Abstract

Rosin has a great influence on the bonding of Pinus massoniana wood, and surface modification is an important way to solve this problem. In this study, Pinus massoniana wood was treated by plasma, and the effects of plasma treatment on the bonding performance and surface characteristics were investigated. The results showed the following: (1) After plasma treatment, the contact angle of Pinus massoniana wood was significantly reduced and the surface energy was significantly increased from 28.42 × 10−7 to 74.75 × 10−7 J·cm−2, and the surface wettability was also greatly improved. (2) Plasma high-energy particles experience simultaneous physical and chemical effects on the surface of Pinus massoniana wood. The former formed a micro-etched roughness on the wood surface and led to the increase in surface dispersion force, while the latter increased the aggregation and activity of polar groups on the wood surface and the degradation of some wood components and rosin, resulting in the increase in surface polar force and the enhancement of wettability. (3) After plasma treatment, the reactivity of wood was enhanced, and the cross-linking degree with adhesive and the heat release were increased. The bonding strength of Pinus massoniana wood could be improved: dry bonding from 5.08 to 5.38 MPa, boiling-water bonding strength from 4.12 to 4.53 MPa, cold-water bonding strength from 3.84 to 4.51 MPa, and the bonding stability and reliability of glued specimens were also improved.

1. Introduction

Pinus massoniana is an endemic and resource-rich native tree species growing in subtropical areas of China and a typical coniferous species in southeastern humid subtropical areas of China. Pinus massoniana, which mainly exists in artificial forests, is most widely distributed among the main afforestation trees in China [1,2,3]. This wood has the advantages of high mechanical strength, clear and beautiful natural patterns, harmonious colors, and an appearance close to that of high-quality precious wood [4,5,6,7].

Pinus massoniana wood is rich in rosin, which has great influence on bonding. First, the special components of rosin hinder the wetting and penetration of adhesive on the wood surface, preventing the formation of enough glue-nails and leading to the decrease in bonding strength. Second, rosin changes the characteristics and the flow of adhesive and even hinders the curing of the adhesive. Finally, rosin overflows to the wood surface, resulting in unstable bonding. Surface modification is an important way to solving the problem of poor bonding of Pinus massoniana wood. Degreasing rosin before bonding is a widely used method at present [8,9,10,11,12]. There are many degreasing methods, including physical [13,14,15], chemical [16,17], and comprehensive degreasing [18,19,20]. The contribution of the degreasing rosin treatment of Pinus massoniana wood before bonding to the improvement in the bonding performance is far less than the influence of the wood properties of Pinus massoniana wood itself, but the environmental protection property of the degreasing process is controversial, and it is also a complex process.

Among the many wood surface treatment technologies, wood treated by plasma does not involve the drying process, toxic by-products, or wastewater treatment used in the traditional wet chemical treatment. It is also simple and environmentally friendly and is considered one of the most promising treatment methods. The research on plasma treatment of wood mostly focuses on the wettability, morphology, and chemical composition of wood [21,22,23,24]. Du et al. [25,26,27,28,29,30,31,32] conducted the earliest and most systematic research on plasma treatment of the wood surface and affirmed the important role of plasma technology in strengthening wood bonding. The results of his research showed that the contact angle of Chinese fir surface decreased to zero after plasma treatment, the treatment effect was still very obvious even under very weak treatment conditions, and the wood surface was evidently etched by plasma with uneven pits left; that is, a roughened surface unique to plasma treatment was formed on the surface, and the wettability of wood increased. Different gas plasmas have different etching effects on wood. O2 plasma etching is the most serious, N2 plasma etching is the least significant, and air plasma etching is between the two. After the wood surface is treated by plasma, some cellulose molecules on the wood surface are decomposed or chains are broken, which effectively produces a large number of reactive groups. This number increases with the extension in the plasma treatment time.

Based on current reports, plasma treatment can facilitate full diffusion, permeation, and cross-linking of adhesive on the wood surface and finally improve wood bonding performance by changing the surface morphology and chemical composition of wood, generating active free radicals, and enhancing wood wettability. However, the improvement in plasma treatment on bonding performance varies with the variety of wood. In this study, Pinus massoniana wood was treated by plasma, and the effects of plasma treatment on the bonding performance and surface characteristics were investigated, aiming to provide scientific guidance for the efficient utilization of Pinus massoniana wood and other woods rich in rosin.

2. Materials and Methods

2.1. Materials

Melamine (with a purity of 99 wt%, AR), urea (with a purity of 99 wt%, AR), and formaldehyde (with a purity of 37 wt%, AR) were bought from Sinopharm Chemical Reagent Co., Ltd. (Shanghai, China). MUF resin adhesive was made in the laboratorywith viscosity of 13.6 s (Ford Cup with hole diameter of 3.5 mm) and solid content of 53%. Pinus massoniana (PM) wood was purchased in a market with the size of 2200 mm × 130 mm × 10 mm and moisture content of 10%–14%.

2.2. Pinus massoniana Wood with Plasma Treatment

A CTD-2000F plasma device (Suman plasma, Nanjing, China) was turned on to perform treatment on PM wood with the size of 30 mm × 25 mm × 10 mm (Figure 1). The treatment time was a variable factor, being 1 min, 2 min, and 4 min. Considering the time effect of plasma treatment, 24 specimens for each treating time were tested and used within 30 min.

Figure 1.

DBD ordinary pressure plasma device.

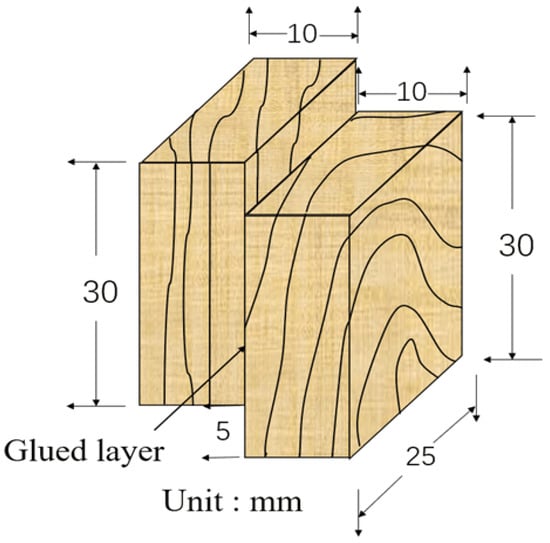

2.3. Preparation and Performance Test of Glued-Wood

PM glued wood was prepared in the laboratory as shown in Figure 2. MUF resin was coated on the glued wood on one side with a resin content of 160 g/m2, followed by hot pressing under a pressing temperature of 150 °C, pressing time of 10 min, and pressing pressure of 2.0 MPa. The prepared glued wood was placed in the laboratory at a temperature of 20 ± 2 °C and relative humidity of 65% ± 5% for 3 days, and then the shear bonding strength and peeling rate were tested by reference to [33,34]. The final value was the average of 12 specimens.

Figure 2.

Schematic diagram of glued wood.

2.4. Permeability Test of Wood Surface

PM wood with the size of 25 mm × 25 mm × 10 mm was immersed in a beaker filled with MUF resin adhesive in the direction perpendicular to the liquid adhesive. After impregnation for 90 s, the specimen was taken out and the adhesive on the surface was wiped. The permeability was calculated according to mass change of wood.

2.5. Wettability Test of Wood Surface

The contact angle was tested after the liquid dropped for 2 s using the static liquid drop method. The wetting liquids were CH2I2 and glycerol, and the contact angle was measured using a JC2000A static liquid drop measuring instrument. The surface energy was calculated according to the references [35,36]. The dispersion force and non-dispersion force of glycerol are 37 × 10−7 and 26.4 × 10−7 J/cm2, respectively, and those of CH2I2 are 48.5 × 10−7 and 2.3 × 10−7 J/cm2, respectively.

2.6. Fourier Transform-Infrared Spectroscopy (FT-IR) Test

Specimen preparation: The surface PM wood of about 0.2 cm in thickness was ground into powder, and 1–2 mg of wood powder was blended with 100–200 mg of KBr, tableted, and dried at room temperature. Testing instrument: A Varian 1000 infrared spectrometer (Varian, Palo Alto, CA, USA). Test conditions: KBr tableting method, scanning range of 400–4000 cm−1, scanning times 32.

2.7. Differential Scanning Calorimetry (DSC) Test

Specimen preparation: The surface PM wood of about 0.2 cm in thickness was ground into powder, and 3 g of wood powder was evenly blended with 10% MUF. Testing instrument: PerkinElmer DSC (NETZSCH, Selb, Germany). Test condition: N2 protection, temperature range of 30–250 °C, and heating rate of 10, 15, and 20 K/min.

2.8. X-ray Diffraction (XRD) Test

The surface PM wood of about 0.2 cm in thickness was ground into powder using TTR XRD (RIGAKU, Tokyo, Japan) under the parameters of Cu target (λ = 0.154060 nm), 5–80° 2θ scanning interval, 0.02° step, 6°/min scanning rate, 120 mA tube current, and 40 kV tube voltage. The crystallinity was calculated by reference to [37,38].

2.9. Scanning Electron Microscope (SEM) Test

Specimen preparation: The PM surface wood with the size of 10 mm × 10 mm × 1 mm was used. Testing instrument: an S-3400N SEM produced by Hitachi (Tokyo, Japan). Test conditions: acceleration voltage of 12.5 kV, room temperature, and the wood surface was observed after metal spraying.

3. Results and Discussion

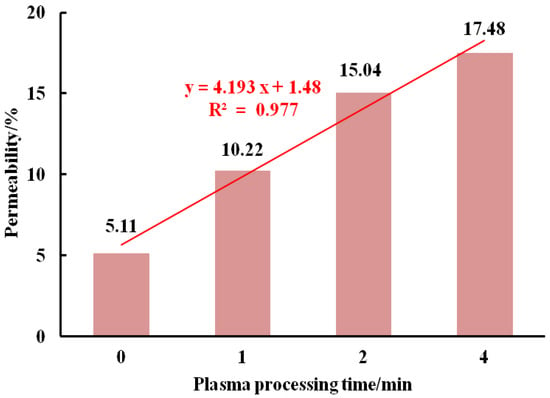

3.1. Effect of Plasma Treatment of MUF Permeation on Pinus massoniana Wood Surface

The effect of plasma treatment of MUF permeation on the surface of PM wood is shown in Figure 3. The permeation rate without plasma treatment was only 5.11%, which was attributed to the hydrophobic and nonpolar rosin on the surface of PM wood. The permeation rate increased linearly with the extension of plasma treatment time (y = 4.193x + 1.48, R2 = 0.977). This was because with the increase in plasma treatment time, the longer the interaction time between high-energy particles of plasma and the surface of PM wood, the more obvious the physical and chemical effects of plasma on the surface of PM wood. On the one hand, the etching effect and the roughness of the surface were improved, and the diffusion of MUF on the surface was accelerated. On the other hand, the more the polar groups were introduced on the wood surface, the higher the affinity between MUF and wood surface, and the faster the diffusion of MUF on the surface [39,40]. Wood is a porous material, and adhesives can penetrate into the inner cavity of wood (pits and cell cavities) to form glue-nails, which is the premise and key for glued wood to obtain excellent bonding strength. The permeability of PM wood treated by plasma was significantly enhanced, which laid a good foundation for PM wood to achieve good bonding performance.

Figure 3.

Effect of plasma treatment time on permeability of PM wood.

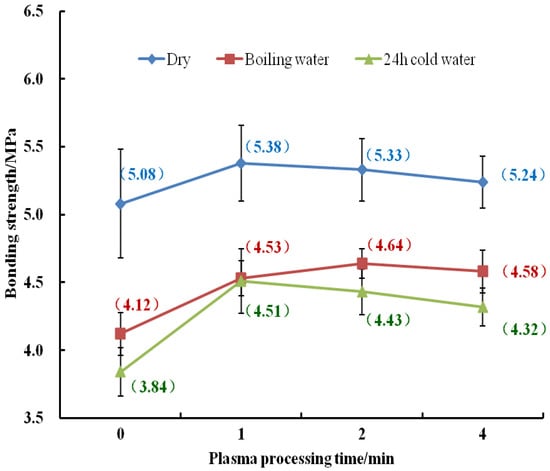

3.2. Effect of Plasma Treatment on the Bonding Performance of Pinus massoniana Glued Wood

As shown in Figure 4, the dry bonding strength, boiling-water bonding strength, and cold-water bonding strength of PM glued wood without plasma treatment were 5.18, 4.22, and 3.84 MPa, respectively, while those of PM glued wood after plasma treatment were evidently improved, but the strength values changed little between plasma treatment times of 1, 2, and 4 min.

Figure 4.

Effect of plasma treatment time on bonding performance of PM glued wood.

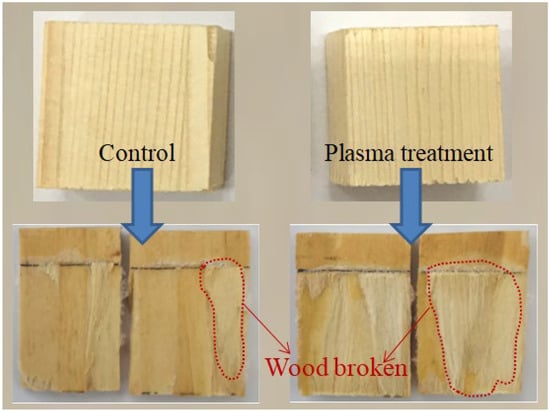

The wet peeling rate can show the bonding stability of glued wood. From Table 1, it can be seen that the total peeling rate and the maximum at the glue line of untreated PM glued wood in boiling water were 18.77% and 37.62%, respectively; however, peeling did not occur for PM glued wood after plasma treatment. In addition, as shown in Figure 5, the PM glued wood with plasma treatment had a higher wood failure rate, which proved that plasma treatment of PM wood can not only improve the bonding strength, but also improve the bonding stability and reliability of glued wood.

Table 1.

Effect of plasma treatment time on the peeling rate of PM glued wood.

Figure 5.

Photos of wood failure of PM glued wood.

3.3. Wettability Analysis of Pinus massoniana Wood Surface

To explore how plasma improved the bonding strength of PM wood, the surface characteristics of PM wood should be emphasized. Wettability of wood is an important parameter used to study the characteristics of the wood surface; it refers to the close bonding degree of liquid adhesive with the wood surface and is generally expressed according to the contact angle. The smaller the contact angle is, the better the wettability is. Generally speaking, the adhesive cannot wet the wood surface if the contact angle is greater than 90°, and, on the contrary, the adhesive can wet the wood surface when the angle is less than 90° [25,26,27].

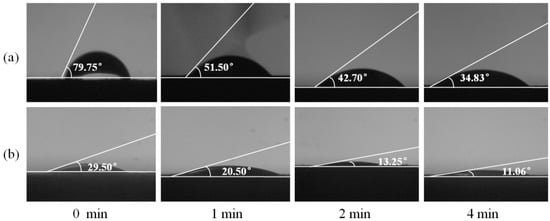

As seen in Figure 6, the contact angles based on glycerol or CH2I2 were all less than 90°, which showed that the surface of PM wood could be wetted even though it contained some rosin. When the test liquid was glycerol, the contact angle of untreated PM wood was 79.75°. The contact angle of wood treated by plasma gradually decreased with the extension of treatment time, and it decreased to 34.83° with a decrease of 56.3% at a treatment time of 4 min. Similarly, when the test liquid was CH2I2, the contact angle also gradually decreased, and it ranged from 29.50° to 11.06° with a decrease of 62.5% at a treatment time of 4 min. The decrease in the amplitude of the contact angle obtained by glycerol was significantly higher than that by CH2I2 because the polarity and surface tension of glycerol and CH2I2were different; the former was a polar molecule with surface tension of 63.4 mN/m and the latter was a nonpolar molecule with a surface tension of 50.8 mN/m. Generally speaking, only when the surface energy of the wood is greater than the surface tension of the liquid can the liquid be fully spread on the surface of the wood, thus showing a small contact angle [25,26,27,28].Plasma high-energy particles experienced a series of physical and chemical changes on the surface of PM wood [24,25,26,27,39,41], increasing the polar groups and surface energy on the wood surface, and polar glycerol can be more easily spread on wood surface. In addition, polar groups produced on the surface of PM wood was not only beneficial to the wetting, diffusion, and penetration of adhesive on the wood surface, but also could increase the reaction sites between the adhesive and wood, thus improving the bonding performance.

Figure 6.

Effect of plasma treatment time on surface contact angle of PM wood: (a) test liquid of glycerol, (b) test liquid of CH2I2.

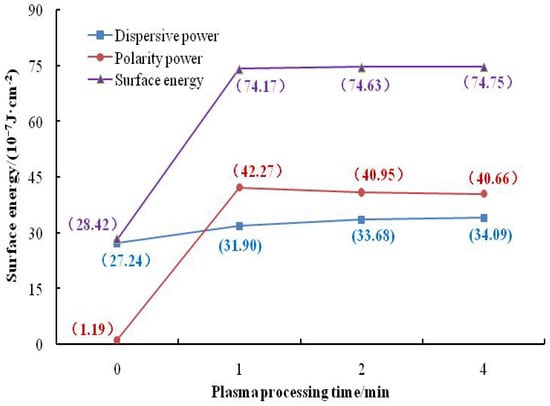

Surface energy consists of the polar force component and the dispersion force component, which are also important for the study of the surface characteristics of materials. It can be seen from Figure 7 that the surface energy of PM wood increased significantly after plasma treatment at 1 min, from 28.42 × 10−7 to 74.17 × 10−7 J·cm−2, but then with the extension of treatment time, the surface energy changed little. The effect of plasma treatment on the polar force was consistent with the change law of surface energy, indicating that the increase in surface energy was mainly caused by the increase in the polar force component. This was because a large number of polar groups were generated on the surface of PM wood after plasma treatment, and when the plasma treatment time was 1 min, the active groups forming on the surface reached saturation, so that the polar force component basically remained unchanged with the extension of treatment time. The orientation force between polar molecules on the wood surface, and the induced force between nonpolar molecules and polar molecules, were enhanced as the polar force increased. This provided the wood surface with enough surface energy to overcome the surface tension of adhesive, so that the adhesive could more easily spread, wet, and permeate on the wood surface.

Figure 7.

Effect of plasma treatment time on surface energy of PM wood.

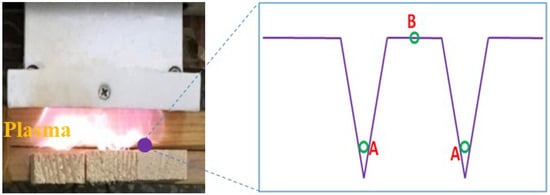

In addition, plasma treatment could also increase the dispersion force component of the PM wood surface to a certain extent, from 27.24 × 10−7 to 42.27 × 10−7 J·cm−2, which might be ascribed to the following two reasons [26,29,42]: (1) The dispersion force component mainly refers to the force between nonpolar molecules, and the increase in nonpolar molecules causes the increase in the dispersion force. (2) The change in the surface force field leads to the change in the dispersion force. In this study, the latter was the main reason for the increase in the dispersion force component, namely, the wood surface was etched by plasma treatment, and the surface force field became uneven due to the increase in the surface roughness. As shown in Figure 8, the mass points distributed around the rough pit point A were denser than those at the planar point B, so the dispersion force was greater at point A and the dispersion force of the whole roughened surface increased accordingly. So, the wood was a wettable material, and the surface roughness could make the contact angle smaller, which was more conducive to the wetting of MUF adhesive on the surface of PM wood and further improved the bonding performance.

Figure 8.

Schematic diagram of wood surface roughness caused by plasma treatment. Note: A is the rough pit point, B is the planar point, and the green dot is the mass point.

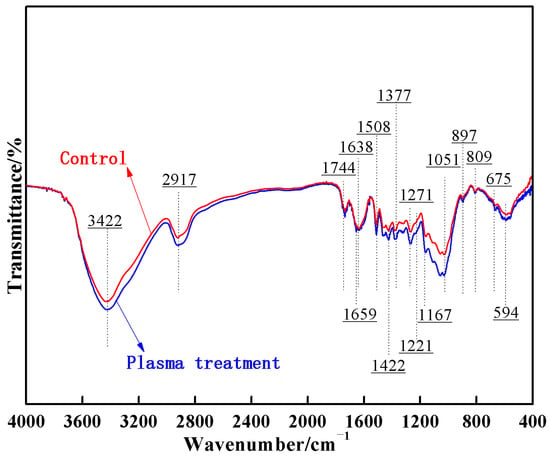

3.4. FT-IR Analysis of Surface Wood of Pinus massoniana

As shown in Figure 9, PM wood is mainly composed of cellulose, hemicellulose, and lignin, in addition to carboxylic acids, esters, etc. Results showed the O-H stretching vibration peak at 3422 cm−1, the C-H stretching vibration peak at 2917 cm−1, and the C=O stretching vibration peak of hemicellulose or rosin at 1744 cm−1. The peak at 1638 cm−1 was the C=O stretching vibration peak of lignin benzene ring, the C-C vibration peak of benzene ring skeleton from lignin was at 1508 cm−1, 1422 cm−1 was the C-H bending vibration peak of cellulose, 1377 cm−1 was the C-H bending vibration of cellulose and hemicellulose, 1271 cm−1 was the C-OH stretching vibration peak of lignin, 1167 cm−1 was the ether bond C-O-C stretching vibration peak of cellulose and hemicellulose, 1051 cm−1 was the C-O stretching vibration peak of cellulose and hemicellulose, 897 cm−1 was the C-H bending vibration peak of cellulose and hemicellulose, 809 cm−1 was the C-H out-of-plane bending vibration peak (mannose structure), and 675 cm−1 and 594 cm−1 were the C-H bending vibration peaks of the lignin benzene ring skeleton [8,9,10].

Figure 9.

FT-IR results of Pinus massoniana surface wood before and after plasma treatment.

After plasma treatment, the peak at 1271 cm−1 shifted to 1221 cm−1, meaning the increase in syringyl lignin. This indicated the degradation of lignin, and chemical bonds were broken. The peak at 1638 cm−1 shifted to 1659 cm−1, manifesting that the peculiar aromatic ring structure of lignin provided a gathering place for lone pair electrons and plasma oxidated hydroxyl into conjugated carbonyl, which improved electron density and enhanced reactivity [43].

After plasma treatment, the intensities increased of the O-H peak at 3422 cm−1, the C-H peak at 2917 cm−1, the carbonyl peak at1744 cm−1, the C-H peak at 1377 cm−1, and the C-O-C peak at 1167 cm−1 indicating that groups such as -CH2-, -CH3, and -OH on the molecular chain of lignin, cellulose, hemicellulose, and even rosin, were broken. Furthermore, the broken groups reacted to generate new compounds or reacted with nitrogen-containing and oxygen-containing radicals generated during plasma treatment to form oxygen-containing functional groups, such as hydroxyl, carbonyl, carboxyl, and acyl. The increase in the content of these polar groups contributed to more active molecular movements of lignin, cellulose, and hemicellulose.

In summary, cellulose, hemicellulose, lignin, and even rosin of PM wood were oxidized by plasma to form active groups on the wood surface, and oxygen or nitrogen in the air became high-energy particles under plasma treatment, which produced a large number of polar groups on the wood surface. Due to the increase in interfacial activity and the aggregation of polar groups, it was easier for the adhesive to wet, penetrate, and experience a cross-linking reaction on the wood surface.

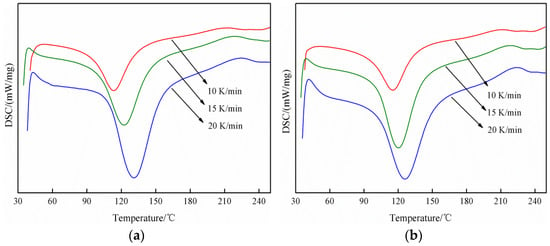

3.5. Analysis of Cross-Linking Reaction between Pinus massoniana Wood and MUF

DSC was used to measure the change in enthalpy during the cross-linking reaction between MUF adhesive and PM wood. Figure 10 shows the DSC curves of PM wood and MUF adhesive at different heating rates β (10, 15, and 20 K/min) before and after plasma treatment, and the corresponding result parameters are listed in Table 2. The exothermic peak of the cross-linking reaction between PM wood and MUF was a single exothermic peak, and, with the increase in the heating rate, the peak curing temperature increased and the temperature range widened. This was because with the increase in the heating rate, the thermal effect per unit time and the temperature difference increased, and the exothermic peak of the cross-linking reaction shifted to a high temperature accordingly [44,45,46,47,48]. At the same heating rate, the heat released by the reaction between plasma-treated PM wood and MUF was higher than that of untreated PM wood. As the heating rate increased, the difference between the heat release was larger. This showed that a large number of active groups were indeed produced on the wood surface after plasma treatment, which reacted more fully with MUF and released more heat.

Figure 10.

DSC curves at different heating rates. Note: (a) PM wood and MUF adhesive; (b) PM wood with plasma treatment and MUF adhesive.

Table 2.

The parameters of DSC results.

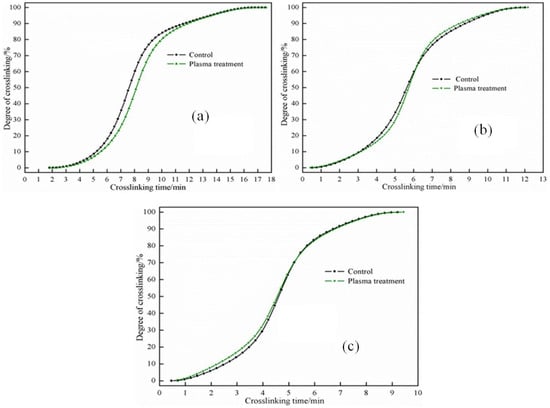

By integrating the DSC curves, the cross-linking reaction degree between PM wood and MUF adhesive at heating rates of 10, 15, and 20 K/min was obtained, which was an important index to measure the cross-linking reaction (Figure 11). With the increase in the heating rate, that is, from Figure 1 to Figure 2 and then to Figure 3, the time required for the complete reaction was 17.6, 12.3, and 9.5 min, respectively, indicating that the time to reach the same curing degree was gradually shortened with the increase in the heating rate; that is, the cross-linking reaction was accelerated.

Figure 11.

Cross-linking degree between Pinus massoniana wood and MUF resin; (a–c) are the heating rates of 10, 15, and 20 K/min.

When the heating rate was 10 K/min, the cross-linking reaction rate of PM wood treated by plasma was lower than that of untreated wood. At the heating rate of 15 K/min, the curves of all PM wood samples had an intersection point at about the cross-linking degree of 65%. When the reaction degree was lower than 65%, the cross-linking reaction rate of PM wood after plasma treatment was lower than that of untreated PM wood, and when it was higher than 65%, the situation was the opposite. When the heating rate was 20 K/min, the cross-linking reaction degree curves of PM wood before and after plasma treatment coincided in the range of 60%–100%, and when the reaction degree was lower than 60%, the cross-linking reaction rate of PM wood after plasma treatment was higher than that of untreated wood. This also proved that the surface reactivity of PM wood was enhanced under plasma treatment.

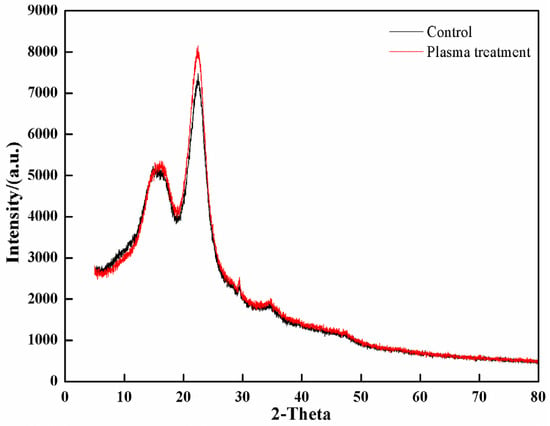

3.6. Crystallinity Analysis of Pinus massoniana Surface Wood

The effect of plasma treatment on 2θ and crystallinity of PM wood cellulose is shown in Figure 12. There were two significant peaks in XRD curves. The maximum diffraction peak was at 2θ = 22°, indicating the maximum intensity of the diffraction angle in the crystalline region (I002). The minimum diffraction peak was at 2θ = 18°, denoting the scattering intensity of the diffraction peak in the non-crystalline region (Iam) [49,50,51]. Before and after plasma treatment of PM wood, the diffraction angle of I002 crystal plane was 22.47°, indicating that plasma treatment had no significant effect on the position of the diffraction peak in the crystalline region, and that the distance of crystal layers was not changed. The crystallinity before treatment was 45.82% and after treatment was 51.21%, indicating the increase in the crystallinity of cellulose was another reason for the improvement in the bonding strength after plasma treatment [9,52,53,54].

Figure 12.

XRD curves of PM wood before and after plasma treatment.

3.7. SEM Analysis of Pinus massoniana wood

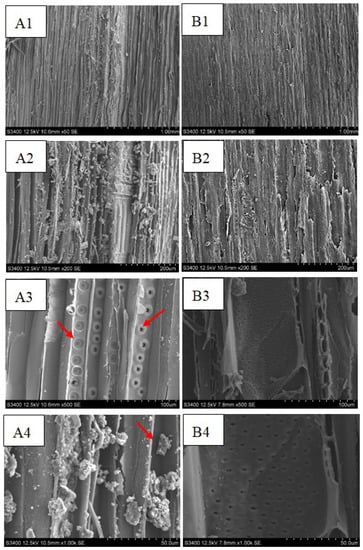

Figure 13 shows the SEM image of the PM wood surface. Without plasma treatment, the surface was smooth (A1), and rosin was dispersed on resin channels and pits (A3). After magnification, it was observed that the pits on the cell wall were covered by rosin (A4) and most pits were closed (A3), indicating the poor wettability of untreated PM wood. After plasma treatment, the smooth surface was etched by plasma to form a linear roughened surface; the structure became denser (B1), the surface rosin and even the rosin around pits were degraded, and some of the originally obstructed pit channels were unblocked (B3 and B4), which could facilitate the deep diffusion, wetting, and permeation of MUF into wood and contribute to the formation of enough glue-nails [9,20].

Figure 13.

SEM images of PMwood before (group A) and after (group B) plasma treatment. Note. (A1–A4) and (B1–B4) indicate resolutions of 1 mm, 200 μm, 100 μm and 50 μm, respectively.

Combining the previous analysis of wettability, it could be seen that physical and chemical effects took place simultaneously on the surface of PM wood due to plasma high-energy particles. The former formed a micro-etched roughness on the wood surface and led to the increase in surface dispersion force, while the latter increased the aggregation and activity of polar groups on the wood surface and the degradation of some wood components and rosin, resulting in the increase in polar force and the enhancement of wettability on the wood surface. A large number of reports exist on the thermal treatment and alkali treatment of wood, in which the wood surface becomes rough after treatment; however, this is mostly macroscopic roughness, which may not facilitate the bonding despite the promotion of adhesive permeation [55]. Because of plasma treatment, the surface of PM wood became rough, in the form of microscopic roughness, which was better for permeation and bonding.

4. Conclusions

In this study, Pinus massoniana wood was treated by plasma, and the bonding performance and surface characteristics of Pinus massoniana wood were mainly investigated. The results showed that: (1) After plasma treatment, the surface contact angle of Pinus massoniana wood was significantly reduced, the surface energy was significantly improved, and the surface wettability was also greatly improved. (2) Plasma high-energy particles led to the simultaneous physical and chemical effects on the surface of Pinus massoniana wood. The former formed a micro-etched roughness on the wood surface and led to the increase in surface dispersion force, while the latter increased the aggregation and activity of polar groups on the wood surface and the degradation of some wood components and rosin, resulting in the increase in surface polar force and the enhancement of wettability. (3) The surface of Pinus massoniana wood became rough after plasma treatment, in the form of microscopic roughness. Greater roughness was better for adhesive permeation and bonding. (4) After plasma treatment, the reactivity of wood was enhanced, and the cross-linking degree with the adhesive and the heat release were increased. The bonding strength of Pinus massoniana wood was improved, and the bonding stability and reliability of glued specimens were also improved. (5) Plasma treatment is a dry process that only changes the physical and chemical structure of the wood surface, while having little effect on the wood’s color. Thus, it has broad application prospects in the field of wood surface modification.

Author Contributions

Conceptualization, Z.W., J.L. and X.X.; methodology, Y.T., Z.W., J.L. and X.X.; validation, L.Y., B.Z., D.L. and G.X.; formal analysis, L.Y., B.Z., D.L., M.T. and G.X.; investigation, Y.T., L.Y., B.Z., D.L. and G.X.; resources, Z.W., M.T. and J.L.; writing—original draft preparation, Y.T., J.L. and X.X.; writing—review and editing, Y.T., Z.W., J.L. and X.X.; visualization, J.L. and X.X.; supervision, Z.W. and X.X. All authors have read and agreed to the published version of the manuscript.

Funding

This work was supported by Science-Technology Support Foundation of Guizhou Province of China ([2019]2308 and [2020]1Y128), Forestry Science and Technology Research Project of Guizhou Forestry Bureau ([2017]14 and [2020]C14), Talents from Guizhou Science and Technology Cooperation Platform ([2019]01-3), the Cultivation Project of Guizhou University of China ([2019]37).

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Du, M.; Ding, M.; Cai, Q. The transcriptomic responses of Pinus massoniana to drought stress. Forests 2018, 9, 326. [Google Scholar] [CrossRef]

- Yan, J.; Li, K.; Peng, X.; Huang, Z.; Liu, S.; Zhang, Q. The mechanism for exclusion of Pinus massoniana during the succession in subtropical forest ecosystems: Light competition or stoichiometric homoeostasis? Sci. Rep. 2015, 5, 10994. [Google Scholar] [CrossRef] [PubMed]

- An, N.; Ding, G.; Chen, H.; Nong, Y.; Huang, D. Relationship between resin yield and tree factors of Pinus massoniana. J. Northwest For. Univ. 2018, 33, 106–110. [Google Scholar]

- Wang, Z.; Lin, L.; Fu, F.; Zhou, Y.; Li, S.; Peng, L.; Yi, S. Research progress on high-intensity microwave treatment and failure mechanism of wood. J. For. Eng. 2022, 7, 13–21. [Google Scholar]

- Yuan, G.; Yang, T.; Zhang, M.; Li, H.; Wang, C.; Deng, Z.; Wang, Z. Research on the functional modification of plantation wood by inspiring of biomimetic mineralization. J. For. Eng. 2023, 8, 21–29. [Google Scholar]

- Yu, L.; Tian, M.; Li, L.; Wu, Z.; Chen, S.; Chen, J.; Xi, X. Study of nano colloidal silica sol based protectant on the prevention of masson pine. Wood Res. 2020, 65, 797–808. [Google Scholar] [CrossRef]

- Yang, Z.; Xia, H.; Tan, J.; Feng, Y.; Huang, Y. Selection of superior families of Pinus massoniana in southern China for large-diameter construction timber. J. For. Res. 2020, 31, 475–484. [Google Scholar] [CrossRef]

- Zhang, B.; Yu, L.; Zhang, Q.; Li, D.; Tu, Y.; Xiao, G.; Wu, Z.; Liang, J. Effects of fire retardants on mechanical properties and water resistance of Pinus massoniana particleboard. Wood Res. 2022, 67, 411–422. [Google Scholar] [CrossRef]

- Wu, Z.; Deng, X.; Li, L.; Xi, X.; Tian, M.; Yu, L.; Zhang, B. Effects of heat treatment on interfacial properties of Pinus Massoniana wood. Coatings 2021, 11, 543. [Google Scholar] [CrossRef]

- Zhang, Y.; Chen, H.; Yang, Z.; Qin, L. Effect of pretreatment on surface roughness and wettability of preservative treated Masson pine. J. For. Eng. 2023, 8, 53–58. [Google Scholar]

- Xu, W.; Zhou, J. Fundamental research and application progress of transparent wood interface. J. For. Eng. 2023, 8, 1–9. [Google Scholar]

- Qiao, J. Study on drying characteristics of Masson Pine deresination wood. Appl. Mech. Mater. 2014, 654, 31–34. [Google Scholar] [CrossRef]

- Yang, X.; Liu, Y.; Li, X. Resin removal from Pinus massoniana lumber by microwave technology. China Wood Ind. 2018, 32, 40–43. [Google Scholar]

- Cheng, X.; Liu, Y.; Quan, P.; Wei, Y.; Li, Y.; Xiong, X.; Xie, J.; Li, X. Study on drying and degreasing characteristics with atmospheric pressure steam for Masson pine wood. J. Cent. South Univ. For. Technol. 2017, 37, 108–113. [Google Scholar]

- Liu, Y.; Li, X.; Fu, F.; Wu, Y.; Hu, Y.; Peng, W.; Yang, X. Microwave deresination of Masson pine: Model formulation and solution. Sci. Silvae Sci. 2010, 46, 115–118. [Google Scholar]

- Wang, P.; Zhou, D. Surface characteristics of an alkaline degreasing treatment on Pinus massoniana veneer. J. Zhejiang A&F Univ. 2012, 29, 778–782. [Google Scholar]

- Yang, Z.; Xie, L.; Peng, W. Strong alkaline degreasing technology of Masson pine veneer. J. For. Eng. 2004, 18, 39–40. [Google Scholar]

- Li, S.; Liu, W. Effect of joint methods on the structural strength of Pinus massoniana furniture. J. Northwest For. Univ. 2014, 29, 169–173. [Google Scholar]

- Wei, P.; Huang, S.; Zhou, D. Study on property change of Pinus massoniana veneer before and after degreasing treatment. J. Southwest For. Univ. 2012, 32, 86–89. [Google Scholar]

- Tian, M.; Zhang, B.; Wu, Z.; Yu, L.; Li, L.; Xi, X. Effects of steam heat-treatment on properties of Pinus massoniana wood and its bonding performance. J. Renew. Mater. 2021, 9, 789–801. [Google Scholar] [CrossRef]

- Qu, G.; Liang, D.; Qu, D.; Huang, Y.; Liu, T.; Mao, H.; Ji, P.; Huang, D. Simultaneous removal of cadmium ions and phenol from water solution by pulsed corona discharge plasma combined with activated carbon. Chem. Eng. J. 2013, 228, 28–35. [Google Scholar] [CrossRef]

- Georg, A.; Evelyn, H.; Andrey, L.; Holger, M.; Wolfgang, V.; Arndt, W. Plasma treatment of wood and wood-based materials to generate hydrophilic or hydrophobic surface characteristics. Wood Mater. Sci. Eng. 2009, 4, 52–60. [Google Scholar]

- Sokołowska, A.; Szawłowski, J.; Frąckowiak, I.; Rudnicki, J.; Boruszewski, P.; Beer, P.; Olszyna, A. Plasma-chemical surface engineering of wood. J. Achiev. Mater. Manuf. Eng. 2009, 37, 694–697. [Google Scholar]

- Arndt, W.; Georg, A.; Evelyn, H.; Holger, M.; Wolfgang, V. Plasma treatment of wood–plastic composites to enhance their adhesion properties. J. Adhes. Sci. Technol. 2008, 22, 2025–2037. [Google Scholar]

- Du, G.; Hua, Y.; Wang, Z. Surface performance of Chinese fir wood treated by microwave plasma. China Wood Ind. 1998, 12, 17–20. [Google Scholar]

- Du, G.; Hua, Y.; Wang, Z. Wood surface ablation under microwave plasma. Sci. Silvae Sci. 1999, 35, 95–99. [Google Scholar]

- Du, G.; Yang, Z.; Qiu, J. Study on Alnus nepalensis surface treated by microwave plasma with ESR and XPS. Sci. Silvae Sci. 2004, 40, 148–151. [Google Scholar]

- Du, G.; Hua, Y.; Cui, Y.; Wang, Z. X-ray photoelectron spectroscopic (XPS) analysis of wood surface treatment with microwave plasma. Sci. Silv. 1999, 35, 104–109. [Google Scholar]

- Du, G.; Sun, Z.; Huang, L. Effect of microwave plasma on surface wettability of common teak wood. J. Northeast For. Univ. 2007, 35, 31–33. [Google Scholar]

- Du, G.; Yang, Z.; Qiu, J.; Huang, L. ESR analysis of wood surface activated by microwave plasma. J. For. Eng. 2002, 16, 28–30. [Google Scholar]

- Fang, Q.; Cui, H.; Du, G. Surface wettability, surface free energy, and surface adhesion of microwave plasma-treated Pinus yunnanensis wood. Wood Sci. Technol. 2015, 50, 285–296. [Google Scholar] [CrossRef]

- Duan, Z.; Hu, M.; Jiang, S.; Du, G.; Zhou, X.; Li, T. Cocuring of epoxidized soybean oil-based wood adhesives and the enhanced bonding performance by plasma treatment of wood surfaces. ACS Sustain. Chem. Eng. 2022, 10, 3363–3372. [Google Scholar] [CrossRef]

- GB/T 26899-2011; Test Method for Structural Glued Laminated Timber. Beijing Forestry University: Beijing, China, 2011.

- Zhang, B.; Wu, Z.; Liang, J.; Yu, L.; Xi, X.; Lei, H.; Du, G. Effects of polyethylene glycol on the flexibility of cold-setting melamine-urea-formaldehyde resin. Eur. J. Wood Wood Prod. 2022, 80, 975–984. [Google Scholar] [CrossRef]

- Žigon, J. Interactions of a waterborne coating with plasma pre-treated densified beech wood. Eur. J. Wood Wood Prod. 2021, 79, 1383–1394. [Google Scholar] [CrossRef]

- Wu, Z.; Xi, X.; Lei, H.; Du, G.; Zhang, B.; Wang, X.; Wang, H. Modification of tannin-soy based coordination with plasma in plywood. J. Southwest For. Univ. 2017, 37, 199–205. [Google Scholar]

- Yang, F.; Jin, C.; Wang, S.; Wang, Y.; Wei, L.; Zheng, L.; Gu, H.; Lam, S.; Naushad, M.; Li, C. Bamboo-based magnetic activated carbon for efficient removal of sulfadiazine: Application and adsorption mechanism. Chemosphere 2023, 323, e138245. [Google Scholar] [CrossRef]

- Cuadro, P.; Belt, T.; Kontturi, K.S.; Reza, M.; Kontturi, E.; Vuorinen, T.; Hughes, M. Cross-linking of cellulose and poly(ethyleneglycol) with citric acid. React. Funct. Polym. 2015, 90, 21–24. [Google Scholar] [CrossRef]

- Talviste, R.; Galmiz, O.; Stupavská, M.; Ráhel, J. Effect of DCSBD plasma treatment distance on surface characteristics of wood and thermally modified wood. Wood Sci. Technol. 2020, 54, 651–665. [Google Scholar] [CrossRef]

- Cavalcante Cordeiro, R.; Villela Pacheco, L.; Schierl, S.; Víana, H.; AntounSimão, R. Effects of different plasma treatments of short fibers on the mechanical properties of polypropylene-wood composites. Polym. Compos. 2016, 39, 1468–1479. [Google Scholar] [CrossRef]

- Avramidis, G.; Wascher, R.; Militz, H.; Viöl, W. Impact of air-plasma treatment at atmospheric pressure on wood and wood extractives. Int. Wood Prod. J. 2016, 25, 76–79. [Google Scholar] [CrossRef]

- Altgen, D.; Bellmann, M.; Wascher, R.; Mai, C. Enhanced urea-formaldehyde adhesive spreading on plasma treated wood particles. Eur. J. Wood Wood Prod. 2016, 74, 617–620. [Google Scholar] [CrossRef]

- Wu, Z.; Chen, S.; Liang, J.; Li, L.; Xi, X.; Deng, X.; Zhang, B.; Lei, H. Plasma treatment induced chemical changes of alkali lignin to enhance the performances of lignin-phenol-formaldehyde resin adhesive. J. Renew. Mater. 2021, 9, 1959–1972. [Google Scholar] [CrossRef]

- Xiao, G.; Liang, J.; Li, D.; Tu, Y.; Zhang, B.; Gong, F.; Gu, W.; Tang, M.; Ding, X.; Wu, Z.; et al. Fully bio-based adhesive from tannin and sucrose for plywood manufacturing with high performances. Materials 2022, 15, 8725. [Google Scholar] [CrossRef] [PubMed]

- Li, C.; Ye, H.; Ge, S.; Yao, Y.; Ashok, B.; Hariram, N.; Liu, H.; Tian, H.; He, Y.; Guo, G. Fabrication and properties of antimicrobial flexible nanocomposite polyurethane foams with in situ generated copper nanoparticles. J. Mater. Res. Technol. 2022, 19, 3603–3615. [Google Scholar] [CrossRef]

- Li, C.; Tang, Y.; Wang, Y.; Yuan, X.; Zhang, B.; Wu, Z.; Tian, H. A novel environment-friendly adhesive based on recycling of Broussonetia papyrifera leaf forestry waste protein. Forests 2022, 13, 291. [Google Scholar] [CrossRef]

- Xu, G.; Zhang, Q.; Xi, X.; Lei, H.; Cao, M.; Du, G.; Wu, Z. Tannin-based wood adhesive with good water resistance crosslinked by hexanediamine. Int. J. Biol. Macromol. 2023, 234, 123644. [Google Scholar] [CrossRef]

- Xiao, G.; Liang, J.; Wu, Z.; Lei, H.; Gong, F.; Gu, W.; Tu, Y.; Li, D. A composite whole-biomass tannin-sucrose-soy protein wood adhesive with high performance. Forests 2023, 14, 1250. [Google Scholar] [CrossRef]

- Li, H.; Wang, Y.; Xie, W.; Tang, Y.; Yang, F.; Gong, C.; Wang, C.; Li, X.; Li, C. Preparation and characterization of soybean protein adhesives modified with an environmental-friendly tannin-based resin. Polymers 2023, 15, 2289. [Google Scholar] [CrossRef]

- Dong, Y.; Tan, Y.; Wang, K.; Cai, Y.; Li, J.; Sonn, E.C.; Li, C. Reviewing wood-based solar-driven interfacial evaporators for desalination. Water Res. 2022, 223, e119011. [Google Scholar] [CrossRef]

- Gu, H.; Yan, J.; Liu, Y.; Yu, X.; Feng, Y.; Yang, X.; Lam, S.; Naushad, M.; Li, C.; Sonne, C. Autochthonous bioaugmentation accelerates phenanthrene degradation in acclimated soil. Environ. Res. 2023, 224, e115543. [Google Scholar] [CrossRef]

- Žigon, J.; Kovač, J.; Zaplotnik, R.; Saražin, J.; Šernek, M.; Petrič, M.; Dahle, S. Correction to: Enhancement of strength of adhesive bond between wood and metal using atmospheric plasma treatment. Cellulose 2020, 27, 6411–6424. [Google Scholar] [CrossRef]

- Safin, R.; Khasanshin, R.; Galyavetdinov, N.; Salimgaraeva, R.; Mukhametzyanov, S.; Safina, A.; Kraysman, N. Improving the physical and mechanical performance of laminated wooden structures by low-temperature plasma treatment. Coatings 2021, 11, 918. [Google Scholar] [CrossRef]

- Žigon, J.; Saražin, J.; Šernek, M.; Kovač, J.; Dahle, S. The effect of ageing on bonding performance of plasma treated beech wood with urea-formaldehyde adhesive. Cellulose 2021, 28, 2461–2478. [Google Scholar] [CrossRef]

- Gumowska, A.; Kowaluk, G. Bonding of birch solid wood of sawmill surface roughness with use of selected thermoplastic biopolymers. Ann. Wars. Univ. Life Sci. SGGW For. Wood Technol. 2019, 106, 9–15. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).