2.1.1. Objective Function

Minimizing the total energy consumption (

), total energy cost (

), and total carbon emissions (

) represents the ultimate goal of this system. The load rate (

) of each component serves as a critical decision variable for these parameters, allowing for the optimization of energy structure, component capacities, and load rates to achieve the best possible outcomes.

where

is the objective function,

is different energy components,

is the constraint function,

is the number of decision variables, and

is the number of constraint functions.

The overall gain of the system, which serves as the economic objective, aims to enhance the system’s competitiveness by maximizing its economic efficiency while fulfilling the ultimate goal. The optimization of the objective function leads to the maximization of the overall gain of the system.

where

is the system’s overall gain,

is the system’s total income,

is the system’s total expenses,

is the total equipment,

is the present value factor for specific components of the equipment,

is the flow of energy,

is cost,

is the depreciation coefficient of the equipment, and

is the equipment residual value coefficient. The superscript

is production,

is energy storage,

is energy purchase,

is fixed asset depreciation,

is equipment residual value, and

is energy sales. The subscript

is each individual piece of equipment,

is the system’s energy demand,

is load intervals, and

is time steps.

2.1.2. Constraint Conditions

In this system, the load ratios of various components are constrained by the balance of different resources, power generation, energy storage, and supply.

For solar photovoltaic panels, their electrical output is nonlinearly correlated with solar radiation, which can be described by the following calculation formula:

where

,

,

,

,

,

,

,

, and

are the photovoltaics, refrigeration unit, lithium bromide absorption chiller, CHP, gas boiler, power grid, natural gas station, wind turbine, and ground source heat pump,

,

,

, and

represent electricity, heat, cool, and gas loads,

is the capacity of the energy component,

is solar radiation in kW, and

is wind speed in m/s.

For the wind turbine, its electrical output is nonlinearly related to wind speed.

For the ground source heat pump, its electrical input is nonlinearly related to its load rate.

For airborne main engines and double-working condition main engines, their electrical input is nonlinearly related to their load rate.

For lithium bromide refrigeration machines, their heat input is nonlinearly related to their load rate.

For CHP and gas boilers, their gas flow rate is nonlinearly related to their load rate.

The power grid can be regarded as a flexible generator with constant efficiency, and its output can be calculated with Equation (22), with the output power not exceeding its maximum carrying capacity.

where

is the electrical output power from the grid in kWh.

The CHP and gas boilers are dispatchable variables; the output power of the natural gas station is calculated with Equation (25).

where

represents the natural gas flow rate, and the gas flow rate (m

3/h) is converted into power (kW) by using the calorific value of natural gas (kWh/m

3).

The energy storage and output power within a certain period can be expressed as shown in Equation (18), with the maximum energy storage and power transmission conditions subjected to the constraints of Equations (20) and (21).

where

is the total stored energy of each piece of energy storage equipment,

is the energy storage power within a certain time period,

is the energy storage efficiency of the energy storage component,

is the energy transfer efficiency of the energy storage component,

is the duration of energy storage and transfer for the energy storage component,

is the number of components, and

and

denote the efficient storage and output energy related to the total energy storage, respectively.

In the integrated energy systems, electricity is the most commonly used energy source, and its energy structure is also the most complex. The electricity balance equation for it is as follows:

where

is the power consumed by the user, which refers to the power inputted into the user load. Its unit is kW.

Its heat energy balance equation is as follows:

The cold energy balance equation is as follows:

Due to the widespread adoption and utilization of natural gas, many energy systems now incorporate natural gas as a primary clean energy source. This system will also introduce gas equilibrium considerations:

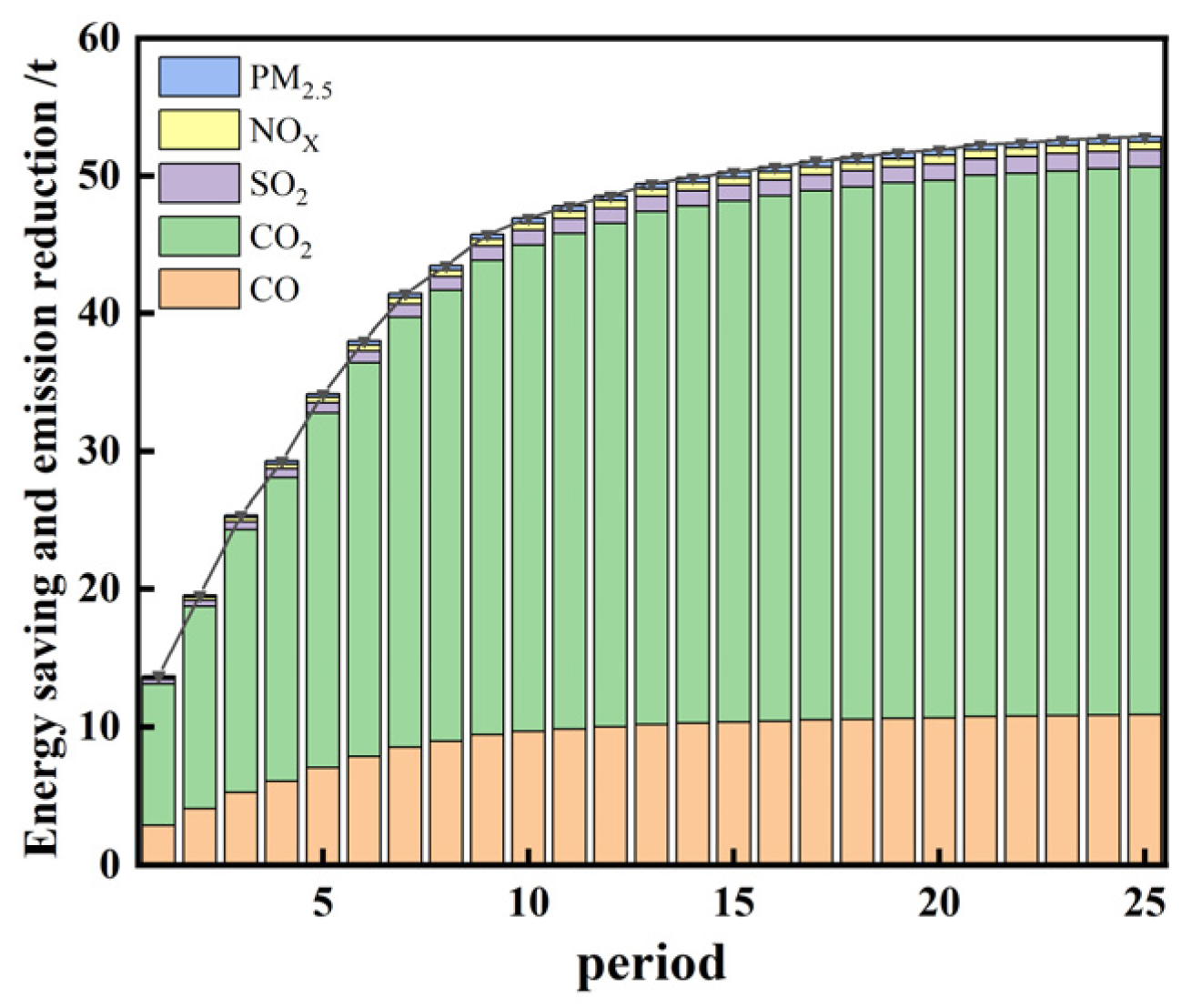

The external energy consumption of the system comprises electricity and natural gas. By considering the consumption factors, energy prices, and emission factors associated with these two energy sources, the energy consumption (

), energy costs (

), and carbon emissions (

) can be calculated.

where

is energy consumption in kWh,

is the energy cost in dollars,

is carbon emissions in kg,

is the duration of continuous operation in hours,

is the consumption factor,

is energy prices in dollars/kWh, and

is the emission factor in kg/kWh.

The system utilizes energy storage in the form of stored energy, which incurs corresponding energy consumption (

) during the storage process. This consumption is mainly associated with the power and consumption factors of all storage components. The energy released from the storage components is considered a positive value of power, which implies an increase in energy consumption, carbon emissions, and energy cost. Similarly, the energy input into the storage components is represented by negative power, which reduces energy consumption, carbon emissions, and energy costs. Therefore,

can be positive or negative. Additionally, the cost (

) and carbon emissions (

) of storing energy can be calculated.

where

is the charge and discharge power in kW.

Additionally, the system incorporates surplus energy selling as a means to capitalize on price differentials, particularly in peak and off-peak electricity pricing, by choosing to sell excess energy during off-peak hours, thereby reducing energy costs. Consequently, the total energy consumption (

) at a given time encompasses the consumption of energy resources (

), storage energy (

), and the revenue generated from selling energy (

). Similarly, total energy costs (

) and carbon emissions (

) can be computed.

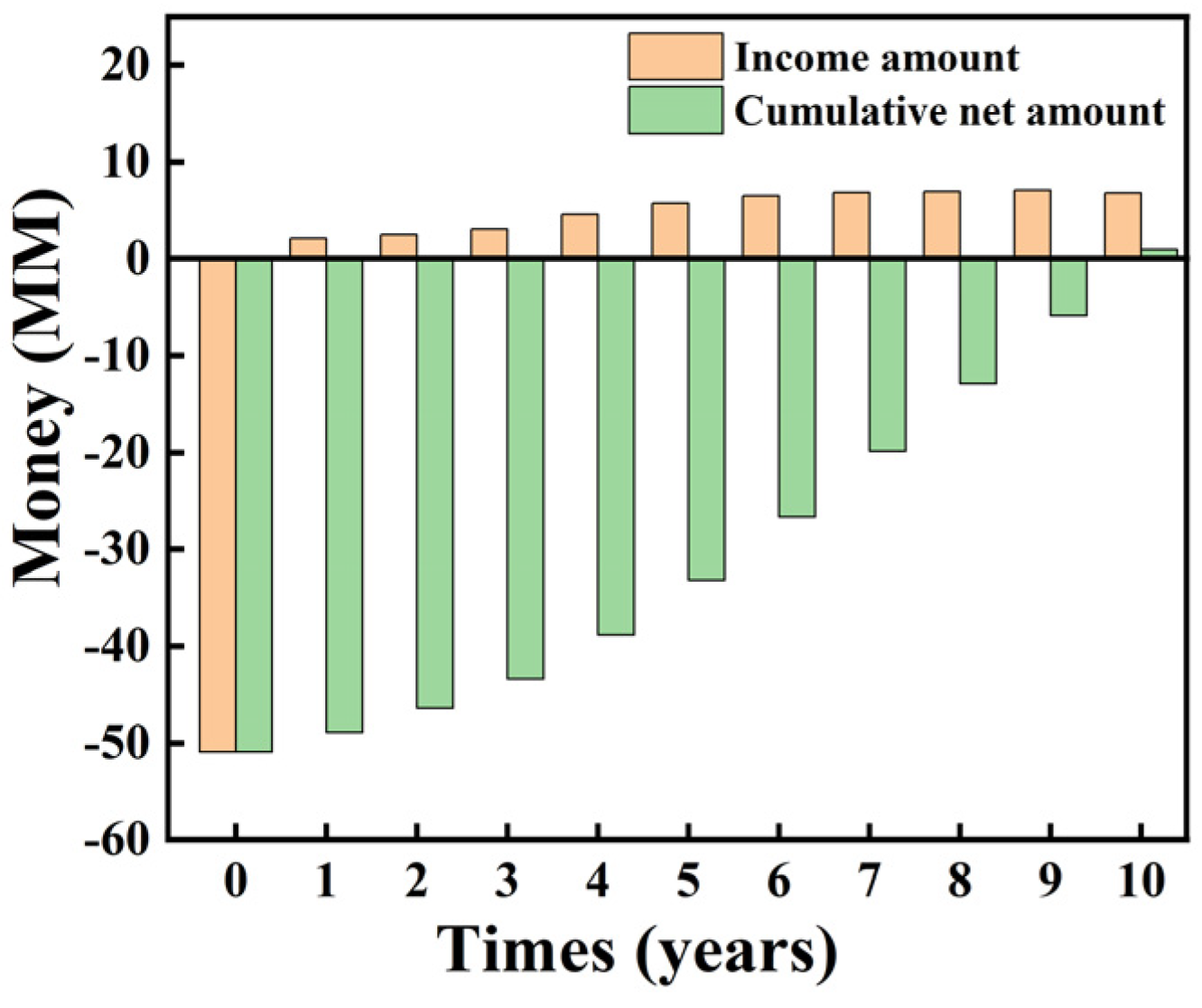

2.1.3. Economic Viability

To validate the feasibility of the system operating with different energy structures, two crucial economic parameters are introduced: net present value (NPV) and internal rate of return (IRR).

NPV refers to the difference between the discounted value of future cash flows generated by an energy structure investment and the project’s investment cost. When

NPV > 0, it indicates that the energy structure can yield profits while meeting the benchmark rate of return. The calculation formula for

NPV is as follows:

where

is cash inflows for each period,

is the initial capital investment, and

is the periodic interest rate.

IRR is a closely related concept to

NPV and refers to the discount rate at which the total present value of cash inflows equals the total present value of cash outflows, resulting in a net present value of zero. The calculation formula for

IRR is as follows:

The economic evaluation of the system’s energy structure is conducted using the IRR. When the IRR exceeds the current discount rate, the NPV of the energy structure becomes greater than zero, indicating the feasibility of this energy structure. Conversely, if the IRR falls below the current discount rate, the energy structure is considered unfeasible. The economic feasibility of the energy structure is assessed by calculating both pre-tax and post-tax values through system operation.

2.1.4. Energy and Component Cycle Optimization Method

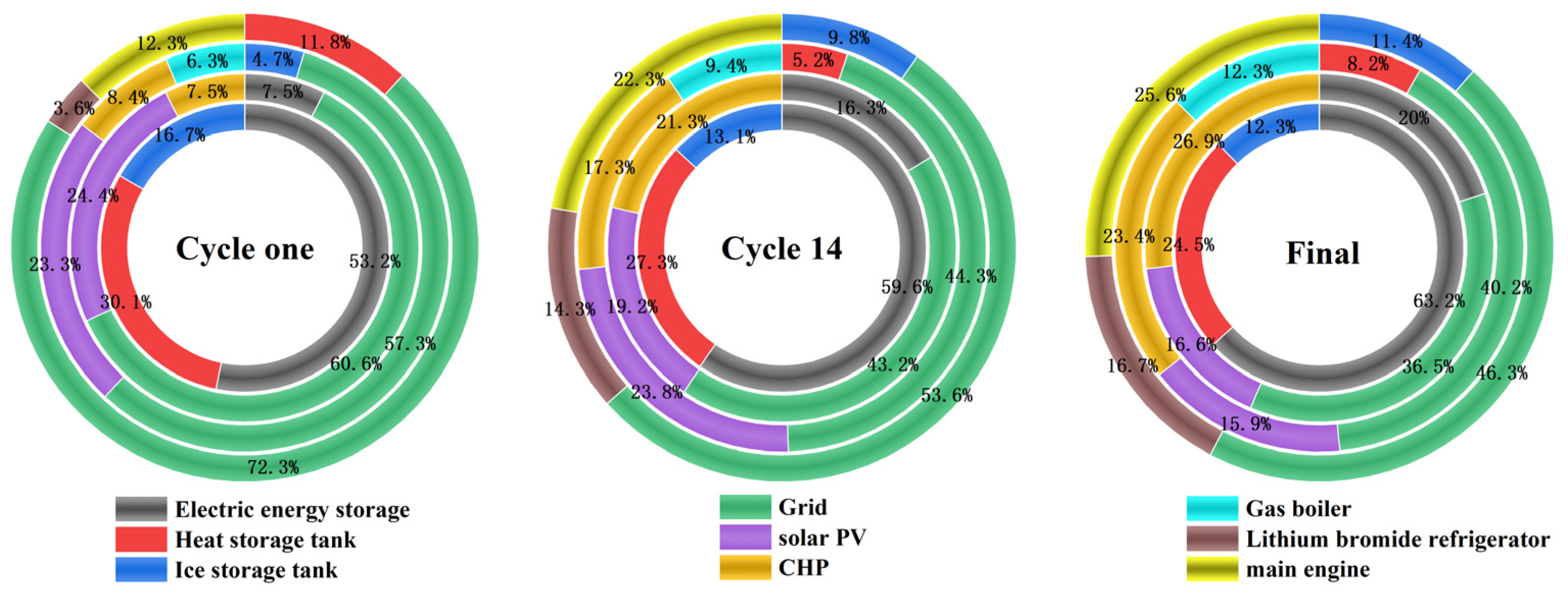

In the optimization design and operation of integrated energy systems, the energy and component cycle (ECC) optimization method will be employed, coupled with scenario simulations. Scenario simulations utilize data related to energy structure and component parameters, combined with functions within neural networks, to perform simulations using data derived from daily scenario models. It enables the calculation of real-time data on component operation, energy consumption, and energy conservation effects. Scenario simulations over a single cycle are used to describe the uncertainty of energy demand and energy resources in an integrated energy system. Additionally, random system disturbances are introduced to simulate special circumstances that may occur in real-world situations. The ECC optimization method uses component capacity, power, and energy attributes as variables, with the ultimate goals of minimizing the total energy consumption (), total energy cost (), and total carbon emissions () and ensuring the economic feasibility of the energy structure.

By generating random scenario data over cycles through simulation, this method is employed to evaluate and optimize system design solutions. The optimization process is continually refined on a per-cycle basis, ultimately yielding real-time simulation data, energy savings, and economic feasibility for the energy structure. This process involves eight main steps:

Define decision variables. The primary decision variables in this approach encompass component parameters and energy attributes.

Establish operating cycles. Following the scenario simulation method, determine the total operating duration and operating cycles to assess the initial design solution set periodically.

Configure optimization scheme parameters based on the decision variables and operational cycles; set optimization scheme parameters.

Simulate real-time operations. Utilizing component capacities, energy attributes, and operational cycles defined in the initial design solutions, simulate the operational states and power profiles of each component to meet the energy demands and constraints of the current real-time scenario.

Compute scheme performance. Based on the real-time scenario simulation results, calculate the power profiles of various components, total energy cost, total carbon emissions, and total energy consumption over the operational cycle.

Evaluate schemes. Assess the optimization and improvements needed for the current operational cycle based on the performance from the simulation.

Determine the termination conditions. If the simulated runtime reaches the predefined operational time, exit the ECC optimization method and output all the result data. Otherwise, continue with step 8.

Update optimization schemes. According to the results of the simulation and evaluation, retain certain optimization schemes within the collection and remove others to accommodate new optimization methods. Then, return to step 4 to continue the cycle simulation.