Influence of Hybridizing Flax and Hemp-Agave Fibers with Glass Fiber as Reinforcement in a Polyurethane Composite

Abstract

:1. Introduction

2. Experimental Procedure

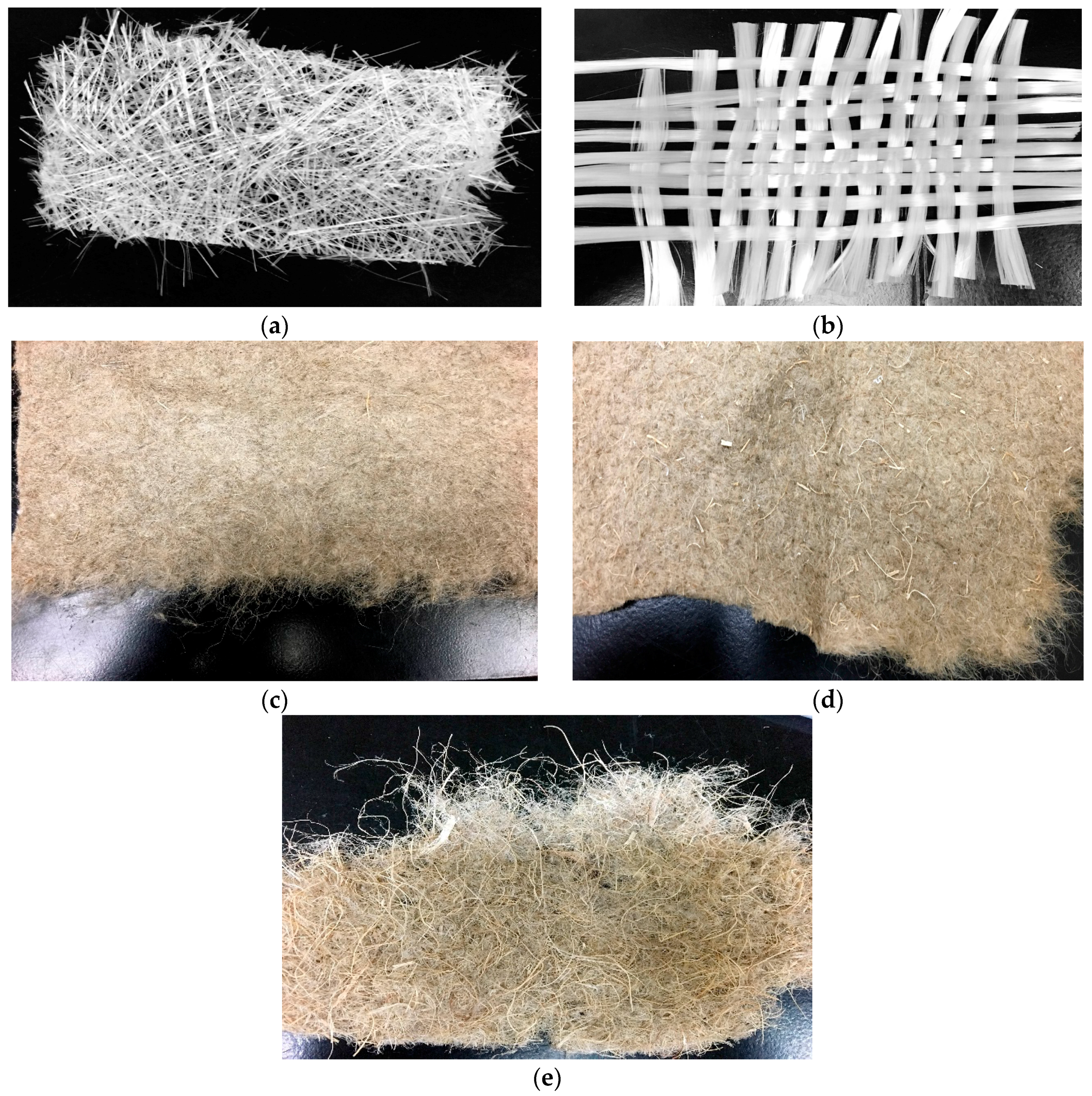

2.1. Fiber Mats

2.2. PU Resin

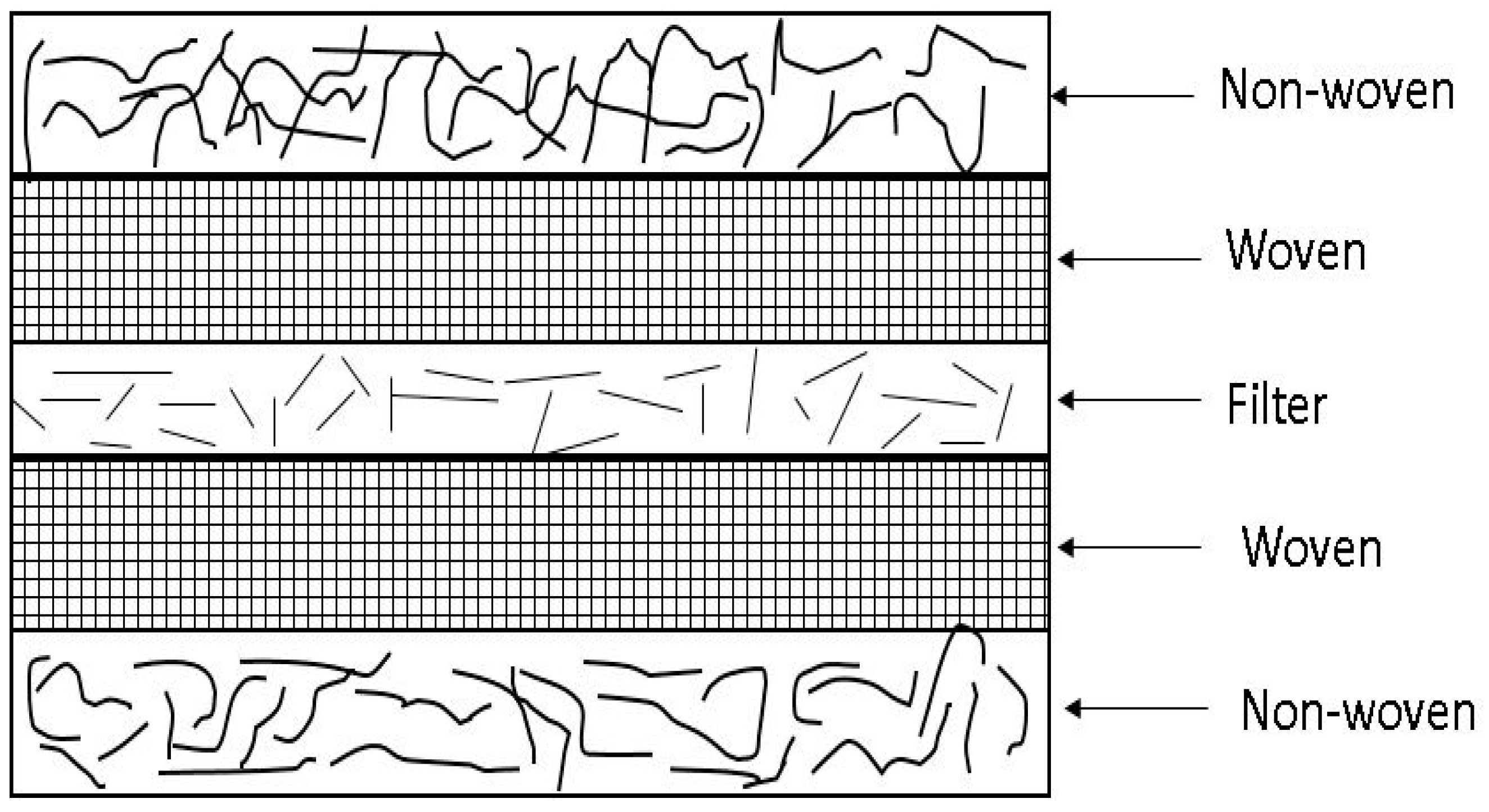

2.3. Sample Preparation

2.4. Testing and Measurements

2.4.1. Void Content of Composites

2.4.2. Water Absorption Test

2.4.3. Coefficient of Linear Thermal Expansion (CLTE)

2.4.4. Flexural Properties

2.4.5. Compression Properties

2.4.6. Hardness

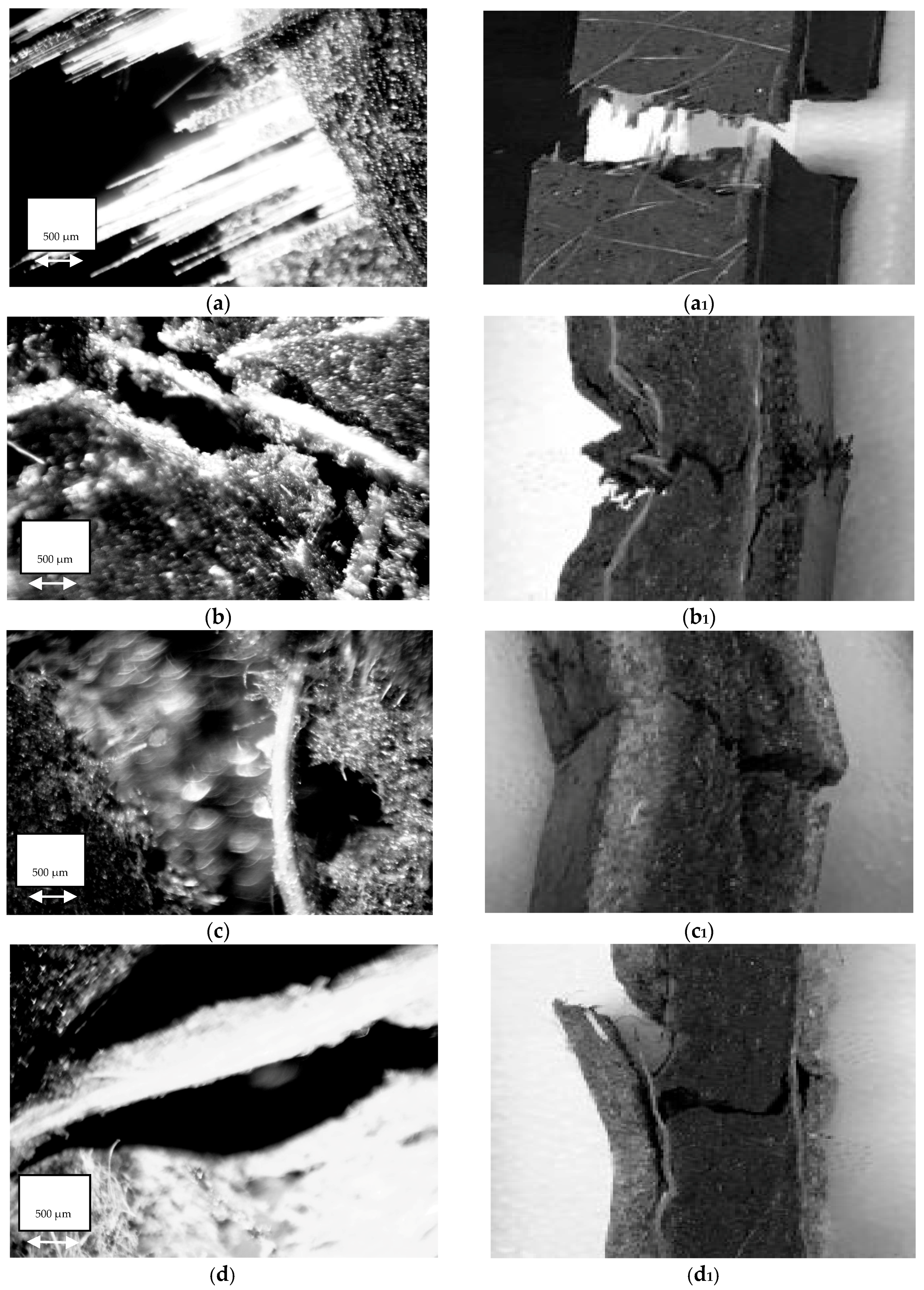

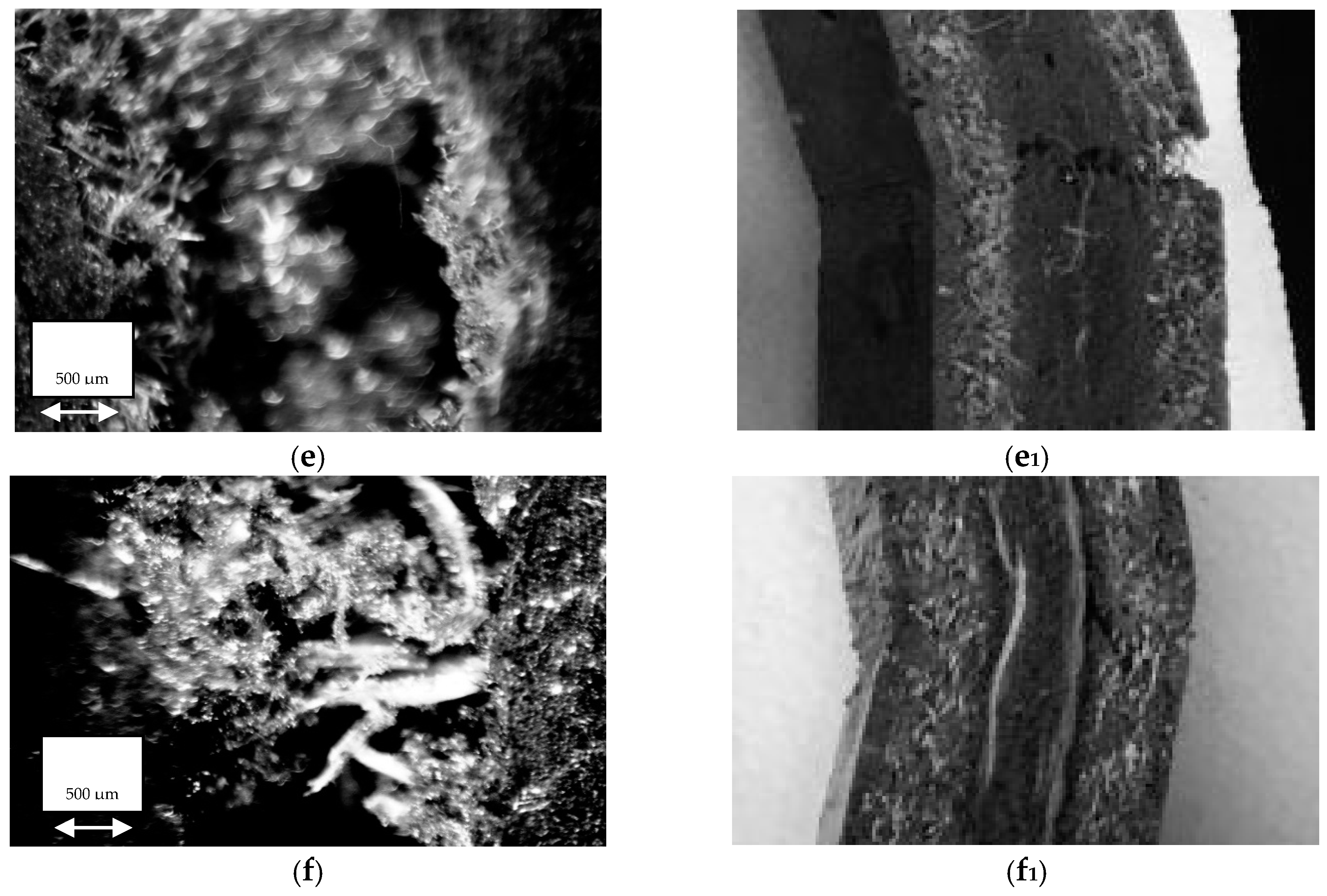

2.5. Light Microscope Images

2.6. Statistical Analysis

3. Results and Discussion

3.1. Void Content

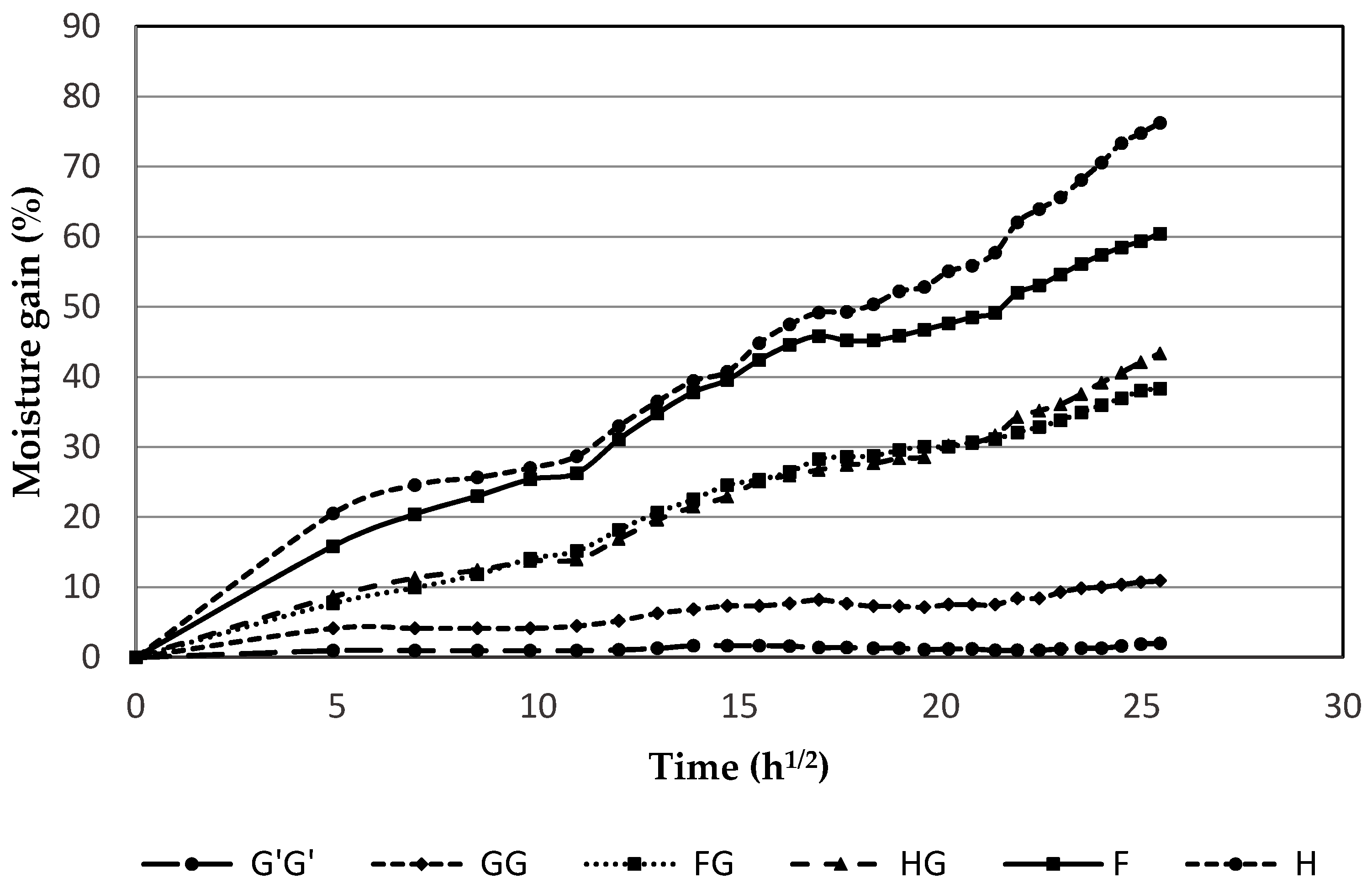

3.2. Water Absorption

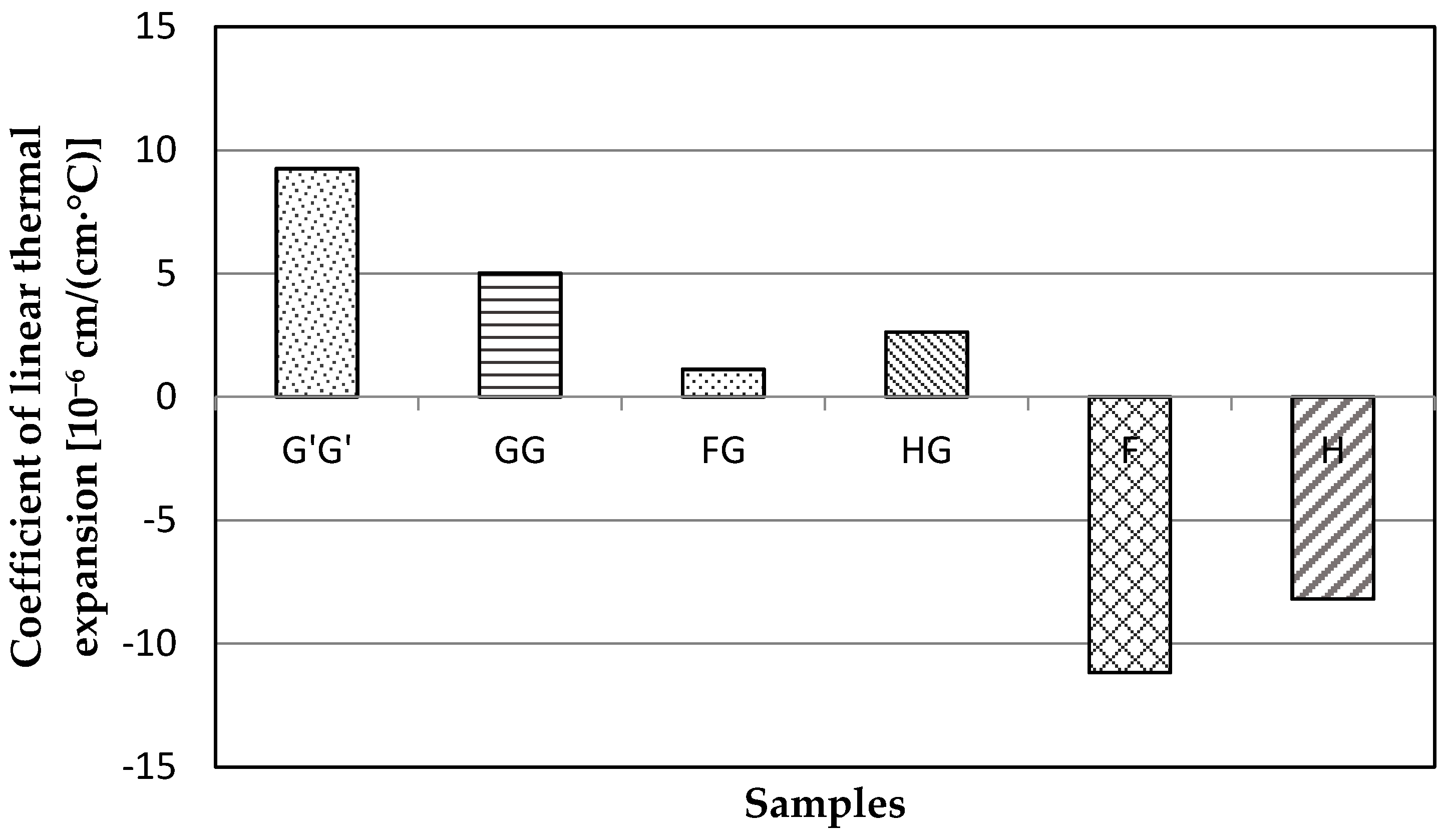

3.3. Coefficient of Linear Thermal Expansion (CLTE)

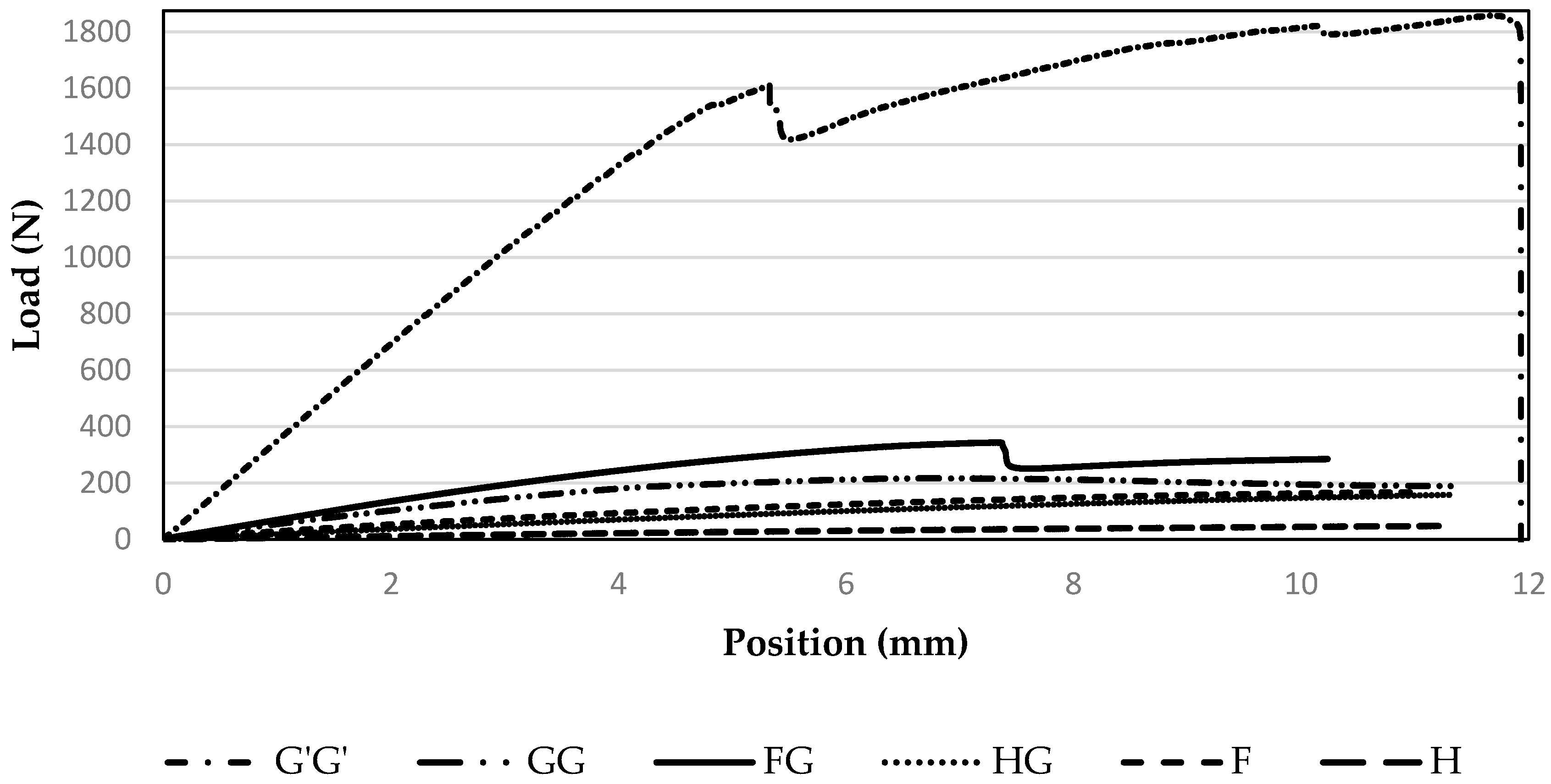

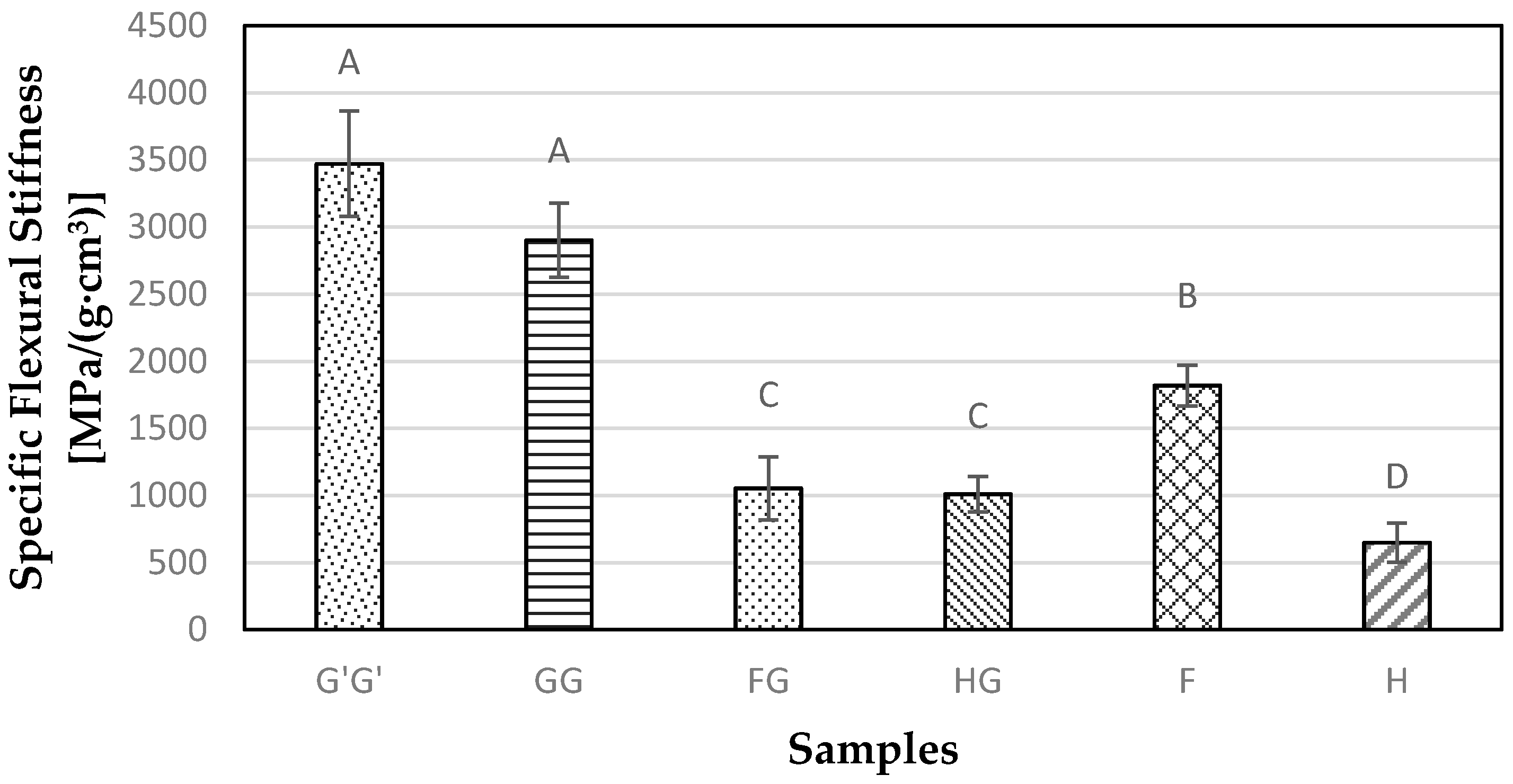

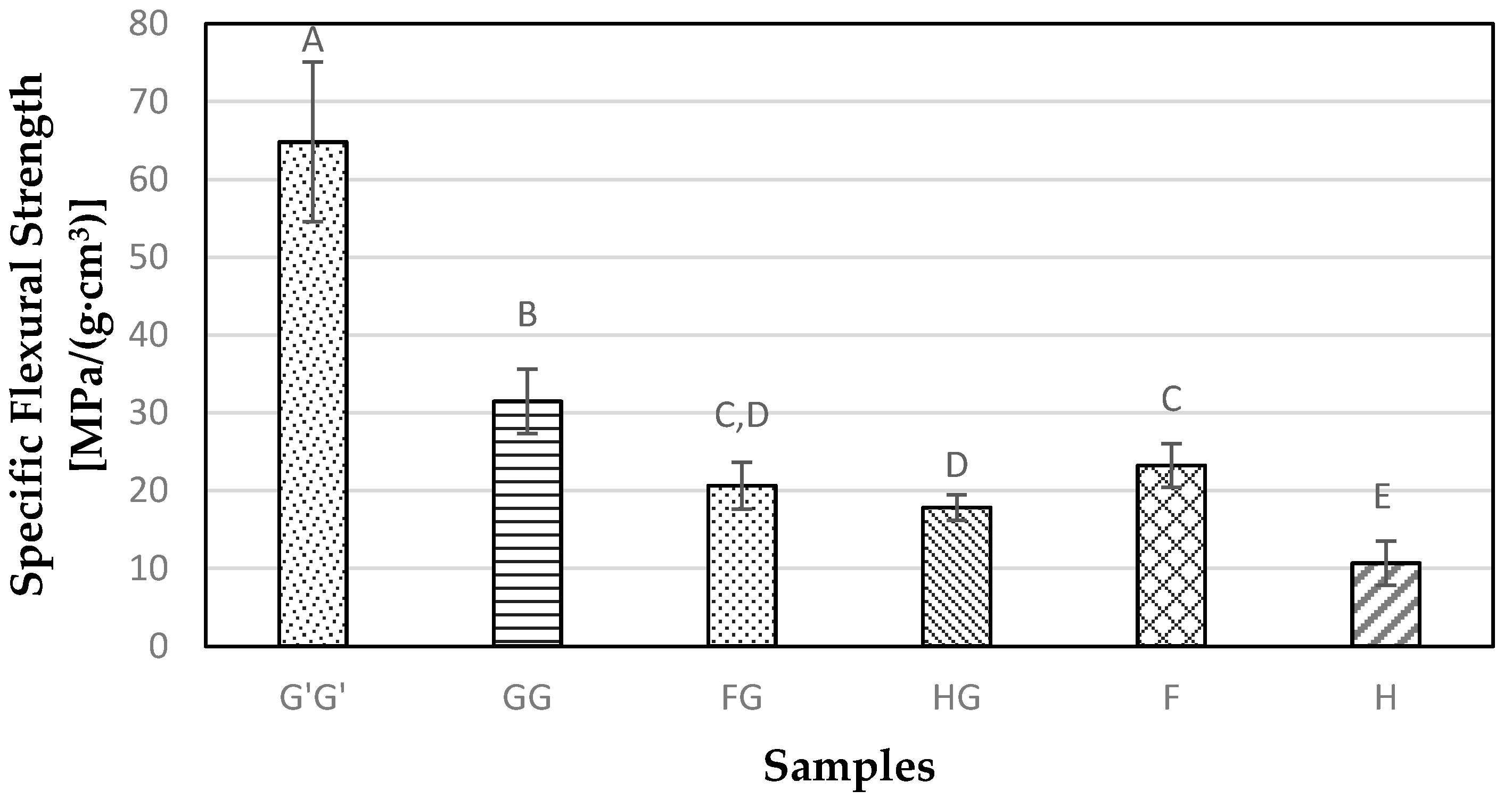

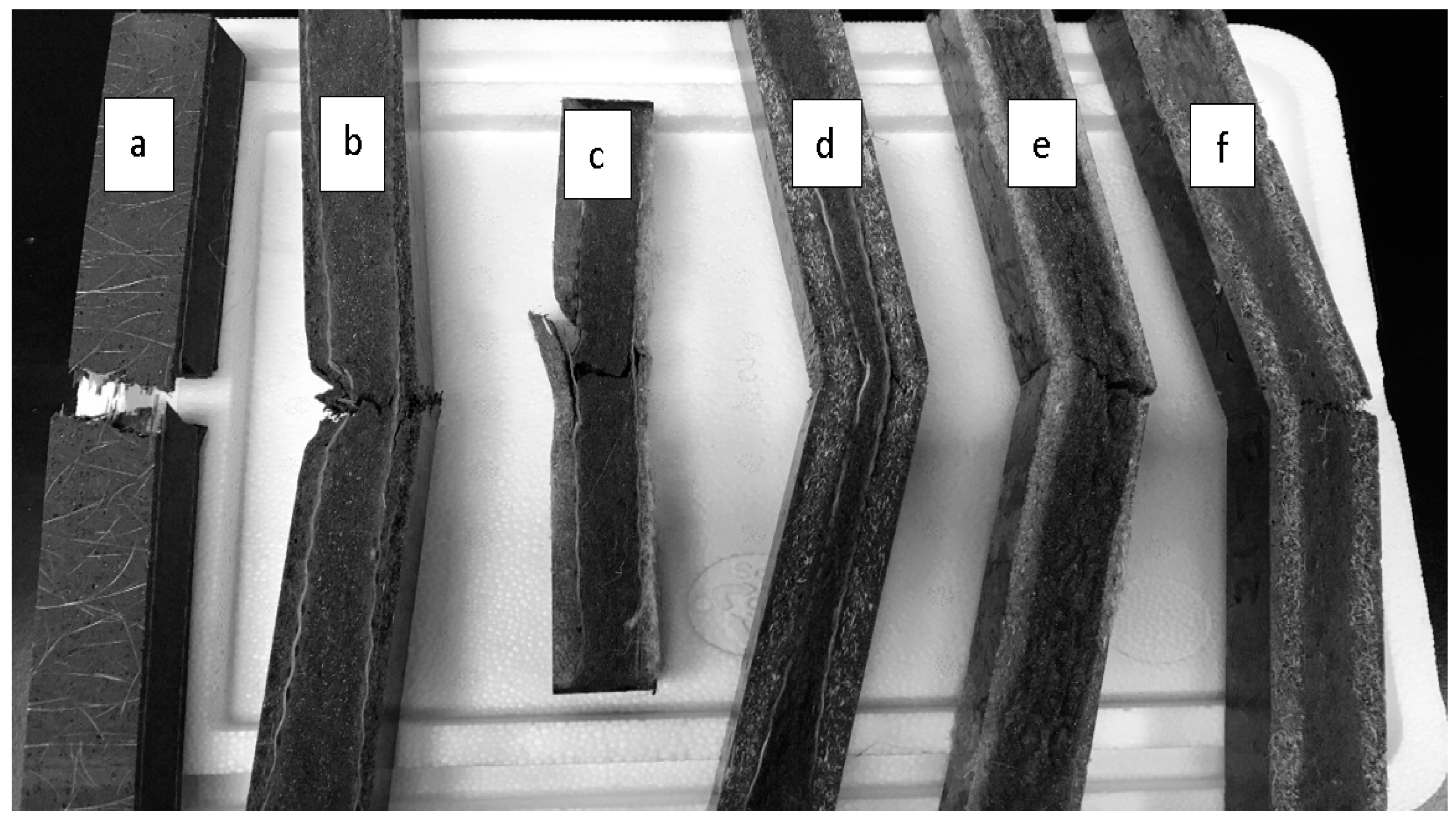

3.4. Flexural Properties

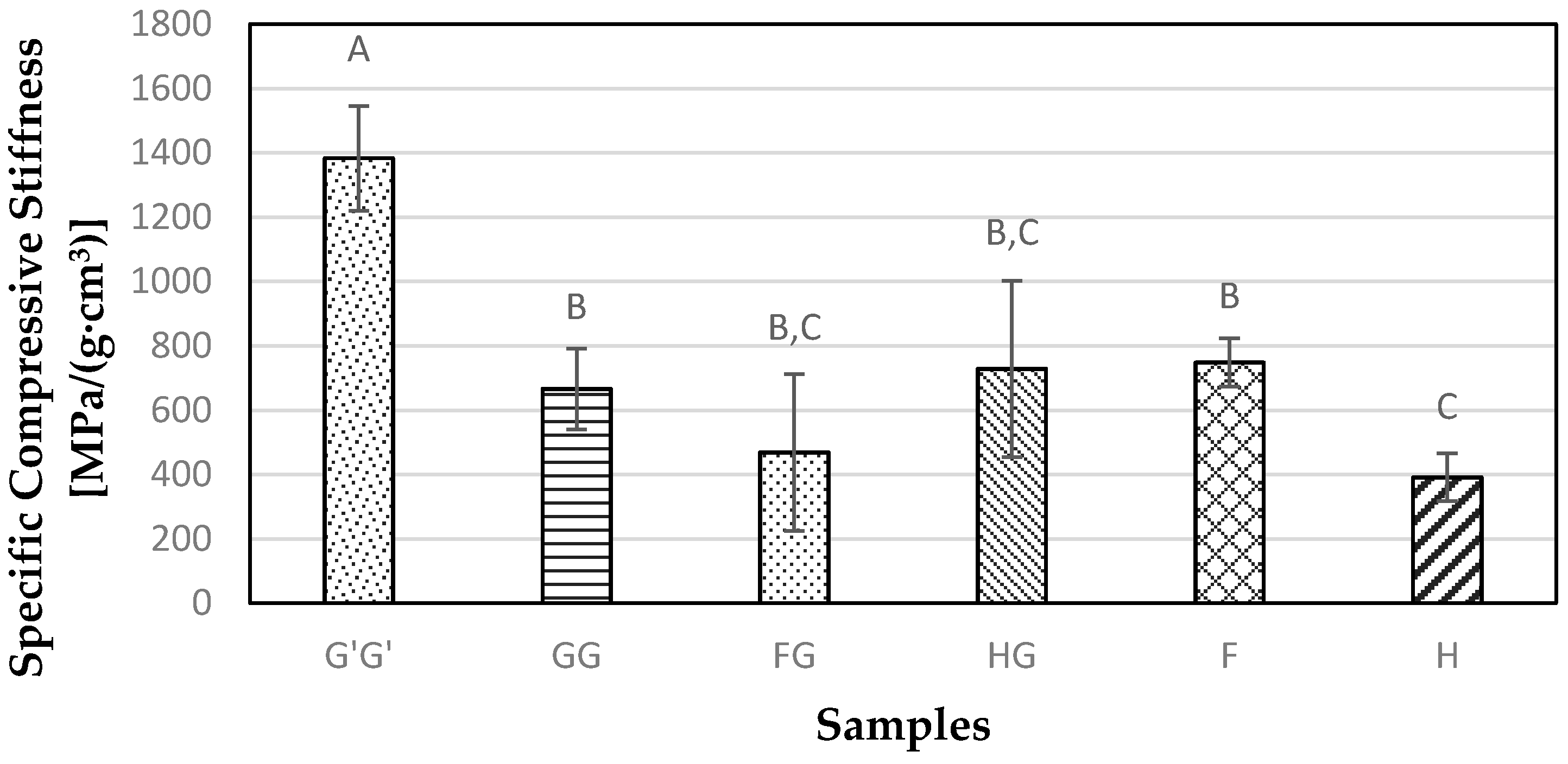

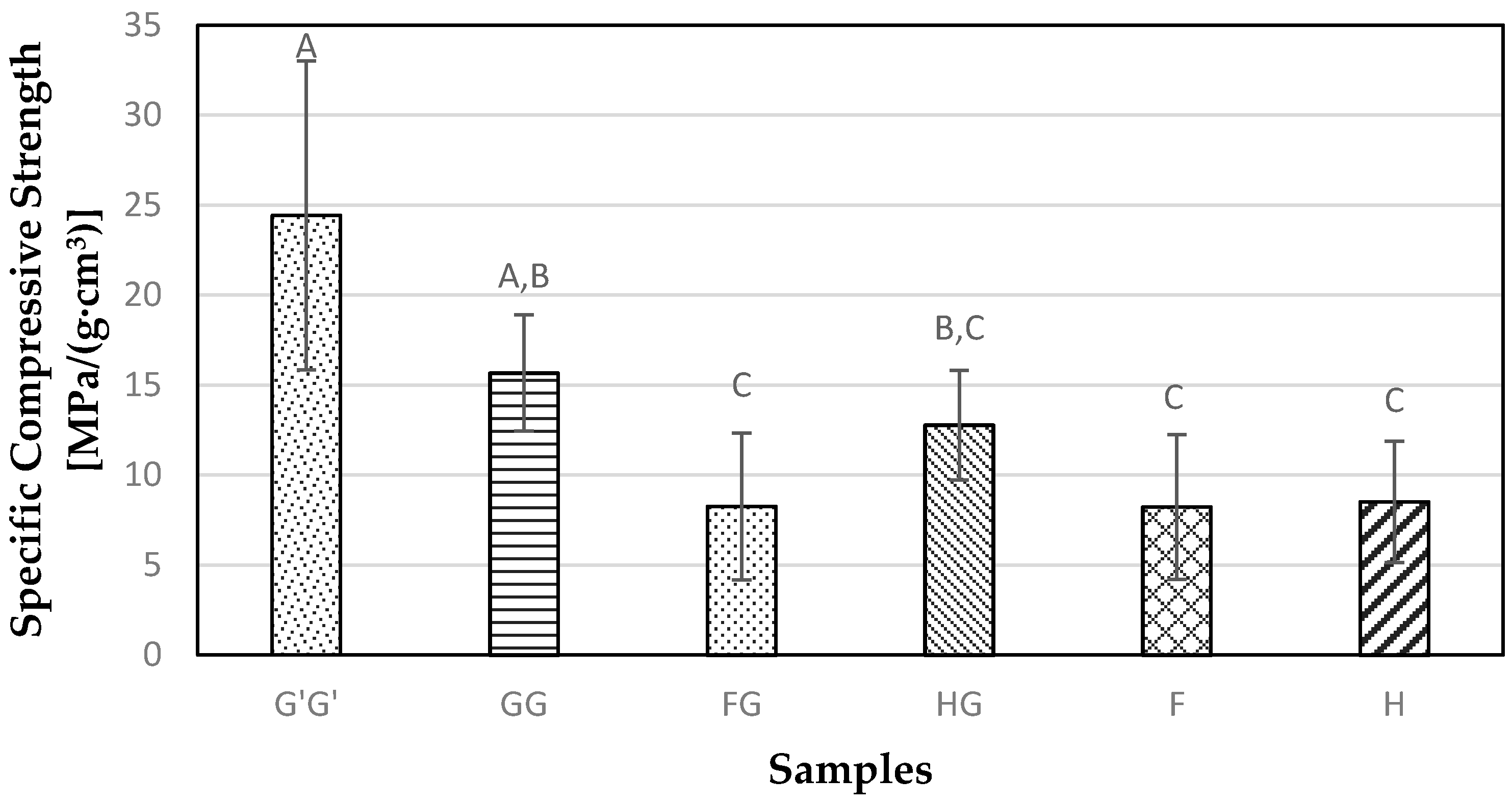

3.5. Compressive Properties

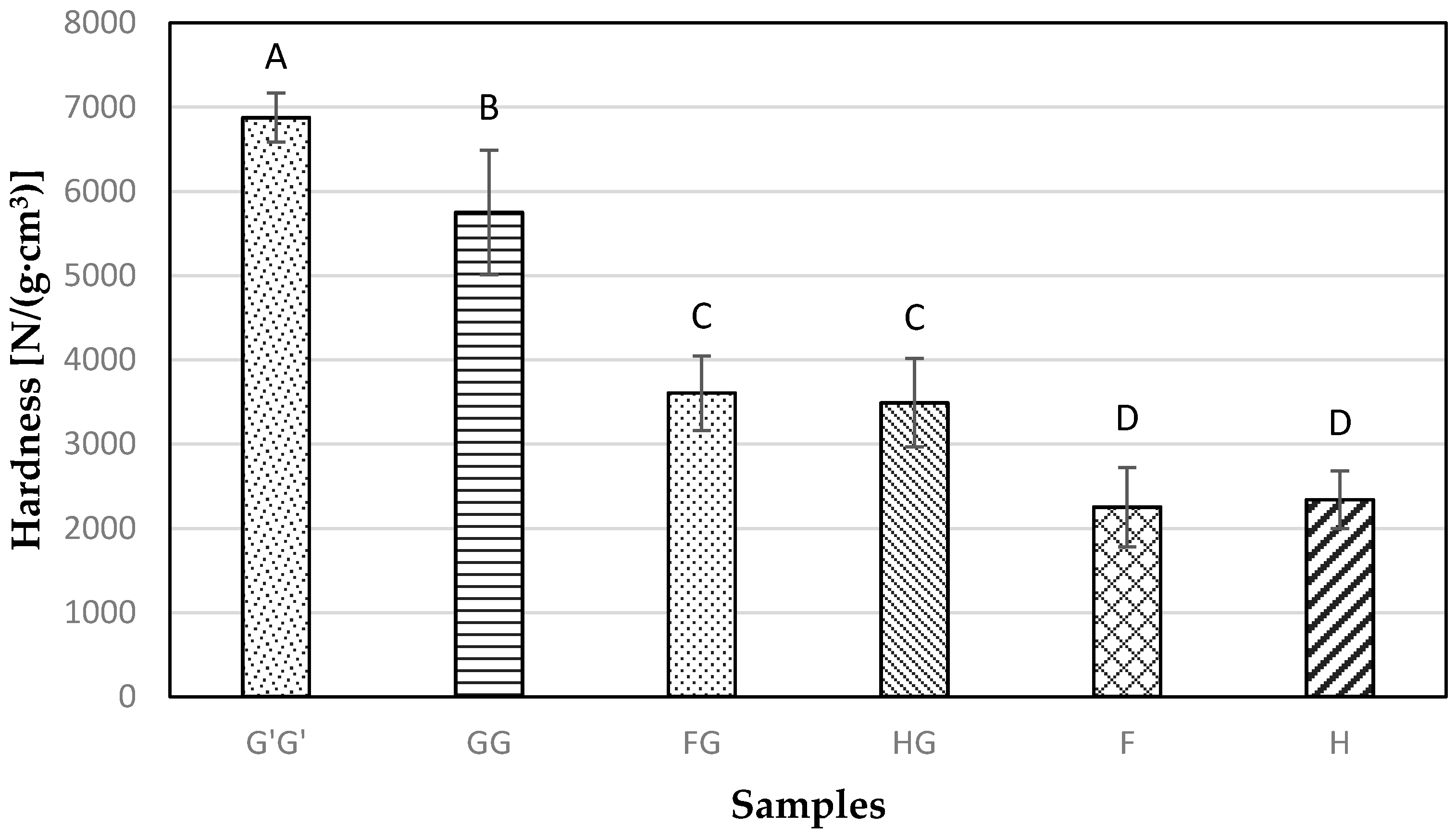

3.6. Hardness Testing

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Muhammad, P.; Mohini, M.S. Carbon storage potential in natural fiber composites. Resour. Conserv. Recycl. 2003, 39, 325–340. [Google Scholar]

- Wambua, P.; Ivens, J.; Verpoest, I. Natural fibres: Can they replace glass in fibre reinforced plastics? Compos. Sci. Technol. 2003, 63, 1259–1264. [Google Scholar] [CrossRef]

- Monteiro, S.N.; Terrones, L.A.H.; D’Almeida, J.R.M. Mechanical performance of coir fiber/polyester composites. Polym. Test. 2004, 27, 591–595. [Google Scholar] [CrossRef]

- Bos, H.L.; Van Den Oever, M.J.A.; Peters, O.C.J.J. Tensile and compressive properties of flax fibres for natural fibre reinforced composites. J. Mater. Sci. 2002, 37, 1683–1692. [Google Scholar] [CrossRef]

- Niu, P.F.; Liu, B.Y.; Wei, X.M.; Wang, X.J.; Yang, J. Study on mechanical properties and thermal stability of polypropylene/hemp fiber composites. J. Reinf. Plast. Compos. 2011, 30, 36–44. [Google Scholar]

- Kazuya, O.; Toru, F.; Yuzo, Y. Development of bamboo-based polymer composites and their mechanical properties. Compos. Part A 2004, 35, 377–383. [Google Scholar]

- Davoodi, M.M.; Sapuan, S.M.; Ahmad, D.; Ali, A.; Khalina, A.; Jonoobi, M. Mechanical properties of hybrid kenaf/glass reinforced epoxy composite for passenger car bumper beam. Mater. Des. 2010, 31, 4927–4932. [Google Scholar] [CrossRef]

- Naozumi, T.; Kohei, U.; Koichi, O.; Mitsuhiro, S. Biodegradation of aliphatic polyester composites reinforced by abaca fiber. Polym. Degrad. Stab. 2004, 86, 401–409. [Google Scholar]

- Jawaid, M.; Khalil, H.P.S.A.; Hassan, A.; Dungani, R.; Hadiyane, A. Effect of jute fibre loading on tensile and dynamic mechanical properties of oil palm epoxy composites. Compos. Part B 2013, 45, 619–624. [Google Scholar] [CrossRef]

- Saunders, J.H.; Frisch, K.C. Polyurethanes: Chemistry and Technology; Parts I and II; Interscience Publishers: New York, NY, USA, 1962. [Google Scholar]

- Dwan’isa, J.P.L.; Mohanty, A.K.; Misra, M.; Drzal, L.T. Biobased polyurethane and its composite with glass fiber. J. Mater. Sci. 2004, 39, 2081–2087. [Google Scholar]

- Saheb, D.N.; Jog, J.P. Natural fiber polymer composites: A review. Adv. Polym. Technol. 1999, 18, 351–363. [Google Scholar] [CrossRef]

- John, M.J.; Thomas, S. Biofibres and biocomposites. Carbohydr. Polym. 2008, 71, 343–364. [Google Scholar] [CrossRef]

- Koradiya, S.B.; Patel, J.P.; Parsania, P.H. The preparation and physicochemical study of glass, jute and hybrid glass-jute bisphenol-c-based epoxy resin. Polym. Plast. Technol. 2010, 49, 1445–1449. [Google Scholar] [CrossRef]

- Wong, K.J.; Nirmal, U.; Lim, B.K. Impact behavior of short and continuous fiber-reinforced polyester composites. J. Reinf. Plast. Comp. 2010, 29, 3463–3474. [Google Scholar] [CrossRef]

- De Carvalho, L.H.; Moraes, G.S.; D’Almeida, J.R.M. Influence of water absorption and pre-drying conditions on the tensile mechanical properties of hybrid lignocelluloses fiber/polyester composites. J. Reinf. Plast. Comp. 2009, 28, 1921–1932. [Google Scholar] [CrossRef]

- ASTM D2734. Standard Test Method for Void Content of Reinforced Plastics; ASTM International: West Conshohocken, PA, USA, 2009. [Google Scholar]

- ASTM D570. Standard Test Method for Water Absorption of Plastics; ASTM International: West Conshohocken, PA, USA, 2010. [Google Scholar]

- ASTM D6341. Standard Test Method for Determination of the Linear Coefficient of Thermal Expansion of Plastic Lumber and Plastic Lumber Shapes Between −30 and 140 °F (−34.4 and 60 °C); ASTM International: West Conshohocken, PA, USA, 2014. [Google Scholar]

- ASTM D790. Standard Test Methods for Flexural Properties of Unreinforced and Reinforced Plastics and Electrical Insulating Materials; ASTM International: West Conshohocken, PA, USA, 2015. [Google Scholar]

- ASTM D695. Standard Test Method for Compressive Properties of Rigid Plastics; ASTM International: West Conshohocken, PA, USA, 2010. [Google Scholar]

- ASTM D1037. Standard Test Methods for Evaluating Properties of Wood-base Fiber and Particle Panel Materials; ASTM International: West Conshohocken, PA, USA, 2012. [Google Scholar]

- Kishore, M.R. Jute-glass sandwich composites. J. Reinf. Plast. Comp. 1985, 4, 186–194. [Google Scholar]

- Bismarck, A.; Askargorta, I.A.; Springer, J.; Lampke, T.; Wielage, B.; Stamboulis, A. Surface characterization of flax, hemp and cellulose fibres: Surface properties and the water uptake behaviour. Polym. Compos. 2002, 23, 872–894. [Google Scholar] [CrossRef]

- Tserki, V.; Matzinos, P.; Zafeiropoulos, N.E.; Panayiotou, C. Development of biodegradable composites with treated and compatibilized lignocellulosic fibers. J. Appl. Polym. Sci. 2006, 100, 4703–4710. [Google Scholar] [CrossRef]

- Agrawal, R.K.; Drzal, L.T. Adhesion mechanisms of polyurethanes to glass surfaces. Part II. Phase separation in polyurethanes and its effects on adhesion to glass. J. Adhes. Sci. Technol. 1995, 9, 1381–1400. [Google Scholar] [CrossRef]

| Fiber Mats | Type | Average Fiber Length (mm) | Average Fiber Diameter (µm) | Arial Weight of Mat (g/m2) | Mat Thickness (mm) | Source |

|---|---|---|---|---|---|---|

| Glass | Non-woven (spunlaid) | 37.08 | 40 | 450 | 1.25 | SpaceAge Synthetics, Fargo, ND, USA |

| Glass | Woven (bi-axial) | 304.80 | 100 | 600 | 1.50 | SpaceAge Synthetics, Fargo, ND, USA |

| Flax1 | Non-woven (needle punched) | 63.25 | 20 | 500 | 4.00 | Hemp-Flax, Groningen, Netherlands |

| Flax2 | Non-woven (needle punched) | 77.56 | 40 | 550 | 5.50 | Composite Innovation Centre, Winnipeg, MB, Canada |

| Hemp-Agave | Non-woven (needle punched) | 71.51 | 200 | 352 | 5.40 | Composite Innovation Centre, Winnipeg, MB, Canada |

| Sample Name | Non-Woven Mat | Woven Mat | Filter | PU Resin (Weight %) | Mold Size (mm3) | Panel Density (g/cm3) |

|---|---|---|---|---|---|---|

| G’G’ | Glass | Glass | Glass | 67–70 | 254 × 254 × 25.4 | 0.45 |

| GG | Glass | Glass | Glass | 65 | 317.5 × 317.5 × 25.4 | 0.22 |

| FG | Flax1 | Glass | Glass | 65 | 203.2 × 203.2 × 19.1 | 0.33 |

| HG | Hemp-Agave | Glass | Glass | 62 | 317.5 × 317.5 × 25.4 | 0.22 |

| F | Flax2 | - | Glass | 77 | 317.5 × 317.5 × 25.4 | 0.20 |

| H | Hemp-Agave | - | Glass | 77 | 317.5 × 317.5 × 25.4 | 0.16 |

| Type of Composites | Void Content (%) |

|---|---|

| Commercial Glass Fiber (G’G’) | 1.4 |

| Glass Fiber (GG) | 4.8 |

| Flax1 and Glass Fiber (FG) | 4.8 |

| Hemp-Agave and Glass Fiber (HG) | 5.2 |

| Only Flax2 Fiber (F) | 7.9 |

| Only Hemp-Agave Fiber (H) | 4.1 |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pandey, P.; Bajwa, D.; Ulven, C.; Bajwa, S. Influence of Hybridizing Flax and Hemp-Agave Fibers with Glass Fiber as Reinforcement in a Polyurethane Composite. Materials 2016, 9, 390. https://doi.org/10.3390/ma9050390

Pandey P, Bajwa D, Ulven C, Bajwa S. Influence of Hybridizing Flax and Hemp-Agave Fibers with Glass Fiber as Reinforcement in a Polyurethane Composite. Materials. 2016; 9(5):390. https://doi.org/10.3390/ma9050390

Chicago/Turabian StylePandey, Pankaj, Dilpreet Bajwa, Chad Ulven, and Sreekala Bajwa. 2016. "Influence of Hybridizing Flax and Hemp-Agave Fibers with Glass Fiber as Reinforcement in a Polyurethane Composite" Materials 9, no. 5: 390. https://doi.org/10.3390/ma9050390

APA StylePandey, P., Bajwa, D., Ulven, C., & Bajwa, S. (2016). Influence of Hybridizing Flax and Hemp-Agave Fibers with Glass Fiber as Reinforcement in a Polyurethane Composite. Materials, 9(5), 390. https://doi.org/10.3390/ma9050390