Effects of Cyclic Load Amplitude and Count on the Roughness and Friction Coefficient of the Round-End Wood Mortise–Tenon Joint

Abstract

1. Introduction

2. Materials and Methods

2.1. Wood Materials

2.2. Experimental Design

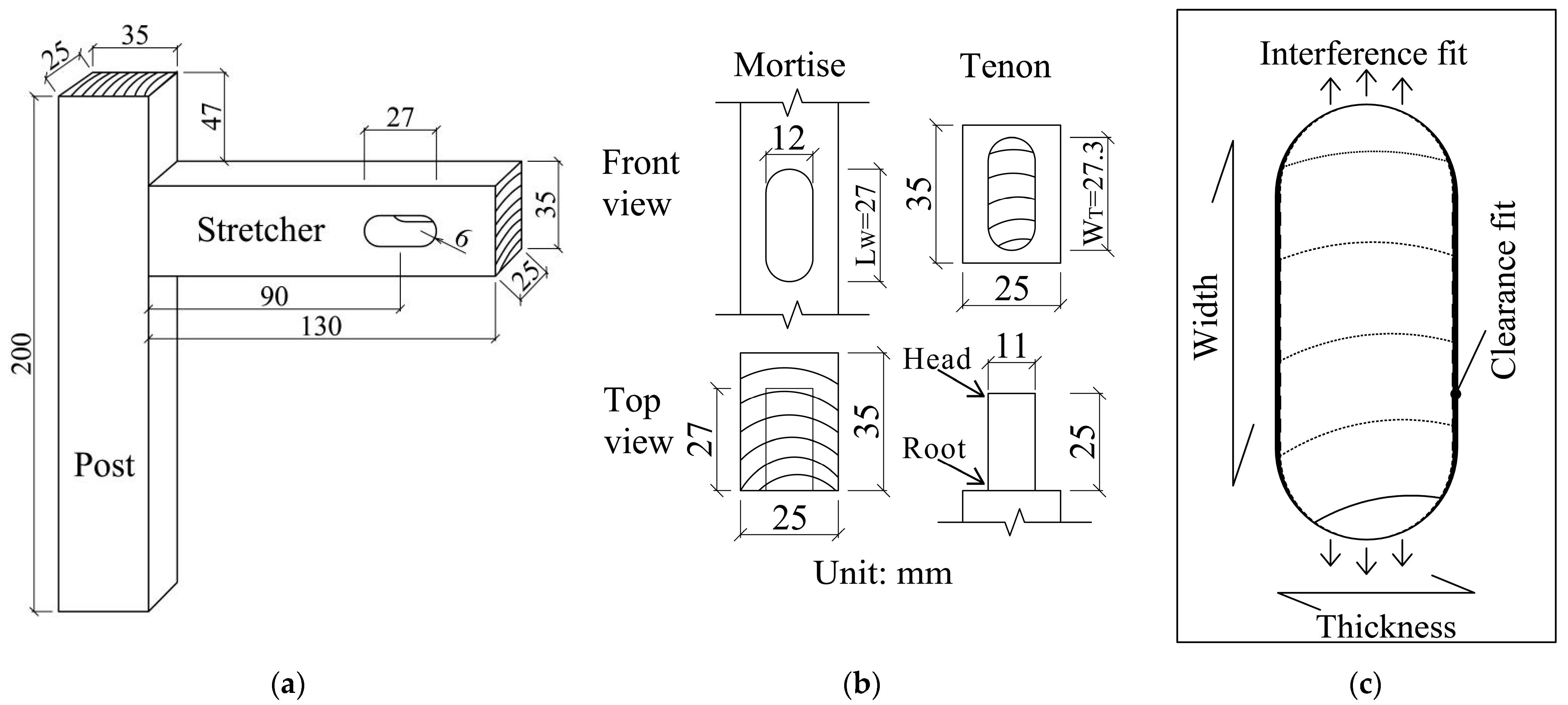

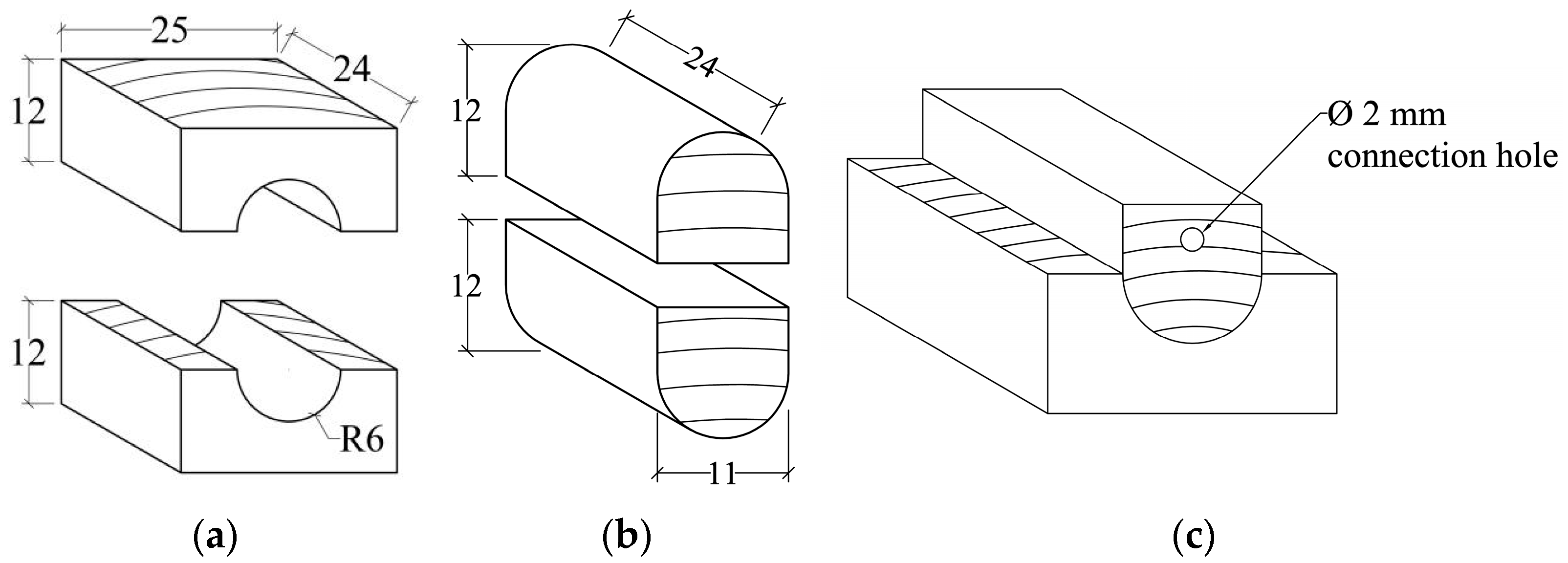

2.3. Sample Preparations

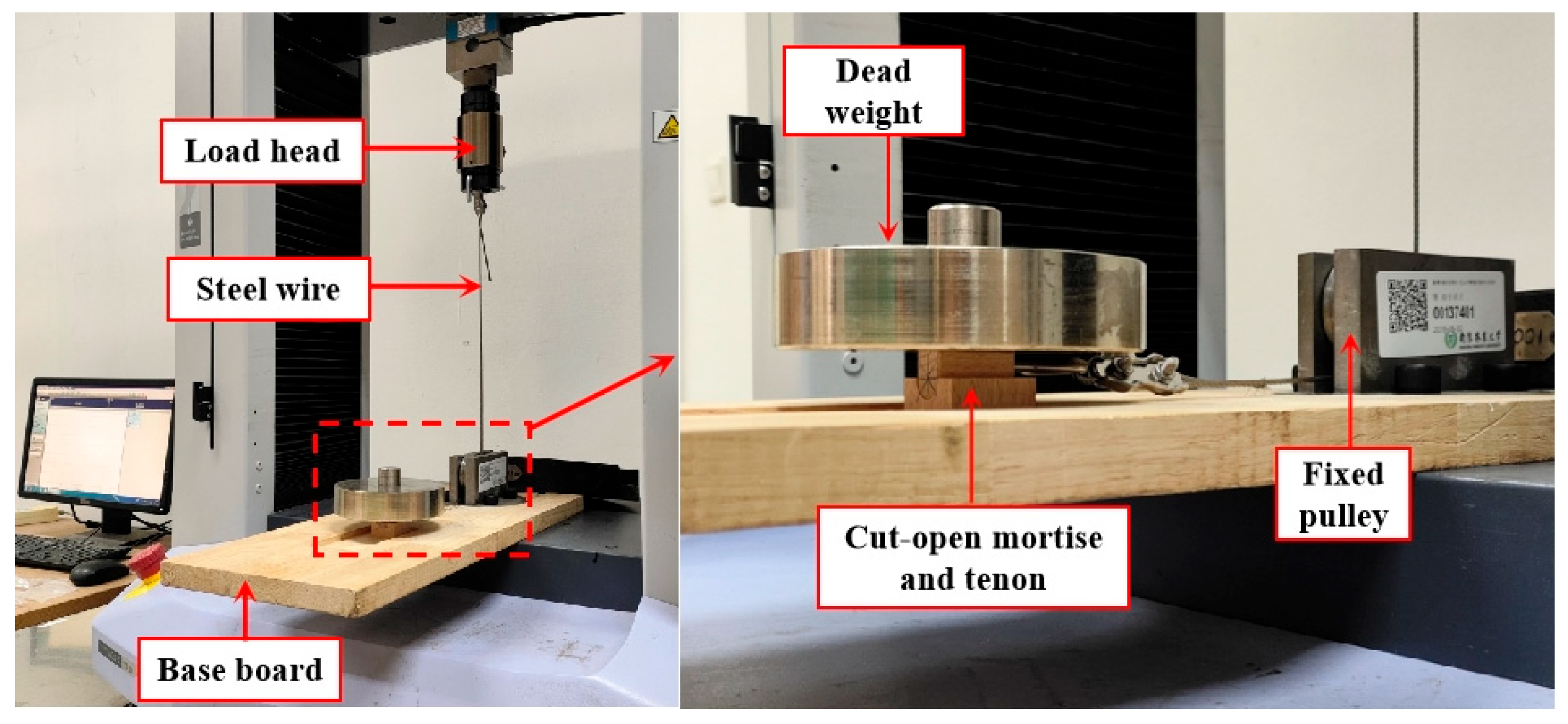

2.4. Testing Methods

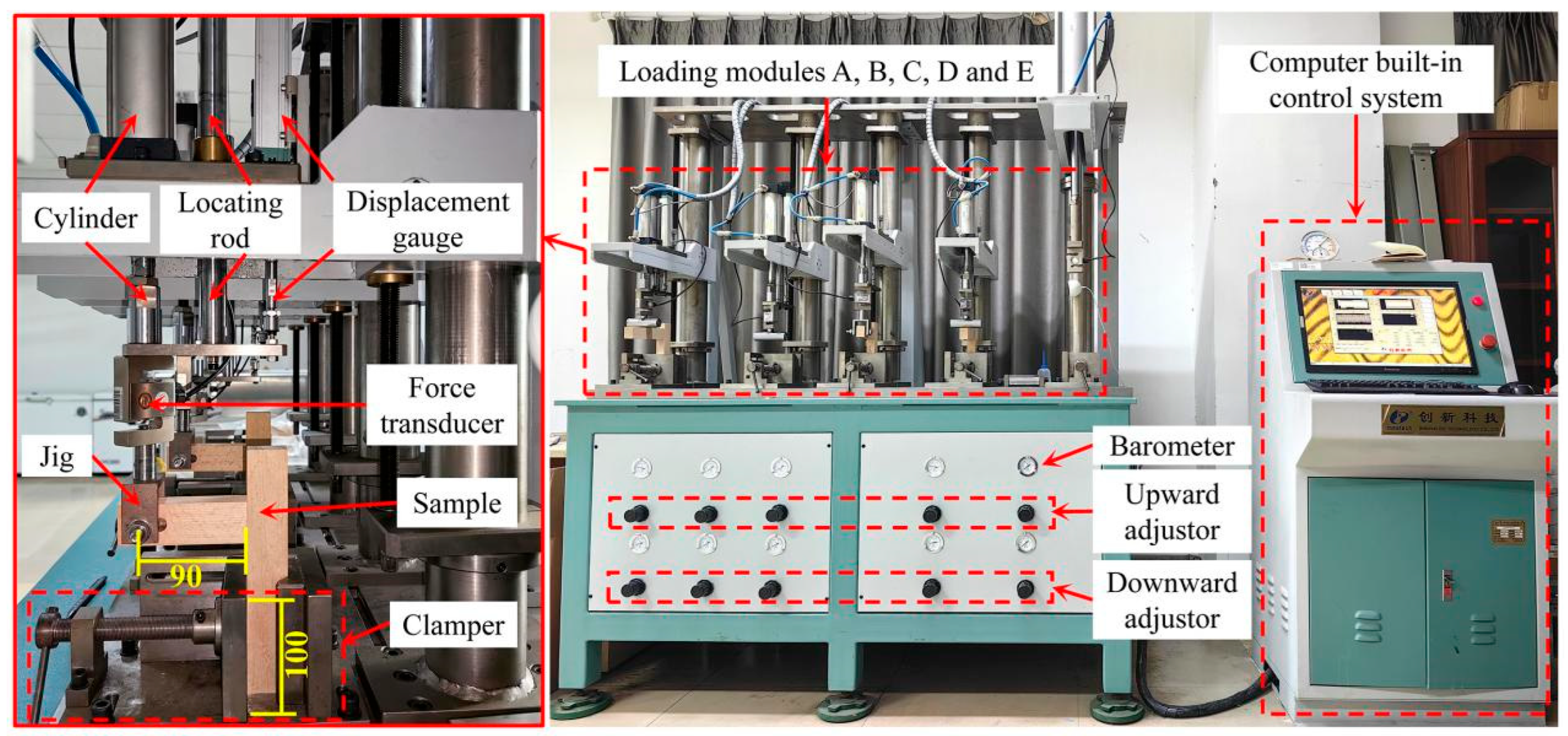

2.4.1. Cyclic Load Test

2.4.2. Roughness Measurement

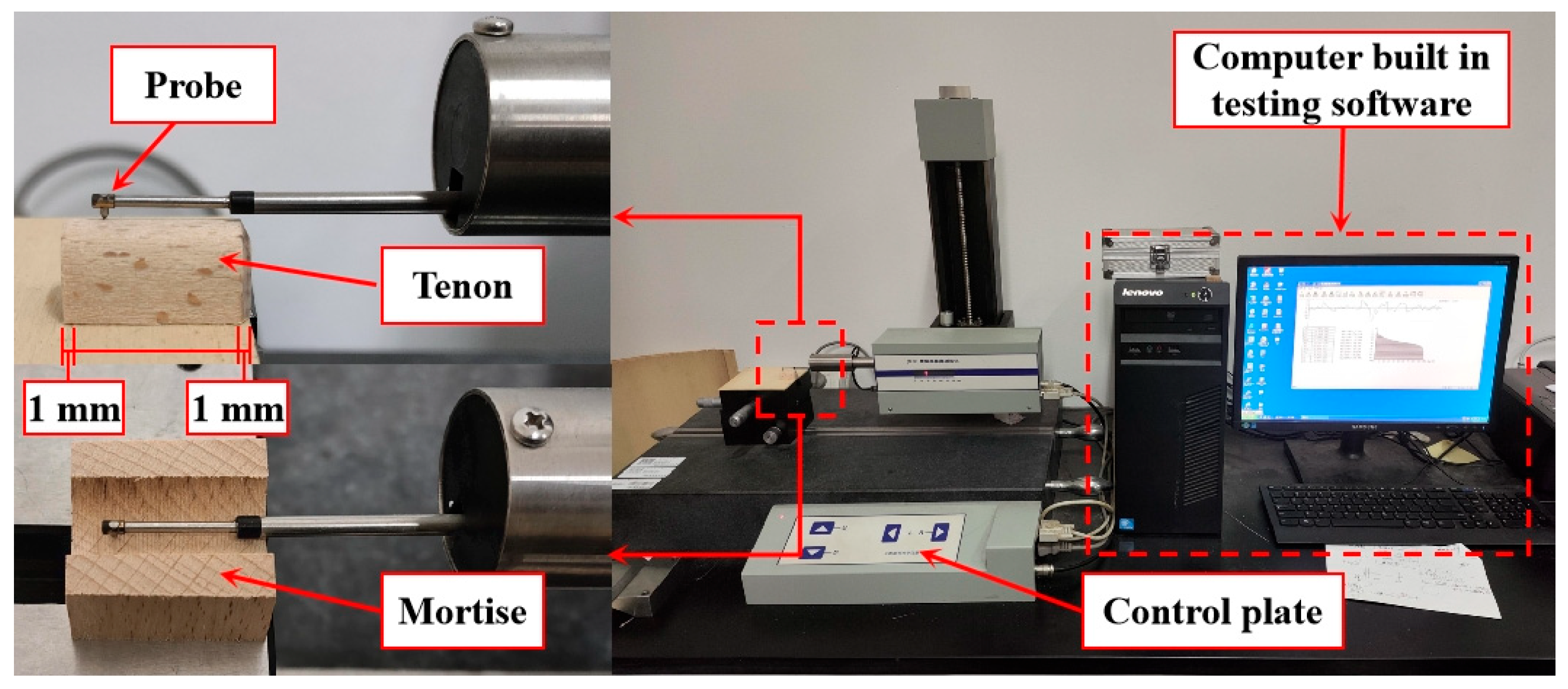

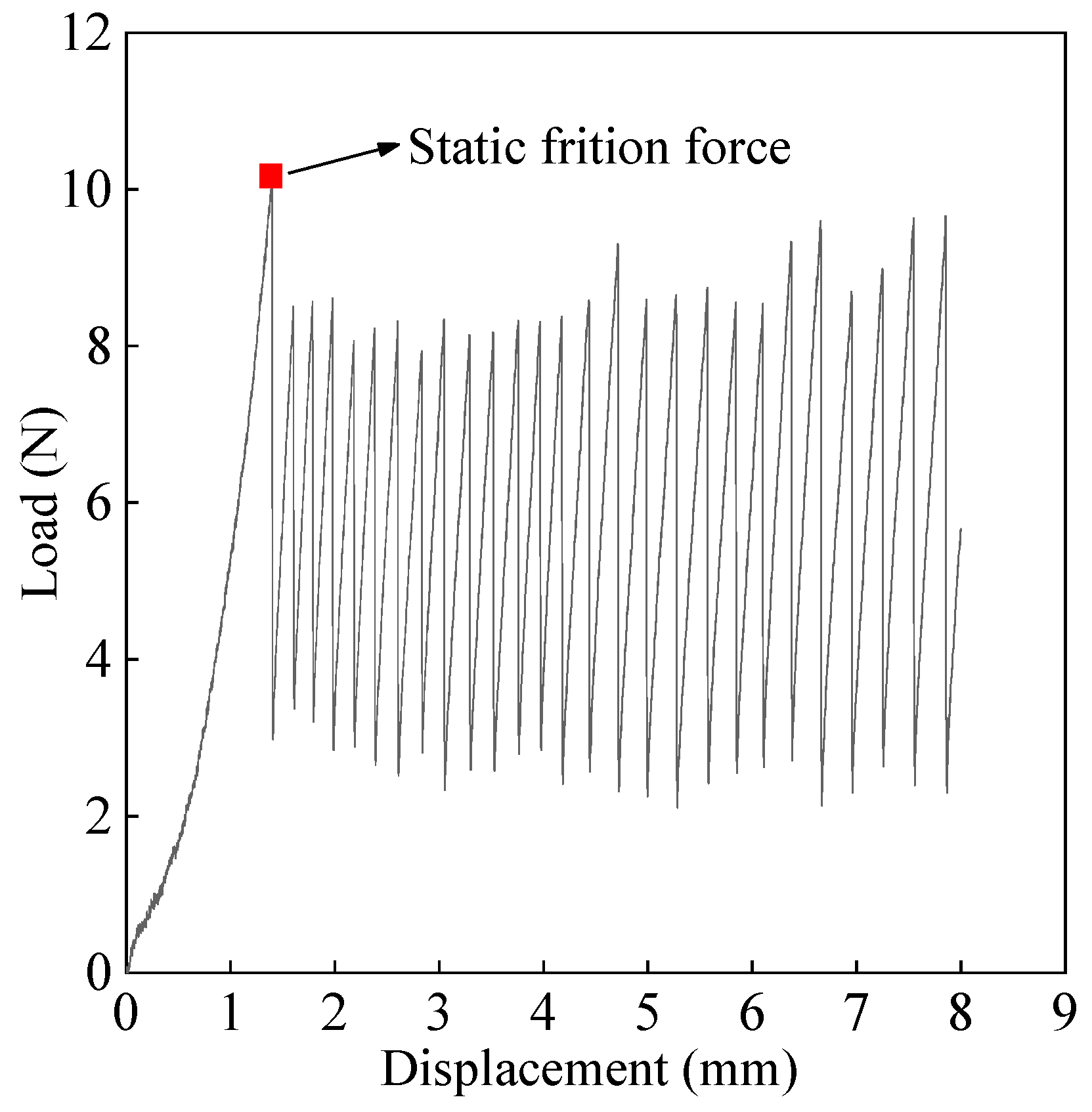

2.4.3. Friction Coefficient Measurement

2.5. Statistical Analysis

3. Results and Discussion

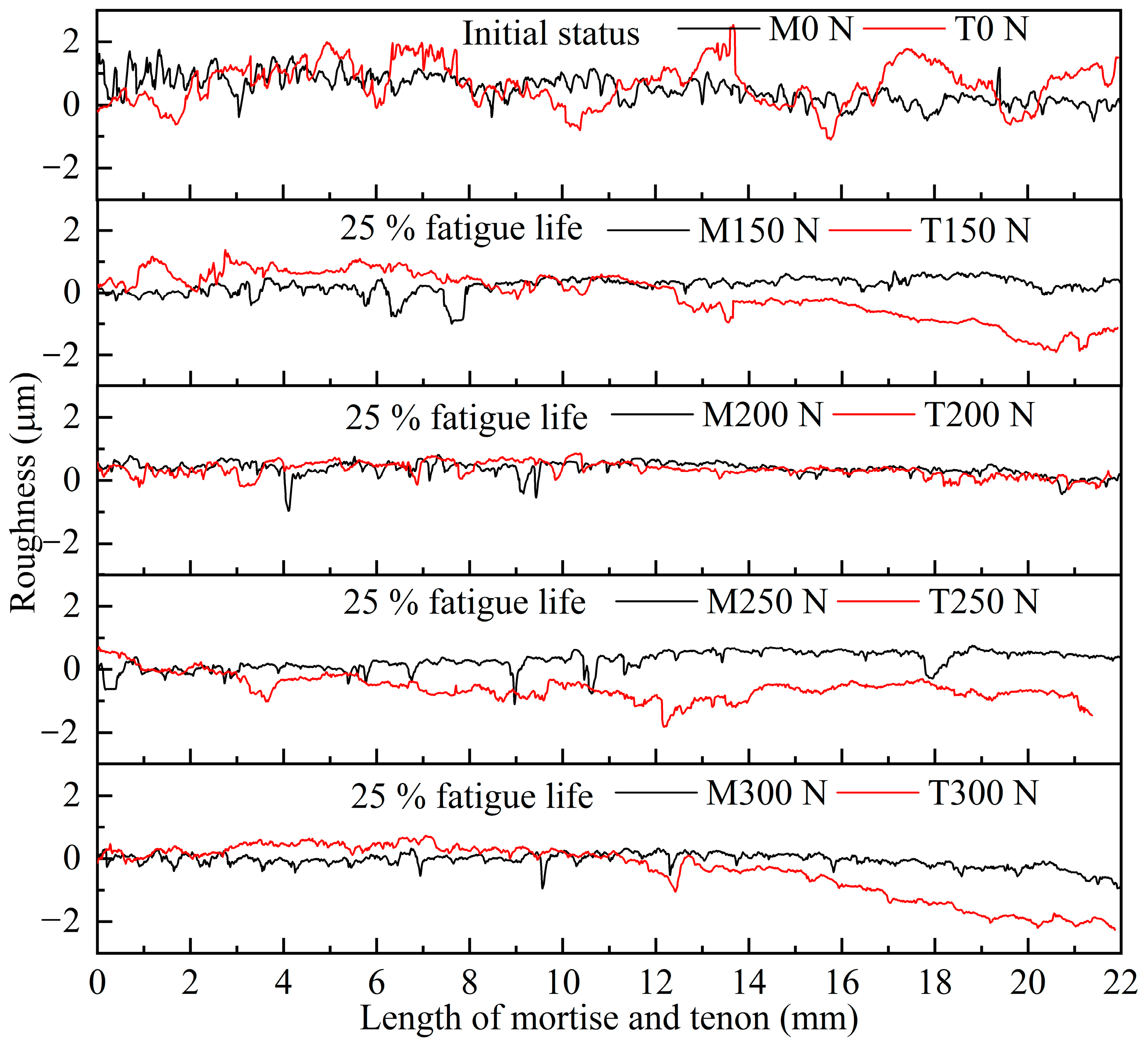

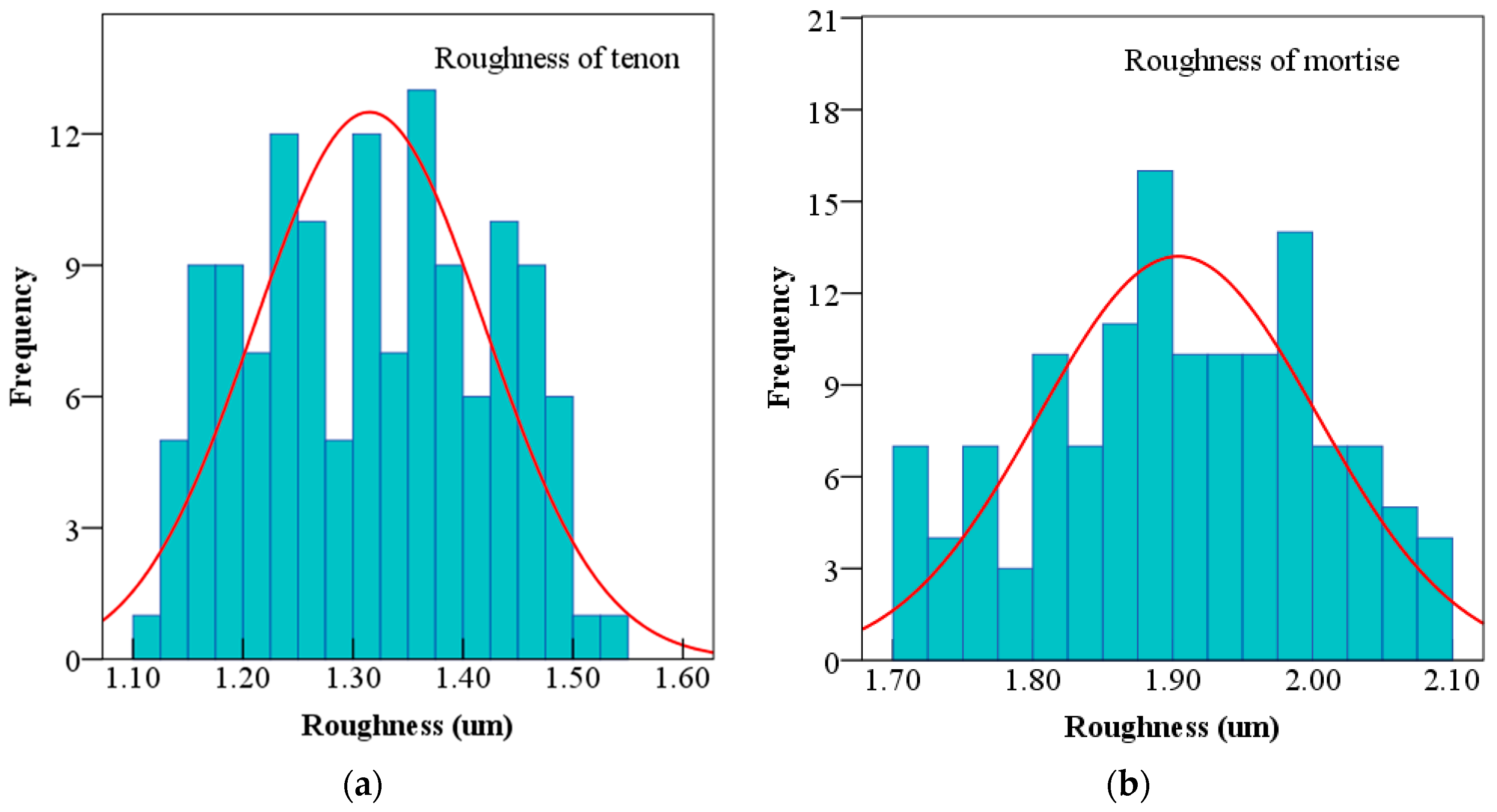

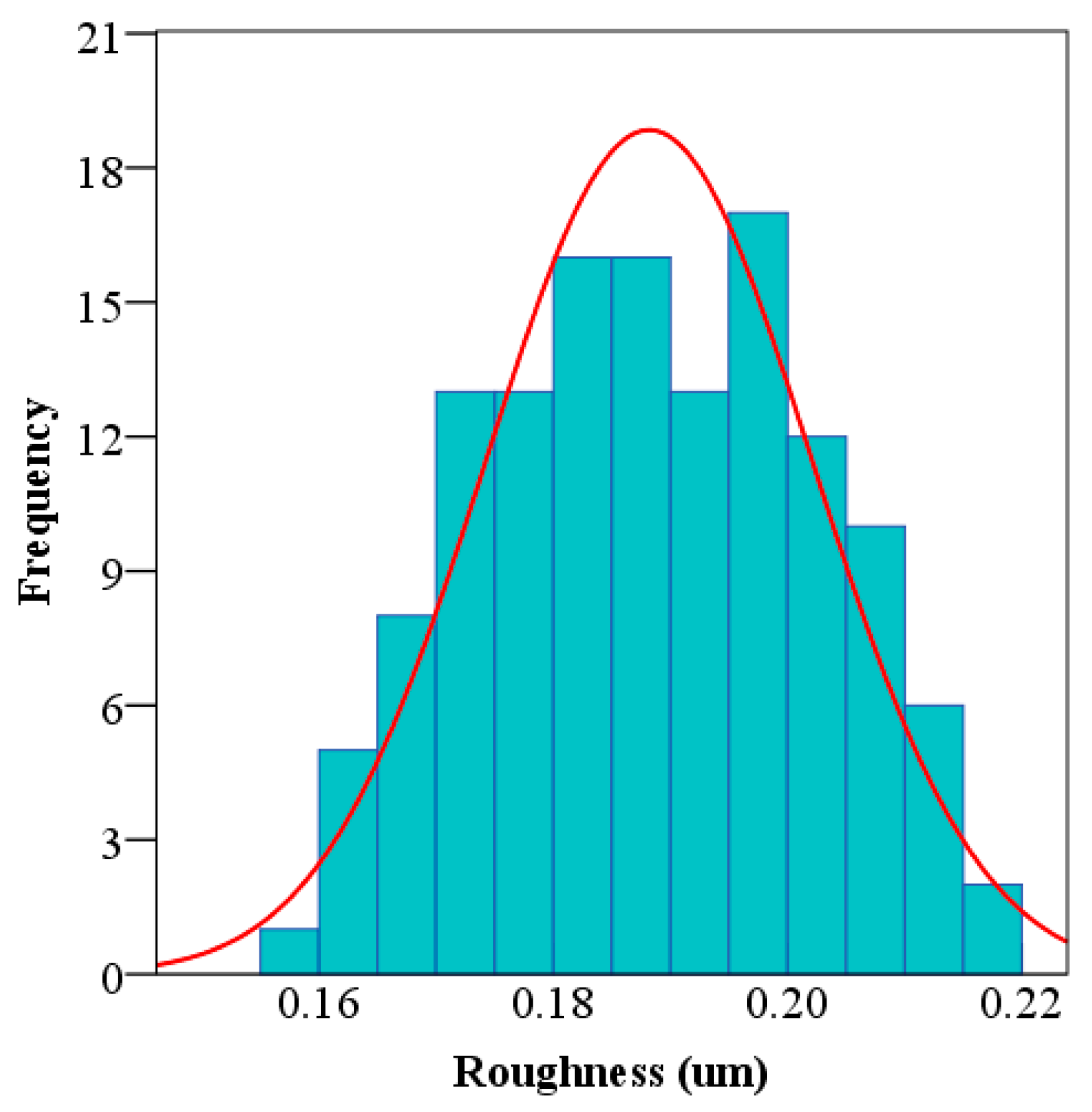

3.1. Effects on the Roughness of Mortise and Tenon

3.2. Effects on the Friction Coefficient Between Tenon and Mortise

3.3. Relationships Between Roughness and Friction Coefficient

4. Limitations and Future Work

5. Conclusions

- (1)

- Both CLA and CLC have significant effects on RM, RT, and the friction coefficient of the round-end M–T joint, but the effect of CLA is much greater than that of CLC.

- (2)

- The RM, RT, and friction coefficient between mortise and tenon decrease non-linearly as the CLA and CLC increase, complying with the law of power function.

- (3)

- The relationships between the friction coefficient and RM and RT can be well fitted by a quadratic model during fatigue evolution progression at each of the four CLAs.

- (4)

- The fatigue evolution progressions of RM, RT, and the friction coefficient between mortise and tenon provide a new insight for understanding the fatigue of the round-end M–T joint, and supply basic data for numerically modeling the fatigue of the round-end M–T joint using FEM.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Yan, Y.; Xu, Z.; Zhu, L.; Lv, J. Innovative design model for the mortise and tenon structure. BioResources 2024, 19, 5413–5434. [Google Scholar] [CrossRef]

- Zhou, C.; Luo, Y.; Kaner, J. Exploring the impact of display types of information about autonomous driving in semi-autonomous vehicles on drivers’ situation awareness and take-over performance under different driving scenarios. PLoS ONE 2025, 20, e0329760. [Google Scholar] [CrossRef] [PubMed]

- Hang, J.; Han, Y.; Yan, X.; Li, J. Effect of shellac–rosin microcapsules on the self-healing properties of waterborne primer on wood surfaces. Coatings 2025, 15, 1003. [Google Scholar] [CrossRef]

- Xu, X.; Xiong, X.; Yue, X.; Zhang, M. A parametric optimized method for three-dimensional corner joints in wooden furniture. Forests 2023, 14, 1063. [Google Scholar] [CrossRef]

- Zhang, W.; Zou, Y.; Yan, X.; Li, J. Influence of two types of microcapsule composites on the performance of thermochromic UV coatings on bleached poplar wood surfaces. Coatings 2025, 15, 1001. [Google Scholar] [CrossRef]

- Likos, E.; Haviarova, E.; Eckelman, C.A.; Erdil, Y.Z.; Özcifci, A. Effect of tenon geometry, grain orientation, and shoulder on bending moment capacity and moment rotation characteristics of mortise and tenon joints. Wood Fiber Sci. 2012, 44, 462–469. [Google Scholar]

- Miao, Y.; Pan, S.; Xu, W. Staple holding strength of furniture frame joints constructed of plywood and solid wood. Forests 2022, 13, 2006. [Google Scholar] [CrossRef]

- Záborský, V.; Boruvka, V.; Kašicková, V.; Ruman, D. Effect of wood species, adhesive type and annual ring directions on the stiffness of rail to leg mortise and tenon furniture joints. BioResources 2017, 12, 7016–7031. [Google Scholar] [CrossRef]

- Chen, B.; Guan, H. A novel method and validation for obtaining the optimal interference fit of round-end mortise-and-tenon joint. Wood Mater. Sci. Eng. 2023, 18, 1619–1629. [Google Scholar] [CrossRef]

- Hu, W.; Yu, R. Study on the strength mechanism of the wooden round-end mortise-and-tenon joint using the digital image correlation method. Holzforschung 2024, 78, 519–530. [Google Scholar] [CrossRef]

- Korkut, I.; Donertas, M.A. The influence of feed rate and cutting speed on the cutting forces, surface roughness and tool–chip contact length during face milling. Mater. Des. 2007, 28, 308–312. [Google Scholar] [CrossRef]

- Jiang, S.; Buck, D.; Tang, Q.; Guan, J.; Wu, Z.; Guo, X.; Zhu, Z.; Wang, X. Cutting force and surface roughness during straight-tooth milling of Walnut wood. Forests 2022, 13, 2126. [Google Scholar] [CrossRef]

- Đukić, I.; Merhar, M.; Jovanović, J. Analysis of theoretical machined surface roughness profile after sawing solid oak wood (Quercus robur L.) along the grain with a circular saw. Wood Mater. Sci. Eng. 2023, 18, 1534–1544. [Google Scholar] [CrossRef]

- Fujiwara, Y.; Fujii, Y.; Okumura, S. Relationship between roughness parameters based on material ratio curve and tactile roughness for sanded surfaces of two hardwoods. J. Wood Sci. 2005, 51, 274–277. [Google Scholar] [CrossRef]

- Kilic, M.; Hiziroglu, S.; Burdurlu, E. Effect of machining on surface roughness of wood. Build. Environ. 2006, 41, 1074–1078. [Google Scholar] [CrossRef]

- Luo, B.; Zhang, J.; Bao, X.; Liu, H.; Li, L. The effect of granularity on surface roughness and contact angle in wood sanding process. Measurement 2022, 165, 108133. [Google Scholar] [CrossRef]

- Adamčík, L.; Dzurenda, L.; Banski, A.; Kminiak, R. Comparison of surface roughness of beech wood after sanding with an eccentric and belt sander. Forests 2023, 15, 45. [Google Scholar] [CrossRef]

- Yu, Y.; Buck, D.; Yang, H.; Du, X.; Song, M.; Wang, J.; Zhu, Z. Cutting power, temperature, and surface roughness, a multiple target assessment of beech during diamond milling. Forests 2023, 14, 1163. [Google Scholar] [CrossRef]

- Fu, W.; Guan, H.; Chen, B. Investigation on the influence of moisture content and wood section on the frictional properties of beech wood surface. Tribol. Trans. 2021, 64, 830–840. [Google Scholar] [CrossRef]

- Karlinasari, L.; Lestari, A.T.; Priadi, T. Evaluation of surface roughness and wettability of heat-treated, fast-growing tropical wood species sengon (Paraserianthes falcataria (L.) I.C.Nielsen), jabon (Anthocephalus cadamba (Roxb.) Miq), and acacia (Acacia mangium Willd.). Int. Wood Prod. J. 2018, 9, 142–148. [Google Scholar] [CrossRef]

- Pelit, H.; Arısüt, U. Roughness, wettability, and morphological properties of impregnated and densified wood materials. BioResources 2023, 18, 429–446. [Google Scholar] [CrossRef]

- Kang, C.W.; Hashitsume, K.; Jang, E.; Kolya, H. Relationship between wood anatomical features and surface roughness characteristics. Wood Research 2023, 68, 455–464. [Google Scholar] [CrossRef]

- Thoma, H.; Peri, L.; Lato, E. Evaluation of wood surface roughness depending on species characteristics. Maderas. Cienc. Y Tecnol. 2015, 17, 285–292. [Google Scholar] [CrossRef]

- Dong, Y.; Yan, X. Preparation of high self-healing diels–alder (DA) synthetic resin and its influence on the surface coating properties of poplar wood and glass. Coatings 2025, 15, 988. [Google Scholar] [CrossRef]

- Wang, Y.; Jia, M.; Qi, Y.; Ji, X.; Sun, S.; Zhao, Z. Preparation and investigation of a novel plywood eco-friendly adhesive composed with lactic acid and polyvinyl alcohol. Wood Mater. Sci. Eng. 2025, 19, 1–13. [Google Scholar] [CrossRef]

- Chang, W.; Han, Y.; Yan, X.; Li, J. Preparation and performance characterization of melamine-formaldehyde-microencapsulated waterborne topcoat–brass powder–waterborne acrylic coating. Coatings 2025, 15, 951. [Google Scholar] [CrossRef]

- Qi, Y.; Wang, L.; Sun, S.; Zhao, Z. A comparison of the mechanical properties, chemical composition, and thermoplastic rheological properties of small-and large-diameter round timber. Wood Mater. Sci. Eng. 2025, 19, 1–9. [Google Scholar] [CrossRef]

- Zhang, N.; Zhu, Y.; Yan, X. Effect of tea tree essential oil@chitosan microcapsules on surface coating properties of pine wood. Coatings 2025, 15, 938. [Google Scholar] [CrossRef]

- Deng, J.; Yan, X. Preparation of tung oil microcapsules coated with chitosan–arabic gum and its effect on the properties of UV coating. Polymers 2025, 17, 1985. [Google Scholar] [CrossRef]

- Liu, Q.; Gao, D.; Xu, W. Effect of paint process on the performance of modified poplar wood antique. Coatings 2021, 11, 1174. [Google Scholar] [CrossRef]

- Chang, W.; Deng, J.; Yan, X. Influence of chitosan–sodium tripolyphosphate-coated tung oil microcapsules on the UV coating performance of cherry wood surface. Coatings 2025, 15, 949. [Google Scholar] [CrossRef]

- Qi, Y.; Sun, Y.; Zhou, Z.; Huang, Y.; Li, J.; Liu, G. Response surface optimization based on freeze-thaw cycle pretreatment of poplar wood dyeing effect. Wood Res. 2023, 68, 293–305. [Google Scholar] [CrossRef]

- Zhong, Z.; Hiziroglu, S.; Chan, C. Measurement of the surface roughness of wood based materials used in furniture manufacture. Measurement 2013, 46, 1428–1487. [Google Scholar] [CrossRef]

- Hu, W.; Guan, H. A finite element model of semi-rigid mortise-and-tenon joint considering glue line and friction coefficient. J. Wood Sci. 2019, 65, 14. [Google Scholar] [CrossRef]

- Fu, W.; Guan, H. Numerical and theoretical analysis of the contact force of oval mortise and tenon joints concerning outdoor wooden furniture structure. Wood Sci. Technol. 2022, 56, 1205–1237. [Google Scholar] [CrossRef]

- Eckelman, C.A. The fatigue strength of two-pin moment-resisting dowel joints. For. Prod. J. 1970, 20, 42–45. [Google Scholar]

- Wu, W.; Xu, W.; Wu, S. Mechanical performance analysis of double-dovetail joint applied to furniture T-shaped components. BioResources 2024, 19, 5862–5879. [Google Scholar] [CrossRef]

- Xu, X.; Zhang, M.; Yue, X.; Xiong, X. Design of furniture mortise-and-tenon joints: A review of mechanical properties and design recommendations. Wood Mater. Sci. Eng. 2025, 19, 1–15. [Google Scholar] [CrossRef]

- Ratnasingam, J.; Perkins, M.; Reid, H. Fatigue: It’s relevance to furniture. HolzalsRoh Werkst. 1997, 55, 297–300. [Google Scholar] [CrossRef]

- Fu, W.; Guan, H.; Li, W.; Sawata, K.; Zhao, Y. Elastoplastic performance of wood under compression load considering cross-grain orientation and moisture content. Eur. J. Wood Wood Prod. 2023, 81, 111–124. [Google Scholar] [CrossRef]

- Haviarova, E.; Eckelman, C.A.; Erdil, Y. Design and testing of environmentally friendly wood school chairs for developing countries. For. Prod. J. 2001, 51, 58–64. [Google Scholar]

- Eckelman, C.; Erdil, Y.; Haviarova, E. School chairs for developing countries: Designing for strength and durability, simplicity, and ease of construction. For. Prod. J. 2003, 53, 63–70. [Google Scholar]

- Eckelman, C.; Haviarova, E. Performance tests of school chairs constructed with round mortise and tenon joints. For. Prod. J. 2006, 56, 51–57. [Google Scholar]

- Likos, E.; Haviarova, E.; Eckelman, C.A.; Erdil, Y.; Ozcifci, A. Static versus cyclic load capacity of side chairs constructed with mortise and tenon joints. Wood Fiber Sci. 2013, 45, 223–227. [Google Scholar]

- Uysal, M.; Haviarova, E.; Eckelman, C.A. A comparison of the cyclic durability, ease of disassembly, repair, and reuse of parts of wooden chair frames. Mater. Des. 2015, 87, 75–81. [Google Scholar] [CrossRef]

- Haviarova, E.; Eckelman, C.A.; Erdil, Y. Design and testing of wood school desk frames suitable for production by low technology methods from waste wood residues. For. Prod. J. 2001, 51, 79–88. [Google Scholar]

- Haviarova, E.; Eckelman, C.A.; Joscak, P. Analysis, design, and performance testing of a gate-leg table. Wood Fiber Sci. 2008, 40, 279–287. [Google Scholar]

- Erdil, Y.; Eckelman, C.A.; Haviarova, E. Design and construction of school work tables for developing countries. For. Prod. J. 2009, 59, 50–56. [Google Scholar]

- Ratnasingam, J.; Ioras, F. Effect of adhesive type and glue-line thickness on the fatigue strength of mortise and tenon furniture joints. Eur. J. Wood Wood Prod. 2013, 71, 819–821. [Google Scholar] [CrossRef]

- Ratnasingam, J.; Ioras, F. Static and fatigue strength of oil palm wood used in furniture. J. Appl. Sci. 2010, 10, 986–990. [Google Scholar] [CrossRef][Green Version]

- Ratnasingam, J.; Ioras, F. Bending and fatigue strength of mortise and tenon furniture joints made from oil palm lumber. Eur. J. Wood Wood Prod. 2011, 69, 677–679. [Google Scholar] [CrossRef]

- Hu, W.; Luo, M.; Yu, R.; Zhao, Y. Effects of the selected factors on cyclic load performance of T-shaped mortise-and-tenon furniture joints. Wood Mater. Sci. Eng. 2024, 20, 1092–1101. [Google Scholar] [CrossRef]

- Džinčić, I.; Živanić, D. The influence of fit on the distribution of glue in oval tenon/mortise joint. Wood Res. 2014, 59, 297–302. [Google Scholar]

- Hu, W.; Guan, H.; Zhang, J. Finite element analysis of tensile load resistance of mortise-and-tenon joints considering tenon fit effects. Wood Fiber Sci. 2018, 50, 121–131. [Google Scholar] [CrossRef]

| CLC | CLA (N) | |||

|---|---|---|---|---|

| 150 | 200 | 250 | 300 | |

| 25% | 3 | 3 | 3 | 3 |

| 50% | 3 | 3 | 3 | 3 |

| 75% | 3 | 3 | 3 | 3 |

| 100% | 3 | 3 | 3 | 3 |

| Sources | RT | RM | ||

|---|---|---|---|---|

| F-Value | p-Value | F-Value | p-Value | |

| CLA | 679 | <0.001 * | 285 | <0.001 * |

| CLC | 202 | <0.001 * | 226 | <0.001 * |

| CLA × CLC | 3 | 0.003 | 1.5 | 0.16 |

| Component | CLA (N) | Roughness, Ra (μm) | |||

|---|---|---|---|---|---|

| CLC (%) | |||||

| 25% | 50% | 75% | 100% | ||

| Tenon | 150 | 1.479 (1.8) A,a | 1.442 (1.4) B,a | 1.403 (1.3) C,a | 1.368 (1.0) D,a |

| 200 | 1.459 (1.5) A,b | 1.366 (1.7) B,b | 1.324 (1.5) C,b | 1.295 (1.8) D,b | |

| 250 | 1.350 (2.2) A,c | 1.284 (2.3) B,c | 1.233 (1.8) C,c | 1.212 (2.6) C,c | |

| 300 | 1.247 (1.5) A,d | 1.195 (1.3) B,d | 1.161 (1.1) C,d | 1.141 (2.4) C,d | |

| Mortise | 150 | 2.055 (2.2) A,a | 2.005 (2.5) B,a | 1.952 (2.6) C,a | 1.917 (2.1) D,a |

| 200 | 2.030 (2.7) A,b | 1.969 (2.4) B,b | 1.899 (2.1) C,b | 1.858 (2.7) D,b | |

| 250 | 1.985 (1.9) A,c | 1.894 (2.2) B,c | 1.835 (2.3) C,c | 1.789 (2.9) D,c | |

| 300 | 1.886 (2.4) A,d | 1.815 (2.4) B,d | 1.739 (2.6) C,d | 1.724 (2.1) D,d | |

| Sources | Friction Coefficient | |

|---|---|---|

| F-Value | p-Value | |

| CLA | 48 | <0.001 * |

| CLC | 54 | <0.001 * |

| CLA × CLC | 1.3 | 0.24 |

| CLA (N) | CLC in Percentage of Fatigue Life (%) | ||||

|---|---|---|---|---|---|

| 0 | 25 | 50 | 75 | 100 | |

| 150 | 0.365 (8.4) A | 0.205 (3.7) B,a | 0.202 (3.5) B,a | 0.195 (4.1) C,a | 0.192 (2.7) C,a |

| 200 | 0.365 (8.4) A | 0.204 (4.9) B,a | 0.193 (5.1) C,b | 0.187 (3.7) C,b | 0.179 (5.1) D,b |

| 250 | 0.365 (8.4) A | 0.200 (5.0) B,a | 0.184 (5.1) C,c | 0.176 (2.8) D,c | 0.172 (3.4) D,bc |

| 300 | 0.365 (8.4) A | 0.191 (3.2) B,b | 0.181 (3.1) C,c | 0.170 (4.0) D,d | 0.165 (3.4) D,c |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shu, F.; Hu, W.; Zhang, T. Effects of Cyclic Load Amplitude and Count on the Roughness and Friction Coefficient of the Round-End Wood Mortise–Tenon Joint. Forests 2025, 16, 1635. https://doi.org/10.3390/f16111635

Shu F, Hu W, Zhang T. Effects of Cyclic Load Amplitude and Count on the Roughness and Friction Coefficient of the Round-End Wood Mortise–Tenon Joint. Forests. 2025; 16(11):1635. https://doi.org/10.3390/f16111635

Chicago/Turabian StyleShu, Fangjie, Wengang Hu, and Tianxing Zhang. 2025. "Effects of Cyclic Load Amplitude and Count on the Roughness and Friction Coefficient of the Round-End Wood Mortise–Tenon Joint" Forests 16, no. 11: 1635. https://doi.org/10.3390/f16111635

APA StyleShu, F., Hu, W., & Zhang, T. (2025). Effects of Cyclic Load Amplitude and Count on the Roughness and Friction Coefficient of the Round-End Wood Mortise–Tenon Joint. Forests, 16(11), 1635. https://doi.org/10.3390/f16111635