Abstract

In this study, biodegradable bamboo fiber/PLA composites (BPCs) modified using bamboo charcoal (BC)/ZnO were prepared. The effects of BC/ZnO addition on the mechanical properties and antibacterial properties of BPCs were investigated. The chemical structure, microscopic morphology, and crystallization of the composites were analyzed using FTIR, SEM, and XRD, respectively. The results showed that in terms of mechanical strength, when the addition of BC was 2%, the tensile impact and flexural strength of the BPCs were most obviously improved, with a tensile strength of 51.6 MPa. However, when the addition of BC was more than 2%, the uneven dispersion of too much BC in the BPCs resulted in a reduction in their mechanical strength. A certain amount of ZnO did not affect the crystallinity of the BPCs. In addition, the uneven distribution of ZnO and its poor compatibility with PLA resulted in a deterioration in the tensile properties of the BPCs. In terms of antibacterial properties, when 2% ZnO was added, the BPCs had better antibacterial properties against Escherichia coli and Staphylococcus aureus, with values of 58.9% and 52.5% against both, respectively. BPC biodegradable materials with both mechanical strength and antimicrobial properties have promising medical uses.

1. Introduction

Sustainable development is a global concern. Over recent decades, the use of petroleum-based products has accelerated due to their low manufacturing cost, corrosion resistance, and exceptional special mechanical properties [1,2]. This has also triggered a series of environmental problems, such as climate warming and white goods waste, threatening both humans and living organisms [3]. As a solution to these problems, the development and use of eco-materials, such as natural fibers or other biodegradable materials, is essential to achieving sustainable development [4,5]. Bamboo–plastic composites (BPCs) are composite materials that combines bamboo and its processing residues with plastics. They are known for their commendable mechanical properties, superior weather resistance, dimensional stability, and eco-friendly nature [6,7]. BPCs are widely used in outdoor construction, transportation, and decorative applications [8,9], and are a possibly environmentally sustainable alternative.

Polylactic acid (PLA) is a bio-based biodegradable that is synthesized through the ring-opening polymerization of propylene glycol ester. It presents an eco-friendly alternative to traditional petroleum-based plastics. Although PLA offers a notable tensile strength, high modulus, and biodegradability [10,11], its inherent deficiencies, such as brittleness, diminished toughness, and high production cost, limit its broad application [12,13]. Bamboo charcoal is a solid pyrolysis by-product obtained from bamboo or bamboo processing residues under conditions of high temperature and deficient atmosphere. Due to its developed porosity and large surface area, researchers have reported that bamboo charcoal has the potential to strengthen and toughen biocomposites. The efforts to improve the mechanical properties of PLA have focused on increasing its crystallinity by introducing inorganic fillers, such as montmorillonite, carbon nanotubes, and bamboo charcoal [14]. Guo et al. [14] examined the effect of the bamboo charcoal (BC) content on the properties of PLA/BC composites and found that the careful addition of BC improved both the mechanical properties and hydrophobicity. D’Urso et al. [15] investigated melt stabilization using high-surface-area graphite and carbon black. The results showed that adding only 0.1 wt. % of the CB maintained the molecular weight of PLA during the melting process. In recent years, several studies have focused on modified composites from PLA and bamboo fiber, with composite ratios typically ranging from 2:8 to 4:6 [16,17,18]. However, little attention has been given to the high proportion of composites made of BC-modified PLA with an excess of bamboo fiber, which have the potential to improve the utilization of bamboo processing residues and reduce the product costs.

Although BPC products have advantages, they face challenges from microbial exposure during installation and usage, with antibacterial performance being a key concern. Bamboo’s inherent nutrient-rich composition makes it susceptible to mold growth, which can impact both its appearance and functionality [19,20]. This constituent facilitates mold growth in specific environments, making the products highly susceptible to mold contamination. Extensive research has been conducted on bamboo’s susceptibility to mold. However, this research has primarily focused on the bamboo itself [21,22]. It is important to note that the BPC materials, which are commonly used for structural and ornamental purposes, are also susceptible to contamination by other bacteria commonly found in their environment, including pathogens such as Escherichia coli (E. coli) [23] and Staphylococcus aureus (S. aureus) [24]. Inorganic nano-antibacterial agents, such as silicon dioxide (SiO2) [25], zinc/copper oxide (ZnO/CuO) [26], and nano zinc oxide (ZnO) [27], have shown promise in various applications. ZnO is known for its bacterial resistance at lower concentrations, non-toxicity, and thermal stability. For instance, PLA/ZnO nanocomposite-coated paper has been used for antibacterial packaging [28]. Guan et al. [29] investigated the antibacterial properties of ZnO/CuO nanoparticle bio-polymerized films against various pathogens. The study showed significant growth inhibition in both dark and light conditions. Therefore, it is important to explore the antibacterial properties of BPCs to ensure their widespread and sustainable use in diverse applications.

This research aims to improve the mechanical performance of BPCs by incorporating BC and ZnO while studying their antibacterial effects. BPC composites were prepared with varying concentrations of BC and ZnO. The structural, interfacial, and surface properties of the composites were analyzed using Fourier transform infrared spectroscopy (FTIR) and field emission scanning electron microscopy (FE-SEM). The crystallization propensity of the composites under the influence of BC and ZnO was examined using X-ray diffraction (XRD) analysis, and their mechanical strengths were evaluated. The antibacterial efficacy against E. coli and S. aureus was evaluated via a 24 h incubation test. This study presents a thorough evaluation of the mechanical and antibacterial properties of BPC biodegradable materials, providing fundamental datas for their broader adoption in various applications.

2. Materials and Methods

2.1. Materials

Bamboo fiber was purchased from Jiangxi Shuangshuang Machinery Manufacturing Co. Ltd. (Yichun, China). Polylactic acid (PLA) (ρ = 1.25 g/cm3, 4032D) was purchased from Nature Works Co. Ltd. (Plymouth, CA, USA). Bamboo charcoal (BC, 200 mesh) was purchased from Changsha House of Bamboo Charcoal Co. Ltd. (Changsha, China). Zinc oxide (ZnO, AR, 99%) was purchased from Shanghai Yuanye Bio-Technology Co. Ltd. (Shanghai, China). Anhydrous ethanol (AR, ≥99.7%) was purchased from Nanjing Chemical Reagent Co. Ltd. (Nanjing, China). Staphylococcus aureus (S. aureus) and Escherichia coli (E. coli) were obtained from laboratory culture strains. Beef and yeast pastes, peptone, and tryptone were purchased from Beijing Solarbio Technology Co. Ltd. (Beijing, China). The PLA and bamboo fibers were vacuum-dried at 103 °C until they reached an absolute constant weight and stored in dry containers before use.

2.2. Preparation of Bamboo Fiber Complexes

First, different amounts of ZnO or BC were ultrasonically dispersed in anhydrous ethanol at a mass ratio of 1:10; then, the mixture was blended with bamboo fiber and dried at 80 °C to prepare the bamboo fiber complexes. (Anhydrous ethanol was used to disperse the bamboo charcoal and ZnO and to maintain the water content of the bamboo fiber.) Detailed material composition ratios are shown in Table 1.

Table 1.

Composition of BPC (mass percentage, %).

2.3. Preparation of BPC

The bamboo fiber complex was thoroughly mixed with PLA at 160 °C for 8 min using a double-roller open mill (ZG-160, Dongguan Zheng Xin Electromechanical Science and Technology Ltd. Dongguan, China). The diameter of the rollers was 100 mm, the distance between the two rollers was 8 mm, and the rotational speed was 10 rpm. The blends were then compression-molded at 160 °C for 3 min to prepare the BPCs. The specifications for the hollow rectangular frame mold were 200 mm × 200 mm × 4 mm. The samples were prepared for the further evaluation of their mechanical and antibacterial properties.

2.4. Preparation of Culture Medium

The preparation of nutrient agar (NA) medium: First, 3.00 g of beef paste, 10.00 g of peptone, 5.00 g of sodium chloride, and 20.00 g of agar fiber were dissolved in 1000 mL of deionized water using a mechanical stirrer to obtain a well-distributed solution. Then, the pH of solution the was adjusted to 7.4–7.6 (±1); after this, the solution was divided into 250 mL triangular vials, and they were sealed with aseptic film. The solution was then sterilized at 121 °C for 20 min and then cooled to 60 °C. Finally, the solution was added to Petri dishes (90 mm in diameter), with a filling of one third of the dish thickness.

The preparation of Luria–Bertani (LB) medium: First, 5.00 g of yeast paste, 10.00 g of tryptone, 10.00 g of sodium chloride, and 15.00 g of agar fiber were dissolved in 1000 mL of deionized water using a mechanical stirrer to obtain a well-distributed solution. Then, the pH of the solution was adjusted to 7.0–7.2 (±1). The solution then underwent the same sterilization and packaging procedure as the NA medium.

2.5. Characterization

2.5.1. Conformal Testing of BPCs

The Fourier transform infrared (FTIR) spectra of the BPCs were obtained using a VERTEX 80 infrared spectrometer instrument (Bruker, Germany). The spectra of the samples were recorded in the range of 4000–400 cm−1 with a resolution of 0.5 cm−1 and scanned 32 times. FE-SEM (QUANTA 200, FEI, Peabody, MA, USA) coupled with EDS energy spectroscopy was used to investigate the cross-sectional microscopic structure (the cross section of the samples was prepared using liquid nitrogen) and element distribution of the BPCs. In addition, X-ray diffraction (XRD) was performed to investigate the effect of BC and ZnO on the crystallization capacity of PLA within the BPC matrix. The scanning range was from 5 to 90 degrees, and the scanning speed was 0.02 degrees per second.

2.5.2. Mechanical Properties Testing of BPCs

The tensile properties of the BPCs were evaluated using a versatile electronic testing machine (CMT6104, Shenzhen Xinsansi Material Testing Co, Ltd. Shenzhen, China). The tensile specimen size was 50 mm × 10 mm × 4 mm according to GB/T 1040-92 and the crosshead speed was set to 5 mm/min. The bending performance of the BPCs was tested according to GB/T 1449–2005 with a specimen size of 50 mm × 10 mm × 4 mm and a crosshead speed of 5 mm/min. The impact strength of the BPCs was tested in accordance with GB/T1451-2005 using a Charpy impact machine (ZBC1251-1, Shenzhen Xinsansi Material Testing Co., Ltd. Shenzhen, China). The impact specimen size was 80 mm × 10 mm × 4 mm. All the tests were repeated six times in parallel.

2.5.3. Antibacterial Performance Testing of BPCs

The antibacterial efficacy of the BPCs was evaluated according to JIS Z 2801-2010. First, the BPC, BPC/BC/ZnO-2, and BPC/BC/ZnO-3 samples with a sample size of 10 mm × 10 mm × 4 mm were subjected to high-temperature steam sterilization at 121 °C for 30 min using an applicator rod, forceps, and reagent gun. After sterilization, each plate culture medium received an injection of 100 μL of an S. aureus bacterial solution, which was evenly distributed using a spreading rod. Five plates were set up for each sample, with a piece of BPC placed in the center of each set of plates. The procedure for E. coli was identical to that described above. The plates were then sealed with aseptic film and incubated in a constant temperature, constant humidity chamber at 37 °C for 24 h to determine the antibacterial effect. The antibacterial diameter was measured to evaluate the effect of each sample against S. aureus and E. coli. The untreated BPC served as the control group for antibacterial evaluation, and the antibacterial efficacy of each sample against the bacteria was calculated using Formula (1).

In the equation, R represents the antibacterial rate of the BPCs against S. aureus and E. coli in %, d0 represents the antibacterial diameter of the BPCs in mm, and d1 represents the antibacterial diameter of BPC/BC/ZnO-2 and BPC/BC/ZnO-3 in mm.

3. Results and Analysis

3.1. Performance Analysis of BPC

3.1.1. FTIR Analysis

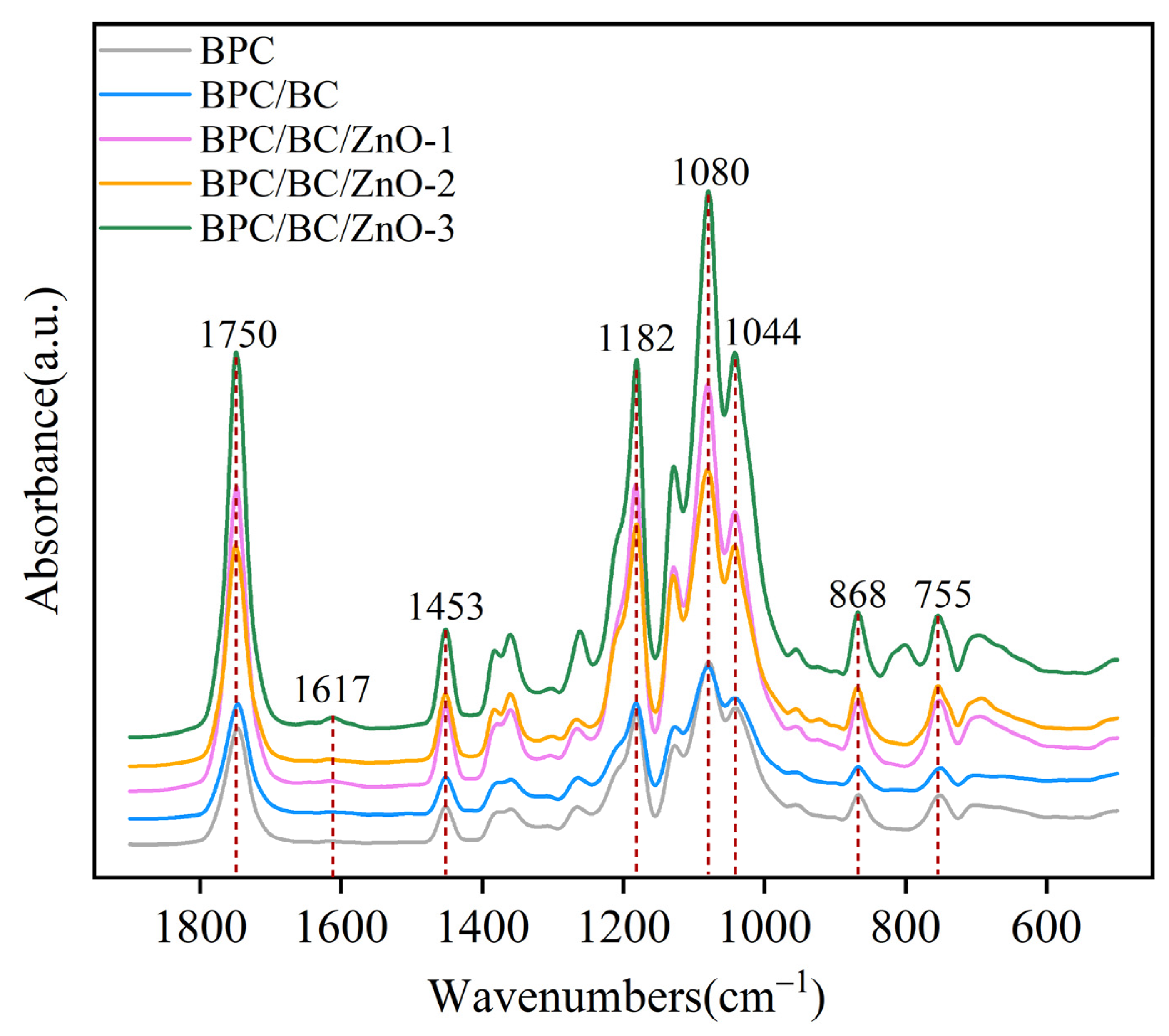

FTIR is commonly used to study the intermolecular interactions and phase behavior of polymers.

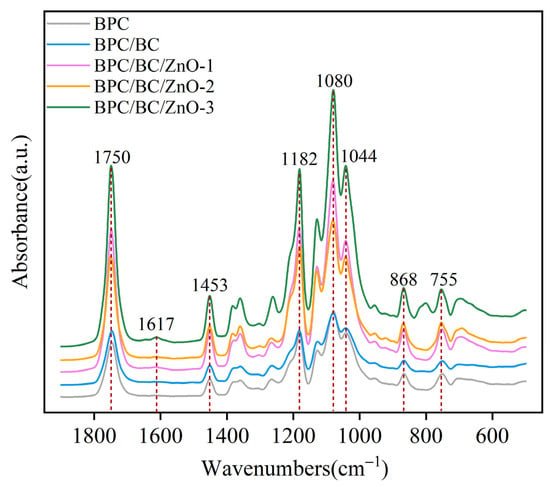

In this study, the interaction between PLA, BC, and ZnO was investigated using FTIR spectroscopy. Figure 1 shows the FTIR spectra of the BPC thermally blended with 1 wt. %, 2 wt. %, and 3 wt. % BC/ZnO composites and a comparison with the FTIR spectra of the BPC and BPC/BC. In Figure 1, the BPC sample modified with BC and ZnO showed no shift in the position of its absorption peak in the absorption range of 1900–500 cm−1, indicating that BC and ZnO did not interact at the molecular level with the structure of the functional groups of cellulose, hemicellulose, lignin, and other components in the BPC [13]. Compared with the unmodified BPC samples, there was only a difference in the absorption intensity. Among them, the absorption peaks of the BPCs at 1750 cm−1 and 1080 cm−1 were attributed to the asymmetric stretching vibration of the C-O-C ester bond [30], while the absorption peak at 1182 cm−1 was attributed to the symmetric stretching vibration of the C=O bond [31]; the absorption peak at 1453 cm−1 was generated by the stretching vibration of the C-H bond; and the absorption peak at 1044 cm−1 was attributed to a C-CH3 stretching vibration peak [32]. The intensity of the absorption peaks of BPC/BC/ZnO all increased to a greater extent when ZnO was introduced, which was attributed to the accelerated thermal degradation of PLA by ZnO during the thermal blending of PLA at a high temperature to form Zn salts and zinc lactate of the PLA oligomers [31]. The absorption peaks at 868 cm−1 and 755 cm−1 indicate the presence of zinc lactate. A degraded PLA matrix could lead to tighter adhesion between the PLA and bamboo fibers and BC with more interfacial strength [33].

Figure 1.

Comparison of FTIR spectra with different BC/ZnO addition ratios.

3.1.2. FE-SEM Analysis

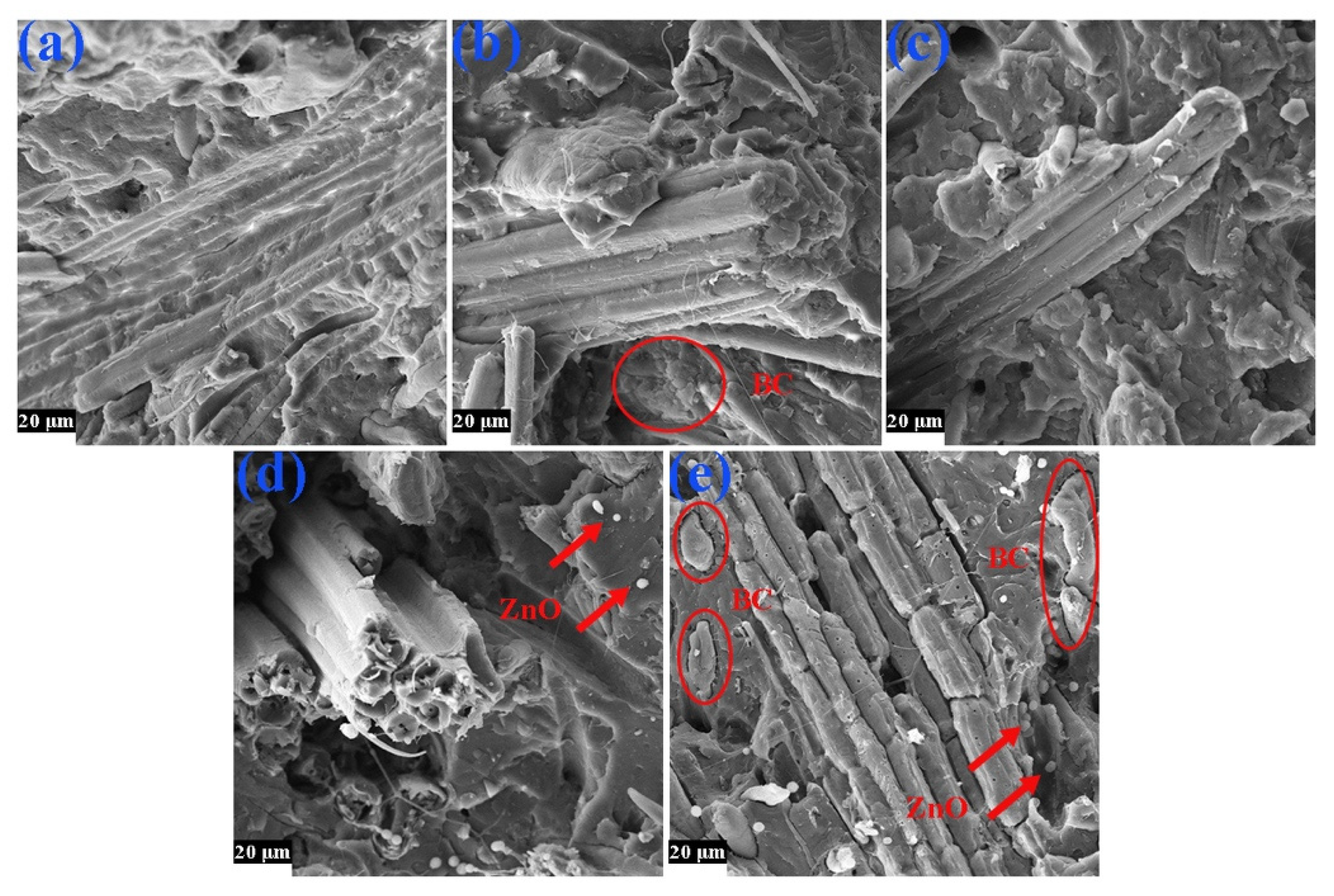

As a typical bio-based material, PLA is known for its degradability. With abundant ester bonds on its molecular structure, PLA exhibits a hydrophobic characteristic. Conversely, bamboo fiber is a hydrophilic natural biomass material. When combining the hydrophilic bamboo fiber with the hydrophobic PLA, interventions, such as surface treatment, blending strategies, or the addition of modifiers, are imperative to improve their compatibility [34,35]. In this study, a concerted approach involving surface treatment, blending techniques, and modifier incorporation was employed to enhance the compatibility of PLA with the bamboo fiber. Specifically, high-temperature thermal blending coupled with the BC modifier was employed to enhance the compatibility of PLA and the bamboo fiber.

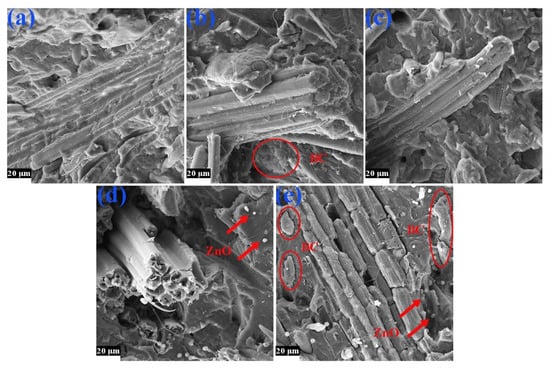

Figure 2 shows SEM images of the brittle surfaces of the BPC, BPC/BC, BPC/BC/ZnO-1, BPC/BC/ZnO-2, and BPC/BC/ZnO-3. In the structure of composites, bamboo fiber in an axial fibrous shape acts as a similar steel bar reinforcing the PLA matrix. There are more or less holes left by the “pulling out” of bamboo fiber from the matrix. In Figure 2a, the BPC shows inadequate adsorption of PLA on the surface of bamboo fiber due to the inherent poor compatibility between the hydrophobic PLA and the hydrophilic bamboo fiber. The addition of BC reduced the flow of melted PLA and even conducted the PLA molecular chains into their pores; thus, in Figure 2b–e, there are wire-drawing phenomena in the structure. Conversely, for BPC/BC/ZnO-2, as shown in Figure 2b, there is a significant improvement in the amalgamation between the PLA and bamboo fibers, and no noticeable cracks were observed, indicating tighter integration between the two phases. However, with the increasing addition of ZnO into BPC/BC from 1% to 3%, the agglomeration of bamboo fibers in BPC/BC/ZnO-3 became noticeable, as shown in Figure 2e. This phenomenon can be attributed to two factors: first, the introduction of BC reduceed the fluidity of molten BPC to a certain extent, which prevents the complete dispersion of ZnO particles between the bamboo fibers and PLA during blending; second, the inherent pro-adhesive property of ZnO hindered its dispersion among the bamboo fiber particles [36]. As a result, the ZnO particles remain incompletely dispersed in the blends.

Figure 2.

FE-SEM images of surface morphologies of different BPC materials: (a) BPC; (b) BPC/BC; (c) BPC/BC/ZnO-1; (d) BPC/BC/ZnO-2; and (e) BPC/BC/ZnO-3.

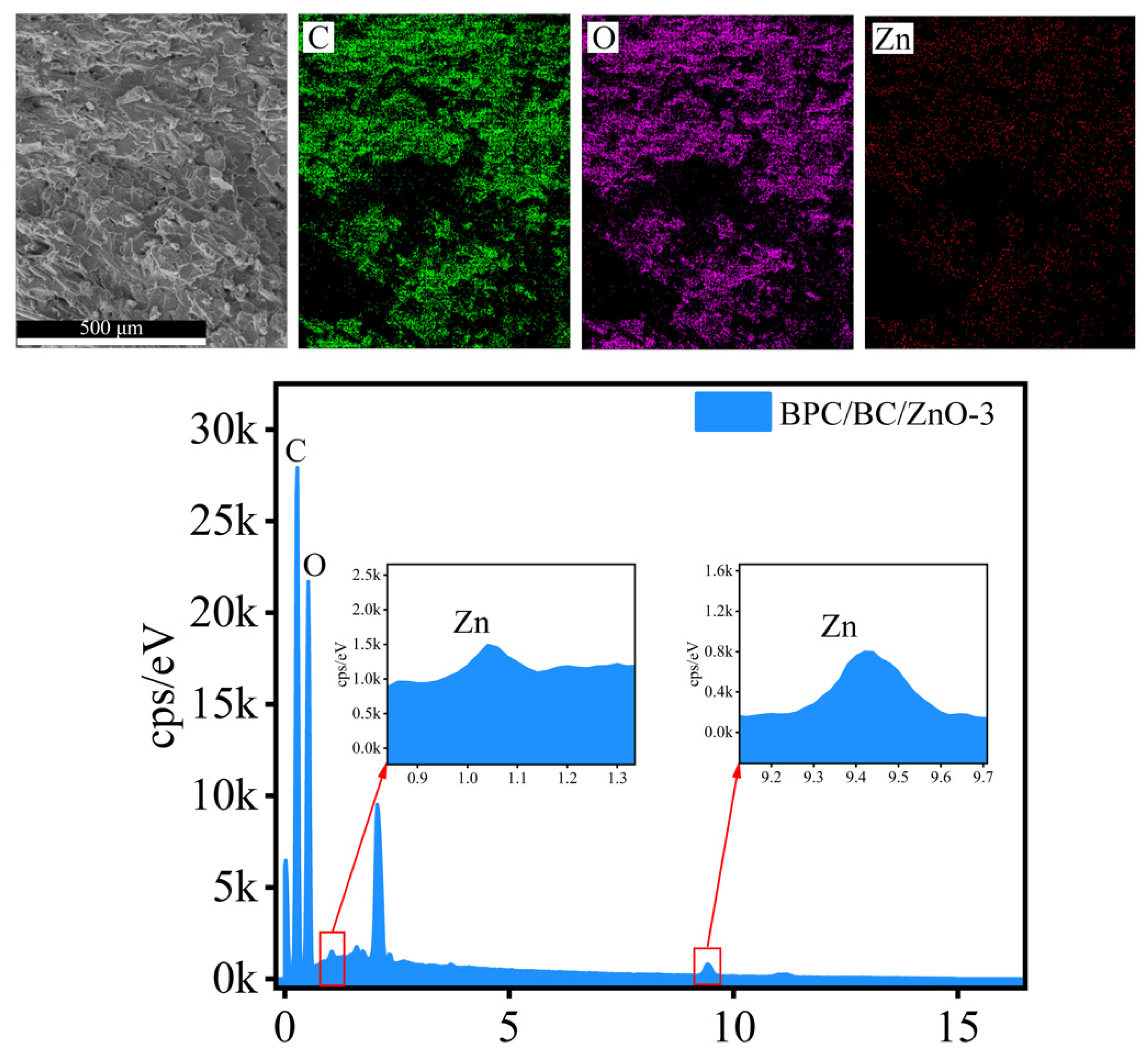

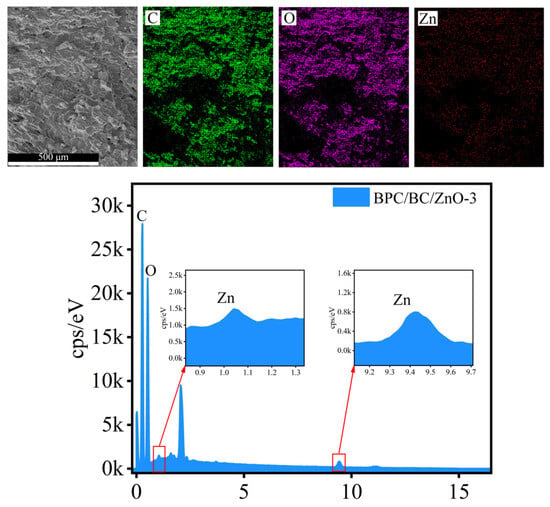

Figure 3 shows the EDS images of BPC/BC/ZnO-3. From Figure 3 (BPC/BC/ZnO-3), an uneven distribution of C, O, and Zn elements was observed, indicating the non-uniform dispersion of ZnO in the BPC. In addition, the non-uniform dispersed ZnO also promotes the aggregation of bamboo fibers and leads to the uneven distribution of bamboo fibers and PLA.

Figure 3.

EDS diagram of surface element distribution of BPC/BC/ZnO-3 material.

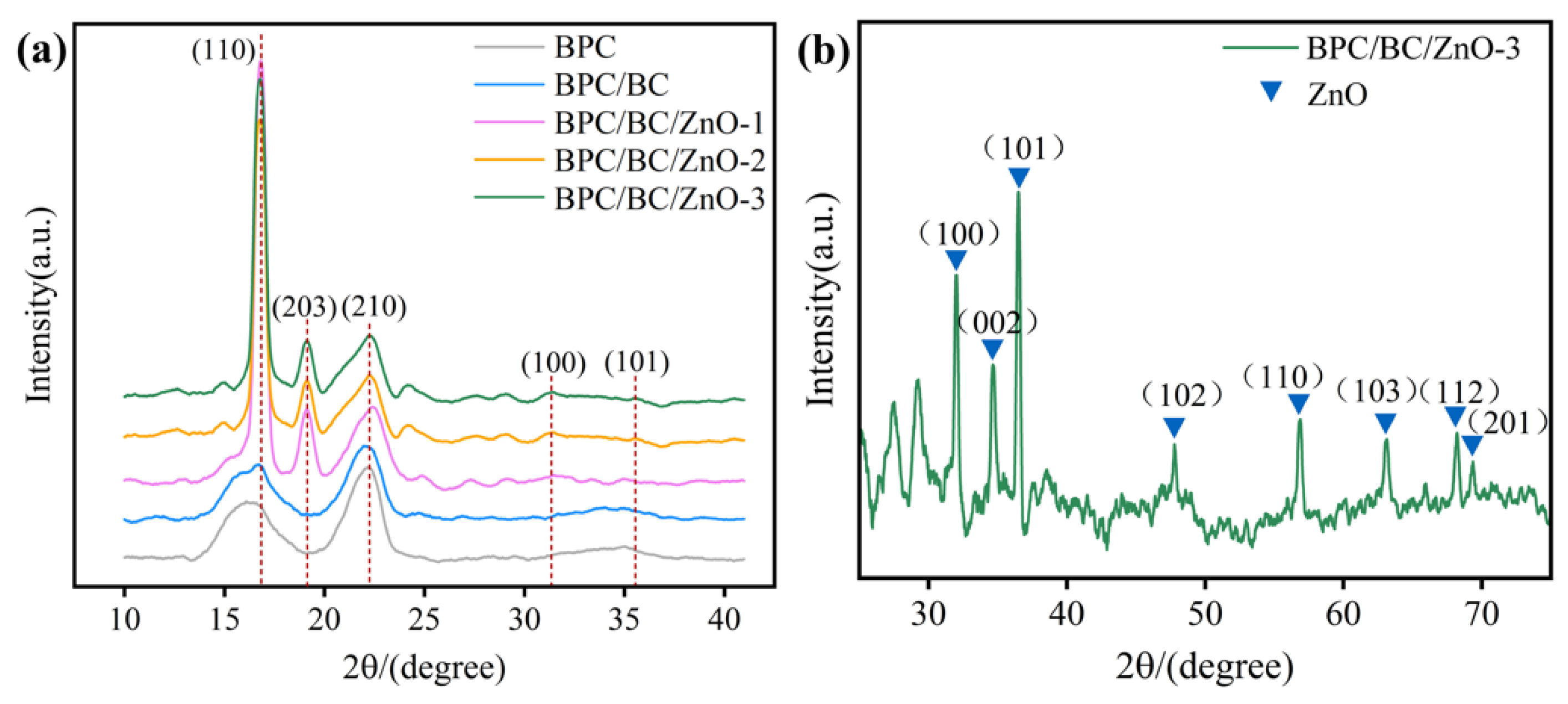

3.1.3. XRD Analysis

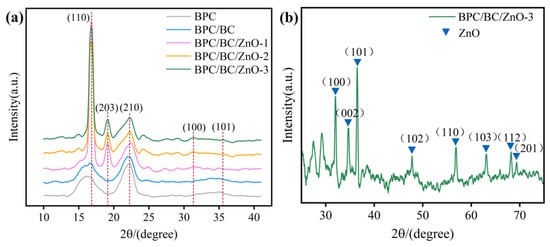

XRD analysis was applied to verify the effect of BC and ZnO addition on the crystallinity of PLA/bamboo fiber, as shown in Figure 4. From Figure 4a, it can be seen that the BPC and BPC/BC show peaks at 2θ = 16.8° and 22.2°, which correspond to the (110) and (210) crystal planes of cellulose I, respectively, indicating the polycrystalline nature of these BPCs [37,38]. Moreover, the incorporation of 2% BC has little effect on the positions of these peaks, with some increase in their intensities, suggesting that BC addition has a limited effect on BPC crystallinity. Then, after the incorporation of 1%–3% ZnO, a significant increase in the intensity of diffraction peaks within the 15–25° range was observed in BPC/BC/ZnO. In particular, a dramatically intense (110) crystallographic plane was observed, accompanied by a decrease in the intensity of the non-crystallized peaks at 15–16°.

Figure 4.

XRD patterns of different BPC materials: (a) BPC, BPC/BC, and BPC/BC with different proportions of ZnO added; (b) BPC/BC/ZnO-3.

In addition, a new diffraction peak appeared at 2θ = 19.1°, which corresponds to the (203) crystallographic plane of the α-type crystalline phase of PLA in BPC/BC/ZnO [37,39]. Notably, the addition of ZnO significantly increased the crystallinity of the BPCs, which greatly enhanced their crystallization capability. Figure 4b shows the XRD spectrum of BPC/BC-3 ZnO, with distinct crystallographic peaks attributed to ZnO, including (100), (002), (101), (102), (110), (103), (112), and (201), indicating the presence of ZnO [40]. The appearance of these characteristic diffraction peaks can be correlated with the chemical change induced by ZnO in the oligomer after high-temperature PLA degradation, leading to the formation of zinc lactate and the corresponding Zn salts, as inferred from the FTIR results.

3.2. Mechanical Property Analysis of BPCs

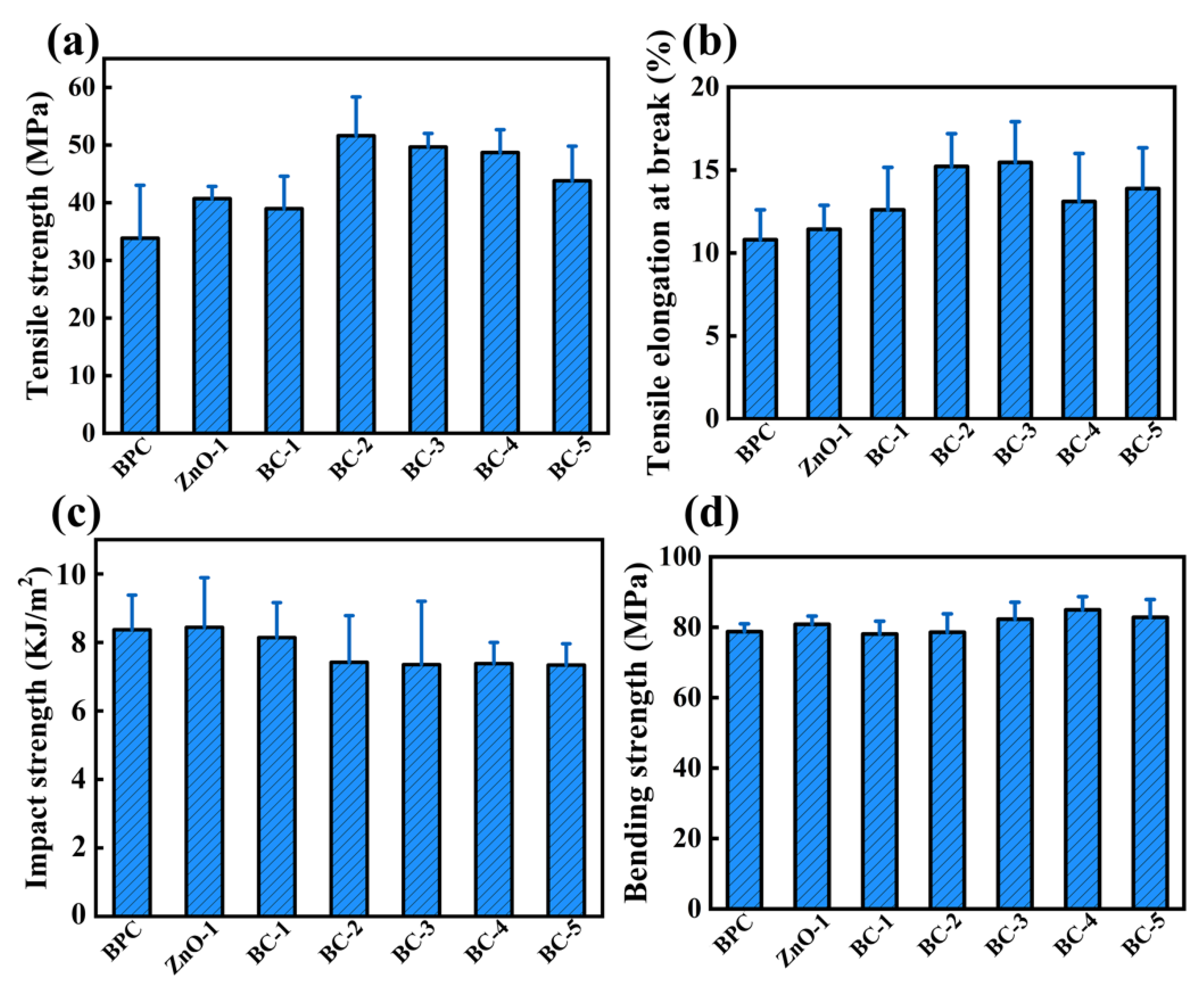

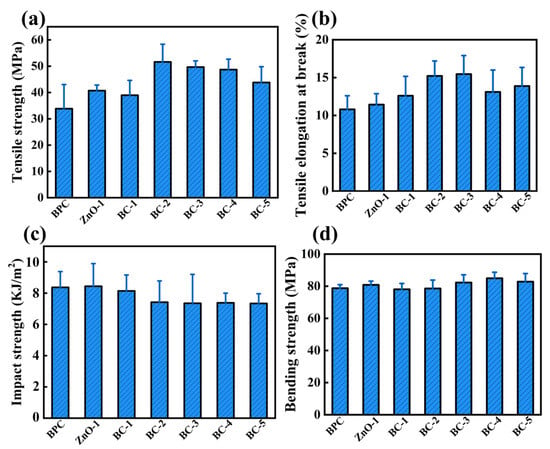

Figure 5 illustrates the effect of different BC additions on the mechanical properties of the BPCs. As shown in Figure 5a, BC significantly enhances the tensile strength and tensile elongation at break of the BPCs, which reaches 33.6 MPa. However, the tensile strength of BPC/BC increases with the addition of BC up to 2% but then decreases with further increases in BC content. When BC was added at a concentration of 2%, BPC/BC-2 exhibited the highest tensile strength of 51.6 MPa, which represents a 53% increase compared to that of the BPC. When the BC content was up to 5%, the tensile strength of BC-5 was still higher than that of BPC. This improvement can be attributed to the high diameter ratio and surface uniformity dispersion of BC, which facilitates heteronuclear interaction with PLA in the BPC. Additionally, BC reduces the grain size of PLA [41], thereby enhancing the tensile properties of the BPCs. It has been reported that BC has a self-lubricating effect [10]; when the BC was added to the BPC, the BC, with the benefit of its self-lubricating effect, would fill the gaps between bamboo fiber and PLA [42]. Furthermore, Porous BC and PLA molecular chains would form a cross-linked structure, when the PLA particle was thoroughly melted, the PLA molecular chains could stretch into the porosity of BC, forming a van der Waals force and mechanical interlocking [43]. The three phases of PLA, bamboo fiber, and bamboo charcoal formed a ternary system. However, if there is too much BC in BPC, the BC will be unevenly dispersed and agglomerated, creating more defects and stress concentration points in BPC, which ultimately reduces its tensile strength as well as tensile elongation at break [14,41]. To analyze the influence of ZnO on BPCs, BPC/BC/ZnO was prepared with the addition of 1% ZnO. The resulting tensile strength of 40.7 MPa was, significantly, 20% higher than that of the pure BPC. This increase is attributed to the strengthening effect of small amounts of rigid ZnO particles that were properly dispersed in the BPC.

Figure 5.

Effect of BC on the mechanical properties of BPC: (a) tensile strength; (b) tensile elongation at break; (c) impact strength; (d) bending strength.

Figure 5c shows the effect of various BC additives on the impact strength of the BPCs. The pure BPC shows an impact strength of 8.4 kJ/m2. After the addition of BC, the impact strength of BPC gradually decreases, and with increasing BC content, the impact strength gradually decreases. For the BPC with 5% BC, the impact strength is 7.3 kJ/m2, which is about 12% less than that of the pure BPC. This decrease in impact strength is probably attributed to the stiffness of BC, which requires less energy to resist impact fracture. However, when an appropriate amount of BC was added, its enhancement of the impact properties of BPC specimens was small. In Figure 5d, the bending strength shows a pattern of initial increase followed by a subsequent decrease with the increasing BC addition, which is consistent with previous findings [10]. From the above results, the BPC with a 2% BC addition exhibits optimum tensile properties and maintains comparable flexural properties with the pure BPC, with a slight decrease in impact properties. Therefore, the BPC with 2% BC content was combined with ZnO to fabricate an antibacterial bamboo–plastic composite for further investigation.

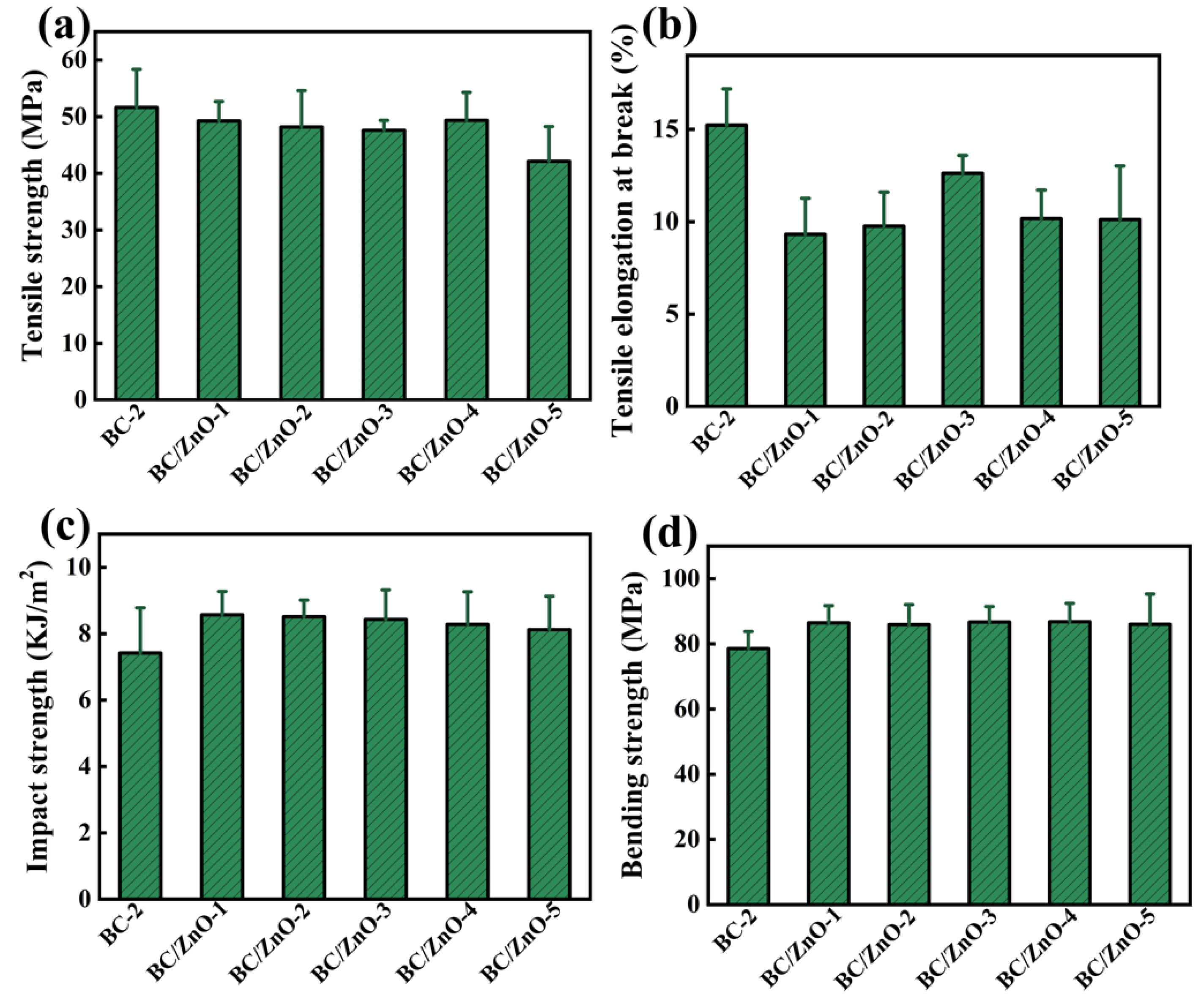

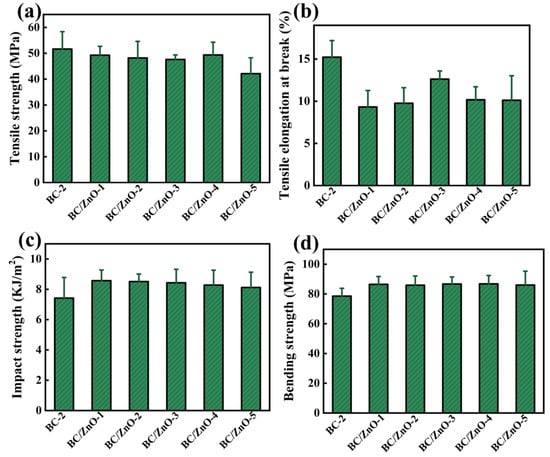

Figure 6 shows the mechanical properties of BPC/BC/ZnO. Figure 6a shows the tensile strengths of the BPCs with different ZnO additions. Initially, the BPC with only 2% BC showed a tensile strength of 51.6 MPa. However, after the introduction of ZnO, BPC/BC/ZnO showed a slight decrease in tensile strength. For example, with 3% ZnO addition, BPC/BC/ZnO-3 exhibited a tensile strength of 47.6 MPa, marking a 7.8% decrease compared to that of the 2% BC specimen, but significantly exceeding the tensile strength of the pure BPC specimen (33.9 MPa). This observed decrease in tensile strength and elongation at break of the BPC specimens upon ZnO addition can be attributed to the poor compatibility between ZnO and the PLA matrix. Under external loading, the significant stiffness difference between ZnO and PLA, along with the bamboo fibers, causes premature debonding near the ZnO interface and hinders stress transfer in the BPCs [42]. This is consistent with the SEM observation results, demonstrating that excessive ZnO exacerbates its inadequate bonding with PLA, thereby reducing the tensile properties.

Figure 6.

Effect of ZnO on the mechanical properties of BPC: (a) tensile strength; (b) tensile elongation at break; (c) impact strength; (d) flexural strength.

Figure 6c,d details the impact and flexural strengths of BPC/BC/ZnO. Upon the introduction of ZnO into BPC with 2% BC, a significant improvement in impact strength was observed, as evidenced by the 8.6 kJ/m2 impact strength and 86.5 MPa flexural strength of BPC/BC/ZnO-1. This improvement can be attribute to the distribution of ZnO within the BPCs, which induces stress concentration under loading conditions, induces yielding in the PLA matrix, and consequently, increases the energy absorption and toughness of the BPCs [44,45].

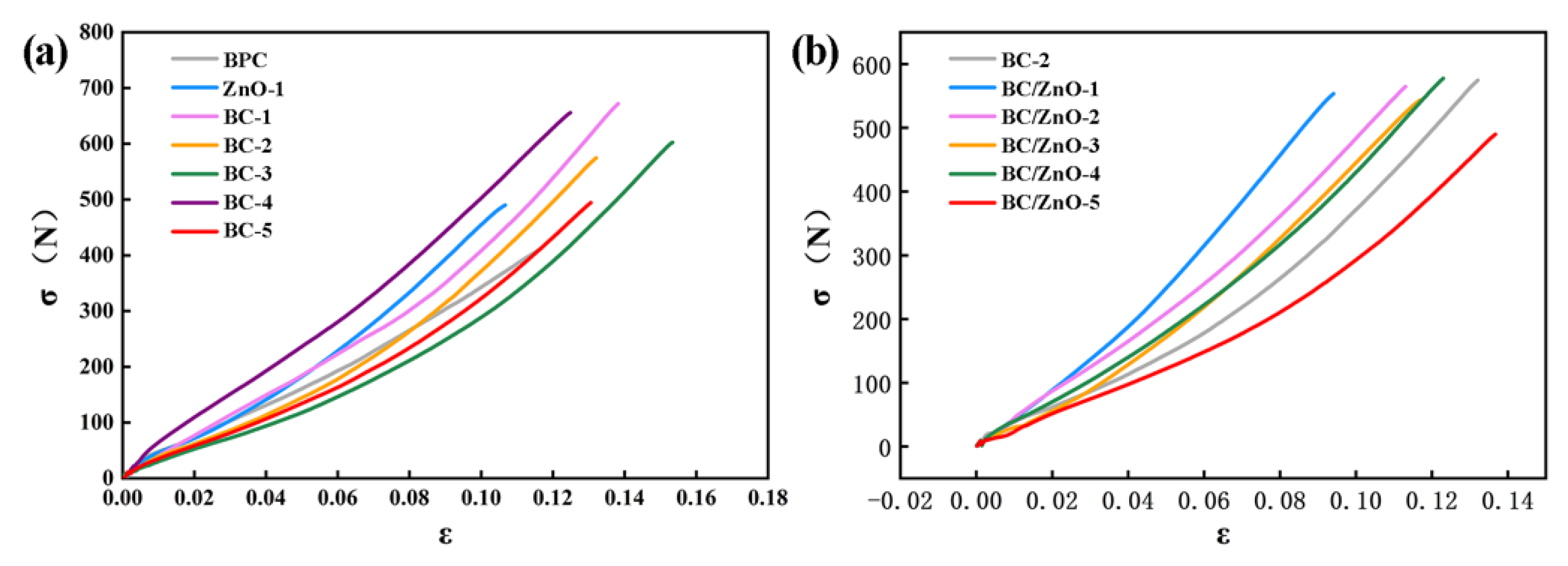

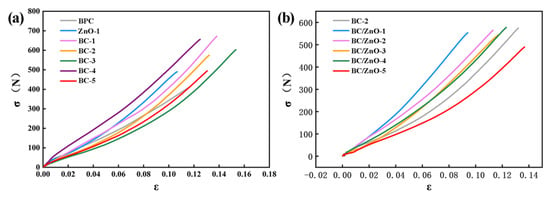

Figure 7 shows a tensile stress–strain curve of the BPC after the sequential addition of BC and ZnO. The stress–strain curves indicate that the BPCs have viscoelastic deformation. In Figure 7a, the stress of the BPC increases with the increase in ε. However, the stress δ does not show an increasing pattern with the increase in the amount of BC but fluctuates within a certain range. In Figure 7b, the stress variation in the BPC is the same as that of the former, which fluctuates within a certain range with the increase in BC/ZnO amount. This variation is consistent with the trend of tensile strength variation in the BPC in Figure 5 and Figure 6.

Figure 7.

Stress–strain curves for the tensile strength of BPC: (a) BPC/BC and (b) BPC/BC/ZnO.

3.3. Analysis of Antibacterial Properties of BPCs

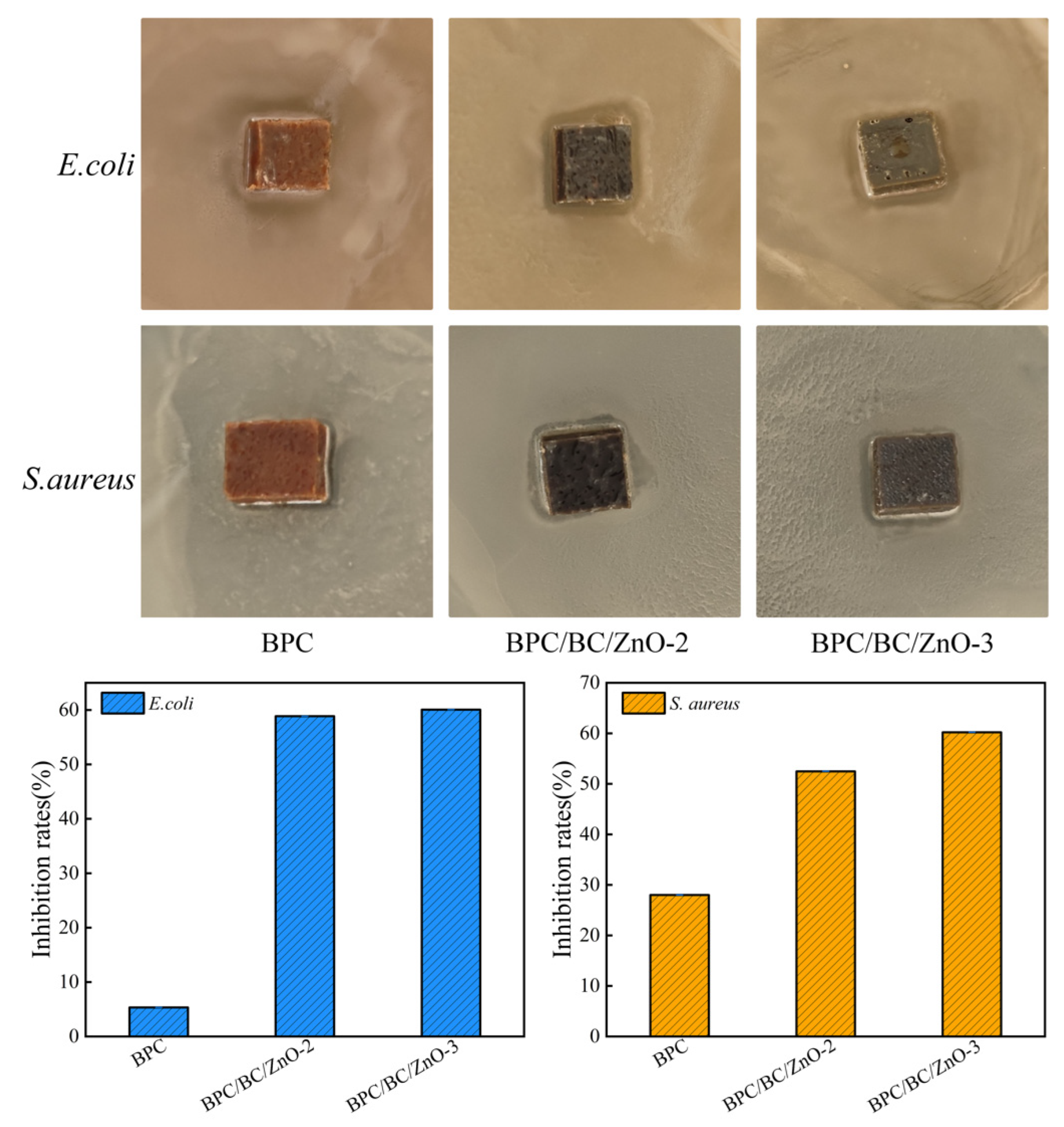

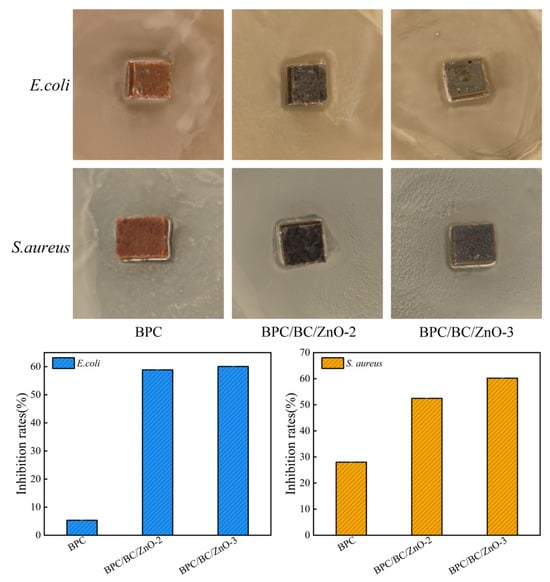

Due to the lack of inherent antibacterial properties in certain natural and synthetic fibers, common pathogenic bacteria, such as E. coli and S. aureus, pose contamination risks to BPC materials in certain environments [46]. Given this susceptibility, it is imperative to evaluate the antibacterial properties of BPC materials to counteract such bacterial contamination. The antibacterial cycle test method was used to evaluate the efficacy of the BPC, BPC/BC/ZnO-2, and BPC/BC/ZnO-3 against E. coli and S. aureus after a 24 h incubation period, and subsequently, antibacterial performance results were obtained.

Figure 8 illustrates the antibacterial effect of BPC, BPC/BC/ZnO-2, and BPC/BC/ZnO-3 on E. coli and S. aureus. Notably, both BPC/BC/ZnO-2 and BPC/BC/ZnO-3 exhibited antibacterial activity against E. coli and S. aureus, as indicated by their effective inhibition zones. Specifically, BPC/BC/ZnO-2 showed inhibition areas of 149.8 mm2 and 116.0 mm2, with inhibition rates of 58.9% and 52.5% against E. coli and S. aureus, respectively. Correspondingly, BPC/BC/ZnO-3 showed areas of 153.4 mm2 and 156.1 mm2, with inhibition rates of 60.1% and 60.2% against E. coli and S. aureus, respectively. In Figure 8, the formation of antibacterial circles by BPC/BC/ZnO-2 and BPC/BC/ZnO-3 around the test zones after 24 h demonstrates their antibacterial activity against both these bacterial strains. However, this efficacy was compromised by several factors, mainly related to the preparation of BPC/BC/ZnO-2 and BPC/BC/ZnO-3.

Figure 8.

The antibacterial efficiencies of BPC, BPC/BC/ZnO-2, and BPC/BC/ZnO-3 against S. aureus and E. coli.

Despite the encapsulation of ZnO in the PLA, bamboo fiber, and BC after blending, the incomplete release of Zn2+ limited the antibacterial effect, even under higher-humidity conditions, thus limiting its effectiveness [47,48]. Notably, the marginal differences in antibacterial efficacy between BPC/BC/ZnO-2 and BPC/BC/ZnO-3, despite the 1% variance in ZnO content, indicate the effect of encapsulation. In addition, the chemical changes observed in PLA and ZnO, as identified by FTIR, may have hindered the functionality of some effective antibacterial ZnO components. In conclusion, while ZnO contents above 2% in BPC/BC showed significant antibacterial effects against E. coli and S. aureus, the antibacterial efficacy remained comparable within the lower addition ranges.

4. Conclusions

The aim of this study was to research the synergistic effect of BC and ZnO on the mechanical and antibacterial properties of BPCs. We investigated the different BC addition ratios on the mechanical strength of BPCs and the reinforcement effect of ZnO on their antibacterial properties at a high bamboo-to-plastic ratio. BPCs synergistically reinforced with BC and ZnO were successfully prepared. The results showed that the mechanical strength of the BPCs was significantly enhanced by the addition of 2% BC, while the introduction of ZnO imparted better antibacterial properties. These reinforced composites not only improve upon the application performance of the conventional BPC material but also show great potential in the field of sustainable and environmentally friendly materials while maintaining good biodegradability. Furthermore, this study provides a new perspective for the functionalization and performance optimization of bio-based composites and promotes research on biodegradable composites.

Author Contributions

Conceptualization, H.H.; data curation, C.L., S.Z. and S.Y.; formal analysis, C.L., S.Z., M.P. and S.Y.; funding acquisition, H.H.; methodology, H.H. and M.P.; project administration, H.H. and M.P.; software, C.L. and S.Y.; supervision, H.H.; writing—original draft, C.L. and S.Z.; writing—review and editing, H.H. and M.P. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Development of Comprehensive Utilization Technology for Philippine Bamboo Processing (20203BDH80W009), the Research and Application Development of Key Technologies for Bamboo Charcoal and Bamboo Leaf Extraction Based on Full Bamboo Utilization (20223BBH80004), the Study on the Preparation of Antibacterial Bamboo Plastic Composite Materials by Bamboo Charcoal Modification ([2020] No.02), and the Development of Functional Bamboo Plastic Multicomponent Composite Materials (2019511501).

Data Availability Statement

Dataset available on request from the corresponding author.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Lee, S.H.; Md Tahir, P.; Osman Al-Edrus, S.S.; Uyup, M.K.A. Bamboo Resources, Trade, and Utilisation. In Multifaceted Bamboo: Engineered Products and Other Applications; Springer: Berlin/Heidelberg, Germany, 2023; pp. 1–14. [Google Scholar]

- Chen, F.; He, Y.; Wei, X.; Han, S.; Ji, J.; Wang, G. Advances in strength and toughness of hierarchical bamboo under humidity and heat. J. For. Eng. 2023, 8, 10–18. (In Chinese) [Google Scholar] [CrossRef]

- Wang, Z.; Zhang, X.; Yao, L.; Zhang, Q. Experimental study and numerical simulation on the macro and micro mechanical properties of bamboo. J. For. Eng. 2022, 7, 31–37. (In Chinese) [Google Scholar] [CrossRef]

- Khalil, H.A.; Bhat, I.; Jawaid, M.; Zaidon, A.; Hermawan, D.; Hadi, Y. Bamboo fibre reinforced biocomposites: A review. Mater. Des. 2012, 42, 353–368. [Google Scholar] [CrossRef]

- Zhang, B. Resource recycling of renewable bamboo material in building field. New Chem. Mater. 2016, 44, 30–32. [Google Scholar]

- Bari, E.; Morrell, J.J.; Sistani, A.; Firoozbehi, F.; Haghdoost, Y.; Najafian, M.; Ghorbani, A. Assessment of physical and mechanical properties of bamboo-plastic composites. Polym. Compos. 2019, 40, 2834–2839. [Google Scholar] [CrossRef]

- Kim, B.J.; Yao, F.; Han, G.; Wu, Q. Performance of bamboo plastic composites with hybrid bamboo and precipitated calcium carbonate fillers. Polym. Compos. 2012, 33, 68–78. [Google Scholar] [CrossRef]

- Sukmawan, R.; Takagi, H.; Nakagaito, A.N. Strength evaluation of cross-ply green composite laminates reinforced by bamboo fiber. Compos. Part B Eng. 2016, 84, 9–16. [Google Scholar] [CrossRef]

- Besi, M.K.S. A review on mechanical properties of bamboo fiber reinforced polymer composite. Aust. J. Basic Appl. Sci. 2013, 7, 247–253. [Google Scholar]

- Qian, S.; Sheng, K.; Yao, W.; Yu, H. Poly (lactic acid) biocomposites reinforced with ultrafine bamboo-char: Morphology, mechanical, thermal, and water absorption properties. J. Appl. Polym. Sci. 2016, 133, 20. [Google Scholar] [CrossRef]

- Wang, N.; Zhang, X.; Ma, X.; Fang, J. Influence of carbon black on the properties of plasticized poly (lactic acid) composites. Polym. Degrad. Stab. 2008, 93, 1044–1052. [Google Scholar] [CrossRef]

- Tan, M.A.; Yeoh, C.K.; Teh, P.L.; Rahim, N.A.A.; Song, C.C.; Voon, C.H. Effect of zinc oxide suspension on the overall filler content of the PLA/ZnO composites and cPLA/ZnO composites. e-Polymers 2023, 23, 20228113. [Google Scholar] [CrossRef]

- Hu, H.; Pan, Z.; Chen, B.; Zhao, Y.; Ren, X. Research progress in bio-based material modification of polylactic acid. Mod. Chem. Res. 2022, 17, 77–80. Available online: https://kns-cnki-net-443.webvpn.zafu.edu.cn/KXReader/Detail?invoice=PL762EnyJbR74A4klCvkztw%2BLvGIHbM10g%2FmBdWx84xHY6DgTAl36xiAOKmb3Z9AHwR3oi7SPwuJlrXJKjcwtMOjTUAAl3nN%2BBcRUEKL9E7SPP4S3BTLbV74v%2FlXvqBhqp9CDDd6yBLnrAeeFAG52BlS7PfvuH52TjfAMN92R%2FY%3D&DBCODE=CJFQ&FileName=ZJTY202217024&TABLEName=cjfdlast2022&nonce=946602D948FA47F28D74AA8FBAE5DBB8&TIMESTAMP=1707807440382&uid= (accessed on 8 February 2024). (In Chinese).

- Guo, J.; Tsou, C.-H.; Yu, Y.; Wu, C.-S.; Zhang, X.; Chen, Z.; Yang, T.; Ge, F.; Liu, P.; Guzman, M.R.D. Conductivity and mechanical properties of carbon black-reinforced poly (lactic acid) (PLA/CB) composites. Iran. Polym. J. 2021, 30, 1251–1262. [Google Scholar] [CrossRef]

- D’Urso, L.; Acocella, M.R.; Guerra, G.; Iozzino, V.; De Santis, F.; Pantani, R. PLA melt stabilization by high-surface-area graphite and carbon black. Polymers 2018, 10, 139. [Google Scholar] [CrossRef]

- Sheng, K.; Zhang, S.; Qian, S.; Lopez, C.A.F. High-toughness PLA/Bamboo cellulose nanowhiskers bionanocomposite strengthened with silylated ultrafine bamboo-char. Compos. Part B Eng. 2019, 165, 174–182. [Google Scholar] [CrossRef]

- Song, X.; Weng, Y.; Zhang, C.; Huang, Z. Study on Modification and Properties of Polylatic Acid/Bamboo Flour Composites. China Plast. 2020, 34, 21–29. (In Chinese) [Google Scholar] [CrossRef]

- Xia, Y.; Lu, Q.; Ge, T.; Ming, L.; Qi, Y. Analysis of factors affecting the properties of polylactic acid bamboo powder composites. Agric. Dev. Equip. 2018, 80–82. Available online: https://kns-cnki-net-443.webvpn.zafu.edu.cn/kcms2/article/abstract?v=BS8_DD2Uwa5Cyh-RL5dsbzVA6to70nrA4ehqybraFONny8cCtt4lD90dx8P0nZp5mAZztowyX0Gv0NDadW4PDbLAbEajziCZhFebOnwClg0nsf6lTrbxjXSS45TPSvcwuSIUTR-XvLuClmN3CQtiA==&uniplatform=NZKPT&language=CHS (accessed on 8 February 2024).

- Tang, X.; Guan, M.; Xu, X.; Yong, C. Effect of ultrasonic-antibacterial paraffin treatment on the antifungal performance of bamboo. J. For. Eng. 2022, 7, 45–51. (In Chinese) [Google Scholar] [CrossRef]

- Yuan, T.; Yin, X.; Huang, Y.; Li, X.; Wang, X.; Chen, L.; Li, Y. Hydrothermal treatment of bamboo and its effect on nano-mechanic and anti-mildew property. J. Clean. Prod. 2022, 380, 135189. [Google Scholar] [CrossRef]

- Yang, K.; Li, X.; Wu, Y.; Zheng, X. A simple, effective and inhibitor-free thermal treatment for enhancing mold-proof property of bamboo scrimber. Eur. J. Wood Wood Prod. 2021, 79, 1049–1055. [Google Scholar] [CrossRef]

- Zhao, Z.; Qin, C.; Piao, X.; Yan, Y.; Cao, Y.; Wang, Z.; Jin, C. Improving the Hydrophobicity, Dimensional Stability and Mold Resistance of Bamboo by Paraffin/Microcrystalline Wax/Stearic Acid Modification. Constr. Build. Mater. 2023, 414, 134902. [Google Scholar] [CrossRef]

- Liu, J.; Huang, J.; Hu, Z.; Li, G.; Hu, L.; Chen, X.; Hu, Y. Chitosan-based films with antioxidant of bamboo leaves and ZnO nanoparticles for application in active food packaging. Int. J. Biol. Macromol. 2021, 189, 363–369. [Google Scholar] [CrossRef]

- Prapruddivongs, C.; Sombatsompop, N. Wood, silver-substituted zeolite and triclosan as biodegradation controllers and antibacterial agents for poly (lactic acid) (PLA) and PLA composites. J. Thermoplast. Compos. Mater. 2017, 30, 583–598. [Google Scholar] [CrossRef]

- Lu, Y.; Chen, Y.; Fan, H.; Peng, B.; Shi, B. A novel nano-SiO2 tannage for making chrome-free leather. In Proceedings of the 32nd Congress of the International Union of Leather Technologists and Chemist Societies, IULTCS 2013, Istanbul, Turkey, 29–31 May 2013; Available online: https://scholar.google.com/scholar?hl=zh-CN&as_sdt=0%2C5&q=A+novel+nano-SiO2+tannage+for+making+chrome-free+leather&btnG= (accessed on 8 February 2024).

- Zhang, H.; Lu, Y.; Zhang, G.; Li, S.; Li, X.; Liu, Y.; Yue, L. Synthesis and antibacterial properties of Ag/Cux O composite material on copper foam. Plat. Finish. 2023, 45, 31–36. [Google Scholar]

- Wang, J.; Li, J.; Zhuang, X.; Pan, X.; Yu, H.; Sun, F.; Song, J.; Jin, C.; Jiang, Y. Improved mould resistance and antibacterial activity of bamboo coated with ZnO/graphene. R. Soc. Open Sci. 2018, 5, 180173. [Google Scholar] [CrossRef]

- Zhang, H.; Hortal, M.; Jordá-Beneyto, M.; Rosa, E.; Lara-Lledo, M.; Lorente, I. ZnO-PLA nanocomposite coated paper for antimicrobial packaging application. LWT 2017, 78, 250–257. [Google Scholar] [CrossRef]

- Guan, G.; Zhang, L.; Zhu, J.; Wu, H.; Li, W.; Sun, Q. Antibacterial properties and mechanism of biopolymer-based films functionalized by CuO/ZnO nanoparticles against Escherichia coli and Staphylococcus aureus. J. Hazard. Mater. 2021, 402, 123542. [Google Scholar] [CrossRef]

- García, N.; Lamanna, M.; D’Accorso, N.; Dufresne, A.; Aranguren, M.; Goyanes, S. Biodegradable materials from grafting of modified PLA onto starch nanocrystals. Polym. Degrad. Stab. 2012, 97, 2021–2026. [Google Scholar] [CrossRef]

- Anžlovar, A.; Kržan, A.; Žagar, E. Degradation of PLA/ZnO and PHBV/ZnO composites prepared by melt processing. Arab. J. Chem. 2018, 11, 343–352. [Google Scholar] [CrossRef]

- Thanki Paragkumar, N.; Edith, D.; Jean-Luc, S. Surface characteristics of PLA and PLGA films. Appl. Surf. Sci. 2006, 253, 2758–2764. [Google Scholar] [CrossRef]

- Ahmadzadeh, Y.; Babaei, A.; Goudarzi, A. Assessment of localization and degradation of ZnO nano-particles in the PLA/PCL biocompatible blend through a comprehensive rheological characterization. Polym. Degrad. Stab. 2018, 158, 136–147. [Google Scholar] [CrossRef]

- Li, W.; He, X.; Zuo, Y.; Wang, S.; Wu, Y. Study on the compatible interface of bamboo fiber/polylactic acid composites by in-situ solid phase grafting. Int. J. Biol. Macromol. 2019, 141, 325–332. [Google Scholar] [CrossRef] [PubMed]

- Qian, S.; Sheng, K. PLA toughened by bamboo cellulose nanowhiskers: Role of silane compatibilization on the PLA bionanocomposite properties. Compos. Sci. Technol. 2017, 148, 59–69. [Google Scholar] [CrossRef]

- Tan, M.A.; Yeoh, C.K.; Teh, P.L.; Rahim, N.A.; Song, C.C.; Mansor, N.S.S.; Lim, J.H. Effect of infill density with ZnO concentration on the mechanical properties of 3D printed PLA/ZnO composites. AIP Conf. Proc. 2022, 2496, 020019. [Google Scholar] [CrossRef]

- Komal, U.K.; Lila, M.K.; Singh, I. PLA/banana fiber based sustainable biocomposites: A manufacturing perspective. Compos. Part B Eng. 2020, 180, 107535. [Google Scholar] [CrossRef]

- Zhang, Y.; Wu, J.; Wang, B.; Sui, X.; Zhong, Y.; Zhang, L.; Mao, Z.; Xu, H. Cellulose nanofibril-reinforced biodegradable polymer composites obtained via a Pickering emulsion approach. Cellulose 2017, 24, 3313–3322. [Google Scholar] [CrossRef]

- Nonato, R.; Mei, L.; Bonse, B.; Chinaglia, E.; Morales, A. Nanocomposites of PLA containing ZnO nanofibers made by solvent cast 3D printing: Production and characterization. Eur. Polym. J. 2019, 114, 271–278. [Google Scholar] [CrossRef]

- Shankar, S.; Wang, L.-F.; Rhim, J.-W. Incorporation of zinc oxide nanoparticles improved the mechanical, water vapor barrier, UV-light barrier, and antibacterial properties of PLA-based nanocomposite films. Mater. Sci. Eng. C 2018, 93, 289–298. [Google Scholar] [CrossRef]

- Ho, M.-P.; Lau, K.-T.; Wang, H.; Hui, D. Improvement on the properties of polylactic acid (PLA) using bamboo charcoal particles. Compos. Part B Eng. 2015, 81, 14–25. [Google Scholar] [CrossRef]

- Lizundia, E.; Penayo, M.C.; Guinault, A.; Vilas, J.L.; Domenek, S. Impact of ZnO nanoparticle morphology on relaxation and transport properties of PLA nanocomposites. Polym. Test. 2019, 75, 175–184. [Google Scholar] [CrossRef]

- Zou, D.; Zheng, X.; Ye, Y.; Yan, D.; Xu, H.; Si, S.; Li, X. Effect of Different Amounts of Bamboo Charcoal on Properties of Biodegradable Bamboo Charcoal/Polylactic Acid Composites. Int. J. Biol. Macromol. 2022, 216, 456–464. [Google Scholar] [CrossRef] [PubMed]

- Jamnongkan, T.; Jaroensuk, O.; Khankhuean, A.; Laobuthee, A.; Srisawat, N.; Pangon, A.; Mongkholrattanasit, R.; Phuengphai, P.; Wattanakornsiri, A.; Huang, C.-F. A Comprehensive evaluation of mechanical, thermal, and antibacterial properties of PLA/ZnO nanoflower biocomposite filaments for 3D printing application. Polymers 2022, 14, 600. [Google Scholar] [CrossRef] [PubMed]

- Wen, T.; Shi, P.; Zhao, T.; Yang, J.; Liu, Y. Properties of nano-ZnO modified PLA/PBS composite and foaming system. Eng. Plast. Appl. 2017, 45, 17–22. [Google Scholar]

- Prang Rocky, B.; Thompson, A.J. Investigation and comparison of antibacterial property of bamboo plants, natural bamboo fibers and commercial bamboo viscose textiles. J. Text. Inst. 2021, 112, 1159–1170. [Google Scholar] [CrossRef]

- Chong, W.J.; Shen, S.; Li, Y.; Trinchi, A.; Simunec, D.P.; Kyratzis, I.L.; Sola, A.; Wen, C. Biodegradable PLA-ZnO nanocomposite biomaterials with antibacterial properties, tissue engineering viability, and enhanced biocompatibility. Smart Mater. Manuf. 2023, 1, 100004. [Google Scholar] [CrossRef]

- Baek, Y.-W.; An, Y.-J. Microbial toxicity of metal oxide nanoparticles (CuO, NiO, ZnO, and Sb2O3) to Escherichia coli, Bacillus subtilis, and Streptococcus aureus. Sci. Total Environ. 2011, 409, 1603–1608. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).