Options for Optimizing the Drying Process and Reducing Dry Matter Losses in Whole-Tree Storage of Poplar from Short-Rotation Coppices in Germany

Abstract

1. Introduction

- In the case of whole tree storage of poplar, what effect does the stack height have on the weight losses and drying?

- Can covering the soil with a fleece lead to better ventilation, and thus to improved drying of the storage pile?

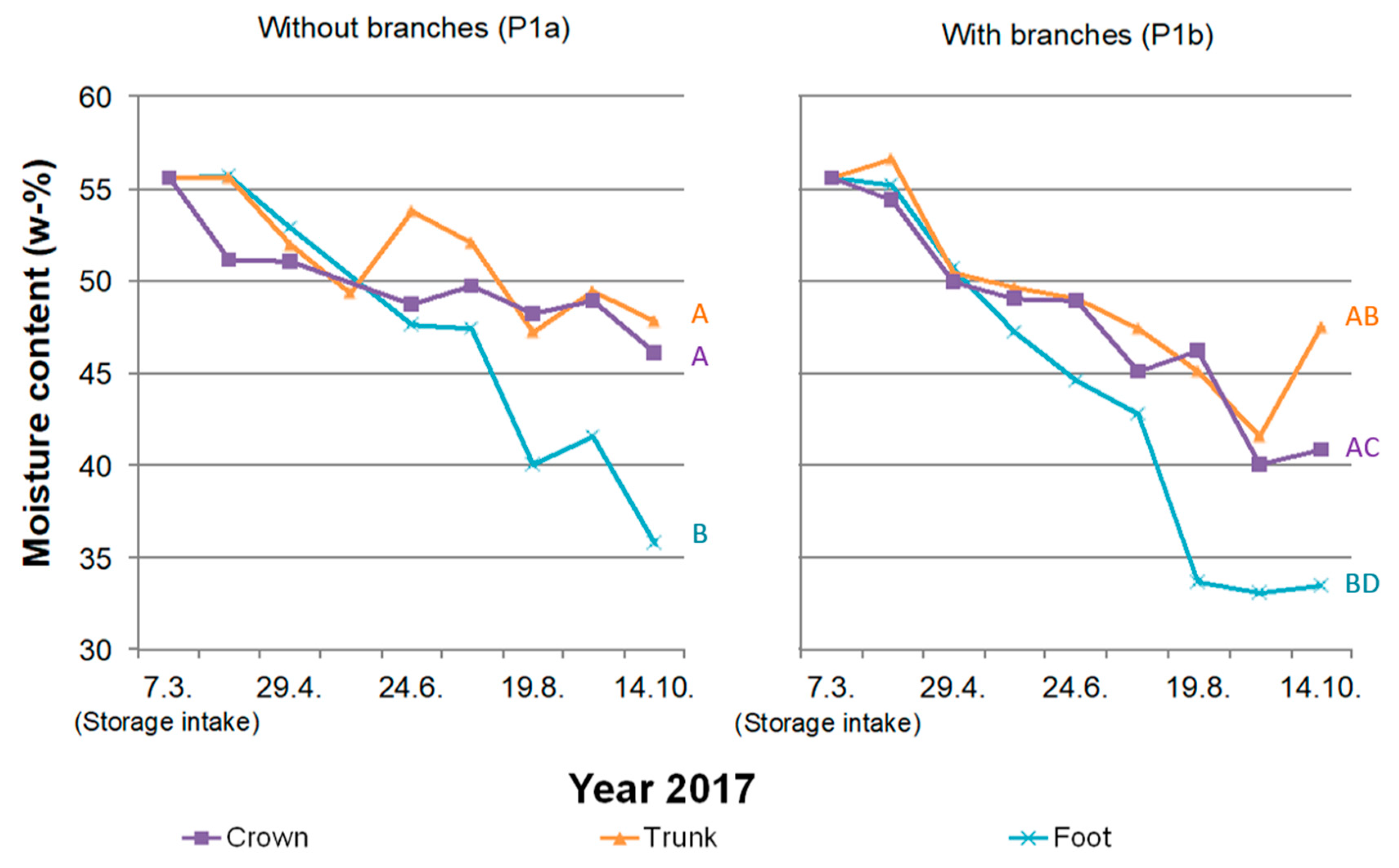

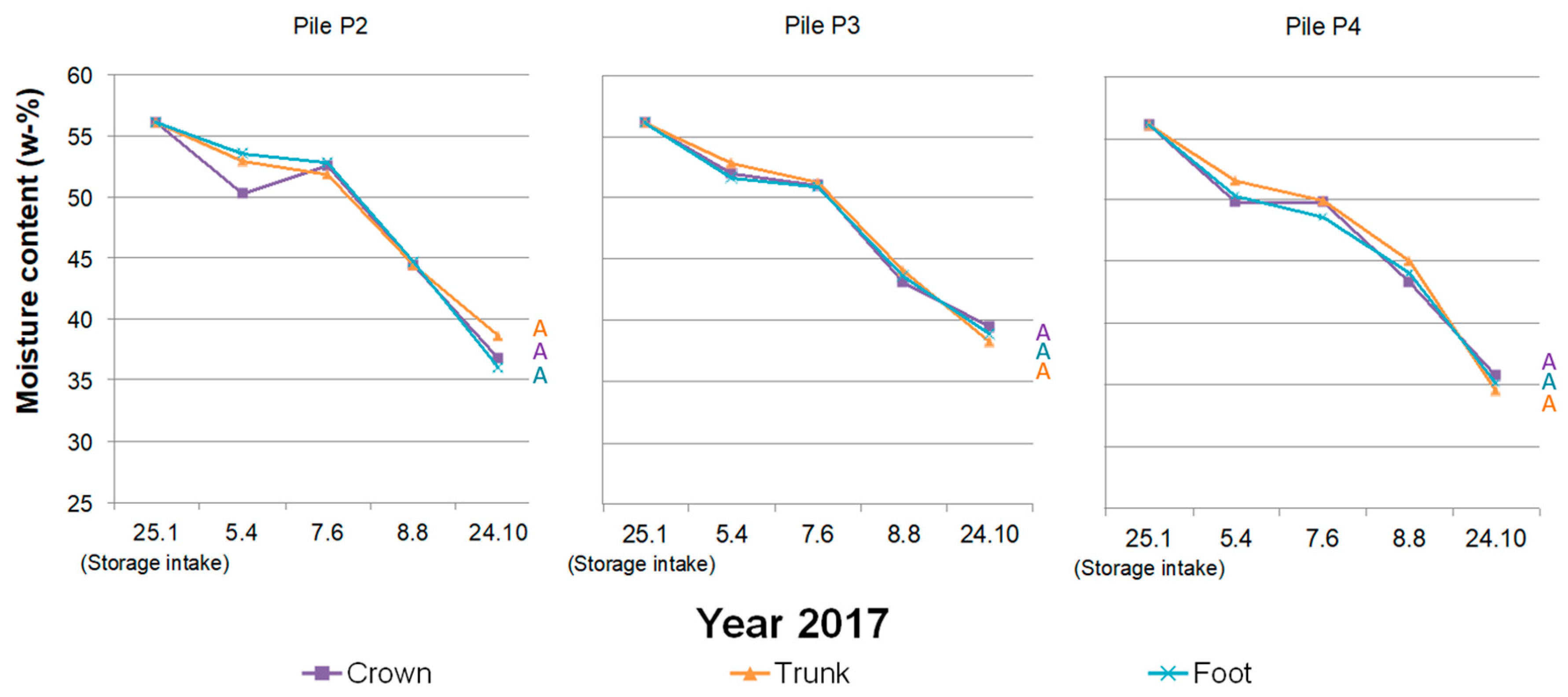

- Is there a difference in the drying behavior of poplar stems with and without branches?

- What effect do the different weather conditions from year to year have on the storage?

- What influence does the tree trunk diameter have on the storage losses and drying behavior?

2. Materials and Methods

2.1. Trial Setup at the Potsdam Site

| Li | dry matter loss at time i | [%] |

| min | wet mass at storage intake | [kg] |

| mout, i | wet mass at time i | [kg] |

| Xin | moisture content at storage intake (on wet basis) | [%] |

| Xout, i | moisture content at time i (on wet basis) | [%] |

2.2. Trial Setup at the Schwarzbach Site

2.3. Statistical Data Analysis

3. Results

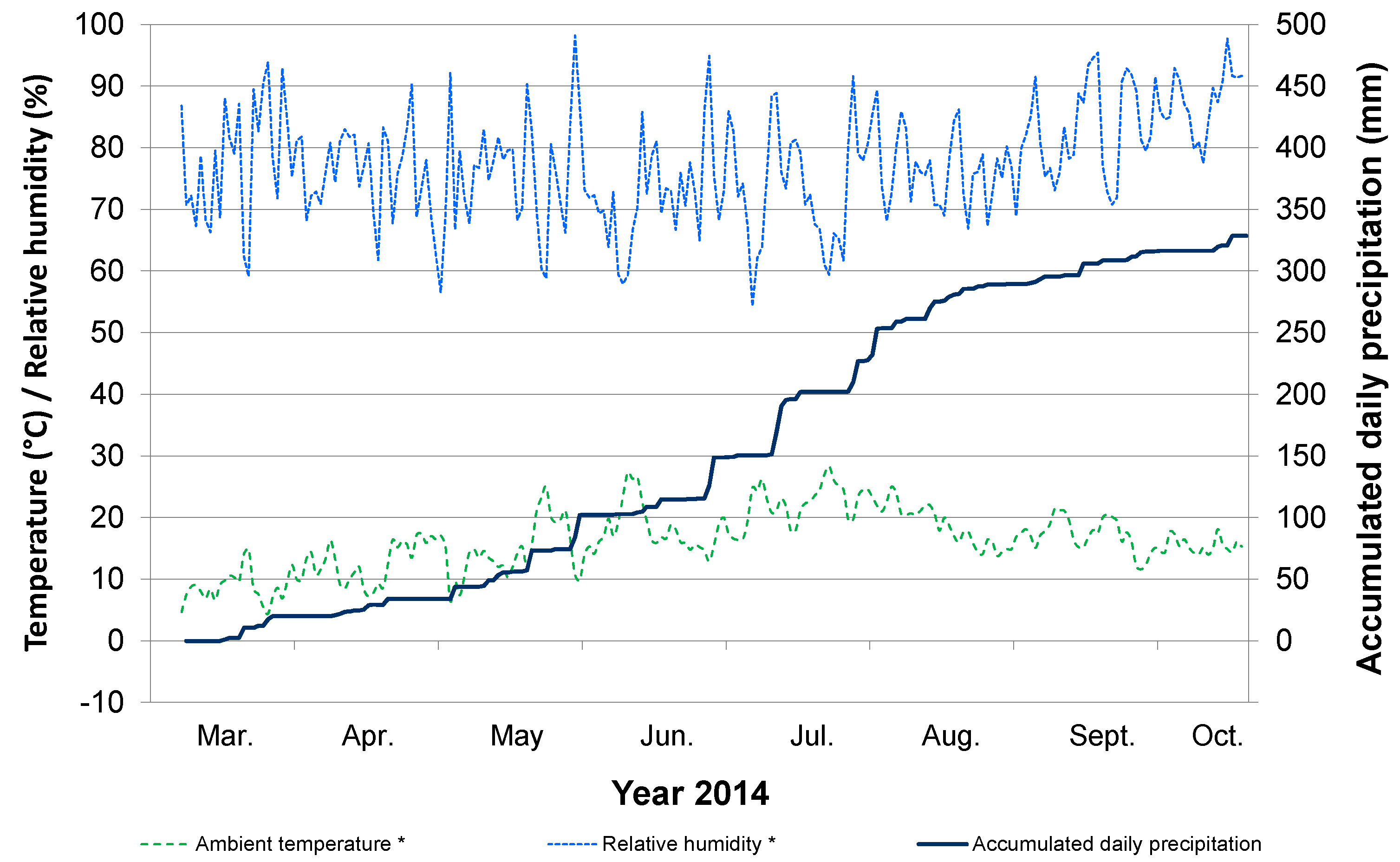

3.1. Weather Conditions Potsdam

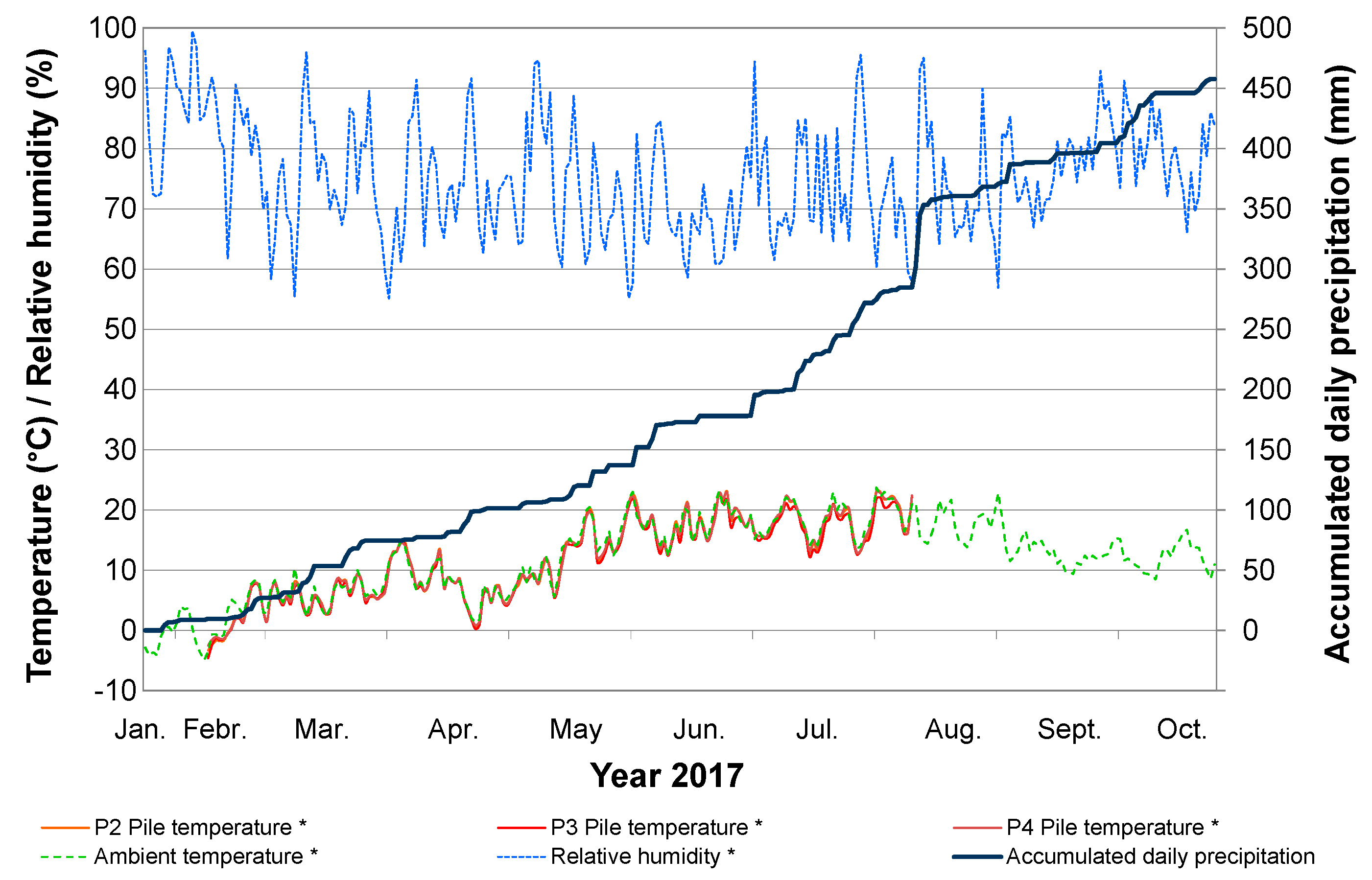

3.2. Weather Conditions Schwarzbach

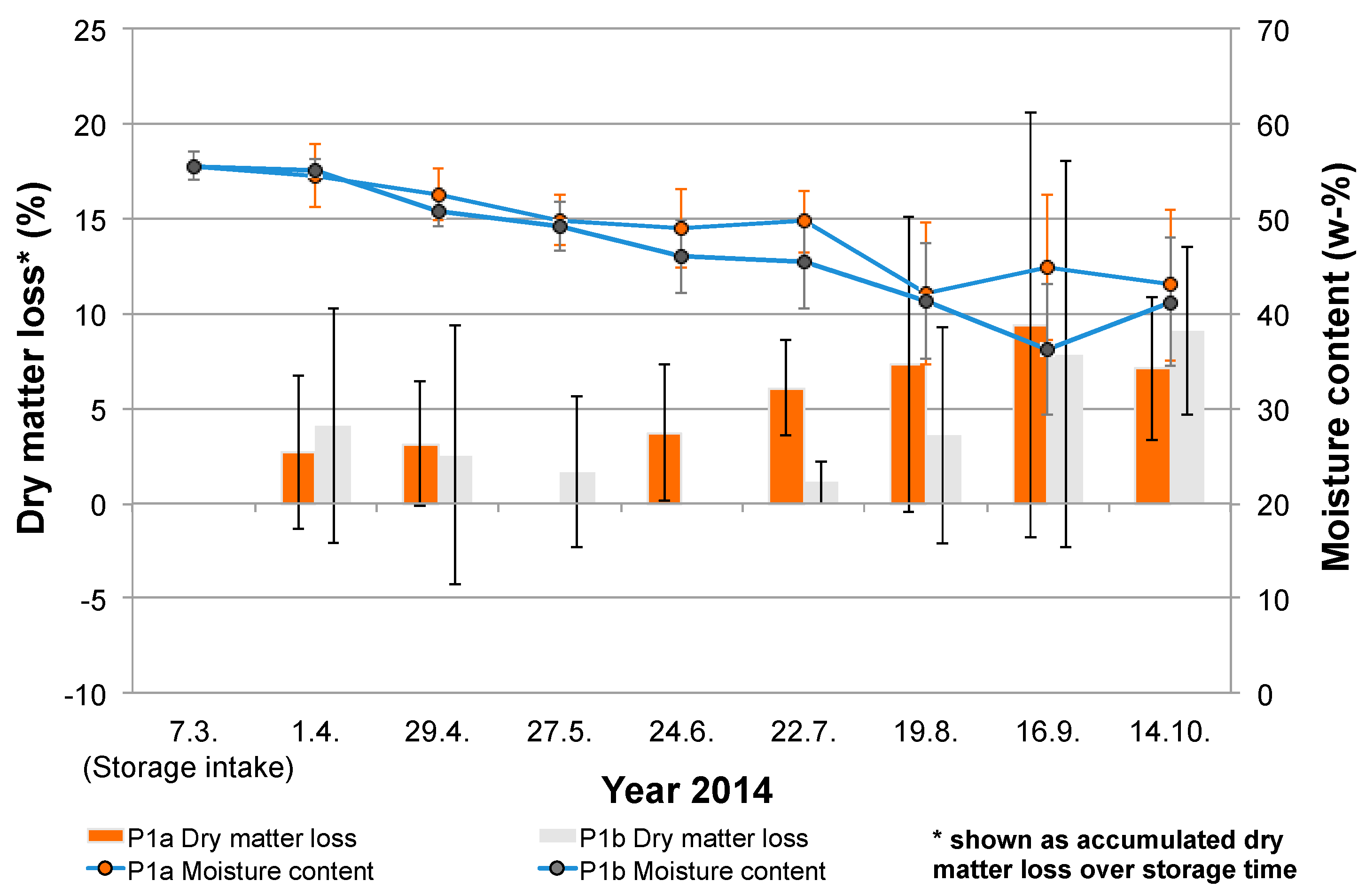

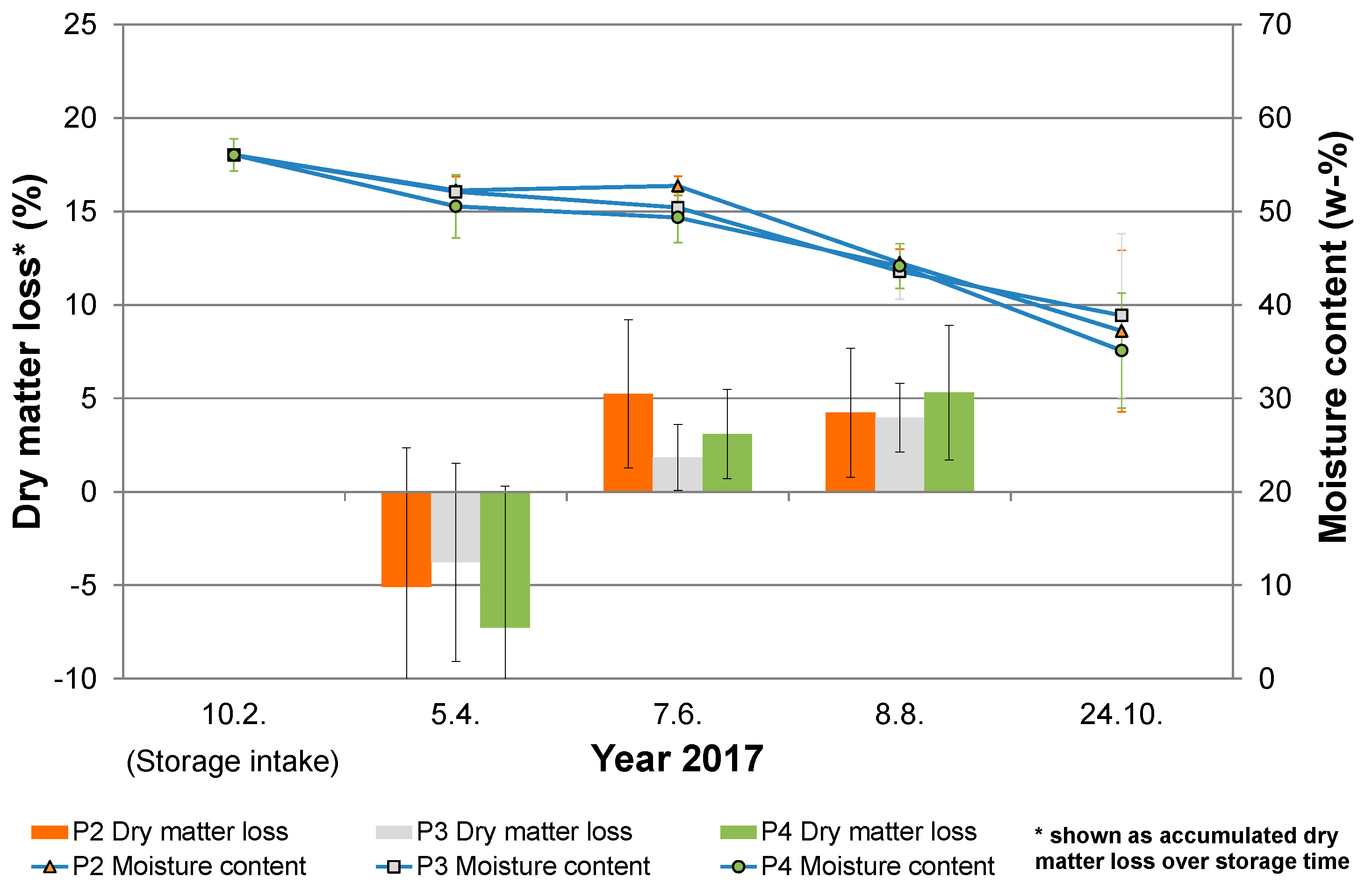

3.3. Dry Matter Losses

3.4. Mean Moisture Contents

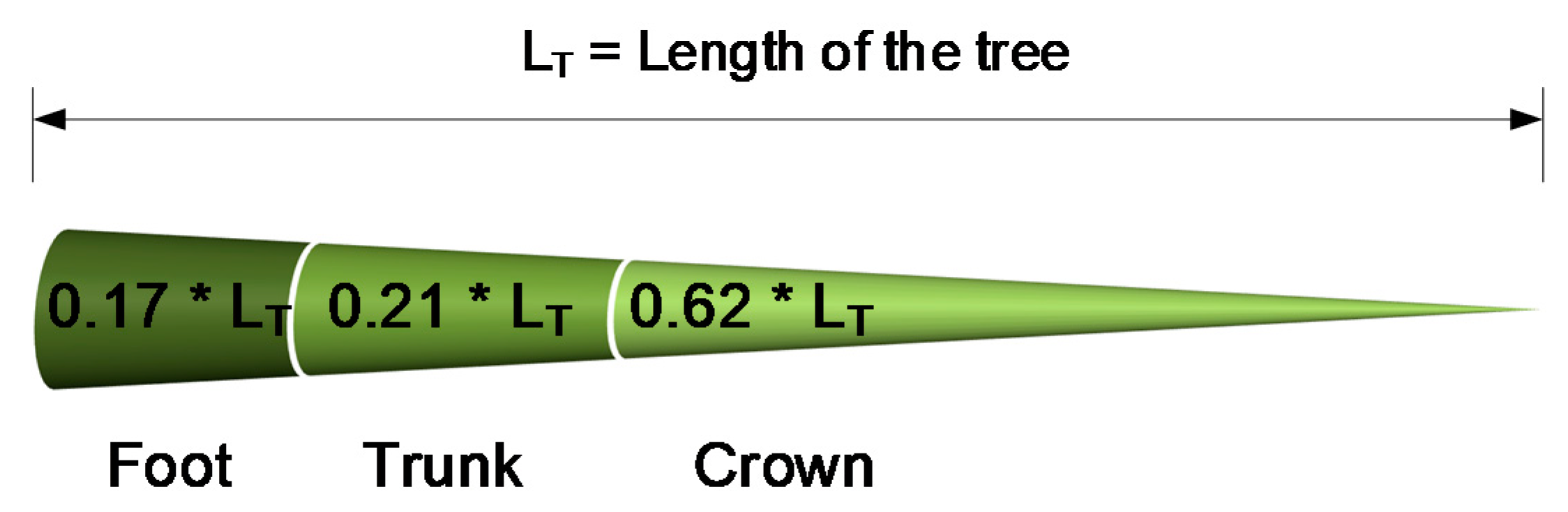

3.5. Drying Behaviour as a Function of Pile Layer and Tree Section

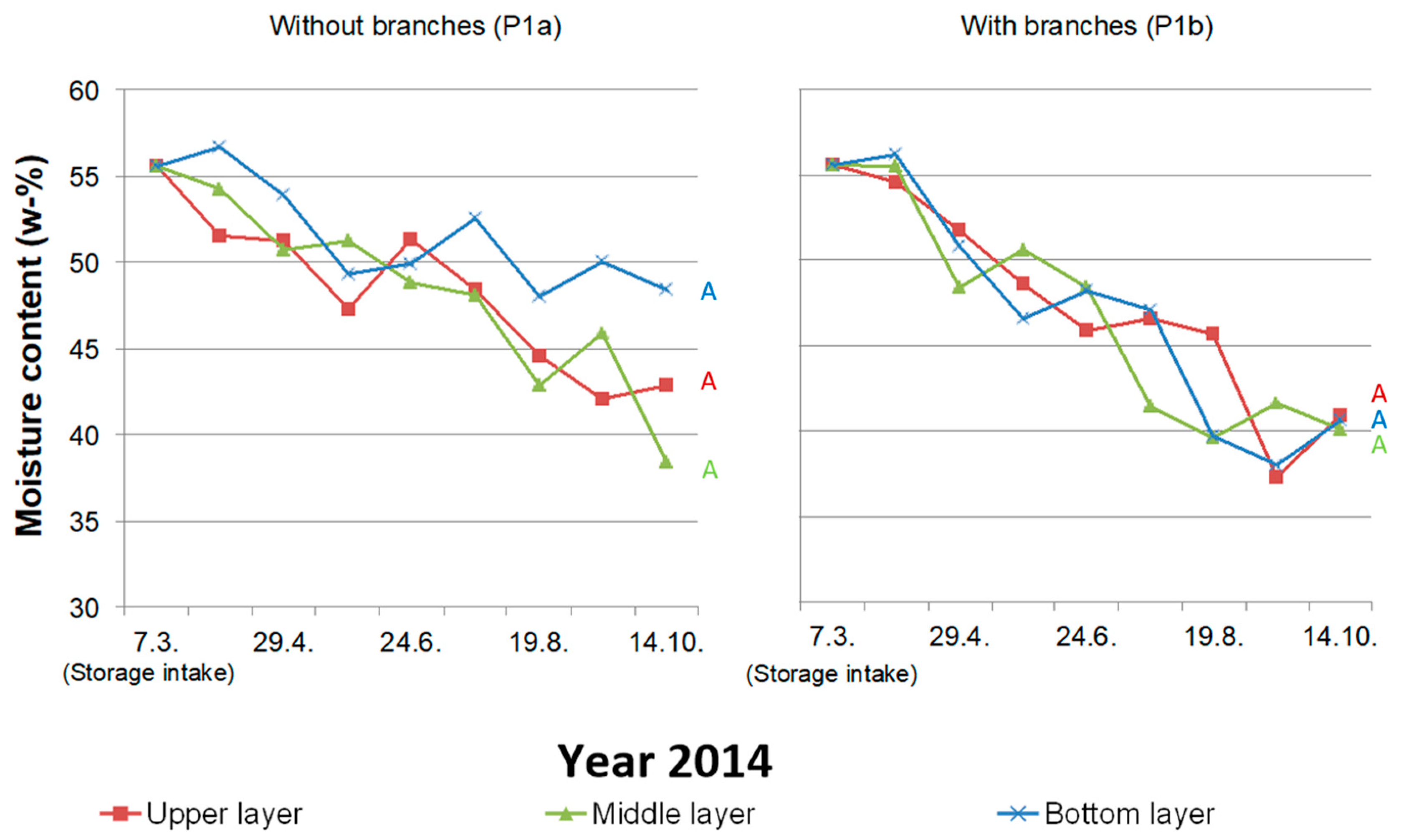

3.5.1. Development of Moisture Contents by Pile Layer

3.5.2. Development of Moisture Contents by Tree Section

3.6. Ash Contents

4. Discussion

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Appendix A

References

- González-García, S.; Bacenetti, J. Exploring the production of bio-energy from wood biomass. Italian case study. Sci. Total Environ. 2019, 647, 158–168. [Google Scholar] [CrossRef] [PubMed]

- Schweier, J.; Schnitzler, J.P.; Becker, G. Selected environmental impacts of the technical production of wood chips from poplar short rotation coppice on marginal land. Biomass Bioenergy 2016, 85, 235–242. [Google Scholar] [CrossRef]

- FNR: Mediathek—Anbaufläche für Nachwachsende Rohstoffe. Available online: https://mediathek.fnr.de/anbauflache-fur-nachwachsende-rohstoffe.html (accessed on 6 March 2020).

- Veste, M.; Böhm, C. Agrarholz—Schnellwachsende Bäume in der Landwirtschaft: Biologie—Ökologie—Management; Springer: Berlin/Heidelberg, Germany, 2018; p. 529. [Google Scholar]

- Chimento, C.; Almagro, M.; Amaducci, S. Carbon sequestration potential in perennial bioenergy crops: The importance of organic matter inputs and its physical protection. GCB Bioenergy 2016, 8, 111–121. [Google Scholar] [CrossRef]

- Rytter, R.-M.; Rytter, L.; Högbom, L. Carbon sequestration in willow (salix spp.) plantations on former arable land estimated by repeated field sampling and c budget calculation. Biomass Bioenergy 2015, 83, 483–492. [Google Scholar] [CrossRef]

- Scholz, V.G.; Heiermann, M.; Kern, J.; Balasus, A. Environmental impact of energy crop cultivation. Arch. Agron. Soil Sci. 2011, 57, 805–837. [Google Scholar] [CrossRef]

- Orság, M.; Fischer, M.; Tripathi, A.M.; Žalud, Z.; Trnka, M. Sensitivity of short rotation poplar coppice biomass productivity to the throughfall reduction—Estimating future drought impacts. Biomass Bioenergy 2018, 109, 182–189. [Google Scholar] [CrossRef]

- Quinn, L.D.; Straker, K.C.; Guo, J.; Kim, S.; Thapa, S.; Kling, G.; Lee, D.K.; Voigt, T.B. Stress-tolerant feedstocks for sustainable bioenergy production on marginal land. BioEnergy Res. 2015, 8, 1081–1100. [Google Scholar] [CrossRef]

- Kanzler, M.; Böhm, C.; Mirck, J.; Schmitt, D.; Veste, M. Microclimate effects on evaporation and winter wheat (triticum aestivum l.) yield within a temperate agroforestry system. Agrofor. Syst. 2018, 93, 1821–1841. [Google Scholar] [CrossRef]

- Pecenka, R.; Ehlert, D.; Lenz, H. Efficient harvest lines for short rotation coppices (SRC) in agriculture and agroforestry. Agron. Res. 2014, 12, 151–160. [Google Scholar]

- Stolarski, M.J.; Śnieg, M.; Krzyżaniak, M.; Tworkowski, J.; Szczukowski, S. Short rotation coppices, grasses and other herbaceous crops: Productivity and yield energy value versus 26 genotypes. Biomass Bioenergy 2018, 119, 109–120. [Google Scholar] [CrossRef]

- Djomo, S.N.; De Groote, T.; Gobin, A.; Ceulemans, R.; Janssens, I.A. Combining a land surface model with life cycle assessment for identifying the optimal management of short rotation coppice in Belgium. Biomass Bioenergy 2019, 121, 78–88. [Google Scholar] [CrossRef]

- Berhongaray, G.; El Kasmioui, O.; Ceulemans, R. Comparative analysis of harvesting machines on an operational high-density short rotation woody crop (SRWC) culture: One-process versus two-process harvest operation. Biomass Bioenergy 2013, 58, 333–342. [Google Scholar] [CrossRef]

- Vanbeveren, S.P.P.; De Francesco, F.; Ceulemans, R.; Spinelli, R. Productivity of mechanized whip harvesting with the Stemster MKIII in a short-rotation coppice established on farmland. Biomass Bioenergy 2018, 108, 323–329. [Google Scholar] [CrossRef]

- Vanbeveren, S.P.P.; Spinelli, R.; Eisenbies, M.; Schweier, J.; Mola-Yudego, B.; Magagnotti, N.; Acuna, M.; Dimitriou, I.; Ceulemans, R. Mechanised harvesting of short-rotation coppices. Renew. Sust. Energ. Rev. 2017, 76, 90–104. [Google Scholar] [CrossRef]

- Schweier, J.; Spinelli, R.; Magagnotti, N.; Becker, G. Mechanized coppice harvesting with new small-scale feller-bunchers: Results from harvesting trials with newly manufactured felling heads in Italy. Biomass Bioenergy 2015, 72, 85–94. [Google Scholar] [CrossRef]

- Schweier, J.; Becker, G. Harvesting of short rotation coppice-harvesting trials with a cut and storage system in Germany. Silva Fenn. 2012, 46, 287–299. [Google Scholar] [CrossRef][Green Version]

- Pecenka, R.; Hoffmann, T. Harvest technology for short rotation coppices and costs of harvest, transport and storage. Agron. Res. 2015, 13, 361–371. [Google Scholar]

- Landgraf, D.; Bärwolff, M.; Burger, F.; Pecenka, R.; Hering, T.; Schweier, J. Produktivität, Management und Nutzung von Agrarholz. In Agrarholz—Schnellwachsende Bäume in der Landwirtschaft: Biologie—Ökologie—Management; Veste, M., Böhm, C., Eds.; Springer: Berlin/Heidelberg, Germany, 2018; pp. 447–510. [Google Scholar]

- Kuptz, D.; Schulmeyer, F.; Hüttl, K.; Dietz, E.; Turowski, P.; Zormaier, F.; Borchert, H.; Hartmann, H. Optimale Bereitstellungsverfahren für Holzhackschnitzel; Technologie- und Förderzentrum (TFZ): Straubing, Germany, 2015. [Google Scholar]

- Kuptz, D.; Dietz, E.; Schreiber, K.; Schön, C.; Mack, R.; Wiesbeck, M.; Blum, U.; Borchert, H.; Hartmann, H. Holzhackschnitzel aus dem Kurzumtrieb—Brennstoffqualität und Verbrennungsverhalten; Technologie- und Förderzentrum (TFZ): Straubing, Germany, 2018. [Google Scholar]

- Idler, C.; Pecenka, R.; Lenz, H. Influence of the particle size of poplar wood chips on the development of mesophilic and thermotolerant mould during storage and their potential impact on dry matter losses in piles in practice. Biomass Bioenergy 2019, 127, 105273. [Google Scholar] [CrossRef]

- Hofmann, N.; Mendel, T.; Kuptz, D.; Schulmeyer, F.; Borchert, H.; Hartmann, H. Lagerung von Holzhackschnitzeln—Trockenmasseverluste, Änderungen der Brennstoffqualität und Kosten; Technologie- und Förderzentrum (TFZ): Straubing, Germany, 2017. [Google Scholar]

- Krigstin, S.; Wetzel, S.; Jayabala, N.; Helmeste, C.; Madrali, S.; Agnew, J.; Volpe, S. Recent health and safety incident trends related to the storage of woody biomass: A need for improved monitoring strategies. Forests 2018, 9, 538. [Google Scholar] [CrossRef]

- Heinek, S.; Polanz, S.; Huber, M.B.; Hofmann, A.; Monthaler, G.; Fuchs, H.P.; Larch, C.; Giovannini, A. Biomass conditioning—Degradation of biomass during the storage of woodchips. In Proceedings of the 21st European Biomass Conference and Exhibition, Kopenhagen, Denmark, 3–7 June 2013. [Google Scholar]

- Lenz, H.; Pecenka, R.; Idler, C.; Dumfort, S.; Whittaker, C.; Ammon, C.; Hartung, E. Continuous weighing of a pile of poplar wood chips—A comparison of methods to determine the dry matter losses during storage. Biomass Bioenergy 2017, 96, 119–129. [Google Scholar] [CrossRef]

- Barontini, M.; Scarfone, A.; Spinelli, R.; Gallucci, F.; Santangelo, E.; Acampora, A.; Jirjis, R.; Civitarese, V.; Pari, L. Storage dynamics and fuel quality of poplar chips. Biomass Bioenergy 2014, 62, 17–25. [Google Scholar] [CrossRef]

- Pecenka, R.; Lenz, H.; Idler, C. Influence of the chip format on the development of mass loss, moisture content and chemical composition of poplar chips during storage and drying in open-air piles. Biomass Bioenergy 2018, 116, 140–150. [Google Scholar] [CrossRef]

- Pecenka, R.; Lenz, H.; Idler, C.; Daries, W.; Ehlert, D. Development of bio-physical properties during storage of poplar chips from 15 ha test fields. Biomass Bioenergy 2014, 65, 13–19. [Google Scholar] [CrossRef]

- Horváth, Z.; Marosvölgyi, B.; Idler, C.; Pecenka, R.; Lenz, H. Storage problems of poplar chips from short rotation plantations with special emphasis on fungal development. Acta Silv. Lignaria Hung. 2012, 8, 123–132. [Google Scholar]

- Bärwolff, M.; Hering, T. Fremdenergiefreie Trocknungsvarianten für Holz aus Kurzumtriebsplantagen; Thüringer Landesanstalt für Landwirtschaft: Dornburg, Germany, 2012; p. 11. [Google Scholar]

- Barontini, M.; Crognale, S.; Scarfone, A.; Gallo, P.; Gallucci, F.; Petruccioli, M.; Pesciaroli, L.; Pari, L. Airborne fungi in biofuel wood chip storage sites. Int. Biodeterior. Biodegrad. 2014, 90, 17–22. [Google Scholar] [CrossRef]

- Jirjis, R.; Pari, L.; Sissot, F. Storage of poplar wood chips in northern Italy. In Proceedings of the World Bioenergy, Jonkoping, Sweden, 27–29 May 2008. [Google Scholar]

- Schmidt, O. Wood and Tree Fungi; Springer: Berlin/Heidelberg, Germany, 2006. [Google Scholar]

- Lenz, H. Optimale Technologien zur verlustarmen Lagerung von Holzhackschnitzeln aus KUP in der Praxis. In Proceedings of the Nutzung Nachwachsender Rohstoffe—Bioökonomie 3.0, Dresden, Germany, 17–18 March 2016. [Google Scholar]

- Gigler, J.K.; Van Loon, W.K.P.; Van Den Berg, J.V.; Sonneveld, C.; Meerdink, G. Natural wind drying of willow stems. Biomass Bioenergy 2000, 19, 153–163. [Google Scholar] [CrossRef]

- Scholz, V.; Boelke, B.; Burger, F.; Hofmann, M.; Hohm, C.; Lorbacher, F.R. Produktion von Pappeln und Weiden auf Landwirtschaftlichen Flächen (Growing Poplar and Willow on Agricultural Land); Kuratorium für Technik und Bauwesen in der Landwirtschaft: Darmstadt, Germany, 2008; Volume 79, p. 40. [Google Scholar]

- Lenz, H. Vergleich der Verfahrensketten Hackschnitzellinie und Rutenlinie zur Ernte von Kurzumtriebsgehölzen. Master’s Thesis, Christian-Albrechts-Universität Kiel, Kiel, Germany, 2011. [Google Scholar]

- Erber, G.; Huber, C.; Stampfer, K. To split or not to split: Feasibility of pre-storage splitting of large poplar (populus spp. L.) fuelwood logs. Fuel 2018, 220, 817–825. [Google Scholar] [CrossRef]

- Manzone, M. Energy and moisture losses during poplar and black locust logwood storage. Fuel Process. Technol. 2015, 138, 194–201. [Google Scholar] [CrossRef]

- Civitarese, V.; Spinelli, R.; Barontini, M.; Gallucci, F.; Santangelo, E.; Acampora, A.; Scarfone, A.; Del Giudice, A.; Pari, L. Open-air drying of cut and windrowed short-rotation poplar stems. Bioenergy Res. 2015, 8, 1614–1620. [Google Scholar] [CrossRef]

- Guidi, W.; Piccioni, E.; Ginanni, M.; Bonari, E. Bark content estimation in poplar (populus deltoides l.) short-rotation coppice in central Italy. Biomass Bioenergy 2008, 32, 518–524. [Google Scholar] [CrossRef]

- International Organization for Standardization. ISO 18134-2:2017 Solid Biofuels—Determination of Moisture Content—Oven Dry Method—Part 2: Total Moisture—Simplified Method; ISO: Geneva, Switzerland, 2017. [Google Scholar]

- International Organization for Standardization. EN ISO 14775 Solid Biofuels—Determination of Ash Content; ISO: Geneva, Switzerland, 2009. [Google Scholar]

- Espinoza, O.; Bond, B. Vacuum drying of wood—State of the art. Curr. For. Rep. 2016, 2, 223–235. [Google Scholar] [CrossRef]

| Place | Planting Layout | Rotation | Age | SDCH a | Harvest Date | Harvesting System |

|---|---|---|---|---|---|---|

| Years | cm | dd-mm-yyyy | ||||

| Potsdam (52.26° N; 13.01° E) | Double row (2.25 m × 0.75 m × 0.55 m) b | 5th | 4 | 7.0 | 03-03-2014 | Manual with a chainsaw |

| Schwarzbach (50.79° N; 11.86° E) | Single row (3.0 m × 1.0 m) c | 1st | 8 | 12.6 | 25-01-2017 | Manual with a chainsaw |

| Parameter | Unit | Number of Samples Per Pile | Methodology/Specification | |

|---|---|---|---|---|

| Storage Intake (Trial P1/P2–4) | Per Sampling (Trial P1/P2–4) | |||

| Weather conditions Outdoor temperature Relative atmospheric humidity Precipitation | °C % mm | Daily averages Daily averages Daily sum | German Weather Service Potsdam (52.23° N; 13.03° E) for trial P1 respectively Gera Leumnitz (50.52° N; 12.07° E) for trial P2–4 | |

| Pile temperature | °C | Continuous | Gemini Type Tinytag TGP-4017 (United Kingdom) | |

| Moisture content (X) a | % | n = 40/20 | n = 15 b/18 c | EN ISO 18134-2, [44] |

| Dry matter loss (Li) | % | n = 5/6 | Equation (1), [29] | |

| Ash content d | % | n = 5/10 | n = 15/3 | EN 14775, [45] |

| Pile | Pile Location | Pile Dimensions width × depth × height | Volume | Fleece Underlay * |

|---|---|---|---|---|

| Unit | m | m3 | - | |

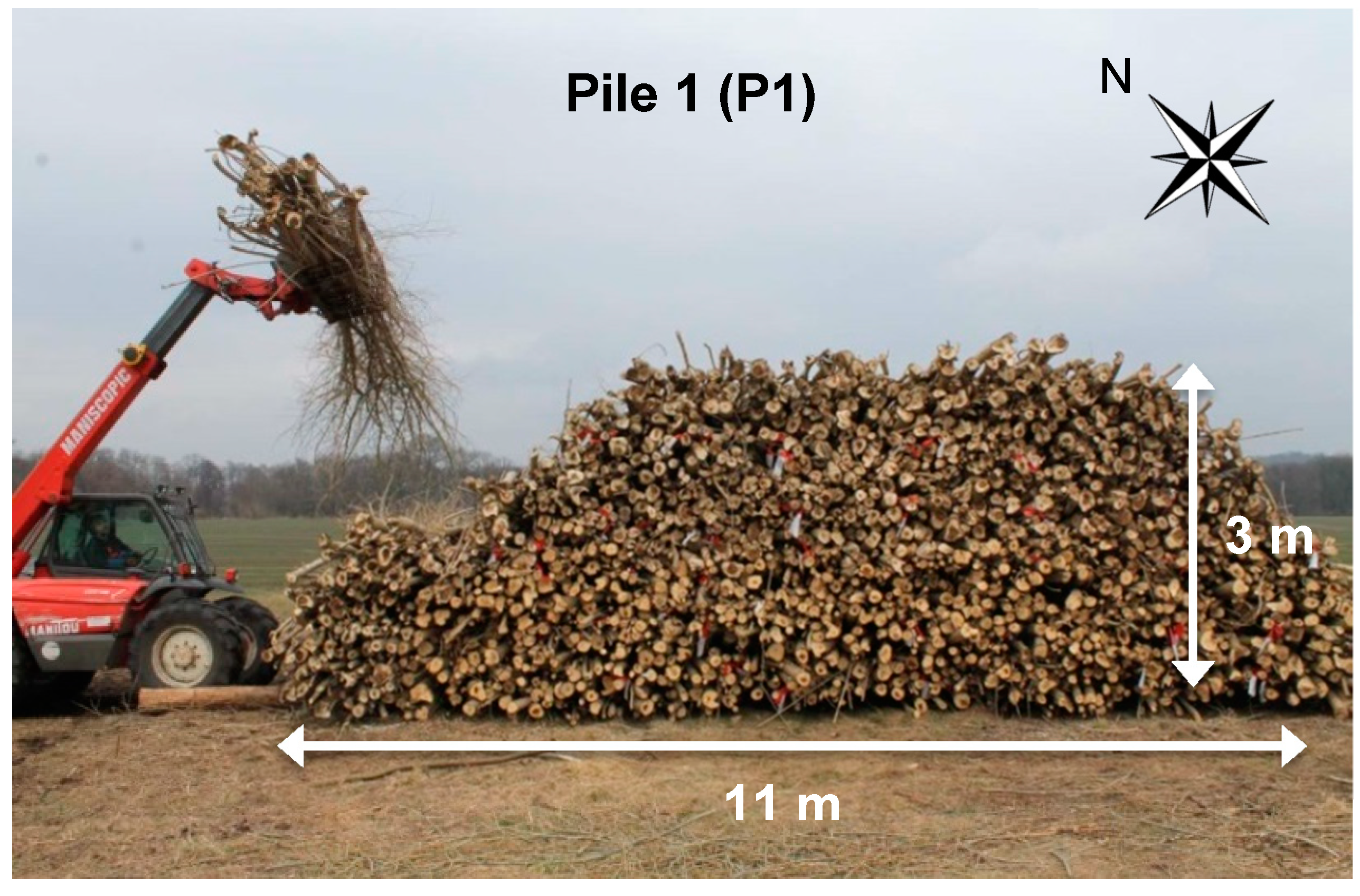

| P1 | Potsdam | 11 × 10 × 3 | 300 | no |

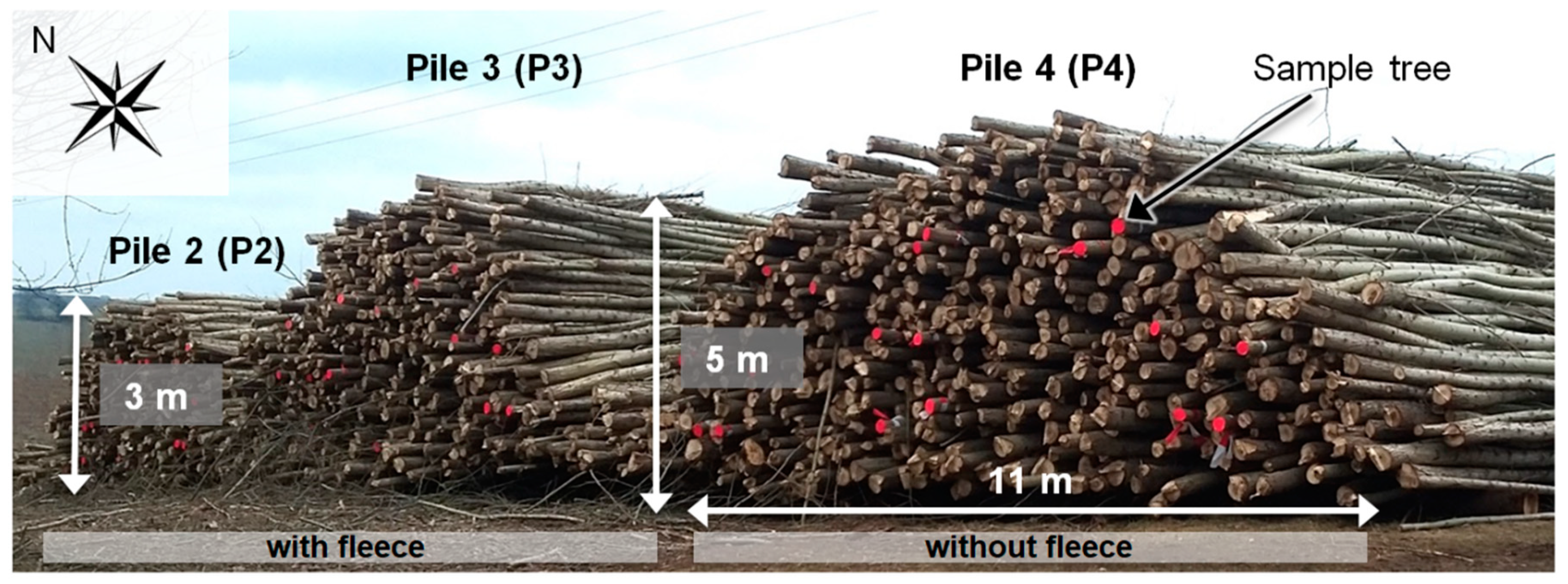

| P2 | Schwarzbach | 11 × 14 × 3 | 350 | yes |

| P3 | Schwarzbach | 11 × 14 × 5 | 600 | yes |

| P4 | Schwarzbach | 11 × 14 × 5 | 600 | no |

| Material Parameter | Dry Matter Loss | Moisture Content a | Ash Content b | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Unit | % | % | % | ||||||||||||

| Pile | P1a | P1b | P2 | P3 | P4 | P1a | P1b | P2 | P3 | P4 | P1a | P1b | P2 | P3 | P4 |

| Storage intake | 55.5 ± 1.5 | 56.0 ± 1.7 | 1.76 ± 0.12 | 1.67 ± 0.16 | |||||||||||

| Storage outtake | 7.1 ± 3.8 | 9.1 ± 4.4 | 4.2 ± 3.5 | 4.0 ± 1.8 | 5.3 ± 3.6 | 43.0 ± 8.0 | 41.2 ± 6.7 | 44.5 ± 1.5 | 43.6 ± 3.0 | 44.1 ± 2.4 | 1.37 ± 0.16 | 1.49 ± 0.11 | 1.47 ± 0.11 | 1.44 ± 0.11 | |

| 24.10.17 | 37.2 ± 8.6 | 38.9 ± 8.8 | 35.1 ± 6.2 | ||||||||||||

| Material Parameter | Moisture Content a | |||||

|---|---|---|---|---|---|---|

| Without Branches | With Branches | |||||

| Unit | % | |||||

| Pile | P2 | P3 | P4 | P2 | P3 | P4 |

| 07.06.17 | 52.7 ± 1.0 | 50.4 ± 0.8 | 49.4 ± 2.7 | 47.9 ± 3.4 | 49.7 ± 1.1 | 51.2 ± 1.1 |

| 08.08.17 | 44.5 ± 1.5 | 43.6 ± 3.0 | 44.1 ± 2.4 | 48.1 ± 1.0 | 44.8 ± 3.9 | 44.6 ± 2.8 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pecenka, R.; Lenz, H.; Hering, T. Options for Optimizing the Drying Process and Reducing Dry Matter Losses in Whole-Tree Storage of Poplar from Short-Rotation Coppices in Germany. Forests 2020, 11, 374. https://doi.org/10.3390/f11040374

Pecenka R, Lenz H, Hering T. Options for Optimizing the Drying Process and Reducing Dry Matter Losses in Whole-Tree Storage of Poplar from Short-Rotation Coppices in Germany. Forests. 2020; 11(4):374. https://doi.org/10.3390/f11040374

Chicago/Turabian StylePecenka, Ralf, Hannes Lenz, and Thomas Hering. 2020. "Options for Optimizing the Drying Process and Reducing Dry Matter Losses in Whole-Tree Storage of Poplar from Short-Rotation Coppices in Germany" Forests 11, no. 4: 374. https://doi.org/10.3390/f11040374

APA StylePecenka, R., Lenz, H., & Hering, T. (2020). Options for Optimizing the Drying Process and Reducing Dry Matter Losses in Whole-Tree Storage of Poplar from Short-Rotation Coppices in Germany. Forests, 11(4), 374. https://doi.org/10.3390/f11040374