Abstract

The increasing demand for sustainable raw materials in engineered wood production has prompted the evaluation of alternative raw materials. In this context, indigenous black poplar (Populus nigra) was analyzed as a potential alternative, by testing its wettability, characterized by contact angle, determined by the sessile drop method, to predict its adhesion when used as strands for OSB and LSL production. Surface tension was tested on strands with a wide range of surface roughnesses. The results show minor but statistically significant difference in favor of black poplar, which has somewhat lower contact angle values (62.01°) than hybrid poplar (64.71°), based on 300 measurements each. The absorption of the liquid into the strands, evaluated on a smaller sample, follows a logarithmic relation with time. These results also show a slightly faster decrease in contact angle in case of indigenous poplar, compared to hybrid poplar. The results indicate that the adhesion of indigenous poplar strands does not present extra challenges, compared to the currently more frequent hybrid poplar strands.

1. Introduction

Wood is a well-established material in the construction of traditional family houses, but based on the European Commission’s sustainable built environment policy [1] it is also a potential candidate as a major construction material of the future. It can be used in many forms, from solid wood CLT prefab wall elements, through heat and sound isolation panels and glulam load bearing arches and beams. Due to climate change, the availability of wood species is changing, and alternatives are needed for the traditional coniferous wood species, in the construction sector also.

This research targets the suitability of an indigenous Hungarian wood species, black poplar (Populus nigra) for Laminated Strand Lumber (LSL) production, a strand-based engineered wood product (EWP). EWPs, including LSL, are made of thin veneer sheets or strands with adhesives. Bondability is a crucial aspect of LSL production, as relatively small (5–15 cm long) strands are unified by an adhesive to form a large sized load-bearing product. In the meantime, it is complicated to test the adhesive strength of the strands, as it is an expectation that the bond should be stronger than the strength of the bonded parts, furthermore a standard procedure is also missing. In such cases a solution is offered by evaluating the wettability of the surfaces (by measuring the contact angle), since, if a liquid wets a surface well, adhesion is expected to be strong.

Contact angle measurements, as described by [2] are commonly used to assess the wettability of wood surfaces and provide valuable insights into adhesive bonding behavior. The surface tension of solid wood surfaces affects the wettability and thus the adhesion of various adhesives and coating materials. Measuring the contact angle of wood is the way of calculating surface tension based on the Young-Dupré equation. Several publications report contact angle measurements with different test liquids under various conditions. The results can be compared only if the test conditions are similar.

Wood, a complex and anisotropic material, exhibits unique wetting behavior due to its inherent characteristics: hygroscopicity, porosity, surface roughness, and chemical heterogeneity. Unlike homogeneous surfaces (e.g., metals, polymers), liquids and water interacting with wood demonstrate a complex response. Droplets do not only spread across the surface but also infiltrate into the wood’s structure, leading to both surface and subsurface wetting phenomena [3]. The dynamic nature of this interaction is evident in the time-dependent evolution of droplet shape and contact angle. Researchers, including [4,5,6], have extensively investigated these temporal changes to understand and model the equilibrium state where contact angle measurements are typically performed. While the contact angle varies with measurement time, the surface tension remains a unique and constant characteristic of a particular surface.

Numerous factors can influence wettability and surface tension beyond just the contact angle measurement. On a macroscale, wood’s anatomical structure exhibits a distinct cylindrical pattern characterized by alternating bands of earlywood and latewood. This inherent structural heterogeneity significantly influences its surface properties. Numerous studies, including [6,7,8], have extensively investigated the impact of this anatomical variability on wood surface wettability and surface tension.

Earlier research consistently showed that increased surface roughness accelerates the spreading of liquids on solid surfaces. Milling and sanding of beech wood were shown to significantly affect surface wettability and surface free energy. Sanding produced surfaces with more favorable thermodynamic characteristics for adhesion compared to milling [9]. Moreover, ref. [10] demonstrated that wood exhibits pronounced time-dependent contact angle reduction due to liquid penetration and surface roughness, highlighting the limitations of static angle measurements for porous substrates. Adhesives spread on wood with distinct dynamic contact-angle behavior [6], underscoring the role of surface energy and porosity in adhesive–wood interactions. Absorption, swelling, and surface heterogeneity were identified [11] as key factors complicating reliable contact-angle measurements on wood and related materials. There is also an approach proposed by [5] to determine an equilibrium contact angle on wood, emphasizing that liquid sorption and spreading must both be considered when characterizing wettability. It was also reported [12] that the polarity of test liquids strongly influences wetting behavior on wood surfaces, with polar liquids generally exhibiting faster spreading and lower contact angles.

A comprehensive understanding of wood surface characteristics, including its roughness and material properties, provides valuable technical insights for addressing critical issues such as adhesive bonding, impregnation processes, joint strength, blade sharpness optimization, and waste minimization [13,14]. Other authors investigated the effect of planing, sanding, and other common mechanical surface treatments on the wetting process of wood [15]. Their experiments showed that these treatments, by modifying the roughness and microstructure of the wood surface, produced clear differences in wettability and thus in the way water interacted with the material.

It is well-established that earlywood, characterized by larger vessel elements and a thinner cell wall structure, possesses a rougher surface texture compared to latewood. This inherent surface roughness of earlywood directly influences its wetting behavior. Numerous studies, including those by [8,16], have consistently demonstrated that earlywood exhibits lower contact angles compared to latewood. In [16] researchers specifically investigated contact angles on tangential surfaces of Douglas-fir wood, and unequivocally demonstrated the significantly higher wettability of earlywood compared to latewood. However, the specific role of chemical composition, particularly the distribution of extractives, in influencing surface tension and wetting behavior remain largely unclarified.

Heartwood and sapwood exhibit different wettability characteristics; heartwood formation leads to pit closure and a high concentration of stored extractives, reducing the wood surface’s wettability [17]. Furthermore, special features like red heart influence the surface free energy of wood, compared to the properties of unaffected xylem. When comparing the wettability and surface free energy among red heart, mature wood, and sapwood, red heart showed the lowest wettability and surface free energy, while sapwood exhibited the most favorable properties for adhesion and coating [18].

Ref. [19] investigated the influence of moisture content (MC) on the wettability of sanded birch wood surfaces. They found a significant increase in contact angle and a decrease in surface tension with increasing MC.

The macroscopic structure of softwoods like pine, and hardwoods like poplar, differs significantly, raising questions about their wettability. On a submicroscopic scale, the cell wall composition of hardwood and softwood varies in terms of cellulose, hemicelluloses, and lignin content [16,20,21]. pMDI tends to wet softwood more effectively than hardwood, due to the former’s higher lignin content [22]. These differences may pose significant challenges when producing glued structural materials and wood based composites.

Poplar, particularly hybrid varieties, exhibit high productivity in short rotation plantations, yielding up to 24 tons of oven-dry biomass per hectare per year [23]. While possessing lower strength properties compared to traditional softwoods, poplar has demonstrated potential as a suitable feedstock for strand-based composites like OSB and LSL. Studies by [24,25,26] have shown that reduced wood density and strength do not necessarily translate to inferior composite board quality.

Ref. [27] conducted a study on the wettability of pine and hybrid poplar strands for OSB production using contact angle measurements. They compared the adhesive spreading of melamine urea formaldehyde (MUF) and polymeric methylene diphenyl diisocyanate (pMDI) resins. Results showed that pMDI exhibited lower wettability on poplar compared to pine, indicating potentially better adhesion on pine. In contrast, both wood species demonstrated relatively poor wettability with MUF, suggesting potential challenges in achieving strong bonds with this adhesive system. It can be assumed that considerable research has focused on determining the absolute contact angle values typical of different wood species, whereas the present study aims to use contact angle measurements to compare the properties of similarly prepared samples from two different species.

Ref. [28] reported promising results for MDI-bonded OSB utilizing poplar from short rotation plantations, including species such as Populus alba, Populus balsamifera, and Populus tremula. Despite the growing interest in poplar as an OSB raw material, information regarding its wettability with various resin systems, particularly in comparison to traditional softwoods like pine or spruce, remains limited.

The purpose of this study was to analyze the potential of indigenous poplar as an alternative by testing its wettability, characterized by contact angle, to predict its adhesion behavior, with particular respect to strands used for OSB and LSL production. There is well-developed literature available for the hybrid poplars, but research data on indigenous poplars like black poplar (Populus nigra) is limited. The main question is whether indigenous poplar strands can be expected to bond with the same results as hybrid poplar strands. The research aims to investigate the surface tension (contact angle), as well as rate of spreading/absorption of water into black poplar, compared to hybrid poplars.

2. Materials and Methods

The contact angle measurements were performed by the sessile drop method, using a PG-X goniometer connected to a PC (Figure 1). The goniometer registers the data of the measured contact angle with a frequency of 10/s, until the drop spreads and is absorbed by the sample. The goniometer automatically determines the contact angle and records the data as a time series, starting from the value registered at the drop touching the surface, until the contact angle becomes zero, when the drop is absorbed by the wood surface. This results in roughly 100–150 contact angle data points for one single drop release. Table 1 shows the technical specifications of the instrument.

Figure 1.

The PG-X goniometer used for the measurements.

Table 1.

Technical specifications of the PG-X goniometer.

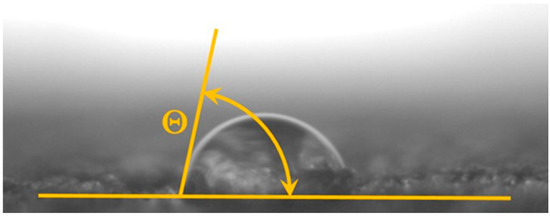

The shape of the contact angle is determined by the adhesion and cohesion forces, which result in a distorted sphere shape of the test liquid drop. The contact angle is defined (geometrically) as the angle formed by a liquid drop at the three-phase boundary where liquid, gas, and solid intersect, as represented in Figure 2. When the contact angle θ (theta) is under 90°, t the surface is considered wettable (hydrophilic). If 90° ≤ θ < 180° the surface is poorly wettable (hydrophobic). If θ tends to zero, the the surface is completely wettable. If θ tends to 180° there is no wetting, the internal cohesion forces of the liquid are stronger than the attractive forces, and the surface in not wettable.

Figure 2.

Image of a contact angle θ with a distilled water drop.

When bonding wood, the shape of an adhesive drop or any interlocutory test liquid drop is expected to spread on the surface. When the drop spreads over the flat surface, the contact angle value decreases, which implies that the contact angle is inversely proportional to the wettability.

Our study involved measuring the contact angle on 300 hybrid poplar and 300 indigenous poplar strands (Figure 3). Strands used in the experiment were manufactured in the Vásárosnamény plant of the SWISS KRONO Kft., Hungary. The company separated shipments of logs into indigenous and hybrid categories based on appearance, and produced strands using a traditional ring flaker. Logs originated from various growth sites in Hungary, Slovakia and Romania with various site conditions, and consequent variation of size, growth and material properties. DNA analysis, performed on green strands at the Forest Research Institute in Sárvár, Hungary showed that the hybrid strands were hybrids of Populus nigra and Populus deltoides (i.e., they are some kind of Populus × euramericana hybrid), while the indigenous poplar strands were evidently unhybridized Populus nigra.

Figure 3.

Indigenous and Hybrid poplar strands (from left to right).

The measurements involved 300 strands chosen randomly for both raw materials, with a target thickness of 1 mm, and lengths between 40 mm to 190 mm. Surface roughness of the strands varied from smooth (similar to ones planed with a sharp planer) to rough with raised fibres. Surface roughness was reported to be a strong influencer of the contact angle [26], our test was intended to cover the whole range of roughness of industry-produced strands, therefore surface roughness was not altered. To overcome the influence of roughness, we choose a large sample size of 300 tests each during experiment planning, to increase the reliability of the evaluation.

Prior to testing, strands were conditioned to ~12% moisture content in a climate chamber set to 22 °C and 65% R.H., which resulted in average moisture content values of 10.65% and 10.87% for indigenous and hybrid poplar, respectively. Preliminary tests were conducted to find the appropriate drop size, as it has to be adapted to the roughness and to the permeability of the tested surface. Notably, droplet rebound may influance contact angle measurements after impact on a solid surface [29]. According to [30] the time elapsed between droplet impingement (impact) and the partial rebound event scales with the capillary time of the liquid. The “capillary time” is characteristic of the liquid’s surface tension and density. After several preliminary tests the authors gained the experience, that considering the thickness of the strands and the penetration characteristics of the poplar species, the drop needs to be big enough to persist on the surface until the bouncing effect of the drop deposited by the goniometer attenuates and the tangent to the contact angle can be adjusted. Smaller drop volumes of 1 through 4 μL were absorbed too quickly. The test liquid used for measurements was distilled water with a drop volume of 5 µL, dropped from a height of 2 mm. Specimens were placed on a non-permeable surface, in case strands are completely soaking through onto the test surface. Such phenomenon may influence the results, but since this affects both types of materials equally, it is appropriate for comparative testing.

In addition to the single contact angle value, the bouncing behavior of the drop was also evaluated on a subset of 30 strands, randomly chosen from the 300 strands, for both materials. The goal was to evaluate the rate of spreading/absorption into the material. For these strands, the full time series was evaluated.

3. Results

For a short period after dropping, the drop is not stabilized, but changes shape rapidly (“bouncing”). During this bouncing period the drop is not suitable to reflect the real contact angle. The extent and duration of bouncing is supposed to be influenced by many factors; first of all by the size of the drop, by the rigidity/elasticity of the surface, the microstructure of the surface, the permeability of the surface etc.

In order to decide on when to measure the correct contact angle value, the bouncing effect was investigated by evaluating 30 of the 300 contact angle datasets for both indigenous and hybrid poplar specimens. It was deduced that the bouncing behavior of the same volume drop was not consistent, as short bouncing and long bouncing cases were equally identified. Earlier tests showed the extent and variability of the bouncing effect to be smaller on massive solid wood samples, which led to the 1 s value to be picked for analysis on such specimens. A possible reason for the wide variation in bouncing time and amplitude in black and hybrid poplar strands may be the variability of surface roughness. Another reason may be that the strands are thin and, not being fixed to a support, they may also have an elastic reaction to the impact caused by the drop. Taking into account all of these considerations, the list of contact angle values was investigated individually for all measurements, and the first contact angle data after the attenuation of the bouncing was selected for analysis. The phenomenon of bouncing observed for solid wood and thin materials should be the focus of further study.

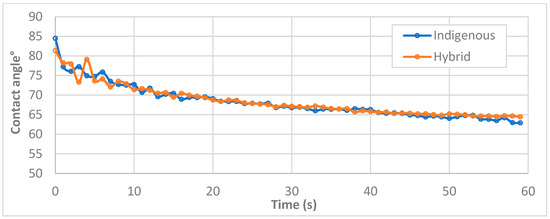

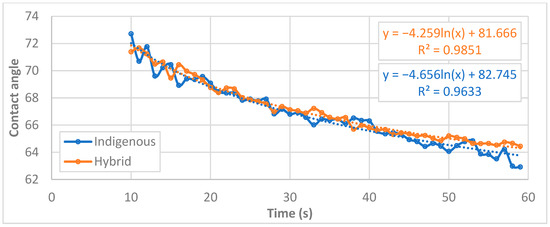

Another important consideration is the rate of water spreading and absorption into the strands of the two wood species. Unfortunately, there is a lot of variability in the results of individual tests. To compare the absorption of the strands of the two wood species, the time series from 30 random strands, out of the total of 300 strands, were averaged, to see how fast the contact angle changes in time after the release of the drop.

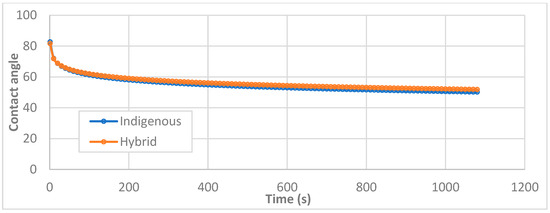

Figure 4 shows the attenuation of the distilled water test liquid drop for both wood species, as average of 30 measurements, whilst Figure 5 displays the same contact angle data series after the data of the first 10 second’s bouncing was removed. This graph also displays the logarithmic decay trendline fit on the data sets, using the least-squares method, for both species. While the individual data sets vary considerably, the trendline fits the average data very closely, with coefficients of determination above 0.96 (significant with p < 0.001). Figure 6 shows an extrapolation of the results for these two sample series. This graph shows that, on a longer time scale, there is very little difference in the behavior of black poplar and hybrid poplar.

Figure 4.

Contact angle attenuation as average of 30 measurement on both wood species.

Figure 5.

Contact angle attenuation (test liquid spreading) after eliminating the 10 s bouncing period.

Figure 6.

The logarithmic function of spreading of distilled water test liquid on indigenous and hybrid poplar strands, extrapolated.

Based on the above results it appears that the indigenous poplar strands absorbed distilled water slightly faster than the hybrid ones, but the difference is not considerable. The spreading of liquids can be expected to follow a logarithmic function on these species. However, the absorption of a liquid into the wood surface is influenced by the molecular weight of the liquid also. Distilled water with its low molecular weight is suitable to describe the trend of spreading, and to show the possible differences between the species.

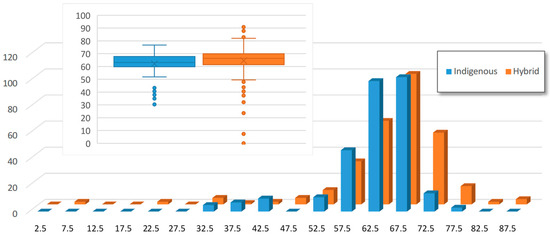

Table 2 provides the basic statistical data of the 300 measured contact angle values. The distribution appears to follow the normal distribution for both wood species (Figure 7). In case of indigenous poplar, all 300 values were lower than 90°, leading to the conclusion that good surface wetting can be expected.

Table 2.

Statistical parmeters of the contact angle measured on the two poplar species (N = 300).

Figure 7.

Distribution of contact angle data measured on indigenous and hybrid poplar strands.

Statistical significance testing was performed to compare the wettability of the two types of materials. Based on the results of a non-paired t-test, there is a significant difference between both the average and variance of contact angle values of indigenous and hybrid poplar strands, (p < 0.01 for both parmeters). Since there was a high number of samples, the general trend can be also reported, that the hybrid poplar samples had somewhat higher contact angle values compared to indigenous poplar specimens.

In terms of practical application, even though the difference between the two materials is significant, in absolute terms it is less than 3°, which makes little practical difference. The variation of the results is significantly lower for indigenous poplar, which means that its bondability is much more consistent than that of hybrid poplar, where a few strands even had contact angles above 90° (poorly wettable.) Considering its quick spreading, which is associated with the absorption of the liquid into the substrate, when adhesive bonding is performed, special attention needs to be accorded to the amount of adhesive used for bonding, as there might be too much adhesive absorption into the wood, leaving the glueline free of the necessary amount of adhesive. Increased amounts of adhesive might be necessary compared to more traditionally used species.

Historically, softwood species have been the primary raw material for strand-based composites. An earlier study [14] used distilled water to measure the contact angle values for spruce, a frequently used species for OSB production. Values ranging from 85.33° to 67.63° were reported on a scale of roughness from the roughest (sanded with a grit size of 60) to the finest (sanded/polished with a grit size of 600). For spruce, the average contact angle value over 13 different consecutive roughnesses ranging between these two extremes was 75.37°, with most values being above 70°, with only one exception: 67.63° for surfaces sanded with a grit size of 180. Many further studies reported on the relationship between machining methods/roughnesses and wettability (e.g., [9]) Considering that the roughness of the strands in this experiment also had a high variability from the roughest to the smoothest, the two results are suitable for comparison. It can be concluded, that the average contact angle values of 62.08° and 64.71° measured on indigenous and hybrid poplar, respectively, are significantly lower than the contact angle values of earlier tested spruce surfaces. This leads to the conclusion that black poplar has a better wettability than spruce, as wettability is inversely proportional to the contact angle.

Ref. [31] reported initial contact angles ~77°, decreasing to ~51° after 4 weeks of outdoor exposure (Western red cedar; cited as an example of weathering behaviour relevant for softwoods such as spruce). A study aimed at demonstrating how weathering reduces contact angle [32] reported an initial contact angle for low-density spruce of ~77°, falling to ~42° after 3 months and ~37° after 6 months of outdoor exposure. A heat-treatment study [33] on Picea abies (spruce) (sessile-drop, 5 µL drops): reports directional (tangential/radial) contact angles of 30.87° and 27.37° to show how heat treatment alters measured values. These results are not comparable with the results of the current study as contact angle was specified as an average of 30 seconds’ worth of continuously decreasing contact angle data. Sitka spruce was reported around 60° in a contact-angle survey across wood species by [30].

4. Conclusions

Contact angle measurements were performed on indigenous and hybrid poplar strands with distilled water. The results were suitable to compare the wettability of black poplar (Populus nigra) and a hybrid poplar (Populus × euramericana) strands, as well as with more traditional EWP raw materials. The experimental results yielded several important conclusions, including:

- There was a significant, but relatively small difference in the wettability of indigenous and hybrid poplar (with respective contact angles of 62.08° and 64.71°. This difference is unlikely to influence practical application.

- The wettability of hybrid poplar showed significantly higher variation than that of indigenous poplar, which means that the latter is likely to be more consistent in terms of gluability.

- The rate of water absorption into the material follows a logarithmic relationship with a high degree of precision (r2 > 0.96). This was slightly faster in case of indigienous poplar, but there was very little difference in terms of spreading (rate of absorption) between the two materials.

- Compared to traditional strand raw materials like spruce, poplar’s wettability is significantly higher, which is beneficial from an adhesion point of view. However, the high permeability of and fast absorption of water into poplar points to potential adhesion problems and increased adhesive requirements.

The phenomenon of drop bouncing is an important issue that requires more in-depth investigation that goes beyond the scope of this paper. Surface roughness of poplar is likely to be a complex and important factor in surface tension measurement. Both of these issues are recommended topics for future research. Other important factors influencing measurements results, like the importance of specimen thickness and dropping height are also worthy of more in-depth investigation in the future.

Author Contributions

Conceptualization: C.M.C.; Formal analysis, A.A.O.A. and T.A.; Funding acquisition, L.B.; Investigation, A.A.O.A.; Methodology, C.M.C.; Resources, L.B.; Supervision, T.A. and L.B.; Validation, T.A.; Writing—original draft, A.A.O.A.; Writing—review & editing, L.B. All authors have read and agreed to the published version of the manuscript.

Funding

This article was made in frame of the project TKP2021-NKTA-43 which has been implemented with the support provided by the Ministry of Culture and Innovation of Hungary from the National Research, Development and Innovation Fund, financed under the TKP2021-NKTA funding scheme.

Data Availability Statement

The raw data supporting the conclusions of this article will be made available by the authors on request.

Acknowledgments

Raw materials were provided by the Swiss-Krono Ltd. in Vasarosnameny. The authors gratefully acknowledge the assistance of Attila Benke and Klara Cseke in the DNA-based identification of the raw materials.

Conflicts of Interest

The authors declare that this study received funding from the Swiss-Krono Ltd. in Vasarosnameny in the form of raw materials. The funder was not involved in the study design, collection, analysis, interpretation of data, the writing of this article or the decision to submit it for publication. The authors declare that they have no further conflict of interest.

References

- European Parliament and Council of the European Union. Regulation (EU) 2024/3110 of 27 November 2024 laying down harmonised rules for the marketing of construction products and repealing Regulation (EU) No 305/2011. Off. J. Eur. Union 2024, L 123, 1–106. [Google Scholar]

- Gindl, M.; Sinn, G.; Gindl, W.; Reiterer, A.; Tschegg, S. A comparison of different methods to calculate the surface free energy of wood using contact angle measurements. Colloids Surfaces A Physicochem. Eng. Asp. 2001, 181, 279–287. [Google Scholar] [CrossRef]

- Piao, C.; Winandy, J.E.; Shupe, T.F. From hydrophilicity to hydrophobicity: A critical review: Part I. Wettability and surface behavior. Wood Fiber Sci. 2010, 42, 490–510. [Google Scholar]

- Chen, C.M. Measuring the wetting of wood surfaces by adhesives. Mokuzai Gakkaishi J. Jpn. Wood Res. Soc. 1973, 18, 451–456. [Google Scholar]

- Liptáková, E.; Kúdela, J. Analysis of the Wood-Wetting Process. Holzforschung 1994, 48, 139–144. [Google Scholar] [CrossRef]

- Shi, S.Q.; Gardner, D.J. Dynamic adhesive wettability of wood. Wood Fiber Sci. 2001, 33, 58–68. [Google Scholar]

- Scheikl, M.; Dunky, M. Measurement of Dynamic and Staue Contact Angles on Wood for the Determination of its Surface Tension and the Penetration of Liquids into the Wood Surface. Holzforschung 1998, 52, 89–94. [Google Scholar] [CrossRef]

- Shupe, T.E.; Hse, C.Y.; Choong, E.T.; Groom, L.H. Effect of wood grain and veneer side on loblolly pine veneer wettability. For. Prod. J. 1998, 48, 95–97. [Google Scholar]

- Kúdela, J.; Javorek, Ľ.; Mrenica, L. Influence of milling and sanding on beech wood surface properties. Part II. Wetting and thermo-dynamical characteristics of wood surface. Ann. Wars. Univ. Life Sci.—SGGW Land Reclam. 2016, 95, 154–158. [Google Scholar]

- Gardner, D.J.; Generalia, N.C.; Gunnells, D.W.; Wolcott, M.P. Dynamic Wettability of Wood. Langmuir 1991, 7, 2498–2502. [Google Scholar] [CrossRef]

- Hubbe, M.A.; Gardner, D.J.; Shen, W. Contact Angles and Wettability of Cellulosic Surfaces: A Review of Proposed Mechanisms and Test Strategies. BioResources 2015, 10, 8657–8749. [Google Scholar] [CrossRef]

- Kúdela, J. Wetting of Wood Surface by Liquids of a Different Polarity. Wood Res. 2014, 59, 11–24. [Google Scholar]

- Keturakis, G.; Juodeikienė, I. Investigation of Milled Wood Surface Roughness Gintaras. Mater. Sci. 2007, 13, 47–51. [Google Scholar]

- Papp, E.A.; Csiha, C. Contact angle as function of surface roughness of different wood species. Surf. Interfaces 2017, 8, 54–59. [Google Scholar] [CrossRef]

- Liptáková, E.; Kúdela, J.; Bastl, Z.; Spirovová, I. Influence of mechanical surface treatment of wood on the wetting process. Holzforschung 1995, 49, 369–375. [Google Scholar] [CrossRef]

- Herczeg, A. Wettability of wood. For. Prod. J. 1965, 15, 499–505. [Google Scholar]

- Hameed, M.; Roffael, E. Über die Benetzbarkeit von Splint- und Kernholz der Kiefer, Douglasie und Lärche. Eur. J. Wood Wood Prod. 1999, 57, 287–293. [Google Scholar] [CrossRef]

- Slováčková, B.; Mišíková, O.; Schmidtová, J. Comparing wettability and surface free energy of false heartwood, ripe wood and sapwood in beech (Fagus sylvatica L.). Drvna Ind. 2024, 75, 297–309. [Google Scholar] [CrossRef]

- Benkreif, R.; Brahmia, F.Z.; Csiha, C. Influence of moisture content on the contact angle and surface tension measured on birch wood surfaces. Eur. J. Wood Wood Prod. 2021, 79, 907–913. [Google Scholar] [CrossRef]

- Higuchi, T. Biochemistry and Molecular Biology of Wood; Springer Series in Wood Science; Springer: Berlin/Heidelberg, Germany, 1997. [Google Scholar] [CrossRef]

- Wagenführ, R. Anatomie des Holzes: Strukturanalytik, Identifizierung, Nomenklatur, Mikrotechnologie, 5th completely revised ed.; DRW-Verl: Leinfelden-Echterdingen, Germany, 1999. [Google Scholar]

- Rowell, R. (Ed.) The Chemistry of Solid Wood. In Advances in Chemistry; American Chemical Society: Washington, DC, USA, 1984; Volume 207. [Google Scholar] [CrossRef]

- Röhle, H.; Ali, W.; Hartmann, K.U.; Steinke, C. Wachstum und Biomasseproduktion schnellwachsender Baumarten im Kurzumtrieb. In AGROWOOD-Kurzumtriebsplantagen in Deutschland und europäische Perspektiven; Bemmann, A., Knust., C., Eds.; Weißensee Verlag: Berlin, Germany, 2010; pp. 103–116. [Google Scholar]

- Geimer, R.L.; Crist, J.B. Structural flakeboard from short-rotation, intensively cultured hybrid Populus clones. For. Prod. J. 1980, 30, 42–48. [Google Scholar]

- Maloney, T.M.; Lentz, M.T.; Canbron, G. Oriented strandboard from Douglas fir, hemlock, spruce, cedar, and poplar. Res. Rept. 1995, 2996–3808. [Google Scholar]

- Peters, J.J.; Bender, D.A.; Wolcott, M.P.; Johnson, J.D. Selected properties of hybrid poplar clear wood and composite panels. For. Prod. Soc. 2002, 52, 45–54. [Google Scholar]

- Rathke, J.; Sinn, G. Evaluating the wettability of MUF resins and pMDI on two different OSB raw materials. Eur. J. Wood Wood Prod. 2013, 71, 335–342. [Google Scholar] [CrossRef]

- Wegener, G. Oriented structural boards (OSB) from fast-growing poplar and willow. In Industrial End-Uses of Fast-Grown Species, Proceedings of the Eurowood Technical Workshop Proceedings, Florence, Italy, 31 May–1 June 1999; Istituto per la Ricerca sul Legno: Firenze, Italy, 1999. [Google Scholar]

- Antonini, C.; Villa, F.; Bernagozzi, I.; Amirfazli, A.; Marengo, M. Drop rebound after impact: The role of the receding contact an-gle. Langmuir 2013, 29, 16045–16050. [Google Scholar] [CrossRef]

- Baek, S.; Yong, K. Impact dynamics on SLIPS: Effects of liquid droplet’s surface tension and viscosity. Appl. Surf. Sci. 2020, 506, 144689. [Google Scholar] [CrossRef]

- Kalnins, M.A.; Feist, W.C. Increase in Wettability of Wood with Weathering. Forest Prod. J. 1993, 43, 55–57. [Google Scholar]

- Mantanis, G.I.; Young, R.A. Wetting of Wood. Wood Sci. Technol. 1997, 31, 339–353. [Google Scholar] [CrossRef]

- Kılınçarslan, Ş.; Şimşek, Y. Determination of Contact Angle Values of Heat-Treated Spruce (Picea abies) Wood with Image Analysis Program. Biomed. J. Sci. Technol. Res. 2019, 18, 13750–13751. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).