Development of an Integrated Forestry Survey Device for Tree Height and DBH

Abstract

1. Introduction

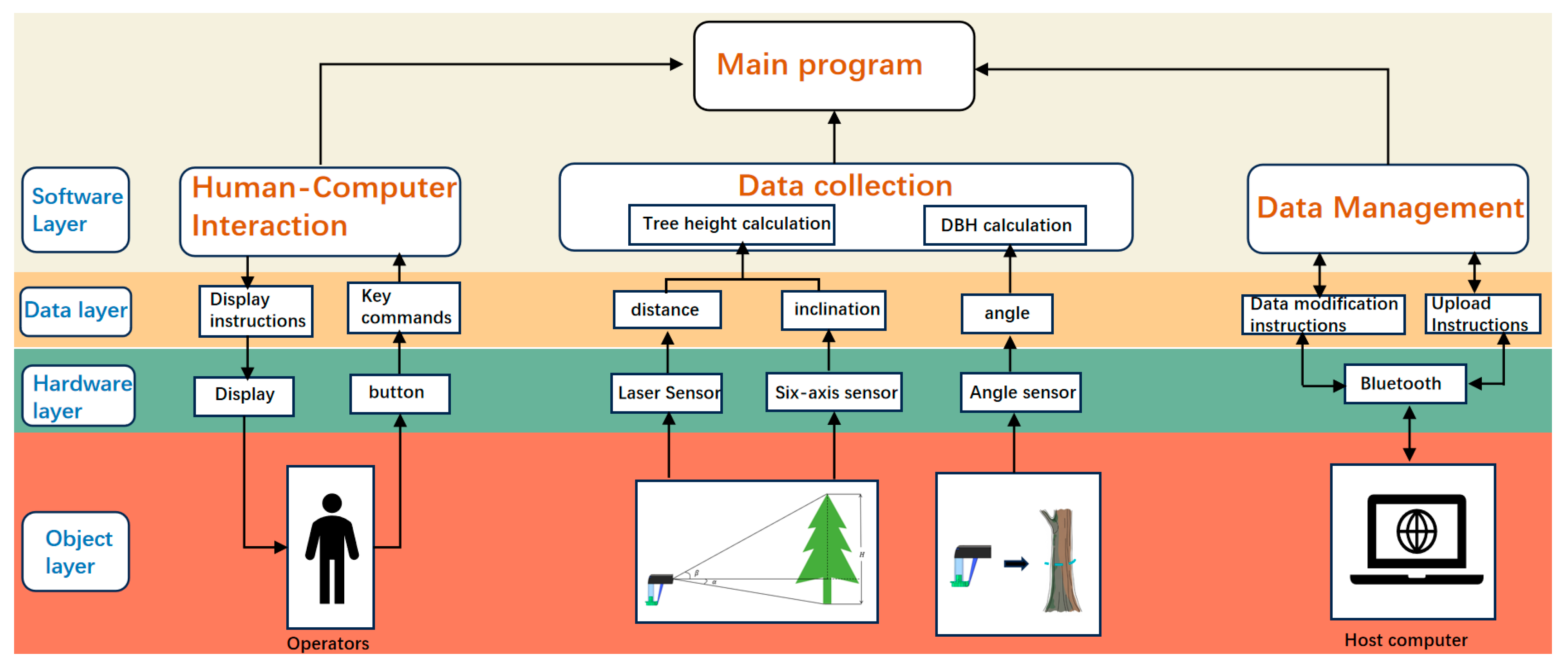

2. Development of Integrated Tree Measurement Device

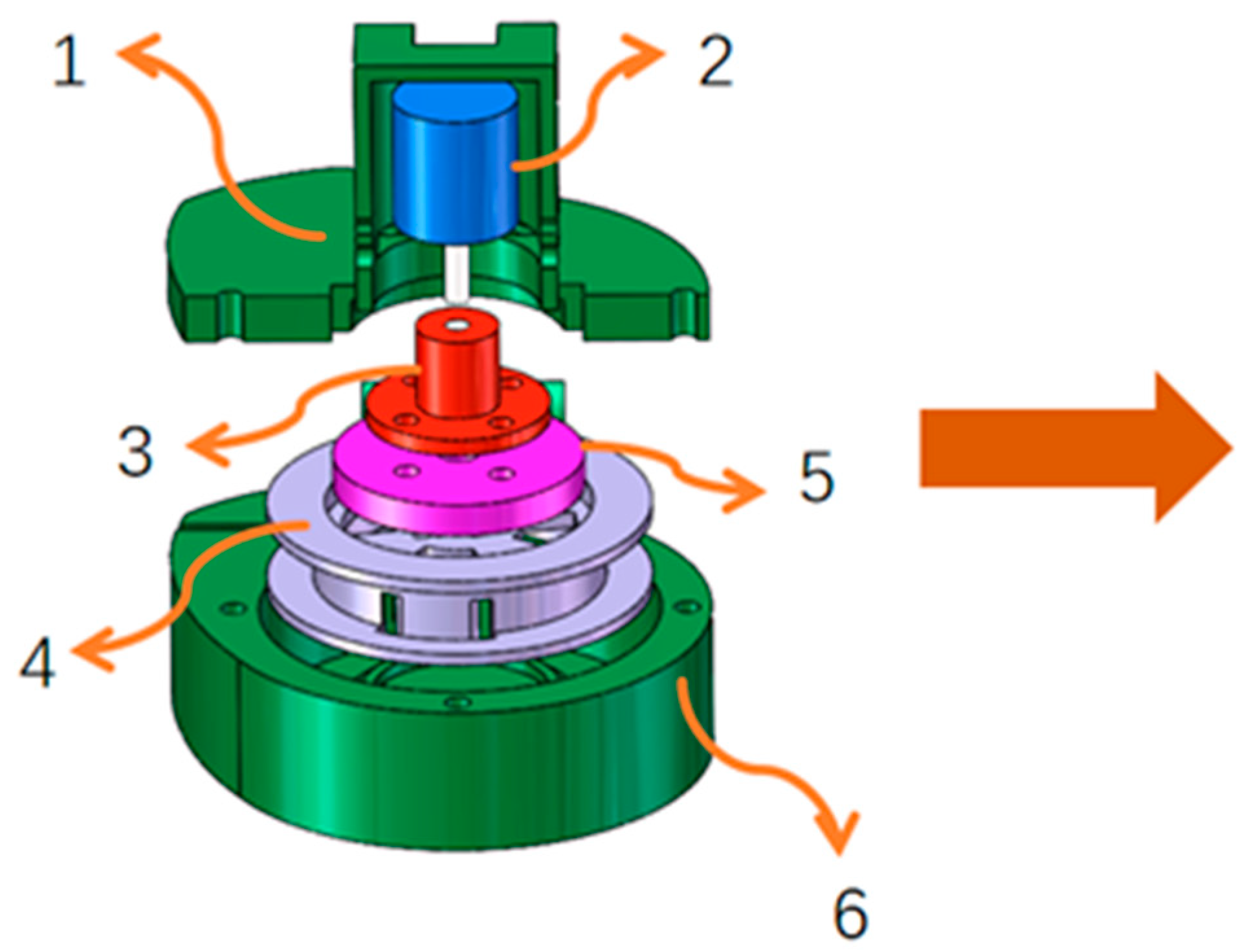

2.1. Mechanical Structure Design

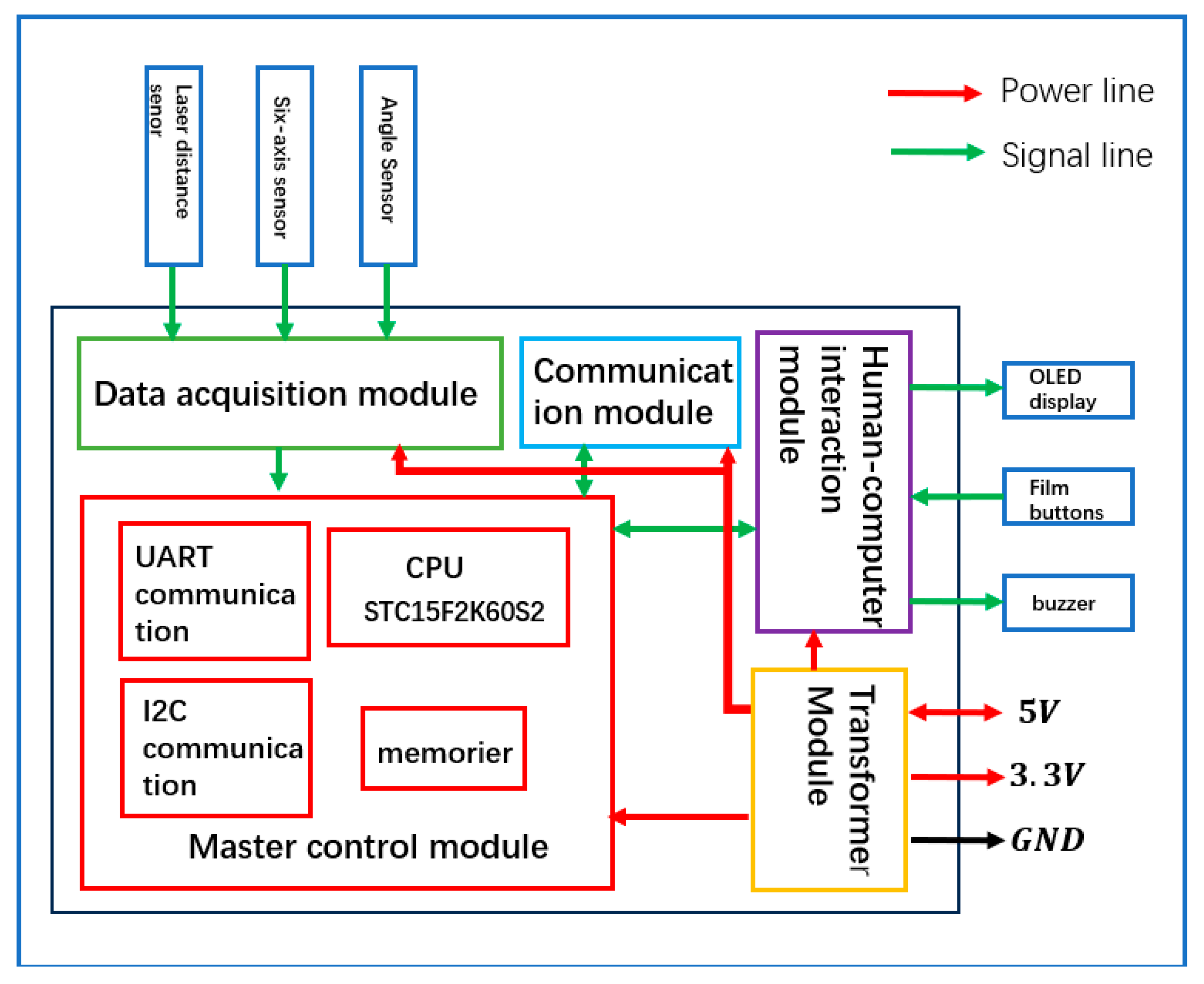

2.2. Circuit and Component Integration Design

2.2.1. Main Control Module

2.2.2. Transformer Module

2.2.3. Human–Computer Interaction Module

2.2.4. Data Acquisition Module

2.3. Design Principles

2.3.1. Tree Height Design Principles

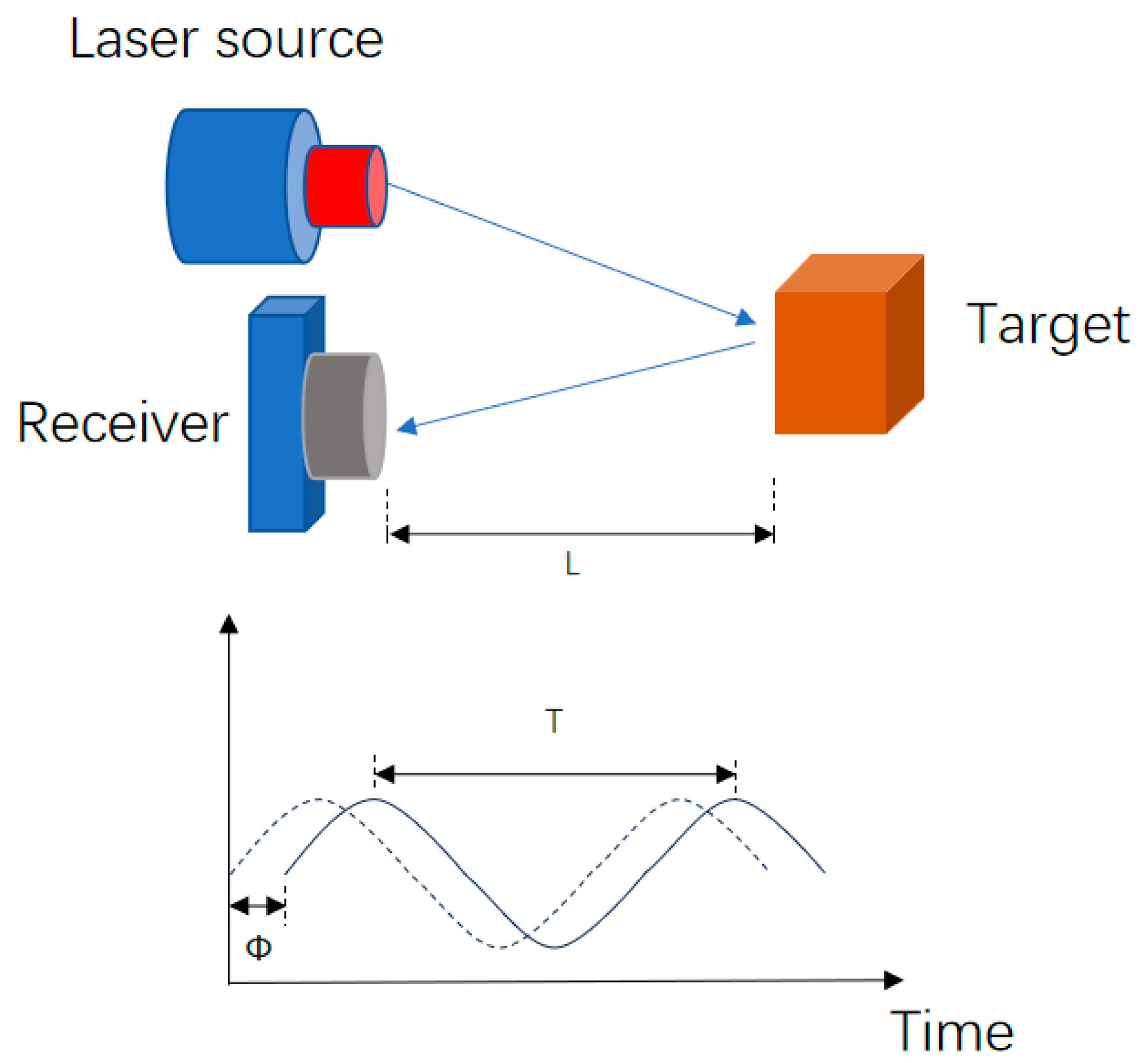

L1-40 Distance Sensor Principle

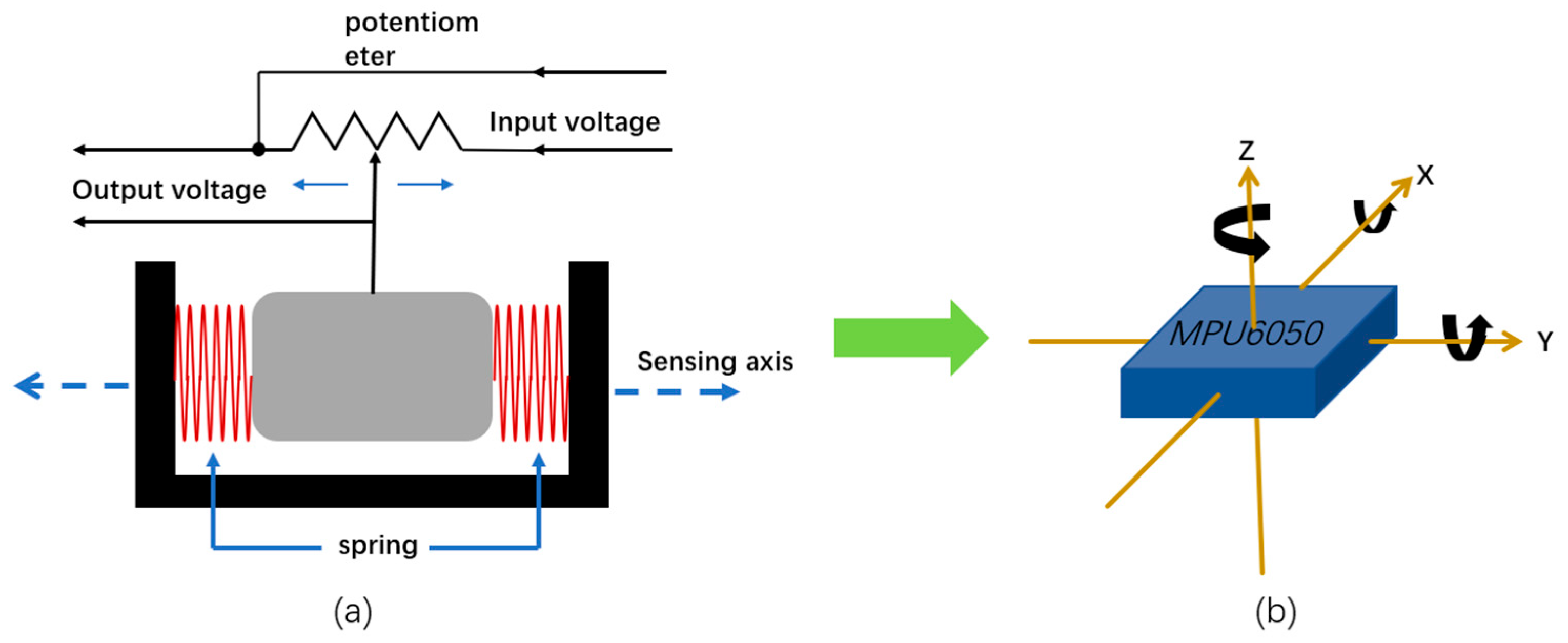

MPU6050 Six-Axis Sensor Principle

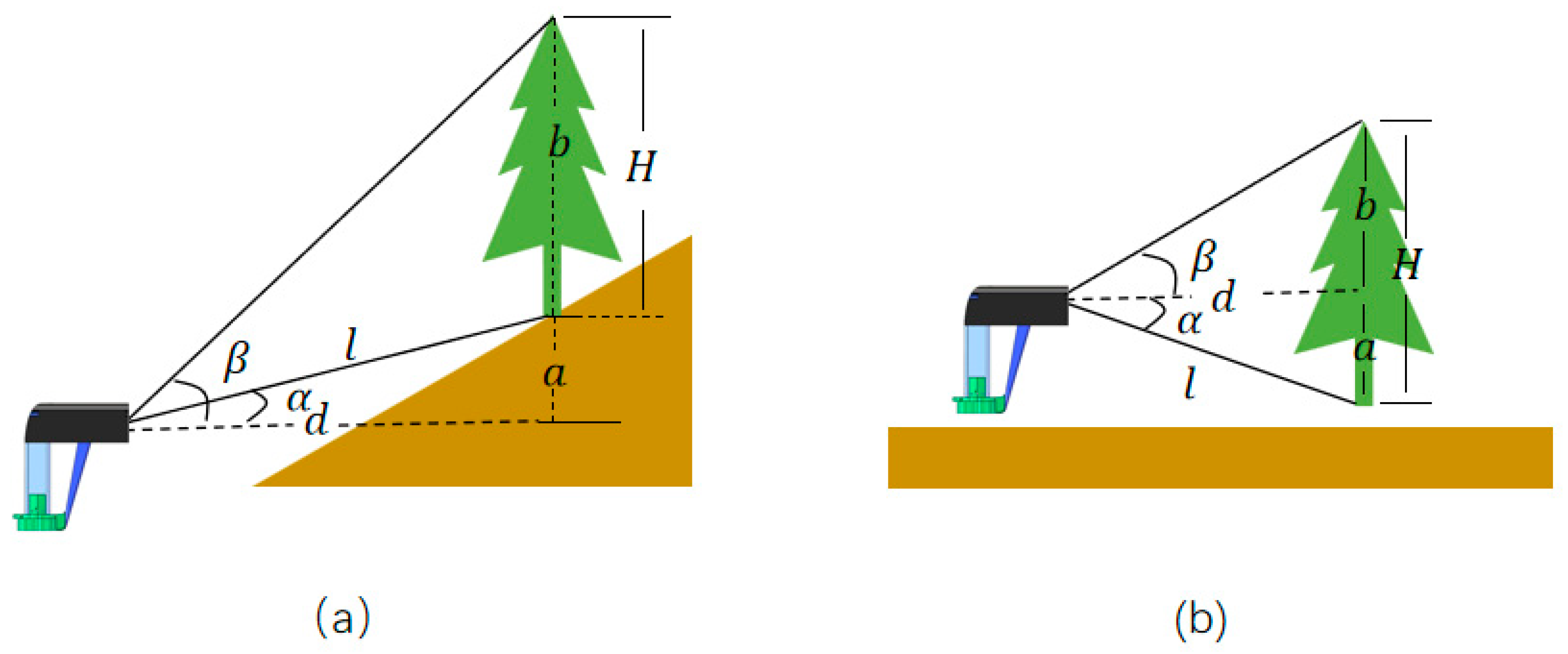

Principles of Tree Height Measurement

2.3.2. Principles of the DBH Design

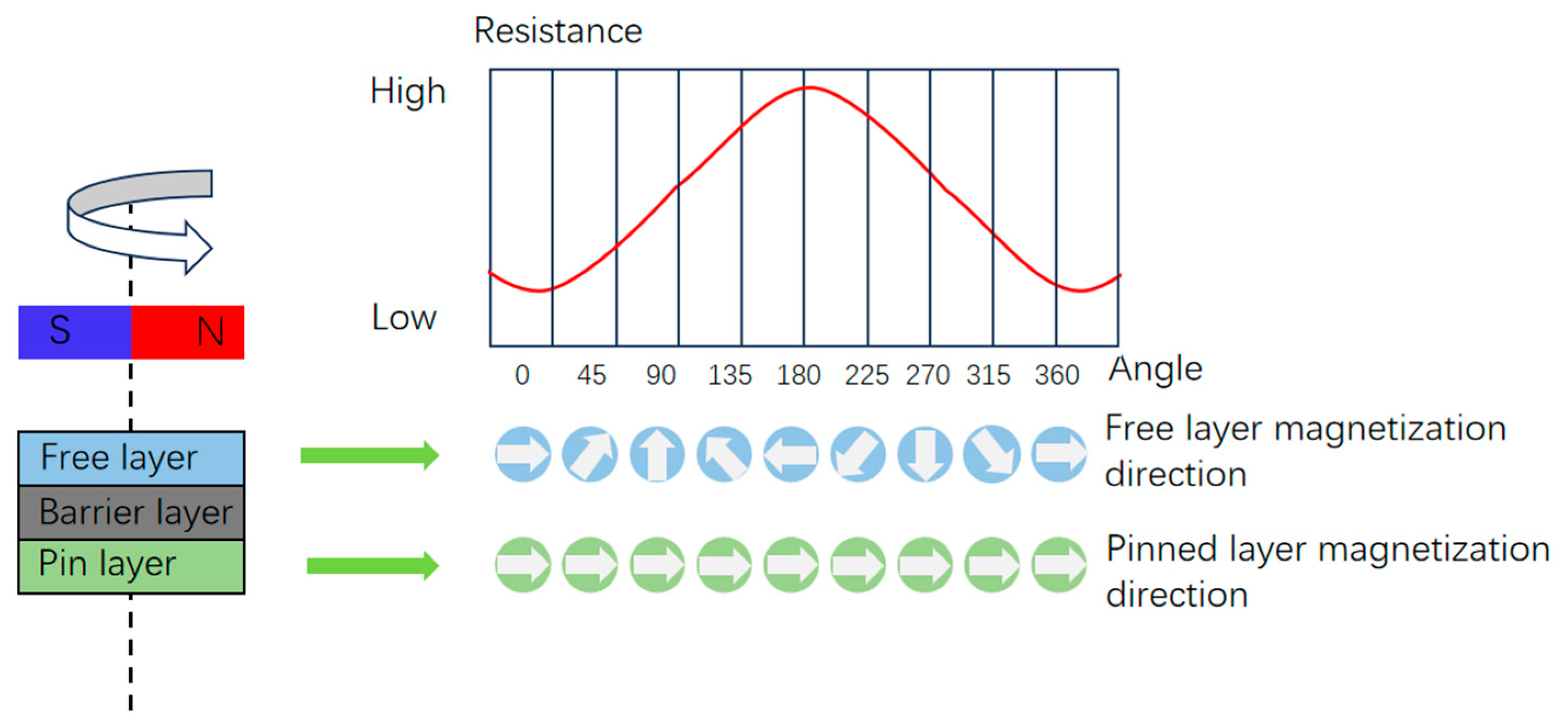

Principle of Tunnel Magnetoresistance Effect Angle Detection

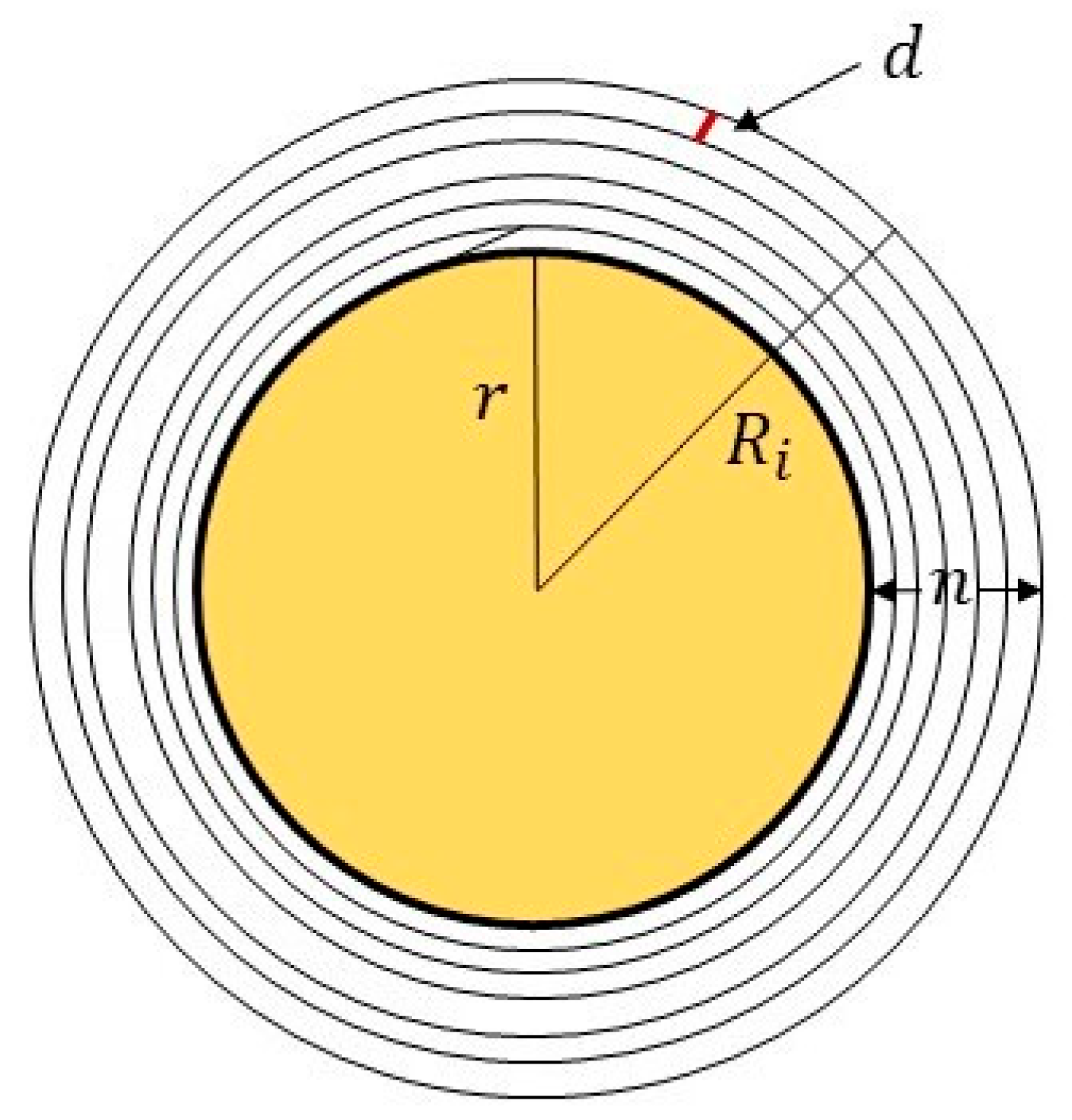

DBH Conversion Principle

- Tape Thickness: As described in Formula (8), the physical measurement process already accounts for the cumulative effect of the tape thickness. Formulas (9)–(11) are corrected for the default thickness.

- Tape Elasticity: We assume that the operator applies a consistent and slight pulling force during measurement. Under these conditions, the elastic deformation of the tape is minimal and can be ignored.

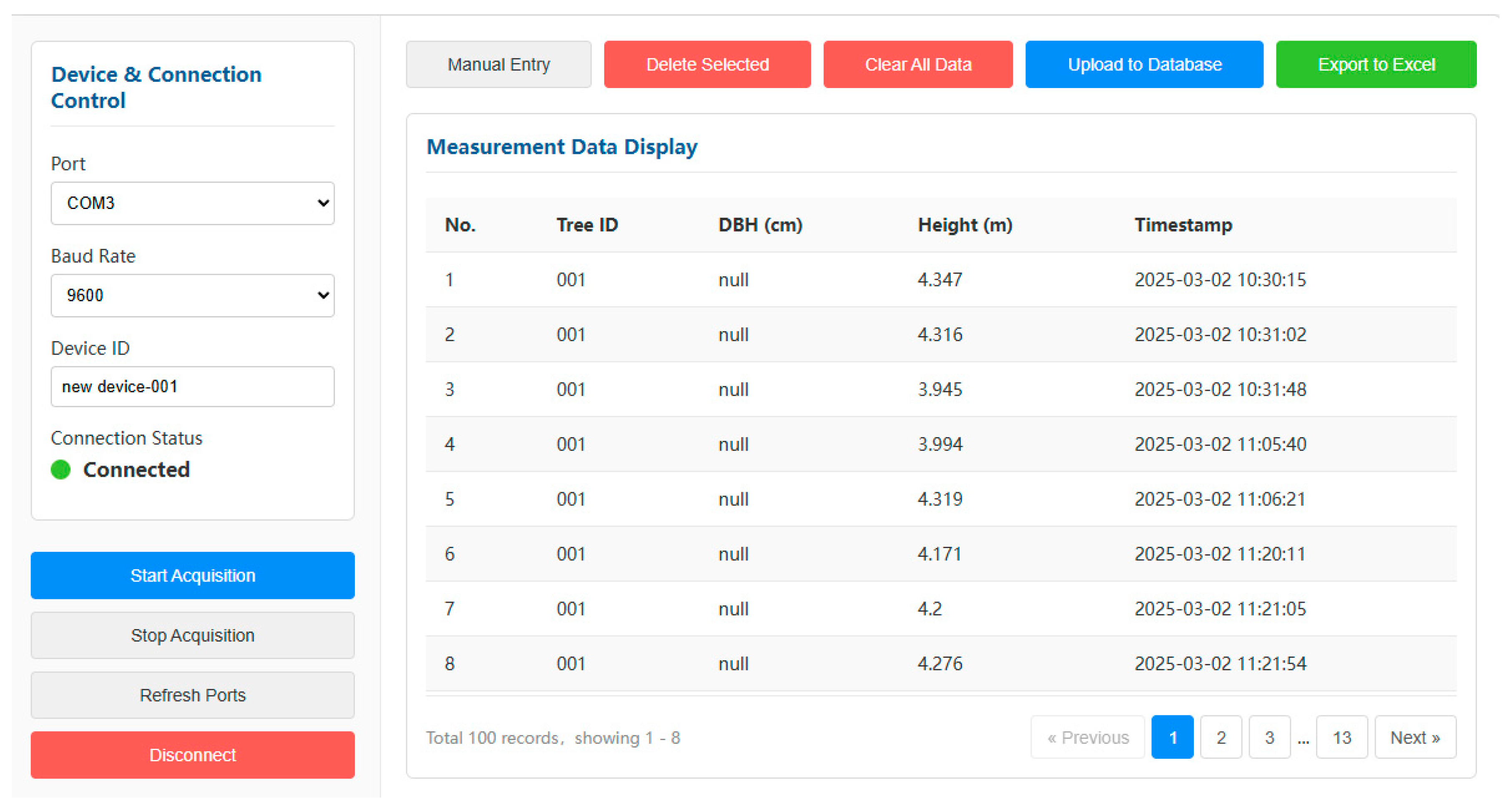

3. Software Design

4. Experiments and Analysis

4.1. Experimental Location and Subjects

4.2. Experimental Procedure

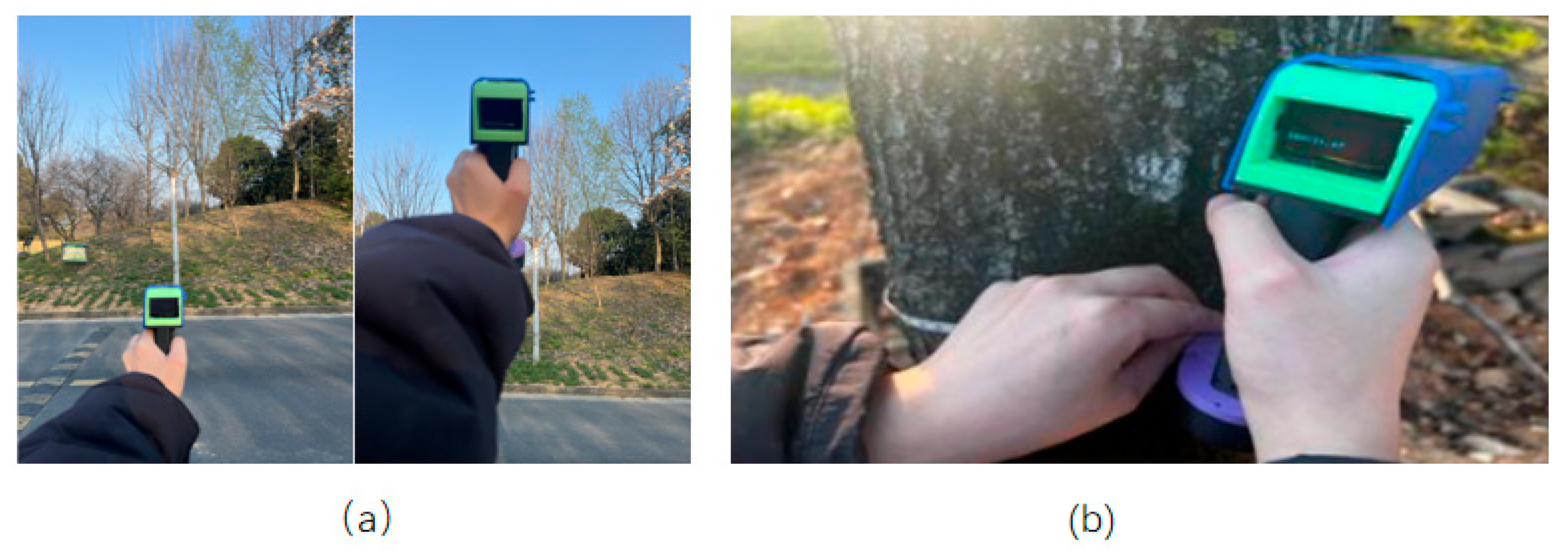

4.3. Tree Height Measurement Process

4.4. DBH Measurement Process

4.5. Measurement Accuracy and Efficiency Evaluation

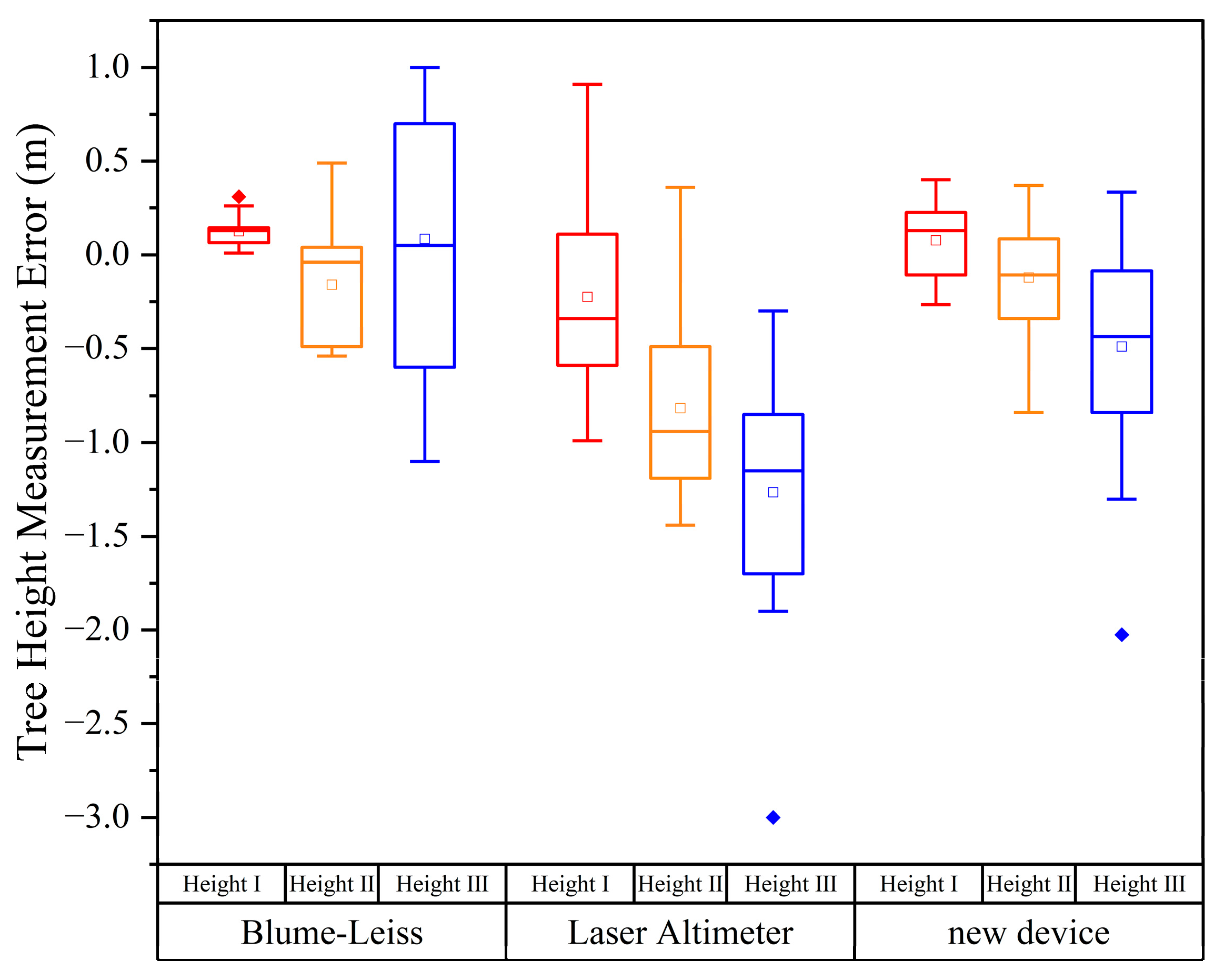

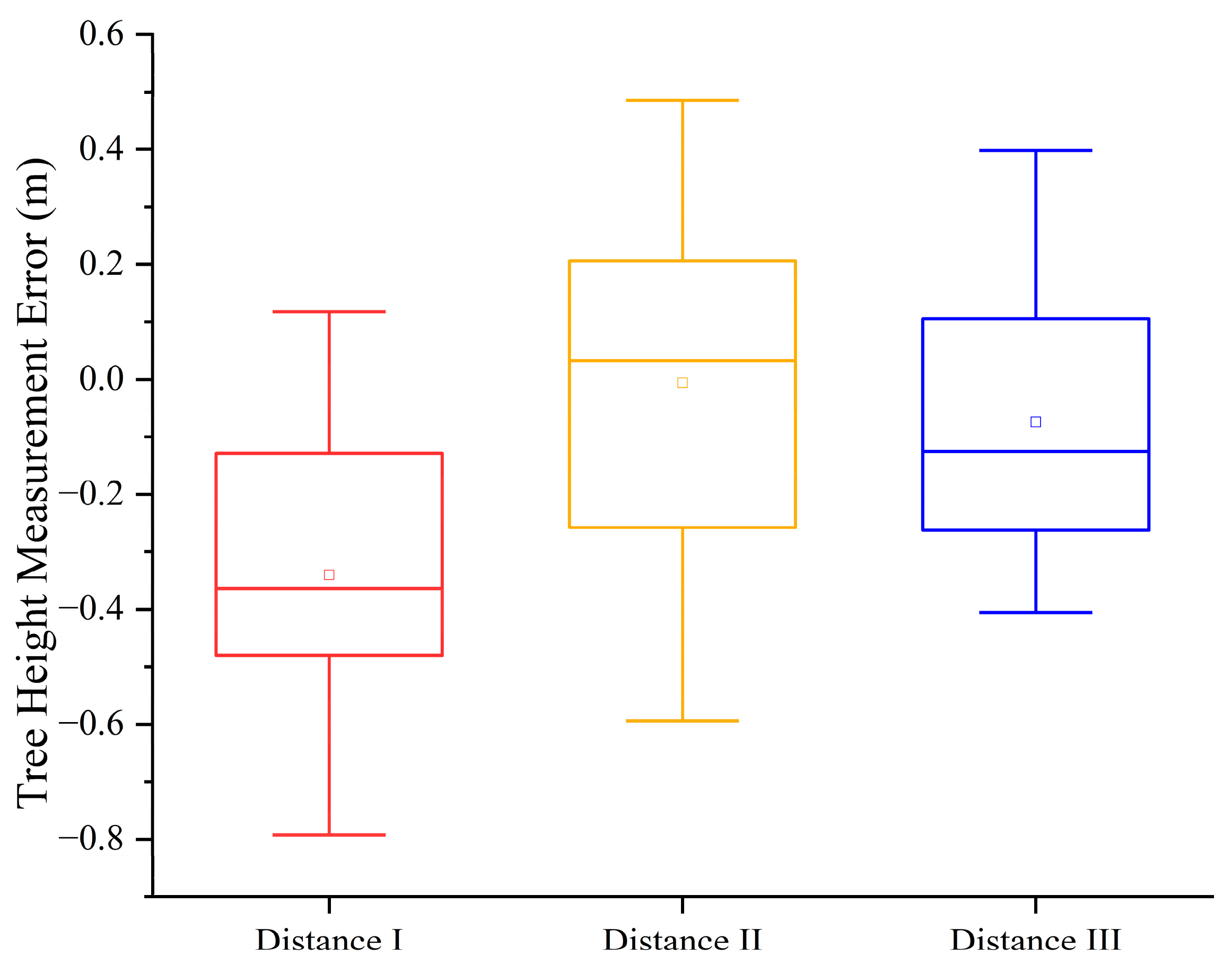

5. Result

6. Discussion

7. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Appendix A

| Component | Approximate Price (USD) |

|---|---|

| MPU6050 Six-Axis Sensor | 5 |

| STC15F2K60S2 Microcontroller | 1 |

| L1-40 Laser Sensor | 50 |

| JY-ME01-TTL Angle Sensor | 10 |

| 1.54-inch OLED Display | 10 |

| Lithium Battery and Power Module | 5 |

| 3D Printed Casing and Mechanical Parts | 5 |

| Other (Buttons, Wires, PCB, etc.) | 10 |

| Tree ID | Species | True Height (m) | Number of Measurements |

|---|---|---|---|

| 1 | Prunus mume | 4.19 | Used in Exp 1 (20 measurements) |

| 2 | Koelreuteria paniculata | 8.74 | Used in Exp 1 (20 measurements) |

| 3 | Koelreuteria paniculata | 15.8 | Used in Exp 1 (20 measurements) |

| 4 | Photinia serratifolia (Desf.) Kalkmanr | 4.92 | Used in Exp 3 (20 measurements) |

| 5 | Prunus mume | 4.12 | Used in Exp 3 (20 measurements) |

| 6 | Pinus tabuliformis Carrière | 6.2 | Used in Exp 3 (20 measurements) |

| 7 | Koelreuteria paniculata | 8.74 | Used in Exp 2 (20 × 3 = 60 measurements total) |

| Species | Sample Size (Number of Trees) | DBH Range (cm) |

|---|---|---|

| Platanus × acerifolia | 27 | [11.11, 15.79] |

| Phyllostachys edulis | 15 | [6.27, 13.68] |

| Cinnamomum cassia | 12 | [19.94, 38.7] |

| Cinnamomum camphora | 10 | [22.7, 42.8] |

| Magnolia denudata | 9 | [8.25, 21.7] |

| Ginkgo biloba | 7 | [20.13, 32.68] |

| Total | 80 | [8.25, 42.8] |

References

- Feldpausch, T.R.; Lloyd, J.; Lewis, S.L.; Brienen, R.J.W.; Gloor, M.; Mendoza, A.M.; Lopez-Gonzalez, G.; Banin, L.; Abu Salim, K.; Affum-Baffoe, K.; et al. Tree height integrated into pantropical forest biomass estimates. Biogeosciences 2012, 9, 3381–3403. [Google Scholar] [CrossRef]

- Zeng, W.; Tomppo, E.; Healey, S.P.; Gadow, K.V. The national forest inventory in China: History-results-international context. For. Ecosyst. 2015, 2, 23. [Google Scholar] [CrossRef]

- Fortin, M.; Van Couwenberghe, R.; Perez, V.; Piedallu, C. Evidence of climate effects on the height-diameter relationships of tree species. Ann. For. Sci. 2019, 76, 1. [Google Scholar] [CrossRef]

- Sullivan, M.J.P.; Lewis, S.L.; Hubau, W.; Qie, L.; Baker, T.R.; Banin, L.F.; Chave, J.; Cuni-Sanchez, A.; Feldpausch, T.R.; Lopez-Gonzalez, G.; et al. Field methods for sampling tree height for tropical forest biomass estimation. Methods Ecol. Evol. 2018, 9, 1179–1189. [Google Scholar] [CrossRef] [PubMed]

- Feng, Z.; Du, P.; Yan, H.; Zeng, W.; Liu, J.; Feng, H. Practice and exploration for establishing new generation technology system of forest resources investigation and monitoring. For. Grassl. Resour. Res. 2018, 3, 5–14. [Google Scholar] [CrossRef]

- Zhang, Q.; Sun, Y.; Zheng, X.; Zhang, S.; Fang, L. Development of a Real-Time Continuous Measurement System for Tree Radial Direction. Forests 2023, 14, 1876. [Google Scholar] [CrossRef]

- Li, S.; Fang, L.; Sun, Y.; Xia, L.; Lou, X. Development of measuring device for diameter at breast height of trees. Forests 2023, 14, 192. [Google Scholar] [CrossRef]

- Zhao, K.; Li, S.; Wang, J.; Sun, L.; Fang, L.; Ji, J. Development and Application of Tree Radial Measurement Device. Forests 2024, 15, 1710. [Google Scholar] [CrossRef]

- Iizuka, K.; Yonehara, T.; Itoh, M.; Kosugi, Y. Estimating tree height and diameter at breast height (DBH) from digital surface models and orthophotos obtained with an unmanned aerial system for a Japanese cypress (Chamaecyparis obtusa) forest. Remote Sens. 2017, 10, 13. [Google Scholar] [CrossRef]

- Liu, G.; Wang, J.; Dong, P.; Chen, Y.; Liu, Z. Estimating individual tree height and diameter at breast height (DBH) from terrestrial laser scanning (TLS) data at plot level. Forests 2018, 9, 398. [Google Scholar] [CrossRef]

- Yu, D.; Feng, Z.; Cao, Z.; Jiang, J. Error analysis of measuring diameter at breast height and tree height and volume of standing tree by total station. Trans. Chin. Soc. Agric. Eng. 2016, 32, 160–167. [Google Scholar]

- Amann, M.C.; Bosch, T.M.; Lescure, M.; Myllylae, R.A.; Rioux, M. Laser ranging: A critical review of unusual techniques for distance measurement. Opt. Eng. 2001, 40, 10–19. [Google Scholar]

- Gordon, P.; Toth, C.K. Introduction to laser ranging, profiling, and scanning. In Topographic Laser Ranging and Scanning; CRC Press: Boca Raton, FL, USA, 2018; pp. 1–28. [Google Scholar]

- Antoni, R. Infrared detectors: An overview. Infrared Phys. Technol. 2002, 43, 187–210. [Google Scholar] [CrossRef]

- Fedorov, D.S.; Ivoilov, A.Y.; Zhmud, V.A.; Trubin, V.G. Using of measuring system MPU6050 for the determination of the angular velocities and linear accelerations. Autom. Softw. Enginery 2015, 11, 75–80. [Google Scholar]

- Huang, J. Design of angle detection system based on MPU6050. In Proceedings of the 7th International Conference on Education, Management, Information and Computer Science (ICEMC 2017), Shenyang, China, 16–18 June 2016. [Google Scholar]

- Hiroyoshi, I.; Inoue, J.-I. Theory of tunnel magnetoresistance. J. Magn. Soc. Jpn. 2006, 30, 1–37. [Google Scholar] [CrossRef]

- Li, J.; Liu, H.; Bi, T. Tunnel magnetoresistance-based noncontact current sensing and measurement method. IEEE Trans. Instrum. Meas. 2022, 71, 9503609. [Google Scholar] [CrossRef]

- Zitong, Z.; Zhang, K.; Leng, Q. Tunneling magnetoresistance (TMR) materials and devices for magnetic sensors. In Spintronics: Materials, Devices and Applications; John Wiley & Sons: Hoboken, NJ, USA, 2022; pp. 51–92. [Google Scholar]

- Freitas, P.Á.; Ferreira, R.; Cardoso, S.; Cardoso, F. Magnetoresistive sensors. J. Phys. Condens. Matter 2007, 19, 165221. [Google Scholar] [CrossRef]

- Chen, S.; Lin, X.; Liang, W.; Zheng, L. Fujian sheng senlin ziyuan jiance tixi chouyang diaocha zhong xiongjing celiang jingdu fanwei de jingzhun queding [Precise Determination of the DBH Measurement Accuracy Range in the Sampling Survey of Fujian Province’s Forest Resources Monitoring System]. Linye Kancha Sheji [For. Prospect Des.] 2017, 37, 5–9. (In Chinese) [Google Scholar]

- Deering, M.H. Performance of Tree Height Measurement Instruments & Technology in New Zealand Forestry. Ph.D. Thesis, University of Canterbury, Christchurch, New Zealand, 2025. [Google Scholar]

- Sookjai, D.; Sonkaew, T.; Junthakhao, L.; Torkittikul, P. Comparative Accuracy and Precision Assessment of Survey Instruments for Teak Tree Height Measurement and Carbon Sequestration Estimation. Wittayasara Integr. Apply Eng. Ind. Technol. 2025, 18, 27–40. [Google Scholar]

- Lämås, T. The Haglöf PosTex ultrasound instrument for the positioning of objects on forest sample plots. In Arbetsrapport/Sveriges Lantbruksuniversitet, Institutionen för Skoglig Resurshushållning; Institutionen för Skoglig Resurshushållning, Sveriges Lantbruksuniversitet: Uppsala, Sweden, 2010; Number 296. [Google Scholar]

- Martin, A.J. Accuracy and precision in urban forestry tools for estimating total tree height. Arboric. Urban For. (AUF) 2022, 48, 319–332. [Google Scholar]

- Vasilescu, M.M. Standard Error of Tree Height Using “Vertex III”. Bull. Transilv. Univ. Brasov Ser. II For. Wood Ind. Agric. Food Eng. 2013, 6, 75–80. [Google Scholar]

- Gaudin, S.; Richard, J.B. Comparaison des Dendromètres Vertex III et TruPulse 200b pour la Mesure de la Hauteur Totale des Arbres. 2021. Available online: https://hal.science/hal-03447616/ (accessed on 14 September 2025).

| Height | Blume-Leiss | Laser Altimeter | Test Device | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| BIAS/cm | relBIAS/% | RMSE/cm | relRMSE/% | SD/cm | 95% CI for BIAS | BIAS/cm | relBIAS/% | RMSE/cm | relRMSE/% | SD/cm | 95% CI for BIAS | BIAS/cm | relBIAS/% | RMSE/cm | relRMSE/% | SD/cm | 95% CI for BIAS | |

| 4.19 | 13 | 3.01 | 15 | 3.47 | 7.41 | [9.53, 16.47] | −23 | −5.37 | 53 | 12.58 | 48.9 | [−45.89, −0.11] | 8 | 1.85 | 22 | 5.26 | 21.1 | [−1.875, 17.875] |

| 8.74 | −16 | −1.82 | 33 | 3.78 | 29.7 | [−29.9, −2.1] | −82 | −9.33 | 94 | 10.73 | 47.7 | [−104.32, −59.68] | 12 | −1.39 | 32 | 3.71 | 30.9 | [−2.5, 26.46] |

| 15.8 | 9 | 0.54 | 68 | 4.3 | 69.2 | [−23.39, 41.39] | −127 | −8.01 | 140 | 8.87 | 62 | [−156.02, −97.98] | 49 | −3.09 | 77 | 4.88 | 61.1 | [20.4, 77.9] |

| Mean | 2 | 0.58 | 39 | 3.85 | 77 | −7.57 | 96 | 10.73 | 18 | −0.88 | 44 | 4.33 | ||||||

| Distance | BIAS/cm | relBIAS/% | RMSE/cm | relRMSE/% | SD/cm | p-Value (vs. Zero Bias) 1 | 95% CI for BIAS |

|---|---|---|---|---|---|---|---|

| 5 m | 34 | −3.89 | 42 | 4.80 | 25.6 | <0.001 | [22.02, 35.98] |

| 10 m | 1 | −0.06 | 28 | 3.24 | 29 | 0.93 | [−12.57, 14.57] |

| 15 m | 7 | −0.85 | 23 | 2.59 | 21.9 | 0.15 | [−3.25, 17.25] |

| Mean | 14 | −1.60 | 31 | 3.55 |

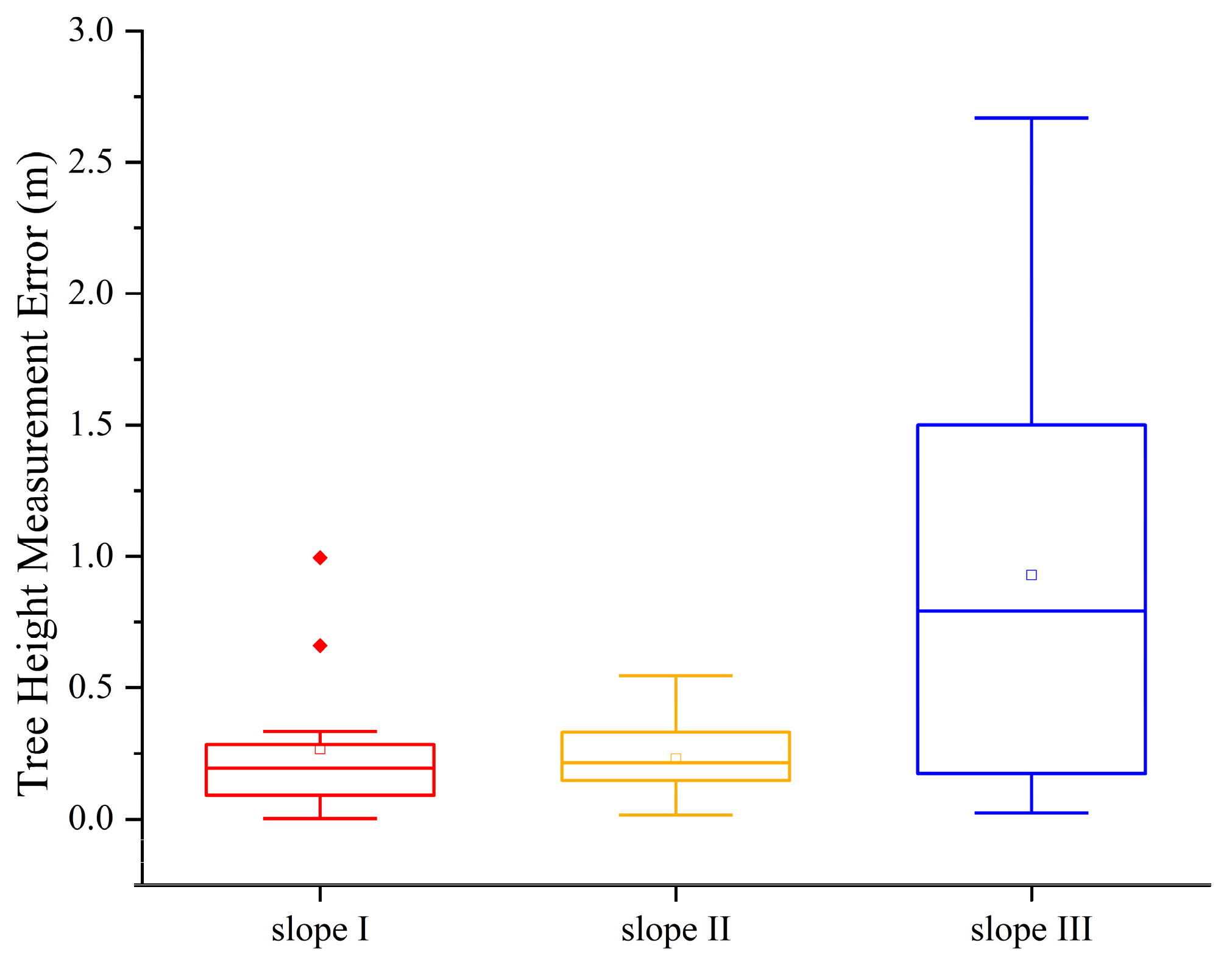

| Slope | BIAS/cm | relBIAS/% | RMSE/cm | relRMSE/% | SD/cm | p-Value (vs. Zero Bias) 1 | 95% CI for BIAS |

|---|---|---|---|---|---|---|---|

| 4.73° | 14 | 2.89 | 32 | 6.55 | 29.7 | <0.001 | [0.1, 27.9] |

| 19.87° | 8 | 1.94 | 26 | 6.41 | 25.8 | <0.001 | [−4.07, 20.07] |

| 37.52° | 54 | 8.69 | 111 | 17.85 | 99.2 | <0.001 | [7.57, 101.43] |

| Mean | 25 | 4.51 | 55 | 10.27 |

| Tree Species | Number of Trees | BIAS | relBIAS | RMSE | relRMSE | 95% CI for BIAS |

|---|---|---|---|---|---|---|

| Platanus × acerifolia | 27 | 0.14 | 0.93 | 0.17 | 1.17 | [0.09, 0.18] |

| Phyllostachys edulis | 15 | 0.11 | 1.19 | 0.13 | 1.42 | [0.07, 0.14 |

| Cinnamomum cassia | 12 | 0.26 | 0.87 | 0.3 | 1.03 | [0.15, 0.37] |

| Cinnamomum camphora | 10 | 0.21 | 0.51 | 0.45 | 1.14 | [−0.09, 0.51] |

| Magnolia denudata | 9 | 0.02 | 0.05 | 0.22 | 1.82 | [−0.16, 0.2] |

| Ginkgo biloba | 7 | 0.15 | 0.6 | 0.23 | 0.87 | [−0.01, 0.32] |

| Total | 80 | 0.15 | 0.79 | 0.25 | 1.28 | [0.10, 0.19] |

| Operation Method | Number | Field Time (s) | Internal Work Time (s) | Average Time Spent on a Single Tree (s) | Manpower Time (s) | Average Time per Tree (s) |

|---|---|---|---|---|---|---|

| Blume-Leiss and circumference ruler | 3 | 317.5 | 89.4 | 16.96 | 1041.9 | 43.41 |

| New device | 1 | 345.9 | 0 | 14.41 | 345.9 | 14.41 |

| Height (m) | Instrument | BIAS | p-Value (vs. Zero Bias) 1 | RMSE | p-Value (vs. New Device) 2 |

|---|---|---|---|---|---|

| 4.19 | New Device | 8 | 0.117 | 22 | - |

| Blume-Leiss | 13 | <0.001 | 15 | 0.29 | |

| Laser Altimeter | −23 | 0.54 | 53 | 0.03 | |

| 8.74 | New Device | 12 | 0.095 | 32 | - |

| Blume-Leiss | −16 | 0.027 | 33 | 0.71 | |

| Laser Altimeter | −82 | <0.001 | 94 | <0.001 | |

| 15.8 | New Device | 49 | 0.002 | 77 | - |

| Blume-Leiss | 9 | 0.589 | 68 | 0.003 | |

| Laser Altimeter | −127 | <0.001 | 140 | <0.001 |

| Nikon Forestry Pro II | Haglöf Vertex 5 | New Device | |

|---|---|---|---|

| Laser | Ultrasonic | Laser, TMR, MPU6050 | |

| Core Function | Height, Angle, distance | Height, Angle, distance | Height, DBH |

| Height Accuracy | ±0.2 m | Resolution: =0.1 m | RMSE: 0.3~0.5 m |

| DBH Measurement | No | No | Yes |

| Estimated Price | ~USD 500 (Retail Price) | ~USD 2000 (Retail Price) | ~USD 150 (Retail Price) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, A.; Zheng, X.; Zhao, K.; Zhang, S.; Sun, L.; Fang, L. Development of an Integrated Forestry Survey Device for Tree Height and DBH. Forests 2025, 16, 1529. https://doi.org/10.3390/f16101529

Xu A, Zheng X, Zhao K, Zhang S, Sun L, Fang L. Development of an Integrated Forestry Survey Device for Tree Height and DBH. Forests. 2025; 16(10):1529. https://doi.org/10.3390/f16101529

Chicago/Turabian StyleXu, Ao, Xianfang Zheng, Kejie Zhao, Shaobin Zhang, Linhao Sun, and Luming Fang. 2025. "Development of an Integrated Forestry Survey Device for Tree Height and DBH" Forests 16, no. 10: 1529. https://doi.org/10.3390/f16101529

APA StyleXu, A., Zheng, X., Zhao, K., Zhang, S., Sun, L., & Fang, L. (2025). Development of an Integrated Forestry Survey Device for Tree Height and DBH. Forests, 16(10), 1529. https://doi.org/10.3390/f16101529