Modulus of Elasticity and Bending Strength of Scots Pine (Pinus sylvestris L.) Wood from Commercial Thinnings

Abstract

1. Introduction

2. Materials and Methods

3. Results and Discussion

3.1. Density and Bending Properties by Stand Type

3.2. Models for Modulus of Elasticity and Bending Strength

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- PxWeb. Stand Development Classes on Forest Land Available for Wood Production (1000 ha) by Inventory, Region and Stand Development Class. Available online: https://statdb.luke.fi/PXWeb/pxweb/en/LUKE/LUKE__04%20Metsa__06%20Metsavarat/1.14_Metsikoiden_kehitysluokat_puuntuotannon.px/ (accessed on 3 July 2023).

- Wall, T.; Fröblom, J.; Kilpeläinen, H.; Lindblad, J.; Heikkilä, A.; Song, T.; Stöd, R.; Verkasalo, E. Harvennusmännyn Hankinnan ja Sahauksen Kehittäminen. WOOD WISDOM—Tutkimusohjelman Hankekonsortion Loppuraportti; Metsäntutkimuslaitos: Joensuu, Finland, 2005. [Google Scholar]

- Kortesmaa, T.; Salo-Kauppinen, R. E-Yearbook of Food and Natural Resource Statistics for 2018; Natural Resources Institute Finland (Luke): Helsinki, Finland, 2019. [Google Scholar]

- Mauno, T. Pieniläpimittaisen Puun Tulevaisuudet. Master’s Thesis, University of Eastern Finland, Joensuu, Finland, 2021. [Google Scholar]

- Niinistö, T. Wood in Energy Generation 2022 (Provisional). Natural Resources Institute Finland. Available online: https://www.luke.fi/en/statistics/wood-consumption/wood-in-energy-generation-2022-provisional (accessed on 24 July 2023).

- Vuokila, Y. Nuoren Männikön Kasvureaktio Ensiharvennuksen Jälkeen; Metsäntutkimuslaitos: Helsinki, Finland, 1981. [Google Scholar]

- Äijälä, O.; Koistinen, A.; Sved, J.; Vanhatalo, K.; Väisänen, P. Metsänhoidon Suositukset. Available online: https://metsanhoidonsuositukset.fi/fi (accessed on 3 July 2023).

- Guller, B. The Effects of Thinning Treatments on Density, MOE, MOR and Maximum Crushing Strength of Pinus brutia Ten. Wood. Ann. For. Sci. 2007, 64, 467–475. [Google Scholar] [CrossRef]

- Mäkinen, H.; Hynynen, J. Wood Density and Tracheid Properties of Scots Pine: Responses to Repeated Fertilization and Timing of the First Commercial Thinning. For. Int. J. For. Res. 2014, 87, 437–447. [Google Scholar] [CrossRef]

- Bowyer, J.L.; Shmulsky, R.; Haygreen, J.G. Forest Products and Wood Science: An Introduction, 5th ed.; Blackwell Publishing: Ames, IA, USA, 2007. [Google Scholar]

- Kollmann, F.F.P.; Côté, W.A. Principles of Wood Science and Technology. Vol. 1, Solid Wood; Springer: Berlin/Heidelberg, Germany, 1968. [Google Scholar]

- Uusvaara, O. Viljelymänniköstä Saadun Sahatavaran Laatu ja Arvo; Metsäntutkimuslaitos: Helsinki, Finland, 1983. [Google Scholar]

- Halinen, M. The Effect of the Growth Rate of Young Scots Pine on the Quality of Sawn Goods. Silva Fenn. 1985, 19, 4. [Google Scholar]

- Lämsä, P.; Kellomäki, S.; Väisänen, H. Nuorten Mäntyjen Oksikkuuden Riippuvuus Puuston Rakenteesta ja Kasvupaikan Viljavuudesta; Metsäntutkimuslaitos: Helsinki, Finland, 1990. [Google Scholar]

- Mäkinen, H.; Saranpää, P.; Linder, S. Wood-Density Variation of Norway Spruce in Relation to Nutrient Optimization and Fibre Dimensions. Can. J. For. Res. 2002, 32, 185–194. [Google Scholar] [CrossRef]

- Kärkkäinen, M. Puun Rakenne ja Ominaisuudet; Metsäkustannus Oy: Hämeenlinna, Finland, 2007. [Google Scholar]

- Lindström, H.; Reale, M.; Grekin, M. Using Non-Destructive Testing to Assess Modulus of Elasticity of Pinus sylvestris Trees. Scand. J. For. Res. 2009, 24, 247–257. [Google Scholar] [CrossRef]

- Kozakiewicz, P.; Jankowska, A.; Mamiński, M.; Marciszewska, K.; Ciurzycki, W.; Tulik, M. The Wood of Scots Pine (Pinus Sylvestris L.) from Post-Agricultural Lands Has Suitable Properties for the Timber Industry. Forests 2020, 11, 1033. [Google Scholar] [CrossRef]

- Fengel, D.; Wegener, G. Wood: Chemistry, Ultrastructure, Reactions; Walter de Gruyter: Berlin, Germany, 1989. [Google Scholar]

- Fries, A.; Ericsson, T. Genetic Parameters for Early Wood and Latewood Densities and Development with Increasing Age in Scots Pine. Ann. For. Sci. 2009, 66, 404. [Google Scholar] [CrossRef]

- Büyüksarı, Ü.; As, N.; Dundar, T. Mechanical Properties of Earlywood and Latewood Sections of Scots Pine Wood. BioResources 2017, 12, 4004–4012. [Google Scholar] [CrossRef]

- Hakkila, P. Ensiharvennuspuun Hyödyntäminen. Metsätieteen Aikakauskirja 1996, 4, 428–433. [Google Scholar] [CrossRef]

- Huuskonen, S.; Hynynen, J.; Ojansuu, R. Stand Characteristics and External Quality of Young Scots Pine Stands in Finland. Silva Fenn. 2008, 42, 245. [Google Scholar] [CrossRef]

- Gryc, V.; Vavrčík, H.; Horn, K. Density of Juvenile and Mature Wood of Selected Coniferous Species. J. For. Sci. 2011, 57, 123–130. [Google Scholar] [CrossRef]

- Niemistö, P.; Kilpeläinen, H.; Poutiainen, E. Effect of First Thinning Type and Age on Growth, Stem Quality and Financial Performance of a Scots Pine Stand in Finland. Silva Fenn. 2018, 52, 7816. [Google Scholar] [CrossRef]

- Warensjö, M. Compression Wood in Scots Pine and Norway Spruce: Distribution in Relation to External Geometry and the Impact on Dimensional Stability in Sawn Wood. Ph.D. Thesis, Swedish University of Agricultural Sciences, Umeå, Sweden, 2003. [Google Scholar]

- Kretschmann, D.E. Mechanical Properties of Wood. In Wood Handbook: Wood as an Engineering Material; General Technical Report; Forest Products Laboratory: Madison, WI, USA, 2010; pp. 100–145. [Google Scholar]

- Sjöström, E. Puukemia: Teoreettiset Perusteet ja Sovellutukset, 4th ed.; Otakustantamo: Espoo, Finland, 1989. [Google Scholar]

- Richter, C. Wood Characteristics: Description, Causes, Prevention, Impact on Use and Technological Adaptation; Springer: Cham, Switzerland, 2015. [Google Scholar]

- Thibaut, B.; Gril, J. Growth Stresses. In Wood Quality and Its Biological Basis; Barnett, J.R., Jeronimidis, G., Eds.; Blackwell Publishing Ltd.: Oxford, UK, 2003; pp. 137–156. [Google Scholar]

- Zobel, B.J.; Sprague, J.R. Juvenile Wood in Forest Trees; Timell, T.E., Ed.; Springer Series in Wood Science; Springer: Berlin/Heidelberg, Germany, 1998. [Google Scholar] [CrossRef]

- Zobel, B.J.; van Buijtenen, J.P. Wood Variation; Timell, T.E., Ed.; Springer Series in Wood Science; Springer: Berlin/Heidelberg, Germany, 1989. [Google Scholar] [CrossRef]

- Sauter, U.H.; Mutz, R.; Munro, B.D. Determining Juvenile-Mature Wood Transition in Scots Pine Using Latewood Density. Wood Fiber Sci. 1999, 31, 416–425. [Google Scholar]

- Dumail, J.F.; Castera, P. Transverse Shrinkage in Maritime Pine Juvenile Wood. Wood Sci. Technol. 1997, 31, 251–264. [Google Scholar] [CrossRef]

- Larson, P.R. Wood Formation and the Concept of Wood Quality; Bulletin No. 74; School of Forestry, Yale University: New Haven, CT, USA, 1969; p. 54. [Google Scholar]

- Larson, P.R.; Kretschmann, D.E.; Clark, A., III; Isebrands, J.G. Formation and Properties of Juvenile Wood in Southern Pines: A Synopsis; General Technical Report FPL-GTR-129; US Department of Agriculture, Forest Service, Forest Products Laboratory: Madison, WI, USA, 2001; 42p. [CrossRef]

- Burdon, R.; Walker, J.; Megraw, B.; Evans, R.; Cown, D. Juvenile Wood (Sensu Novo) in Pine: Conflicts and Possible Opportunities for Growing, Processing and Utilization. N. Z. J. For. 2004, 49, 24–31. [Google Scholar]

- Thörnqvist, T. Ungdomsved i Barrträd. [Juvenile Wood in Coniferous Trees]; Report No. 10; Institutionen för Skog-Industri-Marknad Studier, Sveriges Lantbruksuniversitet SIMS: Uppsala, Sweden, 1990; Available online: http://www.diva-portal.org/smash/get/diva2:744609/FULLTEXT01.pdf (accessed on 4 July 2023).

- Wiedenhoeft, A. Structure and Function of Wood. In Wood Handbook: Wood as an Engineering Material; General Technical Report; Forest Products Laboratory: Madison, WI, USA, 2010; pp. 62–79. [Google Scholar]

- Bradic, S.; Avramidis, S. Impact of Juvenile Wood on Hemlock Timber Drying Characteristics. For. Prod. J. 2007, 57, 53–59. [Google Scholar]

- Pikiński, P.M.; Szaban, J.; Šilingienė, G.; Korzeniewicz, R.; Pazdrowski, W. Selected Physical and Mechanical Properties of Scots Pine (Pinus Sylvestris L.) Wood from Stands of Younger Age Classes as Criteria for Rational Utilization of Timber. Balt. For. 2021, 27, 1. [Google Scholar] [CrossRef]

- Stöd, R.; Verkasalo, E.; Heinonen, J. Quality and Bending Properties of Sawn Timber from Commercial Thinnings of Scots Pine (Pinus Sylvestris L.). Balt. For. 2016, 22, 148–162. [Google Scholar]

- Kučera, B. Skandinavisk Norm for Testing av Små Feilfrie Prøver av Heltre; Department of Forestry, Agricultural University of Norway: Evenstad, Norway; Norwegian Forest Research Institute: Ås, Norway, 1992; p. 104. [Google Scholar]

- ISO 3349:1975; Wood—Determination of Modulus of Elasticity in Static Bending. International Organization for Standardization: Geneva, Switzerland, 1975. Available online: https://www.iso.org/standard/8633.html (accessed on 24 July 2023).

- ISO 3133:1975; Wood—Determination of Ultimate Strength in Static Bending. International Organization for Standardization: Geneva, Switzerland, 1975. Available online: https://www.iso.org/standard/8291.html (accessed on 24 July 2023).

- Verkasalo, E.; Leban, J.-M. MOE and MOR in Static Bending of Small Clear Specimens of Scots Pine, Norway Spruce and European Fir from Finland and France and Their Prediction for the Comparison of Wood Quality. Pap. Puu-Pap. Timber 2002, 84, 332–340. [Google Scholar]

- Jalava, M. Suomalaisen Männyn, Kuusen, Koivun ja Haavan Lujuusominaisuuksista. Strength Properties of Finnish Pine, Spruce, Birch and Aspen. Comm. Inst. For. Fenn. 1945, 33, 1–66. [Google Scholar]

- Hudson, W. The Strength Properties of European Redwood and Whitewood; Special Report No. 24; Ministry of Technology, Forest Products Research: Princes Risborough, Aylesbury, UK, 1967.

- Auty, D.; Achim, A.; Macdonald, E.; Cameron, A.D.; Gardiner, B.A. Models for Predicting Clearwood Mechanical Properties of Scots Pine. For. Sci. 2016, 62, 403–413. [Google Scholar] [CrossRef]

- Repola, J. Models for Vertical Wood Density of Scots Pine, Norway Spruce and Birch Stems, and Their Application to Determine Average Wood Density. Silva Fenn. 2006, 40, 673–685. [Google Scholar] [CrossRef]

- Roszyk, E.; Mania, P.; Iwańska, E.; Kusiak, W.; Broda, M. Mechanical Performance of Scots Pine Wood from Northwestern Poland—A Case Study. Bioresources 2020, 15, 6781–6794. [Google Scholar] [CrossRef]

- Schönfelder, O.; Zeidler, A.; Borůvka, V.; Bílek, L. Influence of Site Conditions and Silvicultural Practice on the Wood Density of Scots Pine (Pinus sylvestris L.)—A Case Study from the Doksy Locality, Czech Republic. J. For. Sci. 2017, 63, 457–462. [Google Scholar] [CrossRef]

- Verkasalo, E. Relationships of the Modulus of Elasticity and the Structure of Finnish Scots Pine Wood. Silva Fenn. 1992, 26, 155–168. [Google Scholar] [CrossRef][Green Version]

- Yang, J.L.; Evans, R. Prediction of MOE of Eucalypt Wood from Microfibril Angle and Density. Holz Roh- Werkst. 2003, 61, 449–452. [Google Scholar] [CrossRef]

- Li, M.; Ren, H.; Wang, Y.; Gong, Y.; Zhou, Y. Comparative Studies on the Mechanical Properties and Microstructures of Outerwood and Corewood in Pinus radiata D. Don. J. Wood Sci. 2021, 67, 60. [Google Scholar] [CrossRef]

- Machado, J.S.; Cruz, H.P. Within Stem Variation of Maritime Pine Timber Mechanical Properties. Holz Roh- Werkst. 2005, 63, 154–159. [Google Scholar] [CrossRef]

- Tsehaye, A.; Buchanan, A.H.; Walker, J.C.F. Selecting Trees for Structural Timber. Holz Roh- Werkst. 2000, 58, 162–167. [Google Scholar] [CrossRef]

- Mackes, K.; Shepperd, W.; Jennings, C. Evaluating the Bending Properties of Clear Wood Specimens Produced from Small-Diameter Ponderosa Pine Trees. For. Prod. J. 2005, 55, 72–80. [Google Scholar]

- Eriksson, D. Wood—An Anatomical Structure in the Tree and an Engineering Material in Industry; Swedish University of Agricultural Sciences: Umeå, Sweden, 2008; Available online: https://res.slu.se/id/publ/18881 (accessed on 3 July 2023).

- Šilinskas, B.; Varnagirytė-Kabašinskienė, I.; Aleinikovas, M.; Beniušienė, L.; Aleinikovienė, J.; Škėma, M. Scots Pine and Norway Spruce Wood Properties at Sites with Different Stand Densities. Forests 2020, 11, 587. [Google Scholar] [CrossRef]

- Dias, A.; Gaspar, M.J.; Carvalho, A.; Pires, J.; Lima-Brito, J.; Silva, M.E.; Louzada, J.L. Within- and between-Tree Variation of Wood Density Components in Pinus Nigra at Six Sites in Portugal. Ann. For. Sci. 2018, 75, 58. [Google Scholar] [CrossRef]

- Kärkkäinen, M.; Raivonen, M. Mechanical Strength of Reaction Wood. Silva Fenn. 1977, 11, 87–96. [Google Scholar] [CrossRef]

- Cockrell, R.A.; Knudson, R.M. A Comparison of Static Bending, Compression and Tension Parallel to Grain and Toughness Properties of Compression Wood and Normal Wood of a Giant Sequoia. Wood Sci. Technol. 1973, 7, 241–250. [Google Scholar] [CrossRef]

| Stand Type | Site Type (Number of Stands) | N | Density (kg/m³) | Std. Dev. (kg/m³) | MOE (GPa) | Std. Dev. (GPa) | MOR (MPa) | Std. Dev. (MPa) |

|---|---|---|---|---|---|---|---|---|

| First thinning | Myrtillus type (2) | 40 | 410.5 | 29.7 | 7.8 | 1.4 | 66.0 | 8.8 |

| Vaccinium type (2) | 42 | 466.6 | 67.6 | 9.7 | 1.8 | 81.1 | 15.2 | |

| Vaccinium vitis-idaea transformed type (2) | 46 | 432.1 | 36.7 | 8.3 | 1.4 | 70.0 | 9.8 | |

| Second thinning | Myrtillus type (1) | 81 | 446.6 | 56.6 | 10.0 | 2.4 | 80.3 | 17.6 |

| Vaccinium type (1) | 89 | 467.2 | 53.8 | 10.2 | 1.9 | 84.8 | 14.9 | |

| Calluna type (1) | 27 | 513.3 | 64.8 | 11.7 | 1.6 | 94.5 | 14.1 | |

| Dwarf-shrub transformed type (1) | 22 | 519.2 | 49.5 | 11.3 | 1.5 | 96.2 | 10.0 | |

| Final felling | Myrtillus type (2) | 277 | 455.4 | 60.9 | 10.1 | 2.5 | 81.8 | 17.8 |

| Stand Type | Stem Part | N | Density (kg/m³) | Std. Dev. (kg/m³) | MOE (GPa) | Std. Dev. (GPa) | MOR (MPa) | Std. Dev. (MPa) |

|---|---|---|---|---|---|---|---|---|

| First thinning | 0–4 m (Butt log) | 26 | 411.8 | 30.4 | 7.7 | 1.4 | 65.8 | 9.0 |

| 4–8 m (Middle log) | 14 | 408.1 | 29.4 | 7.9 | 1.4 | 66.4 | 8.6 | |

| Second thinning | 0–4 m (Butt log) | 26 | 482.3 | 68.4 | 11.5 | 2.8 | 91.9 | 20.7 |

| 4–8 m (Middle log) | 24 | 439.1 | 46.5 | 10.0 | 2.2 | 78.9 | 15.1 | |

| >8 m (Top log) | 31 | 422.6 | 35.2 | 8.9 | 1.5 | 71.7 | 10.0 | |

| Final felling | 0–4 m (Butt log) | 70 | 491.0 | 83.5 | 11.2 | 3.1 | 90.7 | 24.1 |

| 4–8 m (Middle log) | 64 | 450.4 | 60.4 | 10.3 | 2.7 | 82.7 | 18.2 | |

| >8 m (Top log) | 143 | 440.2 | 36.6 | 9.4 | 1.8 | 77.1 | 11.4 |

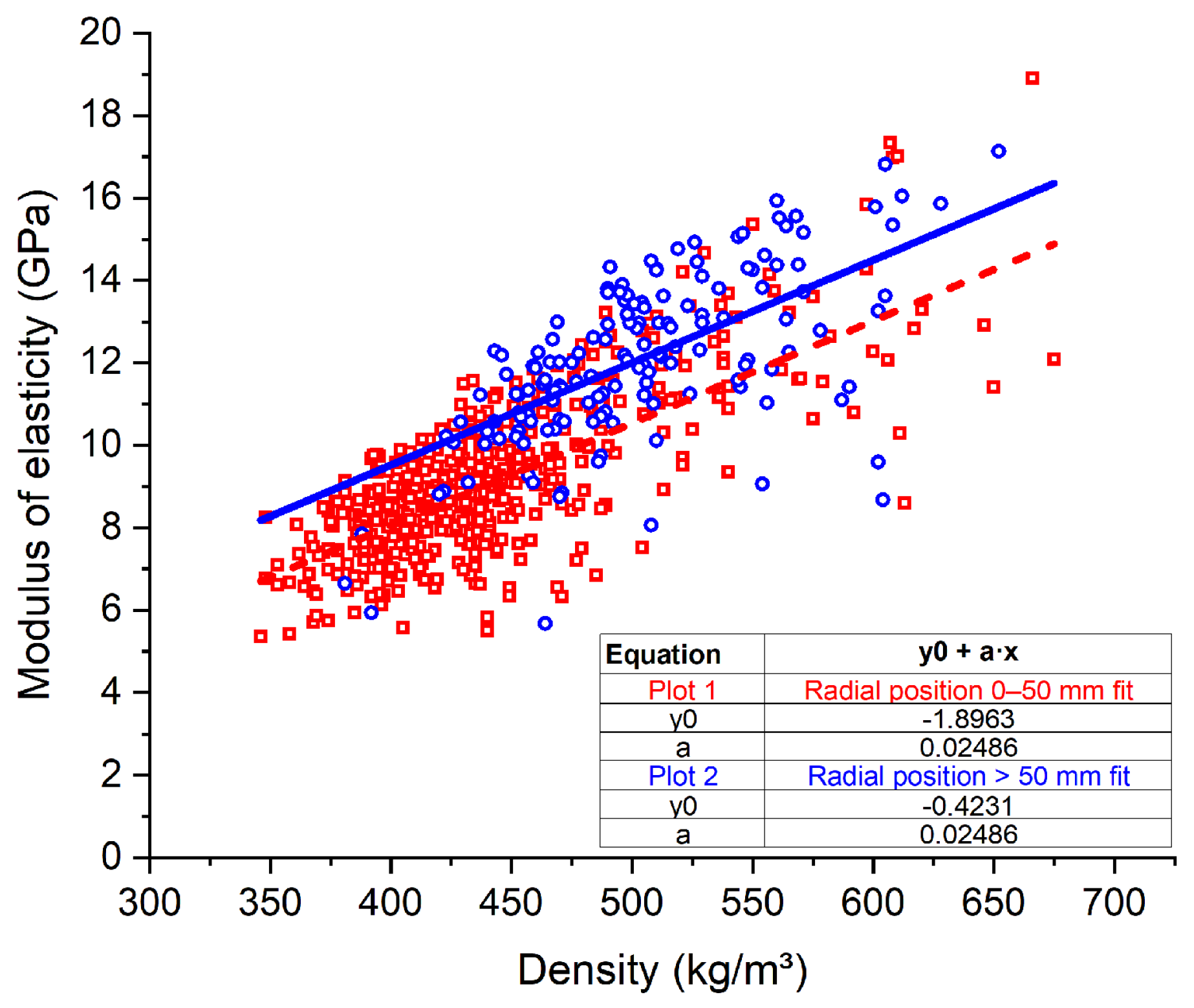

| Variable | Estimate | Std. Error | t-Value | Sig. |

|---|---|---|---|---|

| Intercept | −1.896 | 0.4799 | −3.951 | <0.001 |

| Density | 0.025 | 0.0010 | 24.289 | <0.001 |

| Radial position > 50 mm | 1.473 | 0.1379 | 10.680 | <0.001 |

| Random Effect | Estimate | |||

| Stand | 0.120 | |||

| Tree | 0.586 | |||

| Residual | 1.270 | |||

| Fitting Statistics | ||||

| R² | 66.3% | |||

| Bias | 0.08 (0.86%) | |||

| RMSE | 1.35 (13.7%) |

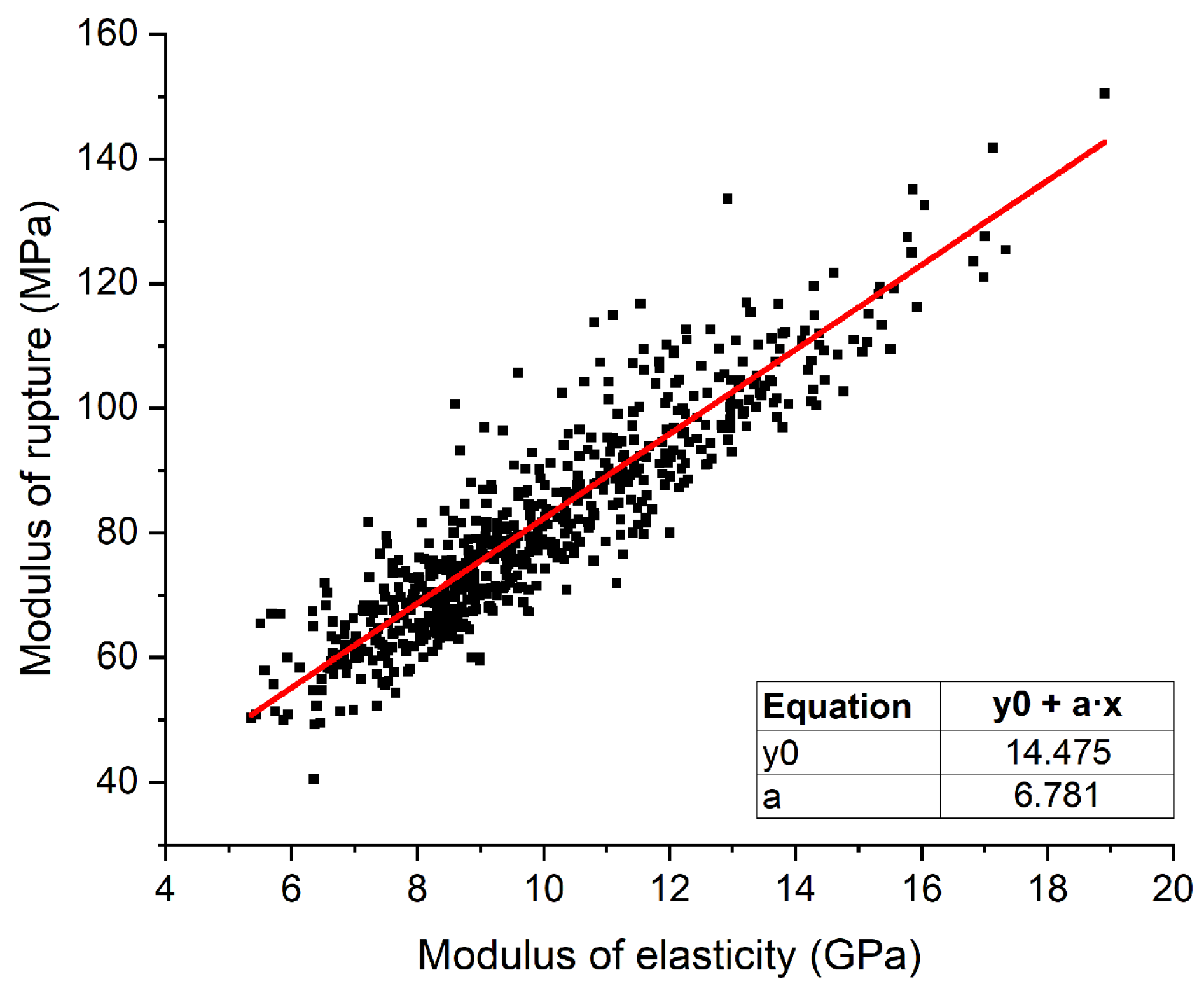

| Equation (4) | Equation (5) | |||||||

|---|---|---|---|---|---|---|---|---|

| Variable | Estimate | Std. Error | t-Value | Sig. | Estimate | Std. Error | t-Value | Sig. |

| Intercept | −29.126 | 2.4675 | −11.804 | <0.001 | 14.475 | 1.3169 | 10.992 | <0.001 |

| Density | 0.237 | 0.0053 | 44.560 | <0.001 | ||||

| Radial position > 50 mm | 5.759 | 0.7289 | 7.901 | <0.001 | ||||

| MOE | 6.781 | 0.1189 | 57.009 | <0.001 | ||||

| Random Effect | Estimate | Estimate | ||||||

| Stand | 2.852 | 2.067 | ||||||

| Tree | 7.087 | 11.106 | ||||||

| Residual | 37.324 | 37.989 | ||||||

| Fitting Statistics | ||||||||

| R² | 84.6% | 83.3% | ||||||

| Bias | 0.58 (0.7%) | –0.46 (–0.6%) | ||||||

| RMSE | 6.72 (8.3%) | 7.01 (8.6%) | ||||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Stöd, R.; Marttila, J.; Tomppo, L.; Haapala, A.; Verkasalo, E. Modulus of Elasticity and Bending Strength of Scots Pine (Pinus sylvestris L.) Wood from Commercial Thinnings. Forests 2024, 15, 567. https://doi.org/10.3390/f15030567

Stöd R, Marttila J, Tomppo L, Haapala A, Verkasalo E. Modulus of Elasticity and Bending Strength of Scots Pine (Pinus sylvestris L.) Wood from Commercial Thinnings. Forests. 2024; 15(3):567. https://doi.org/10.3390/f15030567

Chicago/Turabian StyleStöd, Reeta, Juhani Marttila, Laura Tomppo, Antti Haapala, and Erkki Verkasalo. 2024. "Modulus of Elasticity and Bending Strength of Scots Pine (Pinus sylvestris L.) Wood from Commercial Thinnings" Forests 15, no. 3: 567. https://doi.org/10.3390/f15030567

APA StyleStöd, R., Marttila, J., Tomppo, L., Haapala, A., & Verkasalo, E. (2024). Modulus of Elasticity and Bending Strength of Scots Pine (Pinus sylvestris L.) Wood from Commercial Thinnings. Forests, 15(3), 567. https://doi.org/10.3390/f15030567