Data-Driven Optimization of Forestry and Wood Procurement toward Carbon-Neutral Logistics of Forest Industry

Abstract

:1. Introduction

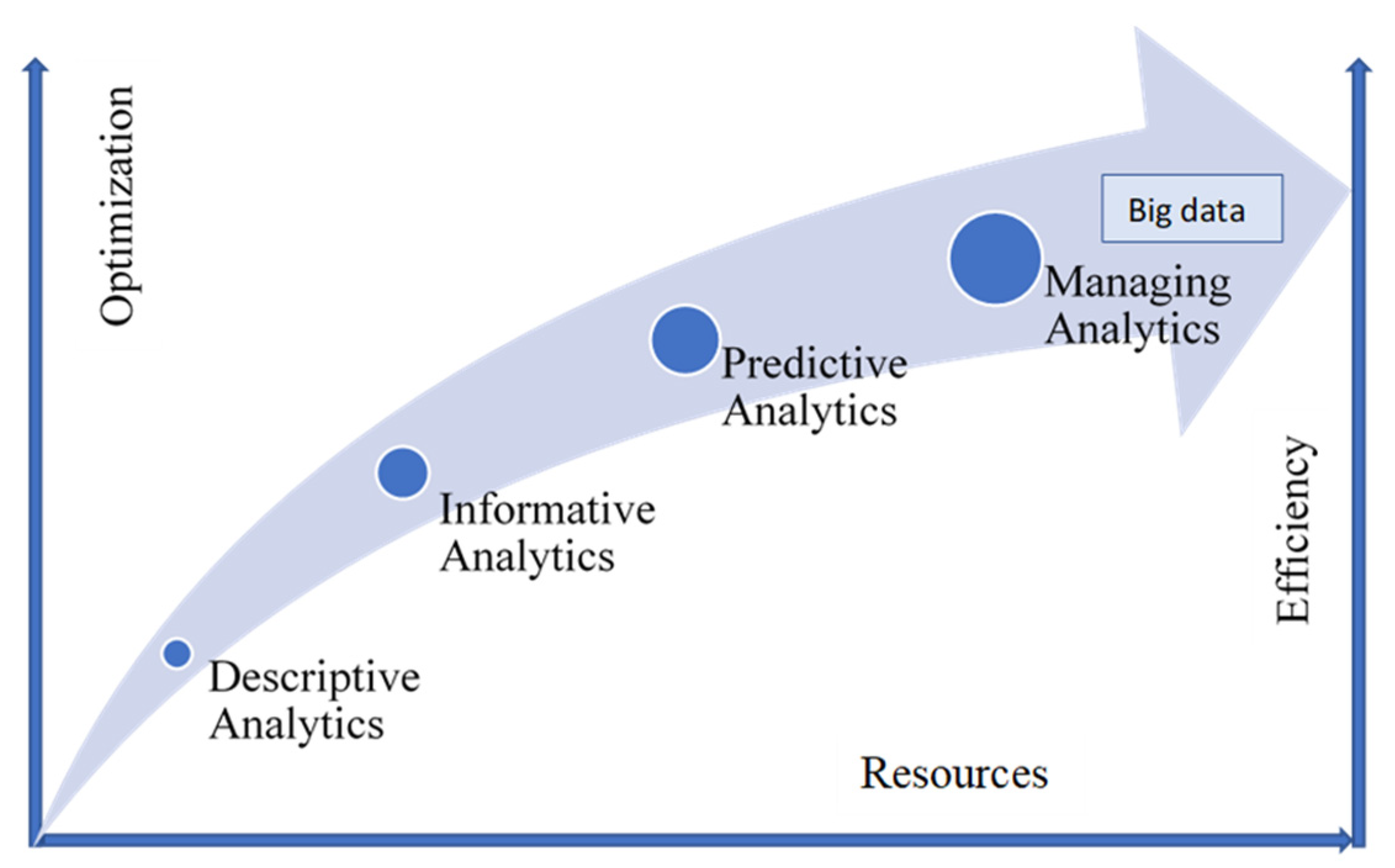

1.1. Data-Driven Approach to SC Management

1.2. Northern Finland as a Carbon-Neutral Wood Procurement Area

1.3. Strategic WSCM

1.4. Research Problem and Aims of Study

- (1)

- How do long-distance transportation modes impact WSC practices?

- (2)

- How do market situations of wood resources impact WSC practices?

- (3)

- What implications does the integration of data-driven applications in WSCM have on strategies?

2. Materials and Methods

2.1. Database

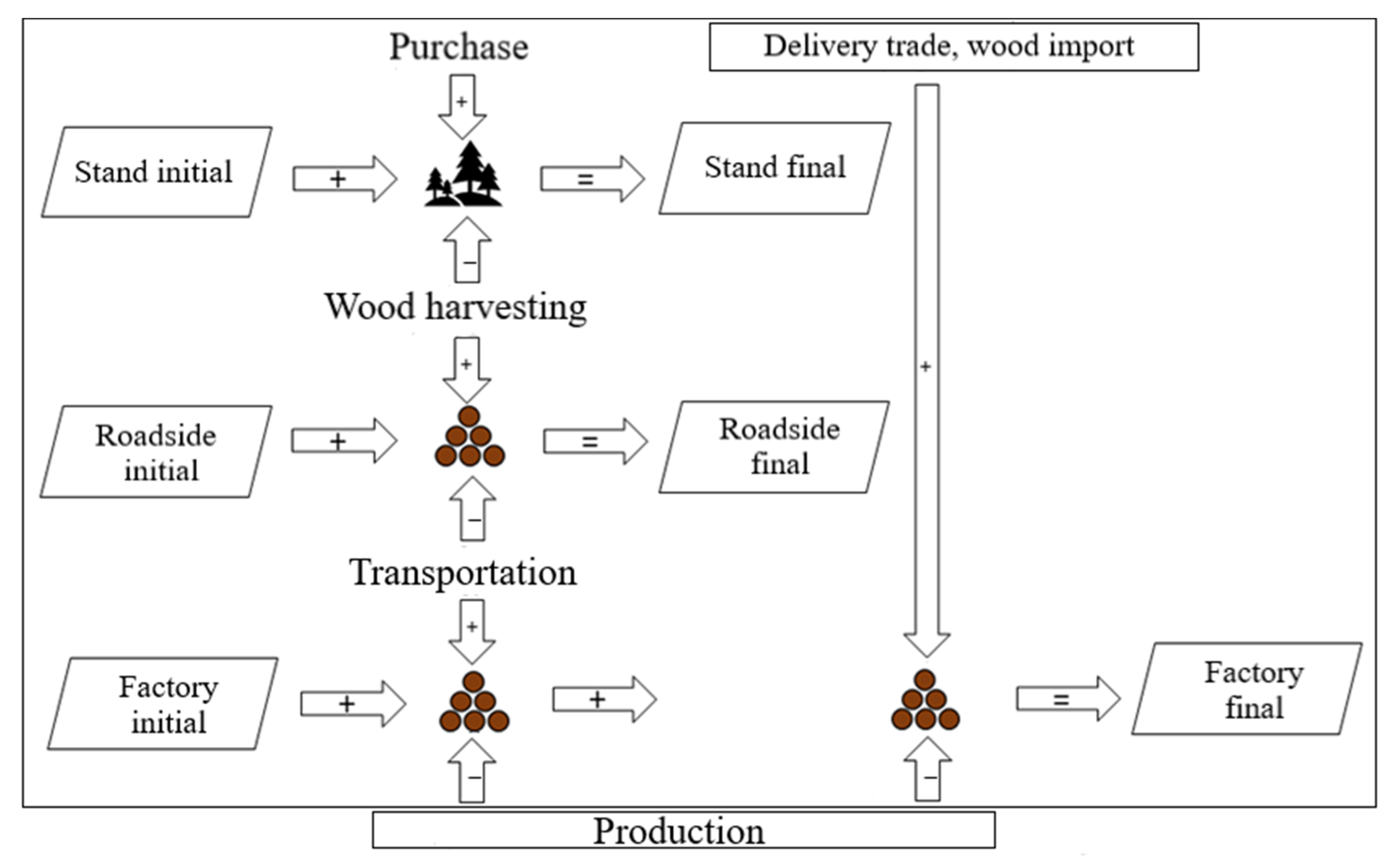

2.2. Data-Driven Wood Flow Optimization

2.3. Scenario and Sensitivity Analyses

2.4. Wood Flow Model and Strategic Scenarios of Forest Industry

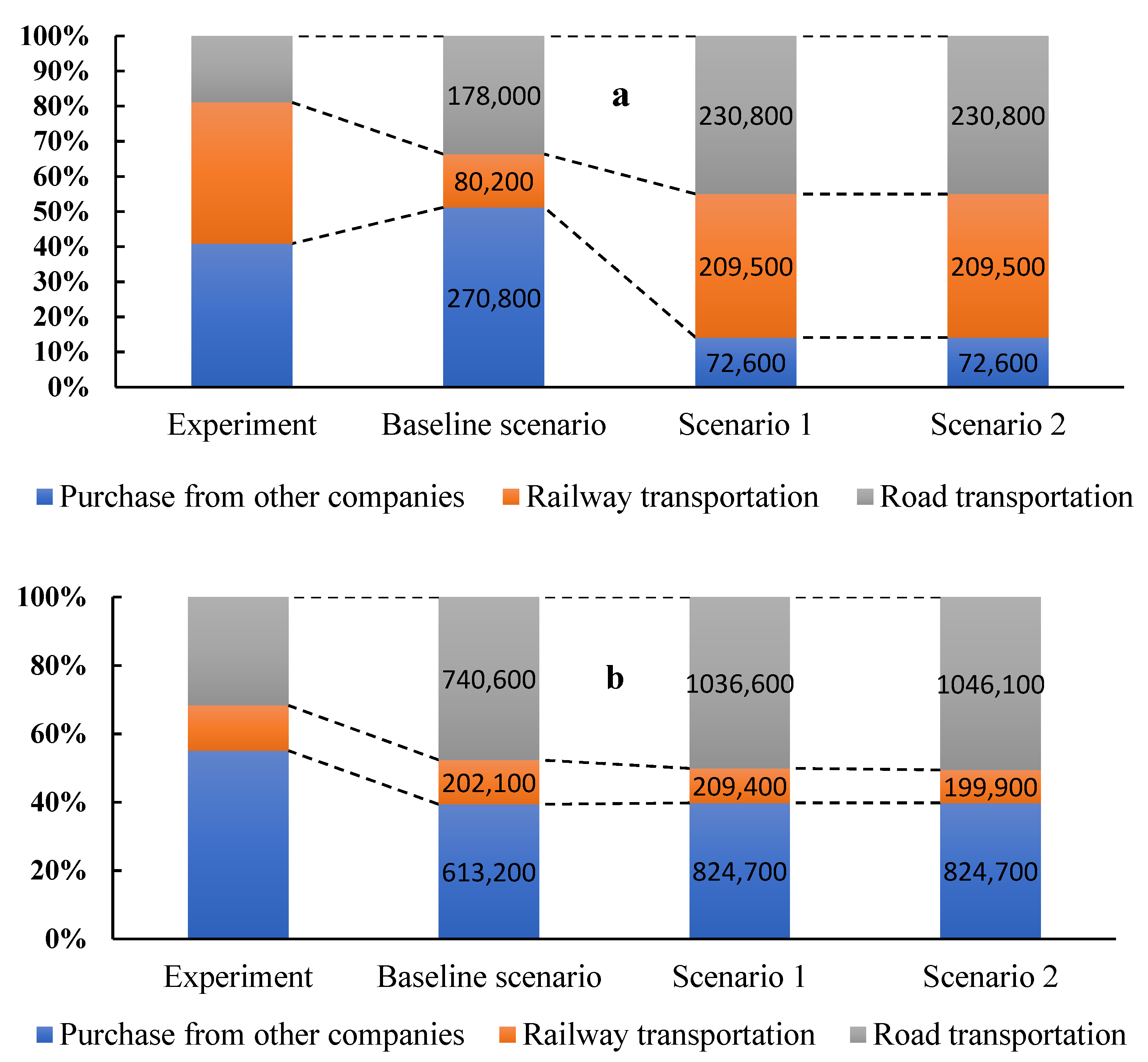

- (1)

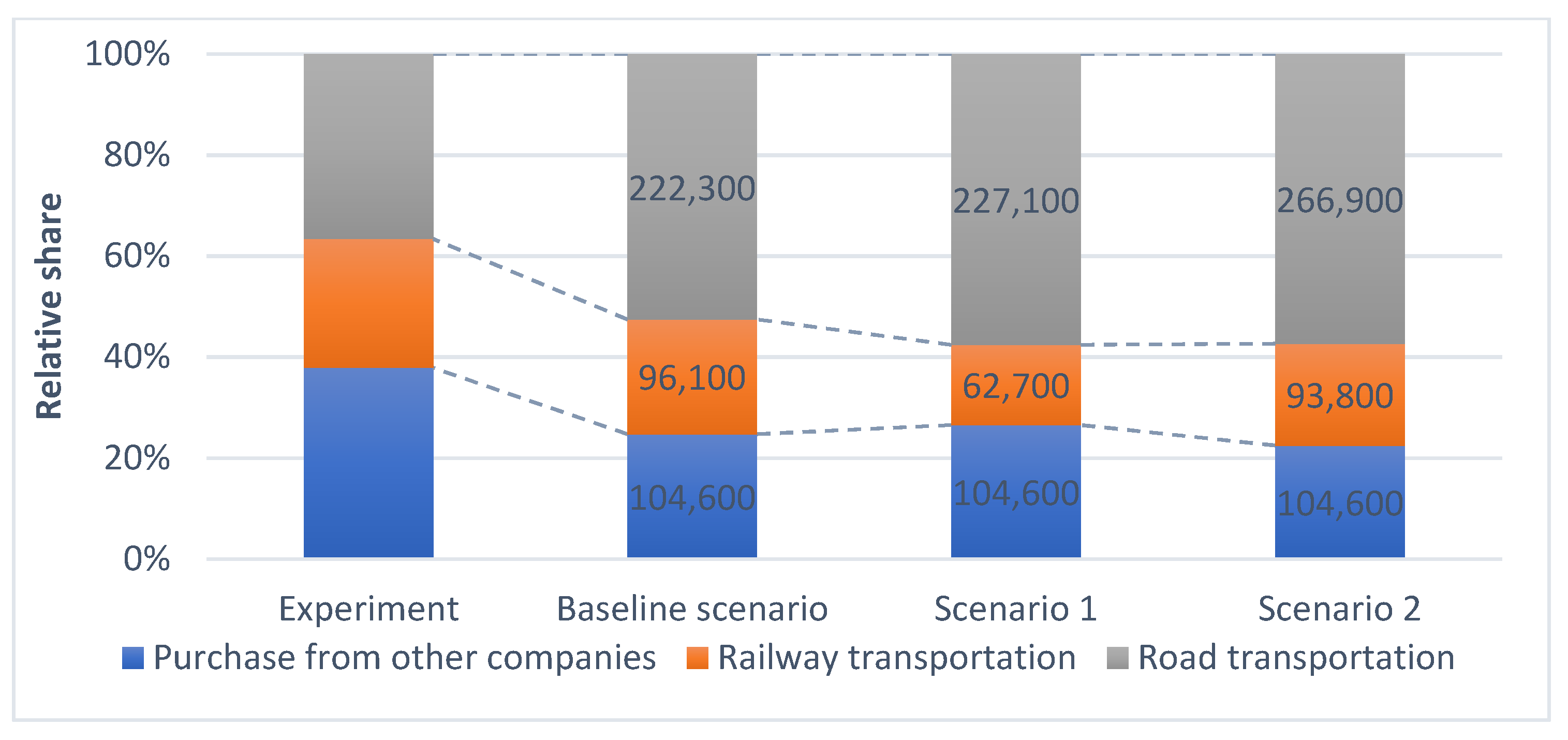

- “Baseline” ScenarioThe optimal wood order of sawmills, 422,966 m3, was applied as the experiment. The wood flows were optimized according to the presented model. The two scenarios for new supply situations were:

- (2)

- “The decreasing sawmill wood demand” Scenario 1The wood order of sawmills was reduced to 400 000 m3 per year in integrate A. The demand for pulpwood was increased 1.35 times in integrate B, corresponding to 2.7 million m3 of annual wood order. As the supply amounts of pulpwood increase, so do the quantities of logs. In order to maintain a useable distribution of wood assortments and “global optimum solution”, the wood orders of certain private sawmills were increased in the model by 10%.

- (3)

- “The increasing sawmill wood demand” Scenario 2The wood order of sawmills increased to 480,000 m3 per year in integrate A. Correspondingly, the wood order of private sawmills decreased in the model, and the demand for pulpwood increased 1.35 times in integrate B, corresponding to 2.7 million m3 of annual wood order.

3. Results

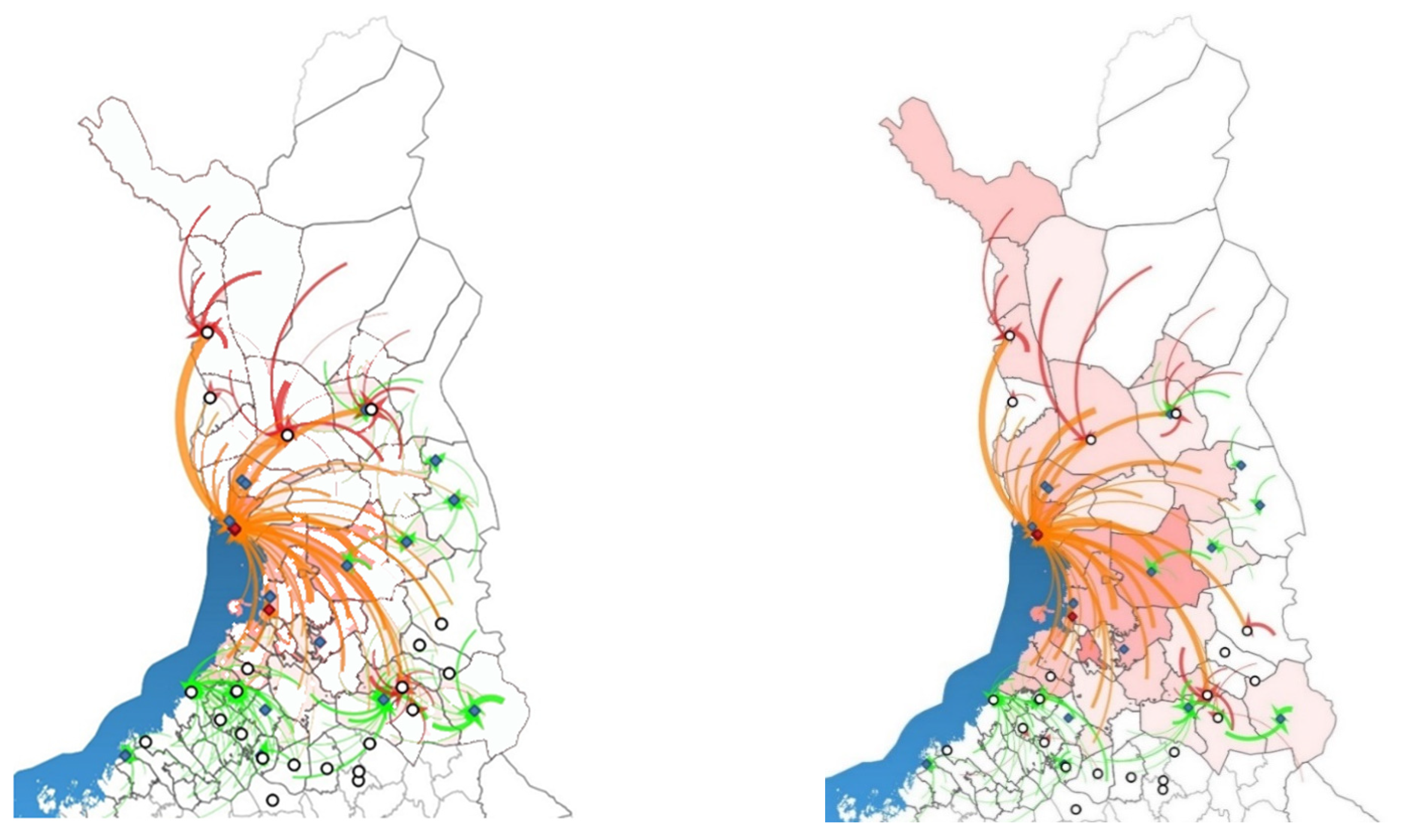

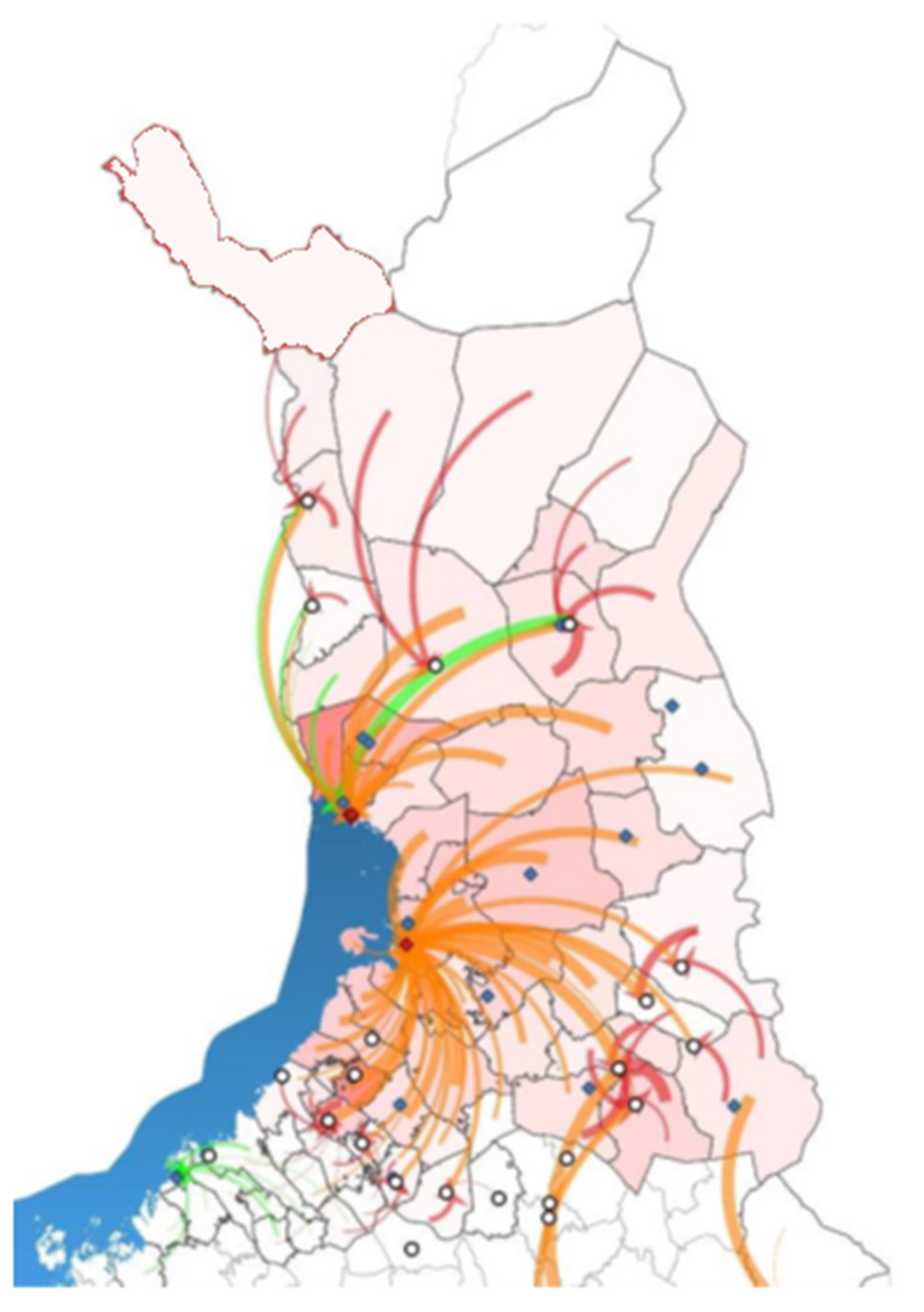

3.1. Logistics Optimum of Baseline Scenario

3.2. Comparison of Pine Log Wood Flows between Logistics Baseline Scenario and Initial Experiment

3.3. Comparison of Pulpwood Flows between Logistics Baseline Scenario and Initial Experiment

3.4. Optimum Solutions of Pine Log WSCs in Logistics Scenarios

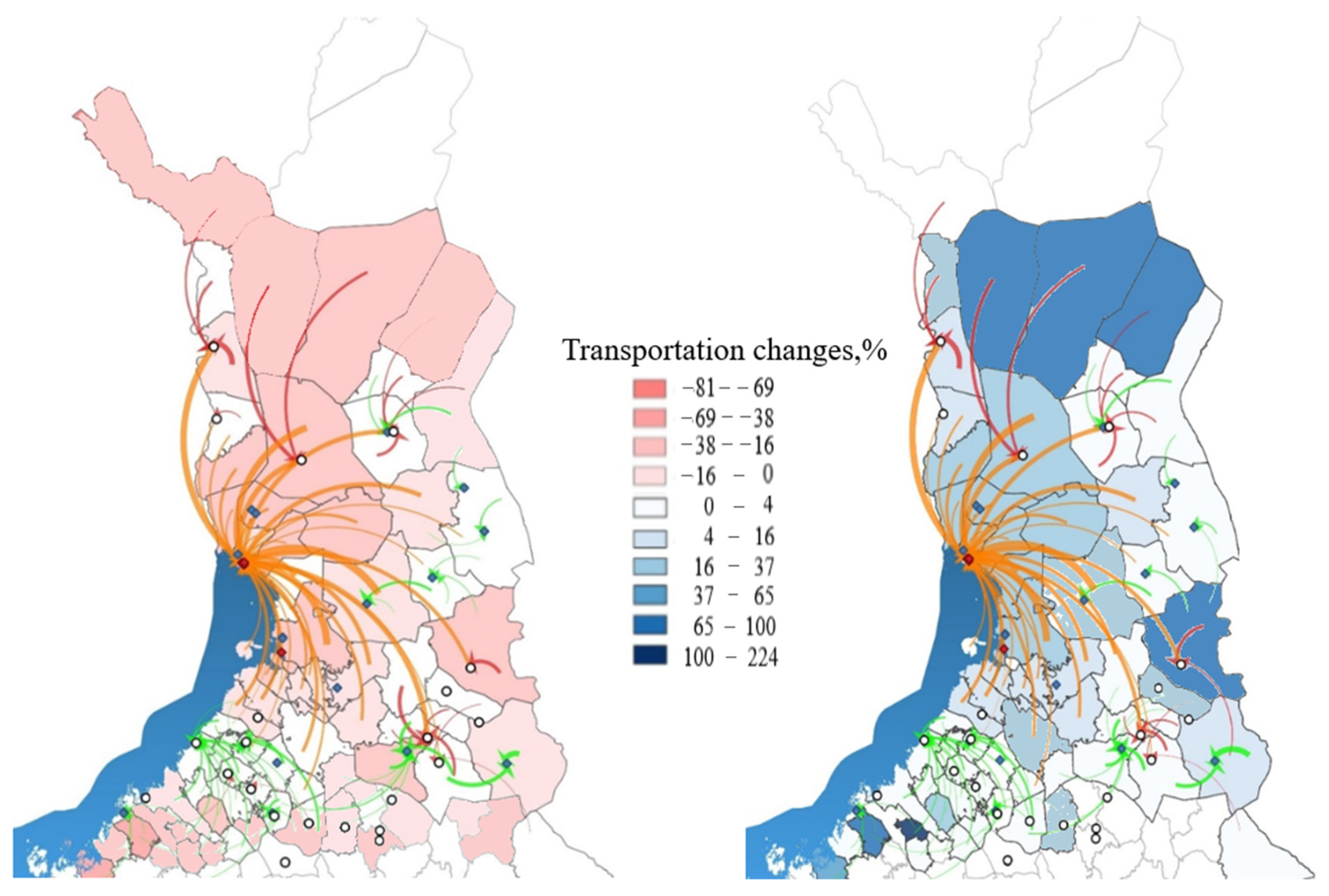

3.5. Market Shares of WSCs in Municipalities of Logistics Scenarios

4. Discussion

4.1. Benefits and Shortcomings of Data-Driven Wood Flow Optimization

4.2. Impacts of Intermodal Network on Transport Logistics

4.3. Implications of Market Shares for WSCM

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Rodrigues, V.S.; Pettit, S.; Harris, I.; Beresford, A.; Piecyk, M.; Yang, Z.; Ng, A. UK supply chain carbon mitigation strategies using alternative ports and multimodal freight transport operations. Transp. Res. Part E Logist. Transp. Rev. 2015, 78, 40–56. [Google Scholar] [CrossRef] [Green Version]

- Palander, T. Tactical Models of Wood-Procurement Teams for Geographically Decentralized Group Decision-Making. Ph.D. Thesis, University of Eastern Finland, Joensuu, Finland, 1998. [Google Scholar]

- Carlsson, D.; Rönnqvist, M. Supply chain Management in forestry–case studies at Södra Cell AB. Eur. J. Oper. Res. 2005, 163, 589–616. [Google Scholar] [CrossRef]

- Qu, W.; Rezaei, J.; Maknoon, Y.; Tavasszy, L. Hinterland freight transportation replanning model under the framework of synchromodality. Transp. Res. Part E Logist. Transp. Rev. 2019, 131, 308–328. [Google Scholar] [CrossRef]

- Heinold, A.; Meisel, F. Emission limits and emission allocation schemes in intermodal freight transportation. Transp. Res. Part E Logist. Transp. Rev. 2020, 141, 101963. [Google Scholar] [CrossRef]

- Giusti, R.; Manerba, D.; Bruno, G.; Tadei, R. Synchromodal logistics: An overview of critical success factors, enabling technologies, and open research issues. Transp. Res. Part E Logist. Transp. Rev. 2019, 129, 92–110. [Google Scholar] [CrossRef]

- D’Amours, S.; Rönnqvist, M.; Weintraub, A. Using Operational Research for Supply Chain Planning in the Forest Products Industry. Inf. Syst. Oper. Res. 2008, 46, 265–281. [Google Scholar] [CrossRef]

- Rönnqvist, M.; D’Amours, S.; Weintraub, A.; Jofre, A.; Gunn, E.; Haight, R.G.; Martell, D.; Murray, A.; Romero, C. Operations research challenges in forestry: 33 open problems. Ann. Oper. Res. 2015, 232, 11–40. [Google Scholar] [CrossRef]

- Wu, Z.; Pagell, M. Balancing priorities: Decision-making in sustainable supply chain management. J. Oper. Manag. 2011, 29, 577–590. [Google Scholar] [CrossRef]

- Palander, T.; Haavikko, H.; Kärhä, K. Towards sustainable wood procurement in forest industry—The energy efficiency of larger and heavier vehicles in Finland. Renew. Sustain. Energy Rev. 2018, 96, 100–118. [Google Scholar] [CrossRef]

- Dekker, R.; Bloemhof-Ruwaard, J.; Mallidis, I. Operations Research for Green Logistics—An Overview of Aspects, Issues, Contributions and Challenges. Eur. J. Oper. Res. 2012, 219, 671–679. [Google Scholar] [CrossRef] [Green Version]

- Palander, T. Environmental benefits from improving transportation efficiency in wood procurement systems. Transp. Res. Part D Transp. Environ. 2016, 44, 211–218. [Google Scholar] [CrossRef]

- Palander, T.; Haavikko, H.; Kortelainen, E.; Kärhä, K.; Borz, S. Improving Environmental and Energy Efficiency in Wood Transportation for a Carbon-Neutral Forest Industry. Forests 2020, 11, 1194. [Google Scholar] [CrossRef]

- Acuna, M. Timber and Biomass Transport Optimization: A Review of Planning Issues, Solution Techniques and Decision Support Tools. Croat. J. For. Eng. 2017, 38, 279–290. [Google Scholar]

- Meade, L.; Sarkis, J. Strategic analysis of logistics and supply chain management systems using the analytical network process. Transp. Res. Part E Logist. Transp. Rev. 1998, 34, 201–215. [Google Scholar] [CrossRef]

- McKinnon, A. The economic and environmental benefits of increasing maximum truck weight: The British experience. Transp. Res. Part D Transp. Environ. 2005, 10, 77–95. [Google Scholar] [CrossRef]

- Yu, W.; Chavez, R.; Jacobs, M.A.; Feng, M. Data-driven supply chain capabilities and performance: A resource-based view. Transp. Res. Part E Logist. Transp. Rev. 2018, 114, 371–385. [Google Scholar] [CrossRef]

- Wang, Y.; Zeng, Z. Data-Driven Solutions to Transportation Problems; eBook; Elsevier: Amsterdam, The Netherlands, 2018; ISBN 9780128170274/9780128170267. [Google Scholar]

- Dunke, F.; Nickel, S. A data-driven methodology for the automated configuration of online algorithms. Decis. Support Syst. 2020, 137, 113343. [Google Scholar] [CrossRef]

- Huo, X.; Wu, X.; Li, M.; Zheng, N.; Yu, G. The allocation problem of electric car-sharing system: A data-driven approach. Transp. Res. Part D Transp. Environ. 2020, 78, 102192. [Google Scholar] [CrossRef]

- Raji, I.O.; Shevtshenko, E.; Rossi, T.; Strozzi, F. Industry 4.0 technologies as enablers of lean and agile supply chain strategies: An exploratory investigation. Int. J. Logist. Manag. 2021, 32, 1150–1189. [Google Scholar] [CrossRef]

- Cámara, S.; Fuentes, J.; Marín, J. Cloud computing, Web 2.0, and operational performance: The mediating role of supply chain integration. Int. J. Logist. Manag. 2015, 23, 426–458. [Google Scholar] [CrossRef]

- Novais, L.; Maqueira-Marin, J.M.; Moyano-Fuentes, J. Lean Production implementation, Cloud-Supported Logistics and Supply Chain Integration: Interrelationships and effects on business performance. Int. J. Logist. Manag. 2020, 31, 629–663. [Google Scholar] [CrossRef]

- Soinio, J.; Tanskanen, K.; Finne, M. How logistics-service providers can develop value-added services for SMEs: A dyadic perspective. Int. J. Logist. Manag. 2012, 23, 31–49. [Google Scholar] [CrossRef]

- Tu, M. An exploratory study of Internet of Things (IoT) adoption intention in logistics and supply chain management a mixed research approach. Int. J. Logist. Manag. 2018, 29, 131–151. [Google Scholar] [CrossRef]

- Brinch, M.; Stentoft, J.; Kronborg Jensen, J.; Rajkumar, C. Practitioners understanding of big data and its applications in supply chain management. Int. J. Logist. Manag. 2018, 29, 555–574. [Google Scholar] [CrossRef]

- Tortorella, G.; Fogliatto, F.S.; Gao, S.; Chan, T.K. Contributions of Industry 4.0 to supply chain resilience. Int. J. Logist. Manag. 2021; ahead-of-print. [Google Scholar] [CrossRef]

- Natural Resources Institute. Felling of Industrial Wood by Owner Group and Province; Statistics database; Natural Resources Institute Finland: Helsinki, Finland, 2019; Available online: https://stat.luke.fi/ (accessed on 23 April 2022).

- Peltola, H.; Kellomäki, S. Impacts of climate change on the functioning and structure of the forest ecosystem and on forest management and timber production. In Climate Change—Whether Forests Adapt; Research Papers; Riikonen, J., Vapaavuori, E., Eds.; The Finnish Forest Research Institute: Helsinki, Finland, 2005; pp. 99–113. [Google Scholar]

- Haavikko, H.; Kärhä, K.; Poikela, A.; Korvenranta, M.; Palander, T. Fuel Consumption, Greenhouse Gas Emissions, and Energy Efficiency of Wood-Harve sting Operations: A Case Study of Stora Enso in Finland. Croat. J. For. Eng. 2022, 43, 79–97. [Google Scholar] [CrossRef]

- Strandström, M. Timber Harvesting and Long-Distance Transportation of Roundwood in 2018; Result Series; Metsäteho: Helsinki, Finland, 2019; (In Finnish with English Summary). [Google Scholar]

- Finnish Forest Centre. Northern Wood Roads Project; Finnish Forest Centre: Helsinki, Finland, 2018; Available online: https://www.metsakeskus.fi/sites/default/files/pohjoisen-puun-tiet-tuloskooste.pdf (accessed on 23 April 2022).

- Palander, T.; Borz, S.; Kärhä, K. Impacts of Road Infrastructure on the Environmental Efficiency of High-capacity Transportation in Harvesting of Renewable Wood. Energies 2021, 14, 453. [Google Scholar] [CrossRef]

- Iikkanen, P.; Lappi, T. Upgrading of the Rail Network’s Raw Timber Loading Site Network. Proposal for Measures Required by the Target State; Research Reports; Traficom: Helsinki, Finland, 2018. [Google Scholar]

- Abril, M.; Barber, F.; Ingolotti, L.; Salido, M.A.; Tormos, P.; Lova, A. An assessment of railway capacity. Transp. Res. Part E Logist. Transp. Rev. 2008, 44, 774–806. [Google Scholar] [CrossRef] [Green Version]

- Carlsson, D.; Rönnqvist, M. Wood Flow Problems in the Swedish Forestry; Skogforsk Report; Skogforsk: Uppsala, Sweden, 1999. [Google Scholar]

- Carlsson, D.; D’Amours, S.; Martel, A.; Rönnqvist, M. Supply chain planning models in the pulp and paper industry. Inf. Syst. Oper. Res. 2009, 47, 167–183. [Google Scholar] [CrossRef]

- Palander, T.; Vesa, L. Potential methods of adjustment to declining imports of Russian roundwood for the Finnish pulp and paper industry. Int. J. Logist. Manag. 2011, 22, 222–241. [Google Scholar] [CrossRef]

- Hetemäki, L.; Hänninen, R.; Toppinen, A. Short-term forecasting models for the Finnish forest sector: Lumber exports and sawlog demand. For. Sci. 2004, 50, 461–472. [Google Scholar]

- Shahi, S.; Pulkki, R. Supply chain network optimization of the Canadian forest products industry: A critical review. Am. J. Ind. Bus. Manag. 2013, 3, 631–643. [Google Scholar] [CrossRef] [Green Version]

- Tzanova, P. Time series analysis for short-term forest sector market forecasting. Austrian J. For. Sci. 2017, 134, 205–229. [Google Scholar]

- Kärhä, K.; Tamminen, T.; Leinonen, T.; Suvinen, A. Reducing seasonality in wood harvesting operations in Finland. In Proceedings from Joint Seminar Arranged by NB-NORD and NOFOBE, Lappeenranta, Finland, 14–16 June 2017; Scandinavian Forest Economics No. 47; Hoen, H.F., Glosli, C., Eds.; Lappeenranta, Finland, 2017; pp. 121–127. [Google Scholar]

- Ministry of Agriculture and Forestry. Forest Damages Prevention Act (1087/2013); Ministry of Agriculture and Forestry: Helsinki, Finland, 2013. [Google Scholar]

- Venäläinen, P.; Alanne, H.; Ovaskainen, H.; Poikela, A.; Strandström, M. Seasonal Costs and Mitigation Measures in the Wood Supply Chain; Result Series; Metsäteho: Helsinki, Finland, 2017; (In Finnish with English Summary). [Google Scholar]

- Palander, T. Applying dynamic multiple-objective optimization in inter-enterprise collaboration to improve the efficiency of energy wood transportation and storage. Scand. J. For. Res. 2015, 30, 346–356. [Google Scholar] [CrossRef]

- Hewitt, M.; Frejinger, E. Data-driven optimization model customization. Eur. J. Oper. Res. 2020, 287, 438–451. [Google Scholar] [CrossRef]

- Palander, T.; Takkinen, J. The Optimum Wood Procurement Scenario and Its Dynamic Management for Integrated Energy and Material Production in Carbon-Neutral Forest Industry. Energies 2021, 14, 4404. [Google Scholar] [CrossRef]

- Metsälehti. Wood Buyers. 2018. Available online: https://www.metsalehti.fi/puukauppa/234870-2/ (accessed on 23 April 2022).

- Statistics Finland. Forestry Machinery and Truck Cost Index; Statistics Finland: Helsinki, Finland, 2021; Available online: https://www.stat.fi/til/ (accessed on 23 April 2022).

- Palander, T.; Kärhä, K. Improving Energy Efficiency in a Synchronized Road-Transportation System by Using a TFMC (Transportation Fleet-Management Control) in Finland. Energies 2019, 12, 670. [Google Scholar] [CrossRef] [Green Version]

- Arunachalam, D.; Kumar, N.; Kawalek, J.P. Understanding big data analytics capabilities in supply chain management: Unravelling the issues, challenges and implications for practice. Transp. Res. Part E Logist. Transp. Rev. 2018, 114, 416–436. [Google Scholar] [CrossRef]

- Power, D.J. Understanding Data-Driven Decision Support Systems. Inf. Syst. Manag. 2008, 25, 149–154. [Google Scholar] [CrossRef]

- Taha, H.A. Operations Research: An Introduction, 8th ed.; Pearson Prentice Hall: Upper Saddle River, NJ, USA, 2007; 813p. [Google Scholar]

- Dantzig, G.B. Application of the Simplex Method to a Transportation Problem, Activity Analysis of Production and Allocation; Koopmans, T.C., Ed.; John Wiley and Sons: New York, NY, USA, 1951; pp. 359–373. [Google Scholar]

- Palander, T. Local factors and time-variable parameters in tactical planning models: A tool for adaptive timber procurement planning. Scand. J. For. Res. 1995, 10, 370–382. [Google Scholar] [CrossRef]

- Hämäläinen, J. Towards the Digitalization of Wood Management. Main Results of the Forest Big Data Project; Result Series; Metsäteho: Helsinki, Finland, 2016; (In Finnish with English Summary). [Google Scholar]

- Lehtonen, E. A Large-Scale Optimization Model for Tactical Wood Procurement Planning. Master’s Thesis, Aalto University, Helsinki, Finland, 2016. [Google Scholar]

- Iikkanen, P.; Keskinen, S.; Korpilahti, A.; Räsänen, T.; Sirkiä, A. Nationwide Optimization Model for Raw Wood Flows; Research Reports; Traficom: Helsinki, Finland, 2010. [Google Scholar]

- Korhonen, K.; Ihalainen, A.; Packalen, T.; Salminen, O.; Hirvelä, H.; Härkönen, K. Lapland’s Forest Resources and Logging Opportunities; Luonnonvarakeskus: Helsinki, Finland, 2015; Available online: https://jukuri.luke.fi/handle/10024/531533 (accessed on 23 April 2022).

| Province | P | S | B | Total | |||

|---|---|---|---|---|---|---|---|

| LW | PW | LW | PW | LW | PW | ||

| Northern Ostrobothnia | 1286 | 2579 | 527 | 666 | 7 | 1188 | 6253 (−29) |

| Kainuu | 824 | 1603 | 275 | 393 | 2 | 566 | 3663 (−28) |

| Lapland | 1183 | 2293 | 176 | 403 | 0 | 451 | 4506 (−38) |

| Total | 3293 | 6475 | 978 | 1462 | 9 | 2205 | 14,422 (−32) |

| Wood Assortment | Road Transport | Railway Transport | Total | ||||||

|---|---|---|---|---|---|---|---|---|---|

| m3 × 10−3 | € × 10−3 | € × m−3 | m3 × 10−3 | € × 10−3 | € × m−3 | m3 × 10−3 | € × 10−3 | € × m−3 | |

| Pine log | 371 | 2738 | 7.38 | 119 | 456 | 3.83 | 490 | 3194 | 6.52 |

| Spruce log | 119 | 679 | 5.71 | - | - | - | 119 | 679 | 5.71 |

| Pulpwood | 1119 | 7911 | 7.07 | 576 | 2604 | 4.52 | 1695 | 10,515 | 6.20 |

| Spruce pulpwood (fiber) | 180 | 1289 | 7.16 | 78 | 413 | 5.30 | 258 | 1702 | 6.60 |

| Birch pulpwood | 515 | 3430 | 6.66 | 234 | 1310 | 5.60 | 749 | 4740 | 6.33 |

| Total | 2304 | 16,007 | 6.97 | 1007 | 4671 | 4.75 | 3311 | 20,831 | 6.29 |

| Wood Assortment | Road Transport | Railway Transport | Totals | ||||||

|---|---|---|---|---|---|---|---|---|---|

| m3 × 10−3 | € × 10−3 | € × m−3 | m3 × 10−3 | € × 10−3 | € × m−3 | m3 × 10−3 | € × 10−3 | € × m−3 | |

| Pine log | 381 | 3056 | 8.02 | 121 | 506 | 4.18 | 502 | 3561 | 7.09 |

| Spruce log | 140 | 665 | 4.75 | - | - | - | 140 | 665 | 4.75 |

| pulpwood | 1429 | 10,703 | 7.49 | 428 | 1785 | 4.17 | 1857 | 12,488 | 6.72 |

| Spruce pulpwood (fiber) | 181 | 1247 | 6.89 | 87 | 454 | 5.22 | 268 | 1701 | 6.35 |

| Birch pulpwood | 593 | 4145 | 6.99 | 361 | 1845 | 5.11 | 954 | 5990 | 6.28 |

| Totals | 2724 | 19,816 | 7.27 | 997 | 4589 | 4.60 | 3721 | 24.405 | 6.56 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Palander, T.; Vesa, L. Data-Driven Optimization of Forestry and Wood Procurement toward Carbon-Neutral Logistics of Forest Industry. Forests 2022, 13, 759. https://doi.org/10.3390/f13050759

Palander T, Vesa L. Data-Driven Optimization of Forestry and Wood Procurement toward Carbon-Neutral Logistics of Forest Industry. Forests. 2022; 13(5):759. https://doi.org/10.3390/f13050759

Chicago/Turabian StylePalander, Teijo, and Lauri Vesa. 2022. "Data-Driven Optimization of Forestry and Wood Procurement toward Carbon-Neutral Logistics of Forest Industry" Forests 13, no. 5: 759. https://doi.org/10.3390/f13050759

APA StylePalander, T., & Vesa, L. (2022). Data-Driven Optimization of Forestry and Wood Procurement toward Carbon-Neutral Logistics of Forest Industry. Forests, 13(5), 759. https://doi.org/10.3390/f13050759