A Composite Whole-Biomass Tannin–Sucrose–Soy Protein Wood Adhesive with High Performance

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of Tannin–Sucrose–SPIAdhesive

2.3. Preparation of Plywood and the Test of Bonding Strength

2.4. Test of Insoluble Substance Rate in Cured Adhesives

2.5. Differential Scanning Calorimetry (DSC)

2.6. Thermogravimetry (TG)

2.7. X-ray Diffraction (XRD)

2.8. Fourier Transform Infrared Spectroscopy (FT-IR)

2.9. Gas Chromatography–Mass Spectroscopy (GC–MS)

3. Results and Discussion

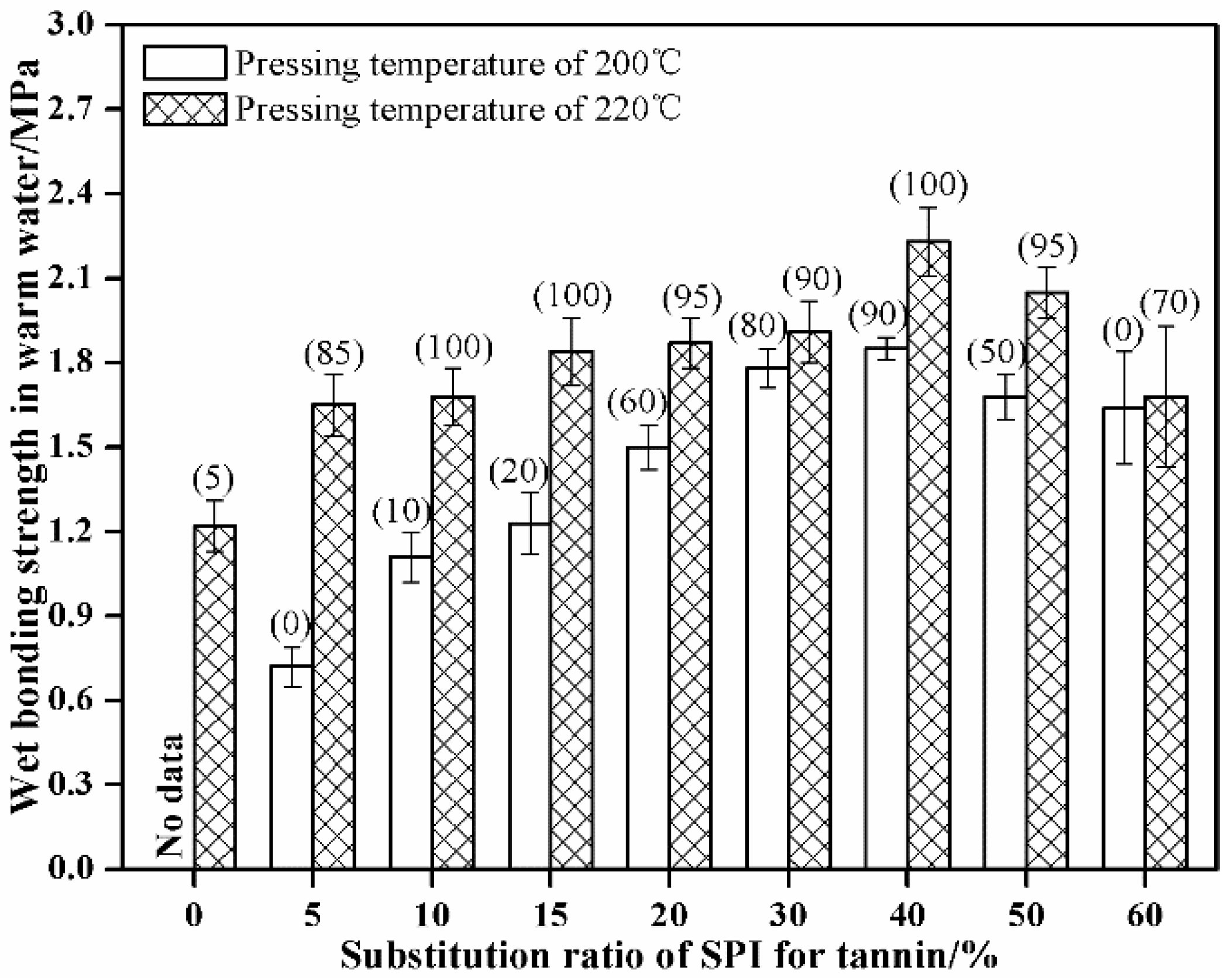

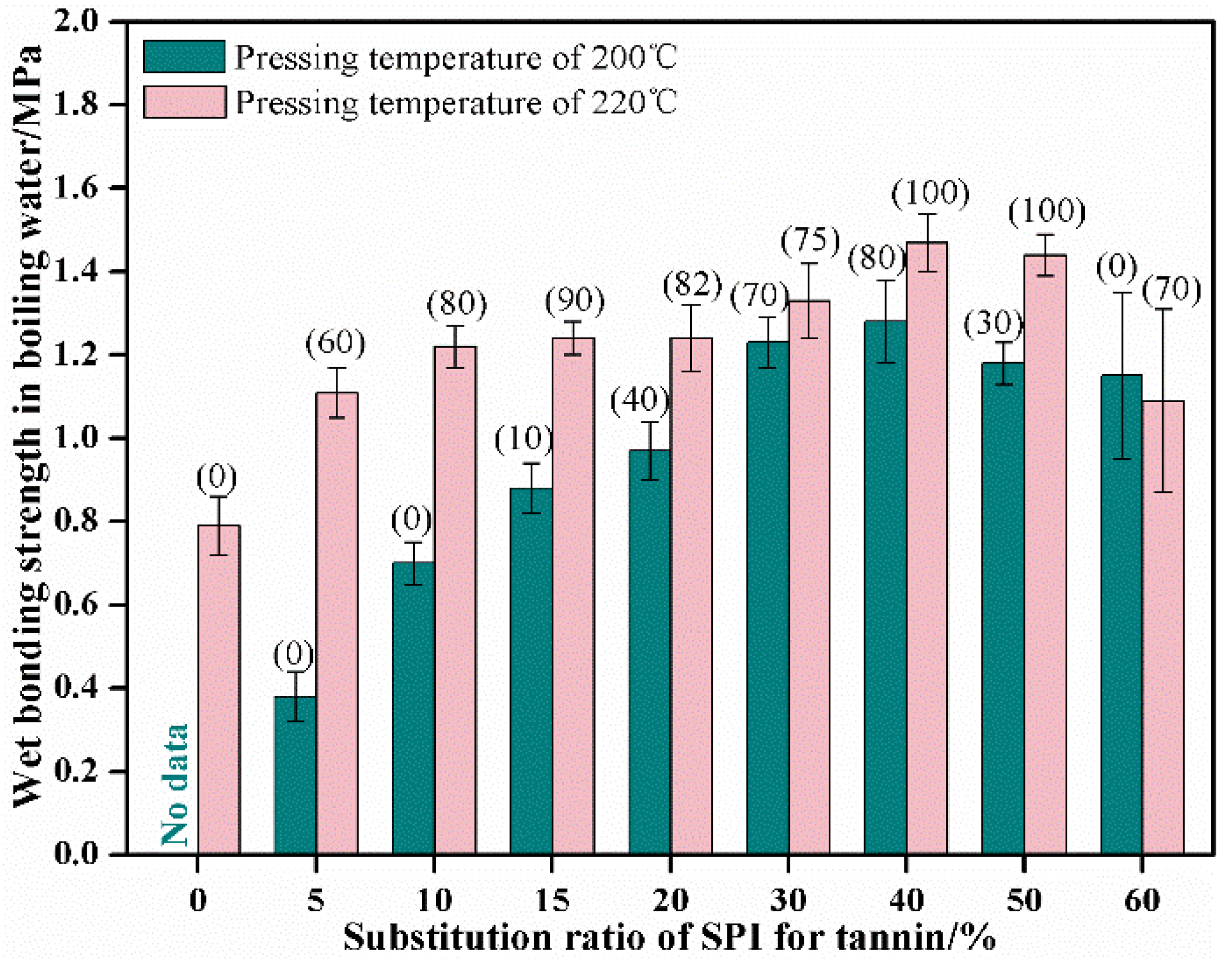

3.1. Effect of Substitution Ratio on the Properties and Bonding Performance of the Composite Adhesive

3.2. Curing Performance Analysis

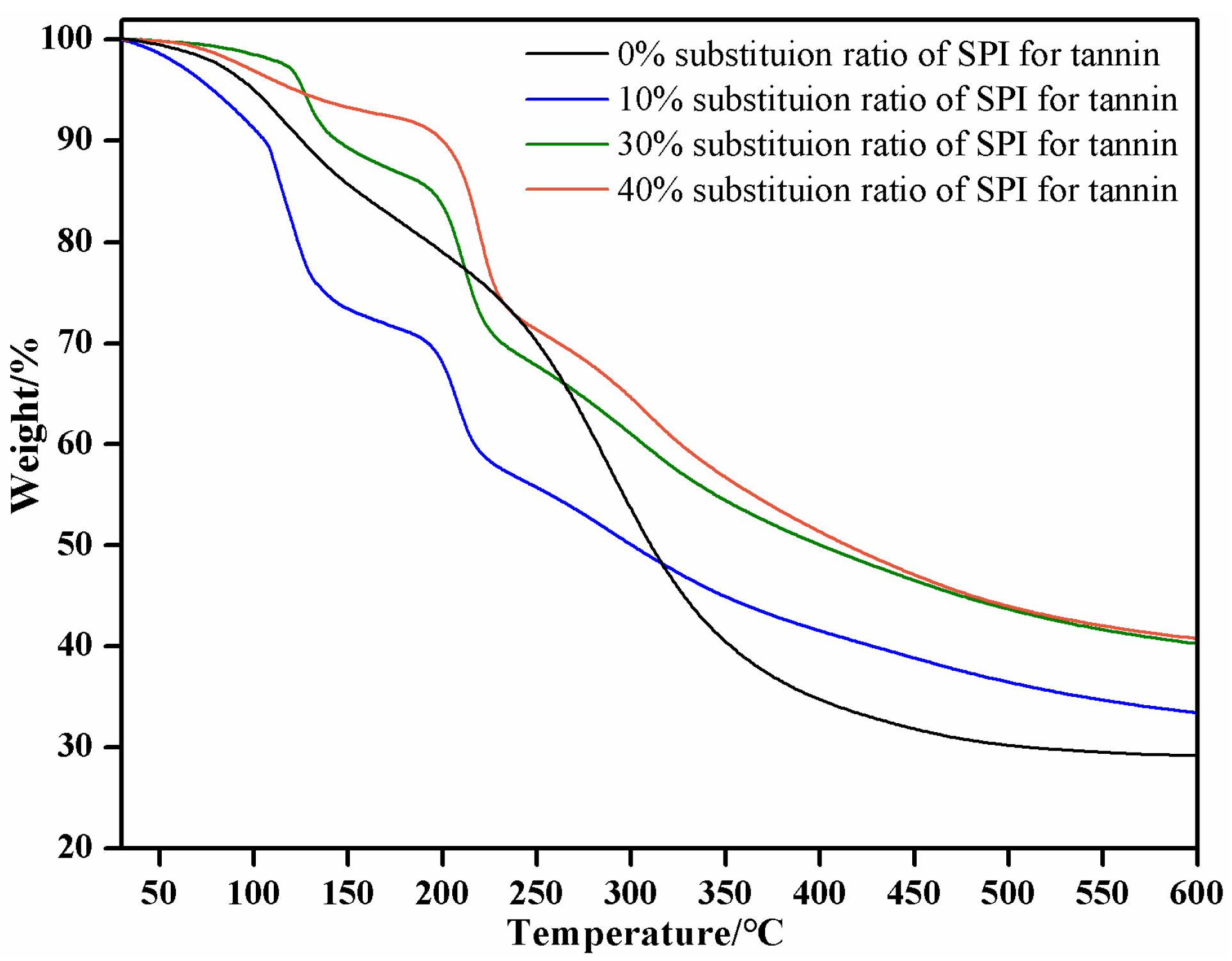

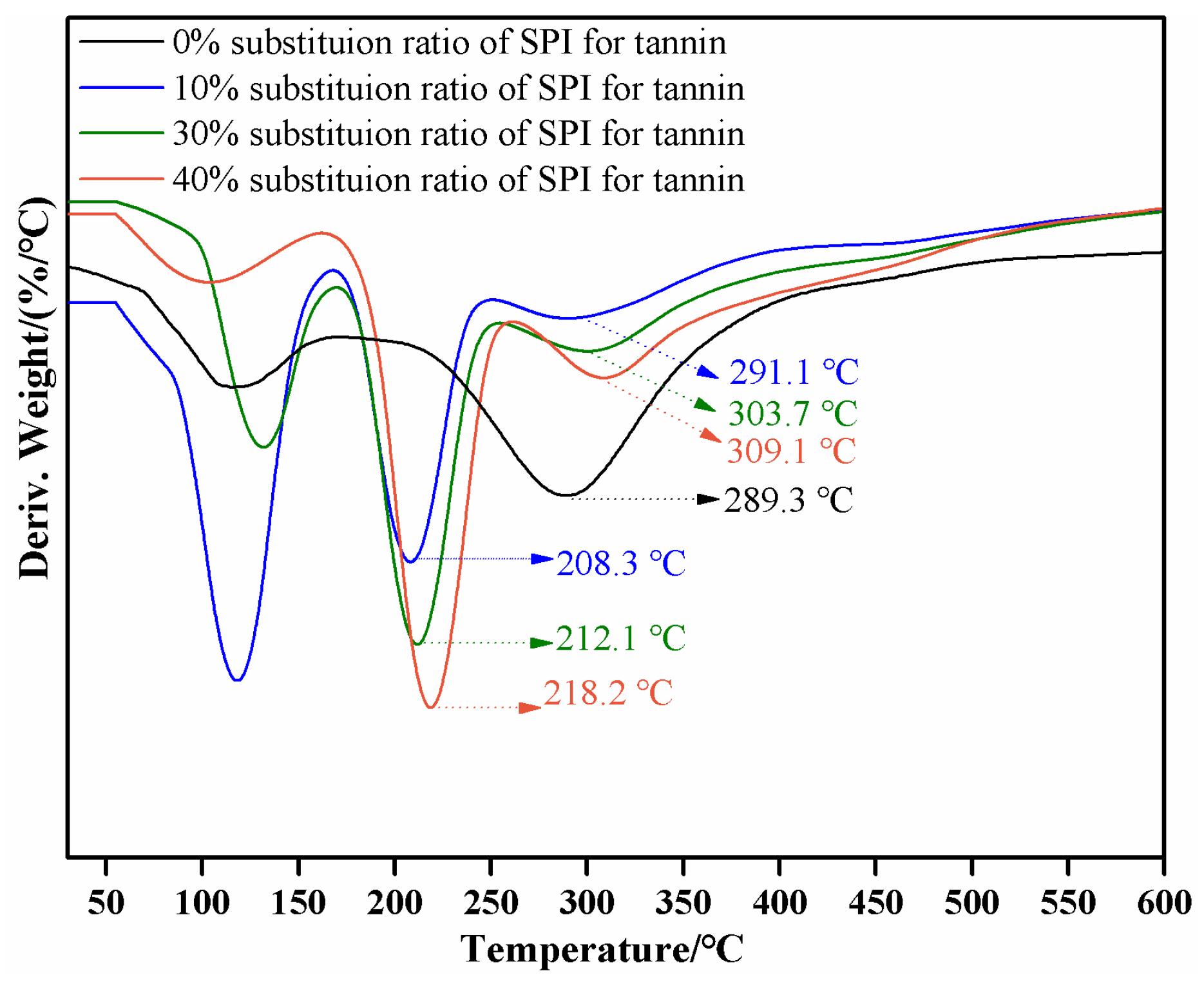

3.3. Thermal Stability Analysis

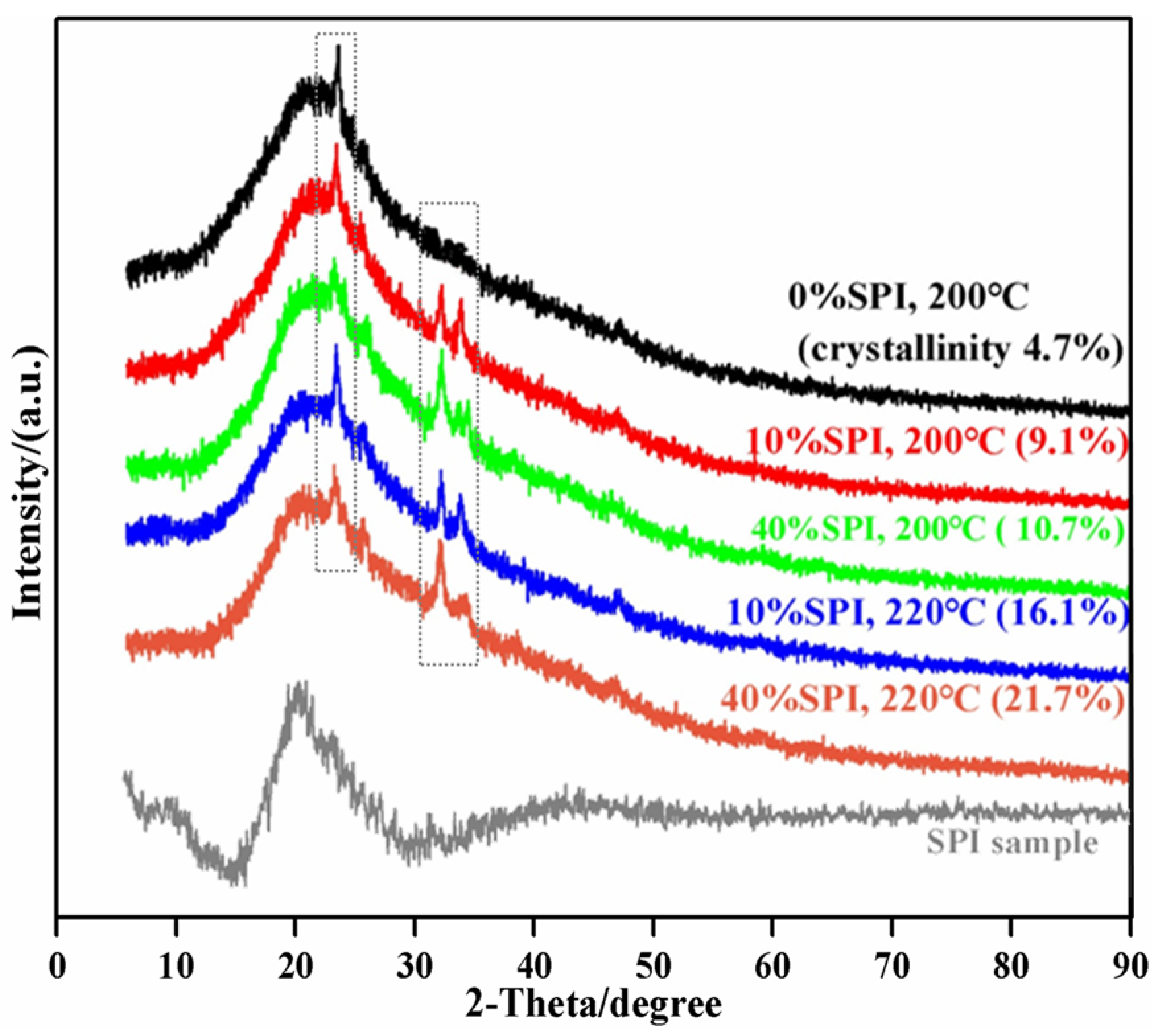

3.4. Crystallization Property Analysis of Cured Adhesive

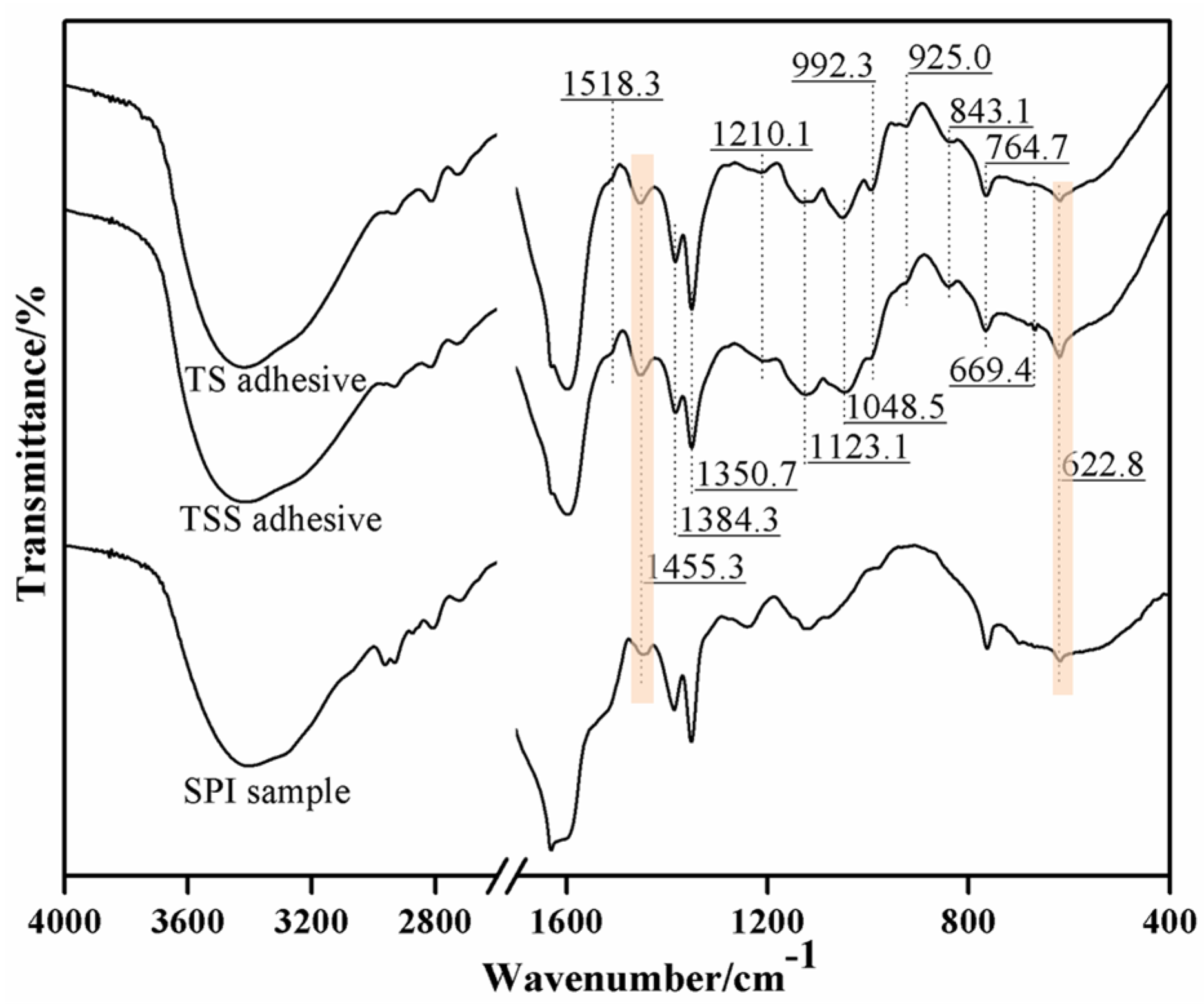

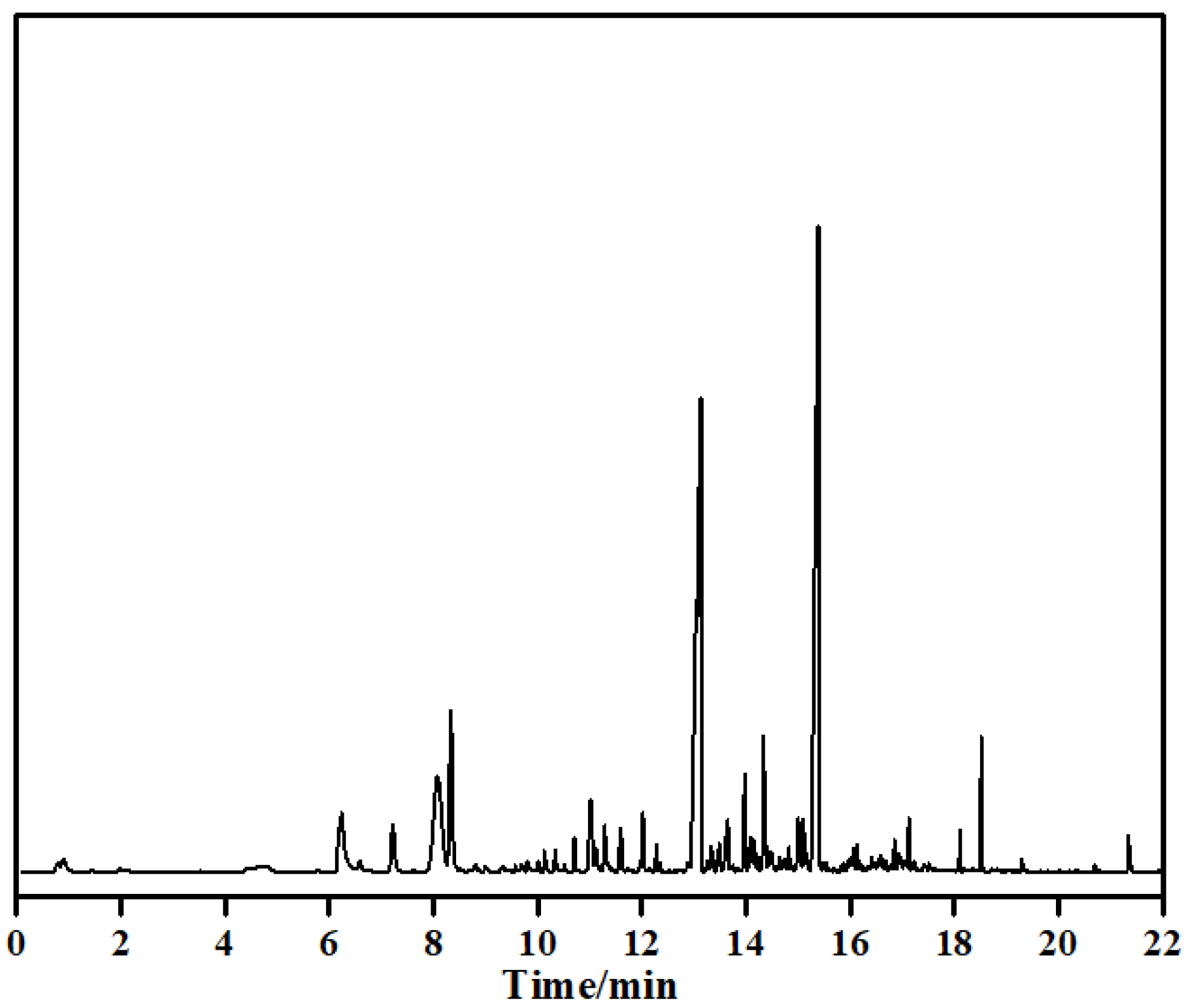

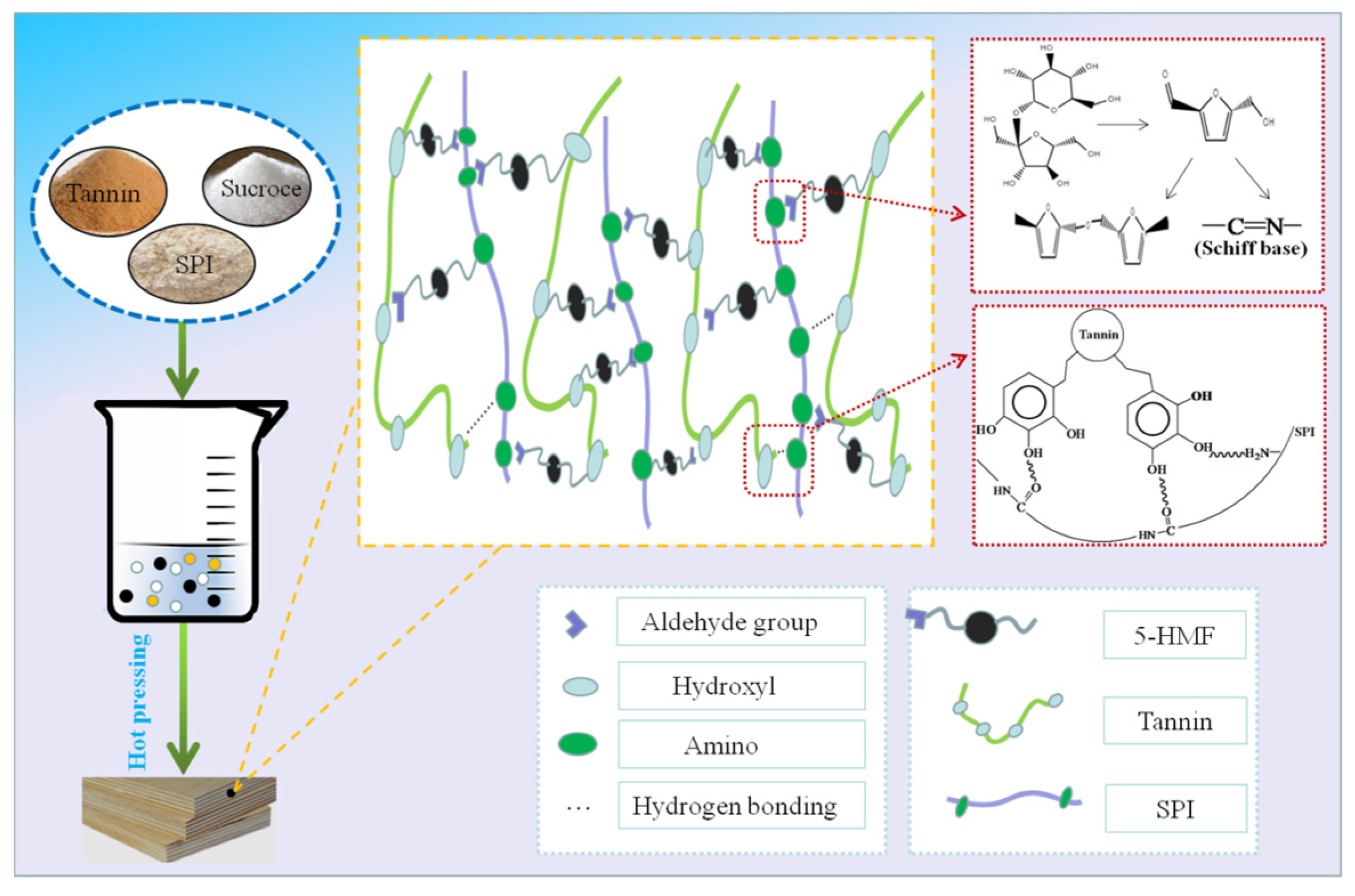

3.5. Bonding Mechanism Analysis of the Tannin–Sucrose–SPI Adhesive

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Xu, C.; Xu, Y.; Chen, M.; Zhang, Y.; Li, J.; Gao, Q.; Shi, S.Q. Soy protein adhesive with bio-based epoxidized daidzein for highstrength and mildew resistance. Chem. Eng. J. 2020, 390, 124622. [Google Scholar] [CrossRef]

- Arbenz, A.; Avérous, L. Chemical modification of tannins to elaborate aromatic biobased macromoleculararchitectures. Green Chemistry 2015, 17, 2626–2646. [Google Scholar] [CrossRef]

- Guigo, N.; Mija, A.; Vincent, L.; Sbirrazzuoli, N. Eco-friendly composite resins based on renewable biomass resources: Polyfurfurylalcohol/lignin thermosets. Eur. Polym. J. 2010, 46, 1016–1023. [Google Scholar] [CrossRef]

- Hussin, M.H.; Latif, N.; Hamidon, T.; Idris, N.; Hashim, R.; Appaturi, J.; Brosse, N.; Ziegler-Devin, I.; Chrusiel, L.; Fatriasari, W. Latest advancements in high-performance bio-based wood adhesives: A critical review. J. Mater. Res. Technol. 2022, 21, 3909–3946. [Google Scholar] [CrossRef]

- Li, C.; Lei, H.; Wu, Z.; Xi, X.; Du, G.; Pizzi, A. Fully biobased adhesive from glucose and citric acid for plywood with high performance. ACS Appl. Mater. Interfaces 2022, 14, 23859–23867. [Google Scholar] [CrossRef]

- Chen, X.; Yang, Z.; Yang, F.; Zhang, J.; Pizzi, A.; Essawy, H.; Du, G.; Zhou, X. Development of easy-handled, formaldehyde-free, high-bonding performance bio-sourced wood adhesives by co-reaction of furfuryl alcohol and wheat gluten protein. Chem. Eng. J. 2023, 462, 142161. [Google Scholar] [CrossRef]

- Li, C.; Tang, Y.; Wang, Y.; Yuan, X.; Zhang, B.; Wu, Z.; Tian, H. A novel environmental-friendly adhesive based on recycling of Broussonetia papyrifera left forestry waste protein. Forests 2022, 13, 291. [Google Scholar] [CrossRef]

- Xu, G.; Zhang, Q.; Xi, X.; Lei, H.; Cao, M.; Du, G.; Wu, Z. Tannin-based wood adhesive with good water resistance crosslinked by hexanediamine. Int. J. Biol.Macromol. 2023, 234, 123644. [Google Scholar] [CrossRef]

- Gholami, M.; Shakeri, A.; Zolghadr, M.; Yamini, G. Non-isocyanate polyurethane from the extracted tannin of sumac leaves: Synthesis, characterization, and optimization of the reaction parameters. Ind. Crop. Prod. 2021, 161, 113195. [Google Scholar] [CrossRef]

- Gonçalves, S.; Ferra, J.; Paiva, N.; Martins, J.; Carvalho, L.H.; Magalhães, F.D. Lignosulphonates as an Alternative to Non-Renewable Binders in Wood-Based Materials. Polymers 2021, 13, 4196. [Google Scholar] [CrossRef]

- Siahkamari, M.; Emmanuel, S.; Hodge, D.B.; Nejad, M. Lignin-Glyoxal: A Fully Biobased Formaldehyde-Free Wood Adhesive forInterior Engineered Wood Products. ACS Sustain. Chem. Eng. 2022, 10, 3430–3441. [Google Scholar] [CrossRef]

- Watcharakitti, J.; Win, E.E.; Nimnuan, J.; Smith, S.M. Modified Starch-Based Adhesives: A Review. Polymers 2022, 14, 2023. [Google Scholar] [CrossRef]

- Maulana, M.I.; Lubis, M.A.R.; Febrianto, F.; Hua, L.S.; Iswanto, A.H.; Antov, P.; Kristak, L.; Mardawati, E.; Sari, R.K.; Zaini, L.H. Environmentally Friendly Starch-Based Adhesives for Bonding High-Performance Wood Composites: A Review. Forests 2022, 13, 1614. [Google Scholar] [CrossRef]

- Din, Z.; Chen, L.; Xiong, H.; Wang, Z.; Ullah, I.; Lei, W.; Shi, D.; Alam, M.; Ullah, H.; Khan, S.A. Starch: An Undisputed Potential Candidate and Sustainable Resource for the Development of Wood Adhesive. Starch Stärke 2020, 72, 1900276. [Google Scholar] [CrossRef]

- Pizzi, A.; Meikleham, N.; Stephanou, A. Induced accelerated autocondensation of polyflavonoid tannins for phenolic polycondensates. II: Cellulose effect and application. J. Appl. Polym. Sci. 1995, 55, 929–933. [Google Scholar] [CrossRef]

- Meikleham, N.E.; Pizzi, A. Acid-catalyzed and alkali-catalyzed tannin-based rigid foams. J. Appl. Polym. Sci. 1994, 53, 1547–1556. [Google Scholar] [CrossRef]

- Rossouw, D. Reaction Kinetics of Phenols and Tannin with Aldehydes. Ph.D. Thesis, University of South Africa, Gauteng, South Africa, 1979. [Google Scholar]

- Boran, S.; Usta, M.; Ondaral, S.; Gümüskaya, E. The efficiency of tannin as a formaldehyde scavenger chemical in medium density fiberboard. Compos. Part B 2012, 43, 2487–2491. [Google Scholar] [CrossRef]

- Bisanda, E.; Ogola, W.; Tesha, J. Characterisation of tannin resin blends for particle board applications. Cement Concrete Comp. 2003, 25, 593–598. [Google Scholar] [CrossRef]

- Liu, S.; Yang, H.; Ran, X.; Yang, L.; Du, G. Synthesis, structure and performance of pulp-based wood adhesives. J. For. Eng. 2022, 7, 132–139. [Google Scholar]

- Grigsby, W.; Warnes, J. Potential of tannin extracts as resorcinol replacements in cold cure thermoset adhesives. Holz RohWerkst. 2004, 62, 433–438. [Google Scholar] [CrossRef]

- Casanova, M.; Morgan, K.T.; Gross, E.A.; Moss, O.R.; Heck, H.D. DNA-protein cross-links and cell replication at specific sites in the nose of F344 rats exposed subchronically to formaldehyde. Fundam. Appl. Toxicol. 1994, 23, 525–536. [Google Scholar] [CrossRef]

- Liang, J.; Wu, Z.; Xi, X.; Lei, H.; Zhang, B.; Du, G. Investigation of the reaction between a soy-based proteinmodel compound and formaldehyde. Wood Sci. Technol. 2019, 53, 1061–1077. [Google Scholar] [CrossRef]

- Xi, X.; Pizzi, A.; Frihart, C.R.; Lorenz, L.; Gerardin, C. Tannin plywood bioadhesives with non-volatile aldehydes generation by specific oxidation ofmono- and disaccharides. Inter. J. Adhes. Adhes. 2020, 98, 102499. [Google Scholar] [CrossRef]

- Li, K.; Geng, X.; Simonsen, J.; Karchesy, J. Novel wood adhesives from condensed tannins and polyethylenimine. Int. J. Adhes. Adhes. 2004, 24, 327–333. [Google Scholar] [CrossRef]

- Sun, G.; Sun, H.; Liu, Y.; Zhao, B.; Zhu, N.; Hu, K. Comparative study on the curing kinetics and mechanism of a lignin-basedepoxy/anhydride resin system. Polymer 2007, 48, 330–337. [Google Scholar] [CrossRef]

- Ghahri, S.; Pizzi, A. Improving soy-based adhesives for wood particleboard by tannins addition. Wood Sci. Technol. 2018, 52, 261–279. [Google Scholar] [CrossRef]

- Pizzi, A. Wood products and green chemistry. Ann. For. Sci. 2016, 73, 185–203. [Google Scholar] [CrossRef]

- Xiao, G.; Liang, J.; Li, D.; Tu, Y.; Zhang, B.; Gong, F.; Gu, W.; Tang, M.; Ding, X.; Wu, Z. Fully bio-based adhesive from tannin and sucrose for plywood manufacturing with high performances. Materials 2022, 15, 8725. [Google Scholar] [CrossRef]

- Zhao, S.; Wang, Z.; Li, Z.; Li, L.; Li, J.; Zhang, S. Core-shell nanohybrid elastomer based on co-deposition strategy to improve performance of soy protein adhesive. ACS Appl. Mater. Inter. 2019, 11, 32414–32422. [Google Scholar] [CrossRef]

- Wu, Z.; Xi, X.; Lei, H.; Liang, J.; Liao, J.; Du, G. Study on soy-based adhesives enhanced by phenol formaldehyde cross-linker. Polymers 2019, 11, 365. [Google Scholar] [CrossRef]

- Wu, Z.; Liang, J.; Lei, H.; Zhang, B.; Xi, X.; Li, L. Study on soy protein-based adhesive cross-linked by glyoxal. J. Renew. Mater. 2021, 9, 205–218. [Google Scholar] [CrossRef]

- Li, C. Preparation and Application on Research of Chemical Crosslinking Modification of Soy Bean Meal-Based Adhesive. Ph.D. Thesis, Beijing Forestry University, Beijing, China, 2015. [Google Scholar]

- GB/T 17657-2022; Test Method for Physical and Chemical Properties of Wood-Based Panels and Veneer Panels. Standards Press: Beijing, China, 2022.

- Kaspchak, E.; Goedert, A.; Mafra, L.; Mafra, M. Effect of divalent cations on bovine serum albumin (BSA) and tannic acid interaction and its influence on turbidity and in vitro protein digestibility. Int. J. Biol.Macromol. 2019, 136, 486–492. [Google Scholar] [CrossRef] [PubMed]

- Wu, Z. Crosslinking Modification of Protein-Based Adhesives and Mechanism. Ph.D. Thesis, Beijing Forestry University, Beijing, China, 2016. [Google Scholar]

- Wu, Z.; Xi, X.; Lei, H.; Du, G.; Zhang, B.; Wang, X.; Wang, H. Modification of tannin-soy based adhesive coordination with plasma in plywood. J. Southwest For. Univ. 2017, 37, 199–205. [Google Scholar]

- Lei, H.; Wu, Z.; Cao, M.; Du, G. Study on the soy protein-based wood adhesive modified by hydroxymethyl phenol. Polymers 2016, 8, 256–265. [Google Scholar] [CrossRef]

- Chen, J.; Chen, X.; Zhu, Q.; Chen, F.; Zhao, X.; Ao, Q. Determination of the domain structure of the 7S and 11S globulins from soy proteins by XRD and FTIR. J. Sci. Food Agric. 2013, 93, 1687–1691. [Google Scholar] [CrossRef]

- Deng, X.; Wu, Z.; Zhang, B.; Lei, H.; Liang, J.; Li, L.; Tu, Y.; Li, D.; Xiao, G. A new wood adhesive based on recycling Camellia oleifera cake-protein: Preparation and properties. Materials 2022, 15, 1659. [Google Scholar] [CrossRef]

- Seino, H.; Uchibori, T.; Nishitani, T.; Inamasu, S. Enzymatic synthesis of carbohydrate esters of fatty acid (I) esterification of sucrose, glucose, fructose and sorbitol. JAOCS 1984, 61, 1761–1765. [Google Scholar] [CrossRef]

- Zhao, Z.; Umemura, K. Investigation of a new natural particleboard adhesive composed of tannin and sucrose. J. Wood Sci. 2014, 60, 269–277. [Google Scholar] [CrossRef]

- Zhao, Z.; Umemura, K. Investigation of a new natural particleboard adhesive composed of tannin and sucrose. 2. Effect ofpressing temperature and time on board properties, and characterization of adhesive. Bioresources 2015, 10, 2444–2460. [Google Scholar] [CrossRef]

- Zhao, H.; Holladay, J.E.; Brown, H.; Zhang, Z.C. Metal chlorides in ionic liquid solvents convert sugars to 5-hydroxymethylfurfural. Science 2007, 316, l597–1600. [Google Scholar] [CrossRef]

- Munshi, M.; Lomate, S.; Deshpande, R.; Rane, V.; Kelkar, A. Synthesis of acrolein by gas-phase dehydration of glycerol over silica supportedBronsted acidic ionic liquid catalysts. J. Chem. Technol. Biot. 2010, 85, 1319–1324. [Google Scholar] [CrossRef]

- Sun, S.; Zhao, Z.; Umemura, K. Further exploration of sucrose-citric acid adhesive: Synthesis and application on plywood. Polymers 2019, 11, 1875. [Google Scholar] [CrossRef] [PubMed]

- Kan, H.; Kan, Y.; He, W.; Gao, Z. Effects of pH value of water-based polymer on properties of a polyamide-based API adhesive. J. For. Eng. 2023, 8, 87–94. [Google Scholar]

- Li, C.; Ye, H.; Ge, S.; Yao, Y.; Ashok, B.; Hariram, N.; Liu, H.; Tian, H.; He, Y.; Guo, G.; et al. Fabrication and properties of antimicrobial flexible nanocomposite polyurethane foams with in situ generated copper nanoparticles. J. Mater. Res. Techno. 2022, 19, 3603–3615. [Google Scholar] [CrossRef]

- Yang, F.; Jin, C.; Wang, S.; Wang, Y.; Wei, L.; Zheng, L.; Gu, H.; Lam, S.; Naushad, M.; Li, C.; et al. Bamboo-based magnetic activated carbon for efficient removal of sulfadiazine: Application and adsorption mechanism. Chemosphere 2023, 323, e138245. [Google Scholar] [CrossRef]

- Zhao, Y.; Zhai, Y.; Xu, Y.; Zhang, L.; Wang, Z. Polymerization and product characteristics of polyphenols of Pinus sylvestris var. mongolicabarks and protein. J. Beijing For. Univ. 2016, 38, 102–107. [Google Scholar]

- Peng, J.; Yan, C.; Yang, F.; Hong, M.; Yang, Z.; Du, G.; Zhou, X. Preparation of tannin-urea-formaldehyde resin by carbonated tannin and its bonding properties. J. For. Eng. 2023, 8, 119–125. [Google Scholar]

- Li, H.; Wang, Y.; Xie, W.; Tang, Y.; Yang, F.; Gong, C.; Wang, C.; Li, X.; Li, C. Preparation and characterization of soybean protein adhesives modified with an environmental-friendly tannin-based resin. Polymers 2023, 15, 2289. [Google Scholar] [CrossRef]

| Substitution Ratio/% | Tannin/g | SPI/g | Sucrose/g | Water/g | SDBS/g |

|---|---|---|---|---|---|

| 0% | 30 | — | 20 | 33.3 | 1.5 |

| 5% | 28.5 | 1.5 | 20 | 33.3 | 1.5 |

| 10% | 27.0 | 3.0 | 20 | 33.3 | 1.5 |

| 15% | 25.5 | 4.5 | 20 | 33.3 | 1.5 |

| 20% | 24.0 | 6.0 | 20 | 33.3 | 1.5 |

| 30% | 21.0 | 9.0 | 20 | 33.3 | 1.5 |

| 40% | 18.0 | 12.0 | 20 | 33.3 | 1.5 |

| 50% | 15.0 | 15.0 | 20 | 33.3 | 1.5 |

| 60% | 12.0 | 18.0 | 20 | 33.3 | 1.5 |

| NO. | TR/min | Compound | MW | CAS | Molecular Formula | Chemical Structure |

|---|---|---|---|---|---|---|

| 1 | 0.9 | Toluene | 92.1 | 000108-88-3 | C7H8 |  |

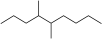

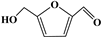

| 2 | 6.19 | Furfural alcohol | 98.0 | 000098-00-0 | C5H6O2 |  |

| 3 | 6.24 | Furfuraldehyde | 96.0 | 000098-01-1 | C5H4O |  |

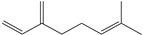

| 4 | 7.22 | Myrcene | 136.1 | 000123-35-3 | C10H16 |  |

| 5 | 8.33 | Dipentene- | 136.1 | 005989-27-5 | C10H16 |  |

| 6 | 9.58 | Benzaldehyde | 106.0 | 000100-52-7 | C7H6O |  |

| 7 | 9.8 | 5-Methyl-2-furaldehyde | 110.0 | 000620-02-0 | C6H6O2 |  |

| 8 | 1.13 | 2(5H)-Furanone | 84.0 | 000497-23-4 | C4H4O2 |  |

| 9 | 11.13 | Benzene, 1,2,3,4-tetramethyl- | 134.1 | 000488-23-3 | C10H14 |  |

| 10 | 11.28 | 1-isopropyl-2-methylbenzene | 134.1 | 000527-84-4 | C10H14 |  |

| 11 | 12.89 | 3-Hydroxy-2-methyl-4-pyrone | 126.0 | 000118-71-8 | C6H6O3 |  |

| 12 | 13.12 | 2,3-dihydro-3,5-dihydroxy-6-me | 144.0 | 028564-83-2 | C6H8O4 |  |

| 13 | 13.64 | 2,5-Piperazinedione,1,4-dimethyl- | 142.0 | 005076-82-4 | C6H10N2O2 |  |

| 14 | 13.98 | Butanimidamide, N-hydroxy- | 102.1 | 027620-10-6 | C4H10N2O |  |

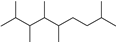

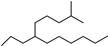

| 15 | 14.34 | 2,3,5,8-Tetramethyldecane | 366.4 | 192823-15-7 | C14H30 |  |

| 16 | 14.64 | Isobornyl methacrylate | 226.3 | 055045-08-4 | C11H24 |  |

| 17 | 15.38 | 5-Hydroxymethylfurfural | 126.0 | 000067-47-0 | C6H6O3 |  |

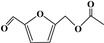

| 18 | 16.14 | 5-Acetoxymethyl-2-furaldehyde | 168.0 | 010551-58-3 | C8H8O4 |  |

| 19 | 16.92 | Dodecane, 2-methyl-6-propyl- | 226.3 | 055045-08-4 | C14H34 |  |

| 20 | 17.12 | Phenol,2,4-bis(1,1-dimethylethyl)- | 206.2 | 000096-76-4 | C14H22O |  |

| 21 | 18.11 | Dimethyl phthalate | 194.1 | 000131-11-3 | C10H10O4 |  |

| 22 | 18.52 | Cedrol | 222.2 | 000077-53-2 | C15H26O |  |

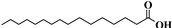

| 23 | 21.34 | Hexadecanoic acid | 256.3 | 000057-10-3 | C16H32O2 |  |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xiao, G.; Liang, J.; Wu, Z.; Lei, H.; Gong, F.; Gu, W.; Tu, Y.; Li, D. A Composite Whole-Biomass Tannin–Sucrose–Soy Protein Wood Adhesive with High Performance. Forests 2023, 14, 1250. https://doi.org/10.3390/f14061250

Xiao G, Liang J, Wu Z, Lei H, Gong F, Gu W, Tu Y, Li D. A Composite Whole-Biomass Tannin–Sucrose–Soy Protein Wood Adhesive with High Performance. Forests. 2023; 14(6):1250. https://doi.org/10.3390/f14061250

Chicago/Turabian StyleXiao, Guoming, Jiankun Liang, Zhigang Wu, Hong Lei, Feiyan Gong, Wen Gu, Yuan Tu, and De Li. 2023. "A Composite Whole-Biomass Tannin–Sucrose–Soy Protein Wood Adhesive with High Performance" Forests 14, no. 6: 1250. https://doi.org/10.3390/f14061250

APA StyleXiao, G., Liang, J., Wu, Z., Lei, H., Gong, F., Gu, W., Tu, Y., & Li, D. (2023). A Composite Whole-Biomass Tannin–Sucrose–Soy Protein Wood Adhesive with High Performance. Forests, 14(6), 1250. https://doi.org/10.3390/f14061250