Evaluation of Castor Oil Cake Starch and Recovered Glycerol and Development of “Green” Composites Based on Those with Plant Fibers

Abstract

:1. Introduction

2. Experimental Section

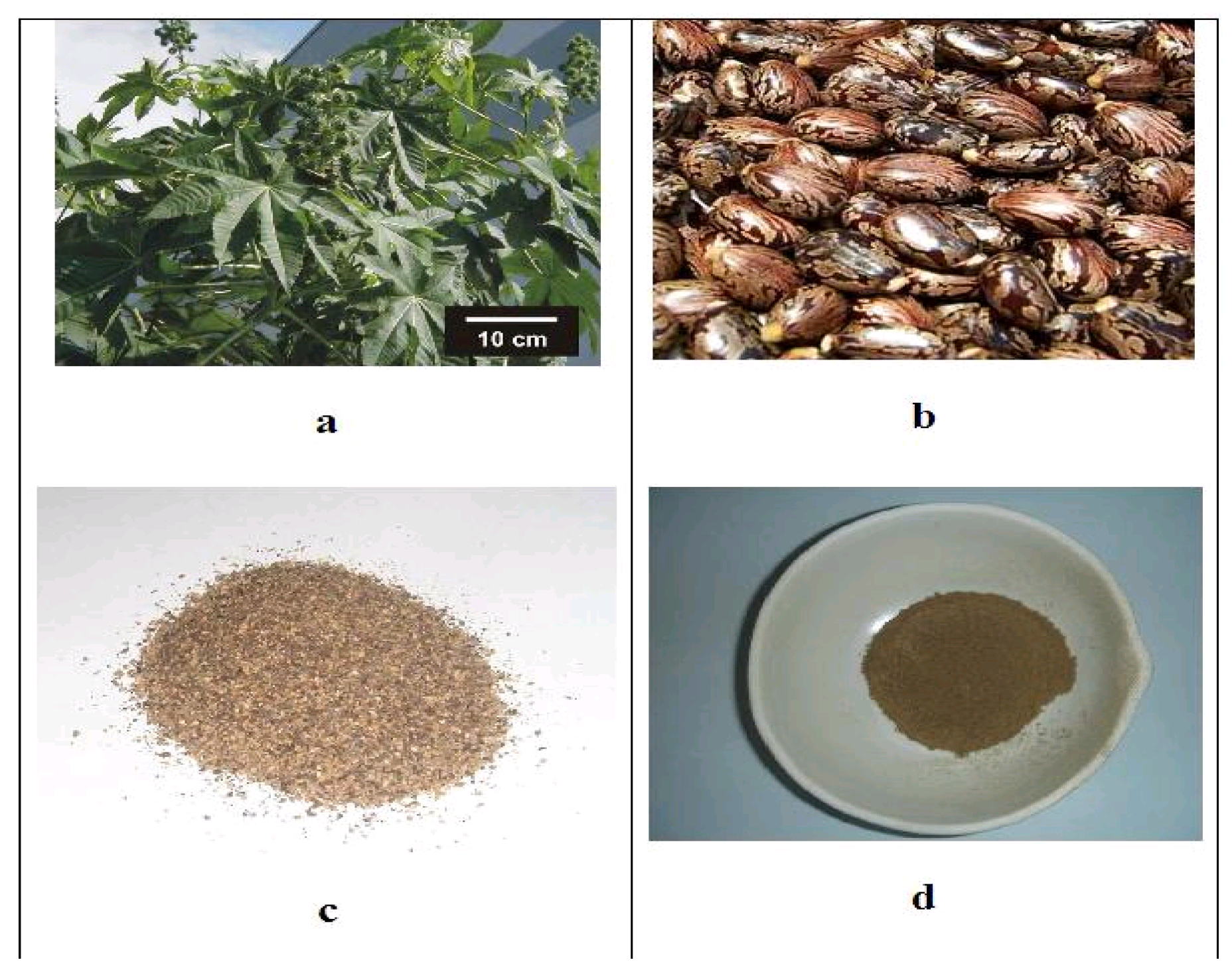

2.1. Materials

2.2. Methods

2.2.1. Preparation of Castor Oil Cake as a Matrix Material

Extract of Excess oil from COC (Treatment to COC)

Castor Oil Cake for Matrix

2.2.2. Characterization of Castor Oil Cake and Glycerol/Recovered Glycerol (RG)

2.2.3. Preparation of Lignocellulosic Fibers for Use as Reinforcements

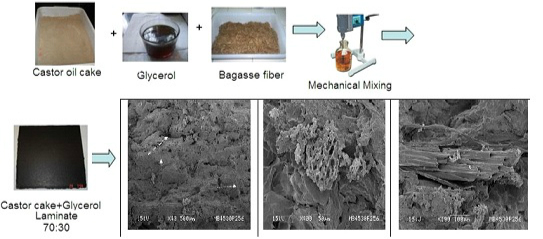

2.2.4. Fabrication of Matrix Laminates and Bio-Composites

| Sample | Constituents of Matrix (%) | Reinforcing Fiber (%) |

|---|---|---|

| COC70 G30 | 70 Castor oil Cake-30 Pure Glycerol | 0 |

| COC70 RG30 | 70 Castor oil Cake-30 Recovered glycerol (RG) | 0 |

| COC45RG25BT | 45 Castor oil Cake-30 Recovered glycerol (RG) | 25 Banana Treated (BT) |

| COC50RG20SBT | 50 Castor oil Cake-30 Recovered glycerol (RG) | 20 Bagasse Treated (SBT) |

2.2.5. Characterization of Prepared Composites

3. Results and Discussion

3.1. Extraction of Excess Oil from Castor Oil Seed

3.2. Moisture Content

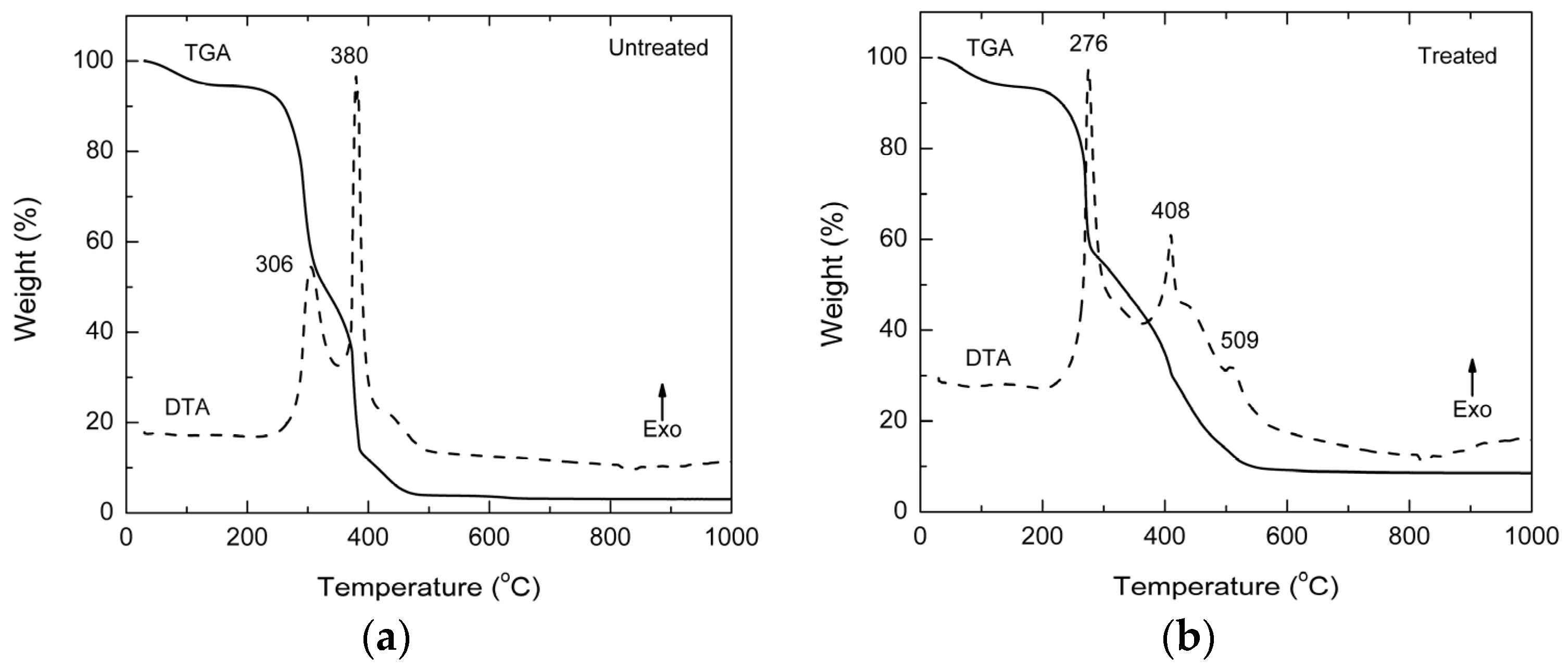

3.3. Thermal Analysis

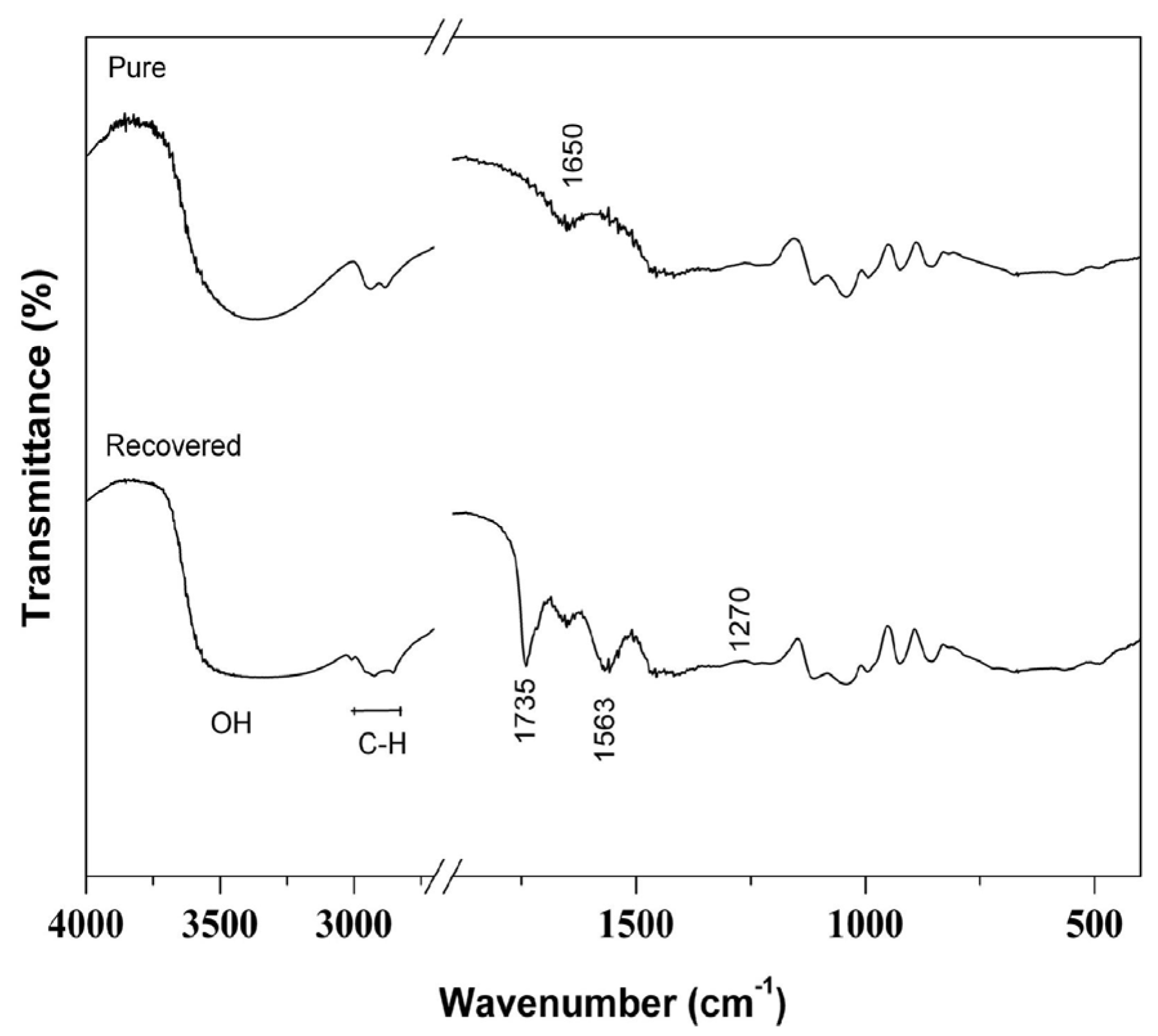

3.4. FTIR Spectroscopy Studies of Recovered Glycerol (RG)

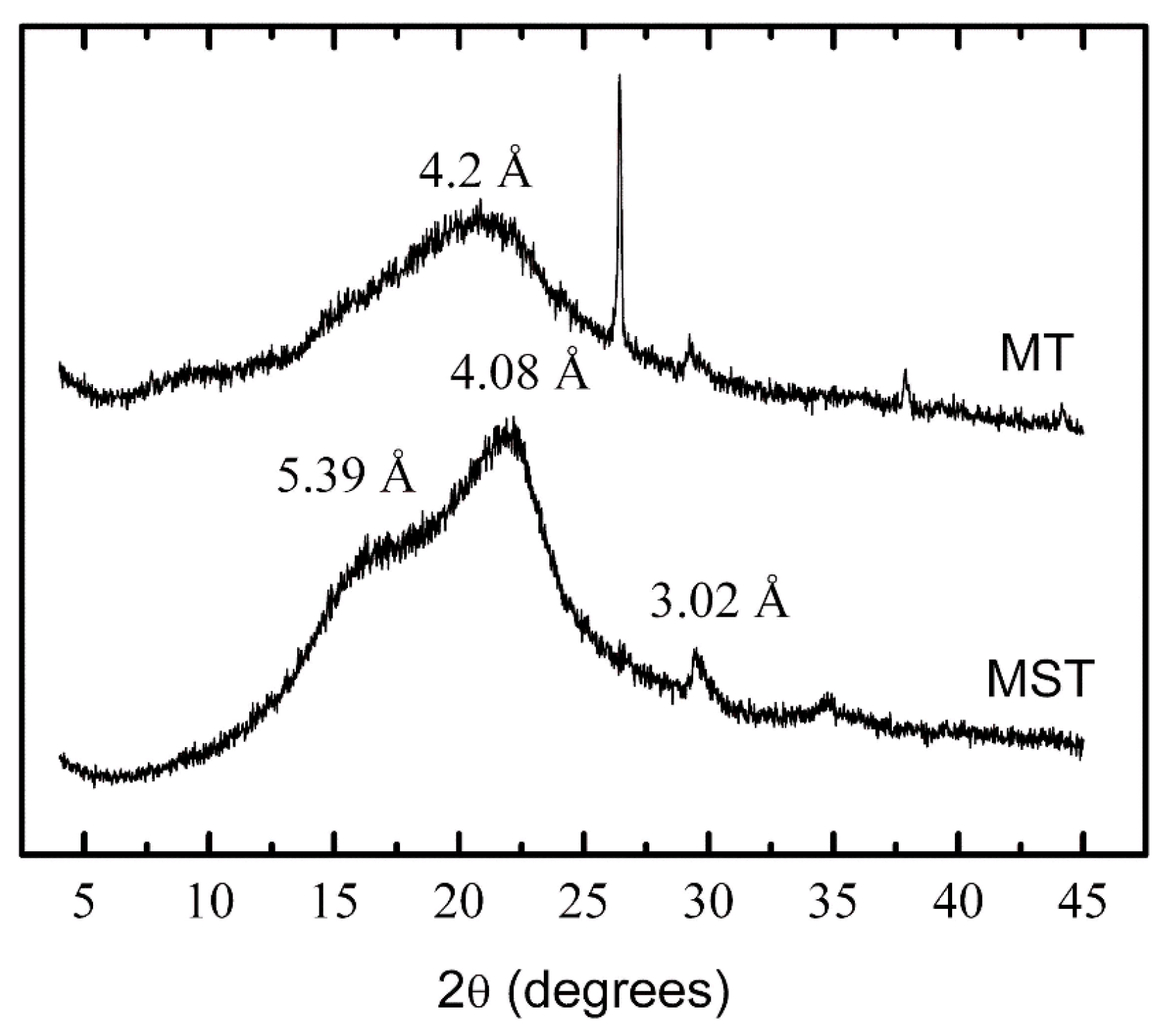

3.5. X-ray Diffraction Studies

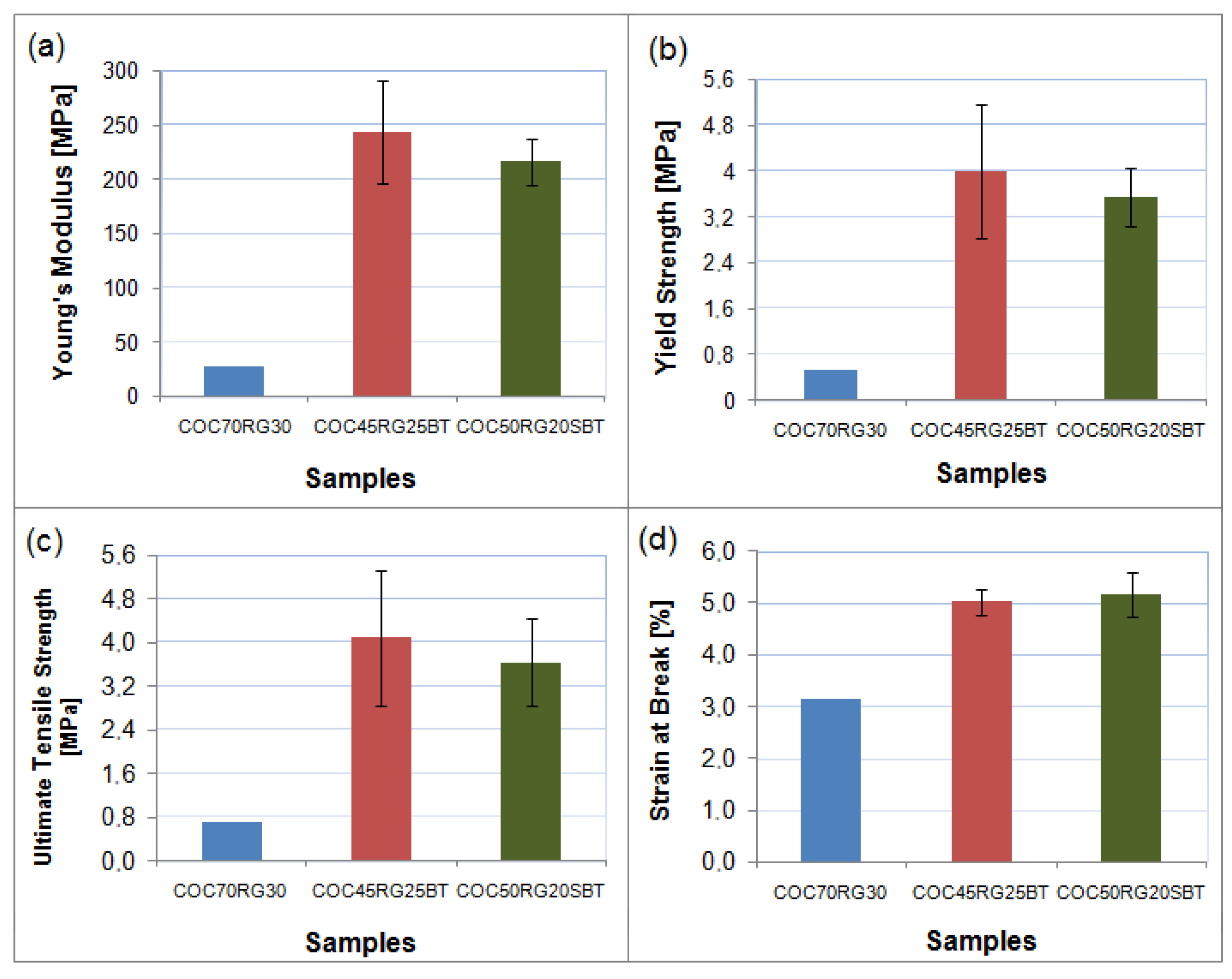

3.6. Tensile Properties

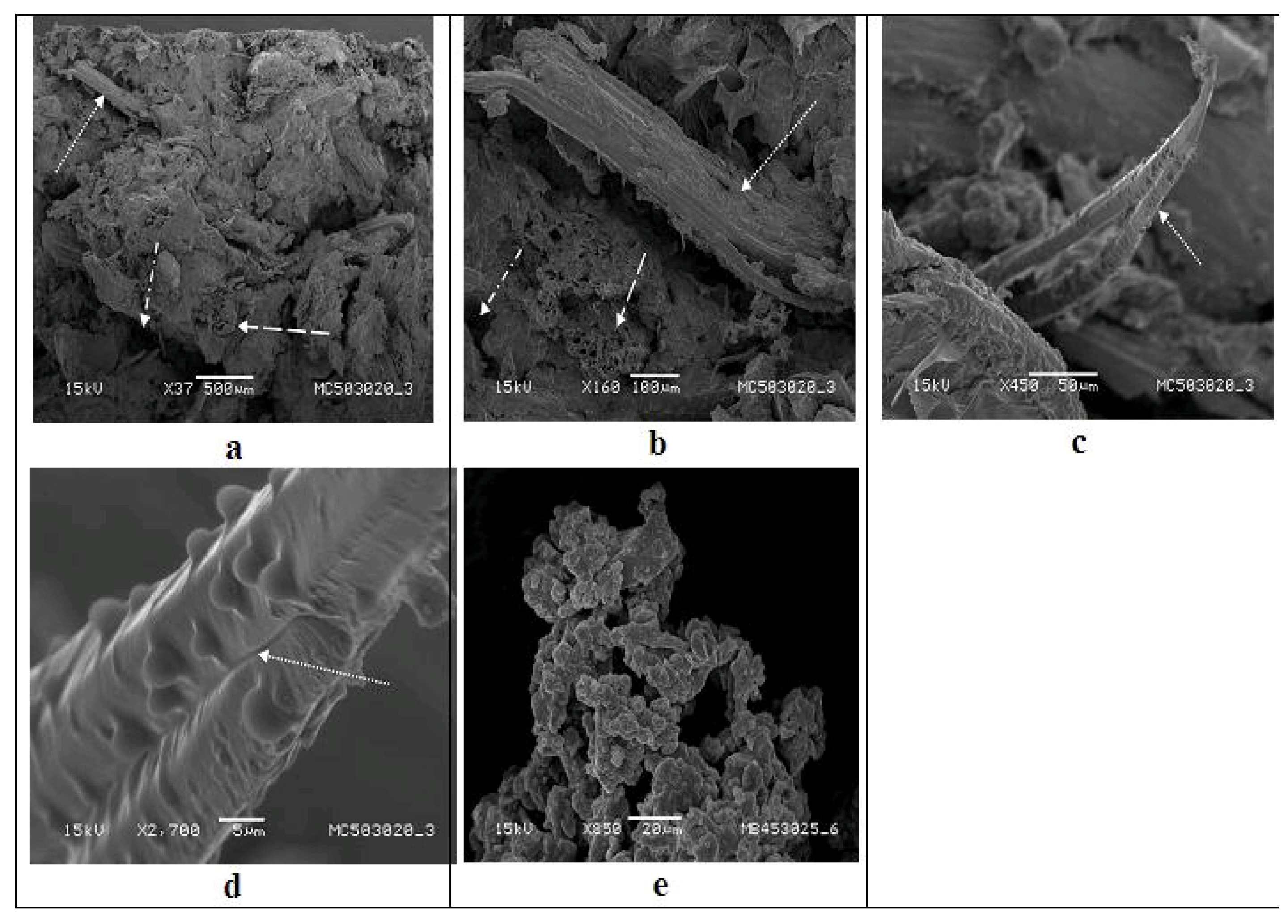

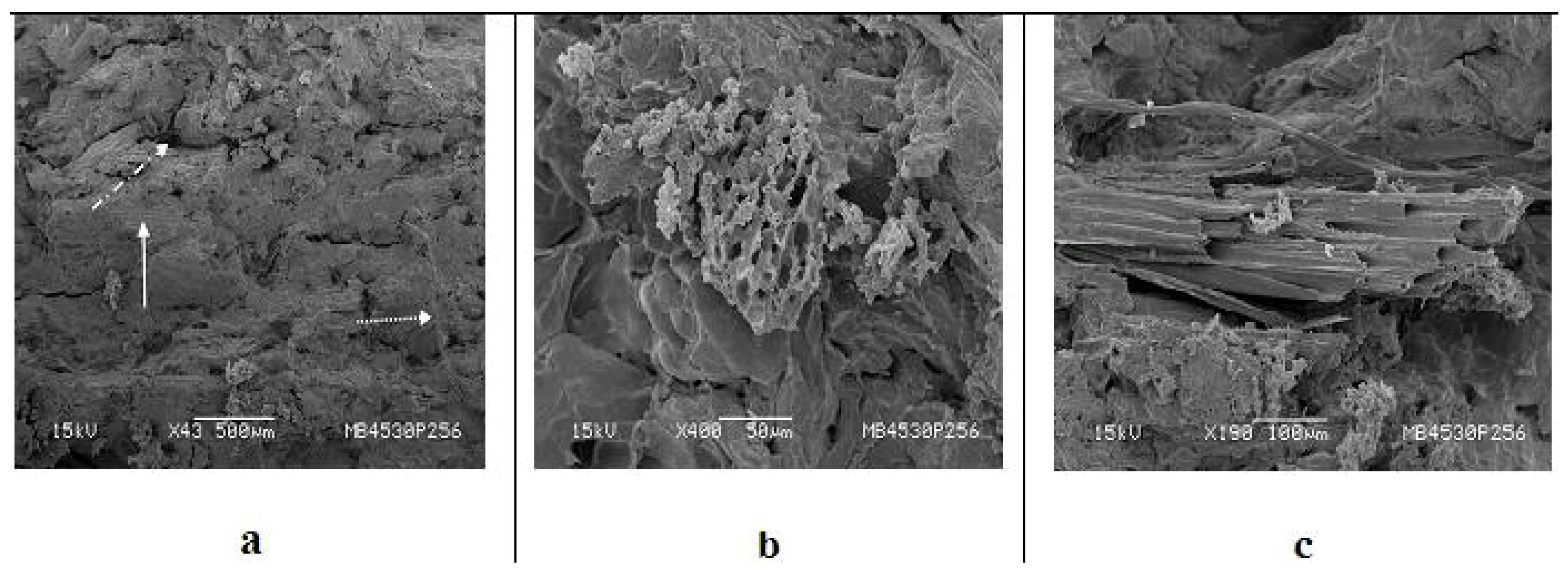

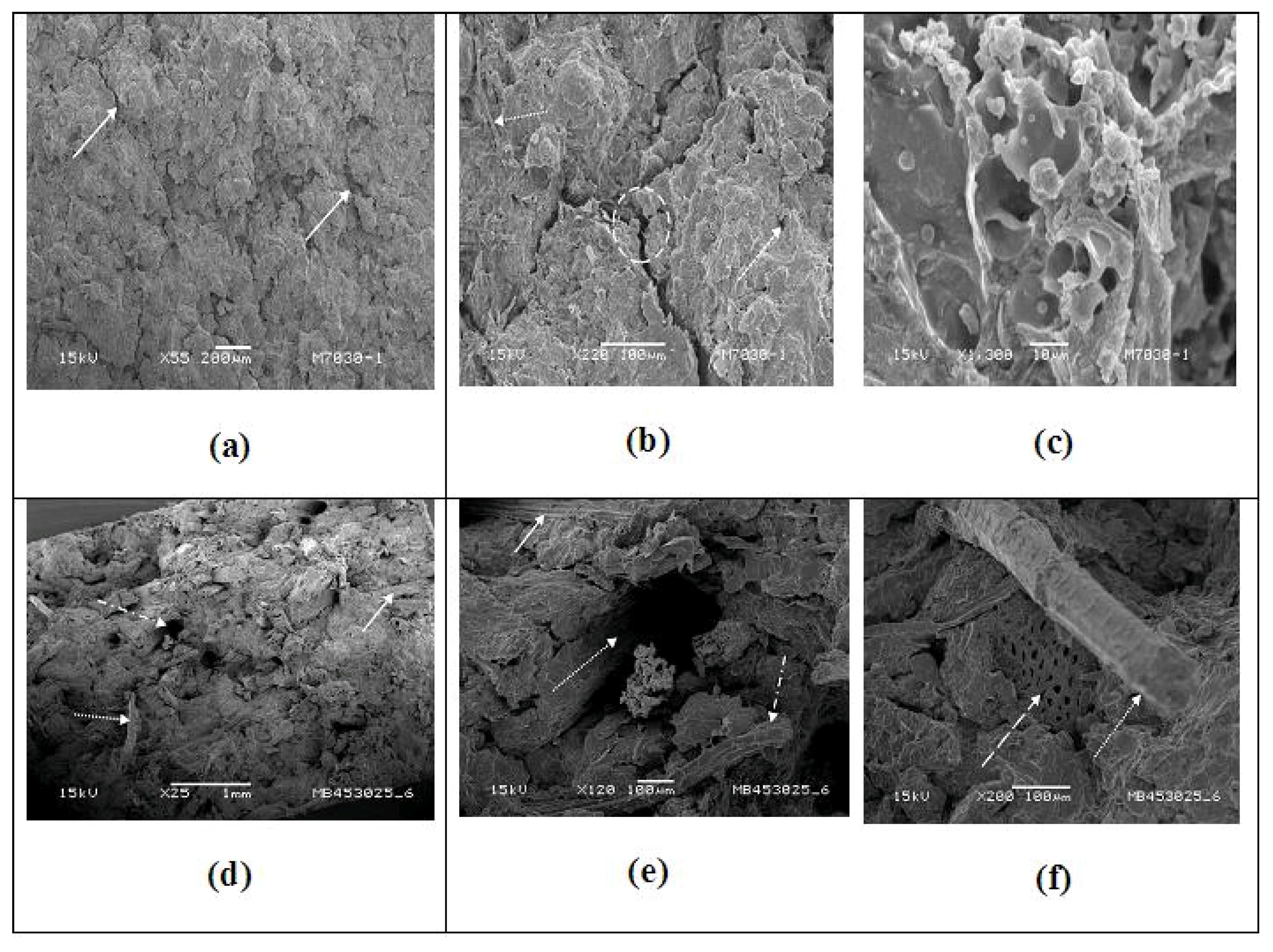

3.7. Fractographic Studies of Castor Bean Cake and Its Composites

3.7.1. Effect of Type of Fibers Used

3.7.2. Effect of Type of Glycerin Used

4. Conclusions

- COC contained about 2.5% excess residual oil compared to the 1.5% reported in good quality solvent-extracted castor bean cakes.

- Moisture contents of COC, recovered glycerol (RG), and both banana and sugarcane bagasse fibers were found to be about 10.8%, 9.3%, 8.5%, and 9.2%, respectively.

- TGA/DTA results of the COC samples, both untreated and treated by solvent extraction, revealed them to be of different in nature in terms of mass loss and ash content.

- FTIR studies of recovered glycerol (RG) and pure glycerol revealed some differences between them in terms of appearance of vibrational bands (present only in RG) due to accumulation of residues from the alkaline trans-esterification process or coming from esters that were not properly separated from glycerin or due to long alkyl chain of fatty acids.

- The treatment of COC enhanced its crystallinity.

- Fiber incorporation significantly improved all the tensile properties of the composites, independent of fiber type.

- Fractographic studies of COC + glycerol (PA) or RG matrix with and without banana fibers revealed smooth fracture surface with the former and rough surface with the latter. In the case of composites, footprints of pullout of fibers lying parallel to the fracture surface have been observed suggesting inducement of fragility in this region.

- Compared to the stiff and brittle surface observed in COC + RG matrix containing fibers, that of COC + glycerol (PA) showed higher plasticity.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Curvelo, A.A.S.; Carvalho, A.J.F.; Agnelli, J.A.M. Thermoplastic starch-cellulosic fibers composites: Preliminary results. Carbohydr. Polym. 2001, 45, 183–188. [Google Scholar] [CrossRef]

- Mishra, S.; Tripathy, S.S.; Misra, M.; Mohanty, A.K.; Nayak, S.K. Novel eco-friendly biocomposites: Biofiber reinforced biodegradable polyester amide composites—Fabrication and processing evaluation. J. Reinf. Plast. Compos. 2002, 21, 55–70. [Google Scholar] [CrossRef]

- Tharanathan, R.N. Biodegradable films and composite coatings: Past, present and future. Trends. Food Sci. Tech. 2003, 14, 71–78. [Google Scholar] [CrossRef]

- Stark, N.M.; Rowlands, R.E. Effects of wood fiber characteristics on mechanical properties of wood/polypropylene composites. Wood Fiber Sci. 2003, 35, 167–174. Available online: http://wfs.swst.org/index.php/wfs/article/view/590 (accessed on 21 January 2016). [Google Scholar]

- Cervera, M.F.; Karjalainen, M.; Airaksinen, S.; Rantanen, J.; Krogars, K.; Heinämäki, J.; Colarte, A.I.; Yliruusi, J. Physical stability and moisture sorption of aqueous chitosan-amylase starch films plasticized with polyols. Eur. J. Pharm. Biopharm. 2004, 58, 69–76. [Google Scholar] [CrossRef] [PubMed]

- Averous, L.; Boquillon, N. Biocomposites based on plasticized starch: Thermal and mechanical behaviors. Carbohydr. Polym. 2004, 56, 111–122. [Google Scholar] [CrossRef]

- Choi, J.S.; Lim, S.T.; Choi, H.J.; Mohanty, A.K.; Drzal, L.T.; Misra, M.; Wibowo, A. Preparation and characterization of plasticized cellulose acetate biocomposite with natural fiber. J. Mater. Sci. 2004, 39, 6631–6633. [Google Scholar] [CrossRef]

- Sousa, M.V.; Monteiro, S.N.; d’Almeida, J.R.M. Evaluation of pre-treatment, size and molding pressure on flexural mechanical behavior of chopped bagasse polyester composites. Polym. Test. 2004, 23, 253–258. [Google Scholar] [CrossRef]

- Gáspar, M.; Benkó, Z.; Dogossy, G.; Réczey, K.; Czigány, T. Reducing water absorption in compostable starch-based plastics. Polym. Degrad. Stab. 2005, 90, 563–569. [Google Scholar] [CrossRef]

- Ma, X.; Yu, J.; Kennedy, J.F. Studies on the properties of natural fibers reinforced thermoplastics starch composites. Carbohydr. Polym. 2005, 62, 19–24. [Google Scholar] [CrossRef]

- Tserki, V.; Matzinos, P.; Panayiotou, C. Novel biodegradable composites based treated lignocellulosic waste flour as filler. Part II: Development biodegradable composites using treated and compatibilized waste flour. Compos. Part A 2006, 37, 1231–1238. [Google Scholar] [CrossRef]

- Ochi, S. Development of high strength biodegradable composites using Manila hemp fiber and starch-based biodegradable resin. Compos. Part A 2006, 37, 1879–1883. [Google Scholar] [CrossRef]

- Satyanarayana, K.G.; Wypych, F. Characterization of natural fibers. In Engineering Biopolymers: Homopolymers, Blends and Composites; Fakirov, S., Bhattacharyya, D., Eds.; Hanser Publishers: Auckland, New Zealand; Munich, Germany; 2007; Volume 1, pp. 3–47. [Google Scholar]

- Torres, F.G.; Arroyo, O.H.; Gomez, C. Processing and mechanical properties of natural fiber reinforced thermoplastic starch biocomposites. J. Thermoplast. Compos. 2007, 20, 207–223. [Google Scholar] [CrossRef]

- Teixeira, E.M. Use of Cassava Starch for the Preparation of New Thermoplastic Materials (Utilização de Amido de Mandioca na Preparação de Novos Materiais Termoplásticos). Ph.D. Thesis, University of São Paulo, São Paulo, Brazil, 7 August 2007. [Google Scholar]

- Mengeloğlu, F.; Karakuş, K. Some properties of Eucalyptus wood filled recycled high density polyethylene polymer-composites. Turk. J. Agric. For. 2008, 32, 537–546. Available online: http://journals.tubitak.gov.tr/agriculture/ issues/tar-08-32-6/tar-32-6-9-0801-7.pdf (accessed on 17 January 2016). [Google Scholar]

- Migneault, S.; Koubaa, A.; Erchiqui, F.; Chaala, A.; Englund, K.; Krause, C.; Wolcott, M. Effect of fiber length on processing and properties of extruded wood-fiber/HDPE composites. J. Appl. Polym. Sci. 2008, 110, 1085–1092. [Google Scholar] [CrossRef]

- Singha, A.S.; Thakur, V.K. Effect of fibre loading on urea-formaldehyde matrix based green composites. Iran. Polym. J. 2008, 17, 861–873. [Google Scholar]

- Kunanopparat, T.; Menut, P.; Morel, M.H.; Guilbert, S. Reinforcement of plasticized wheat gluten with natural fibers: From mechanical improvement to deplasticizing effect. Compos. Part A 2008, 39, 777–785. [Google Scholar] [CrossRef]

- John, M.J.; Thomas, S. Biofibers andbiocomposites. Carbohydr. Polym. 2008, 71, 343–364. [Google Scholar] [CrossRef]

- Satyanarayana, K.G.; Ramos, L.P.; Wypych, F. Comparative study of Brazilian natural fibers and their composites with others. In Natural Fiber Reinforced Polymer Composites; Thomas, S., Pothan, L.A., Eds.; Maney Publishers: Philadelphia, PA, USA, 2008; pp. 473–522. [Google Scholar]

- Satyanarayana, K.G.; Gregorio, G.C.A.; Wypych, F. Biodegradable composites based on lignocellulosic fibers—An overview. Prog. Polym. Sci. 2009, 34, 982–1021. [Google Scholar] [CrossRef]

- Bouafif, H.; Koubaa, A.; Pierre, P.; Cloutier, A. Effects of fiber characteristics on the physical and mechanical properties of wood plastic composites. Compos. Part A 2009, 40, 1975–1978. [Google Scholar] [CrossRef]

- Müller, C.M.O.; Laurindo, J.B.; Yamashita, F. Effect of cellulose fibers on the crystallinity and mechanical properties of starch-based films at different relative humidity values. Carbohydr. Polym. 2009, 77, 293–299. [Google Scholar] [CrossRef]

- Pinto, C.E.S.; Arizaga, G.G.C.; Wypych, F.; Ramos, L.P.; Satyanarayana, K.G. Studies of the effect of molding pressure and incorporation of sugarcane bagasse fibers on the structure and properties of poly (hydroxy butyrate). Compos. Part A 2009, 40, 573–582. [Google Scholar] [CrossRef]

- Machado, A.C.O.M.; Ribeiro, C.M.S.; Freire, D.M.G.; Cunha, L.M.; Castilho, L.R.; Dias, M.L.; Nazerth, N.J. Material Compósito Contendo Material Termoplástico e Material Protéico e Processo de Obtenção. Available online: http://www.patentesonline.com.br/material-comp-sito-contendo-material-termopl-stico-e-material-prot-ico-e-processo-229188.html (accessed on 16 July 2014).

- Guimarães, J.L.; Satyanarayana, K.G.; Wypych, F.; Saul, C.; Ramos, L.P. Studies on the processing and characterization of cornstarch and its composites with banana and sugarcane fibers of Brazil. Carbohydr. Polym. 2010, 80, 130–138. [Google Scholar] [CrossRef]

- Basiji, F.; Safdari, V.; Nourbakhsh, A.; Pilla, S. The effects of fiber length and fiber loading on the mechanical properties of wood-plastic (polypropylene) composites. Turk. J. Agric. For. 2010, 34, 191–196. [Google Scholar] [CrossRef]

- Lomelí, R.M.G.; Satyanarayana, K.G.; Iwakiri, S.; Bolzon, M.G.; Tanobe, V.; Syden-stricker, F.T. Study of the properties of biocomposites: Part I—Cassava starch-green coir fibers of Brazil. Carbohydr. Polym. 2011, 86, 1712–1722. [Google Scholar] [CrossRef]

- Lomelí, R.M.G.; Satyanarayana, K.G.; Iwakiri, S.; Bolzon, M.G.; Tanobe, V.; Sydenstricker, F.T. Bio-composites of cassava starch-green coconut fiber: Part II—Structure and properties. Carbohydr. Polym. 2014, 102, 576–583. [Google Scholar] [CrossRef] [PubMed]

- Thakur, V.K.; Thakur, M.K. Processing and characterization of natural cellulose fibers/thermoset polymer composites. Carbohydr. Polym. 2014, 109, 102–117. [Google Scholar] [CrossRef] [PubMed]

- Thakur, V.K.; Thakur, M.K.; Gupta, R.K. Review: Raw natural fiber-based polymer composites. Int. J. Polym. Anal. Charact. 2014, 19, 256–271. [Google Scholar] [CrossRef]

- Thakur, V.K.; Grewell, D.; Thunga, M.; Kessler, M.R. Novel composites from eco-friendlysoy flour/SBS triblock copolymer. Macromol. Mater. Eng. 2014, 299, 953–958. [Google Scholar] [CrossRef]

- Thakur, V.K.; Kessler, M.R. Free radical induced graft copolymerization of ethyl acrylate onto SOY for multifunctional materials. Mater. Today Commun. 2014, 1, 34–41. [Google Scholar] [CrossRef]

- Thakur, V.K.; Kessler, M.R. Synthesis and characterization of AN-g-SOY for sustainable polymer composites. ACS Sustain. Chem. Eng. 2014, 2, 2454–2460. [Google Scholar] [CrossRef]

- Pappu, A.; Patil, V.; Jain, S.; Mahindrakar, A.; Haque, R.; Thakur, V.K. Advances in industrial prospective of cellulosic macromolecules enriched banana biofibre resources: A Review. Int. J. Biol. Macromol. 2015, 79, 449–458. [Google Scholar] [CrossRef] [PubMed]

- Pagliaro, M.; Ciriminna, R.; Kimura, H.; Rossi, M.; Della Pina, C. From glycerol to value-added products. Angew. Chem. Int. Ed. Engl. 2007, 46, 4434–4440. [Google Scholar] [CrossRef] [PubMed]

- Behr, A.; Eilting, J.; Irawadi, K.; Leschinski, J.; Lindner, F. Improved utilization of renewable resources: New important derivatives of glycerol. Green Chem. 2008, 10, 13–23. [Google Scholar] [CrossRef]

- Frondel, M.; Peters, J. Biodiesel: A new Oildorado? Energy Policy 2007, 35, 1675–1684. [Google Scholar] [CrossRef]

- Brazil: Biofuels Digest. Available online: http://www.biofuelsdigest.com/bdigest/tag/brazil/ (accessed on 21 August 2015).

- USDA Foreign Agriculture Service-GAIN Report, No. BR13005. Available online: http://gain.fas.usda.gov/Recent%20GAIN%20Publications/Biofuels%20Annual_Sao%20Paulo%20ATO_Brazil_9-12-2013.pdf (accessed on 19 December 2013).

- Lacerda, R.S.; Bittante, A.M.Q.B.; Chambi, H.; Gomide, C.A.; Moraes, I.C.F.; Carvalho, R.A.; Sobral, P.J.A. Castor bean cake as raw material for biodegradable material. In Proceedings of the 11th International Congress on Engineering and Food (ICEF11), Athens, Greece, 22–26 May 2011; Taoukis, P.S., Shoforos, N.G., Karathanos, V.T., Saravacos, G.D., Eds.; Cosmosware, Ag. Ioannou 53: Athens, Greece. Available online: www.icef11.org/content/ papers/fms/FMS174.pdf (accessed on 8 July 2014).

- Vanderleia, A. Obtaining of Therm-Molded Composites through the Use of Castor Oil Cake Plastified with Glycerol, Derivative of the Transesterefication of Oils and Fats (Obtenção de Compósitos Termomoldados a Partir da Torta de Mamona Plastificada com Glicerol, Derivado do Processo de Transesterificação de Óleos e Gorduras). Masters’ Thesis, Federal University of Parana (UFPR), Curitiba, Brazil, 2009. [Google Scholar]

- Torta de Mamona - BiodieselBR.com. Available online: http://www.biodieselbr.com/plantas/mamona/torta-de-mamona.htm (accessed on 30 March 2013).

- Makishi, G.L.A.; Lacerda, R.S.; Bittante, A.M.Q.B.; Chambi, H.N.M.; Costa, P.A.; Gomide, C.A.; Carvalho, R.A.; Sobral, P.J.A. Films based on castor bean (Ricinus communis L.) proteins cross linked with glutaraldehyde and glyoxal. Ind. Crop. Prod. 2013, 50, 375–382. [Google Scholar] [CrossRef]

- Alves, E.E.N.; Souza, C.F.; Inoue, K.R.A.; Leite, T.S. Potential of production of biogas from the castor bean (Ricinus communis L.) cake. In Proceedings of Annual International Meeting ofAmerican Society of Agricultural and Biological Engineers (ASABE) Sponsored by ASABE David L., Lawrence Convention Center: Pittsburgh, PA, USA, 20–23 June 2010.

- Stork, R.R.; Rocha, M.C.G.R. Composites of low density polyethylene and castor press cake. Polym. Plast. Technol. 2010, 49, 1352–1355. [Google Scholar] [CrossRef]

- Oliveira, T.G. Desenvolvimento de Filmes Biodegradáveis á Base de Protein da Torta de Mamona (Ricinus Communis L.) Modificada com Glioxal e Reforçados com Fibras de Cellulose. Ph.D. Thesis, Department of Zoology and Food Engineering, University of São Paulo, Pirassununga, Brazil, 2013. [Google Scholar]

- Marina, M.N.K. Potential of the Use of the Castor Oil Cake (Ricinus communis L.) as matrix for the Production of Composites and Nanocompósitos. Potencial do Uso da a Torta de Mamona (Ricinus communis L.) Como Matriz Para Produção de Compósitos e Nanocompósitos. Ph.D. Thesis, Forest and Wood Sciences, UFPR, Curitiba, Brazil, 8 December 2013. [Google Scholar]

- Bittante, A.M.Q.B.; Lacerda, R.S.; Oliveira, T.; Makishi, G.L.A.; Costa, P.A.; Chambi, H.N.M.; Gomide, C.A.; Sobral, P.J.A. Properties of biodegradable films made with proteins extracted from castor bean (Ricinus Communis) cake: Effect of protein extraction pH. Chem. Eng. Trans. 2014, 37, 751–756. [Google Scholar] [CrossRef]

- Burlein, G.A.D.; Rocha, M.C.G. Mechanical and morphological properties of LDPE/ PHB blends filled with castor oil pressed cake. Mater. Res. 2014, 17, 97–105. [Google Scholar] [CrossRef]

- Guimarães, J.L.; Frollini, E.; Silva, C.G.; Wypych, F.; Satyanarayana, K.G. Characterization of banana, sugarcane bagasse and sponge gourd fibers of Brazil. Ind. Crop Prod. 2009, 30, 407–415. [Google Scholar] [CrossRef]

- Guimarães, J.L.; Satyanarayana, K.G.; Wypych, F.; Ramos, L.P.; Trinidade Cursino, A.C. Termomoldagem Direta de Laminados Compósitos Baseados em Torta de Ricinus Communis (Mamona) Plastificado com Glicerol Bruto Recuperado do Processo de Transesterifacação de Óleos Vegetais, Reforçados com Fibras de Origem Natural. Brazil, Intern. Patent BR200602428-A, 29 July 2008. [Google Scholar]

- Guimarães, J.L. Preparation and Characterization of Composites of Plasticized Starch with Glycerol and reinforced with Natural Fibers. Ph.D. Thesis, Federal University of Parana (UFPR), Curitiba, Brazil, 12 August 2010. [Google Scholar]

- Guimarães, J.L.; Ana Cristina, T.C.; Saul, C.K.; Maria Rita, S.; Ramos, L.P.; Wypych, F.; Satyanarayana, K.G. Effect of processing conditions on tensile properties of green composites of castor oil cake starch-plant fibers. J. Bioprocess Biotech. 2014, 5. [Google Scholar] [CrossRef]

- Marina, M.N.K.; Magalhães, W.L.E.; Satyanarayana, K.G.; Elaine, C.L. Evaluation of physical and mechanical properties of nanocomposites of castor oil cake based starch reinforced with nanocellulose. In Proceedings of the VII Workshop on Applied Nanotechnology to Agrobusiness, EMBRAPA Instrumentação, São Carlos, Brazil, 10–13 June 2013; pp. 241–243.

- Satyanarayana, K.G.; Guimarães, J.L.; Wypych, F. Studies on lignocellulosic fibers of Brazil: Part I—Production, processing, structure and properties of Brazilian fibers. Compos. Part A 2007, 38, 1694–1709. [Google Scholar] [CrossRef]

- A. Azevedo Óleos. Available online: http://www.azevedooleos.com.br (accessed on 30 March 2013).

- Melo, W.C.; Santos, A.S.; Santa Anna, L.M.; Pereira, N., Jr. Acid and enzymatic hydrolysis of the residue from Castor Bean (Ricinus cimmunis L.) oil extraction for ethanol production: Detoxification and biodiesel process integration. J. Brazil Chem. Soc. 2008, 19, 418–425. [Google Scholar] [CrossRef]

- ASTM D638–14: Standard Test Method for Tensile Properties of Plastics; ASTM International: West Conshohocken, PA, USA, 2014.

- Albuquerque, M.C.G. Synthesis, Characterization and Application of Heterogeneous Catalysts for the Production of Biofuels (Síntese, Caracterização e Aplicação de Catalisadores Heterogeneous Para Produção de Biocombustíveis). Ph.D. Thesis, Federal University of Ceará, Fortaleza, Brazil, 2008. [Google Scholar]

- Dou, B.L.; Dupont, V.; Williams, P.T.; Chen, H.S.; Ding, Y.L. Thermogravimetric kinetics of crude glycerol. Bioresour. Technol. 2009, 100, 2613–2620. [Google Scholar] [CrossRef] [PubMed]

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons by Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Guimarães, J.L.; Trindade Cursino, A.C.; Ketzer Saul, C.; Sierrakowski, M.R.; Ramos, L.P.; Satyanarayana, K.G. Evaluation of Castor Oil Cake Starch and Recovered Glycerol and Development of “Green” Composites Based on Those with Plant Fibers. Materials 2016, 9, 76. https://doi.org/10.3390/ma9020076

Guimarães JL, Trindade Cursino AC, Ketzer Saul C, Sierrakowski MR, Ramos LP, Satyanarayana KG. Evaluation of Castor Oil Cake Starch and Recovered Glycerol and Development of “Green” Composites Based on Those with Plant Fibers. Materials. 2016; 9(2):76. https://doi.org/10.3390/ma9020076

Chicago/Turabian StyleGuimarães, José Luis, Ana Cristina Trindade Cursino, Cyro Ketzer Saul, Maria Rita Sierrakowski, Luiz Pereira Ramos, and Kestur Gundappa Satyanarayana. 2016. "Evaluation of Castor Oil Cake Starch and Recovered Glycerol and Development of “Green” Composites Based on Those with Plant Fibers" Materials 9, no. 2: 76. https://doi.org/10.3390/ma9020076

APA StyleGuimarães, J. L., Trindade Cursino, A. C., Ketzer Saul, C., Sierrakowski, M. R., Ramos, L. P., & Satyanarayana, K. G. (2016). Evaluation of Castor Oil Cake Starch and Recovered Glycerol and Development of “Green” Composites Based on Those with Plant Fibers. Materials, 9(2), 76. https://doi.org/10.3390/ma9020076