Abstract

This study aimed to evaluate the impact of thermal modification on the physical and mechanical properties of three different wood species from Bosnia and Herzegovina, namely beech wood (Fagus sylvatica L.), linden wood (Tilia cordata), and silver fir wood (Abies alba). The samples underwent thermal modification at five different temperatures (170 °C, 180 °C, 195 °C, 210 °C, and 220 °C) for varying durations (ranging from 78 to 276 min). After treatment, they were exposed to outdoor conditions for twelve months. The study examined the four-point bending strength, tensile force, color change, and surface quality of the modified and unmodified samples. The results showed that outdoor exposure negatively impacted the mechanical properties of the unmodified samples, especially in the linden wood which was 41% and the beech wood which was 42%. Additionally, outdoor exposure caused significant surface cracks in the thermally modified linden and beech wood. The study also found prominent color changes in the modified and unmodified samples during twelve months of exposure. The roughness of the samples was determined with a confocal laser scanning microscope, which showed that the roughness increased on both the axial and the longitudinal surfaces after weathering. The highest roughness for the fir wood was determined to be 15.6 µm. Overall, this study demonstrates the importance of wood modification and its impact on the use-value of wood products.

1. Introduction

Wood is a natural and renewable resource that has been used by humans for thousands of years. It is highly versatile and can be used in a wide range of applications, from furniture and construction to tool making and artwork. However, its outdoor applications are limited due to its susceptibility to wood-destroying organisms such as fungi and insects [1]. Chemical treatments have been utilized to slow down decay [2], but due to environmental concerns and the Biocidal Products Regulation (EC 2000) [3], wood modification has gained attention as an alternative approach to wood protection [4]. Thermal modification is a wood modification technique that involves subjecting wood to high temperatures in the absence of oxygen. This process alters the chemical structure and composition of the wood, resulting in improved physical properties and increased resistance to decay [5]. One of the primary benefits of thermal modification is that it can improve the dimensional stability of wood. Heat treatment reduces the moisture content of the wood, which helps to prevent swelling and shrinkage that can occur with changes in humidity. This makes thermally modified wood more resistant to warping, twisting, and cracking, making it an ideal material for outdoor applications. In addition to improving dimensional stability, thermal modification also increases the wood’s resistance to decay-causing organisms such as fungi and insects. The high temperatures used during the process help to break down complex organic compounds within the wood, reducing its susceptibility to attack by wood-destroying organisms. Another benefit of thermal modification is that it creates a new material that does not pose an environmental hazard compared to untreated wood. Traditional wood treatments involve the use of chemicals that can leach into soil and waterways, potentially harming plants and animals. In contrast, thermal modification does not involve the use of any harmful chemicals, making it a more environmentally friendly option. Thermally modified timber (TMT) is predominantly produced from wood species with low durability, such as Norway spruce (Picea abies), Scots pine (Pinus sylvestris), Radiata pine (Pinus radiata), poplar (Populus sp.), ash (Fraxinus excelsior), African whitewood (Triplochiton scleroxylon), and others [6]. The modification process is carried out in a reduced oxygen environment at elevated temperatures (160 °C to 240 °C) [7,8], which causes chemical and physical changes in the wood, resulting in improved durability and dimensional stability [9]. TMT finds application in indoor and outdoor use as decking, flooring, cladding, garden furniture, and window joinery [10,11,12,13,14].

Outdoor wood is subjected to biotic and abiotic degradation, including weathering, which results in color changes and is a complex process influenced by factors such as precipitation, UV radiation, water, atmosphere, and wind [15,16,17,18]. UV radiation is one of the most influential parameters in the weathering process, leading to the photodegradation of wood, which serves as a suitable substrate for bacteria and fungi [19]. In addition to UV radiation and fungi, other factors contribute to weathering, such as water and wind [16]. Various approaches, such as impregnation with carnauba wax [20] or raw pine resin [20], have been employed to improve wood’s properties against weathering and biodegradation. The first signs of brown rot in Norway spruce require prolonged exposure of about 325 days with suitable decay conditions [21,22,23]. However, due to its better inherent durability, thermally modified wood requires even longer exposure to exhibit signs of decay [24]. Blue stain fungi, on the other hand, develop relatively quickly on the wood surface and are influenced by climate conditions [25,26]. Discoloring fungi and blue stain fungi predominantly affect the aesthetics of wood and wood-based materials [27]. The objective of the present study is to investigate the aesthetic performance of modified wood, including changes in color, roughness, and fungal disfigurement, as well as any potential changes in mechanical properties after outdoor weathering. The findings of this study will provide valuable insights into the long-term performance of thermally modified wood, particularly in outdoor applications where exposure to weathering conditions can accelerate the degradation process. Understanding the effects of wood modification on both physical and mechanical properties can help inform decisions about the use of modified wood in various applications and can guide the development of new wood modification techniques that balance aesthetic appeal with durability and sustainability.

2. Materials and Methods

2.1. Materials

In this study, the selected physical and mechanical properties of three different wood species were investigated. The group of selected materials consisting of twenty samples for each type of unmodified wood and thermally modified wood, specifically European beech (Fagus sylvatica L.), linden (Tilia cordata), and silver fir (Abies alba), were prepared. The analysis of the results presented the mean value of the tested samples for each wood type. All materials originated from western Bosnia. It was wood that was cut in mixed forests with an average age of 50 years. They were free of defects and without signs of degradation. These species were selected as the most important timber species in the region. Their further use in the construction sector is currently limited due to their low durability. The individual wood species were thermally modified (TM) at different maximum temperatures and modification durations, as listed in Table 1. Five samples without visible defects, a full cross-section, and free from knots and resin pockets were prepared for the bending and tensile force test. The timber was planed before thermal modification to the dimensions of 380 × 50 × 20 mm3 for the four-point bending samples and 162 × 22 × 18 mm³ for the tensile samples.

Table 1.

Thermal modification procedures for the three different wood species.

2.2. Thermal Modification Treatment

All samples were labeled according to the experimental design and oven-dried (24 h; 103 °C) before thermal modification. After drying was completed, the samples were cooled in a desiccator, and the respective masses were determined. These data were used to calculate the mass losses due to thermal modification (TM). Subsequently, several rounds of TM were carried out using a commercial process (Silvapro®, Silvaprodukt, Ljubljana, Slovenia), with an initial vacuum applied in the first step of the treatment (Table 1) [28]. The parameters of the heat treatment procedure for testing the mechanical and physical properties of European beech (Fagus sylvatica L.), linden (Tilia cordata), and silver fir (Abies alba), follow those used in commercial processes. Superheated steam is utilized in the thermal modification process of Silvapro® wood. The wood is exposed to a controlled steam atmosphere under high pressure, achieving the desired temperature and moisture level. Once the desired conditions are reached, the wood is held in place for a certain period to ensure sufficient thermal modification. Afterward, a cooling phase commences, which is crucial for achieving the desired wood properties. The exposed wood is gradually returned to room temperature in a controlled manner. The cooling process is managed to ensure that the ambient temperature is maintained below 30 °C for 24 h to guarantee effective thermal modification [28].

2.3. Outdoor Exposure of the Samples

This testing was based on the twelve-month exposure of thermally modified and non-modified samples to outdoor conditions in the territory of Bosnia and Herzegovina, more specifically in Cazin (44.966° N 15.942° E, with an average altitude of 400 m), starting on 7 September 2019. The samples were exposed 0.5 m above the ground in use class 3, as defined by [29] EN 335 (CEN 2013). Ten untreated samples were exposed for each wood species, and ten were modified according to different modification processes. The average air temperature in Cazin ranges from 9.6 °C to 11.4 °C. The mean minimum air temperatures have negative values in January, February, and December, with the lowest temperature in January being between −5 °C and −6 °C. High mean maximum temperatures in July and August (between 25 °C and 27 °C) suggest that summers in the area are relatively warm [30].

2.4. Bending and Tensile Tests

To evaluate the mechanical properties of the samples before and after exposure, bending and tensile strength were determined according to EN 408+A1 (CEN 2010) [31]. Before testing, the samples were conditioned under a standard laboratory climate, T = 20 °C, and a relative humidity of 65%. With a minimum length of about 19 times the cross-sectional thickness, the samples are simply supported and symmetrically loaded by 2-point bending over a range of about 18 times the thickness. The dimensions of the 4-point bending samples were 380 × 50 × 20 mm3. The tensile tests were performed according to the standard EN 408+A1 (CEN 2010) [31]. The dimensions of the tensile test sample were 162 × 22 × 18 mm3. The mechanical test was performed on a SHIMADZU (Kyoto, Japan) shredder type SIL-50KNAG at the Faculty of Technical Engineering in Bihać. The test was performed in ten replicates for each material. The average density of the samples was 0.366 g/cm3, 0.472 g/cm3, and 0.675 g/cm3 for the fir, lindens, and beech samples, respectively. When it comes to the modified samples, the average density for fir was 0.353 g/cm3, for linden, it was 0.455 g/cm3, and for beech, it was 0.655 g/cm3. The average moisture content of the samples was from 8 to 12%.

2.5. Color Analysis

The test samples were scanned and processed using Corel Photo-Paint 8 software. Corel Photo-Paint was used for color analysis as this technique provides the color of the entire surface rather than individual spots. This technique provides reliable measurements, as shown by comparing both techniques [32].

The color measurements were carried out on samples exposed to external weather conditions for twelve months using the CIE Lab system, developed by the International de l’Eclairage Commission (CIE, Colourimetry). Three parameters characterize this system: L*, a*, and b*. The L* axis represents the lightness, which varies from one hundred (white) to zero (black) and is the achromatic axis of the grey, while a* and b* are the chromaticity coordinates.

The color difference ΔE (Equation (1)) from a reference color (L*0, a*0, b*0) to a target color (L*1, a*1, b*1) in CIE Lab space is calculated by determining the Euclidean distance between two colors given by:

By summing (Σ ΔE) the obtained results of the analyzed points (Equation (2)), the course of the color changes can be determined:

2.6. Roughness of the Wood Surface

The surface morphology of the samples in this study was characterized using an Olympus LEXT OLS5000 laser scanning confocal microscope (Tokyo, Japan). The 3D images of the longitudinal surfaces were taken at 50× magnification on an area of 0.26 × 0.26 mm2. The locations of the measurements were randomly selected. For each material combination, five measurements were taken on two random samples. The surface roughness was determined using microscope software (LEXT OLS5000 software package). Several parameters were calculated, but only the parameter Sa, which is the most representative and commonly used to evaluate surface roughness [33], is presented. It expresses the difference in the height of each point as an absolute value compared to the arithmetic mean of the surface. Statistical analysis of the data was performed using Microsoft Excel (Microsoft, 2019, Redmond, WA, USA) and GraphPad Prism (GraphPad Software, 9.0, San Diego, CA, USA).

3. Results and Discussion

3.1. Mass Loss of the Thermally Modified Samples

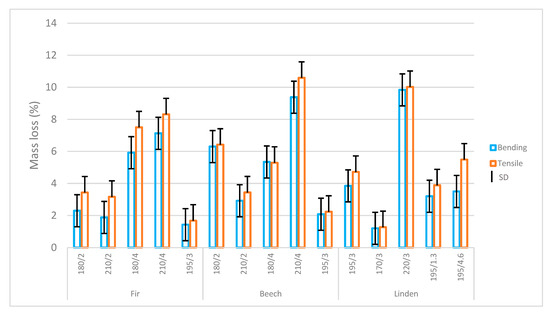

The results indicate a clear trend of increasing mass loss (ML) with rising thermal modification temperature, from 170 °C to 210 °C, for both bending and tensile samples (Figure 1). Among the samples, the lowest ML (1.2%) was observed in the linden wood treated at 170 °C for three hours. On the other hand, the highest ML value (10.02%) was found in the linden wood samples modified at 220 °C for three hours. These results are consistent with the previous literature [34]. The degradation of hemicellulose and lignin is expected to be the primary cause of mass loss at these temperatures, as cellulose tends to be more resistant to thermal degradation than hemicellulose and lignin [35]. The obtained results are similar to those of previous studies that have investigated the mass loss of thermally modified wood species. Čermák et al. [36] reported that the mass loss of beech, oak, spruce, and pine wood specimens increased with the increasing temperature and time of thermal modification in an open reactor system using superheated steam. They found that the mass loss ranged from less than 1.5% at 140 °C and 160 °C to 13.5% (beech), 18.8% (oak), 6.7% (spruce), and 13.5% (pine) at 220 °C for six hours. They also observed that hardwoods were more sensitive to thermal degradation than softwoods, which is consistent with the findings for linden wood. Another study by Wentzel et al. [37] analyzed the reversible changes in the hygroscopicity of thermally modified eucalypt wood from open and closed reactor systems at different temperatures and water vapor pressures. They found that the mass loss of eucalypt wood was influenced by both the temperature and the pressure of the process and that the mass loss was higher in the closed reactor system than in the open reactor system for the same temperature. They reported that the mass loss of eucalypt wood ranged from 0.6% to 8.9% in the open reactor system and from 1.4% to 14.3% in the closed reactor system at temperatures between 160 °C and 240 °C.

Figure 1.

Mass loss of fir, linden, and beech wood after thermal modification.

3.2. Maximum Bending and Tensile Force

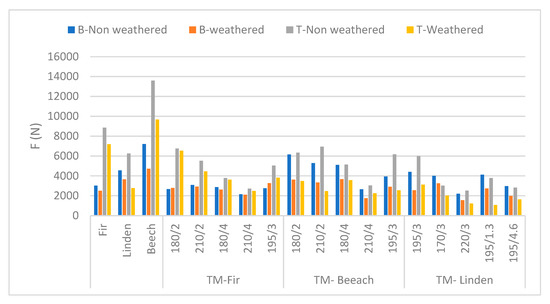

Table 2 shows the comparative results of measuring the maximum bending and tensile force of samples exposed to external conditions and those that were not, i.e., tested under laboratory conditions.

Table 2.

Results of the bending and tensile force tests on the non-weathered and weathered samples after twelve months of exposure.

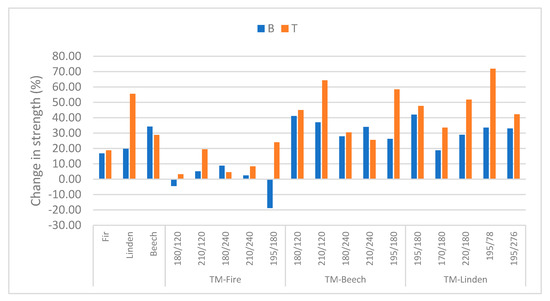

As shown in the results in Table 2, the relationship between the strength in actual applications and the measurement of strength under laboratory conditions tests is different for the given wood species. As the wood constantly changes due to weathering and other degradation phenomena, a decrease in maximum bending strength was observed in the European beech and linden samples. In contrast, silver fir wood’s maximum strength maintained its values at different modification temperatures, as shown in Figure 2.

Figure 2.

Comparison of the bending and tensile force results of the weathered and non-weathered specimens under laboratory conditions.

In general, tests based on bending strength provide better comparative results for silver fir wood than for modified and unmodified linden wood. The percentage reduction in maximum strength for the linden samples ranged from 18% to 41% for the modified samples, while this reduction ranged from 19% to 30% for the unmodified samples. A significant reduction in maximum strength was observed for European beech wood, ranging from 26% to 42% depending on the temperature at which the samples were treated. In comparison, the decrease in the unmodified samples ranged from 34% to 51%, as shown in Figure 3. Thermal modification of silver fir wood had a positive effect on the weathering of the samples. The maximum four-point bending strength was maintained in the non-weathered samples. In the measurements where the samples were treated at a temperature of 180 °C/2 h, there was an increase in maximum strength of about 4%, while at a temperature of 195 °C/3 h, there was an increase of about 18%. Thermally modified fir wood showed better performance after twelve months of exposure than linden and beech wood, which are quite susceptible to abiotic agents. Both linden and beech wood are classified as very susceptible species to decay as of standard EN 350 (CEN 2016) [38]. Tensile testing of thermally modified and unmodified fir, linden, and beech wood compared to wood exposed for twelve months showed favorable mechanical properties for fir wood. The tensile force is shown in Table 2 compared to the experimental measurements on the samples not exposed to external conditions. Fir wood showed the best tensile force at a temperature of 180 °C/2 h, as shown in Figure 2 and Figure 3. The most significant reductions in maximum tensile force of up to 72% were found in thermally modified linden wood treated at 195 °C/3 h and exposed to weathering. Thermally modified beech wood suffered a maximum strength reduction of 63% at a temperature of 210 °C/2 h. This is further evidence that thermal modification has a more positive effect on softwood species. In researchers [39,40,41] reported that the static modulus of elasticity (MOE) and modulus of rupture (MOR) of Scots pine wood increased when modified at 150 °C in an open reactor system using saturated steam, but decreased when modified at 180 °C. They also found that the tensile strength parallel to the grain decreased significantly after heat treatment, while the compressive strength parallel to the fiber increased. They attributed these changes to the degradation of hemicellulose and lignin and the formation of cross-links between cellulose and lignin during thermal modification. In addition, our results are similar to those of Rautkari et al. [41] in terms of the increase in MOE and MOR for fir wood modified at 180 °C/2 h, but different from those of Boonstra et al. [42] in terms of the decrease in bending strength and tensile strength for linden and beech wood modified at higher temperatures.

Figure 3.

Percentage decrease in the mechanical properties of fir, beech, and linden wood.

In the samples that were not thermally modified, the following reductions were observed after twelve months of exposure: 18% in fir wood, 55% in linden wood, and 28% in beech wood compared to the samples that were not exposed to external conditions, which can best be seen in Figure 3. In this case, fir wood showed the slightest reduction in maximum tensile force.

3.3. Color Changes of the Weathered Samples

Color is one of the most important aesthetic parameters. Thermal modification of wood leads to the darkening of the wood. Higher modification intensities are reflected in a darker color (parameter L*). For example, the parameter L* decreased from 85.5 in the reference linden wood to 40.4 in the parallel samples modified at 220 °C for 3 h. However, the darkest color was measured in beech wood modified at 210 °C for 4 h. This color change is well known and has already been analyzed in detail [9]. On the other hand, weathering also causes noticeable color changes in the wood. The non-modified wood species became noticeably darker. This was observed in fir, beech, and linden. The darkest color was observed in the weathered linden wood. The L* component changed from 85.5 to 32.9, resulting in a total color change (ΔE) of 53.3 (Table 3). The highest color change of linden wood is not surprising, as linden belongs to the most susceptible wood species group with the lowest amount of biologically active extractives [2,21]. The dark color of the wood is a function of two processes. First, weathering causes the degradation of lignin and the associated leaching of degradation products from the wood. This results in a silvery color. Secondly, the darker color is also associated with melamine pigments (Table 4) secreted by blue and sapstain fungi [43]. However, less noticeable changes were found in the thermally modified wood. The main reason for this is the fact that modified wood is already darker, so blue staining does not cause such a noticeable change in the L* component as reported for non-modified species. However, for the samples modified with the most severe process (210 °C), weathering causes the lightening of the samples. For example, the L* component of beech wood modified at 210 °C for 4 h changed from 29.2 to 34.5 after twelve months of weathering. The main reason for this phenomenon is the degradation of lignin on the surface and the leaching of quinones after UV irradiation. The visual appearance, such as color change and cracking, of the thermally modified samples before and after weathering can be seen in Figure 4. Our results are in line with those of previous studies that investigated the color change of thermally modified wood. Spear et al. [44] reviewed functional treatments for modified wood and reported that thermally modified timber is generally a darker color than the original untreated timber, but exposure to sunlight and rainfall leads to a relatively rapid change of color towards a silver–grey form. They also stated that color change is a function of two processes: the degradation of lignin and the associated leaching of degradation products from the wood, and the melanin pigments secreted by blue and sapstain fungi.

Table 3.

Influence of the modification parameters and weathering on wood color, expressed in the CIE Lab system.

Table 4.

Microscopic images of the selected materials before and after weathering. The size of the microscopic images is 0.26 × 0.26 mm2.

Figure 4.

The visual appearance of thermally modified beech wood specimens (210 °C, 2 h) before (left) and after weathering (right).

The laser scanning confocal microscopic analysis confirmed the respective hypothesis. As can be seen on the surface of the weathered samples (Table 4), there are melamine deposits that also influence the chemical composition of the wood [43].

3.4. Characteristics of Wood Surface Roughness

Roughness characterizes the fine irregularities on a machined surface. These irregularities can be determined by measuring the height, width, and shape of peaks and valleys created by woodworking operations and anatomical structural characteristics [45]. However, since all of the samples were made with the same technical equipment, the main differences in the respective examinations can be attributed to the inherent properties of the wood. Comparing the roughness of the different control surfaces (Table 5), it can be seen that the Sa value for beech (7.5 µm) and linden (7.1 µm) is comparable. In comparison, a significantly higher roughness was determined for fir wood (15.6 µm). This can be related to the anatomy of the respective wood species. Both beech and linden belong to the diffuse-porous deciduous trees with very anatomically homogeneous wood, while fir is a typical representative of conifer trees [46]. In particular, the size of the cells influences the Sa parameter [39]. Because modified wood is more brittle and requires more skill to work with [47] as well, roughness is influenced. However, the average roughness of the modified fir and linden wood was in the same order of magnitude as the roughness of the non-modified wood. For example, the roughness of the reference beech wood was 7.5 µm, while an average roughness of 7.9 µm was measured in the specimens modified at 180 °C for 4 h. On the other hand, a more significant scattering of roughness was observed in the fir wood. However, there is no discernible trend in the respective modification treatment. Weathering increased roughness for all samples, except for the fir wood modified at 180 °C for 2 h, where the roughness remained in the same range. For example, the roughness of the beechwood samples modified at 180 °C for 2 h increased from 9.3 µm to 18.7 µm after twelve months of weathering. This is in line with previous observations [43]. It should be noted that the naturally weathered samples were exposed to the full range of biotic and abiotic factors. They cause the formation of microcracks that affect roughness and water performance [48,49]. In addition, blue stain fungi colonies or weathering, which because there is the occurrence of loose fibers, also contribute to increased roughness. However, as the wood was analyzed at higher magnifications, larger cracks did not affect the roughness parameters.

Table 5.

Influence of the modification parameters and outdoor weathering on the surface roughness.

4. Conclusions

Even short-term weathering of 12 months has a negative effect on the bending and tensile properties of the unmodified linden and beech wood samples. This effect was also observed in the samples modified with milder procedures. The main reason for the loss of mechanical properties can be attributed to the formation of larger surface cracks. However, the effect of thermal modification on the fir samples after 12 months of weathering is positive. In terms of aesthetic performance, all materials perform similarly. All modified and non-modified materials are grey and covered with blue stain fungi. Roughness increased due to weathering in both the modified and non-modified wood species. Based on the measurements, thermally modified fir wood seems to be more suitable for outdoor applications than beech and linden wood. In addition to the findings of this study, the results have important implications for the industrial application of thermally modified wood. The positive effect of thermal modification on the fir wood samples after 12 months of weathering suggests that this wood species may be more suitable for outdoor applications. However, the negative effects of weathering on the mechanical properties of the unmodified and modified beech and linden wood samples highlight the need for the proper protection and maintenance of wood products used in outdoor settings. Furthermore, this study opens up potential avenues for future research in this field. For example, further investigations could focus on the optimization of thermal modification parameters to enhance the resistance of wood to weathering and decay. Additionally, studies could explore the use of different wood species or the combination of wood with other materials to improve the durability and performance of wood products in outdoor applications.

Author Contributions

Conceptualization, M.H. methodology, M.H. and R.H.; validation, R.H. and M.B.; formal analysis, M.H., R.H., L.F. and M.B.; investigation, R.H., M.H., L.F. and D.K.; resources, R.H., M.H., M.B. and L.F.; data curation, R.H., M.B., L.F. and M.H.; writing—original draft preparation, R.H. and M.H.; writing—review and editing, R.H., M.H., D.K., M.B., L.F. and E.K.; visualization, H.D.; supervision, M.H.; project administration, R.H. and M.B.; funding acquisition, M.H. and R.H. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the “Natual Science 432 Foundation of Anhui Province (No. 2008085QC130)”, “Bilateral project between the Republic of 433 Slovenia and Bosnia and Herzegovina” and the research program “P4-0015 Wood and 434 lignocellulosic composites” financed by the Slovenian Research Agency (ARRS). 435.

Data Availability Statement

All data included in this study are available upon request through contact with the corresponding author.

Acknowledgments

The authors acknowledge the financial support of the Slovenian Research Agency (ARRS) within research program P4-0015 (Wood and lignocellulosic composites), a bilateral project between the Republic of Slovenia and Bosnia and Herzegovina and the infrastructural center (IC LES PST 0481-09). Part of the published research was also supported by the Ministry of Agriculture, Forestry and Food in the frame of project V4-2017.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Humar, M.; Lesar, B.; Kržišnik, D. Vpliv Podnebnih Sprememb Na Dinamiko Glivnega Razkroja Lesa v Sloveniji. Acta Silvae Ligni 2021, 125, 53–59. [Google Scholar] [CrossRef]

- Reinprecht, L. Chemical Protection of Wood. Wood Deterioration, Protection and Maintenance; John Wiley & Sons Ltd.: Oxford, UK, 2016. [Google Scholar]

- EC 2000. Regulation (EU) No 528/2012 of the European Parliament and of the Council of 22 May 2012 Concerning the Making Available on the Market and Use of Biocidal Products; Official Journal of the European Communities (L 269): Brussels, Belgium, 2012; pp. 1–15. [Google Scholar]

- Hill, C.A.S. Wood Modification: Chemical, Thermal and Other Processes; Wiley Series in Renewable Resource Ser.; John Wiley & Sons Ltd.: Hoboken, NJ, USA, 2006; Volume 3, ISBN 978-0-470-02174-3. [Google Scholar]

- Jones, D.; Burnard, M.; Fioravanti, M.; Togni, M.; Kutnar, A. Wood Modification in Europe: Processes, Products, Applications; Firenze University Press: Florence, Italy, 2018. [Google Scholar]

- Hill, C.; Altgen, M.; Rautkari, L. Thermal Modification of Wood—A Review: Chemical Changes and Hygroscopicity. J. Mater. Sci. 2021, 56, 6581–6614. [Google Scholar] [CrossRef]

- Esteves, B.M.; Pereira, H.M. Wood Modification by Heat Treatment: A Review. BioResources 2008, 4, 370–404. [Google Scholar] [CrossRef]

- Robert Welzbacher, C.; Brischke, C.; Otto Rapp, A. Influence of Treatment Temperature and Duration on Selected Biological, Mechanical, Physical and Optical Properties of Thermally Modified Timber. Wood Mater. Sci. Eng. 2007, 2, 66–76. [Google Scholar] [CrossRef]

- Candelier, K.; Thevenon, M.-F.; Petrissans, A.; Dumarcay, S.; Gerardin, P.; Petrissans, M. Control of Wood Thermal Treatment and Its Effects on Decay Resistance: A Review. Ann. For. Sci. 2016, 73, 571–583. [Google Scholar] [CrossRef]

- Ugovšek, A.; Šubic, B.; Starman, J.; Rep, G.; Humar, M.; Lesar, B.; Thaler, N.; Brischke, C.; Meyer-Veltrup, L.; Jones, D.; et al. Short-Term Performance of Wooden Windows and Facade Elements Made of Thermally Modified and Non-Modified Norway Spruce in Different Natural Environments. Wood Mater. Sci. Eng. 2018, 14, 42–47. [Google Scholar] [CrossRef]

- Hasanagić, R.; Ganguly, S.; Bajramović, E.; Hasanagić, A. Mechanical Properties Changes in Fir Wood (Abies sp.), Linden Wood (Tilia sp.), and Beech Wood (Fagus sp.) Subjected to Various Thermal Modification Process Conditions. IOP Conf. Ser. Mater. Sci. Eng. 2021, 1208, 012025. [Google Scholar] [CrossRef]

- Chu, D.; Hasanagić, R.; Hodžić, A.; Kržišnik, D.; Hodžić, D.; Bahmani, M.; Petrič, M.; Humar, M. Application of Temperature and Process Duration as a Method for Predicting the Mechanical Properties of Thermally Modified Timber. Forests 2022, 13, 217. [Google Scholar] [CrossRef]

- Hasanagić, R. Optimization of Thermal Modification of Wood by Genetic Algorithm and Classical Mathematical Analysis. J. For. Sci. 2022, 68, 35–45. [Google Scholar] [CrossRef]

- Liang, D.; Ding, Z.; Yan, Q.; Hasanagić, R.; Fathi, L.; Yang, Z.; Li, L.; Wang, J.; Luo, H.; Wang, Q.; et al. A Primary Study on Mechanical Properties of Heat-Treated Wood via in-Situ Synthesis of Calcium Carbonate. J. Renew. Mater. 2023, 11, 435–451. [Google Scholar] [CrossRef]

- Humar, M.; Lesar, B.; Kržišnik, D. Tehnična in Estetska Življenjska Doba Lesa. Acta Silvae Ligni 2020, 121, 33–48. [Google Scholar] [CrossRef]

- Kropat, M.; Hubbe, M.A.; Laleicke, F. Natural, Accelerated, and Simulated Weathering of Wood: A Review. BioResources 2020, 15, 9998–10062. [Google Scholar] [CrossRef]

- Alao, P.; Visnapuu, K.; Kallakas, H.; Poltimäe, T.; Kers, J. Natural Weathering of Bio-Based Façade Materials. Forests 2020, 11, 642. [Google Scholar] [CrossRef]

- Wang, J.; Lu, C.; Liu, Y.; Wang, C.; Chu, F. Preparation and Characterization of Natural Rosin Stabilized Nanoparticles via Miniemulsion Polymerization and Their Pressure-Sensitive Adhesive Applications. Ind. Crop. Prod. 2018, 124, 244–253. [Google Scholar] [CrossRef]

- Acosta, A.P.; Barbosa, K.T.; Amico, S.C.; Missio, A.L.; de Avila Delucis, R.; Gatto, D.A. Improvement in Mechanical, Physical and Biological Properties of Eucalyptus and Pine Woods by Raw Pine Resin in Situ Polymerization. Ind. Crop. Prod. 2021, 166, 113495. [Google Scholar] [CrossRef]

- Brischke, C.; Meyer, L.; Alfredsen, G.; Humar, M.; Francis, L.; Flæte, P.-O.; Larsson-Brelid, P. Natural Durability of Timber Exposed Above Ground—A Survey. Drv. Ind. 2013, 64, 113–129. [Google Scholar] [CrossRef]

- Brischke, C.; Thelandersson, S. Modelling the Outdoor Performance of Wood Products—A Review on Existing Approaches. Constr. Build. Mater. 2014, 66, 384–397. [Google Scholar] [CrossRef]

- Kržišnik, D.; Brischke, C.; Lesar, B.; Thaler, N.; Humar, M. Performance of Wood in the Franja Partisan Hospital. Wood Mater. Sci. Eng. 2018, 14, 24–32. [Google Scholar] [CrossRef]

- Humar, M.; Kržišnik, D.; Lesar, B.; Brischke, C. The Performance of Wood Decking after Five Years of Exposure: Verification of the Combined Effect of Wetting Ability and Durability. Forests 2019, 10, 903. [Google Scholar] [CrossRef]

- Lie, S.K.; Thiis, T.K.; Vestøl, G.I.; Høibø, O.; Gobakken, L.R. Can Existing Mould Growth Models Be Used to Predict Mould Growth on Wooden Claddings Exposed to Transient Wetting? Build. Environ. 2019, 152, 192–203. [Google Scholar] [CrossRef]

- Resultat #1476041—Effects of Climatic Factors and Material Properties on Mould Growth on Untreated Wooden Claddings—Cristin. Available online: https://app.cristin.no/results/show.jsf?id=1476041# (accessed on 21 January 2020).

- Schmidt, O. Wood and Tree Fungi; Springer: Berlin/Heidelberg, Germany, 2006. [Google Scholar] [CrossRef]

- Humar, M.; Vek, V.; Bučar, B. Srce Properties of Blue-Stained Wood. Available online: https://hrcak.srce.hr/25409 (accessed on 12 February 2023).

- Rep, G.; Pohleven, F.; Kosmerl, S. Development of the industrial kiln for thermal wood modification by a procedure with an initial vacuum and commercialisation of modified Silvapro wood. In Proceedings of the 6th European Conference on Wood Modification, Ljubljana, Slovenia, 17–18 September 2012; University of Ljubljana: Ljubljana, Slovenia, 2012; pp. 11–17. [Google Scholar]

- EN 335:2013; Durability of Wood and Wood-Based Products—Use Classes: Definitions, Application to Solid Wood and Wood-Based Products. European Committee for Standardization: Brussels, Belgium, 2013. Available online: https://standards.iteh.ai/catalog/standards/cen/e5d368b1-2232-47e2-8349-ee85cb6c895b/en-335-2013 (accessed on 23 April 2023).

- Federalni Hidrometeorološki Zavod. Available online: https://www.fhmzbih.gov.ba/latinica/index.php# (accessed on 18 July 2020).

- EN 408:2010+A1:2012; Timber Structures—Structural Timber and Glued Laminated Timber—Determination of Some Physical and Mechanical Properties. European Committee for Standardization: Brussels, Belgium, 2012. Available online: https://standards.iteh.ai/catalog/standards/cen/6ffae6c9-5eaf-4c84-8bf3-5132cbfc563c/en-408-2010a1-2012 (accessed on 5 June 2022).

- Mao, J.; Wu, Z.; Feng, X. A Modeling Approach on the Correction Model of the Chromatic Aberration of Scanned Wood Grain Images. Coatings 2022, 12, 79. [Google Scholar] [CrossRef]

- Kraut—Strojniski Prirocnik|PDF. Available online: https://www.scribd.com/doc/70910928/Krautov-strojni%C5%A1ki-priro%C4%8Dnik (accessed on 18 February 2022).

- Torniainen, P.; Elustondo, D.; Dagbro, O. Industrial Validation of the Relationship between Color Parameters in Thermally Modified Spruce and Pine. BioResources 2015, 11, 1369–1381. [Google Scholar] [CrossRef]

- Čermák, P.; Hess, D.; Suchomelová, P. Mass loss kinetics of thermally modified wood species as a time–temperature function. Eur. J. Wood Wood Prod. 2021, 79, 547–555. [Google Scholar] [CrossRef]

- Kržišnik, D.; Lesar, B.; Thaler, N.; Humar, M. Influence of Natural and Artificial Weathering on the Colour Change of Different Wood and Wood-Based Materials. Forests 2018, 9, 488. [Google Scholar] [CrossRef]

- Dafale, N.; Rao, N.N.; Meshram, S.U.; Wate, S.R. Decolorization of Azo Dyes and Simulated Dye Bath Wastewater Using Acclimatized Microbial Consortium—Biostimulation and Halo Tolerance. Bioresour. Technol. 2008, 99, 2552–2558. [Google Scholar] [CrossRef] [PubMed]

- EN 350:2016; Durability of Wood and Wood-Based Products—Testing and Classification of the Durability to Biological Agents of Wood and Wood-Based Materials. European Committee for Standardization: Brussels, Belgium, 2016. Available online: https://standards.iteh.ai/catalog/standards/cen/b02d18a7-87ce-4a20-84c7-c0de641a2780/en-350-2016 (accessed on 18 February 2023).

- Wentzel, M.; Altgen, M.; Militz, H. Analyzing reversible changes in hygroscopicity of thermally modified eucalypt wood from open and closed reactor systems. Wood Sci. Technol. 2018, 52, 889–907. [Google Scholar] [CrossRef]

- Keržič, E.; Lesar, B.; Humar, M. Influence of Weathering on Surface Roughness of Thermally Modified Wood. BioResources 2021, 16, 4675–4692. [Google Scholar] [CrossRef]

- Rautkari, L.; Honkanen, J.; Hill, C.A.; Ridley-Ellis, D.; Hughes, M. Mechanical and physical properties of thermally modified Scots pine wood in high pressure reactor under saturated steam at 120, 150 and 180 °C. Eur. J. Wood Wood Prod. 2014, 72, 33–41. [Google Scholar] [CrossRef]

- Boonstra, M.J.; Van Acker, J.; Tjeerdsma, B.F.; Kegel, E.V. Strength properties of thermally modified softwoods and its relation to polymeric structural wood constituents. Ann. For. Sci. 2007, 64, 679–690. [Google Scholar] [CrossRef]

- ThermoWood® Handbook. Available online: https://thermalwoodcanada.com/images/PDF/Thermowood_handbook.pdf (accessed on 21 April 2023).

- Spear, M.J.; Curling, S.F.; Dimitriou, A.; Ormondroyd, G.A. Review of functional treatments for modified wood. Coatings 2021, 11, 327. [Google Scholar] [CrossRef]

- Wagenfuhr, R. Holzatlas; Fachbuchverlag: Leipzig, Germany, 2007. [Google Scholar]

- Csanády, E.; Magoss, E.; Tolvaj, L. Surface roughness of wood. In Quality of Machined Wood Surfaces; Springer: Berlin/Heidelberg, Germany, 2015; pp. 183–236. [Google Scholar] [CrossRef]

- Žlahtič-Zupanc, M.; Lesar, B.; Humar, M. Changes in Moisture Performance of Wood after Weathering. Constr. Build. Mater. 2018, 193, 529–538. [Google Scholar] [CrossRef]

- Cogulet, A.; Blanchet, P.; Landry, V. The Multifactorial Aspect of Wood Weathering: A Review Based on a Holistic Approach of Wood Degradation Protected by Clear Coating. BioResources 2017, 13, 2116–2138. [Google Scholar] [CrossRef]

- Temiz, A.; Terziev, N.; Eikenes, M.; Hafren, J. Effect of Accelerated Weathering on Surface Chemistry of Modified Wood. Appl. Surf. Sci. 2007, 253, 5355–5362. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).