Flexible Epoxy Resin Formed Upon Blending with a Triblock Copolymer through Reaction-Induced Microphase Separation

Abstract

:1. Introduction

2. Experimental

2.1. Materials

2.2. Synthesis of Flexible Epoxy Resins

2.3. Characterization

3. Results and Discussion

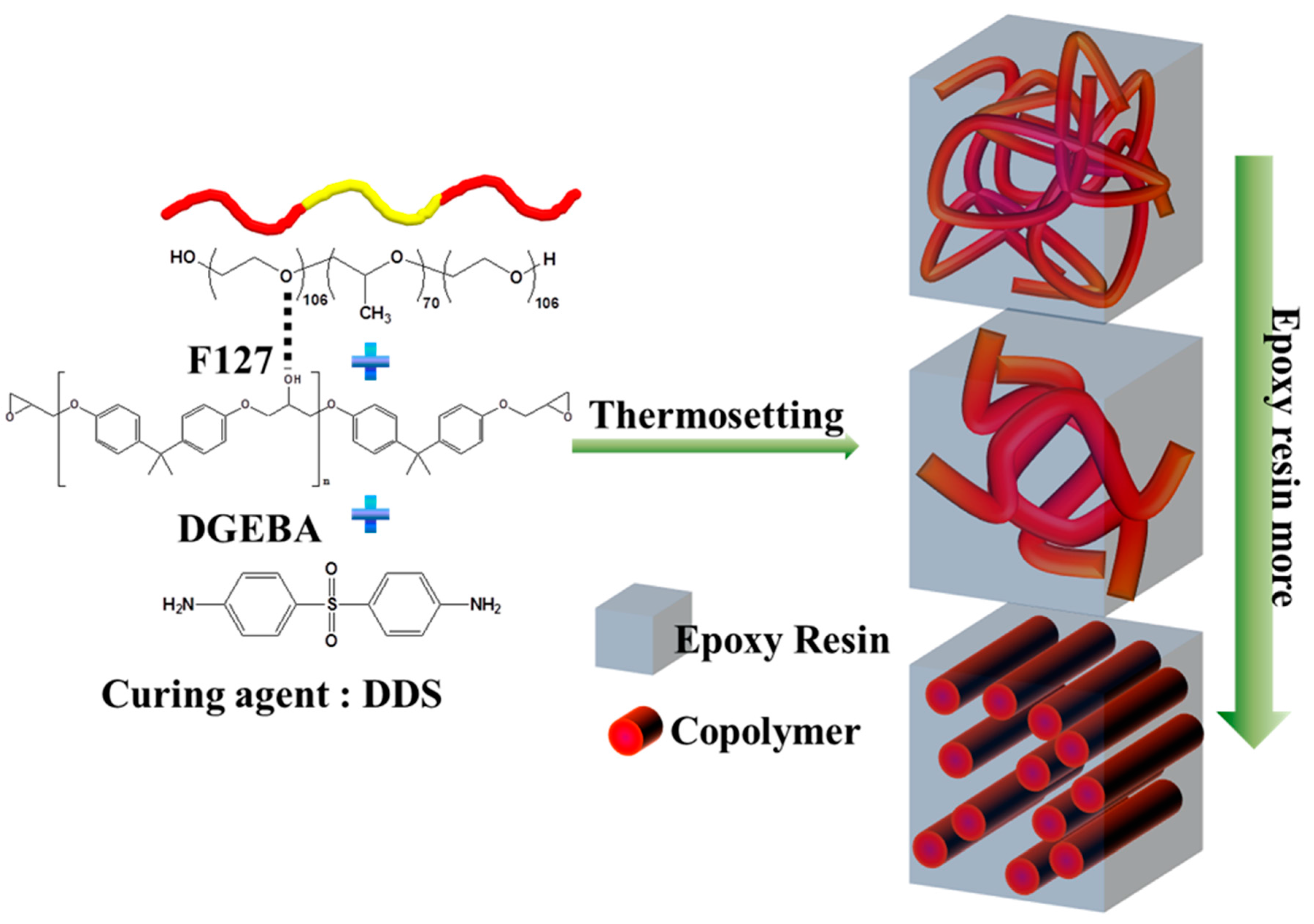

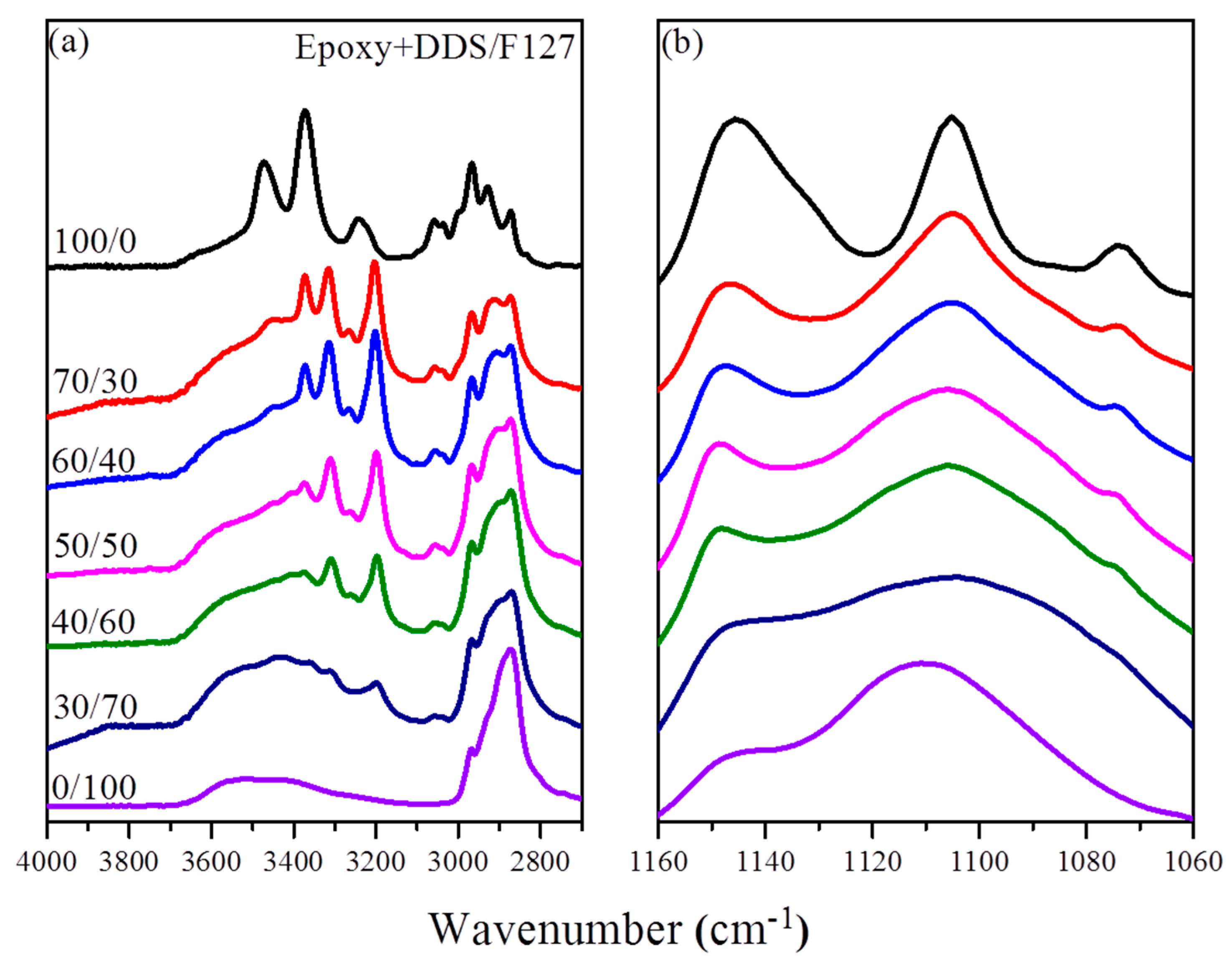

3.1. FTIR Spectroscopic Analyses of DGEBA + DDS/F127 Block Copolymer Blends

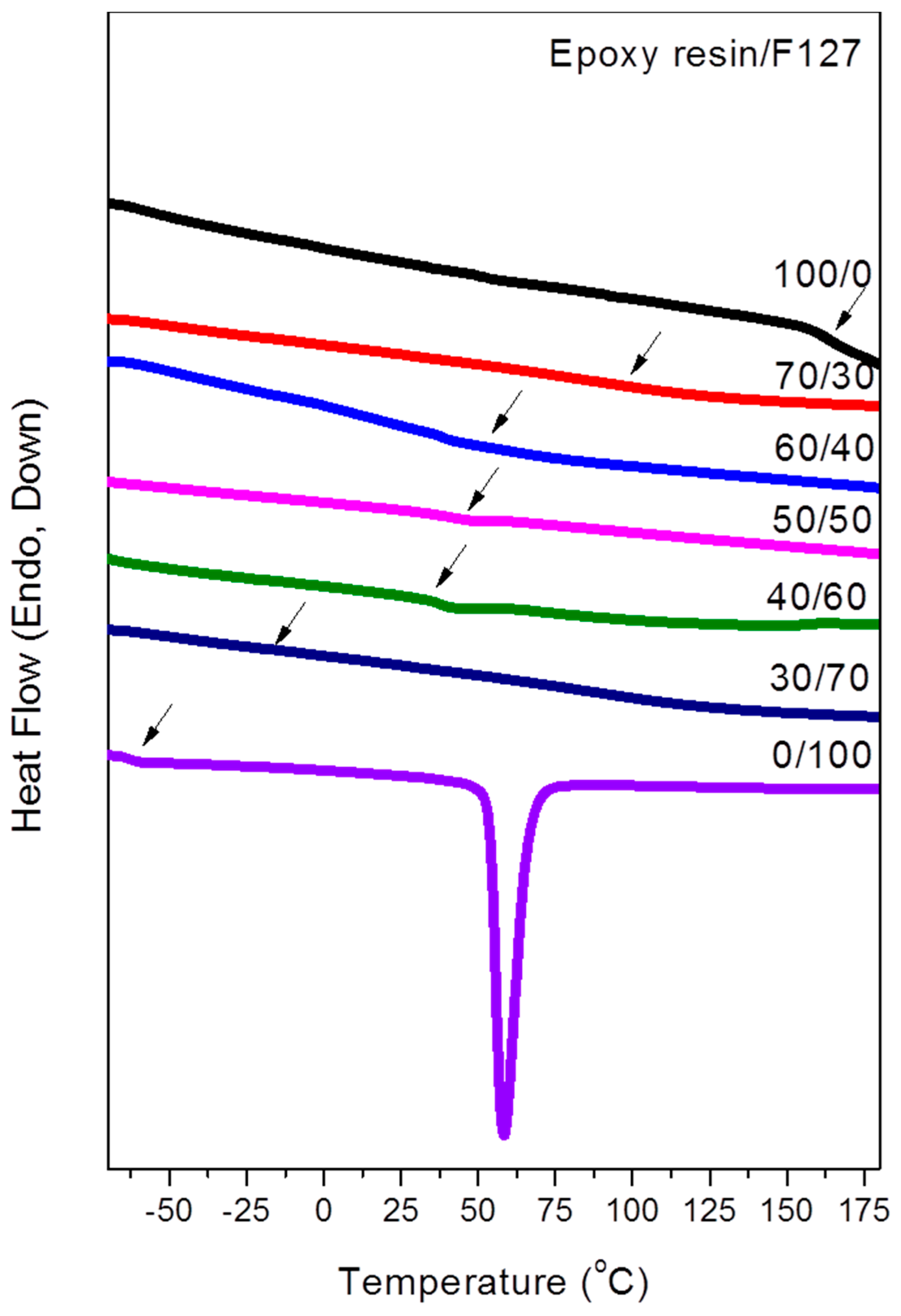

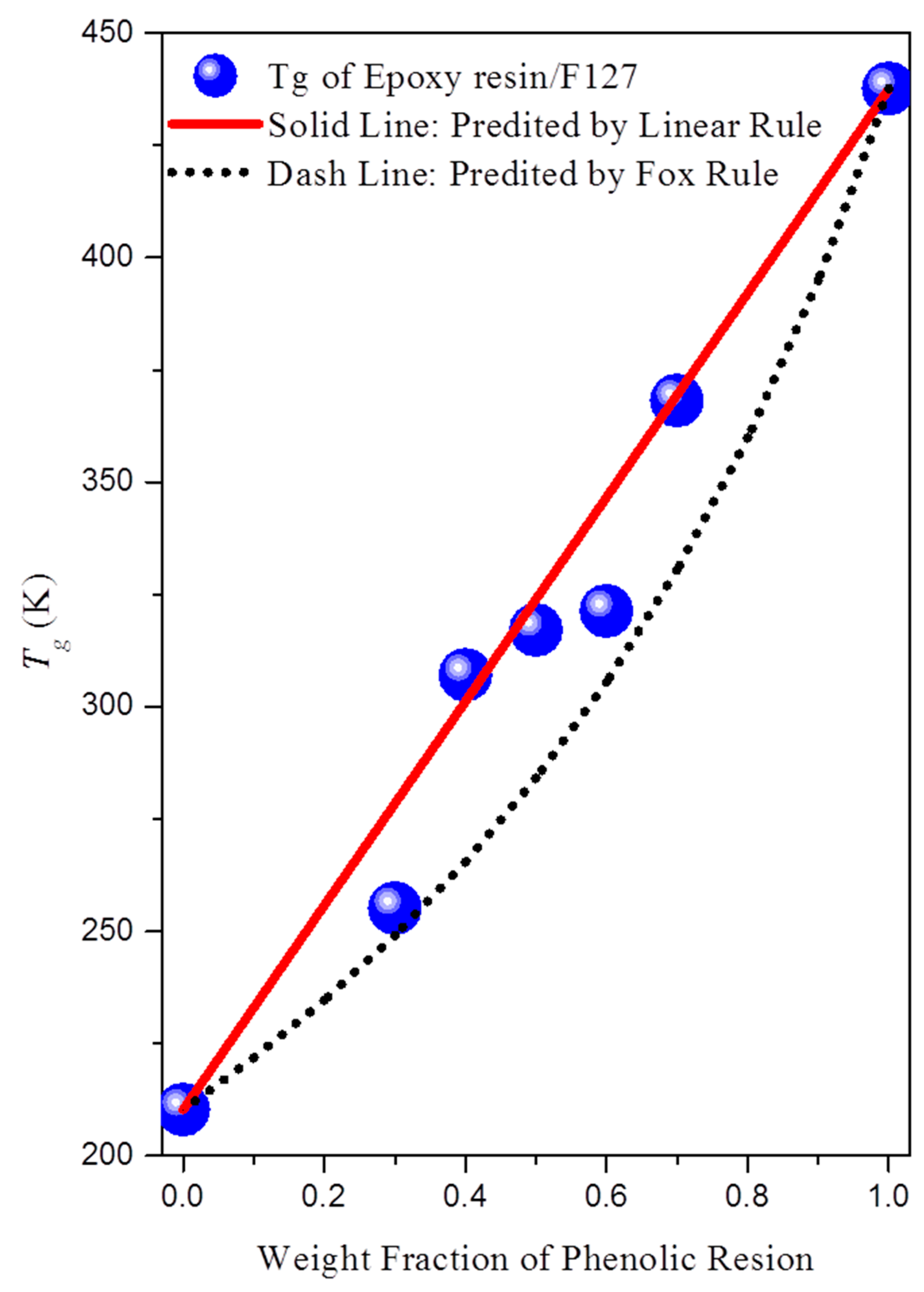

3.2. Thermal Analyses

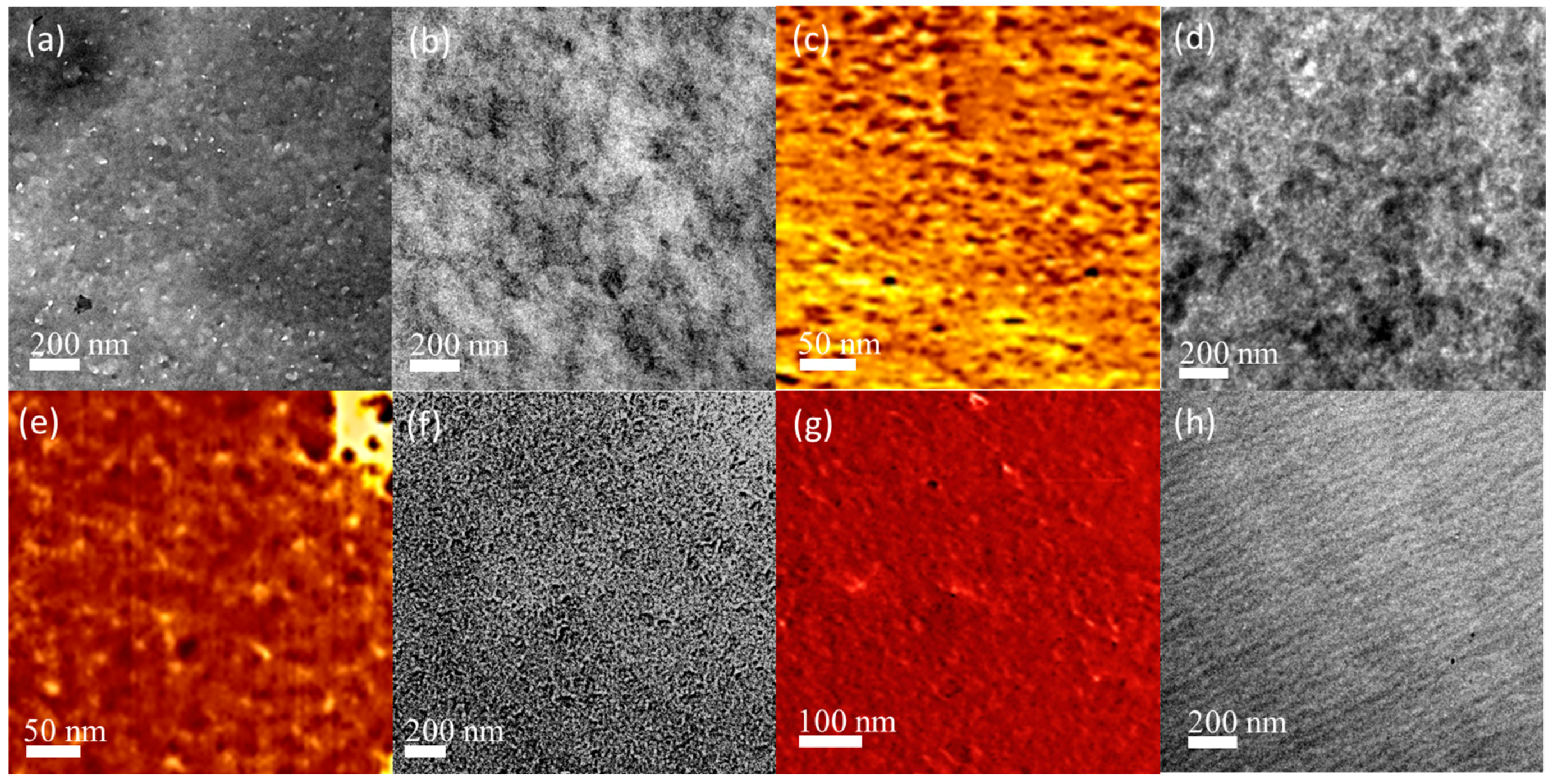

3.3. Phase Behavior of Epoxy Resin/F127 Blends

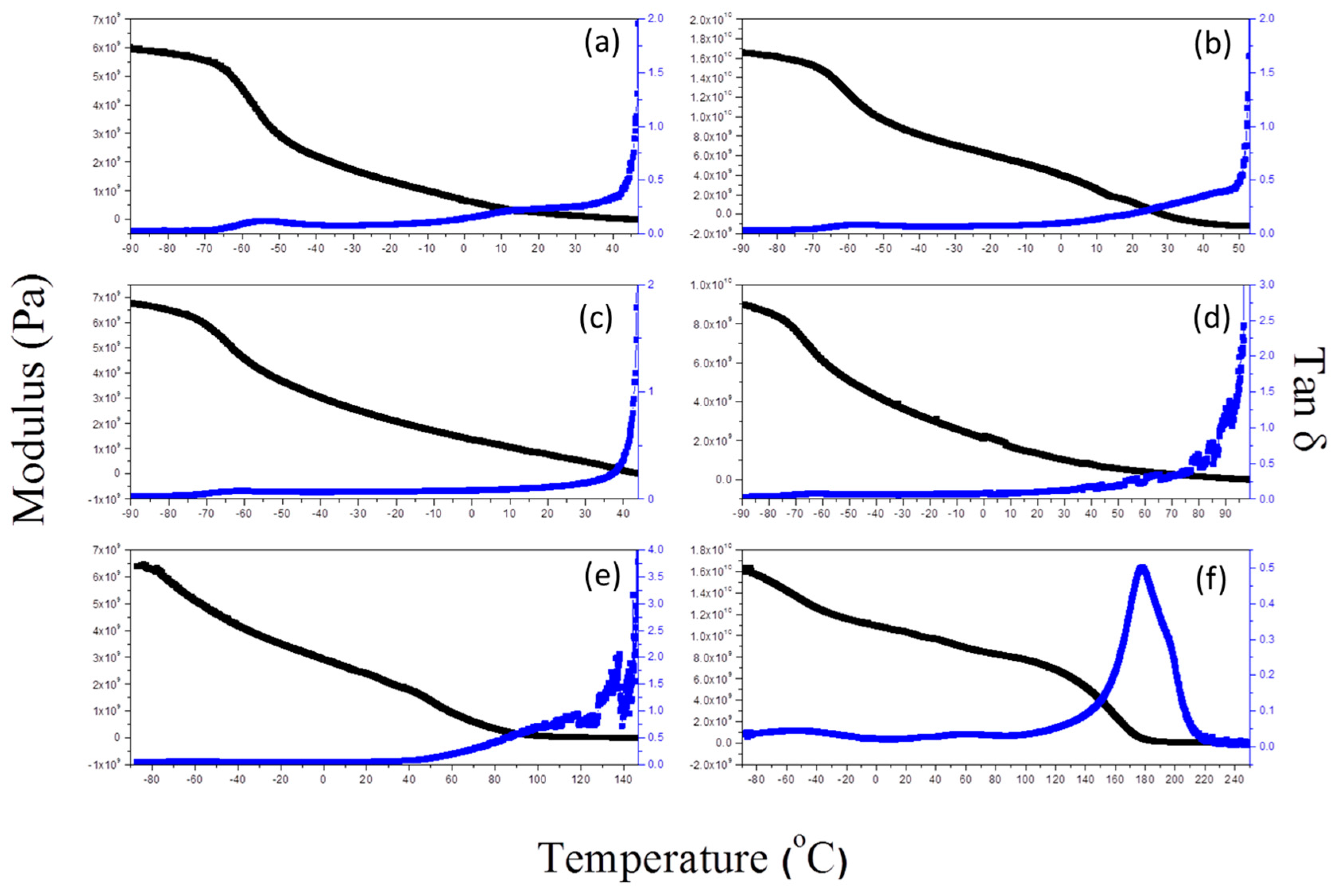

3.4. Mechanical Properties of Epoxy Resin

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Nakamura, Y.; Yamaguchi, M.; Okubo, M.; Matsumoto, T. Effects of particle size on mechanical and impact properties of epoxy resin filled with spherical silica. J. Appl. Polym. Sci. 1992, 45, 1281–1289. [Google Scholar] [CrossRef]

- Ho, T.H.; Wang, C.S. Modification of epoxy resins by hydrosilation for electronic encapsulation application. J. Appl. Polym. Sci. 1994, 54, 13–23. [Google Scholar] [CrossRef]

- Kugel, A.; Chisholm, B.; Ebert, S.; Jepperson, M.; Jarabek, L.; Stafslien, S. Antimicrobial polysiloxane polymers and coatings containing pendant levofloxacin. Polym. Chem. 2010, 1, 442–452. [Google Scholar] [CrossRef]

- Mauro, M.; Acocella, M.R.; Corcione, C.E.; Maffezzoli, A.; Guerra, G. Catalytic activity of graphite-based nanofillers on cure reaction of epoxy resins. Polymer 2014, 55, 5612–5615. [Google Scholar] [CrossRef]

- Johnsen, B.B.; Kinloch, A.J.; Taylor, A.C. Toughness of syndiotactic polystyrene/epoxy polymer blends: Microstructure and toughening mechanisms. Polymer 2005, 46, 7352–7369. [Google Scholar] [CrossRef]

- Puglia, D.; Maria, H.J.; Kenny, J.M.; Thomas, S. Clay nanostructure and its localisation in an epoxy/liquid rubber blend. RSC Adv. 2013, 3, 24634–24643. [Google Scholar]

- Gonzalez, M.; Kadlec, P.; Štěpánek, P.; Strachota, A.; Matějka, L. Crosslinking of epoxy-polysiloxane system by reactive blending. Polymer 2004, 45, 5533–5541. [Google Scholar] [CrossRef] [Green Version]

- Shariatpanahi, H.; Sarabi, F.; Mirali, M.; Hemmati, M.; Mahdavi, F. Polypropylene-organoclay nanocomposite: Preparation, microstructure, and mechanical properties. J. Appl. Polym. Sci. 2009, 113, 922–926. [Google Scholar] [CrossRef]

- Ingram, S.E.; Pethrick, R.A.; Liggat, J.J. Effects of organically modified clay loading on rate and extent of cure in an epoxy nanocomposite system. Polym. Int. 2008, 57, 1206–1214. [Google Scholar] [CrossRef]

- Gârea, S.A.; Iovu, H.; Stoleriu, S.; Voicu, G. Synthesis and characterization of new nanocomposites based on epoxy resins and organophilic clays. Polym. Int. 2007, 56, 1106–1114. [Google Scholar] [CrossRef]

- Chen, W.Y.; Wang, Y.Z.; Kuo, S.W.; Huang, C.F.; Tung, P.H.; Chang, F.C. Thermal and dielectric properties and curing kinetics of nanomaterials formed from poss-epoxy and meta-phenylenediamine. Polymer 2004, 45, 6897–6908. [Google Scholar] [CrossRef]

- Bian, Y.; Mijović, J. Effect of side chain architecture on dielectric relaxation in polyhedral oligomeric silsesquioxane/polypropylene oxide nanocomposites. Polymer 2009, 50, 1541–1547. [Google Scholar] [CrossRef]

- Zeng, K.; Wang, L.; Zheng, S.; Qian, X. Self-assembly behavior of hepta (3, 3, 3-trifluoropropyl) polyhedral oligomeric silsesquioxane-capped poly (ε-caprolactone) in epoxy resin: Nanostructures and surface properties. Polymer 2009, 50, 685–695. [Google Scholar] [CrossRef]

- Dean, J.M.; Verghese, N.E.; Pham, H.Q.; Bates, F.S. Nanostructure toughened epoxy resins. Macromolecules 2003, 36, 9267–9270. [Google Scholar] [CrossRef]

- Thio, Y.S.; Wu, J.; Bates, F.S. Epoxy toughening using low molecular weight poly (hexylene oxide)-poly (ethylene oxide) diblock copolymers. Macromolecules 2006, 39, 7187–7189. [Google Scholar] [CrossRef]

- Thompson, Z.J.; Hillmyer, M.A.; Liu, J.; Sue, H.J.; Dettloff, M.; Bates, F.S. Block copolymer toughened epoxy: Role of cross-link density. Macromolecules 2009, 42, 2333–2335. [Google Scholar] [CrossRef]

- Liu, J.; Thompson, Z.J.; Sue, H.J.; Bates, F.S.; Hillmyer, M.A.; Dettloff, M.; Jacob, G.; Verghese, N.; Pham, H. Toughening of epoxies with block copolymer micelles of wormlike morphology. Macromolecules 2010, 43, 7238–7243. [Google Scholar] [CrossRef]

- Wu, S.; Guo, Q.; Peng, S.; Hameed, N.; Kraska, M.; Stühn, B.; Mai, Y.W. Toughening epoxy thermosets with block ionomer complexes: A nanostructure–mechanical property correlation. Macromolecules 2012, 45, 3829–3840. [Google Scholar] [CrossRef]

- Maiez-Tribut, S.; Pascault, J.P.; Soule, E.R.; Borrajo, J.; Williams, R.J. Nanostructured epoxies based on the self-assembly of block copolymers: A new miscible block that can be tailored to different epoxy formulations. Macromolecules 2007, 40, 1268–1273. [Google Scholar] [CrossRef]

- Xu, Z.; Zheng, S. Reaction-induced microphase separation in epoxy thermosets containing poly (ε-caprolactone)-block-poly (n-butyl acrylate) diblock copolymer. Macromolecules 2007, 40, 2548–2558. [Google Scholar] [CrossRef]

- Ritzenthaler, S.; Court, F.; David, L.; Girard-Reydet, E.; Leibler, L.; Pascault, J.P. ABC triblock copolymers/epoxy-diamine blends. 1. Keys to achieve nanostructured thermosets. Macromolecules 2002, 35, 6245–6254. [Google Scholar] [CrossRef]

- Meng, F.; Xu, Z.; Zheng, S. Microphase separation in thermosetting blends of epoxy resin and poly (ε-caprolactone)-block-polystyrene block copolymers. Macromolecules 2008, 41, 1411–1420. [Google Scholar] [CrossRef]

- Mijovic, J.; Shen, M.; Sy, J.W.; Mondragon, I. Dynamics and morphology in nanostructured thermoset network/block copolymer blends during network formation. Macromolecules 2000, 33, 5235–5244. [Google Scholar] [CrossRef]

- Kosonen, H.; Ruokolainen, J.; Nyholm, P.; Ikkala, O. Self-organized cross-linked phenolic thermosets: Thermal and dynamic mechanical properties of novolac/block copolymer blends. Polymer 2001, 42, 9481–9486. [Google Scholar] [CrossRef]

- Kosonen, H.; Ruokolainen, J.; Nyholm, P.; Ikkala, O. Self-Organized Thermosets: Blends of hexamethyltetramine cured Novolac with poly(2-vinylpyridine)-block-poly (isoprene). Macromolecules 2001, 34, 3046–3049. [Google Scholar] [CrossRef]

- Valkama, S.; Nykänen, A.; Kosonen, H.; Ramani, R.; Tuomisto, F.; Engelhardt, P.; ten Brinke, G.; Ikkala, O.; Ruokolainen, J. Hierarchical porosity in self-sssembled polymers: Post-modification of block copolymer–phenolic resin Complexes by pyrolysis allows the control of micro-and mesoporosity. Adv. Funct. Mater. 2007, 17, 183–190. [Google Scholar] [CrossRef]

- Li, J.G.; Lin, Y.D.; Kuo, S.W. From microphase separation to self-organized mesoporous phenolic resin through competitive hydrogen bonding with double-crystalline diblock copolymers of poly (ethylene oxide-b-ε-caprolactone). Macromolecules 2011, 44, 9295–9309. [Google Scholar] [CrossRef]

- Li, J.G.; Chung, C.Y.; Kuo, S.W. Transformations and enhanced long-range ordering of mesoporous phenolic resin templated by poly (ethylene oxide-b-ε-caprolactone) block copolymers blended with star poly (ethylene oxide)-functionalized silsesquioxane (POSS). J. Mater. Chem. 2012, 22, 18583–18595. [Google Scholar] [CrossRef]

- Chu, W.C.; Li, J.G.; Kuo, S.W. From flexible to mesoporous polybenzoxazine resins templated by poly (ethylene oxide-b-ε-caprolactone) copolymer through reaction induced microphase separation mechanism. RSC Adv. 2013, 3, 6485–6498. [Google Scholar] [CrossRef]

- Li, J.G.; Chu, W.C.; Jeng, U.; Kuo, S.W. In Situ Monitoring of the Reaction-Induced Self-Assembly of Phenolic Resin Templated by Diblock Copolymers. Macromol. Chem. Phys. 2013, 214, 2115–2123. [Google Scholar] [CrossRef]

- Liu, C.C.; Chu, W.C.; Li, J.G.; Kuo, S.W. Mediated competitive hydrogen bonding form mesoporous phenolic resins templated by Poly (ethylene oxide-b-ε-caprolactone-b-l-lactide) triblock copolymers. Macromolecules 2014, 47, 6389–6400. [Google Scholar] [CrossRef]

- Chu, W.C.; Chiang, S.F.; Li, J.G.; Kuo, S.W. Hydrogen Bonding-Mediated Microphase Separation during the Formation of Mesoporous Novolac-Type Phenolic Resin Templated by the Triblock Copolymer, PEO-b-PPO-b-PEO. Materials 2013, 6, 5077–5093. [Google Scholar] [CrossRef]

- Chu, W.C.; Li, J.G.; Wang, C.F.; Jeong, K.U.; Kuo, S.W. Self-assembled nanostructure of polybenzoxazine resins from reaction-induced microphase separation with poly (styrene-b-4-vinylpyridine) copolymer. J. Polym. Res. 2013, 20, 1–9. [Google Scholar] [CrossRef]

- Liang, C.; Dai, S. Synthesis of mesoporous carbon materials via enhanced hydrogen-bonding interaction. J. Am. Chem. Soc. 2006, 128, 5316–5317. [Google Scholar] [CrossRef] [PubMed]

- Liang, C.; Hong, K.; Guiochon, G.A.; Mays, J.W.; Dai, S. Synthesis of a large-scale highly ordered porous carbon film by self-assembly of block copolymers. Angew. Chem. Int. Ed. 2004, 43, 5785–5789. [Google Scholar] [CrossRef] [PubMed]

- Serman, C.J.; Xu, Y.; Painter, P.C.; Coleman, M.M. Poly(vinyl-phenol)—Polyether-blends. Polymer 1991, 32, 516–522. [Google Scholar] [CrossRef]

| Sample | D (nm) 1 | Modulus (Pa) at 25 °C | Tg (°C) | Epoxy Resin/F127 |

|---|---|---|---|---|

| 100% | - | 1 × 1010 | 164.52 | 100/0 |

| 70% | 16.1 | 2.23 × 109 | 98.23 | 70/30 |

| 60% | 24.5 | 1.16 × 109 | 48.22 | 60/40 |

| 50% | 28.5 | 6.07 × 108 | 43.98 | 50/50 |

| 40% | 16.6 | 4.59 × 108 | 33.96 | 40/60 |

| 30% | 15.5 | 1.75 × 108 | −17.97 | 30/70 |

| F127 | 12.8 | - | −62.84 | 0/100 |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chu, W.-C.; Lin, W.-S.; Kuo, S.-W. Flexible Epoxy Resin Formed Upon Blending with a Triblock Copolymer through Reaction-Induced Microphase Separation. Materials 2016, 9, 449. https://doi.org/10.3390/ma9060449

Chu W-C, Lin W-S, Kuo S-W. Flexible Epoxy Resin Formed Upon Blending with a Triblock Copolymer through Reaction-Induced Microphase Separation. Materials. 2016; 9(6):449. https://doi.org/10.3390/ma9060449

Chicago/Turabian StyleChu, Wei-Cheng, Wei-Sheng Lin, and Shiao-Wei Kuo. 2016. "Flexible Epoxy Resin Formed Upon Blending with a Triblock Copolymer through Reaction-Induced Microphase Separation" Materials 9, no. 6: 449. https://doi.org/10.3390/ma9060449

APA StyleChu, W.-C., Lin, W.-S., & Kuo, S.-W. (2016). Flexible Epoxy Resin Formed Upon Blending with a Triblock Copolymer through Reaction-Induced Microphase Separation. Materials, 9(6), 449. https://doi.org/10.3390/ma9060449