Cascade Use of Wood in the Czech Republic

Abstract

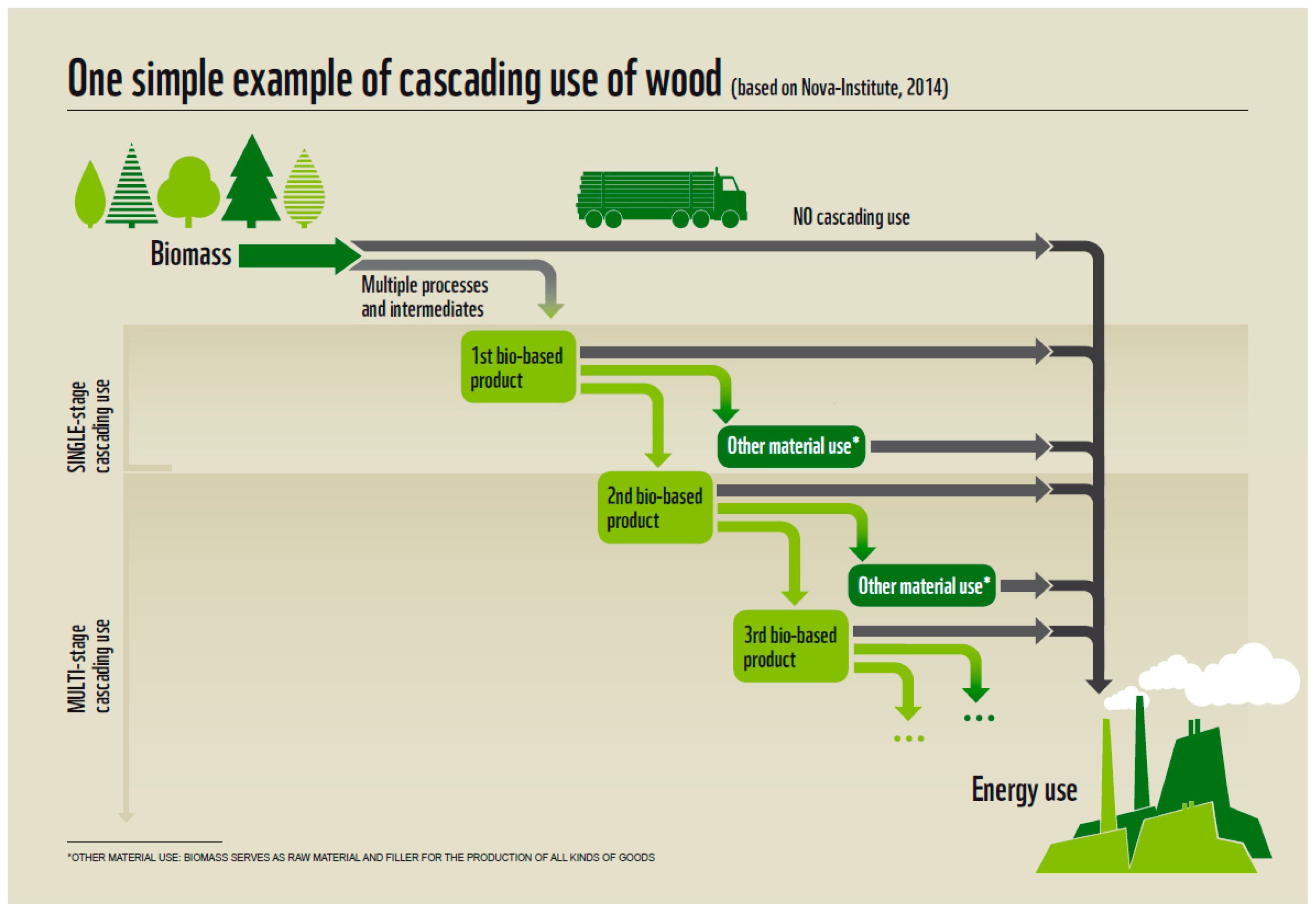

1. Introduction

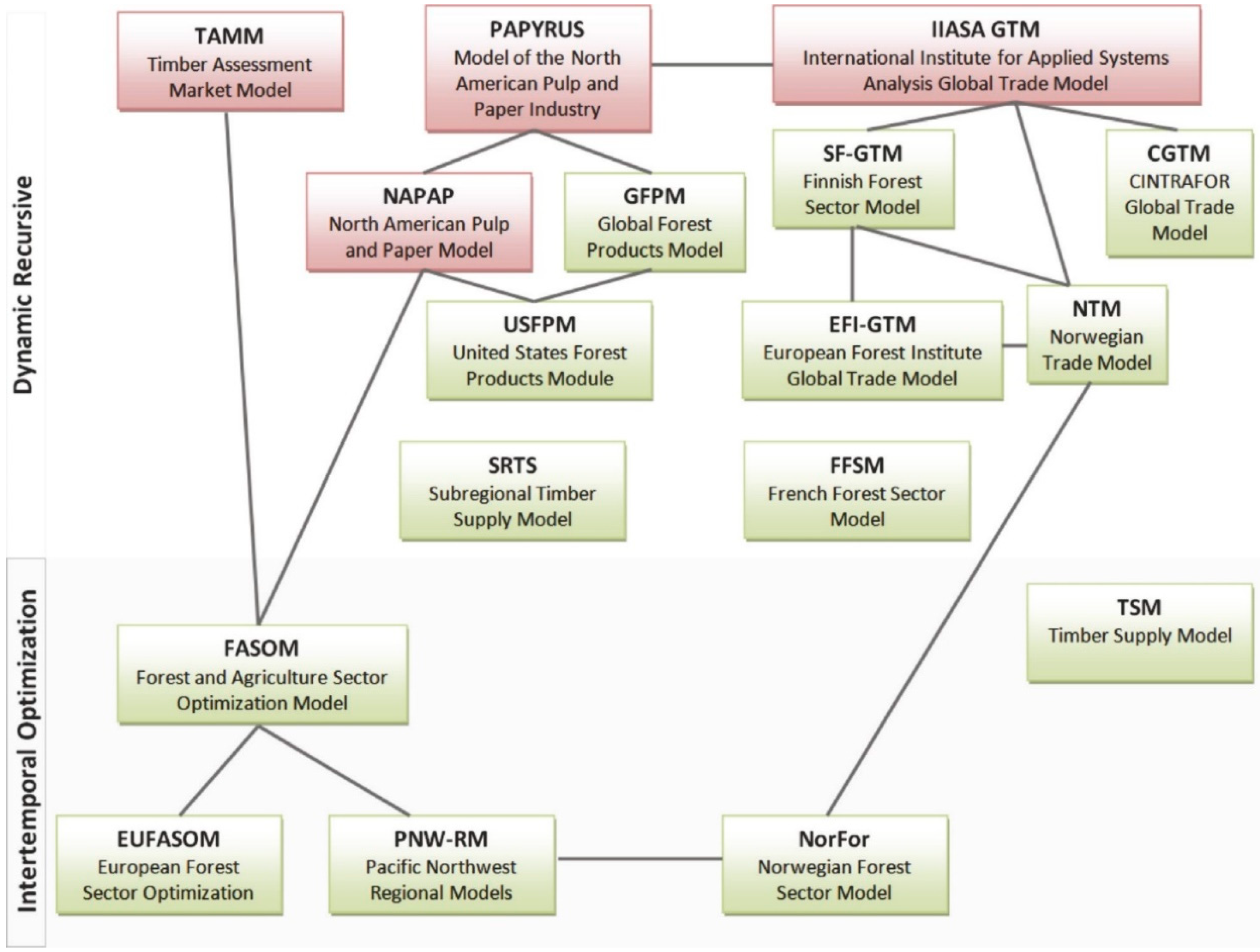

2. Materials and Methods

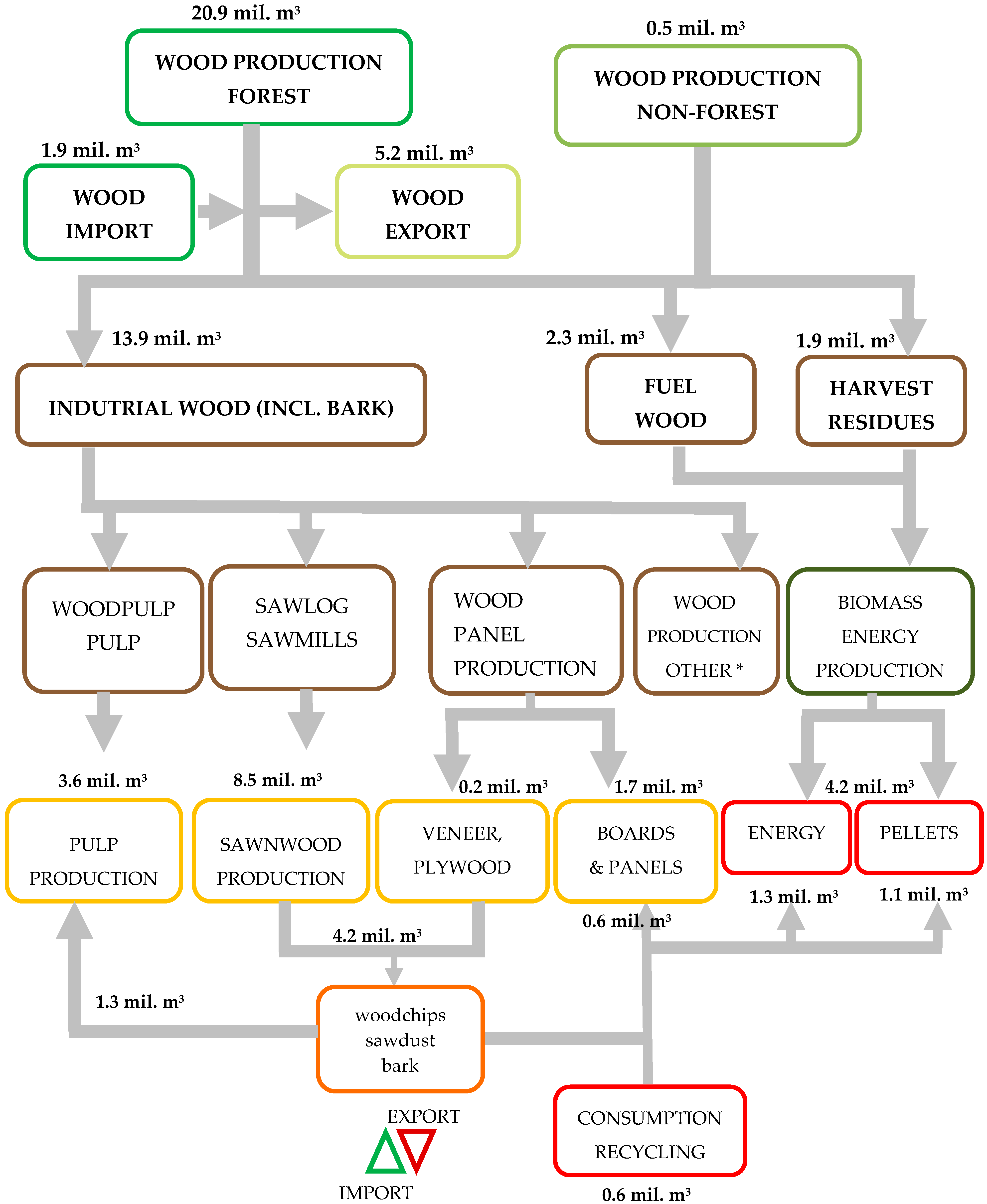

- Sources of roundwood (forest biomass): the analysis of available data sources and evaluation of the general processing potential of individual categories of available wood. The source of information is the Green Report of the Ministry of Agriculture (MA) [34] and statistical data from the Czech Statistical Office (CSO) for forestry [35]. During the analysis, limitations and additional values were identified to gain a comprehensive conception of wood supplies for domestic processing.

- Wood import and export (foreign trade balance): the analysis of roundwood export and import for determining the volume in the wood flow processing focused on the overall trend in identifiable products (at least on the level of roundwood products) according to the Ministry of Agriculture and the CSO. Foreign trade data published by the Ministry of Agriculture were based on the data issued by the CSO. Foreign trade data were obtained from two systems, Intrastat and Extrastat [36]. In the Intrastat report, the data were gained directly from companies (importing and exporting) in connection with data about value added tax (VAT) and trade with European Union (EU) countries. The remaining part of the foreign trade realized, mainly with non-European Union countries, is still subject to common customs procedures. Customs declarations (single administrative documents) were a source of statistical data for the Extrastat report. To analyze the wood flow of domestic processing, it was necessary to know how much wood was exported, what kind of species and qualities were exported, and what trends were developing regarding exports. The same questions apply to the roundwood import analysis.

- Determination of the wood volume entering primary industrial processing without further distinction in energy production and consumption: raw wood volume consumption was calculated as wood production minus export and plus import. This was reported in the statistical report of the Ministry of Agriculture elaborated by the Czech Statistical Office.

- Data corrections. This study worked with the limited official data sources concerning the input of roundwood. This is the main weakness of all known approaches for wood flow monitoring at the national and transregional levels because it is not possible to apply an active and deep method of wood consumption identification. Mathematical-statistical calculations were part of data processing and these compensated for loss of information as a consequence of non-response and the implementation of statistical thresholds. In the foreign trade section, the volume of wood export and import in the correction of non-conformities was identified.

- to find out the types of primary wood processing;

- to assign the individual types of processing to the average values of the disintegration of the material balance of the yield of 1 m3 of input wood (conversion factors);

- to determine the production volumes of individual types of processing;

- to determine the production structure and consumption of byproducts within one type of primary processing and between different types of processing (cascade).

3. Results

3.1. Results of Input Analyses

- roundwood production is reported only as a subset, and does not include all forest owners and wood harvesting in a specified group of respondents;

- it provides no information on the supply of forest biomass and wood or forest residue and wood chips produced in the forest;

- there is no statistical monitoring of bark volume from forest production;

- there is a considerable difference between the statistical monitoring of wood production of the Ministry of Agriculture and that of the National Forest Inventory (NFI; identifies average annual production at the level of 21.83 million m3 of wood).

3.2. Input Data Correction and Calculation

3.3. Cascade Use of Wood

4. Discussion

- −

- to extend collecting data on wood sources to all forest owners regardless of their size;

- −

- to improve accuracy in the values expressing volume of wood;

- −

- to provide statistical monitoring of bark volume from the forest production;

- −

- to harmonize the databases and techniques for monitoring wood production created by official state entities;

- −

- to improve (introduce) the interconnection of data between wood production and its consumption in the primary processing sector.

- −

- the proposal of methods and procedures by collecting data regarding raw wood supply;

- −

- the investigation of methods for monitoring wood use in material and energy use and household consumption directly by state institutions;

- −

- harmonization between data collection regarding raw wood supply from national (domestic) and foreign wood sources;

- −

- possibilities for the integration of the hierarchy principle of wood biomass cascading use into the bioeconomy strategy.

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Mair, C.; Stern, T. Cascading Utilization of Wood: A Matter of Circular Economy? For. Policyecon. Ocial Res. 2017, 3, 281–295. [Google Scholar] [CrossRef]

- Fehrenback, H.; Köppen, S.; Kauertz, B.; Detzel, A.; Wellenreuther, F.; Brietmayer, E.; Essel, R.; Carus, M.; Kay, S.; Wern, B.; et al. Biomass Cascades: Increasing Resource Efficiency by Cascading Use of Biomass—From Theory to Practice; Umweltbundesamt: Dessau-Roßlau, Germany, 2017; p. 29. Available online: http://www.umweltbundesamt.de/publikationen (accessed on 20 June 2019).

- Huang, C.-H.; Ma, H.; Vause, J.; Yu, C.-P. Using material/substance flow analysis to support sustainable development assessment: A literature review and outlook. Resour. Conserv. Recycl. 2012, 68, 104–116. [Google Scholar] [CrossRef]

- Binder, C.R. Material flux analysis and agent analysis as a basis for transition towards improved regional wood flows: The case of Appenzell Ausserrhoden, Switzerland. Ecol. Econ. 2004, 49, 1–17. [Google Scholar] [CrossRef]

- Hekkert, M.P.; Joosten, L.A.J.; Worrell, E. Analysis of the paper and wood flow in the Netherlands. Resour. Conserv. Recycl. 2000, 30, 29–48. [Google Scholar] [CrossRef]

- Mantau, U.; Saal, U.; Jonsson, R.; Steierer, F.; Verkerk, P.J.; Eggers, J.; Anttila, P.; Lindner, M.; Asikainen, A.; Oldenburger, J.; et al. Real Potential for Changes in Growth and Use of EU Forests; Final report; EUwood: Hamburg, Germany, 2010; Available online: http://ec.europa.eu/energy/renewables/studies/doc/bioenergy/euwood_final_report.pdf (accessed on 1 July 2019).

- Mantau, U. Wood Flows in Europe (eu27); Tech. Rep., Project Report, Celle; Cepi: Brussels, Belgium, 2012; p. 24. Available online: http://www.cepi.org/system/files/public/documents/publications/forest/2012/CEPIWoodFlowsinEurope2012.pdf (accessed on 10 April 2019).

- Mantau, U. Wood flow analysis: Quantification of resource potentials, cascades and carbon effects. Biomass Bioenergy 2015, 79, 28–38. [Google Scholar] [CrossRef]

- Sirkin, T.; ten Houten, M. The cascade chain—A theory and tool for achieving resource sustainability with applications for product design. Resour. Conserv. Recycl. 1994, 10, 213–276. [Google Scholar] [CrossRef]

- Carus, M. Cascading concepts and proposal for a new definition. In Presentation Given in Cascading Use of Biomass—From Theory to Practice; VTT Technical Reasearch Centre of Finland: Brussels, Belgium, 2014. [Google Scholar]

- Essel, R.; Breitmayer, E.; Carus, M.; Fehrenbach, H.; von Geibler, J.; Bienge, K.; Baur, F. Discussion Paper: Defining Cascading Use of Biomass; Nova Institute: Hürth, Germany, 14 March 2014; Available online: https://biomassekaskaden.de/wp-content/uploads/2014/04/14-03-14_Cascading_use_Discussionpaper.pdf (accessed on 3 July 2019).

- Kosmol, J.; Kanthak, J.; Herrmann, F.; Golde, M.; Alsleben, C.; Penn-Bressel, G.; Schnitz., S.; Gromke, U. Glossar zum Ressourcenschutz; Umweltbundesamt: Dessau-Roßlau, Germany, 2012. [Google Scholar]

- Olsson, O.; Bruce, L.; Roos, A.; Hektor, B.; Guisson, R.; Lamers, P.; Hartley, D.; Ponitka, J.; Hildebrandt, J.; Thrän, J. Cascading of Woody Biomass: Definitions, Policies and Effects on International Trade, IEA Bioenergy Task 40. 2016. Available online: https://www.researchgate.net/publication/301553375_Cascading_of_woody_biomass_definitions_policies_and_effects_on_inter-national_trade (accessed on 15 June 2019).

- Vis, M.; Mantau, U.; Allen, B. Study on the Optimised Cascading Use of Wood; No 394/PP/ENT/RCH/14/7689. Final report; European Commission: Brussels, Belgium, 2016; p. 337.

- Carus, M.; Raschka, A.; Piotrowski, S. The Development of Instruments to Support the Material Use of Renewable Raw Materials in Germany; Nova-Institut: Hürth, Germany, 2010; Available online: http://www.bio-based.eu/policy/en/index.php (accessed on 3 July 2019).

- Carus, M.; Dammer, L.; Herman, A.; Essel, R. Proposal for a Reform of the Renewable Energy Directives (RED) to a Renewable Energy and Material Directives (REMD); In Nova-paper No. 4 on biobased economy; Nova Institute: Hürth, Germany, 2014. [Google Scholar]

- Fraanje, P.J. Cascading of pine wood. Resour. Conserv. Recycl. 1997, 19, 21–28. [Google Scholar] [CrossRef]

- Keegan, D.; Kretschmer, B.; Elbersen, B.; Panoutsou, C. Review: Cascading the use of biomass. Biofuels Bioprod. Bioref. 2013, 7, 193–206. [Google Scholar] [CrossRef]

- BirdLife Europe; EEB. Cascading Use of Biomass: Opportunities and Obstacles in EU Policies; Policy Briefing by BirdLife Europe and the European Environmental Bureau: Brüssel, Belgium, 2016; Available online: http://www.birdlife.org/sites/default/files/attachments/cascading_use_memo_final.pdf (accessed on 3 July 2019).

- Taskhiri, M.S.; Garbs, M.; Geldermann, J. Sustainable logistics network for wood flow considering cascade utilization. J. Clean. Prod. 2016, 110, 25–39. [Google Scholar] [CrossRef]

- Sokka, L.; Keränen, J.; Koponen, J. Cascading Use of Wood in Finland—With Comparison to Selected EUcountries; Research Report VTT-R-03979-15 at MEE; Ministry of Employment and Economy: Helsinki, Finland, 2015; Available online: https://www.vtt.fi/inf/julkaisut/muut/2015/vtt-r-03979-15.pdf (accessed on 10 April 2019).

- Salmi, O.; Haapalehto, T.; Harlin, A.; Häkkinen, T.; Kangas, H.; Mroueh, U.M.; Qvintus, P. Materiaalitehokkuuden Kehittäminen Suomen Teollisessa Rakenteessa. 2013. Available online: https://www.tem.fi/files/37387/VTT_Materiaalitehokkuus_Revisio2.pdf (accessed on 5 July 2019).

- Lenglet, J.; Courtonne, J.-Y.; Caurla, S. Material flow analysis of the forest-wood supply chain: A consequential approach for logs export policies in France. J. Clean. Prod. 2017, 5, 1296–1305. [Google Scholar] [CrossRef]

- Martire, S.; Tuomasjukka, D.; Lindner, M. Wood Flow Modelling for a More Sustainable Regional Forest-Based Sector. In Proceedings of the Towards a Sustainable Bioeconomy Conference, Barcelona, Spain, 21–23 October 2015; pp. 326–334. [Google Scholar]

- Höher, M.; Strimitzer, L.; Nemestothy, K. Wood flows in Austria in the year 2015. Klimaaktiv Energieholz. 2017. [Google Scholar] [CrossRef]

- Dammer, L.; Bowyer, C.; Breitmayer, E.; Eder, A.; Nanni, S.; Allen, B.; Carus, M.; Essel, R. Mapping Study on Cascading Use of Wood Products; Word Wide Fund for Nature (WWF): Gland, Switzerland, 2016; p. 55. [Google Scholar]

- Latta, G.S.; Baker, J.S.; Beach, R.H.; Rose, S.K.; McCarl, B.A. A multi-sector intertemporal optimization approach to assess the GHG implications of U.S. forest and agricultural biomass electricity expansion. J. For. Econ. 2013, 19, 361–383. [Google Scholar] [CrossRef]

- Džubur, N.; Sunanta, O.; Laner, D. A fuzzy set-based approach to data reconciliation in material flow modeling. Appl. Math. Model. 2017, 43, 464–480. [Google Scholar] [CrossRef]

- Courtonne, J.-Y.; Alapetite, J.; Longaretti, P.-Y.; Dupré, D.; Prados, E. Downscaling material flow analysis: The case of the cereals supply chain in france. Ecol. Econ. 2015, 118, 67–80. [Google Scholar]

- Weimar, H. Der Holzfluss in der Bundesrepublik Deutschland 2009; Tech. rep., Methode und Ergebnis der Modellierung des Sto_flusses von Holz; von Thunen, J.H., Ed.; Institut fur Forst-und Holzwirtschaft: Hamburg, Germany, 2011. [Google Scholar]

- Cencic, O.; Rechberger, H. Material flow analysis with software stan. J. Environ. Eng. Manag. 2008, 18, 3–7. [Google Scholar]

- Mobini, M.; Sowlati, T.; Sokhansanj, S. A simulation model for the design and analysis of wood pellet supply chains. Appl. Energy 2013, 111, 1239–1249. [Google Scholar] [CrossRef]

- Kupčák, V.; Pek, R. The level of the wood raw material base processing in the Czech Republic. Procedia Econ. Financ. 2015, 34, 557–564. [Google Scholar] [CrossRef]

- Ministry of Agriculture of the Czech Republic (MA). Information on Forests and Forestry in the CR. Available online: http://eagri.cz/public/web/en/mze/publications/publications-forest (accessed on 18 May 2017).

- Czech Statistical Office CSO. Forestry. Available online: https://www.czso.cz/csu/czso/lesnictvi-2016 (accessed on 6 September 2018).

- European Commission (EC). EUROSTAT Statistics Database. Available online: http://epp.eurostat.ec.europa.eu/ (accessed on 10 July 2018).

- Babuka, R.; Sujová, A.; Kupčák, V. Scenario Management of Cascade Wood Use: Comparison of Social and Economics Indicators. Mark. Manag. Innov. 2018, 4, 73–85. [Google Scholar] [CrossRef]

- Matějíček, J. Sber Ekonomickych Dat [Collection of Economic Data]. 2014. Available online: http://www.uhul.cz/images/NLP/3Jednani/Seminar_2014/9_Sber_ekonomickych_dat.pdf (accessed on 22 August 2017).

- Ministry of Agriculture of the Czech Republic. Vyhláška Ministerstva Zemědělství č. 84/1996 Sb., o Lesním Hospodářském Plánování [Decree of Ministry of Agriculture No. 84/1996 on Forestry Planning]. Available online: http://eagri.cz/public/web/mze/legislativa/pravni-predpisy-mze/tematicky-prehled/Legislativa-MZe_uplna-zneni_Vyhlaska-1996-84-lesnictvi.html (accessed on 5 May 2017).

- Adolt, R.; Kučera, M.; Kohn, I.; Kratěna, L.; Fejfar, J.; Závadský, J.; Piškytlová, K.; Čech, Z. “Výstupy Národní Inventarizace Lesů” [Output of National Forest Inventory, Wood Production,], Forest Management Institute Information on Czech Forests. 2016. Available online: http://nil.uhul.cz/data/documents/vysledky_projektu_nil2/tezba_drivi_lp_unor_2016.pdf (accessed on 11 September 2017).

- Michal, J.; Sujová, A.; Březina, D. The importance of products made of certified wood materials to consumers in the Czech Republic. Forum Sci. Oeconomia 2018, 6, 119–131. [Google Scholar] [CrossRef]

- Sujová, A.; Březina, D.; Hlaváčková, P. Stanovení dodavatelsko-odběratelských proporcí dříví: Případová studie vybraného kraje ČR. [Determination of the wood supplier-customer proportions in the conditions of the Czech Republic: A case study]. Zprávy Lesn. Výzkumu 2018, 63, 214–221. [Google Scholar]

| Product | Raw Wood Use/m3 of Product |

|---|---|

| Softwood lumber | 1.72 m3 |

| Hardwood lumber | 1.88 m3 |

| Impregnation | 1.07 m3 |

| Softwood plywood | 1.81 m3 |

| Hardwood plywood | 2.43 m3 |

| Veneer | 2.04 m3 |

| OSB | 1.61 m3 |

| MDF | 1.63 m3 |

| Pulp | 4.85 m3 |

| Particleboard | 1.53 m3 |

| in m3 Without Bark | Wood Production (incl., Self-Production) | Export | Import | Consumption | |

|---|---|---|---|---|---|

| Coniferous and Deciduous | Total | 17,616,553 | 5,177,709 | 1,686,768 | 14,125,612 |

| Saw logs | 10,340,681 | ||||

| Of which | Pulp | 4,931,627 | |||

| Fuelwood | 2,344,245 | 195 | 25 | ||

| Coniferous | Total | 15,923,807 | 5,034,094 | 1,486,316 | 12,376,029 |

| Saw logs | 9,868,837 | ||||

| Of which | Pulp | 4,504,892 | |||

| Fuelwood | 1,550,078 | ||||

| Deciduous | Total | 1,692,746 | 143,615 | 200,452 | 1,749,583 |

| Saw logs | 471,844 | ||||

| Of which | Pulp | 426,735 | |||

| Fuelwood | 794,167 |

| Raw Wood in m3 | Total | Coniferous | Deciduous |

|---|---|---|---|

| Wood production (incl. self-production) [32] | 17,616,553 | 15,923,807 | 1,692,746 |

| Wood production by all owners | 18,907,967 | 17,091,131 | 1,816,836 |

| Bark | 1,981,670 | 1,709,132 | 272,538 |

| All owners with bark | 20,889,637 | 18,800,263 | 2,089,374 |

| Production by all without fuelwood with bark | 16,391,873 | 15,427,422 | 964,451 |

| Export | 5,177,709 | 5,034,094 | 143,615 |

| Import | 1,686,763 | 1,486,315 | 200,452 |

| Raw wood consumption without fuelwood and bark | 12,900,932 | 11,879,644 | 1,021,288 |

| Bark consumption without fuel bark | 1,341,178 | ||

| Residue and woodchips consumption | 1,900,000 | ||

| Total raw wood consumption | 16,142,110 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Babuka, R.; Sujová, A.; Kupčák, V. Cascade Use of Wood in the Czech Republic. Forests 2020, 11, 681. https://doi.org/10.3390/f11060681

Babuka R, Sujová A, Kupčák V. Cascade Use of Wood in the Czech Republic. Forests. 2020; 11(6):681. https://doi.org/10.3390/f11060681

Chicago/Turabian StyleBabuka, Róbert, Andrea Sujová, and Václav Kupčák. 2020. "Cascade Use of Wood in the Czech Republic" Forests 11, no. 6: 681. https://doi.org/10.3390/f11060681

APA StyleBabuka, R., Sujová, A., & Kupčák, V. (2020). Cascade Use of Wood in the Czech Republic. Forests, 11(6), 681. https://doi.org/10.3390/f11060681