1. Introduction

The increasing demand for sustainable construction materials has driven significant research into engineered wood products such as glued-laminated timber (GLT or glulam). GLT combines multiple layers of wood bonded with adhesives, which may not only maximize the use of available timber but also enhance structural performance. In this study, GLT manufactured from oak wood derived from low-quality lamellae was the focus. By incorporating finger jointing in the direction along the grain, the exceptionally high inherent variability and defects can be mitigated, leading to improved performance under bending loads and other mechanical stresses. Nevertheless, this study deals with the processing of wood together with its natural defects. Accordingly, during the production of lamellae of a suitable size for GLT manufacturing, the defects of the lower-quality wood were left in the lamellae, which will be detailed in the Materials and Methods section. It should be noted that in addition to GLT, there are already many product types available in the sustainable construction materials category (or under development). Good examples are laminated veneer lumber (LVL), laminated strand lumber (LSL), oriented strand lumber (OSL), solid structural timber (SST or KVH, German: Konstruktionsvollholz) and cross-laminated timber (CLT) [

1,

2]

The mechanical performance of GLTs is predominantly determined by their bending strength and modulus of elasticity (

MoE). These properties are influenced by factors such as wood species, lamella quality, adhesive type and the presence of finger joints. Several studies have focused on quantifying the mechanical properties of GLT [

3,

4,

5]. The work of Kretschmann [

6] highlights the strong relationship between material density and mechanical performance, underscoring the need for rigorous testing methods such as the four-point bending test [

7]. Gaff et al. [

8] demonstrated that modifying the lamella configuration can lead to measurable improvements in bending strength and stiffness, providing a critical benchmark for engineered timber produced from lower quality raw materials. In terms of bending performance, the presence of finger joints introduces discontinuities that can act as stress concentrators, potentially reducing the strength and stiffness of the GLT [

9]. However, when properly designed and manufactured, finger joints can maintain a substantial portion of the wood’s inherent bending strength.

1.1. Finger Jointing and Its Impact on Structural Performance

Finger jointing is a widely used technique to join smaller or defect-free wood elements in order to produce larger structural components. The method increases the bonding area in the right anatomical directions and contributes to a more uniform stress distribution across the joint. As detailed in the publication of Aicher and Stapf [

10], optimal finger joint geometry and joint quality are crucial in achieving a significant increase in bending strength and fatigue resistance. Moreover, Morin-Bernard et al. [

9] provide an extensive overview of how engineered processing methods, including finger jointing, homogenize the variability inherent in lower-grade wood. These improvements are essential for ensuring that the resulting GLT meets the performance criteria outlined in EN 14080 [

7] and is suitable for high-stress applications.

1.2. Adhesive Bonding and Laminated Wood Properties

The adhesive plays a pivotal role in the performance of GLT, particularly when low-quality oak lamellae are used. The adhesive bonding of high-density hardwoods presents unique challenges due to the high density, extractive content, and dimensional stability [

11,

12]. The selection of appropriate adhesives and surface preparation techniques is crucial to achieving strong and durable bonds. Recent research by Gáborík et al. [

11] indicates that the type and quality of adhesive used can significantly affect the mechanical properties of GLT, including bond strength and durability. This study demonstrates that adhesives formulated for improved penetration and curing can effectively compensate for inherent wood variability, leading to better performance under cyclic loading conditions. Complementary evidence from a follow-up study on the impact of adhesive factors on laminated wood further confirms that optimizing the adhesive system is critical for enhancing the overall performance of GLT [

8,

11]. These findings support the use of modern adhesive formulations in conjunction in the future with advanced jointing techniques to produce superior engineered timber. But the samples were prepared using industrial technology currently available on the market.

1.3. Properties of Oak Wood and Its Suitability for GLT

Oak wood is traditionally prized for its density, durability, and distinctive grain, making it a favorable choice for interior design, furnitures and sometimes for structural applications Glavinić et al., (2020) [

13]. However, when low-quality lamellae are used, natural wood defects and variability can compromise performance. Kretschmann [

14] provides comprehensive data on oak’s mechanical properties, emphasizing the challenges of using variable raw material. In response, engineered processing methods such as finger jointing have been applied to improve the structural integrity of oak-based GLT, as discussed in the study of Aicher and Stapf [

10] and Morin-Bernard et al. [

9].

1.4. Non-Destructive Testing (NDT) in Engineered Wood Products

NDT methods are essential tools for assessing the internal quality and long-term performance of solid wood or GLT without causing damage. Techniques such as ultrasonic testing, X ray imaging, and infrared thermography have been effectively used to detect internal defects, evaluate adhesive bond integrity, and monitor moisture content. As highlighted by studies referenced by Sandberg et al. [

15] and supported by EN 14080 [

7], integrating NDT into production processes ensures that quality control is maintained throughout the manufacturing cycle. Recent advancements in NDT have further improved the detection capabilities for engineered wood products, providing reliable data that help predict performance and guide maintenance strategies [

8,

16].

The utilization of lower-quality oak lamellae in GLT production, facilitated by finger jointing technique, offers a sustainable approach to maximizing timber resources [

17]. However, this necessitates a comprehensive understanding of the factors influencing mechanical performance, for which the best information can be ensured by properties of bending strength, modulus of elasticity, density, etc. Additionally, incorporating NDT methods can enhance quality control and ensure compliance with structural performance standards, thereby promoting the broader adoption of oak GLT in structural applications.

The aim is to lay the foundations for the use of lower-quality hardwoods in GLTs. The work presented here evaluates key parameters including four-point bending strength, modulus of elasticity, density and the use of an NDT technique to ensure quality control on small-sized oak GLTs. Requirements are provided by EN 14080 [

7], while recent research has expanded the understanding of how lamella quality influences performance. Accordingly, particular emphasis was placed on the defects of the raw materials during the evaluation of the results.

2. Materials and Methods

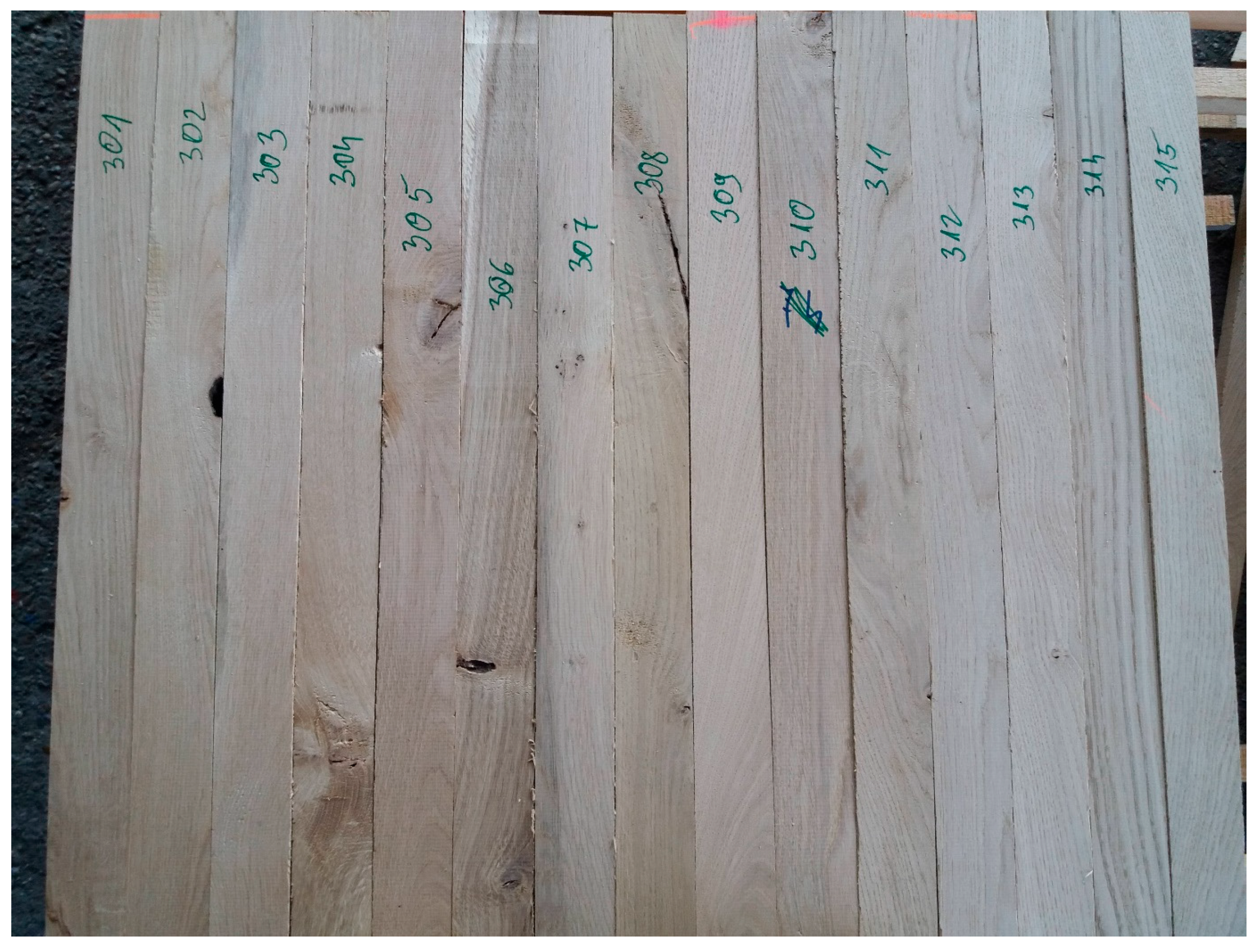

One of the raw materials was a planed lamella made of noble (mostly pedunculate and sessile) oak (

Quercus spp.) with a cross-section of 20 × 50 mm and a length of 500 mm in the grain direction, sourced from the Zala-Fűrész Wood Processing and Trading Ltd. (Lenti, Hungary). The other raw material was 5 × 100 × 1000 mm planed thin oak timber, henceforth referred to as veneer in this study. The total of 736 planed lamellae contained sapwood, slope of grain, and in some cases sawn surfaces due to their smaller thickness, as well as both sound and decayed knots of various sizes, etc. (

Figure 1). Most of the lamellae met the QF3 and QF4 appearance classes specified in EN 975-1 [

18], meaning their quality was low to produce glued laminated timbers. All lamellae were photographed to allow a more detailed documentation of their qualitative description. The veneers were free from wood defects.

After kiln-drying, the raw materials were stored in a woodworking workshop, where they reached an average equilibrium moisture content of 11.2%. Throughout the manufacturing process, uniform climatic conditions were maintained. After planing, the lamellae were joined along the grain using finger joints and bonded in width by edge-joint gluing, producing elements with dimensions of 20 × 90 × 1000 mm. Szolvegy Technobond D3 (Szolvegy Ltd., Szolnok, Hungary) one-component polyvinyl acetate adhesive was used for all gluing. The main properties of the adhesive are as follows: density 1.08 g/cm

3; viscosity (Brookfield): 9.0 ± 2.0 Pas; pH: 3.0 ± 0.4; gel time on 20 °C: 10 min; amount of adhesive: 120–180 g/m

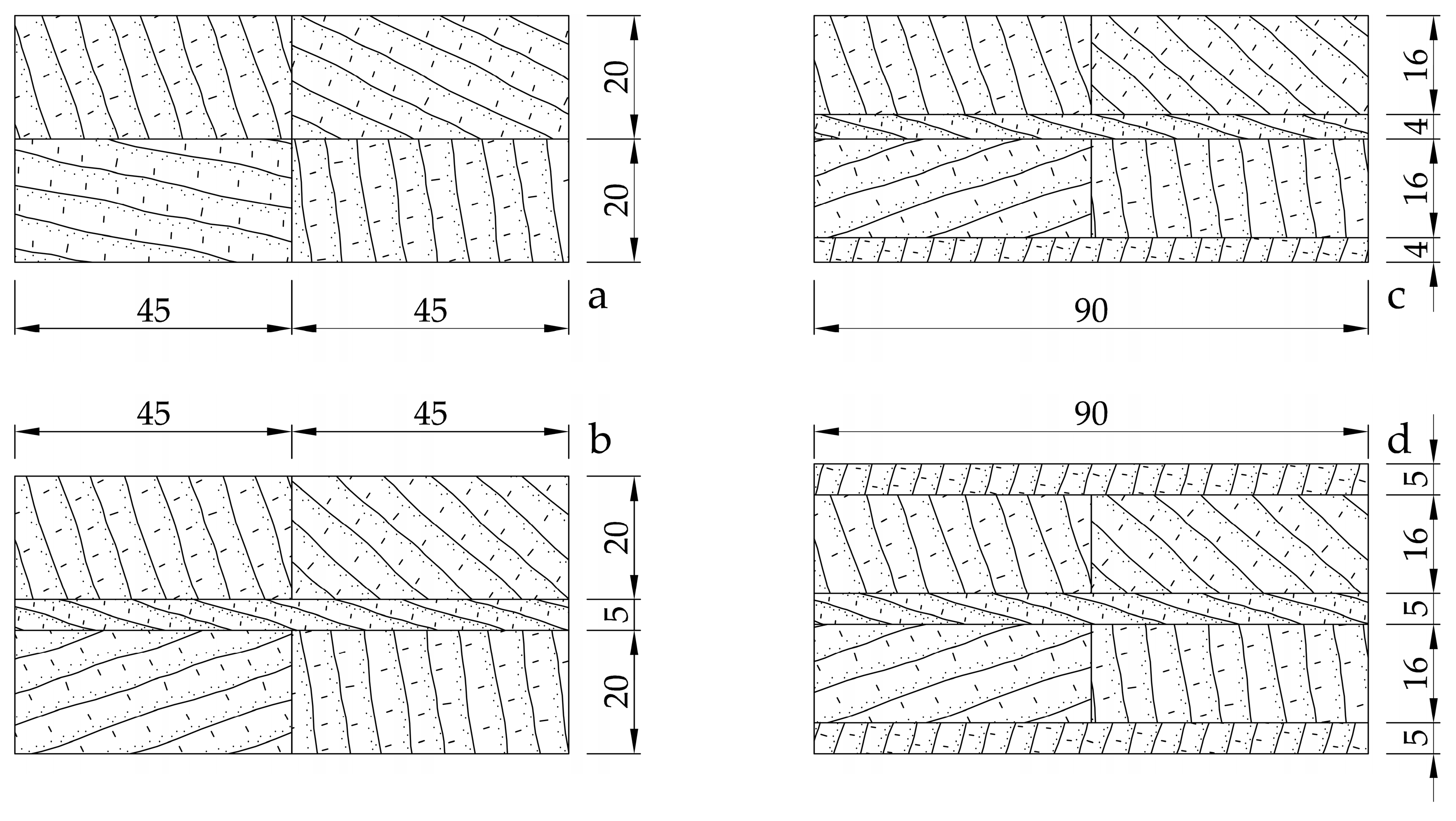

2; pressing time: 2 h; bonding strength: 10.0 MPa. The finger joints were positioned at the center of the elements—and thus to the beams—to enable the examination of the weakest configuration during the bending tests. The elements were then processed into glued-laminated timber (GLT) beams by face-gluing with the same adhesive. All operations described above were carried out in a facility that manufactures softwood structural glued-laminated beams, using the same methods applied for industrially certified load-bearing beams. Therefore, no further details (such as amount of adhesive, pressing parameters) can be disclosed. Four types of small-size beams were produced from the elements (

Table 1). The two-layer beam was made by gluing together only 2 elements, i.e., it was constructed exclusively from lamellae (

Figure 2a). The three-layer beam is a reinforced version of the two-layer beams with a 5 mm thick veneer inserted between the two elements (

Figure 2b). In the four- and five-layer samples, the elements were intentionally thinned to minimize the size effect, enabling more accurate comparison of the modulus of rupture (

MoR) and modulus of elasticity (

MoE) results among the four samples (

Figure 2c,d). The effect of size definitely exists, even if the beams are made of smaller lamellae, which reduces the size effect. In addition, flawless veneers also reduce the size effect, because if the proportion of veneers in the specimens is higher, the proportion of lamellae with wood defects must be lower. According to the weakest link theory, this has a positive effect [

19,

20]. The primary consideration in the test design of the four -layer sample was to examine the effect of reinforcement on the tension side. Therefore, a veneer was used on the tension side but not on the compression side. The aim of this solution was to confirm that, for an asymmetrical structure without reinforcement on the compression side, a significant improvement can be achieved with relatively thin reinforcement on the tension side.

After conditioning to equilibrium moisture content (20 °C and 65% relative humidity), the specimens were subjected to non-destructive testing. The natural longitudinal vibration frequency provides a good estimate of the

MoE [

21]. Measurements were carried out using a Portable Lumber Grader (PLG) timber grading instrument and a Portable Lumber Grader Plus instrument developed for larger specimens (PLG+, Fakopp Bt., Sopron, Hungary). The use of two different testing systems was due to the unavailability of the originally used PLG+ instrument. This, however, made it possible to verify the measurement accuracy of both instruments by comparing their results with static test data—a unique opportunity for oak specimen testing.

Both instruments automatically determined density and dynamic modulus of elasticity (

MoEdyn) [

22,

23]. Vibration was induced at one end of the specimen by tapping with a hammer, while a microphone at the opposite end detected the signal. The specimens were supported at two points on vibration-damping pads to minimize signal distortion. In the PLG instrument, one of the supports was equipped with a scale, whereas in the PLG+ both supports measured weight. The scales automatically transmitted the data to the software. The specimen length was measured by a laser distance sensor and recorded automatically, while the cross-section was measured and entered manually. After sequential decoding of the recorded vibrations, the software determined the longitudinal natural frequency, from which the longitudinal wave propagation speed (sound velocity) was calculated. The software determined density based on the dimensions and mass of the specimen. The

MoEdyn was then computed from the density and sound velocity, derived from the measured longitudinal frequency. The software corrected these values according to several parameters, such as moisture content. The operating principle of the PLG+ instrument is identical, but it provides more accurate results thanks to improved data acquisition and processing [

23].

Subsequently, four-point bending tests were performed according to standard EN 408:2010 + A1 [

24], using different span lengths and roller distances of the crosshead (30 mm roller diameter) corresponding to the sample thicknesses, as shown in

Table 1. The rollers of the crosshead were positioned symmetrically between the supports. In the four-layer specimens, the veneers were always placed on the tension side. The bending tests were conducted on an Instron 4208 universal testing machine (Illinois Tool Works Inc., Glenview, IL, USA) with a loading rate of 6.0 mm/min, in accordance with EN 408:2010 + A1 [

24].

Prior to statistical analysis, any misleading results were removed arising from measurement errors. The outliers were not removed, but the results that were clearly false due to testing errors were. An example of this is the inappropriate automatic selection of data points from the displacement–force curve generated during the bending test, where data points were used to calculate the MoE. Consequently, a total of 136 MoR, 138 MoE, 145 deflection and 146 MoEdin and density results were subjected to statistical analysis and evaluation. A one-way ANOVA Fisher-LSD test was applied at a significance level of 0.05 using a TIBCO Statistica version 14.0.1.25 software (TIBCO Software Inc., Palo Alto, CA, USA).

3. Results and Discussion

Four types of beams with different configurations were tested, each 90 mm wide:

40 mm thick (layer composition: 20 + 20 mm);

45 mm thick (layer composition: 20 + 5 + 20 mm);

40 mm thick (layer composition: 16 + 4 + 16 + 4 mm);

47 mm thick (layer composition: 5 + 16 + 5 + 16 + 5 mm).

Density, dynamically determined modulus of elasticity, static modulus of elasticity in bending, static bending strength, and maximum deflection were separately analyzed. Although the number of specimens per sample varied significantly (

Table 1), the variances were generally low, ranging between 2.3% and 24.3%, and in most cases remained below 10%. Based on this, it can be stated that both the specimens and the tests were performed with adequately high quality.

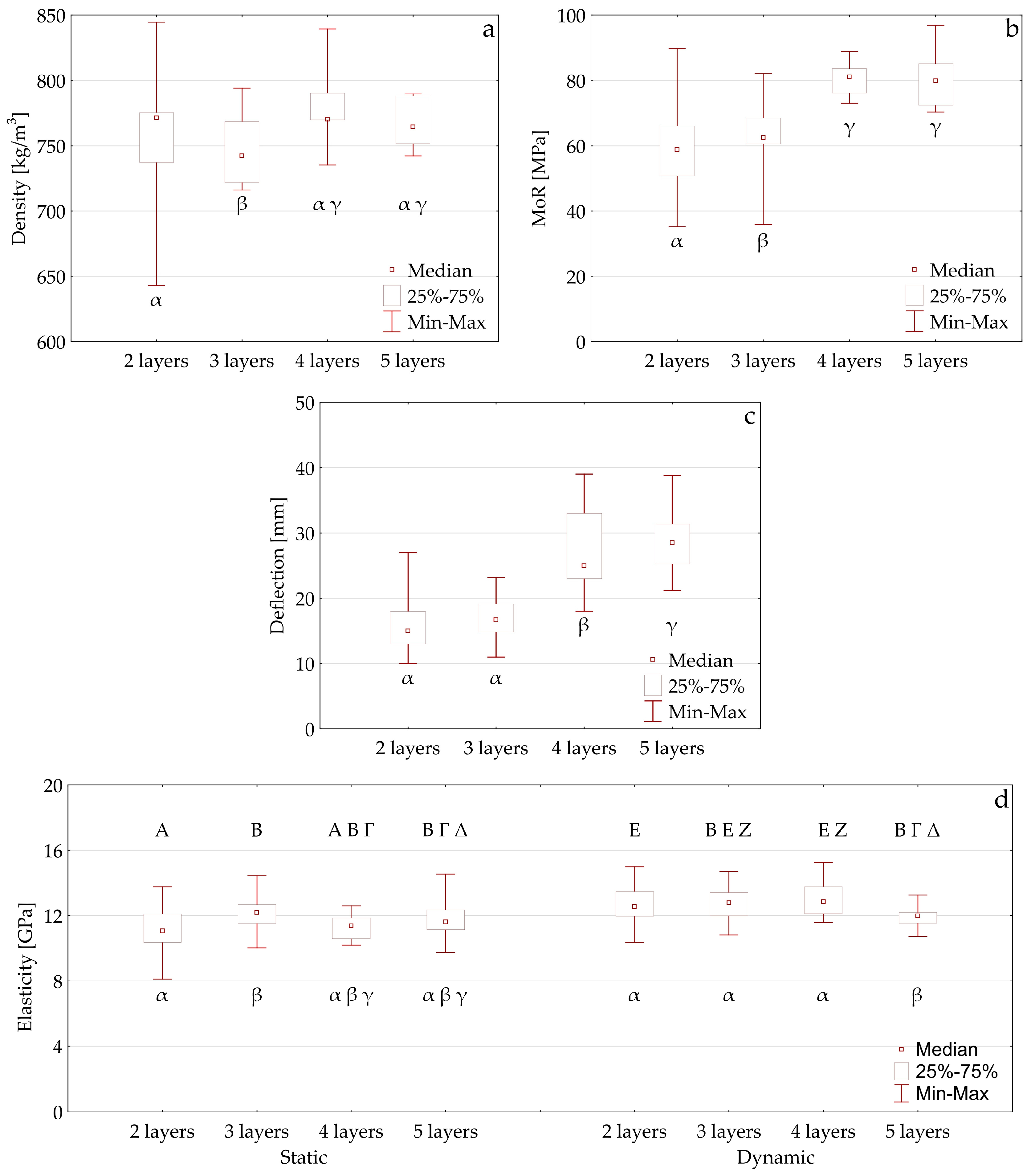

3.1. Density

The average densities of the samples were similar (

Figure 3a), ranging from 746.8 kg/m

3 to 776.7 kg/m

3, representing a 4.0% difference between the averages. It should be noted that in the box plots in

Figure 3, the bars indicate the minimum and maximum values, not the standard deviations. The standard deviations can be inferred from the 25th and 75th percentile ranges. Where relevant, the variances are included in the text. Thus, based on

Figure 3, the statistical results showing significant differences in density,

MoR, deflection, and elasticity are also acceptable despite the long bars. Several statistically significant differences were found among the densities of the four samples: between the two-layer and three-layer, the three-layer and four-layer, and the three-layer and five-layer samples. This can be attributed primarily to the fact that a substantial proportion of each specimen consisted of low-quality lamellae. The lowest proportion of such lamellae was 68.1% in the five-layer beams, while the remaining portion consisted of defect-free oak veneers. The influence of defective lamellae is evident from the fact that the four- and five-layer samples differ from the two- and three-layer samples, in which a higher proportion of wood defects was present. Additionally, many of the lamellae had been classified as low-quality during the preliminary grading mainly due to the presence of knots, which allowed them to be included in this study. In oak wood, the density of knots is similar to the density of clear wood; however, for loose or fallen knots, the local density effectively drops to zero. This increases the variance and can significantly influence the mean values and the observed statistical differences, causing significant differences between samples.

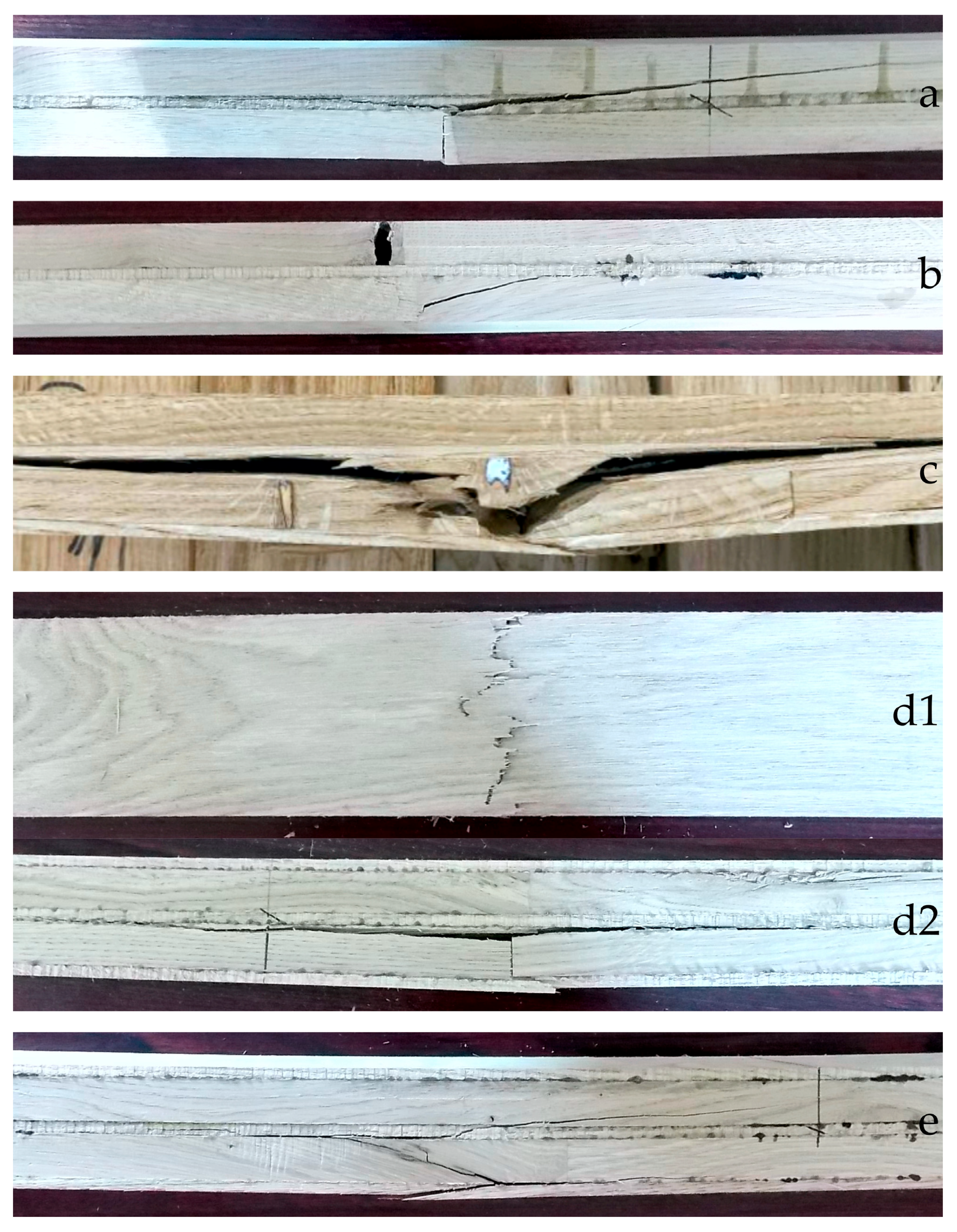

3.2. Modulus of Rupture

Bending strength is an important characteristic of structural elements. Based on statistical analysis, the four-layer and five-layer samples showed no significant difference compared to each other. In other words, placing a veneer layer on the compression side did not improve strength, nor did the 1 mm (25%) increase in all veneer thickness. However, significant differences were observed among all other sample combinations—particularly between the two- and three-layer and four- and five-layer beams—clearly visible in

Figure 3b (maximum difference in averages is 36.4%). This can be directly attributed to the differences in layer configuration, specifically the effect of 4 or 5 mm thick tensile-side veneer reinforcement, as presented in

Table 1. The two-layer beams showed a relatively high variance of 19.4%. They consisted exclusively of low-quality lamellae, and the finger joints were positioned in the middle, which in many cases led to premature and sudden failure (

Figure 4a). In several specimens, problems were caused by the opening of the finger joints on the tension side; this was largely eliminated in the four- and five-layer samples by the presence of defect-free oak veneer, which reduced standard deviation and increased resistance (

Figure 4d1,d2). In the study by Aicher and Stapf [

10], the samples marked G were most similar to those in the present study, with a finger joint bending strength of 66.8 ± 9.3 MPa. Similar results were obtained for the two- and three-layer samples in the present study of 59.0 ± 11.4 MPa and 63.7 ± 8.9 MPa, respectively. The weakest point was generally the finger joint, where failure occurred, which is why the

MoR of the two- and three-layer samples was similar to the finger joint bending strength results of Aicher and Stapf [

10]. This problem has been considerably solved in the four- and five-layer samples. For the three-layer specimens, the addition of a veneer between the two lamellae resulted in only a slight improvement—an average increase of 8.1% in the

MoR. According to the statistical analysis, this effect barely exceeded the 5% significance probability threshold, indicating that the inclusion of a middle lamella layer is unnecessary in terms of

MoR enhancement.

3.3. Failure Types

In most cases, failure was caused at the finger joints placed at the center of the specimens, as was expected during specimen preparation (

Figure 3a,d). At the finger joints, the adhesive strength cannot fully replace the natural tensile strength and shear strength of solid wood in the grain direction. Developing a specialized adhesive and its application for this purpose would be worthwhile, as it could significantly increase the strength values of oak beams. The opening of the finger joints caused such a pronounced weakening that the entire structure failed suddenly. Mostly, the bond line between the flat surfaces split along the length of the beam, eliminating the tensile support of the upper or inner lamella layers, consequently causing a fracture, too. Another major cause of failure was the slope of grain. In many cases, similar to the finger joint failures, the lamellae split almost across their entire cross-section due to the pronounced slope of grain (

Figure 4b). Knots alone rarely cause failure; however, the local slope of grain around knots often led to the aforementioned problems. For larger knots, the local slope of grain extended across the entire cross-section of the relatively thin lamella, effectively acting as a full-section diagonal slope of grain (

Figure 4c).

3.4. Deflection

Deflection is not an intrinsic material property and depends strongly on the cross-section of the specimens and the bending test setup. Nevertheless, this knowledge provides useful information and helps to compare the deformation capabilities of different layer configurations. This is possible in this form, as the test settings complied with the relevant standard (EN 408:2010 + A1), particularly with regard to the ratio of the specimen height to the support span, ensuring comparability between the samples. The statistical analysis of specimen deflection revealed few similarities among the samples. During the four-point bending tests, the specimens exhibited varying levels of deflection (

Figure 3c). The variances were relatively high per samples (16.0%–24.5%), though this cannot be considered excessive given the nature of the property examined. Deflection is strongly influenced by numerous material characteristics, particularly in low-quality wood. For the two- and three-layer samples—where low-grade lamellae dominated—statistically significant similarity was observed. In all other sample comparisons, differences were found. The most striking result shown in

Figure 3c is the pronounced increase in deflection between the three-layer and four-layer specimens, averaging 62.6%. This clearly demonstrates how much a defect-free veneer layer on the tension side can delay fracture and increase

MoR at the same time. It significantly hinders the opening of finger joints and, to a lesser extent, the fracture of lamellae affected by slope of grain or knots—an effect that was already evident in the values of

MoR. The positive effects of defect-free veneers placed on the tension side were already discussed earlier (

Figure 3d,e). Of course, these veneer layers also fractured in many cases, often due to compressive pressure from adjacent finger joints. During bending, the finger joints—tending to open under tension and shift transversely—exerted compressive forces on the veneer, subjecting it to complex stresses that included tension as well. Examining the properties of individual specimens, extremely low deflections were generally associated with low bending strength values. This indicates the presence of critical defects, which cause the wood to fracture after minimal bending, offering little resistance to bending forces. Conversely, in cases of particularly large deflections, high strength was not typically observed. If the finger joints had not been positioned near the central region, where the highest stress occurs, the tested beam types could have achieved significantly higher strength values.

3.5. Static and Dynamic Moduli of Elasticity

In the following, the static and dynamic moduli of elasticity will be presented and analyzed together, allowing easy comparison between samples and measurement methods.

Figure 3d illustrates the results of the statistical analysis. The values obtained from static (

MoE) and dynamic (

MoEdin) tests for the three-layer and five-layer samples did not show statistically significant differences. Here, the

MoEdin values were provided by the PLG+ instrument. However, for the two-layer and four-layer samples, significant differences were observed between

MoE and

MoEdin, with the dynamic test giving, on average, 13.3% and 14.9% higher values, respectively. This discrepancy is partly due to the use of PLG instrument for dynamic tests, which produced results that correlated less well with the four-point static bending tests compared to the PLG+ instrument. Additionally, two other important factors may explain the differences between statically and dynamically determined elasticity. First, vibrations induced by tapping with a hammer easily propagate through weaker glue lines and can bypass knots without much attenuation [

23,

25,

26]. Second, the centrally placed finger joints substantially weaken the static test results, while their effect is not visible in the dynamic measurement. The advantage of the dynamic method is that it yields lower variance than mechanical testing, making engineering of a building structure easier and more reliable. Mechanical testing, however, better reflects real-world applications, where adhesive quality and larger knots together with other wood defects play a more significant role. Nevertheless, as shown by the similarity of

MoE between the three-layer and five-layer samples, this issue can be effectively mitigated by using a suitable instrument with proper calibration. In other words, reliable results can be obtained through non-destructive testing if the appropriate instrument and settings are used. This finding is important and promising for future applications, as it enables rapid in situ analysis and can significantly reduce the amount of wood classified as waste.

For the comparison of elasticity among the samples, the results of the static tests were used. The two-layer sample exhibited higher variance (12.4%) compared to the other samples, which can be explained by the larger sample size (82 specimens) and the proportionally higher amount of wood defects because of the lack of veneer. These specimens were composed exclusively of low-quality lamellae, without any defect-free layers to improve quality. Statistical analysis of the static

MoE tests showed that only the two-layer and three-layer samples differed significantly from each other. In fact, the two-layer and four-layer samples exhibited a strong agreement with a probability of 78.0%. This observation is clearly illustrated in

Figure 3d. The high degree of match—also noticeable in the statistical analysis of the dynamic test results—can be attributed to the lamellae coming from the same source and having similar properties. Similarities in species, moisture content, density, tissue structure and other characteristics are reflected in the comparable

MoE values. Since

MoE was determined between 20% and 40% of the force to fracture, problems occurring near ultimate failure do not affect the calculation of

MoE. Therefore, the numerous wood defects present in the lamellae have a limited influence on

MoE. Due to the way the specimens were assembled, these weaknesses have less impact on other mechanical properties as well, as the overlapping of wood defects with defect-free layers effectively compensates to a certain extent the reduction in properties caused by defects. From the perspective of strength classification according to EN 384:2016 + A1 [

27], the maximum 8.8% difference in

MoE is negligible and would not alter potential grading. The same applies to density, where the maximum difference of 4.0% is also insignificant according to the standard.

In summary of the mechanical tests, it can be stated that specimens reinforced with veneer on the tension side exhibited the same density and MoE as the non-reinforced specimens, while showing lower variance. The MoR was substantially higher, and the deflection at failure was also significantly increased by the veneer-reinforcement. The multi-layer configuration, supplemented with veneer layers, considerably improves the overall performance of the system and simultaneously reduces the negative effects of wood defects. The most critical role is played by the layer located on the tension side, even if it is thin. Its condition and mechanical properties have the most significant impact on the overall performance of the glued-laminated product, including reliability, as evidenced by the reduced variability in the results.

3.6. Comparison with Properties of Solid Wood

Considering that this study focused on glued-laminated oak beams, assembled largely from lamellae containing significant wood defects, it is interesting to compare their properties with those of solid wood—both defect-free and defect-containing. Additionally, a comparison is interesting with GLT made from high-quality raw materials; but there are few literary sources on this topic for both pedunculate and sessile oak [

10,

28]. For the comparison, numerous studies from different authors were consumed and summarized in

Table 2.

All studies examined either pedunculate oak, sessile oak or both. The specimen sizes varied, ranging from 1 m long lamellae with rectangular cross-sections to conventional bending test specimens of 20 × 20 mm square cross-section, and even smaller 20 × 11 mm specimens. One exception was the GLT of Aicher and Stapf [

10], which was 1.8 m long. Bending conditions were similar, with the specimen height-to-support span ratio between 13 and 19. In the second row of the header of

Table 2, the quality of the tested specimens and the bending test method are listed.

The first parameter providing a reliable comparison is density. The average of all density values was 735.3 kg/m

3, with a variance of 4.7%, indicating that the specimens were similar in this regard and the differences were minor, making it meaningful to compare their bending properties. For

MoR, the variance was considerably higher at 28.9%, with an average value of 87.9 MPa for all

MoR results in

Table 2. Notably, of the data used for comparison, the lowest average value of beams—65.4 MPa with a 24.8% variance from the results of the specimens [

17]—was observed for lamellae containing wood defects and 54.4 MPa with a 10.5% variance [

11]. The high prevalence of wood defects inevitably facilitates fracture and consequently lowers the strength. In the present study, similar values were obtained for the two- and three-layer samples. It is important to note that these specimens not only contained lamellae with wood defects but also had finger joints at the center. They were oriented to produce the less favorable result, which aligns approximately with the intrinsic strength of the lamellae. If, together with the weakening effect of the finger joints, the values are similar to those for the lamellae with wood defects, this means that the two-layer adhesion alone improved the strength of the lamellae. Using similarly low-quality lamellae in a two-layer configuration with offset finger joints can already improve the otherwise weak performance of the lamellae. However, reinforcing the tension side with veneer as in the four- and five-layer specimens in this study yields further significant improvement. Based on the current data,

MoR can be expected to increase by 23%–36% solely by using a 4 or 5 mm thick layer of defect-free veneer.

Both

MoE and

MoEdyn correlate well with the literature. The

MoE obtained from static tests shows only 5.9% variance across all results listed in

Table 2, with an average of 12.1 GPa. Together with density, this indicates that the compared wood share similar fundamental properties. The elasticity of the specimens tested is adequate and corresponds to that of high-quality solid oak. For structural design, this is a positive outcome, suggesting that future development should primarily focus on improving

MoR. In line with the literature [

23,

35,

36,

37], dynamic tests produced slightly higher results than static tests, with an average

MoEdyn of 13.0 GPa. The low variance of 7.5% confirms that these measurements were also reliable, although fewer literature data are available for comparison than for static results. The obtained results are consistent with the findings reported in the existing literature.

4. Conclusions

This study investigated the mechanical performance of small-sized glued-laminated timber (GLT) produced from low-quality oak (

Quercus spp.) lamellae, with the objective of extending the structural application of lower-grade hardwoods. Four GLT configurations, consisting of 2–5 layers, were manufactured using industrial finger jointing and bonded with a one-component polyurethane adhesive. The beams were evaluated through non-destructive vibration-based testing (PLG and PLG+) and static four-point bending in accordance with EN 408:2010 + A1 (2012) [

24].

Average densities ranged from 747 to 777 kg/m3, with a variation below 4%. The modulus of rupture of the two- and three-layer GLTs reached 59.0 ± 11.4 MPa and 63.7 ± 8.9 MPa, while the four- and five-layer configurations achieved 80.4 ± 5.0 MPa and 80.0 ± 8.1 MPa, representing a 23%–36% improvement attributable to 5 mm thick veneer reinforcement on the tension side. The static modulus of elasticity ranged between 11.2 ± 1.4 and 12.1 ± 1.0 GPa, while the dynamic modulus of elasticity reached up to 13.0 ± 1.1 GPa. Differences between static and dynamic measurements reflected adhesive layer behavior and localized wood defects, yet both provided consistent and reliable assessments.

Failure was primarily initiated at finger joints and regions of pronounced slope of grain. The application of defect-free veneer layer on the tension side markedly enhanced strength, reduced variances of the measured properties, and improved deflection behavior. These results confirm that GLT beams manufactured mainly from low-quality oak can achieve mechanical performance levels consistent with structural design requirements specified in EN 14080 [

7], validating the approach for industrial-scale production.

Looking to the future, the results suggest that incorporating veneer-reinforced, multi-layer GLT configurations provide a cost-effective and sustainable method for upgrading low-quality hardwoods for load-bearing applications, supporting the broader use of hardwood in modern engineered timber construction.