Energy Optimization in Hotels: Strategies for Efficiency in Hot Water Systems

Abstract

1. Introduction

- The development of mathematical models that describe the behavior of heat recovery in chillers, allowing its integration with the simultaneous production of domestic hot water, using operational data and associated environmental variables;

- The methodology for the modeling of the installation that integrates the components of the domestic hot water (DHW) system, facilitating the proposal of parameters that ensure an efficient operation according to the hot water demand conditions;

- The procedure for energy optimization of the sanitary hot water production system, obtaining the most efficient operation strategy with the lowest consumption and environmental impact;

- Given the importance of the tourism sector and its environmental impact, this article explores the opportunities and challenges associated with energy optimization in domestic hot water systems in the hotel context.

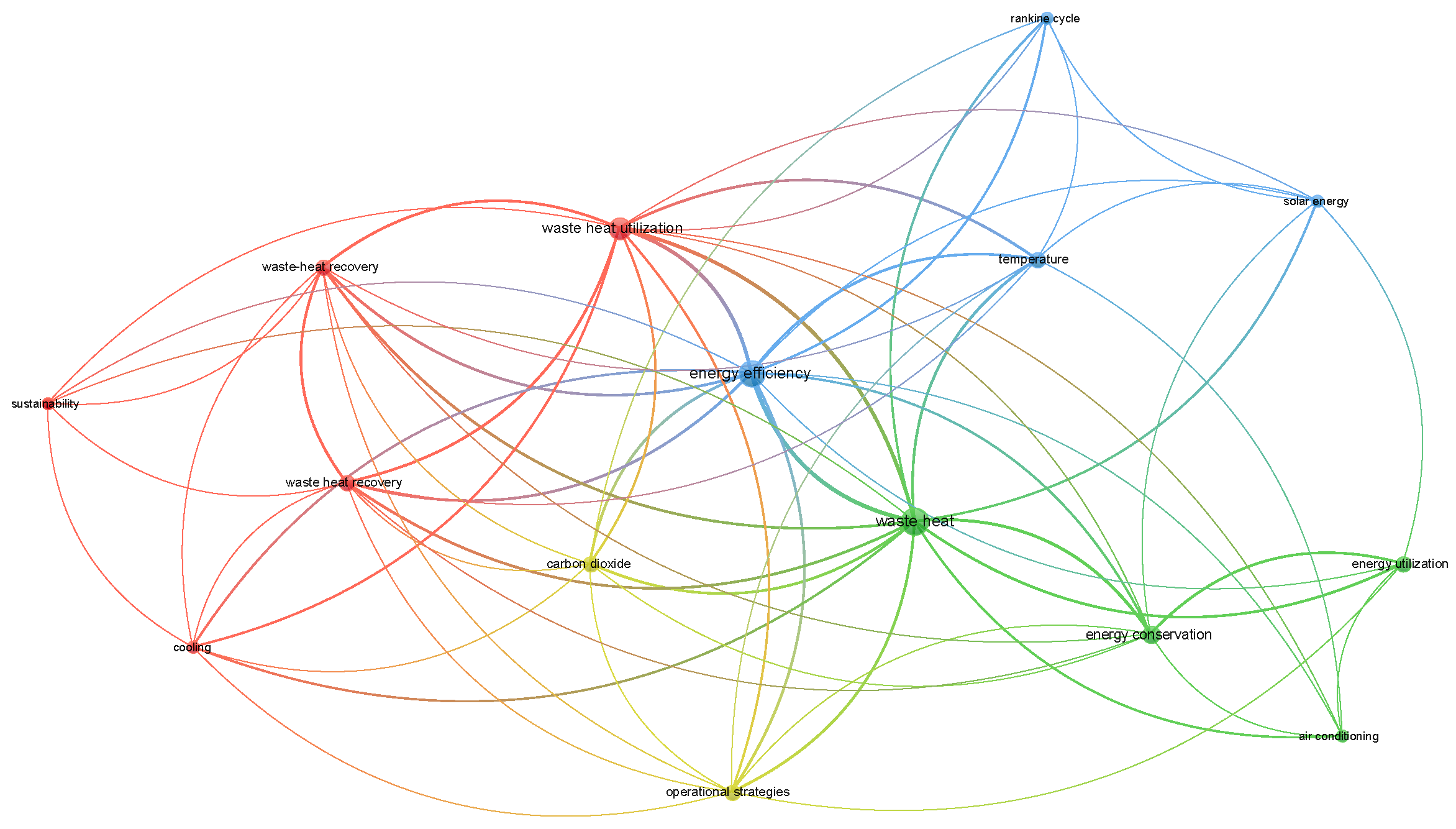

2. State of the Art

2.1. Literature Review

2.2. Methodological Context and Literature Integration

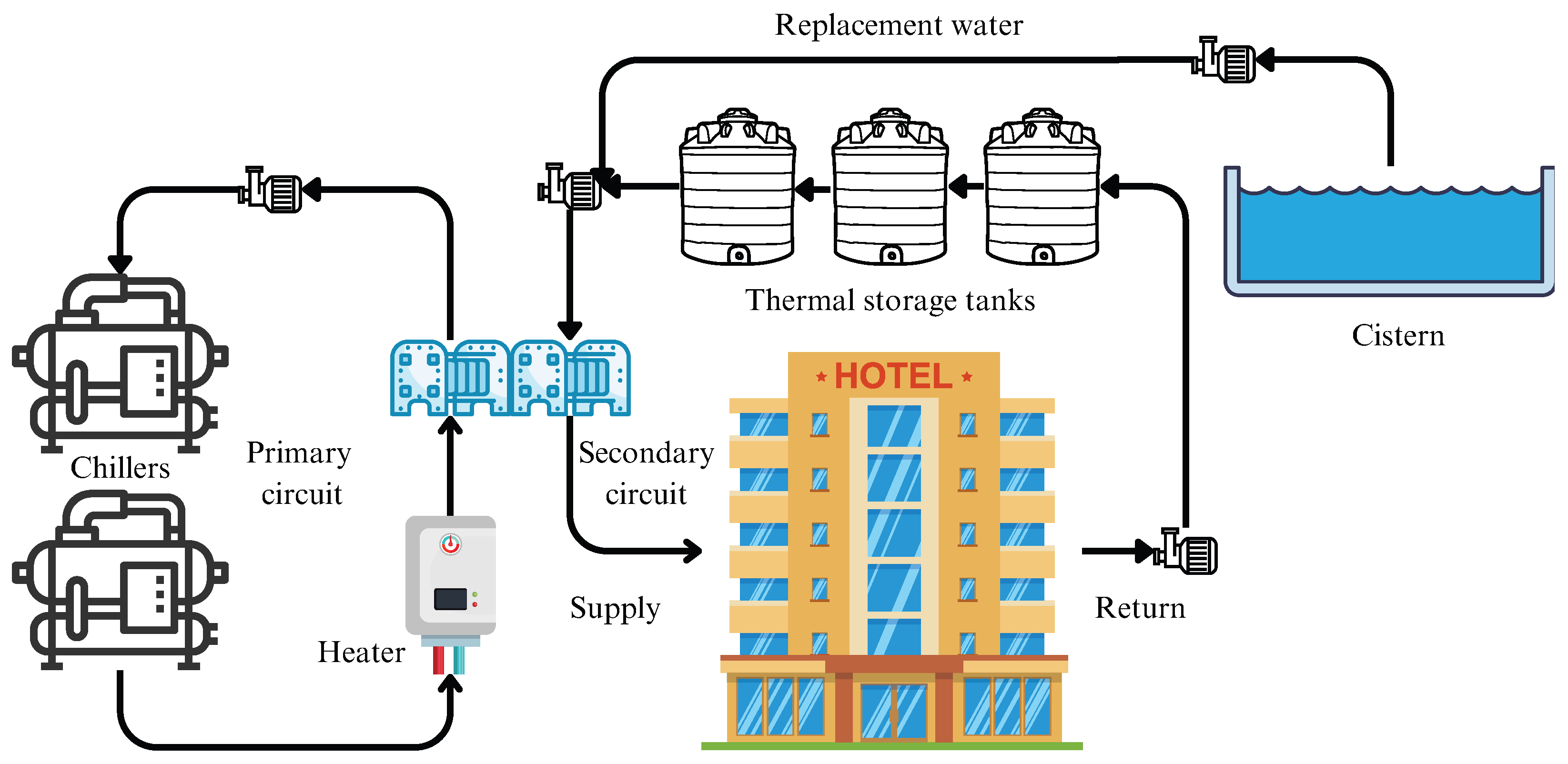

2.3. Domestic Hot Water System

2.4. Heat Recovery in Water Chillers

3. Materials and Methods

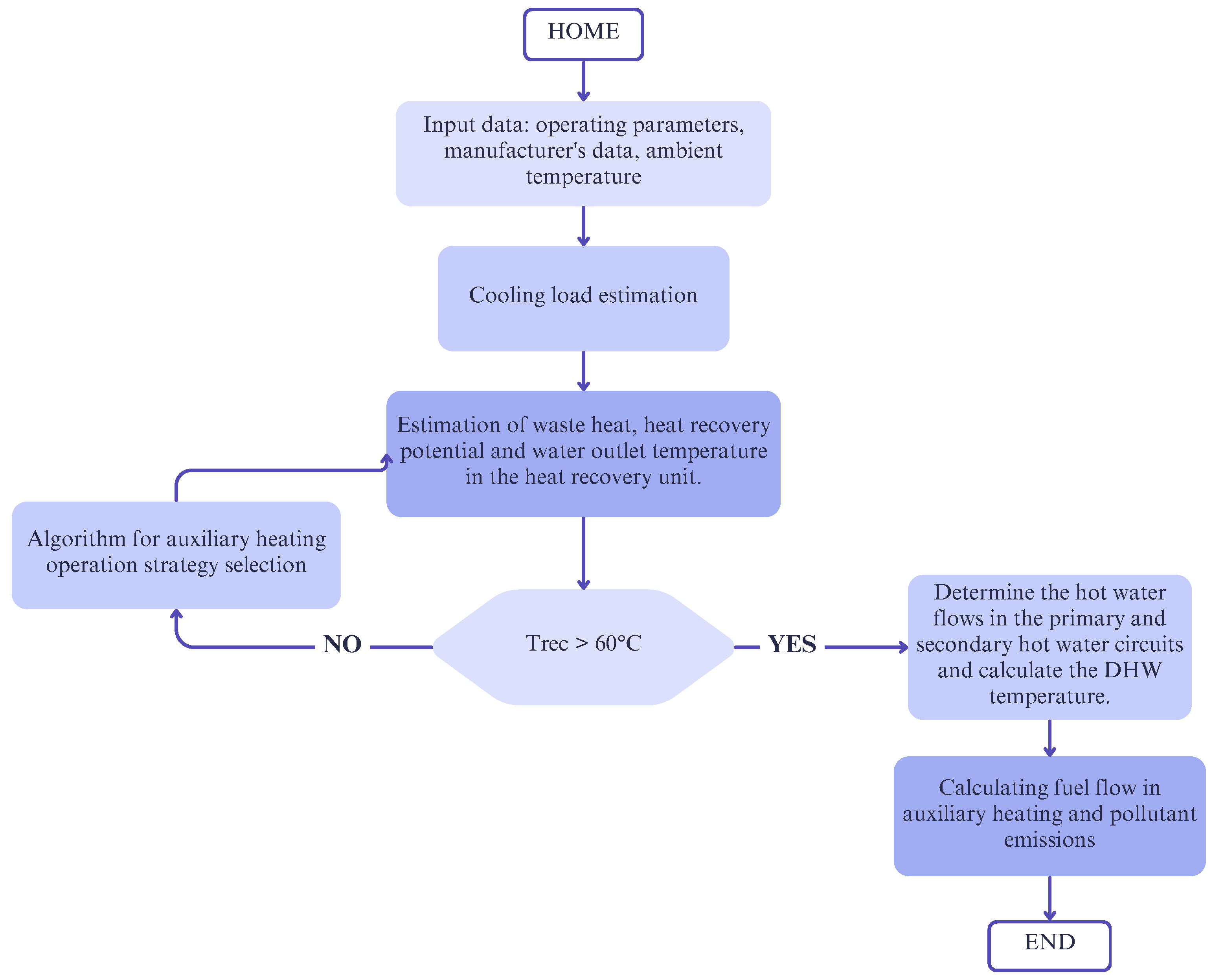

3.1. Methodology for the Development of the Energy Model

- Stationary operating conditions exist;

- Heat losses between the heat exchangers and the surroundings are neglected;

- Heat losses between the hot water supply and return in the insulated pipes are considered to be less than 5 °C;

- Pressure drops in the heat exchangers are neglected;

- Heat losses to the medium in the water chillers are neglected (the rejected heat is the sum of the cooling capacity and the compressor power);

- The system works at constant flow.

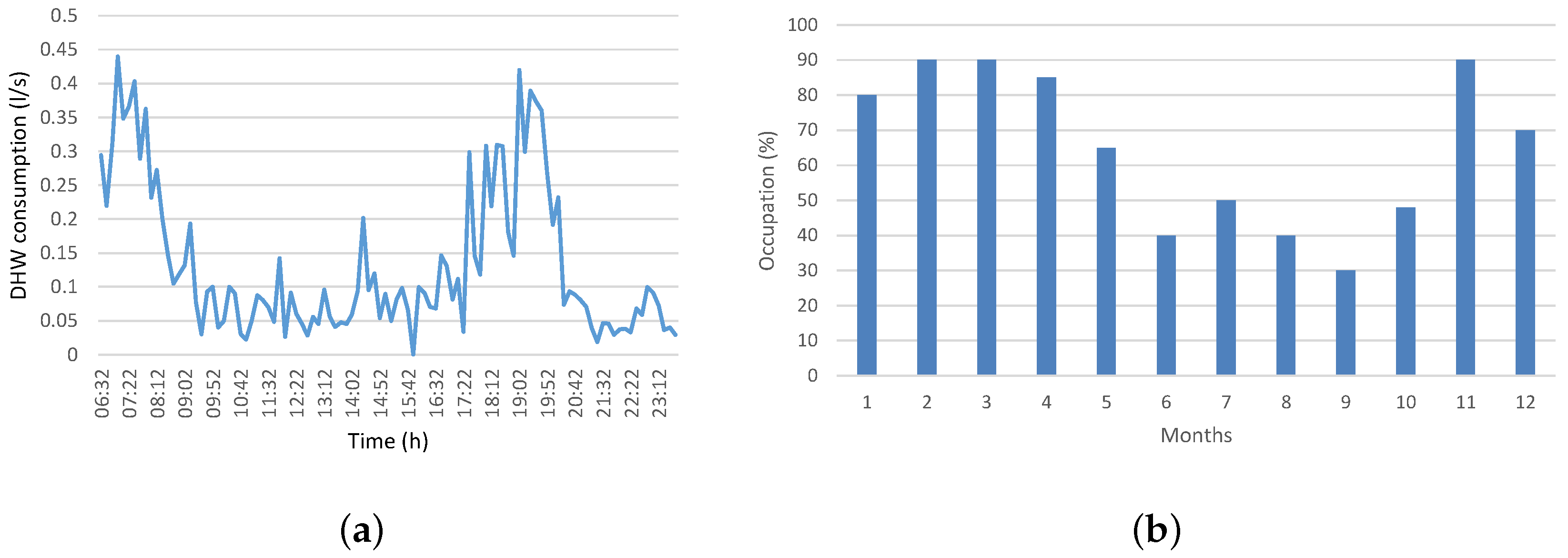

3.2. Case Study: Hotel Facility

3.3. Energy Optimization Procedure

3.3.1. Target Function

- : hot water flow in the primary circuit, kg/s;

- : hot water flow in the secondary circuit, kg/s;

- : temperature at the outlet of the auxiliary heater, °C;

- : the heat recovery temperature, °C.

- : hot water supply temperature, °C;

- : temperature of the storage tanks, °C;

- : temperature of the replenishment water, °C;

- : water temperature at heat recovery, °C;

- : return water flow, kg/s;

- : replenishment water flow, kg/s.

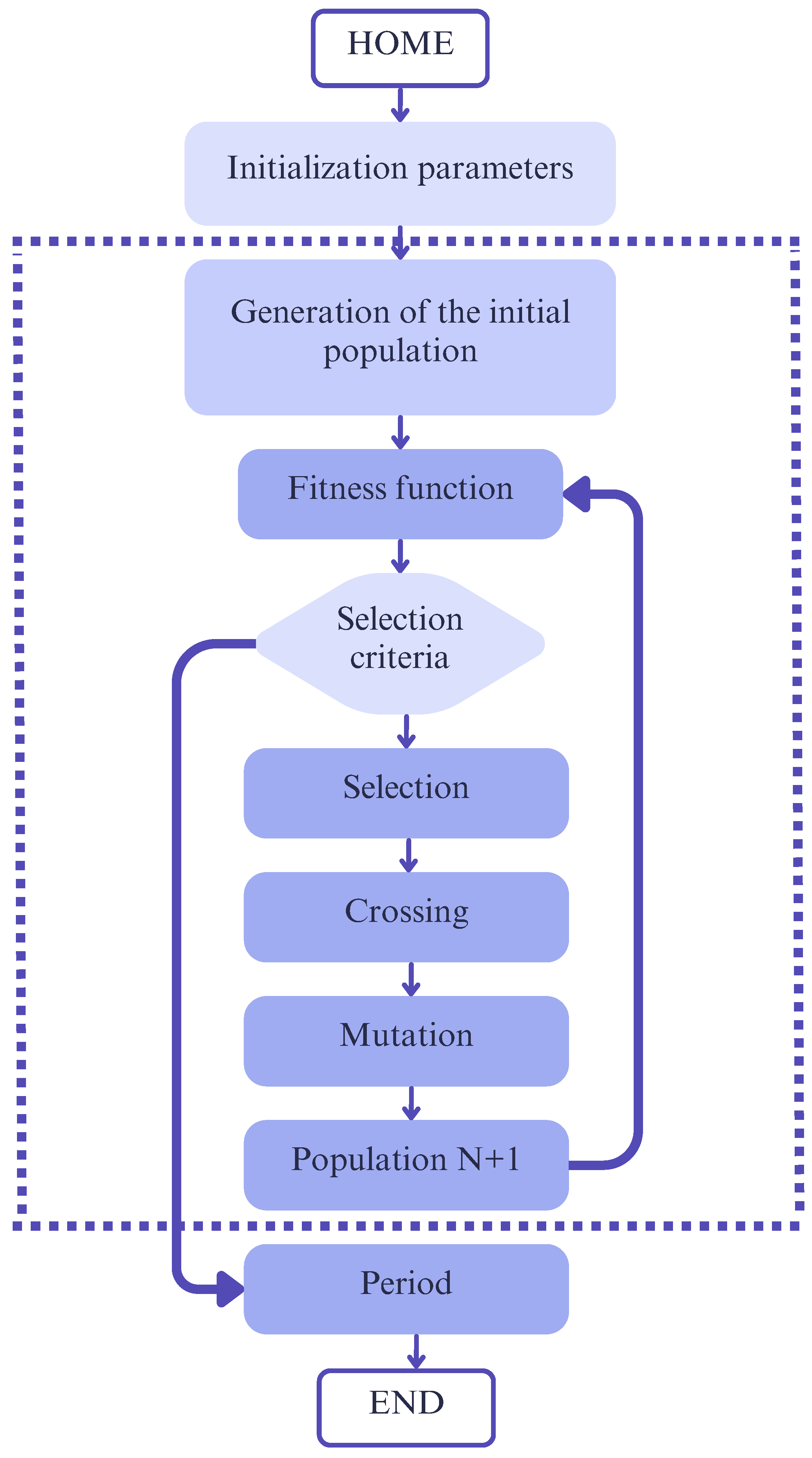

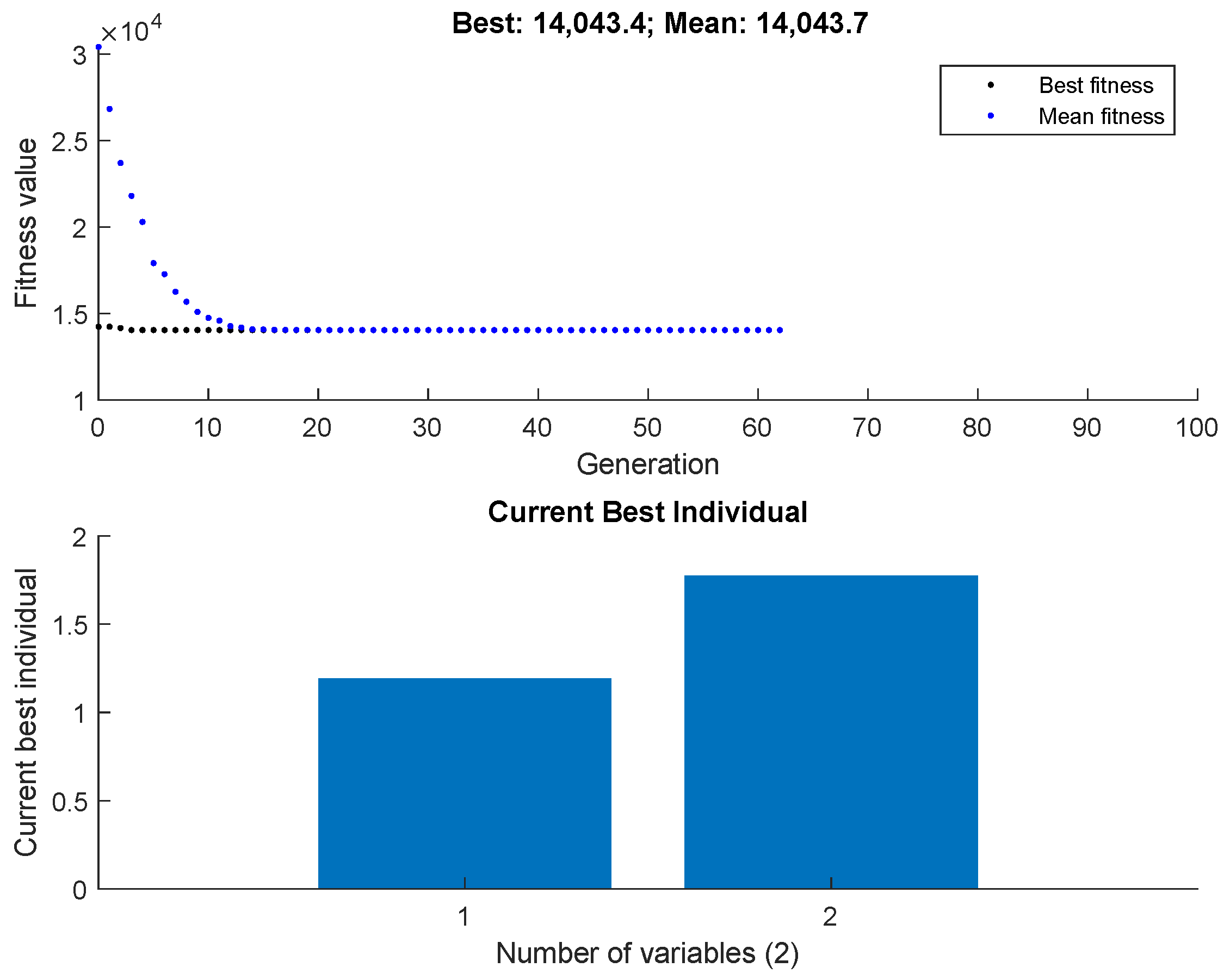

Optimization with Genetic Algorithms

Main Program

- Initial configurations

- Read data from a set of measurements taken every 10 min, stored in the file Datos.mat. These include:

- –

- Total Power (Ptotal)

- –

- Inlet water temperature to the heat recovery system (T6)

- –

- Chilled water temperature (Tah)

- –

- Ambient temperature (Tamb)

- –

- Sanitary water return flow (mRet)

- –

- Sanitary water supply flow (mSum)

- –

- Time vector (tiempo)

- Calculate cooling load () for each compressor using the equation

- Calculate total condensation heat () for each compressor:

- Define chiller operating parameters and calculate recovered heat in the cycle:

- Set parameters for the genetic algorithm:These parameters were selected to strike a balance between robustness and convergence speed [28]:

- Number of variables = 2

- Population size = 200

- Mutation function = @mutationadaptfeasible

- Number of elite individuals = 2

- Crossover fraction = 0.8

- Number of generations = 100

- Stopping criterion for fitness =

- Lower bounds =

- Upper bounds =

- Initial values =

- Objective function = @fitnessFun

- Other parameters = Default values

- Plot the results

- Initialize calculation variables.

- For each time step k (every 10 min):

- Calculate mixing temperature:

- Calculate inlet and outlet temperatures of the hot fluid in the exchanger based on the cold fluid inlet/outlet temperatures and flows .

- Compute the outlet temperatures from the heat recovery system for each chiller.

- Determine the outlet temperature of the recovery unit as the average of the c-point temperatures.

- Perform an iterative process to adjust parameters such that .

- Assume return sanitary water temperature is 5 °C less than the supply temperature.

- Calculate for the next time step.

- Determine auxiliary heating:

- Sum all values over time to compute the final objective function.

4. Results and Discussion

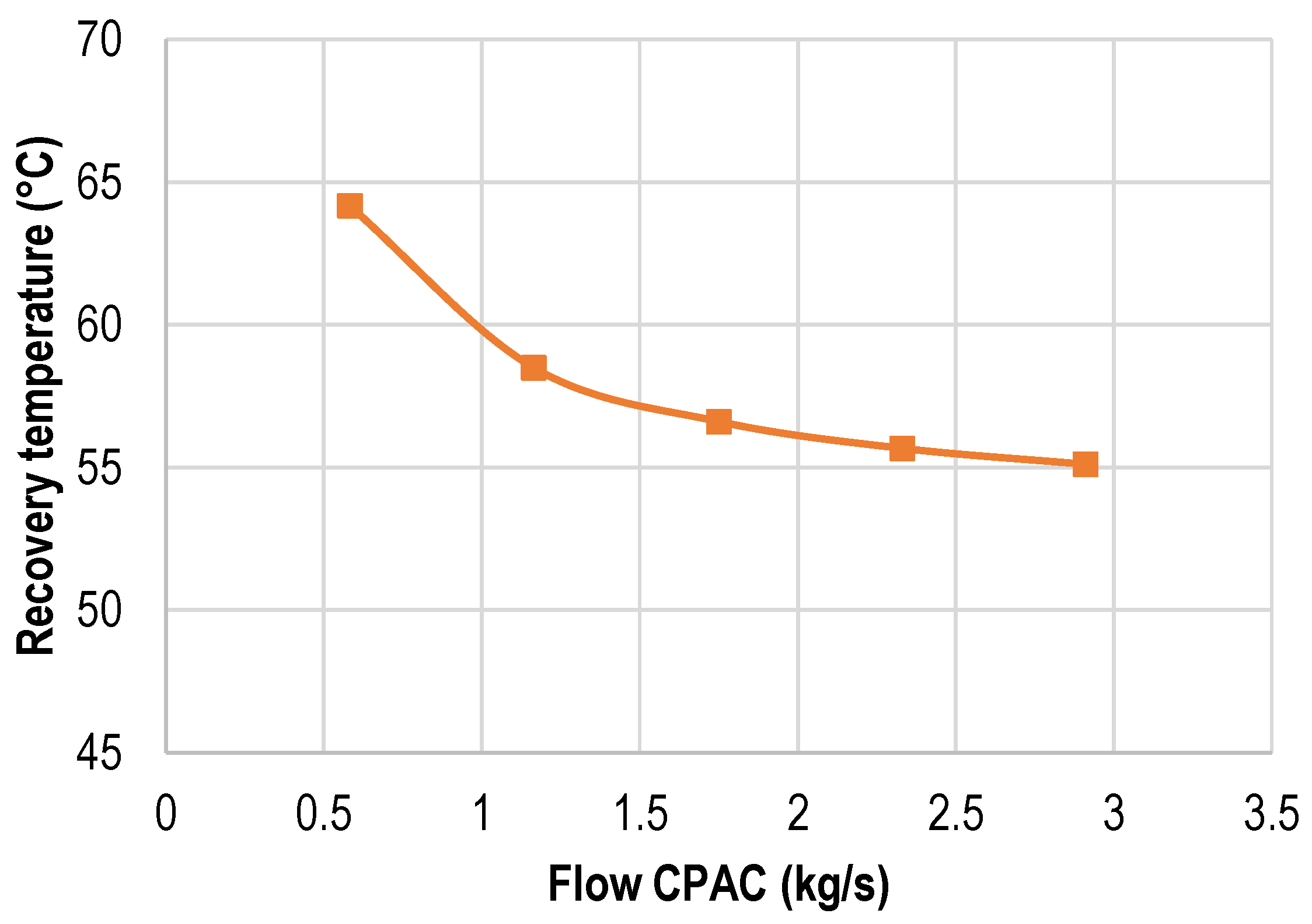

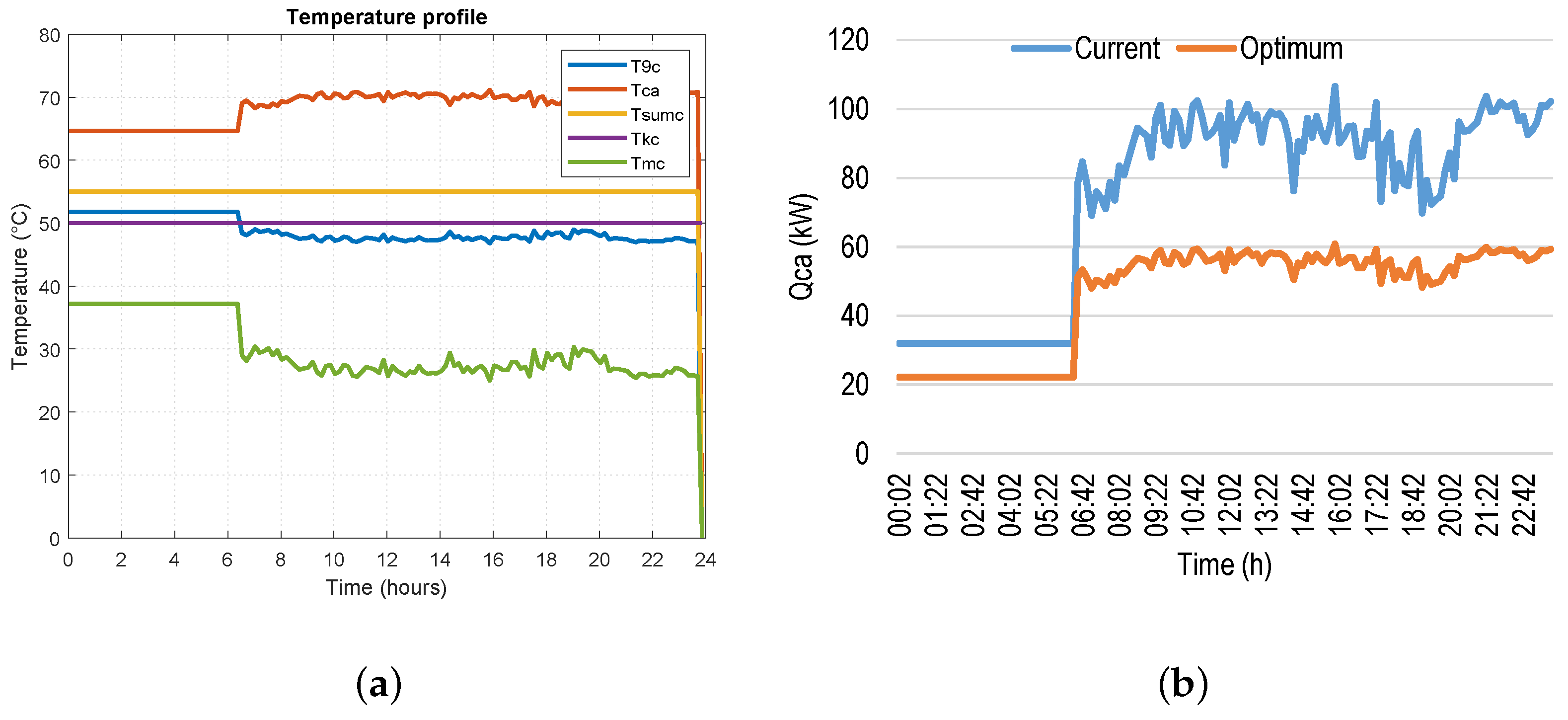

4.1. Results of the Thermodynamic Evaluation

- Nominal regime:pressure of 1.7 bar (−10 °C) and 12.2 bar (46 °C), with corresponding evaporation and condensation temperatures; for the chilled water circuit, supply and return temperatures of 8 °C and 11 °C, respectively;

- Part-load regime:pressure of 1.5 bar (−7 °C) and 11 bar (43 °C), with corresponding evaporation and condensation temperatures; for the chilled water circuit, supply and return temperatures of 8.5 °C and 12 °C, respectively.

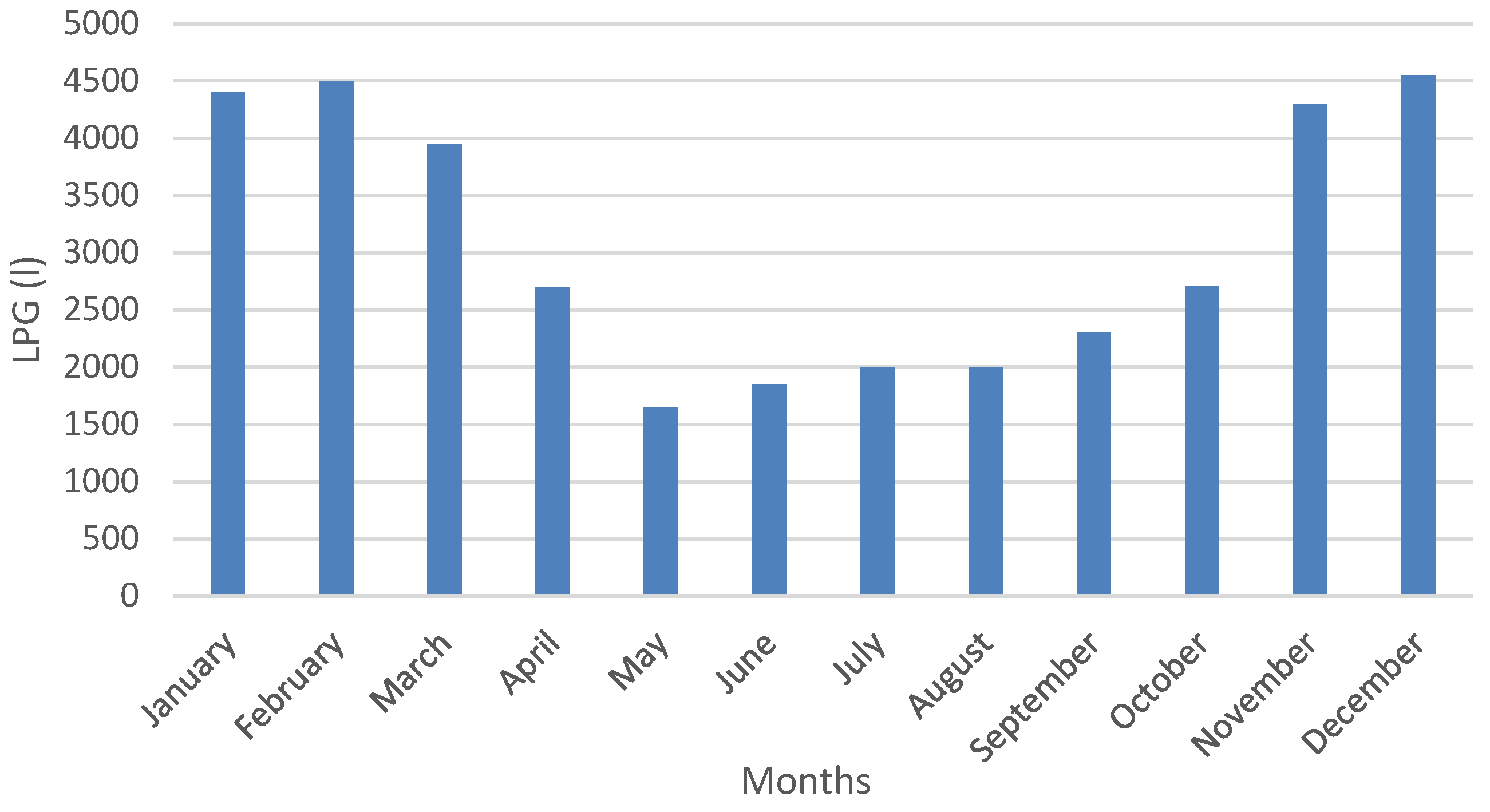

4.2. Economic Analysis and Associated Environmental Impact

4.3. Life Cycle Cost

4.4. Comparison of Results with Literature

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| Abbreviation | Meaning |

| ASHRAE | American Society of Heating Refrigeration and Air-conditioning Engineers |

| COP | Coefficient of performance |

| DHW | Domestic hot water |

| GA | Genetic algorithm |

| HVAC | Heating ventilation and air conditioning |

| IEA | International Energy Agency |

| LPG | Liquefied petroleum gas |

| LCC | Life cycle cost |

| RTO | Real time optimization |

Nomenclature

| Symbol | Description |

| Cp | Specific heat, kJ/kgK |

| Primary circuit mass flow, kg/s | |

| Return water mass flow, kg/s | |

| Replenishment water mass flow, kg/s | |

| Total power, kW | |

| Cooling capacity, kW | |

| Total condensation heat, kW | |

| Heat recovery capacity, kW | |

| Auxiliary heating capacity, kW | |

| Chilled water temperature, °C | |

| Ambient temperature | |

| Auxiliary heater water temperature, °C | |

| Condensation temperature, °C | |

| Thermal storage tanks water temperature, °C | |

| Mix water temperature, °C | |

| Recovery temperature, °C | |

| Replenishment water temperature, °C | |

| Hot water supply temperature, °C | |

| Compression temperature, °C | |

| Inlet water temperature at heat recovery, °C | |

| Outlet water temperature at heat recovery, °C |

References

- Brugger, H.; Eichhammer, W.; Mikova, N.; Dönitz, E. Energy Efficiency Vision 2050: How will new societal trends influence future energy demand in the European countries? Energy Policy 2021, 152, 112216. [Google Scholar] [CrossRef]

- Olajiga, O.K.; Ani, E.C.; Sikhakane, Z.Q.; Olatunde, T.M. A comprehensive review of energy-efficient lighting technologies and trends. Eng. Sci. Technol. J. 2024, 5, 1097–1111. [Google Scholar] [CrossRef]

- Malik, U.M.; Javed, M.A.; Zeadally, S.; ul Islam, S. Energy-efficient fog computing for 6G-enabled massive IoT: Recent trends and future opportunities. IEEE Internet Things J. 2021, 9, 14572–14594. [Google Scholar] [CrossRef]

- Chu, J.; Huang, X. Research status and development trends of evaporative cooling air-conditioning technology in data centers. Energy Built Environ. 2023, 4, 86–110. [Google Scholar] [CrossRef]

- Valero, A.; Valero, A.; Calvo, G. Resumen y análisis crítico del informe especial de la Agencia Internacional de la Energía: El Rol de los minerales críticos en la transición hacia energías limpias. Rev. Metal. 2021, 57, e197. [Google Scholar] [CrossRef]

- Nodal, C.Y.V.; Calvo, M.R.R.; Guerra, C.M.Á.; Plasensia, D.C. Procedimiento Para la Operación Eficiente de Sistemas de Respaldo de ACS en Hoteles.

- Li, Q.; Zhang, L.; Zhang, L.; Wu, X. Optimizing energy efficiency and thermal comfort in building green retrofit. Energy 2021, 237, 121509. [Google Scholar] [CrossRef]

- Pokhrel, S.; Amiri, L.; Poncet, S.; Sasmito, A.P.; Ghoreishi-Madiseh, S.A. Renewable heating solutions for buildings; a techno-economic comparative study of sewage heat recovery and Solar Borehole Thermal Energy Storage System. Energy Build. 2022, 259, 111892. [Google Scholar] [CrossRef]

- Ratajczak, K.; Michalak, K.; Narojczyk, M.; Amanowicz, Ł. Real domestic hot water consumption in residential buildings and its impact on buildings’ energy performance—Case study in Poland. Energies 2021, 14, 5010. [Google Scholar] [CrossRef]

- Pérez-Fargallo, A.; Bienvenido-Huertas, D.; Contreras-Espinoza, S.; Marín-Restrepo, L. Domestic hot water consumption prediction models suited for dwellings in central-southern parts of Chile. J. Build. Eng. 2022, 49, 104024. [Google Scholar] [CrossRef]

- Puschnigg, S.; Lindorfer, J.; Moser, S.; Kienberger, T. Techno-economic aspects of increasing primary energy efficiency in industrial branches using thermal energy storage. J. Energy Storage 2021, 36, 102344. [Google Scholar] [CrossRef]

- Zhang, S.; Ocłoń, P.; Klemeš, J.J.; Michorczyk, P.; Pielichowska, K.; Pielichowski, K. Renewable energy systems for building heating, cooling and electricity production with thermal energy storage. Renew. Sustain. Energy Rev. 2022, 165, 112560. [Google Scholar] [CrossRef]

- Ghamari, V.; Hajabdollahi, H.; Dehaj, M.S.; Saleh, A. Investigating the effect of energy storage tanks on thermoeconomic optimization of integrated combined cooling, heating and power generation with desalination plant. J. Energy Storage 2022, 56, 106120. [Google Scholar] [CrossRef]

- Farhat, O.; Faraj, J.; Hachem, F.; Castelain, C.; Khaled, M. A recent review on waste heat recovery methodologies and applications: Comprehensive review, critical analysis and potential recommendations. Clean. Eng. Technol. 2022, 6, 100387. [Google Scholar] [CrossRef]

- Gong, X.; Li, Y.; Cai, J.; Ma, Z.; He, S.; Pan, B.; Lei, X. A Statistical Analysis of Energy Consumption Survey of Public Buildings in a Hot Summer and Cold Winter Coastal Zone of China. Buildings 2023, 13, 2685. [Google Scholar] [CrossRef]

- Rajić, M.N.; Maksimović, R.M.; Milosavljević, P. Energy management model for sustainable development in hotels within WB6. Sustainability 2022, 14, 16787. [Google Scholar] [CrossRef]

- Christodoulides, P.; Aresti, L.; Panayiotou, G.P.; Tassou, S.; Florides, G.A. Adoption of waste heat recovery technologies: Reviewing the relevant barriers and recommendations on how to overcome them. Oper. Res. Forum 2022, 3, 3. [Google Scholar] [CrossRef]

- Larrinaga, P.; Campos-Celador, Á.; Legarreta, J.; Diarce, G. Evaluation of the theoretical, technical and economic potential of industrial waste heat recovery in the Basque Country. J. Clean. Prod. 2021, 312, 127494. [Google Scholar] [CrossRef]

- Fuentes, E.; Arce, L.; Salom, J. A review of domestic hot water consumption profiles for application in systems and buildings energy performance analysis. Renew. Sustain. Energy Rev. 2018, 81, 1530–1547. [Google Scholar] [CrossRef]

- Ndoye, B.; Sarr, M. Analysis of domestic hot water energy consumption in large buildings under standard conditions in Senegal. Build. Environ. 2008, 43, 1216–1224. [Google Scholar] [CrossRef]

- Pourhedayat, S.; Hu, E.; Chen, L. A comparative and critical review on gas turbine intake air pre-cooling strategies. Therm. Sci. Eng. Prog. 2023, 41, 101828. [Google Scholar] [CrossRef]

- Urban, E.J. Monitoring and Modeling Hot Water Consumption in Hotels for Solar Thermal Water Heating System Optimization. Master’s Thesis, Appalachian State University, Boone, NC, USA, 2011. Available online: https://libres.uncg.edu/ir/asu/f/Urban,%20Eric_2011_Thesis.pdf (accessed on 29 March 2025).

- Vujnović, N.; Dović, D. Cost-optimal energy performance calculations of a new nZEB hotel building using dynamic simulations and optimization algorithms. J. Build. Eng. 2021, 39, 102272. [Google Scholar] [CrossRef]

- Guercio, A.; Curto, D.; Franzitta, V.; Frascati, M.; Milone, D.; Martorana, P.; Mantegna, M. Energy Analyses and Optimization Proposals for Hotels in Sicily: A Case Study. Sustainability 2023, 16, 146. [Google Scholar] [CrossRef]

- Fritzson, P.; Pop, A.; Abdelhak, K.; Asghar, A.; Bachmann, B.; Braun, W.; Bouskela, D.; Braun, R.; Buffoni, L.; Casella, F.; et al. The OpenModelica integrated environment for modeling, simulation, and model-based development. Model. Identif. Control (MIC) 2020, 41, 241–285. [Google Scholar] [CrossRef]

- Tesfay, M. Multilevel Data-Driven Framework for Operating HVAC Systems to Optimize Energy and Comfort in Modern Buildings. Ph.D. Thesis, The University of Nebraska-Lincoln, Lincoln, NE, USA, 2021. [Google Scholar]

- Shboul, B.; Zayed, M.E.; Ashraf, W.M.; Usman, M.; Roy, D.; Irshad, K.; Rehman, S. Energy and economic analysis of building integrated photovoltaic thermal system: Seasonal dynamic modeling assisted with machine learning-aided method and multi-objective genetic optimization. Alex. Eng. J. 2024, 94, 131–148. [Google Scholar] [CrossRef]

- Mihail-Bogdan, C.; Constantin, I.; Horia, N. The influence of Genetic Algorithm parameters over the efficiency of the energy consumption estimation in a low–energy building. Energy Procedia 2016, 85, 99–108. [Google Scholar] [CrossRef]

- Banco Central de Cuba. Banco Central de Cuba. 2025. Available online: https://www.bc.gob.cu/ (accessed on 13 May 2025).

- Gong, G.; Zeng, W.; Wang, L.; Wu, C. A new heat recovery technique for air-conditioning/heat-pump system. Appl. Therm. Eng. 2008, 28, 2360–2370. [Google Scholar] [CrossRef]

- Gong, G.; Chen, F.; Su, H.; Zhou, J. Thermodynamic simulation of condensation heat recovery characteristics of a single stage centrifugal chiller in a hotel. Appl. Energy 2012, 91, 326–333. [Google Scholar] [CrossRef]

- Hengel, F.; Heinz, A.; Rieberer, R. Performance analysis of a heat pump with desuperheater for residential buildings using different control and implementation strategies. Appl. Therm. Eng. 2016, 105, 256–265. [Google Scholar] [CrossRef]

- Suamir, I.N.; Sukadana, I.B.P.; Arsana, M.E. Minimizing temperature instability of heat recovery hot water system utilizing optimized thermal energy storage. J. Phys. Conf. Ser. 2018, 953, 012113. [Google Scholar] [CrossRef]

- Li, F.; Sun, B.; Zhang, C.; Zhang, L. Operation optimization for combined cooling, heating, and power system with condensation heat recovery. Appl. Energy 2018, 230, 305–316. [Google Scholar] [CrossRef]

- Li, H.; Zhou, S.; He, C.; Deng, L.; Li, L.; Li, S.; Zhang, G. A feasible and novel multi-generation system taking advantage of two-stage compressor for luxury hotels. J. Therm. Sci. 2021, 30, 817–827. [Google Scholar] [CrossRef]

| Parameters | Unit | Chiller 1 | Chiller 2 | ||

|---|---|---|---|---|---|

| Part-Load | Nominal | Part-Load | Nominal | ||

| Suction pressure | bar | 1.5 | 1.7 | 1.5 | 2.00 |

| Discharge pressure | bar | 10 | 12.2 | 11 | 12.2 |

| Superheating | °C | 8 | 8 | 3 | 8 |

| Subcooling | °C | 3 | 3 | 3 | 3 |

| Compression work | kJ/kg | 40.96 | 42.65 | 39.12 | 43.07 |

| Compressor outlet temperature | °C | 59.18 | 68.01 | 60.67 | 69.26 |

| Condensation temperature | °C | 40 | 46.32 | 43 | 46.97 |

| Refrigerant flow rate | kg/s | 1.6 | 1.69 | 1.33 | 1.81 |

| Compressor power | kW | 65.54 | 72.08 | 52.03 | 77.96 |

| Cooling capacity | kW | 125.67 | 234.89 | 216.84 | 416.72 |

| Primary circuit water flow | kg/s | 2.91 | 2.91 | 2.91 | 2.91 |

| Recovery heat | kW | 27.61 | 95 | 39.83 | 158.3 |

| Recovery temperature | °C | 55.11 | 60 | 56.11 | 64.99 |

| Heat recovery percentage | % | 8.09 | 21 | 17.86 | 25 |

| COP | - | 2.21 | 4.58 | 3.62 | 4.87 |

| Equipment | Total Power (kW) | Current System | Optimized System | ||||

|---|---|---|---|---|---|---|---|

| Operating Time (h) | Energy Cost ($/year) | Emissions (kgCO2) | Operating Time (h) | Energy Cost ($/year) | Emissions (kgCO2) | ||

| 2.20 | 24 | 13.55 | 1292 | 24 | 5.53 | 527.59 | |

| 1.50 | 24 | 55.45 | 5287 | 24 | 27.48 | 2620 | |

| 99.00 | 18 | 4644 | 282.6 | 6 | 1172.39 | 192.19 | |

| Total | 102.7 | 24 | 4713 | 6862 | 24 | 1205.41 | 3219 |

| Savings | 3507.6 | 3643 | |||||

| Cost Items | Unit | Current System | Optimized (100% Use) | Optimized (25% Use) |

|---|---|---|---|---|

| Initial cost | USD | 1591.97 | 1591.97 | 1591.97 |

| Operation (energy) | USD | 4713.01 | 3153.26 | 1172.39 |

| Maintenance | USD | 37.06 | 37.06 | 37.06 |

| LCC (Life Cycle Cost) | USD | 113,251.00 | 86,068.46 | 50,615.34 |

| Author | Technology | Variables | Results/Scope |

|---|---|---|---|

| [30] | Air conditioning/heat pump with heat recovery | Sanitary water flow rate, chilling water flow rate, inlet and outlet temperatures of evaporator and condenser, cooling capacity, COP | High COP (about 6.0); a supplementary electric heating device is suggested |

| [31] | Vapor compressor chillers with heat recovery | Cooling capacity, power consumption, enthalpies and flow rates of cold and hot water, COP, energy efficiency | Potential for energy savings and improved system performance with significantly higher energy efficiency under optimal conditions |

| [32] | Heat pump with heat recovery | Water temperature at the outlet of heat recovery, temperature difference between discharge and recovery points, water mass flow rate, refrigerant and water side capacity flow rates, COP | Proposes different configuration strategies for the heat recovery; up to 5% savings in electricity with reduced auxiliary energy use in DHW production |

| [33] | Centralized air conditioning systems with heat recovery | Cooling/heating demand, thermal storage tank capacity/design, condensation and hot water temperatures | Optimizes thermal storage to minimize temperature fluctuations in hot water supply |

| [34] | Combined cooling, heating, and power system with heat recovery | COP, hot water temperature, condensation temperature, heat exchange efficiency, heat recovery efficiency | 5% increase in energy savings, 6.36% increase in economic savings, 2.74% reduction in CO2 emissions |

| [35] | Two-stage multigeneration system (heating, cooling, DHW) | Evaporation temperature, sanitary hot water temperature, COP | Significant COP improvements (7.3 in summer, 3.1 in winter); improved heat recovery, reduced energy use |

| This study | Centralized air conditioning system with heat recovery | Cooling/heating demand, hot water mass flow in primary and secondary circuits, cold/hot water temperature, heat recovery temperature, auxiliary heating temp, outlet temp, COP | Optimizes temperature in heat recovery and proposes flow values and temperature targets for auxiliary heating and overall energy efficiency |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Valdivia Nodal, Y.; Iturralde Carrera, L.A.; Zapatero-Gutiérrez, A.; Guerra Plasencia, M.A.Á.; Reyes Calvo, R.; Álvarez-Alvarado, J.M.; Rodríguez-Reséndiz, J. Energy Optimization in Hotels: Strategies for Efficiency in Hot Water Systems. Algorithms 2025, 18, 301. https://doi.org/10.3390/a18060301

Valdivia Nodal Y, Iturralde Carrera LA, Zapatero-Gutiérrez A, Guerra Plasencia MAÁ, Reyes Calvo R, Álvarez-Alvarado JM, Rodríguez-Reséndiz J. Energy Optimization in Hotels: Strategies for Efficiency in Hot Water Systems. Algorithms. 2025; 18(6):301. https://doi.org/10.3390/a18060301

Chicago/Turabian StyleValdivia Nodal, Yarelis, Luis Angel Iturralde Carrera, Araceli Zapatero-Gutiérrez, Mario Antonio Álvarez Guerra Plasencia, Royd Reyes Calvo, José M. Álvarez-Alvarado, and Juvenal Rodríguez-Reséndiz. 2025. "Energy Optimization in Hotels: Strategies for Efficiency in Hot Water Systems" Algorithms 18, no. 6: 301. https://doi.org/10.3390/a18060301

APA StyleValdivia Nodal, Y., Iturralde Carrera, L. A., Zapatero-Gutiérrez, A., Guerra Plasencia, M. A. Á., Reyes Calvo, R., Álvarez-Alvarado, J. M., & Rodríguez-Reséndiz, J. (2025). Energy Optimization in Hotels: Strategies for Efficiency in Hot Water Systems. Algorithms, 18(6), 301. https://doi.org/10.3390/a18060301