

TM caused a notable decrease in the xylan content of black alder wood, reducing it from 16.8% in untreated samples to a range of 12.1%–15.2% in treated specimens. The most intensive regimes (160/180 and 170/60) resulted in the lowest xylan levels, ranging between 12.1% and 12.4%. Based on xylan content, the TM samples can be grouped into three categories. The mildest treatment (160/60) retained the highest xylan concentration (15.8%). Intermediate regimes (160/120 and 170/30) yielded statistically similar values between 13.8% and 14.3%. The most severe treatments, as noted, produced the most significant reduction. Changes in xylan content were found to correlate well with variations in ASE, CWTWC and EMC. These findings support the conclusion that decreasing xylan content contributes to reduced moisture uptake and improved dimensional stability in TM black alder wood. Black alder (

Alnus glutinosa) wood was subjected to thermal treatment in a pressure autoclave using saturated steam or a steam–air mixture at temperatures ranging from 95 to 125 °C for treatment durations of 3, 6, 9, or 12 h. A reduction in dry density of up to 4.6% was recorded, accompanied by a drop in pH from approximately 4.9 to around 3.1. This shift toward increased acidity reflects ongoing thermal degradation, particularly hemicellulose decomposition, the development of conjugated carbonyl structures, and alterations in the lignin network [

1]. Thin veneers of black alder (

Alnus glutinosa) were exposed to TM at 190 °C for durations of 5, 10, 20, and 40 min. The heat exposure led to a noticeable reduction in absorbance at wavelengths corresponding to hemicellulose related functional groups, particularly those linked to C=O and OH vibrations. Simultaneously, increased absorbance in spectral regions associated with aromatic C–H and C=C bonds indicated condensation reactions within the lignin structure. These reactions are associated with the formation of chromophoric systems that contribute to the observed darkening of the material. In contrast, absorbance bands characteristic of cellulose exhibited minimal variation, implying that cellulose remained largely unaffected under the applied temperature and short treatment durations [

9].

In TM black alder wood, mannan content was noticeably reduced, decreasing from 1.5% in untreated samples to a range of 0.9%–1.2% following treatment. The TM regimes 160/60 and 160/120 resulted in comparable mannan levels, with no statistically significant difference between them. Similarly, treatments at 160/180, 170/30, and 170/60 produced closely aligned values, indicating a consistent effect of more intensive thermal exposure on mannan degradation.

TM of black alder wood led to a substantial reduction in acetyl group content, decreasing from 4.1% in untreated samples to between 2.1% and 3.1% after treatment. The most intensive TM regimes (160/180 and 170/60) resulted in the lowest acetyl group levels, ranging from 2.1% to 2.3%. These reductions closely mirrored the trends observed in xylan content, indicating a strong correlation between the two components. This relationship suggests that acetyl group content in TM black alder could serve as a useful indicator for predicting moisture-related properties (ASE, CWTWC and EMC). Similar patterns of xylan and acetyl group degradation were also observed in silver birch (

Betula pendula) and Scots pine (

Pinus sylvestris) wood subjected to the similar TM conditions [

25].

4. Conclusions

The ML of black alder wood following TM ranged from 4.6% to 8.6%, depending on the applied treatment conditions. Dimensional changes after TM were more pronounced tangentially. Overall, the combined shrinkage along these two directions led to a volumetric decrease of approximately 2.8% to 4.7%.

After the first soaking–drying cycle, the ASE of TM black alder wood ranged between 43% and 62%. With each subsequent cycle, ASE values showed a clear downward trend dropping to 18%–45% after the seventh cycle. The CWTWC in TM black alder wood was reduced to a range of 19%–27%, compared to 33%–35% observed in untreated samples. Throughout seven successive soaking–drying cycles, a gradual increase in CWTWC was noted across all TM specimens. TM reduces EMC by approximately 48%–64%, regardless of ambient humidity.

TM had minimal impact on the radial surface hardness while all thermal treatments led to a marked decline in BH on the tangential surface. TM led to reductions in MOR of black alder ranging from 11% to 43%. The most severe reduction was observed under the 160/180 regime. TM resulted in an overall increase in the MOE compared to the untreated reference.

The most pronounced chemical composition changes resulting from TM were observed in the levels of acetone soluble extractives, as well as in the contents of glucan, xylan, and acetyl groups. In contrast, alterations in lignin and mannan content were comparatively minor.

TM substantially improves dimensional stability and moisture resistance in black alder wood. The dark brown color developed during TM enhances its visual appeal, making it a competitively priced alternative to more expensive wood materials. This study expands the knowledge of TM applied to black alder, demonstrating its potential for use in sustainable wood product industries. The TM regimes of 160/60 and 160/180 are not suitable for black alder wood; the former does not significantly improve dimensional stability or reduce moisture absorption, while the latter excessively decreases mechanical strength. The most appropriate treatment regime for black alder wood is 170/60, which provides the highest dimensional stability, the lowest moisture and water absorption, and does not substantially impair mechanical strength.