A Capacity Allocation Method for Long-Endurance Hydrogen-Powered Hybrid UAVs Based on Two-Stage Optimization

Abstract

1. Introduction

2. Mathematical Model

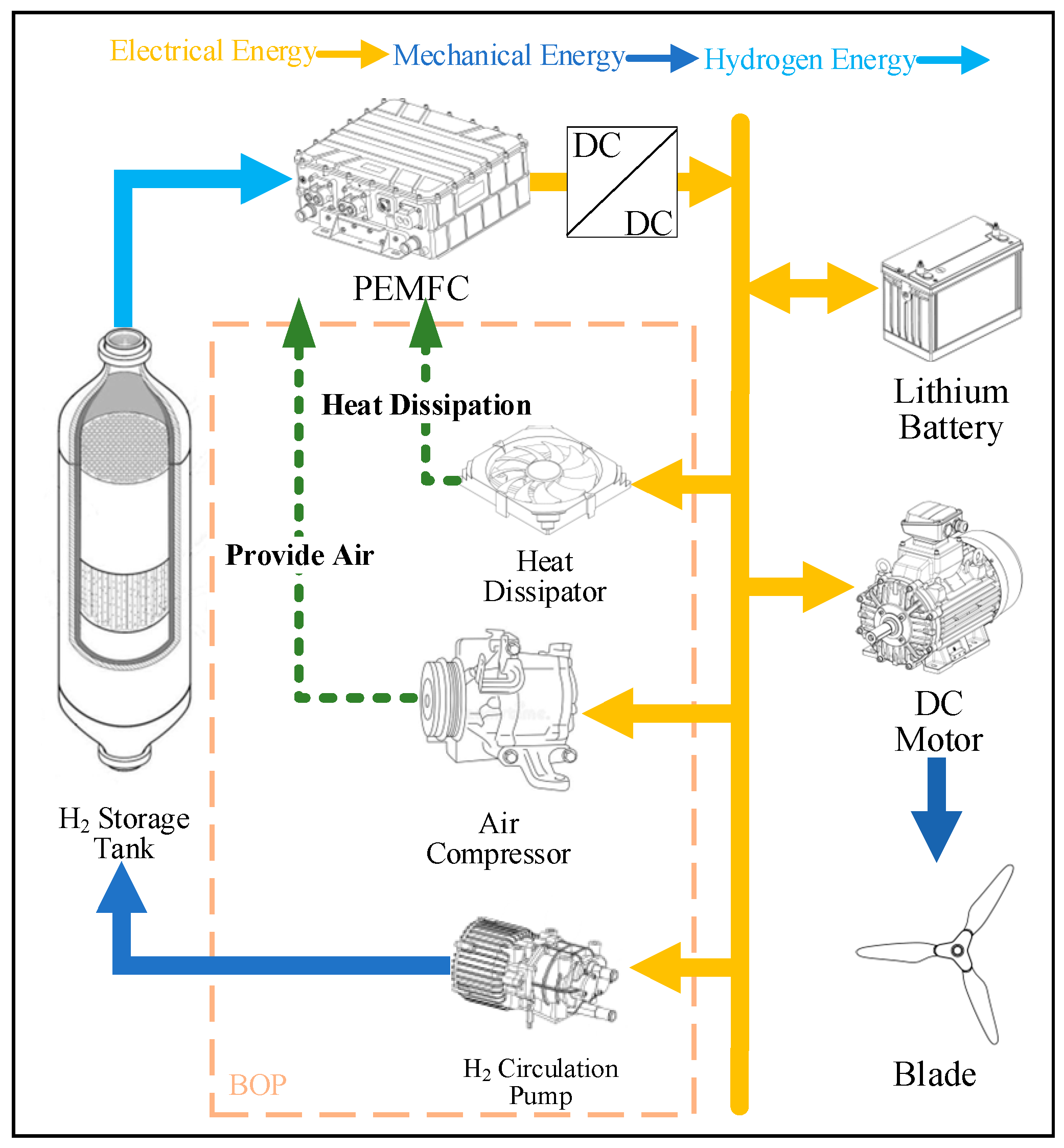

2.1. Hydrogen-Powered Hybrid UAV System Model

2.1.1. Proton Exchange Membrane Fuel Cell

2.1.2. Lithium Battery

2.1.3. Hydrogen Storage Tank

2.1.4. Electric Motor

2.2. Construction of Uncertainty Model

3. Two-Stage Stochastic Optimization Problem

- Step 1: Initial Particle Swarm Generation:

- Step 2: Fitness Calculation:

- Step 3: Update Global Best Particle and Individual Best Particle:

- Step 4: Boundary Check:

- Step 5: Repeat Steps 2–4 until the iteration conditions are met, exit the loop, and obtain the optimal solution.

3.1. Energy Balance Constraint

3.2. Energy Storage Constraint

- (1)

- Before the hydrogen hybrid UAV takes off, the hydrogen storage tank has already stored a certain amount of hydrogen energy.

- (2)

- Due to the continuity of multiple flight missions by the hydrogen hybrid UAV, when the hydrogen fuel is at no less than 20% of its maximum capacity, refueling is not required. Therefore, the amount of hydrogen in the storage tank at the end of the previous flight is assumed to be the same as the starting amount for the next flight.

- (3)

- The storage and withdrawal of hydrogen from the tank do not occur simultaneously. Since the refueling process does not affect the capacity configuration of the hydrogen hybrid UAV, the focus is more on the withdrawal rate, which should not exceed the maximum withdrawal power of the hydrogen storage tank.

4. Results

5. Conclusions

- (1)

- The two-stage stochastic optimization method proposed in this paper effectively addresses the impact of uncertain factors such as wind speed and wind direction. In the first stage, PSO is used to optimize the capacity configuration of the equipment, while the second stage evaluates the expected optimal cost under different scenarios by solving the MILP problem, ultimately achieving the system’s full lifecycle optimization.

- (2)

- This paper constructs a comprehensive evaluation metric that includes both short-term and long-term costs. The short-term costs focus on hydrogen consumption and regular maintenance expenses, while the long-term costs consider equipment investment and amortization of service life. By using a weighted sum, the short-term and long-term objectives are balanced, ensuring that the system meets the immediate operational needs while maintaining long-term sustainability.

- (3)

- To address the uncertainty of wind speed and wind direction, the Monte Carlo method is used to generate random scenarios for these variables. By combining this with the PSO algorithm, the system configuration is continuously optimized. Through iterative optimization, the PSO algorithm effectively finds the optimal solution, thereby improving the overall system performance.

- (4)

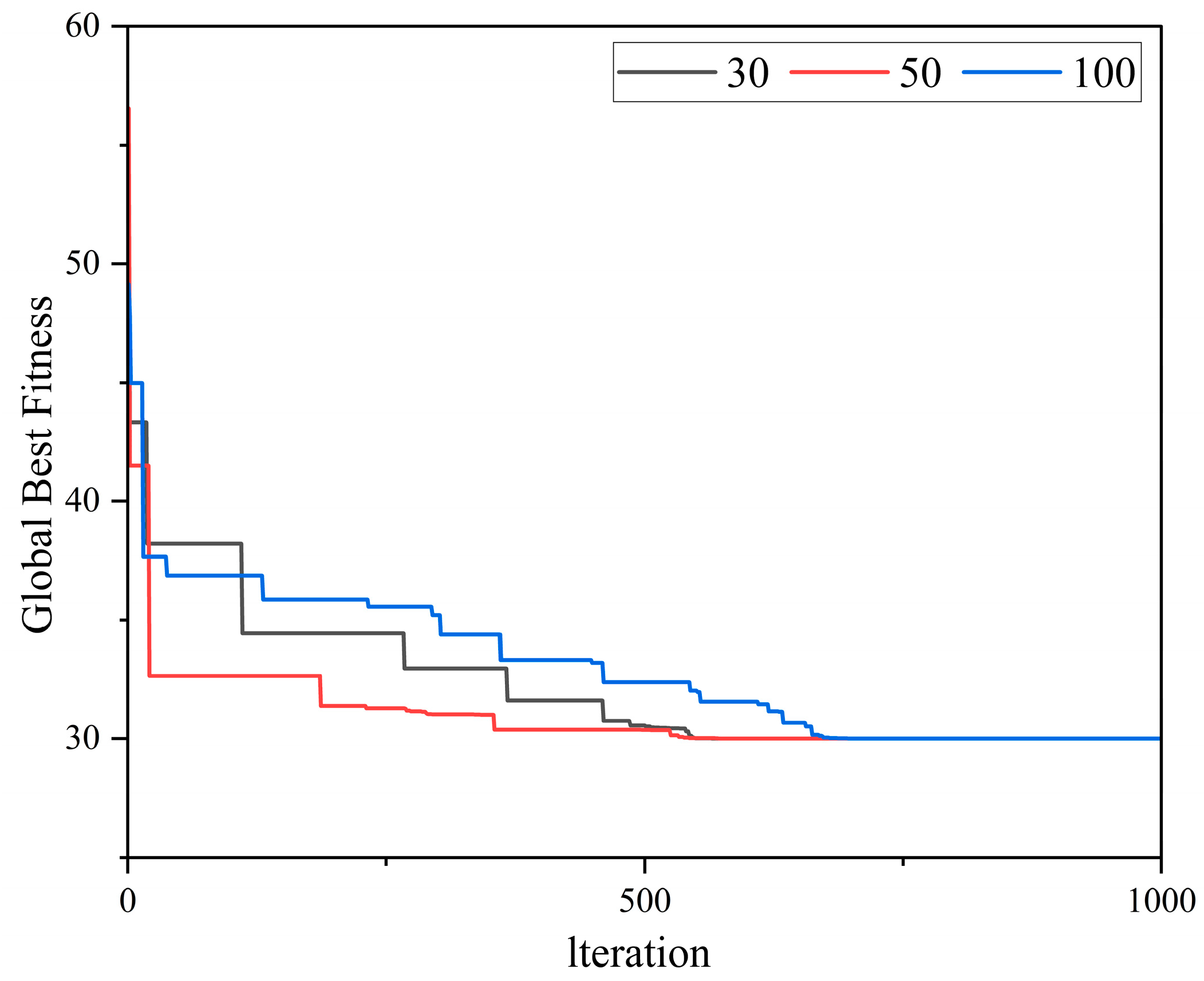

- A sensitivity analysis of the number of particles in the PSO algorithm was conducted, and the results showed that the optimization effect was best when the number of particles was set to 50. This provides valuable guidance for future optimization algorithm configurations, ensuring both computational efficiency and convergence.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

| i | |||

|---|---|---|---|

| 1 | 0.0588460 | 1.325 | 1.0 |

| 2 | −0.06136111 | 1.87 | 1.0 |

| 3 | −0.002650473 | 2.5 | 2.0 |

| 4 | 0.002731125 | 2.8 | 2.0 |

| 5 | 0.001802374 | 2.938 | 2.42 |

| 6 | −0.0012150707 | 3.14 | 2.63 |

| 7 | 0.958842 × 10−4 | 3.37 | 3.0 |

| 8 | −0.1109040 × 10−6 | 3.75 | 4.0 |

| 9 | 0.1264403 × 10−9 | 4.0 | 5.0 |

| Time (min) | Wind Speed (m/s) | Wind Speed Uncertainty (±m/s) | Wind Direction (°) |

|---|---|---|---|

| 0 | 3.5 | ±0.3 | 45 |

| 10 | 3.2 | ±0.3 | 42 |

| 20 | 3.8 | ±0.4 | 47 |

| 30 | 3.6 | ±0.4 | 50 |

| 40 | 4 | ±0.3 | 48 |

| 50 | 3.9 | ±0.5 | 53 |

| 60 | 4.3 | ±0.5 | 57 |

| 70 | 4.5 | ±0.4 | 55 |

| 80 | 4.1 | ±0.5 | 59 |

| 90 | 4.6 | ±0.5 | 63 |

| 100 | 4.8 | ±0.5 | 60 |

| 110 | 4.5 | ±0.5 | 65 |

| 120 | 5 | ±0.4 | 68 |

| 130 | 4.7 | ±0.6 | 66 |

| 140 | 5.2 | ±0.6 | 70 |

| 150 | 5.4 | ±0.6 | 72 |

| 160 | 5.1 | ±0.6 | 75 |

| 170 | 5.3 | ±0.7 | 73 |

| 180 | 5.6 | ±0.7 | 77 |

| 190 | 5.8 | ±0.6 | 75 |

| 200 | 5.4 | ±0.7 | 78 |

| 210 | 5.9 | ±0.7 | 82 |

| 220 | 6.1 | ±0.7 | 80 |

| 230 | 6 | ±0.8 | 85 |

| 240 | 6.2 | ±0.8 | 83 |

| 250 | 6.3 | ±0.8 | 87 |

| 260 | 6.5 | ±0.5 | 89 |

| 270 | 6.6 | ±0.8 | 86 |

| 280 | 6.4 | ±0.9 | 91 |

| 290 | 6.8 | ±0.3 | 88 |

| 300 | 6.9 | ±0.8 | 92 |

| 310 | 6.7 | ±0.4 | 90 |

| 320 | 7 | ±0.9 | 95 |

| 330 | 6.8 | ±1.2 | 93 |

| 340 | 7.2 | ±1.0 | 98 |

| 350 | 7.1 | ±1.0 | 100 |

| 360 | 7.3 | ±0.3 | 97 |

References

- Cho, H.; Mago, P.J.; Luck, R.; Chamra, L.M. Evaluation of CCHP systems performance based on operational cost, primary energy consumption, and carbon dioxide emission by utilizing an optimal operation scheme. Appl. Energy 2009, 86, 2540–2549. [Google Scholar] [CrossRef]

- Gu, W.; Wu, Z.; Yuan, X. Microgrid economic optimal operation of the combined heat and power system with renewable energy. In Proceedings of the IEEE PES General Meeting, Minneapolis, MN, USA, 25–29 July 2010; pp. 1–6. [Google Scholar]

- Liu, C.; Wang, C.; Yin, Y.; Yang, P.; Jiang, H. Bi-level dispatch and control strategy based on model predictive control for community integrated energy system considering dynamic response performance. Appl. Energy 2022, 310, 118641. [Google Scholar] [CrossRef]

- Zhang, Z.; Wang, C.; Lv, H.; Liu, F.; Sheng, H.; Yang, M. Day-ahead optimal dispatch for integrated energy system considering power-to-gas and dynamic pipeline networks. IEEE Trans. Ind. Appl. 2021, 57, 3317–3328. [Google Scholar]

- Li, Y.; Zhang, J.; Wu, X.; Shen, J.; Lee, K.Y. Optimal design of combined cooling, heating and power multi-energy system based on load tracking performance evaluation of adjustable equipment. Appl. Therm. Eng. 2022, 211, 118423. [Google Scholar]

- Rafiei, M.; Ricardez-Sandoval, L.A. New frontiers, challenges, and opportunities in integration of design and control for enterprise-wide sustainability. Comput. Chem. Eng. 2020, 132, 106610. [Google Scholar]

- Lenhoff, A.M.; Morari, M. Design of resilient processing plants—I Process design under consideration of dynamic aspects. Chem. Eng. Sci. 1982, 37, 245–258. [Google Scholar]

- Seferlis, P.; Grievink, J. Process design and control structure screening based on economic and static controllability criteria. Comput. Chem. Eng. 2001, 25, 177–188. [Google Scholar]

- Papadopoulos, A.I.; Seferlis, P.; Linke, P. A framework for the integration of solvent and process design with controllability assessment. Chem. Eng. Sci. 2017, 159, 154–176. [Google Scholar]

- Yu, W.; Li, K.; Li, S.; Ma, X.; Zhang, C. A bi-level scheduling strategy for integrated energy systems considering integrated demand response and energy storage co-optimization. J. Energy Storage 2023, 66, 107508. [Google Scholar]

- Shen, F.; Zhao, L.; Wang, M.; Du, W.; Qian, F. Data-driven adaptive robust optimization for energy systems in ethylene plant under demand uncertainty. Appl. Energy 2022, 307, 118148. [Google Scholar] [CrossRef]

- Yu, J.; Ryu, J.H.; Lee, I.B. A stochastic optimization approach to the design and operation planning of a hybrid renewable energy system. Appl. Energy 2019, 247, 212–220. [Google Scholar] [CrossRef]

- Ioannou, A.; Fuzuli, G.; Brennan, F.; Yudha, S.W.; Angus, A. Multi-stage stochastic optimization framework for power generation system planning integrating hybrid uncertainty modelling. Energy Econ. 2019, 80, 760–776. [Google Scholar] [CrossRef]

- Gong, A.; MacNeill, R.; Verstraete, D.; Palmer, J.L. Analysis of a Fuel-Cell/Battery/Supercapacitor Hybrid Propulsion System for a UAV using a Hardware-in-the-Loop Flight Simulator. In Proceedings of the 2018 AIAA/IEEE Electric Aircraft Technologies Symposium. Cincinnati, Ohio: American Institute of Aeronautics and Astronautics, Cincinnati, OH, USA, 12–14 July 2018. [Google Scholar]

- Zhang, X.; Liu, L.; Dai, Y.; Shen, H. Design and Experiment of Fuel Cell UAV Power System. J. Aeronaut. 2018, 39, 162–171. [Google Scholar]

- Zhang, X.; Liu, L.; Dai, Y. Energy Management and Flight State Coupling of Fuel Cell UAVs. J. Aeronaut. 2019, 40, 92–108. [Google Scholar]

- Fang, M.; Sun, X.; Huang, R.; Qian, G.; Geng, H.; Wen, G.; Xu, C.; Xu, C.; Liu, L. Automatic Detection of Power Pole Towers for High-Resolution Satellite Remote Sensing. Aerosp. Return Remote Sens. 2021, 42, 118–126. [Google Scholar]

- Gong, A.; Palmer, J.L.; Brian, G.; Harvey, J.R.; Verstraete, D. Performance of a hybrid, fuel-cell-based power system during simulated small unmanned aircraft missions. Int. J. Hydrogen Energy 2016, 41, 11418–11426. [Google Scholar] [CrossRef]

- Min, Z.; Lei, T.; Wang, Y.; Zhang, X.; Zhang, X. The Evaluation and Optimization of Power Architecture of Distributed Electrical Propulsion Fuel-cell UAV. In Proceedings of the IECON 2020 The 46th Annual Conference of the IEEE Industrial Electronics Society, Singapore, 18–21 October 2020; pp. 2376–2381. [Google Scholar]

- Zheng, Q.; Zhao, Y. Modeling wind uncertainties for stochastic trajectory synthesis. In Proceedings of the 11th AIAA Aviation Technology, Integration, and Operations (ATIO) Conference, including the AIAA Balloon Systems Conference and 19th AIAA Lighter-Than, Virginia Beach, VA, USA, 20–22 September 2011; p. 6858. [Google Scholar]

| Parameter | Value | Parameter | Value | Parameter | Value |

|---|---|---|---|---|---|

| ω1 | 0.4 | K1 | 0.2 | P1 | 500 |

| ω2 | 0.6 | K2 | 0.4 | P2 | 2000 |

| k1 | 0.1 | K3 | 0.1 | P3 | 300 |

| k2 | 0.9 | K4 | 0.2 | P4 | 100 |

| k3 | 0.5 | C1 | 500 | P1,ev | 50 |

| k4 | 0.5 | C2 | 800 | P2,ev | 250 |

| Pf | 0.0025 | C3 | 20 | P3,ev | 50 |

| Nm | 50 | C4 | 400 | P4,ev | 20 |

| Nmn | 4 | Ne | 4 | Nu | 2000 |

| Parameter | Value |

|---|---|

| N | 50 |

| Max_iteration | 1000 |

| dim | 4 |

| lb | [0, 0, 0, 0] |

| ub | [5, 10, 100, 12] |

| Device | Parameter |

|---|---|

| Fuel cell (Kw) | Pmax = 3.367, Pr = 2.525 |

| Lithium battery (kWh) | Battery Capacity 7.694 |

| Cooling system (W) | Thermal Power 53.128 |

| Hydrogen storage tank (L) | V = 9.328 |

| Indicators | PSO | GA |

|---|---|---|

| The optimal lifecycle cost (CNY ten thousand) | 30.15 | 31.20 |

| Number of iterations | 143 | 256 |

| Computation time (s) | 63 | 102 |

| Post-iteration error (%) | 0.5 | 1.2 |

| Number of feasible solutions (%) | 98 | 92 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, H.; Wang, C.; Yuan, S.; Zhu, H.; Sun, L. A Capacity Allocation Method for Long-Endurance Hydrogen-Powered Hybrid UAVs Based on Two-Stage Optimization. Algorithms 2025, 18, 196. https://doi.org/10.3390/a18040196

Li H, Wang C, Yuan S, Zhu H, Sun L. A Capacity Allocation Method for Long-Endurance Hydrogen-Powered Hybrid UAVs Based on Two-Stage Optimization. Algorithms. 2025; 18(4):196. https://doi.org/10.3390/a18040196

Chicago/Turabian StyleLi, Haitao, Chenyu Wang, Shufu Yuan, Hui Zhu, and Li Sun. 2025. "A Capacity Allocation Method for Long-Endurance Hydrogen-Powered Hybrid UAVs Based on Two-Stage Optimization" Algorithms 18, no. 4: 196. https://doi.org/10.3390/a18040196

APA StyleLi, H., Wang, C., Yuan, S., Zhu, H., & Sun, L. (2025). A Capacity Allocation Method for Long-Endurance Hydrogen-Powered Hybrid UAVs Based on Two-Stage Optimization. Algorithms, 18(4), 196. https://doi.org/10.3390/a18040196