Physical and Chemical Changes in Hydrothermally Modified Wood

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

3.1. Changes of Wood Mass, Volume and Density after Treatment

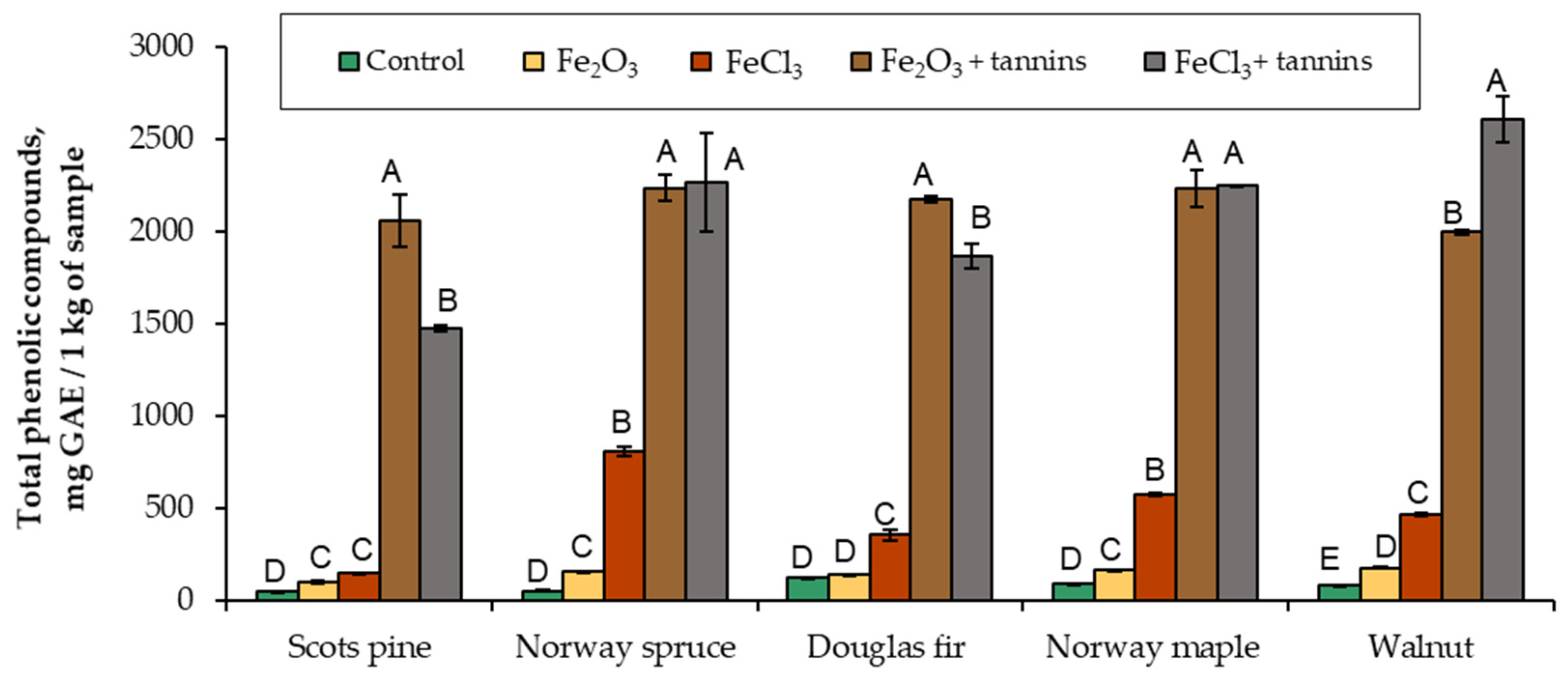

3.2. Chemical Changes of Solutions, Used for Hydrothermal Wood Treatments

3.3. Fe Concentration in Treated Wood

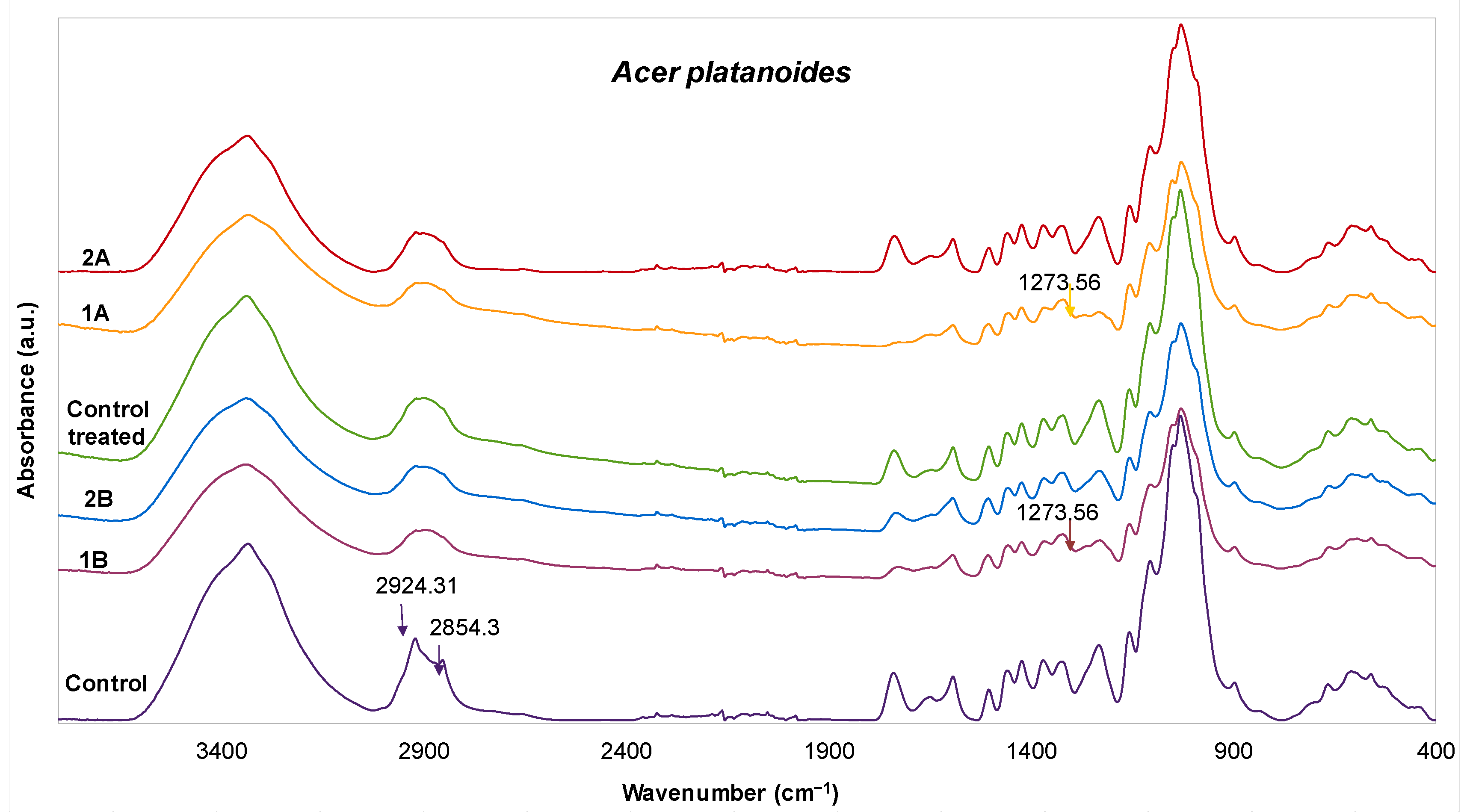

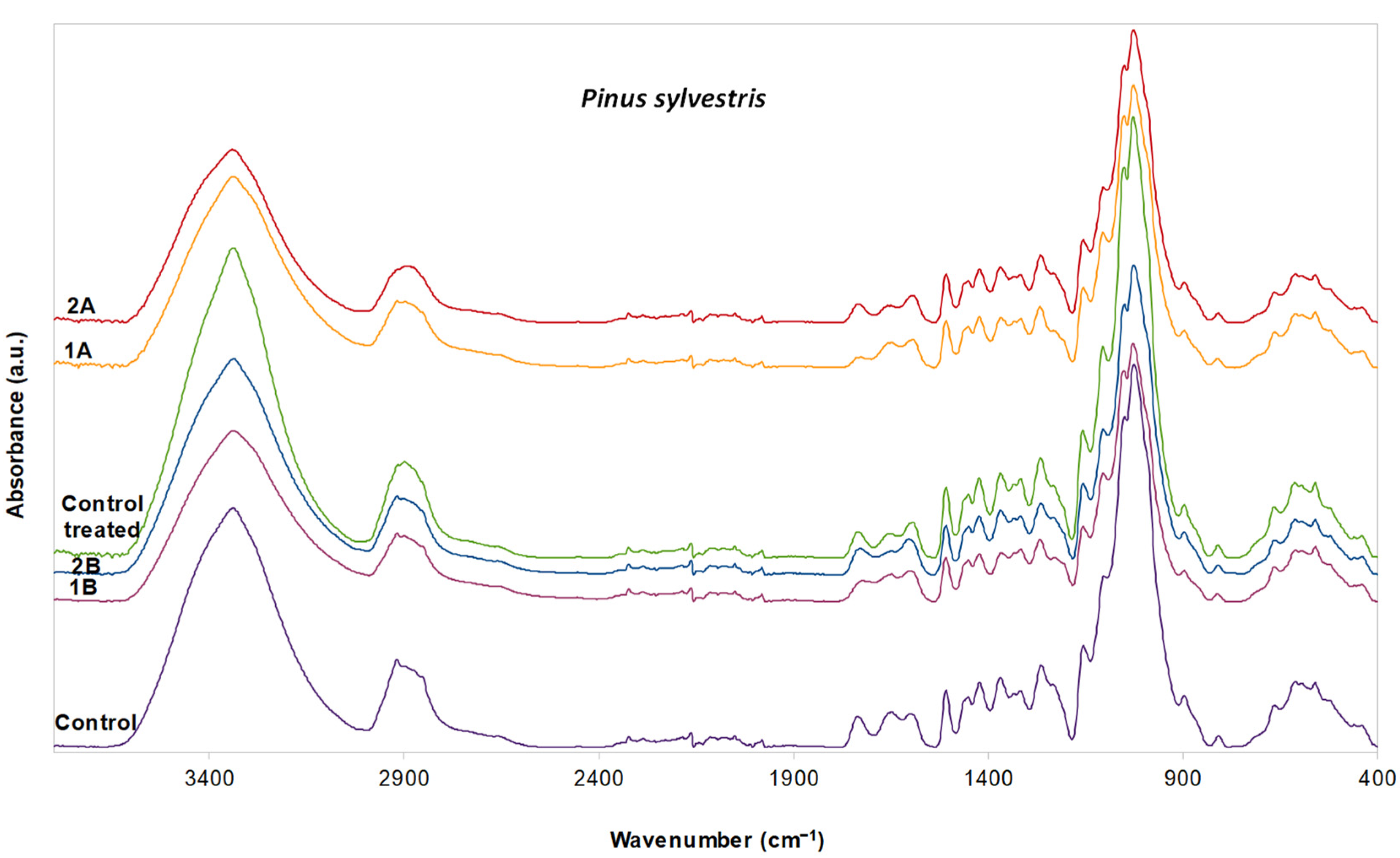

3.4. FTIR Analysis of Wood Samples

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ayadi, N.; Lejeune, F.; Charrier, F.; Charrier, B.; Merlin, A. Color stability of heat-treated wood during artificial weathering. Holz als Roh-und Werkstoff 2003, 61, 221–226. [Google Scholar] [CrossRef]

- Williams, R.S. Weathering of wood. In Handbook of Wood Chemistry and Wood Composites; Rowell, R.M., Ed.; CRC Press: Boca Raton, FL, USA, 2005; pp. 139–185. [Google Scholar]

- Garcia, R.A.; Lopes, J.D.; Nascimento, A.; Latorraca, J.V. Color stability of weathered heat-treated teak wood. Maderas-Cienc. Tecnol. 2014, 16, 453–462. [Google Scholar] [CrossRef] [Green Version]

- Rowell, R.M. Chemical modification of wood: A review. Commonw. For. Bur. 1983, 6, 363–382. [Google Scholar]

- Rowell, R.M. Chemical modification of wood: A short review. Wood Mater. Sci. Eng. 2006, 1, 29–33. [Google Scholar] [CrossRef]

- Kotilainen, R. Chemical Changes in Wood during Heating at 150–260 °C. Ph.D. Thesis, Jyväskylä University, Jyväskylä, Finland, 2000. [Google Scholar]

- Zaman, A.; Alen, R.; Kotilainen, R. Thermal behavior of Scots pine (Pinus sylvestris) and silver birch (Betula pendula) at 200 to 230 °C. Wood Fiber Sci. 2000, 32, 138–143. [Google Scholar]

- Militz, H.; Hill, G. Wood modification: Processes, Properties and Commercialisation. In Proceedings of the 2nd European Conference on Wood Modification, Göttingen, Germany, 6–7 October 2005. [Google Scholar]

- Kocaefe, D.; Shi, J.L.; Yang, D.Q.; Bouazara, M. Mechanical properties, dimensional stability, and mold resistance of heat-treated jack pine and aspen. For. Prod. J. 2008, 58, 88–93. [Google Scholar]

- Gunduz, G.; Korkut, S.; Korkut, D.S. The effects of heat treatment on physical and technological properties and surface roughness of Camiyani Black pine (Pinus nigra Arn. subsp. pallasiana var. pallasiana) wood. Bioresour. Technol. 2008, 99, 2275–2280. [Google Scholar] [CrossRef]

- Bakar, B.F.A.; Hiziroglu, S.; Tahir, P.M. Properties of some thermally modified wood species. Tech. Rep. Mater. Des. 2013, 43, 348–355. [Google Scholar] [CrossRef] [Green Version]

- Hannouz, S.; Collet, R.; Butaud, J.-C.; Bléron, L.; Candelier, K. Mechanical characterization of heat-treated ash wood in relation with structural timber standards. PRO LIGNO-Open Access Sci. J. Field Wood Eng. 2015, 11, 13. [Google Scholar]

- Sidorova, E. Combination of Heating and Preservative Impregnation of Wood for Outdoor Exposure. Ph.D. Thesis, Luleå University of Technology, Luleå, Sweden, 2016. [Google Scholar]

- Sundqvist, B. Colour Changes and Acid Formation in Wood during Heating. Ph.D. Thesis, Luleå University of Technology, Luleå, Sweden, 2004. [Google Scholar]

- Militz, H. Processes and Properties of Thermally Modified Wood Manufactured in Europe. In Development of Commercial Wood Preservatives; Schultz, T., Ed.; ACS Symposium Series; American Chemical Society: Washington, DC, USA, 2008; pp. 372–388. [Google Scholar]

- Vernois, M. Heat treatment of wood in France: State of the art. In Review on Heat Treatments of Wood, Proceedings of the Seminar, COST ACTION E22, Environmental Optimisation of Wood Protection, Antibes, France, 9 February 2001; Rapp, A.O., Ed.; Hamburg BFH: Braunschweig, Germany, 2001; pp. 37–44. [Google Scholar]

- Gouveia, F.N. Thermal Treatments for the Colorimetric Stabilization of Tropical Hardwood (in Portuguese). Ph.D. Thesis, Universidade de Brasília, Brasília, Brazil, 2008. [Google Scholar]

- Wang, W.; Zhu, Y.; Cao, J.; Sun, W. Correlation between dynamic wetting behavior and chemical components of thermally modified wood. Appl. Surf. Sci. 2015, 324, 332–338. [Google Scholar] [CrossRef]

- Yamaguchi, H.; Okuda, K.I. Chemically modified tannin and tannin-copper complexes as wood preservatives. Holzforschung 1998, 52, 596–602. [Google Scholar] [CrossRef]

- Tascioglu, C.; Yalcin, M.; Sen, S.; Akcay, C. Antifungal properties of some wood plant extracts used as wood preservatives. Int. Biodeterior. 2013, 85, 23–28. [Google Scholar] [CrossRef]

- Perron, N.R.; Brumaghim, J.L. A review of the antioxidant mechanisms of polyphenol compounds related to iron binding. Cell Biochem. Biophys. 2009, 53, 75–100. [Google Scholar] [CrossRef] [PubMed]

- Valette, N.; Perrot, T.; Sormani, R.; Gelhaye, E.; Morel-Rouhier, M. Antifungal activities of wood extractives. Fungal Biol. Rev. 2017, 31, 113–123. [Google Scholar] [CrossRef]

- Dai, J.; Mumper, R.J. Plant phenolics: Extraction, analysis and their antioxidant and anticancer properties. Molecules 2010, 15, 7313–7352. [Google Scholar] [CrossRef]

- Brack, D. Background Analytical Study. Sustainable Consumption and Production of Forest Products. Background Study Prepared for the Thirteenth Session of the United Nations Forum on Forests. 2018. Available online: https://www.un.org/esa/forests/wp-content/uploads/2018/04/UNFF13_BkgdStudy_ForestsSCP.pdf (accessed on 13 December 2021).

- Grosse, C.; Noël, M.; Thévenon, M.-F.; Gérardin, P. Improvement of modified wood properties with addition of chestnut tannins in lactic acid-based treatments. J. Wood Chem. Technol. 2019, 39, 124–135. [Google Scholar] [CrossRef]

- Aleinikovas, M.; Varnagirytė-Kabašinskienė, I.; Povilaitienė, A.; Šilinskas, B.; Škėma, M.; Beniušienė, L. Resistance of wood treated with iron compounds against wood-destroying decay and mould fungi. Forests 2021, 12, 645. [Google Scholar] [CrossRef]

- Singleton, V.L.; Rossi, L. Analysis of total phenols and other oxidation substrates and antioxidants by means of folin-ciocalteu reagent. Meth. Enzymol. 1999, 299, 152–178. [Google Scholar]

- Tenorio, C.; Moya, R. Thermogravimetric characteristics, its relation with extractives and chemical properties and combustion characteristics of ten fast-growth species in Costa Rica. Thermochim. Acta 2013, 563, 12–21. [Google Scholar] [CrossRef]

- Candelier, K.; Thevenon, M.F.; Petrissans, A.; Dumarcay, S.; Gerardan, P.; Petrissans, M. Control of wood thermal treatment and its effects on decay resistance: A review. Ann. For. Sci. 2016, 73, 571–583. [Google Scholar] [CrossRef] [Green Version]

- Chaouch, M.; Pétrissans, M.; Pétrissans, A.; Gérardin, P. Use of wood elemental composition to predict heat treatment intensity and decay resistance of different softwood and hardwood species. Polymer Degrad. Stab. 2010, 95, 2255–2259. [Google Scholar] [CrossRef]

- Keiluweit, M.; Nico, P.S.; Johnson, M.G.; Kleber, M. Dynamic molecular structure of plant biomass-derived black carbon (biochar). Environ. Sci. Technol. 2010, 44, 1247–1253. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Hon, D.N.S.; Shiraishi, N. Wood and Cellulosic Chemistry, 2nd ed.; Marcel Dekker Incorporated: New York, NY, USA, 2010. [Google Scholar]

- Canas, S.; Belchior, A.P.; Mateus, A.M.; Spranger, M.I. Kinetics of impregnation/evaporation and release of phenolic compounds from wood to brandy in experimental model. Cienc. Tec. Vitivinicola 2002, 17, 1–14. [Google Scholar]

- Meullemiestre, A.; Petitcolas, E.; Maache-Rezzoug, Z.; Chemat, F.; Rezzoug, S.A. Impact of ultrasound on solid–liquid extraction of phenolic compounds from maritime pine sawdust waste. Kinetics, optimization and large-scale experiments. Ultrason. Sonochem. 2016, 28, 230–239. [Google Scholar] [CrossRef] [PubMed]

- Wang, S.; Gao, B.; Zimmerman, A.R.; Li, Y.; Ma, L.; Harris, W.G.; Migliaccio, K.W. Removal of arsenic by magnetic biochar prepared from pinewood and natural hematite. Bioresour. Technol. 2015, 175, 391–395. [Google Scholar] [CrossRef]

- Zhang, C.; Paterson, G.A.; Liu, Q. A new mechanism for the magnetic enhancement of hematite during heating: The role of clay minerals. Stud. Geophys. Geod. 2012, 56, 845–860. [Google Scholar] [CrossRef]

- Ma, W.; Ding, Y.; Zhang, M.; Gao, S.; Li, Y.; Huang, C.; Fu, G. Nature-inspired chemistry toward hierarchical superhydrophobic, antibacterial and biocompatible nanofibrous membranes for effective UV-shielding, self-cleaning and oil-water separation. J. Hazard. Mater. 2020, 384, 121476. [Google Scholar] [CrossRef]

- Huang, Y.; Lin, Q.; Yu, Y.; Yu, W. Functionalization of wood fibers based on immobilization of tannic acid and in situ complexation of Fe (II) ions. Appl. Surf. Sci. 2020, 510, 145436. [Google Scholar] [CrossRef]

- El-Hage, R.; Brosse, N.; Chrusciel, L.; Sanchez, C.; Sannigrahi, P.; Ragauskas, A. Characterization of milled wood lignin and ethanol organosolv lignin from Miscanthus. Polym. Degrad. Stab. 2009, 94, 1632–1638. [Google Scholar] [CrossRef]

- Cakar, S.; Özacar, M. Fe–tannic acid complex dye as photo sensitizer for different morphological ZnO based DSSCs. Spectrochim. Acta A Mol. Biomol. Spectrosc. 2016, 163, 79–88. [Google Scholar] [CrossRef]

- Cakar, S.; Güy, N.; Özacar, M.; Fındık, F. Investigation of vegetable tannins and their iron complex dyes for dye sensitized solar cell applications. Electrochim. Acta 2016, 209, 407–422. [Google Scholar] [CrossRef]

- Limaye, V.M.; Schütz, C.; Kriechbaum, K.; Wohlert, J.; Bacsik, Z.; Wohlert, M.; Xia, W.; Pléa, M.; Dembele, C.; Sala-zar-Alvarez, G.; et al. Functionalization and patterning of nanocellulose films by surface-bound nanoparticles of hydrolyzable tannins and multivalent metal ions. Nanoscale 2019, 11, 19278–19284. [Google Scholar] [CrossRef] [Green Version]

- Grasel, F.D.S.; Ferrão, M.F.; Wolf, C.R. Development of methodology for identification the nature of the polyphenolic extracts by FTIR associated with multivariate analysis. Spectrochim. Acta A Mol. Biomol. Spectrosc. 2015, 153, 94–101. [Google Scholar] [CrossRef] [PubMed]

- Falcão, L.; Araújo, M.E.M. Tannins characterization in historic leathers by complementary analytical techniques ATR-FTIR, UV–vis and chemical tests. J. Cult. Herit. 2013, 14, 499–508. [Google Scholar] [CrossRef]

- Saha, N.; Saba, A.; Reza, M.T. Effect of hydrothermal carbonization temperature on pH, dissociation constants, and acidic functional groups on hydrochar from cellulose and wood. J. Anal. Appl. Pyrolysis 2019, 137, 138–145. [Google Scholar] [CrossRef]

- Ramage, M.H.; Burridge, H.; Wicher, M.B.; Fereday, G.; Reynolds, T.; Shah, D.U.; Wu, G.; Yu, L.; Fleming, P.; Tingley, D.D.; et al. The wood from the trees: The use of timber in construction. Renew. Sust. Energ. Rev. 2017, 68, 333–359. [Google Scholar] [CrossRef]

- Sharma, V.; Yadav, J.; Kumar, R.; Tesařová, D.; Ekielski, A.; Mishra, P.K. On the rapid and non-destructive approach for wood identification using ATR-FTIR spectroscopy and chemometric methods. Vib. Spectrosc. 2020, 110, 103097. [Google Scholar] [CrossRef]

- Pandey, K.K. A study of chemical structure of soft and hardwood and wood polymers by FT IR spectroscopy. J. Appl. Polym. Sci. 1999, 71, 1969–1975. [Google Scholar] [CrossRef]

- Colom, X.; Carrillo, F.; Nogués, F.; Garriga, P. Structural analysis of photodegraded wood by means of FTIR spectroscopy. Polym. Degrad. Stab. 2003, 80, 543–549. [Google Scholar] [CrossRef]

- Chen, H.; Ferrari, C.; Angiuli, M.; Yao, J.; Raspi, C.; Bramanti, E. Qualitative and quantitative analysis of wood samples by Fourier transform infrared spectroscopy and multivariate analysis. Carbohydr. Polym. 2010, 82, 772–778. [Google Scholar] [CrossRef]

- Traoré, M.; Kaal, J.; Cortizas, A.M. Application of FTIR spectroscopy to the characterization of archaeological wood. Spectrochim. Acta A Mol. Biomol. Spectrosc. 2016, 153, 63–70. [Google Scholar] [CrossRef] [PubMed]

- Lehto, J.; Louhelainen, J.; Huttunen, M.; Alén, R. Spectroscopic analysis of hot-water- and dilute-acid-extracted hardwood and softwood chips. Spectrochim. Acta A Mol. Biomol. Spectrosc. 2017, 184, 184–190. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ping, L.; Pizzi, A.; Guo, Z.D.; Brosse, N. Condensed tannins from grape pomace: Characterization by FTIR and MALDI TOF and production of environment friendly wood adhesive. Ind. Crops Prod. 2012, 40, 13–20. [Google Scholar] [CrossRef]

| Treatment * | Changes (Percent) of Wood Parameters | ||

|---|---|---|---|

| Mass | Volume | Density | |

| Scots pine Pinus sylvestris L. | |||

| Control | −5.3 * ± 0.3 c | −9.2 ± 2.6 b | +4.4 ± 3.1 c |

| Fe2O3 | −4.1 ± 0.7 d | −7.6 ± 1.3 bc | +3.9 ± 1.7 c |

| FeCl3 | −15.6 ± 0.8 a | −11.1 ± 1.3 a | −5.0 ± 1.9 a |

| Fe2O3 + tannic acid | +3.8 ± 2.7 e | −5.9 ± 3.1 c | +10.4 ± 5.2 d |

| FeCl3 + tannic acid | −8.9 ± 1.1 b | −7.9 ± 1.3 b | −1.1 ± 1.8 b |

| Norway spruce Picea abies (L.) H. Karst. | |||

| Control | −4.8 ± 0.4 c | −7.8 ± 2.3 b | +3.3 ± 2.7 b |

| Fe2O3 | −5.8 ± 0.5 bc | −8.4 ± 2.7 ab | +3.0 ± 3.2 b |

| FeCl3 | −13.7 ± 2.5 a | −10.5 ± 2.1 a | −3.6 ± 3.0 a |

| Fe2O3 + tannic acid | −0.6 ± 0.1 d | −3.7 ± 0.8 b | −5.0 ± 1.1 c |

| FeCl3 + tannic acid | −6.4 ± 0.7 b | −7.8 ± 1.1 b | +1.5 ± 1.3 b |

| Douglas fir Pseudotsuga menziesii (Mirb.) Franco | |||

| Control | −10.4 ± 1.2 b | −1.8 ± 0.7 b | −8.7 ± 1.3 b |

| Fe2O3 | −15.5 ± 1.5 a | −3.8 ± 0.9 a | −12.1 ± 2.0 a |

| FeCl3 | −15.5 ± 1.5 a | −3.8 ± 0.9 a | −12.1 ± 2.0 a |

| Fe2O3 + tannic acid | −4.5 ± 1.1 c | −0.7 ± 0.9 c | −3.9 ± 1.2 c |

| FeCl3 + tannic acid | −10.8 ± 1.5 b | −1.9 ± 0.8 b | −9.1 ± 1.9 b |

| Norway maple Acer platanoides L. | |||

| Control | −4.2 ± 0.5 d | −2.6 ± 0.7 d | −1.7 ± 0.8 c |

| Fe2O3 | −3.5 ± 1.1 d | −2.6 ± 0.6 d | −1.0 ± 1.4 c |

| FeCl3 | −20.7 ± 1.4 a | −11.4 ± 1.7 a | −10.5 ± 1.8 a |

| Fe2O3 + tannic acid | −6.3 ± 0.6 c | −7.0 ± 1.2 c | +0.8 ± 1.6 d |

| FeCl3 + tannic acid | −14.5 ± 1.4 b | −9.2 ± 2.2 b | −5.8 ± 2.8 b |

| Walnut Juglans regia L. | |||

| Control | −9.2 ± 1.5 b | −10.1 ± 1.4 a | +1.1 ± 2.3 c |

| Fe2O3 | −4.3 ± 0.7 c | −3.3 ± 1.5 c | −1.0 ± 2.0 bc |

| FeCl3 | −13.9 ± 1.9 a | −9.2 ± 1.4 ab | −5.2 ± 3.1 a |

| Fe2O3 + tannic acid | −3.4 ± 0.8 c | −3.7 ± 1.5 c | +0.4 ± 2.1 b |

| FeCl3 + tannic acid | −9.8 ± 2.0 b | −8.1 ± 1.3 b | −1.9 ± 3.3 b |

| Mean Fe Concentration (mg kg−1) | |||

|---|---|---|---|

| Treatments | Outer Sublayer | Intermediate Sublayer | Inner Sublayer |

| Scots pine Pinus sylvestris L. | |||

| Control * | 111.40 ± 3.70 d | 111.40 ± 3.70 d | 111.40 ± 3.70 d |

| Fe2O3 | 8548.48 ± 1925.16 a | 473.60 ± 32.44 c | 372.59 ± 37.68 b |

| FeCl3 | 5358.97 ± 426.94 b | 653.31 ± 141.13 b | 322.49 ± 12.79 c |

| Fe2O3 + tannic acid | 3903.08 ± 1481.83 c | 1080.95 ± 87.68 a | 876.34 ± 52.31 a |

| FeCl3 + tannic acid | 3224.85 ± 393.19 c | 585.27 ± 91.34 b | 383.67 ± 22.98 b |

| Norway spruce Picea abies (L.) H. Karst. | |||

| Control | 45.00 ± 0.48 d | 45.00 ± 0.48 d | 45.00 ± 0.48 d |

| Fe2O3 | 12,453.94 ± 2096.81 a | 354.39 ± 78.38 d | 324.36 ± 26.11 c |

| FeCl3 | 8589.60 ± 1161.92 b | 1703.88 ± 371.60 b | 763.20 ± 143.67 b |

| Fe2O3 + tannic acid | 5608.70 ± 700.68 c | 937.37 ± 126.64 c | 770.43 ± 128.01 b |

| FeCl3 + tannic acid | 7510.81 ± 1209.56 b | 2798.82 ± 823.61 a | 1094.26 ± 108.84 a |

| Douglas fir Pseudotsuga menziesii (Mirb.) Franco | |||

| Control | 103.85 ± 2.48 d | 103.85 ± 2.48 d | 103.85 ± 2.48 e |

| Fe2O3 | 14,189.04 ± 2520.21 a | 751.68 ± 155.74 b | 565.20 ± 63.27 b |

| FeCl3 | 4457.39 ± 715.83 b | 685.24 ± 60.76 b | 405.52 ± 19.01 c |

| Fe2O3 + tannic acid | 4059.72 ± 410.19 b | 1365.48 ± 64.82 a | 1157.76 ± 7.03 a |

| FeCl3 + tannic acid | 2888.95 ± 218.92 c | 500.15 ± 36.90 c | 325.58 ± 28.54 d |

| Norway maple Acer platanoides L. | |||

| Control | 37.61 ± 3.01 e | 37.61 ± 3.01 d | 37.61 ± 3.01 d |

| Fe2O3 | 15,966.13 ± 1495.33 a | 9327.27 ± 1129.27 a | 7851.80 ± 651.68 a |

| FeCl3 | 4794.83 ± 1364.64 b | 988.27 ± 312.80 b | 608.28 ± 73.77 bc |

| Fe2O3 + tannic acid | 3265.34 ± 451.30 c | 943.79 ± 173.76 bc | 707.02 ± 126.17 b |

| FeCl3 + tannic acid | 1851.71 ± 367.27 d | 492.28 ± 117.50 cd | 407.38 ± 44.58 c |

| Walnut Juglans regia L. | |||

| Control | 196.00 ± 8.74 d | 196.00 ± 8.74 d | 196.00 ± 8.74 e |

| Fe2O3 | 5808.97 ± 3140.73 a | 516.66 ± 100.55 c | 243.80 ± 18.63 d |

| FeCl3 | 3113.23 ± 365.63 bc | 791.47 ± 65.74 b | 614.88 ± 10.11 b |

| Fe2O3 + tannic acid | 4260.61 ± 643.11 b | 1576.83 ± 47.91 a | 1179.18 ± 66.29 a |

| FeCl3 + tannic acid | 2185.00 ± 189.69 c | 828.16 ± 127.60 b | 566.69 ± 6.42 c |

| Frequency Range (cm−1) | Attribution of the Absorption Bands | Attributed to | Reference |

|---|---|---|---|

| 3300 | C–H | Phenolic and aliphatic structures | [49,50] |

| 2924; 2854 | Aromatic C–H stretch | Methoxyl groups and in methyl and methylene groups | [47,51] |

| 1630–1635 | COO stretching, absorbed OH, and conjugated C–O | Cellulose, lignin | [47] |

| 1510 | C=C | Lignin | [52] |

| 1593 | Aromatic skeletal and C=O stretch vibration | Lignin | [48] |

| 1050–1250 | C–O–C | Carbohydrates and cellulose | [52] |

| 1026; 1050–1250 | C–O–C stretching vibration (hemicellulose, cellulose, lignin) | Cellulose and hemicellulose | [47,48] |

| 1230 | C–O–C symmetric stretching and OH plane deformation | Syringyl lignin | [45] |

| 1273 | C–C | Guaiacyl lignin structure | [45,53] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Varnagirytė-Kabašinskienė, I.; Pukalskienė, M.; Šilinskas, B.; Škėma, M.; Aleinikovas, M. Physical and Chemical Changes in Hydrothermally Modified Wood. Forests 2021, 12, 1771. https://doi.org/10.3390/f12121771

Varnagirytė-Kabašinskienė I, Pukalskienė M, Šilinskas B, Škėma M, Aleinikovas M. Physical and Chemical Changes in Hydrothermally Modified Wood. Forests. 2021; 12(12):1771. https://doi.org/10.3390/f12121771

Chicago/Turabian StyleVarnagirytė-Kabašinskienė, Iveta, Milda Pukalskienė, Benas Šilinskas, Mindaugas Škėma, and Marius Aleinikovas. 2021. "Physical and Chemical Changes in Hydrothermally Modified Wood" Forests 12, no. 12: 1771. https://doi.org/10.3390/f12121771

APA StyleVarnagirytė-Kabašinskienė, I., Pukalskienė, M., Šilinskas, B., Škėma, M., & Aleinikovas, M. (2021). Physical and Chemical Changes in Hydrothermally Modified Wood. Forests, 12(12), 1771. https://doi.org/10.3390/f12121771