Abstract

This article deals with the effect of alternating lower (freezing) and higher (heating) temperatures on the static bending characteristics of glued Norway spruce (Picea abies (L.) H. Karst.) and European larch (Larix decidua Mill.) wood. Two types of wood, PUR (polyurethane), and EPI (emulsion polymer isocyanate), were used for the experiment. The thermal loading of glued wood was carried out at temperatures −15 °C/70 °C and −25 °C/70 °C. Static bending characteristics were determined on glued wood samples and compared with the reference samples. Freezing causes an increase in the bending properties of both glued spruce and larch wood. The highest in bending strength was obtained for EPI-glued larch wood subjected to −25 °C/70 °C loading temperature, which is by as much as 20% increase from the reference value. The maximum improvement in the modulus of elasticity was achieved for EPI-glued larch with around 11% increase, although the increased values of bending strength and modulus of elasticity were not significant. The different densities, anatomical structures, and properties of spruce and larch wood can induce varying results between the two wood species.

1. Introduction

The demand for engineered wood products (EWP) is increasing rapidly due to numerous potential benefits provided by wood. Wood possesses some prominent features such as high strength to weight ratio, good fire resistance, and natural appearance, distinguishing it from other materials such as concrete and steel [1]. Wooden elements with entirely different chemical, mechanical and physical properties are connected using nails, screws, and adhesives to create advanced engineered wood structures. It is important to note that careful attention must be given to the many inherited traits of wood during the production of wood products, particularly the anisotropic and biological features [2].

Adhesive is considered the most commonly used fastener globally by the wood industry. The adhesive role can be explained by wetting a wooden surface appropriately and hardening by water loss and chemical cure to provide sufficient strength [3]. The bond formation is a consequence of adhesion (interaction at a molecular level between substrate and adhesive) and cohesion (molecular interaction only among adhesive molecules). Adhesion consists of several physical, mechanical, and chemical interactions between the substrate and adhesive [4,5,6]. The quality of a wood adhesive (WA) bond is profound, and relates to not only wood properties such as surface quality, porosity, surface chemistry, and extractives, but also adhesive properties as strength, viscosity, and cure rate. The efficiency of the WA bond is also affected by processing parameters (pressure, temperature, and several other vital parameters) and mathematical models of bonding [7]. Even after considering all the mentioned factors on the quality of a WA bond, the failure in the WA bond still occurs as an adhesive failure, cohesive failure, or wood failure [8]. The successful formation of a WA bond is related to its current strength and the ability of the WA bond to maintain the current strength appropriately under climate conditions (durability). Equilibrium moisture content (EMC) and temperatures during bonding assembly and after the formation of the WA bond have a significant influence on a WA bond’s mechanical and physical properties.

Alternate shrinking and swelling due to differences in the moisture content of wood and relative humidity of the surrounding environment cause stresses in a WA bond. Comparison of the hydrophobic behavior of wood and adhesive shows that the adhesive is more hydrophobic. Therefore, the changes in the dimensions of the wood are far greater in the conditions of changing the humidity. Thus, the swelling behavior of adhesive is minor compared to wood. The variation in the size of wood and adhesive due to moisture exchange leads to the formation of stress in a WA bond. The more the wood swells, the greater the stress formed, leading to fracture in a WA bond [9]. Konnerth et al. [10] reported that the elastic modulus and hardness of a WA bond were reduced when the WA bond was submerged by water.

In recent years, in cold countries such as Russia, northern Europe, and Canada, wooden construction such as bridges were being subjected to freezing temperatures of −40 °C and −50 °C. Fluctuations in such lower levels of temperature affected the quality of a WA bond. Extensive research has shown various influences of cold weather on wood properties [11,12,13]. The modulus of elasticity, compression, and bending of wood were significantly increased by decreasing temperatures. In other research, Szmutku et al. [14] studied only the effect of freezing temperature on the mechanical properties of spruce wood. They found that the mechanical properties of spruce wood were not changed at −10 °C. In contrast, an insufficient mechanical property of spruce was observed at −1 °C. Yu and Osman [15] investigated the effect of low and moderately high temperatures (−15 and 45 °C) on the tensile shear strength of particle board. Tabor [16] argued that the bonding assembly under cold weather destroys the adhesive performance. This can be attributed to the increased adhesive viscosity, which results in inappropriate adhesive wetting under a cold climate.

Currently, an adhesive system for a wood bond is chosen not just for its strength, adaptability on the wood surface, and curing condition, yet additionally for its durability. Radovic and Rothkopf [17] showed the usability of one-component polyurethane (1C-PUR) adhesives for wood construction by considering ten years of experience. The 1C-PUR adhesive has a few benefits such as curing at room temperature, no emission of volatile organic compounds (VOC), and no mixing required for this adhesive [18]. The bonding strength of wood structure glued by 1C-PUR is high, and the behavior of the adhesive under load is comparatively ductile [18,19]. EPI adhesive is used for bonding different wood species and also for wood–metal bonding. Cold curing, no formaldehyde emission in its formulation, and excellent water resistance, high adhesion strength, heat resistance, and good moisture resistance are the greatest advantages of EPI adhesive [20,21].

Numerous literature and research exist on the effect of high temperature on the mechanical performance of WA bonds [22,23,24]. At a higher temperature, the shear strength of wood and also WA bond decreases [24]. However, there is little research on the effect of cold temperatures on WA bond performance. Several studies investigated the effect of cold weather conditions on bridge timber [25,26,27]. Wang et al. [28,29,30] reported the tensile shear strength of Scots pinewood and bonded area with different adhesive systems exposed to different temperatures from 20 to −60 °C. At this range of temperature, the block shear strength of spruce glulam joints was also investigated. Nonetheless, the influence of thermal loading has not been studied widely for bending characteristics and different wood species.

This paper analyzes the impact of two levels of freezing and heating temperatures on the bending strength of glued specimens of larch and spruce species bonded with two different adhesive systems: 1C-PUR and EPI. This paper firstly provides information on the methodology, including specimen size, timber selection, and thermal loading conditions. Secondly, the paper compares and discusses the bending characteristics for all investigated types of conditions, considering the effect of thermal loading and adhesive types. All experimental results are compared to control samples.

2. Materials and Methods

2.1. Test Sample Preparation

Two European softwood planks, namely Norway spruce (Picea abies (L.) H. Karst.) and European larch planks (Larix decidua Mill.), were selected for this research. The planks were collected from a commercial supplier. The planks were then kiln dried. Subsequently, numerous defect-free lamellae with dimensions of 5 mm × 45 mm × 1500 mm were sawn (Figure 1). All lamellae were air-conditioned in the humidity chamber HCP 108 (Memmert, Germany) under conditions (relative air humidity of 65% ± 5% and temperature of 20 °C ± 2 °C) to achieve equilibrium moisture content of 12%.

Figure 1.

Wood lamellae for specimens.

Adhesive

For this experiment, two types of adhesives, i.e., two-component emulsion polymer isocyanate (EPI), Kestokol WR 11 + hardener WR (Kiilto Oy, Finland), and moisture-curing one-component polyurethane (1c-PUR) Kestopur 1030 (Kiilto Oy, Finland), were used. The durability classes of both adhesives as per ČSN EN 204 [31] and ČSN EN 15425 [32] are D4 and I 70 GP 0.3, respectively. The properties of both adhesives are provided in Table 1.

Table 1.

Properties of PUR and EPI adhesives.

2.2. Methods

2.2.1. Gluing

The adhesive was applied in a thin and delicate layer at 200 g/m2 on the specimen’s surface with the help of a toothed spatula. A total of three glued layers were formed in each specimen. Then, the specimens were cold-pressed in an industrial press GS 6/90 (SCM GROUP S.p.A., Italy) under 1 MPa at an ideal temperature of 20 °C. The pressing time was 40 min for EPI and 120 min for PUR adhesives, respectively (Figure 1). After the completion of the cold-pressing, the specimens with EPI adhesives were kept at room temperature for another seven days for curing. Afterward, the glued specimens were cut to a required bending test sample with dimensions 15 mm × 20 mm × 300 mm) (Figure 2).

Figure 2.

Glued wood samples.

Following this process, all samples were air-conditioned in the humidity chamber HCP 108 (Memmert, Germany) under specific conditions (relative air humidity of 65% ± 5%, and temperature of 20 °C ± 2 °C) to achieve equilibrium moisture content of 12%. A total of 240 conditioned samples were divided into twelve groups (Table 2) for both wood species (20 samples per single group) according to thermal loading temperature and adhesive type.

Table 2.

Average density and moisture content of glued spruce and larch wood.

2.2.2. Thermal Loading

The moisture content and density of the wood samples under thermal loading (freezing–heating temperature) were measured based on the standard ČSN EN 321 [33]. The primary step in this process was to set the temperature of the laboratory freezer (MediLine LGT 3725, Liebherr GmbH, Germany) to the required temperature of −15 °C or −25 °C. After reaching the required temperature, the test pieces were placed in the freezer for 12 h. After freezing, the samples were gauged and estimated. After measurement, the frozen samples were subjected to heating in a thermal chamber (SolidLine ED-S 115, Binder GmbH, Germany) at 70 ± 2 °C for 12 h. After heating, the samples were again weighed and measured (Table 2).

2.2.3. Physical Properties

The impact of the thermal loading on the wood samples was identified by measuring the moisture content and density of the samples. The moisture content and density of the samples were measured subsequently for each loading process (freezing and heating) according to ISO 13061-1 [34] and ISO 13061-2 [35], respectively. Drying to oven-dry state was also carried out according to ISO 13061-1 [34]. The mean value density for spruce and larch wood at moisture content of 12% was reported: 458.15 and 698.75 kg/m3, respectively (Table 2). These reported results are approximately in line with the reported mean value density of the same species at 12% moisture content, which are about 515.6 and 652.1 kg/m3 [36].

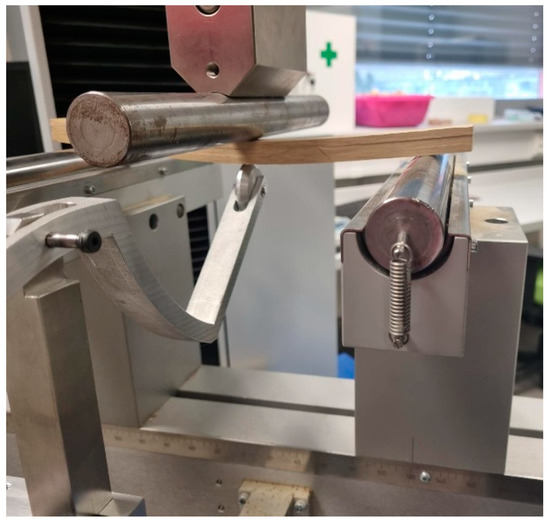

2.2.4. Static Bending

The static bending test was carried out on a 3-point bending principle according to ČSN EN 310 [37] (Figure 3) using the universal testing machine TIRA test 2850 S E5 (TIRA, Germany) with TIRA software. The constant loading speed was set to 6 ± 0.5 mm/min such that the time required to reach failure was between 60 and 90 s. The computer connected to the machine directly recorded the maximum loading force.

Figure 3.

Three-point bending test.

The bending strength fm was calculated using Equation (1),

where

fm is the bending strength (MOR) at failure (MPa);

Fmax is the applied maximum loading force (N);

l1 is the distance between the centers of the supports (mm);

b is the width of the test sample (mm);

t is the thickness of the test sample (mm).

The modulus of elasticity Em was calculated using Equation (2),

where

Em is the modulus of elasticity (MOE) (MPa);

l1 is the distance between the centres of the supports (mm);

b is the width of the test sample (mm);

t is the thickness of the test sample (mm);

F2–F1 is the increment of load on the straight-line portion of the load-deflection curve (F1 shall be approximately 10% and F2 shall be approximately 40% of the maximum load) (N), and a2–a1 is the increment of deflection at the mid-length of the test sample (corresponding to F2–F1).

2.2.5. Statistical Analysis

All values obtained for static bending (MOR and MOE) were converted to 12% moisture content according to standards ISO 13061-3 [38] and 13061-4 [39]. Subsequently, the final values were evaluated with Statistica 13 (TIBCO Software Inc., Palo Alto, Santa Clara, CA, USA) software by analysis of variance (ANOVA). Statistical analysis was based on 95% confidence intervals of the means using Fischer’s F-test. Relationships between variables were studied by using Spearman’s rank correlation, which can evaluate relationships between two variables. A regression model with a coefficient of determination was used to determine the dependence of bending strength (MOR) and modulus of elasticity (MOE) on thermal loading for spruce and larch wood glued with individual adhesives.

3. Results and Discussion

3.1. Effect of Thermal Loading on Moisture Content and Wood Density

The results pertaining to the effect of freezing and subsequent heating on the moisture content and wood density are presented in Table 2. It can be deduced that freezing did not cause any significant change either in the density or moisture content of the wood. This result is consistent with studies by previous researchers published in the literature [40].

This result is expected since wood is stable against thermal expansion/contraction especially between −51 and 130 °C, since the coefficients of thermal expansion/contraction of wood are independent of temperature in this range [41].

The low preliminary moisture content in the wood, which was approximately 12%, represents no free water in the cell lumen, while all the moisture existed only in the cell wall and in the form of bound water. If wood is subjected to very low temperature for longer duration, bound water freezes only to a small amount [42]. Bound water freezes slowly and, even at extremely low temperatures on the Earth, part of it remains in a liquid state inside the wood [41]. Since there was no moisture loss or volume change, the density remained almost stable even after subjected to freezing. Nevertheless, the variations in the density after heating are clear because weight loss occurred in the wood due to loss of moisture.

Wood moisture plays an important role in the freezing process. Because free water freezes more easily in wood, the rate of ice expansion in wood is directly related to the higher moisture content of the wood, resulting in rupture of the cell wall. In the present study, freezing had no effect on bending properties because the moisture content of the wood was low, approximately 12% during freezing. All moisture in the cell wall was limited in the form of water. In addition, if the wood were exposed to very low temperatures for a longer period of time, limited water freezing occurs only slightly [42].

3.2. Effect of Thermal Loading on Mechanical Properties

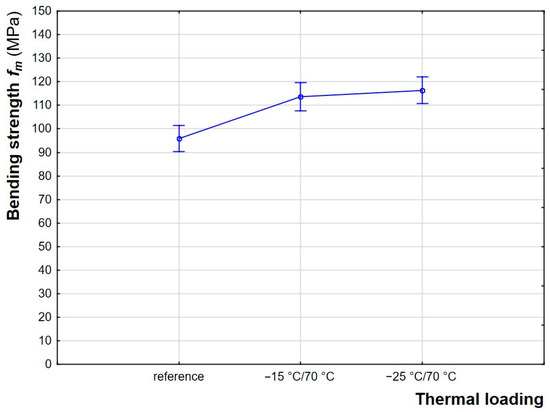

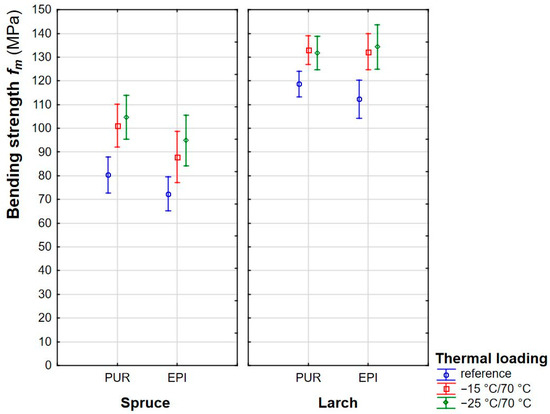

In order to determine a generalized effect of thermal loading on the bending strength of wood, the data from both types of wood were combined and are shown in Figure 4. Thermal loading (altering temperature) could not cause any detrimental impact on the bending strength. Rather, it could positively affect bending strength in both species, though the degree of the improved bending properties varied depending on the wood species. In spruce wood, the increase in the bending parameter due to thermal loading ranged between 22% and 31% from the reference values, and maximum increased value was obtained in EPI glued specimens subjected to −15 °C/70 °C loading temperature.

Figure 4.

The effect of thermal loading on the bending strength.

The effect of thermal loading on the bending parameters in larch wood was similar to that obtained in spruce wood. Thermal loading also caused an increase in the bending characteristics in larch wood ranging between 11% and 20% from the reference values, and the maximum increase was achieved in EPI glued specimens subjected to −25 °C/70 °C loading temperature. The effect of the two thermal loads studied is comparable. Although there was an increase in the bending strength due to thermal loading in both wood species, the enhancement was marginal. These results are in agreement with studies reported by others for the increase in bending strength when the temperature is lowered [11,13,43,44,45,46,47].

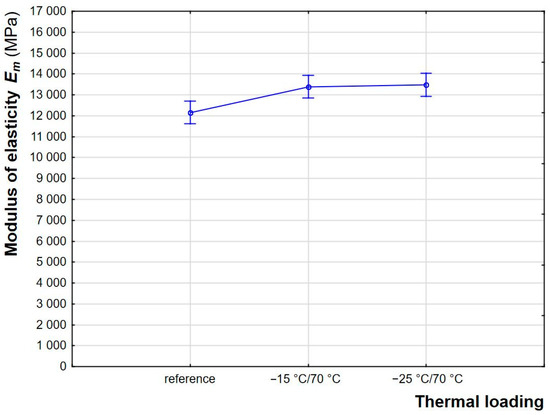

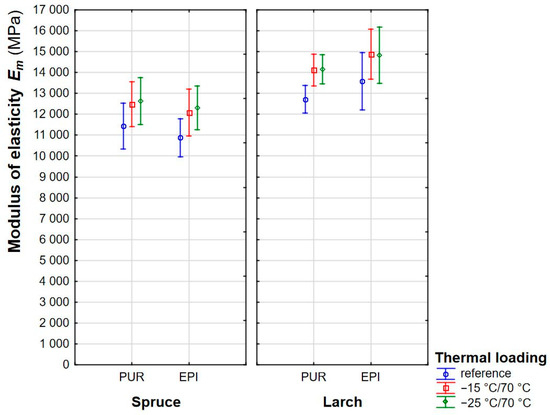

The effect of thermal loading on the modulus of elasticity is shown in Figure 5. From the trend shown, it can be seen that altering temperature causes a positive effect on the modulus of elasticity in both species. For spruce wood, the increase in the modulus of elasticity due to thermal loading ranged between 9% and 13%, and the maximum enhanced value was in EPI glued specimens subjected to −25 °C/70 °C thermal loading.

Figure 5.

The effect of thermal loading on the modulus of elasticity.

Thermal loading for larch wood also caused an increase in the modulus of elasticity ranging between 9% and 11%, and the maximum enhancement was achieved in EPI glued specimens. However, there was a slight increase in the modulus of elasticity resulting from thermal loading in both wood species; it can be deduced that the increased values were not significant.

According to previous results, mechanical properties increase at negative temperatures [12,48]. Studies on frozen and unfrozen Swedish pine (Pinus sylvestris) show a higher MOE value (14.2 GPa) at −20 °C than at +20 °C (11.6 GPa) [11]. This is probably due to the dependence between strength properties and negative temperature [49]. The compressive strength of ice increases exponentially with increasing minus temperature. The slight increase in the values for mechanical properties due to freezing has been associated with compressive forces against the cell wall of the wood due to water expansion [50]. This phenomenon is enhanced by a faster freezing rate [14].

The overall results of the study are shown in Figure 6 and Figure 7. From Figure 6, which shows the effect of wood type, adhesive type, and temperature load on bending strength, it can be summarized that there was a slight increase in the bending strength parameters due to thermal loading in glued spruce and larch wood. Larch wood showed the highest mean value of bending strength of the reference wood for the adhesives PUR and EPI, 118.6 and 112.3 MPa, respectively. The highest mean bending strength after thermal loading was found for glued larch wood with EPI adhesive, followed by glued larch wood with PUR; glued spruce wood with EPI adhesive showed the lowest average values (88 and 94.9 MPa). The average bending properties of spruce wood glued with PUR and exposed to thermal loading are slightly higher than those of spruce wood glued with EPI. Moreover, the mean value of bending strength for glued larch wood shows that there is no significant difference between the results for EPI and PUR adhesives. The values of bending strength for larch wood are significantly higher than that of spruce (p < 0.05). This can be attributed to the higher density of larch wood compared to spruce.

Figure 6.

The effect of wood species, adhesive type, and temperature loading on bending strength.

Figure 7.

The effect of wood species, adhesive type, and temperature loading on the modulus of elasticity.

The overall results of the effect of wood type, adhesive type, and temperature loading on the elastic modulus are shown in Figure 7.

The mean elastic modulus of glued larch wood showed the highest reference value (13,585.0 and 12,718.9 MPa), but the lowest modulus of elasticity was found for the reference value of glued spruce wood (10,874 MPa). EPI glued larch wood showed the highest modulus of elasticity (14,877.5 and 14,833.4 MPa) after thermal loading. However, the lowest average elastic moduli were found for EPI glued spruce wood (12,084.8 and 12,308.8 MPa). The average elastic moduli of both glued wood species were slightly higher than the reference values.

From the graphs presented, it can be stated briefly that glued larch wood specimens have a moderately higher modulus of elasticity compared to spruce. Nevertheless, there is a slight increase in the elastic modulus at both thermal loadings (between 9% and 13%), and a marginal nonsignificant difference between two different thermal loads. This result is consistent with studies by previous researchers who found an increase in the elastic modulus due to a decrease in temperature [11,13,47,51].

3.3. Statistical Analysis

The statistical analysis of the influence of factors and their combinations on bending strength is presented in Table 3, indicating the level of significance (p < 0.05). It was found that all parameters, including wood species, thermal load, and adhesive types on the bending strength, showed significant influence.

Table 3.

Statistical evaluation of bending strength fm.

The statistical analysis of the influence of the factors and their combinations on the elastic modulus is given in Table 4. Indicating the level of significance (p < 0.05), it was found that the parameters including wood type and thermal load on the elastic modulus show a significant effect (p < 0.05). However, there was no significant effect of adhesive type on the elastic modulus (p ≥ 0.500).

Table 4.

Statistical evaluation of modulus of elasticity Em.

Table 5 shows Spearman’s correlation, which expresses the general interdependence between factor groups, bending strength, and modulus of elasticity.

Table 5.

Spearman’s correlation between factor groups, bending strength, and modulus of elasticity.

According to the table, the highest correlation was found between bending strength and modulus of elasticity (0.809). There is also a significant correlation between wood species and bending strength (0.684) and modulus of elasticity (0.420), with higher significance for bending strength. However, there was a low general correlation between thermal loading and bending properties, but the correlation is not significant (0.294 and 0.221). Foundation also showed no significant correlation between wood adhesives and bending properties.

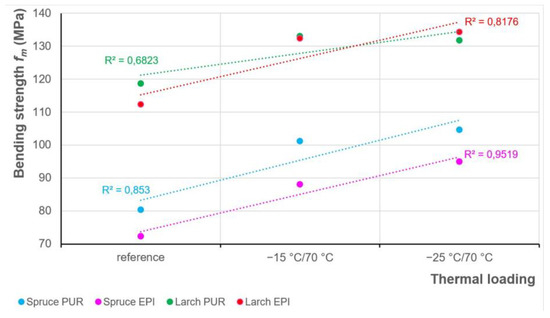

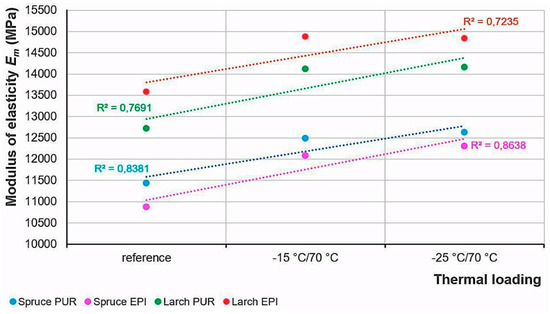

However, when a regression model is used to determine the dependence of bending strength and modulus of elasticity on thermal loading for wood glued with a specific adhesive (PUR or EPI) and made of a specific wood species (spruce or larch), an increasing trend of both bending characteristics and a coefficient of determination can be seen (Figure 8 and Figure 9).

Figure 8.

Correlation between bending strength and thermal loading.

Figure 9.

Correlation between modulus of elasticity and thermal loading.

4. Conclusions

In this study, the bending properties of PUR and EPI glued spruce and larch wood were investigated under thermal loads (freezing and heating) of −15 °C/70 °C and −25/70 °C.

Freezing and heating (thermal loading) does not lead to any detrimental effect on the bending strength and modulus of elasticity of glued spruce and larch wood. In contrast, it causes a slight increase in the bending characteristics of both glued spruce and larch wood. EPI-glued larch wood exhibited the highest increase in bending strength and modulus of elasticity, while EPI glued spruce wood had the least bending strength and modulus of elasticity. Since there is a correlation between wood species and bending properties, the results can be attributed to the different densities, anatomical structures, and properties of spruce and larch wood. There is a significant dependence of bending strength and modulus of elasticity on thermal loading for wood glued with a certain type of adhesive and made with a specific wood species. Thermal loading causes a slight increase in bending properties, while between the two freezing temperatures investigated in this study, the lower freezing temperature (−25 °C) showed a slightly better result, although the difference was not statistically significant.

The results obtained can be of great importance for using wood products that are periodically exposed in a climate characterized by extreme temperatures. This study presents the results of one thermal cycle (12 h exposure to freezing followed by 12 h exposure to heating), although wood products are subjected to such extreme temperatures for longer durations in service conditions. Thus, it is remarkable to mention that increasing the number of cycles could help to better correlate natural conditions with the experimental results.

Author Contributions

M.G., conceptualization, methodology, software, supervision, writing—original draft, and formal analysis; E.K., conceptualization, investigation, writing—review and editing, and supervision; F.R., validation, resources, software, and data curation; T.K., validation, resources, software, and data curation; S.D., validation and visualization; D.L., validation, visualization, writing—review and editing, and investigation. All authors have read and agreed to the published version of the manuscript.

Funding

The authors are grateful for the support of “Advanced research supporting the forestry and wood-processing sector’s adaptation to global change and the 4th industrial revolution”, grant number CZ.02.1.01/0.0/0.0/16_019/0000803 financed by OP RDE, Ministry of Education, Youth and Sports of the Czech Republic. The authors also thank the Internal Grant Agency of the Faculty of Forestry and Wood Science at Czech University of Life Sciences Prague for supporting project IGA A 20-17.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data presented in this study are available on request from the corresponding author. The data are not publicly available to safeguard the anonymity and privacy of the local stakeholders.

Conflicts of Interest

Authors declare no competing interests. The funders had no role in the design of the study, in the collection, analyses, or interpretation of data, in the writing of the manuscript, or in the decision to publish the results.

References

- Huč, S.; Svensson, S.; Hozjan, T. Numerical analysis of moisture-induced strains and stresses in glued-laminated timber. Holzforschung 2019, 21, 45–64. [Google Scholar] [CrossRef]

- Lima, H.; Tripathib, S.; Tangc, J.D. Bonding performance of adhesive systems for cross-laminated timber treated with micronized copper azole type C (MCA-C). Constr. Build. Mater. 2020, 232, 117–208. [Google Scholar] [CrossRef]

- Baier, R.E.; Shafrin, E.G.; Zisman, W.A. Adhesion: Mechanisms that assist or impede it. Science 1986, 162, 1360–1368. [Google Scholar] [CrossRef]

- Pocius, A.V. Adhesion and Adhesives Technology: An Introduction, 3rd ed.; Carl Hanser Verlag: Munich, Germany, 2012; pp. 1–15. [Google Scholar] [CrossRef]

- Frihart, R.C. Wood adhesion and adhesive. In Handbook of Wood Chemistry and Wood Composites, 2nd ed.; CRC Press: Boca Raton, FL, USA, 2012; pp. 216–273. [Google Scholar]

- Pizzi, A.; Mittal, K.L. Handbook of Adhesive Technology; Marcel Dekker: New York, NY, USA, 2003. [Google Scholar]

- Hunt, C.G.; Frihart, C.; Dunky, M.; Rohumaa, A. Understanding Wood Bonds-Going Beyond What Meets the Eye: A Critical Review. Rev. Adhes. Adhes. 2018, 6, 369–440. [Google Scholar] [CrossRef]

- Marra, A.A. Technology of Wood Bonding: Principles in Practice (VNR Structural Engineering); Van Nostrand Reinhold: New York, NY, USA, 1992. [Google Scholar]

- Frihart, C.R. Adhesive bonding and performance testing of bonded wood products. J. ASTM Int. 2005, 2, 455–466. [Google Scholar] [CrossRef]

- Konnerth, J.; Jäger, A.; Eberhardsteiner, J.; Müller, U.; Gindl, W. Elastic properties of adhesive polymers. II. Polymer films and bond lines by means of nanoindentation. J. Appl. Polym. Sci. 2006, 102, 1234–1239. [Google Scholar] [CrossRef]

- Kollmann, F.F.P.; Cote, W.A. Principles of Wood Science and Technology—I: Solid Wood, 1st ed.; Springer: Berlin, Germany, 1968. [Google Scholar] [CrossRef]

- Jiang, J.; Lu, J.; Zhou, Y.; Zhao, Y.; Zhao, L. Compression strength and modulus of elasticity parallel to the grain of oak wood at ultra-low and high temperatures. BioResources 2014, 9, 3571–3579. [Google Scholar] [CrossRef]

- Niemz, P.; Hug, S.; Schnider, T. Influence of temperature on selected mechanical properties of ash, beech, maple and spruce. Forstarchiv 2014, 85, 163–168. [Google Scholar]

- Szmutku, M.B.; Campean, M.; Porojan, M. Strength reduction of spruce wood through slow freezing. Eur. J. Wood Prod. 2013, 71, 205–210. [Google Scholar] [CrossRef]

- Yu, D.; Östman, B. Tensile strength properties of particle boards at different temperatures and moisture contents. Holz Roh-Werkst. 1983, 41, 281–286. [Google Scholar] [CrossRef]

- Tabor, L.J. Adhesives in construction: A contractor’s viewpoint. Int. J. Adhes. Adhes. 1982, 2, 73–76. [Google Scholar] [CrossRef]

- Radovic, B.; Rothkopf, C. Suitability of 1K PUR adhesives for wood construction, taking into account 10 years of experience. Wood 2003, 6, 1–6. [Google Scholar]

- Kägi, A.; Niemz, P.; Mandallaz, D. Influence of moisture content and selected technological parameters on the adhesion of one-part polyurethane adhesives under extreme climatical conditions. Holz Roh-Werkst. 2006, 64, 261–268. [Google Scholar] [CrossRef][Green Version]

- Brandmair, A.; Clauß, S.; Haß, P.; Niemz, P. Gluing of hardwoods with 1C-PUR-adhesives for engineered wood elements. Bauphysik 2012, 34, 210–216. [Google Scholar] [CrossRef]

- Grostad, K.; Bredesen, R. EPI for glued laminated timber. In Proceedings of the Conference on Materials and Joints in Timber Structures Recent Developments of Technology, Stuttgart, Germany, 8–10 October 2013. [Google Scholar] [CrossRef]

- Guo, J.; Hu, H.; Zhang, K.; He, Y.; Guo, X. Revealing the mechanical properties of emulsion polymer isocyanate film in humid environments. Polymers 2018, 10, 652. [Google Scholar] [CrossRef]

- Frangi, A.; Fontana, A.; Mischler, A. Shear behaviour of bond lines in glued laminated timber beams at high temperatures. Wood Sci. Technol. 2004, 38, 119–126. [Google Scholar] [CrossRef]

- Falkner, H.; Teutsch, M. Load-carrying capacity of glued laminated wood girders under temperature influence. Bautechnik 2006, 83, 391–393. [Google Scholar] [CrossRef]

- Clauss, S.; Joscak, M.; Niemz, P. Thermal stability of glued wood joints measured by shear tests. Eur. J. Wood Prod. 2011, 69, 101–111. [Google Scholar] [CrossRef]

- Kainz, J.J.; Ritter, M. Effect of cold temperatures on stress-laminated timber bridge deck. In Proceedings of the 5th World Conference on Timber Engineering, Montreux, Switzerland, 17–20 August 1998; Swiss Federal Institute of Technology Lausanne: Montreux, Switzerland, 1998; pp. 42–49. [Google Scholar]

- Wacker, J.P. Cold Temperature Effects on Stress-Laminated Timber Bridges—A Laboratory Study; Res. Pap. FPL-RP-605; Department of Agriculture, Forest Service, Forest Products Laboratory: Madison, WI, USA, 2003.

- Wacker, J.P. Performance of stress-laminated timber highway bridges in cold climates. In Proceedings of the 14th Conference on Cold Regions Engineering, Duluth, MN, USA, 31 August–2 September 2009; pp. 637–649. [Google Scholar]

- Wang, X.; Hagman, O.; Sundqvist, B.; Ormarsson, S.; Wan, H.; Niemz, P. Impact of cold temperatures on the shear strength of Norway spruce joints glued with different adhesives. Eur. J. Wood Prod. 2015, 73, 225–233. [Google Scholar] [CrossRef]

- Wang, X.; Hagman, O.; Sundqvist, B.; Ormarsson, S.; Wan, H.; Niemz, P. Shear Strength of Scots Pine Wood and Glued Joints in a Cold Climate. BioResource 2016, 11, 944–956. [Google Scholar] [CrossRef]

- Wang, X.; Björnberg, J.; Hagman, O.; Ahmed, S.A.; Wan, H.; Niemz, P. Effect of Low Temperatures on the Block Shear Strength of Norway Spruce Glulam Joints. BioResources 2016, 11, 9638–9648. [Google Scholar] [CrossRef]

- ČSN EN 204; Classification of Thermoplastic Wood Adhesives for Non-Structural Applications. Czech Standardization Agency: Prague, Czech Republic, 2013.

- ČSN EN 15425; Adhesives—One Component Polyurethane (PUR) for Loadbearing Timber Structures—Classification and Performance Requirements. Czech Standardization Agency: Prague, Czech Republic, 2017.

- ČSN EN 321; Wood-Based Panels—Determination of Moisture Resistance under Cyclic Test Conditions. Czech Standardization Agency: Prague, Czech Republic, 2002.

- ISO 13061-1; Physical and Mechanical Properties of Wood—Test Methods for Small Clear Wood Specimens—Part 1: Determination of Moisture Content for Physical and Mechanical Tests. International Organization for Standardization: Geneva, Switzerland, 2014.

- ISO 13061-2; Physical and Mechanical Properties of Wood—Test Methods for Small Clear Wood Specimens—Part 2: Determination of Density for Physical and Mechanical Tests. International Organization for Standardization: Geneva, Switzerland, 2014.

- Gryc, V.; Vavrčík, H.; Horn, K. Density of juvenile and mature wood of selected coniferous species. J. For. Sci. 2011, 57, 123–130. [Google Scholar] [CrossRef]

- ČSN EN 310; Wood-Based Panels—Determination of Modulus of Elasticity in Bending and of Bending Strength. Czech Standardization Agency: Prague, Czech Republic, 1995.

- ISO 13061-3; Physical and Mechanical Properties of Wood—Test Methods for Small Clear Wood Specimens—Part 3: Determination of Ultimate Strength in Static Bending. International Organization for Standardization: Geneva, Switzerland, 2014.

- ISO 13061-4; Physical and Mechanical Properties of Wood—Test Methods for Small Clear Wood Specimens—Part 4: Determination of Modulus of Elasticity in Static Bending. International Organization for Standardization: Geneva, Switzerland, 2014.

- Missio, A.L.; de Cademartori, P.H.G.; Mattos, B.D.; Santini, E.J.; Haselein, C.R.; Gatto, D.A. Physical and mechanical properties of fast-growing wood subjected to freeze-heat treatments. BioResources 2016, 11, 10378–10390. [Google Scholar] [CrossRef]

- Simpson, W.; TenWolde, W.A. Physical and moisture relation of wood. In Wood Handbook: Wood as an Engineering Material—A Laboratory Study; Res. Pap. FPL-RP-605; Department of Agriculture, Forest Service, Forest Products Laboratory: Madison, WI, USA, 1999. [Google Scholar]

- Kärenlampi, P.P.; Tynjälä, P.; Ström, P. Phase transformations of wood cell wall water. J. Wood Sci. 2005, 51, 118–123. [Google Scholar] [CrossRef]

- Chudinov, B.S. Theoretical Research of Thermo Physical Properties and Thermal Treatment of Wood. D.Sc. Dissertation, SibLTI, Krasnoyarsk, Russia, 1966. [Google Scholar]

- Geissen, A. Influence of Temperature and Wood Moisture on the Elastic and Strength Properties of Timber in Freezing Range. Ph.D. Dissertation, Universität Hamburg, Hamburg, Germany, 1976. [Google Scholar]

- Gerhards, C.C. Effect of moisture content and temperature on the mechanical properties of wood: An analysis of immediate effects. Wood Fiber 1982, 14, 4–36. [Google Scholar]

- Forest Products Laboratory. Wood Handbook—Wood as an Engineering Material; General Technical Report FPL-GTR-282; Department of Agriculture, Forest Service, Forest Products Laboratory: Madison, WI, USA, 2021; 543p.

- Cheng, J.Q. Wood Science; China Forestry Publishing House: Beijing, China, 1985. [Google Scholar]

- Green, D.W.; Evans, J.W.; Logan, J.D.; Nelson, W.J. Adjusting modulus of elasticity of lumber for changes in temperature. For. Prod. J. 1999, 49, 82–94. [Google Scholar]

- Merkel, H. Mechanical Properties of Ice. Available online: http://ffden-2.phys.uaf.edu/311_fall2004.web.dir/heike_merkel/Intro.htm (accessed on 1 May 2004).

- Ilic, J. Advantages of pre-freezing for reducing shrinkage-related degrade in eucalypts: General considerations and review of literature. Wood Sci. Technol. 1995, 29, 277–285. [Google Scholar] [CrossRef]

- Zhao, L.; Lu, J.; Zhou, L.; Jiang, J. Effect of Low Temperature Cyclic Treatments on Modulus of Elasticity of Birch Wood. BioResources 2015, 10, 2318–2327. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).