Comparison of Alternative Pulpwood Inventory Strategies and Machine Systems at a Log-Yard Using Simulations

Abstract

1. Introduction

2. Materials and Methods

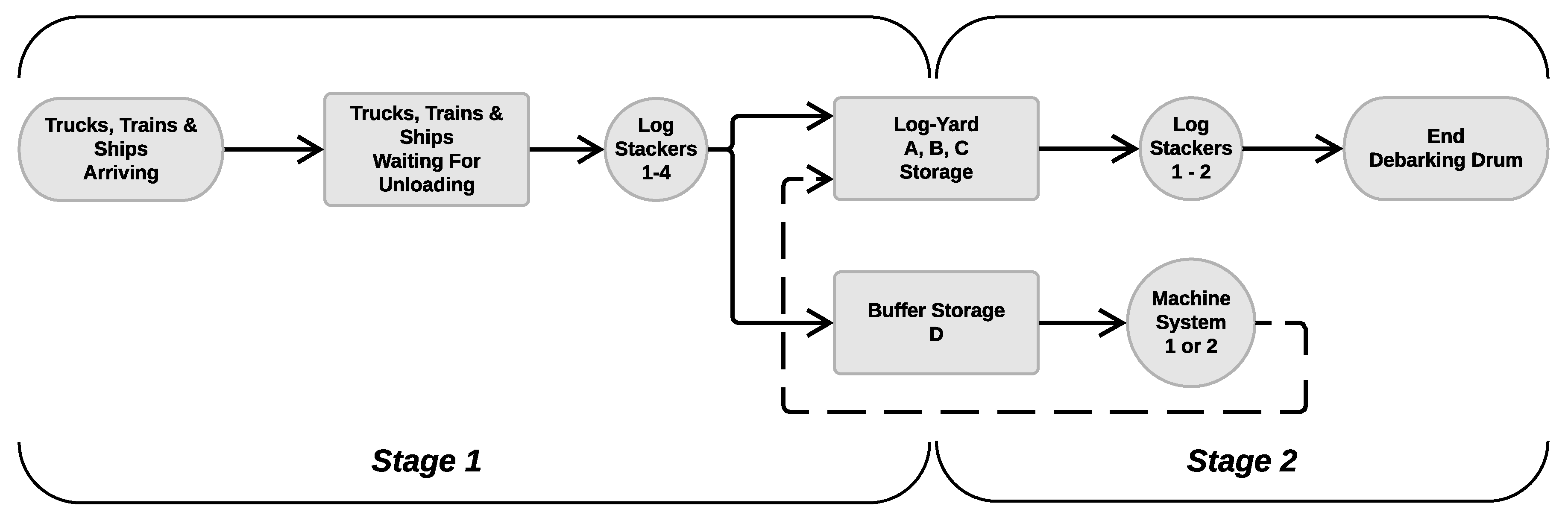

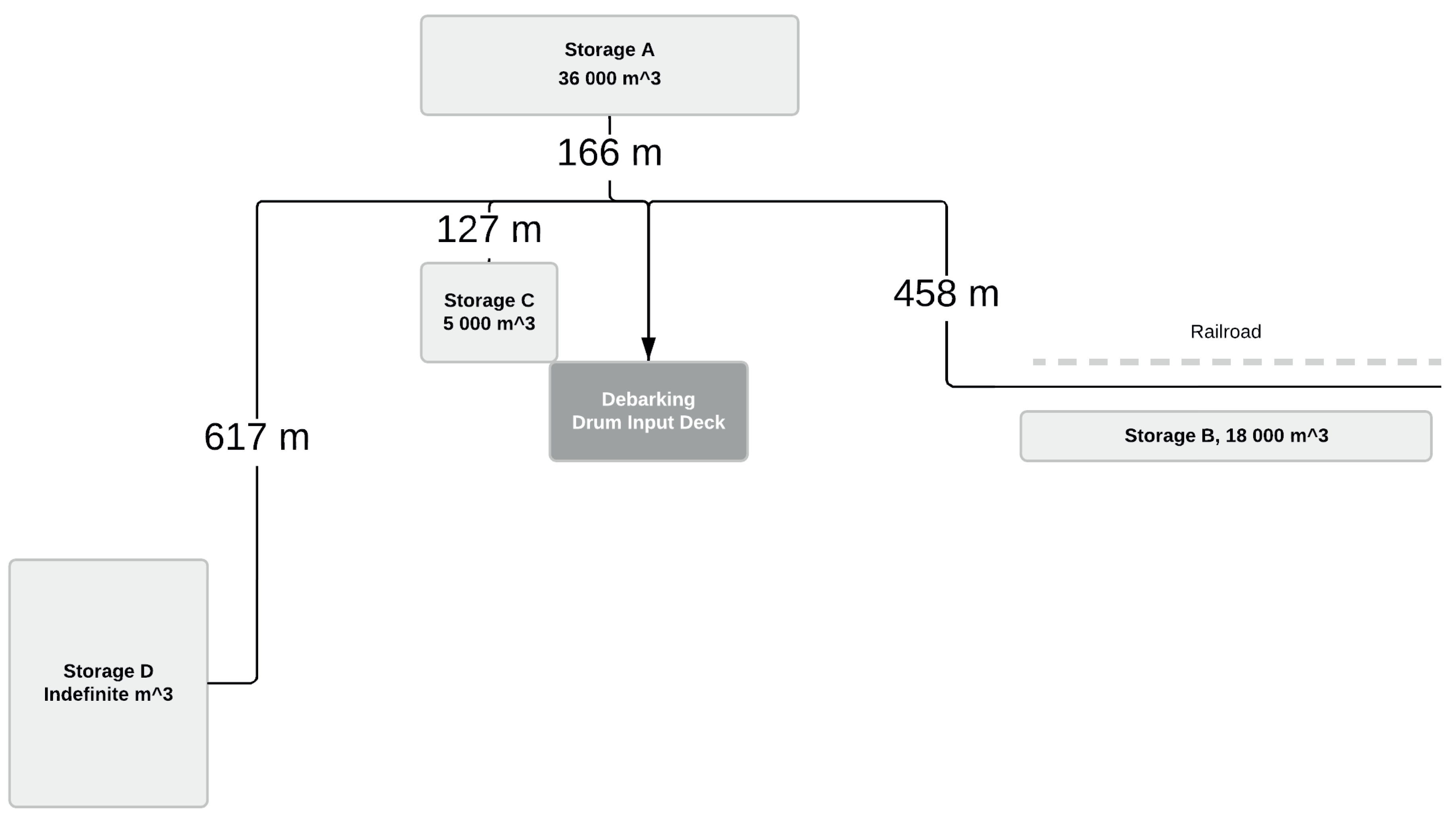

2.1. Stage 1

2.2. Stage 2

2.3. Inventory Strategies

2.4. Analysis and Statistics

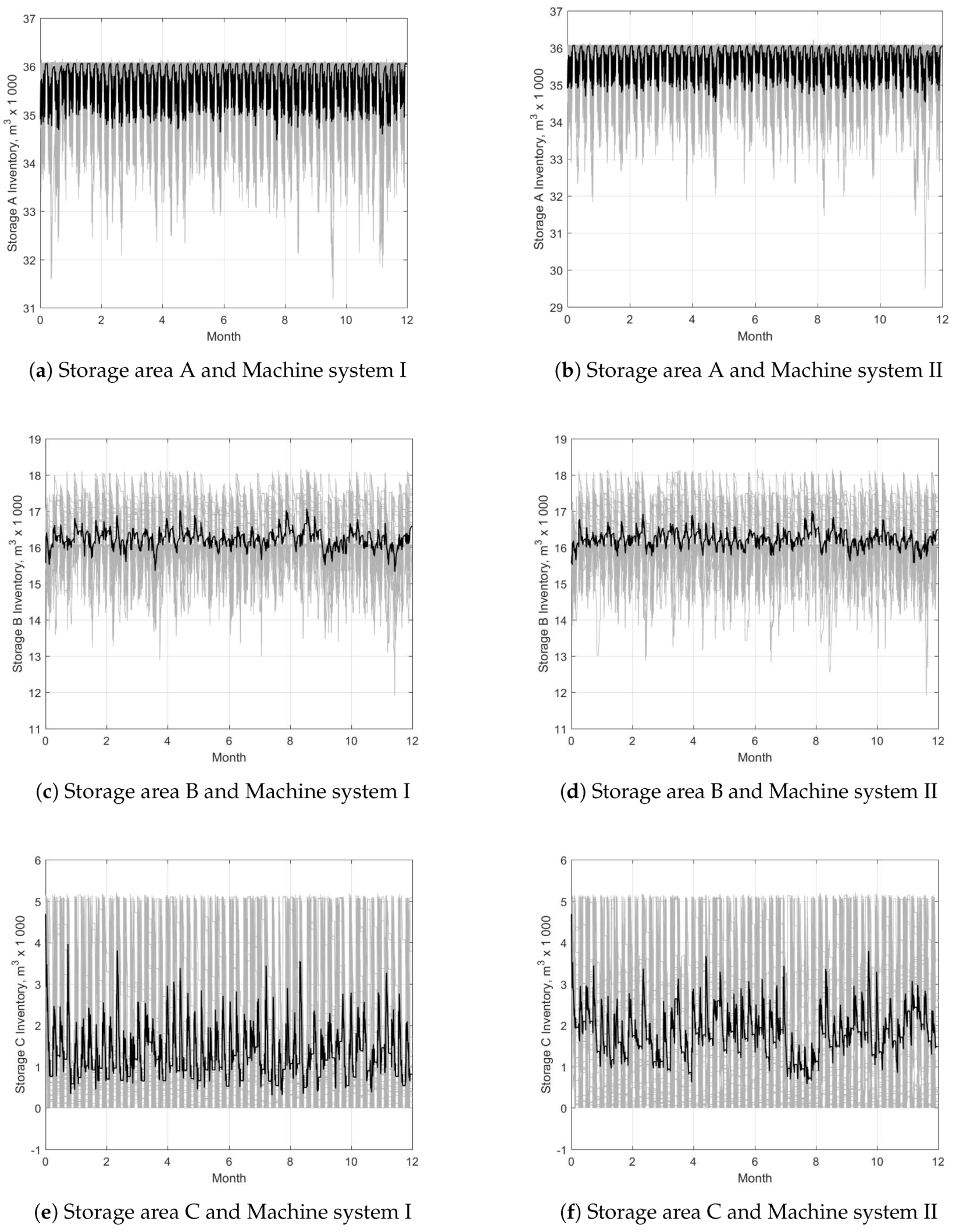

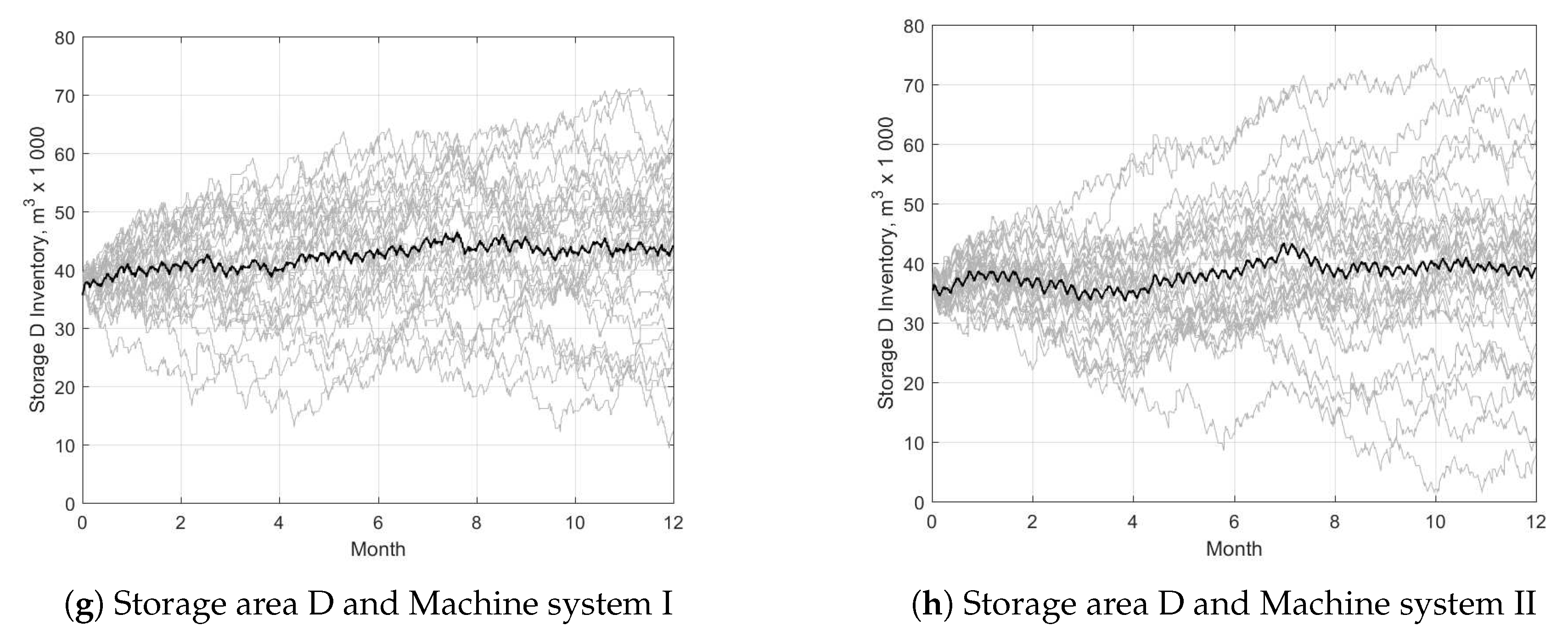

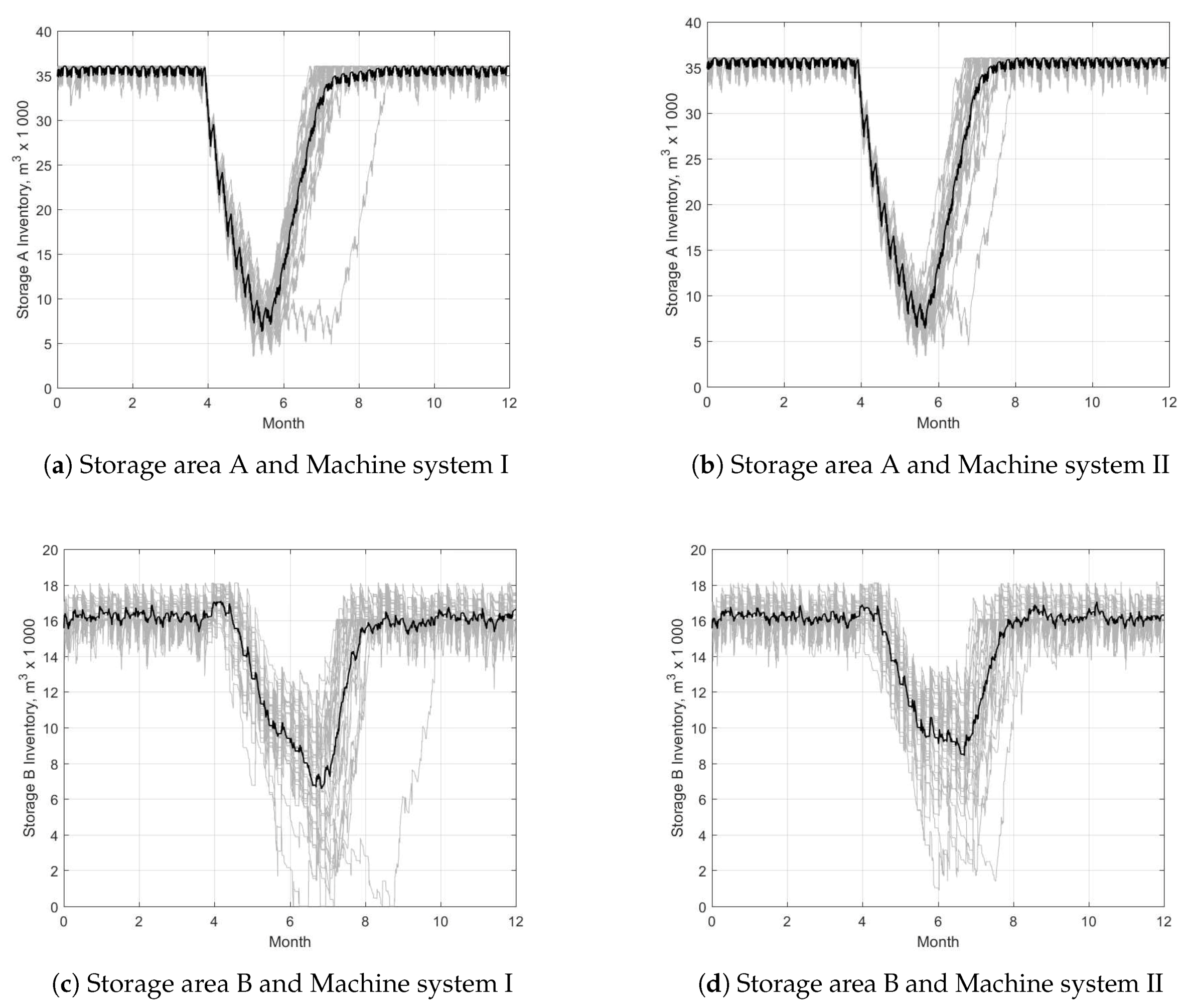

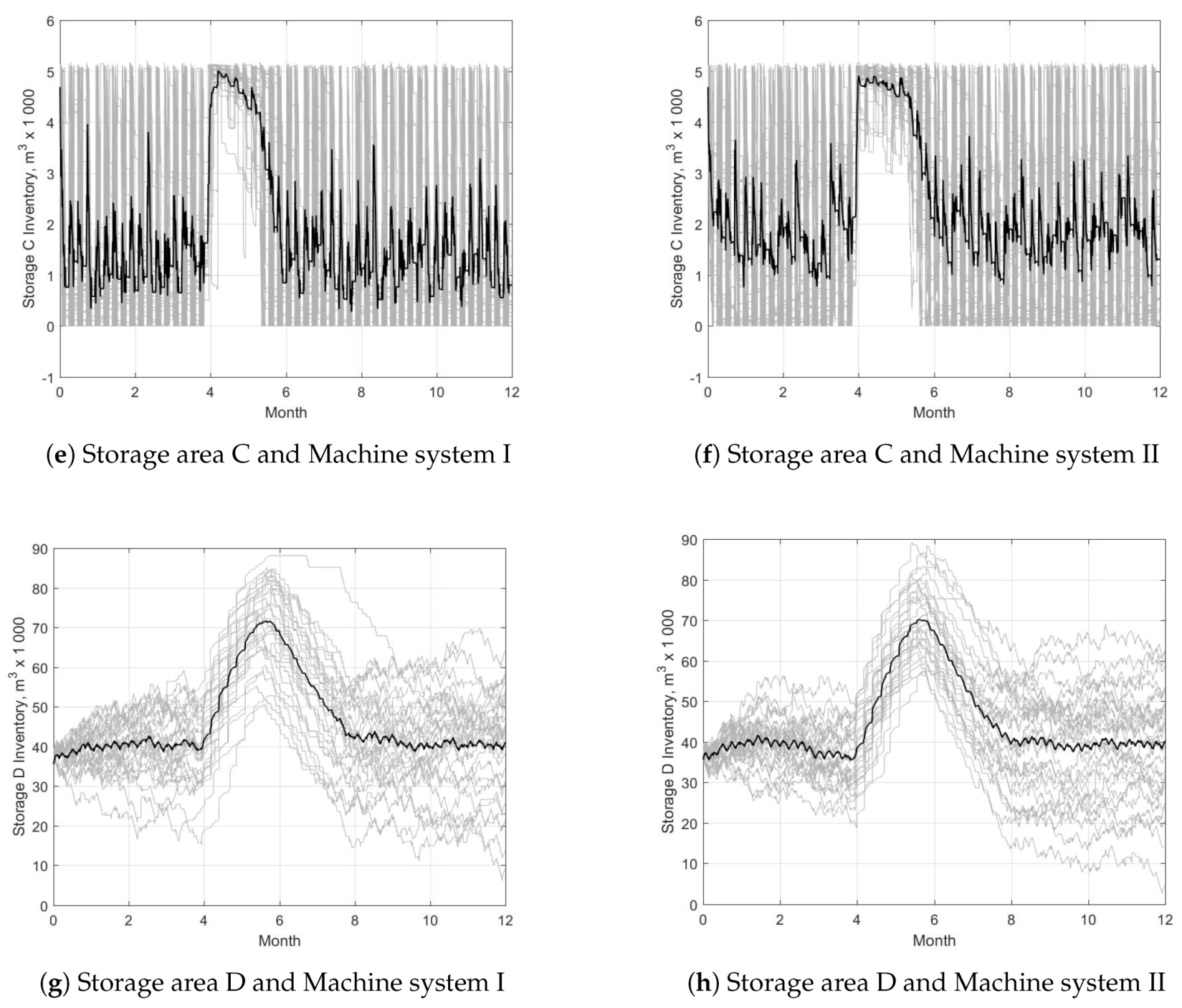

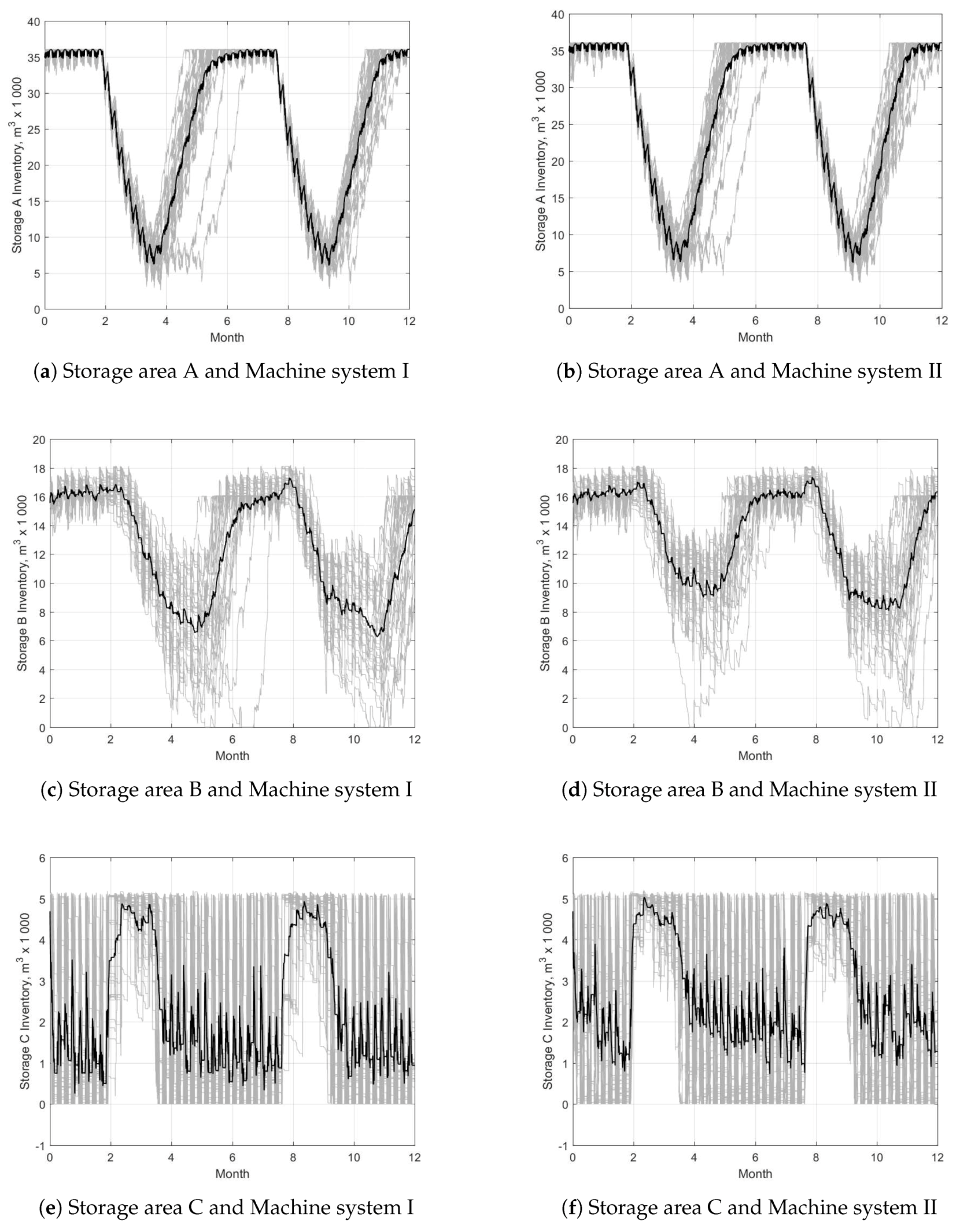

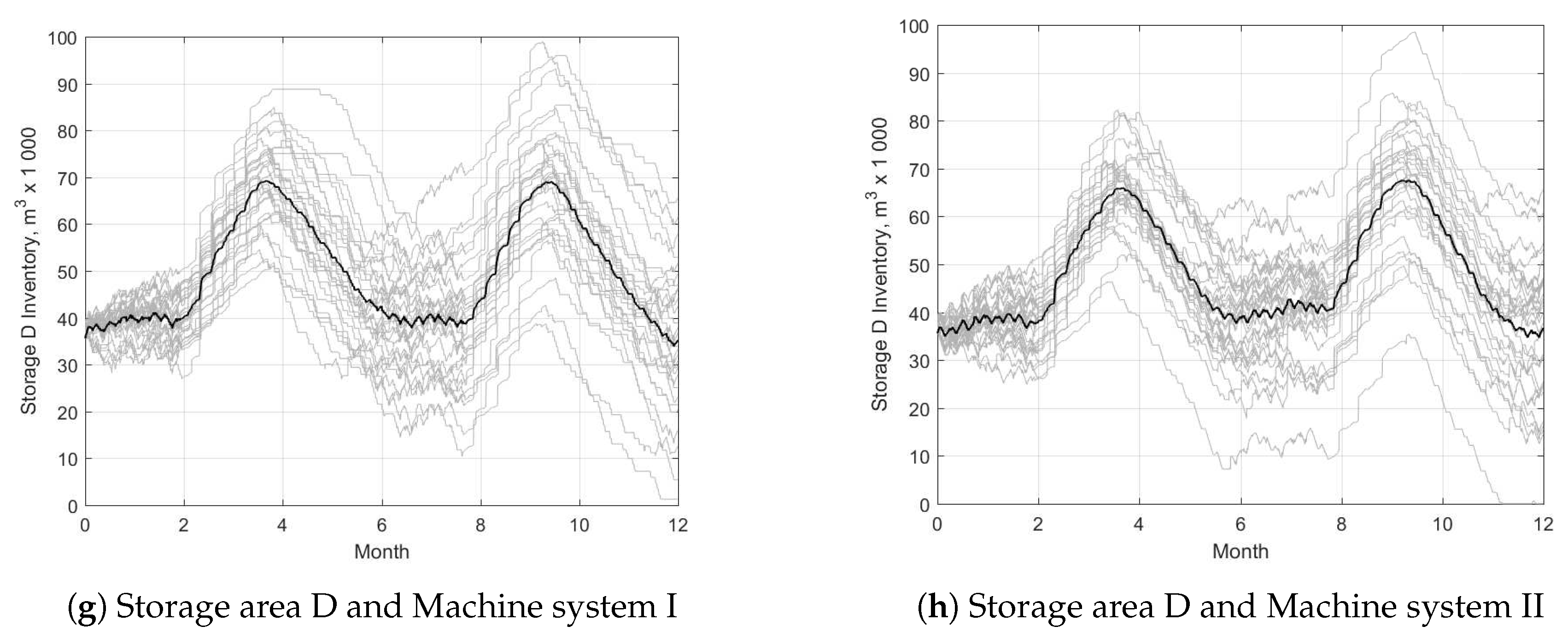

3. Results

4. Discussion

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- FAO. Pulp and paper capacities. In Survey 2016–2021, Forest Policy and Rescources Division; FAO Forestry Department: Rome, Italy, 2017. [Google Scholar]

- Swedish Forest Industries Federation. Produktion Och Handel Med Massa 2018 [Production and Trade of Pulp 2018]; Statistik Om Skog Och Industri: Stockholm, Sweden, 2019. [Google Scholar]

- Enström, J.; Athanassiadis, D.; Öhman, M.; Grönlund, O. Satsa Pårätt Bränsleterminal [Aim for the Right Biomass Terminal]; Report; Skogforsk: Uppsala, Sweden, 2013. [Google Scholar]

- Kons, K.; Bergström, D.; Eriksson, U.; Athanassiadis, D.; Nordfjell, T. Characteristics of Swedish forest biomass terminals for energy. Int. J. For. Eng. 2014, 25, 238–246. [Google Scholar] [CrossRef]

- Virkkunen, M.; Kari, M.; Hankalin, V.; Nummelin, J. Solid Biomass Fuel Terminal Concepts and a Cost Analysis of a Satellite Terminal Concept; VTT Technology 211; Technical Research Centre of Finland (VTT): Espoo, Finland, 2015. [Google Scholar] [CrossRef]

- Väätäinen, K.; Prinz, R.; Malinen, J.; Laitila, J.; Sikanen, L. Alternative operation models for using a feed-in terminal as a part of the forest chip supply system for a CHP plant. Gcb Bioenergy 2017, 9, 1657–1673. [Google Scholar] [CrossRef]

- Liukkoxs, K.; Elowsson, T. The effect of bark condition, delivery time and climate-adapted wet storage on the moisture content of Picea abies (L.) Karst. pulpwood. Scand. J. For. Res. 1999, 14, 156–163. [Google Scholar] [CrossRef]

- Nahmias, S. Perishable inventory theory: A review. Oper. Res. 1982, 30, 680–708. [Google Scholar] [CrossRef] [PubMed]

- Persson, E. Storage of Spruce Pulpwood Effects on Wood and Mechanical Pulp. Ph.D. Thesis, Department of Forest Management and Products, Swedish University of Agricultural Sciences, Uppsala, Sweden, 2001. [Google Scholar]

- March, J.G.; Shapira, Z. Managerial perspectives on risk and risk taking. Manag. Sci. 1987, 33, 1404–1418. [Google Scholar] [CrossRef]

- Robinson, S. Simulation: The Practice of Model Development and Use; John Willey and Sons: Chichester, UK, 2004; Volume 1, p. 5. [Google Scholar]

- Kons, K.; La Hera, P.; Bergström, D. Modelling Dynamics of a Log-Yard Through Discrete-Event Mathematics. Forests 2020, 11, 155. [Google Scholar] [CrossRef]

- Asikainen, A. Simulation of stump crushing and truck transport of chips. Scand. J. For. Res. 2010, 25, 245–250. [Google Scholar] [CrossRef]

- Karttunen, K.; Lättilä, L.; Korpinen, O.J.; Ranta, T. Cost-efficiency of intermodal container supply chain for forest chips. Silva Fenn. 2013, 47, 24. [Google Scholar] [CrossRef]

- Arriagada, R.A.; Cubbage, F.W.; Abt, K.L.; Huggett, R.J., Jr. Estimating harvest costs for fuel treatments in the West. For. Prod. J. 2008, 58, 24. [Google Scholar]

- Eriksson, A.; Eliasson, L.; Jirjis, R. Simulation-based evaluation of supply chains for stump fuel. Int. J. For. Eng. 2014, 1–14. [Google Scholar] [CrossRef]

- Pinho, T.M.; Coelho, J.P.; Moreira, A.P.; Boaventura-Cunha, J. Modelling a biomass supply chain through discrete-event simulation. IFAC-PapersOnLine 2016, 49, 84–89. [Google Scholar] [CrossRef]

- Chiorescu, S.; Gronlund, A. Assessing the role of the harvester within the forestry-wood chain. For. Prod. J. 2001, 51, 77. [Google Scholar]

- Salichon, M.C. Simulating Changing Diameter Distributions in a Softwood Sawmill. Master’s Thesis, Graduate School, Oregon State University, Corvallis, OR, USA, 2005. [Google Scholar]

- Mendoza, G.A.; Meimban, R.J.; Araman, P.A.; Luppold, W.G. Combined log inventory and process simulation models for the planning and control of sawmill operations. In Proceedings of the 23rd CIRP International Seminar on Manufacturing Systems, Nancy, France, 6–7 June 1991; p. 8. [Google Scholar]

- Beaudoin, D.; LeBel, L.; Soussi, M.A. Discrete Event Simulation to Improve Log Yard Operations. INFOR Inf. Syst. Oper. Res. 2013, 50, 175–185. [Google Scholar] [CrossRef]

- Rahman, A.; Yella, S.; Dougherty, M. Simulation model using meta heuristic algorithms for achieving optimal arrangement of storage bins in a sawmill yard. J. Intell. Learn. Syst. Appl. 2014, 6, 125–139. [Google Scholar] [CrossRef]

- Aalto, M.; Raghu, K.C.; Korpinen, O.J.; Karttunen, K.; Ranta, T. Modeling of biomass supply system by combining computational methods—A review article. Appl. Energy 2019, 243, 145–154. [Google Scholar] [CrossRef]

- Lättilä, L. Improving Transportation and Warehousing Efficiency with Simulation-Based Decision Support Systems. Ph.D. Thesis, Faculty of Technology Management, Industrial Management, Lappeenranta University of Technology, Lappeenranta, Finland, 2012. [Google Scholar]

- Taha, H.A. Operations Research: An Introduction, 5th ed.; Macmillan Publishing Company: New York, NY, USA, 1992; Volume 1. [Google Scholar]

- Kendall, K.; Mangin, C.; Ortiz, E. Discrete event simulation and cost analysis for manufacturing optimisation of an automotive LCM component. Compos. Part A Appl. Sci. Manuf. 1998, 29, 711–720. [Google Scholar] [CrossRef]

- Huka, M.A.; Gronalt, M. Log yard logistics. Silva Fenn. 2018, 52, 23. [Google Scholar] [CrossRef]

- Schroer, B.J.; Tseng, F.T. Modelling complex manufacturing systems using discrete event simulation. Comput. Ind. Eng. 1988, 14, 455–464. [Google Scholar] [CrossRef]

- Banks, J.; Carson, J.S., II; Nelson, B.L.; Nicol, D.M. Discrete-Event System Simulation; Pearson: London, UK, 2005. [Google Scholar]

- Hopper, E.; Turton, B. A genetic algorithm for a 2D industrial packing problem. Comput. Ind. Eng. 1999, 37, 375–378. [Google Scholar] [CrossRef]

- Robichaud, S.V.; Beaudoin, D.; Lebel, L. LOG YARD DESIGN USING DISCRETE-EVENT SIMULATION: FIRST STEP TOWARDS A FORMALIZED APPROACH. In Proceedings of the 10th International Conference of Modeling and Simulation-MOSIM’14, Nancy, France, 5–7 November 2014. [Google Scholar]

- Dowsland, K.A.; Dowsland, W.B. Packing problems. Eur. J. Oper. Res. 1992, 56, 2–14. [Google Scholar] [CrossRef]

| Machine System | Empty Storage A | ||

|---|---|---|---|

| Strategy I a | Strategy II | Strategy III | |

| Machine System I a | At 57% rate | 1 time per year | 2 times per year |

| Machine System II | At 57% rate | 1 time per year | 2 times per year |

| Volume Arriving | Volume Delivered | |||

|---|---|---|---|---|

| Avg, m3 | STD, m3 | Avg, m3 | STD, m3 | |

| S1 M1 | 1,178,200 | 14,381 | 1,171,500 | 4397 |

| S1 M2 | 1,174,000 | 19,021 | 1,171,600 | 6745 |

| S2 M1 | 1,178,200 | 14,381 | 1,174,600 | 4402 |

| S2 M2 | 1,177,800 | 17,440 | 1,174,800 | 5064 |

| S3 M1 | 1,174,600 | 17,412 | 1,178,100 | 4170 |

| S3 M2 | 1,180,000 | 15,904 | 1,180,400 | 5659 |

| Scenario | Storage A | Storage B | Storage C | Storage D | Total Inventory | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| m3 | m3 | m3 | m3 | m3 | |||||||

| S1 M1 | Max (Avg Max) | 36,176 | (36,064) | 18,155 | (17,067) | 5203 | (4690) | 71,111 | (46,474) | 127,606 | (100,610) |

| Avg | 35,624 | 16,237 | 1317 | 42,220 | 95,422 | ||||||

| Min (Avg Min) | 31,181 | (34,467) | 11,898 | (15,329) | 0 | (305) | 9405 | (35,592) | 61,257 | (88,553) | |

| S1 M2 | Max (Avg Max) | 36,213 | (36,062) | 18,162 | (17,006) | 5200 | (4690) | 74,417 | (43,429) | 130,262 | (98,794) |

| Avg | 35,631 | 16,233 | 1825 | 38,104 | 91,828 | ||||||

| Min (Avg Min) | 29,489 | (34,527) | 11,898 | (15,515) | 0 | (578) | 1410 | (33,575) | 52,836 | (85,749) | |

| S2 M1 | Max (Avg Max) | 36,198 | (36,064) | 18,168 | (17,097) | 5203 | (5013) | 88,131 | (71,628) | 125,973 | (97,875) |

| Avg | 31,007 | 14,597 | 1776 | 46,166 | 93,569 | ||||||

| Min (Avg Min) | 3480 | (6275) | 0 | (6567) | 0 | (278) | 6275 | (35,592) | 58,163 | (85,553) | |

| S2 M2 | Max (Avg Max) | 36,217 | (36,068) | 18,206 | (17,060) | 5194 | (4912) | 89,196 | (70,178) | 124,874 | (98,351) |

| Avg | 31,093 | 14,893 | 2252 | 44,368 | 92,639 | ||||||

| Min (Avg Min) | 3218 | (6379) | 890 | (8424) | 0 | (756) | 2689 | (35,421) | 53,818 | (87,161) | |

| S3 M1 | Max (Avg Max) | 36,177 | (36,062) | 18,170 | (17,314) | 5191 | (4928) | 98,950 | (69,254) | 127,686 | (95,781) |

| Avg | 25,982 | 12,367 | 2209 | 49,594 | 90,174 | ||||||

| Min (Avg Min) | 2598 | (6008) | 0 | (6250) | 0 | (255) | 1260 | (33,932) | 40,832 | (83,995) | |

| S3 M2 | Max (Avg Max) | 36,269 | (36,062) | 18,148 | (17,362) | 5187 | (5032) | 98,511 | (67,599) | 126,683 | (98,816) |

| Avg | 26,552 | 13,320 | 2646 | 47,793 | 90,341 | ||||||

| Min (Avg Min) | 3438 | (6156) | 0 | (8078) | 0 | (731) | 0 | (34,678) | 43,630 | (84,851) | |

| Productivity, m3/h | Work Time Per Year | Delivered Volume Per Year | ||||

|---|---|---|---|---|---|---|

| Avg, h | STD, h | Capacity Utilization, % | Avg, m3 | STD, m3 | ||

| S1 M1 | 156 | 1249 | 68 | 60.0 | 194,240 | 10,636 |

| S1 M2 | 62 | 3577 | 110 | 81.9 | 222,500 | 6892 |

| S2 M1 | 156 | 1068 | 81 | 51.3 | 166,020 | 12,517 |

| S2 M2 | 62 | 3065 | 113 | 70.2 | 190,450 | 7191 |

| S3 M1 | 155 | 875 | 83 | 42.1 | 135,830 | 12,938 |

| S3 M2 | 62 | 2579 | 156 | 59.0 | 160,340 | 9732 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kons, K.; Hera, P.L.; Bergström, D. Comparison of Alternative Pulpwood Inventory Strategies and Machine Systems at a Log-Yard Using Simulations. Forests 2020, 11, 373. https://doi.org/10.3390/f11040373

Kons K, Hera PL, Bergström D. Comparison of Alternative Pulpwood Inventory Strategies and Machine Systems at a Log-Yard Using Simulations. Forests. 2020; 11(4):373. https://doi.org/10.3390/f11040373

Chicago/Turabian StyleKons, Kalvis, Pedro La Hera, and Dan Bergström. 2020. "Comparison of Alternative Pulpwood Inventory Strategies and Machine Systems at a Log-Yard Using Simulations" Forests 11, no. 4: 373. https://doi.org/10.3390/f11040373

APA StyleKons, K., Hera, P. L., & Bergström, D. (2020). Comparison of Alternative Pulpwood Inventory Strategies and Machine Systems at a Log-Yard Using Simulations. Forests, 11(4), 373. https://doi.org/10.3390/f11040373