Fabrication of Fe-Based Diamond Composites by Pressureless Infiltration

Abstract

:1. Introduction

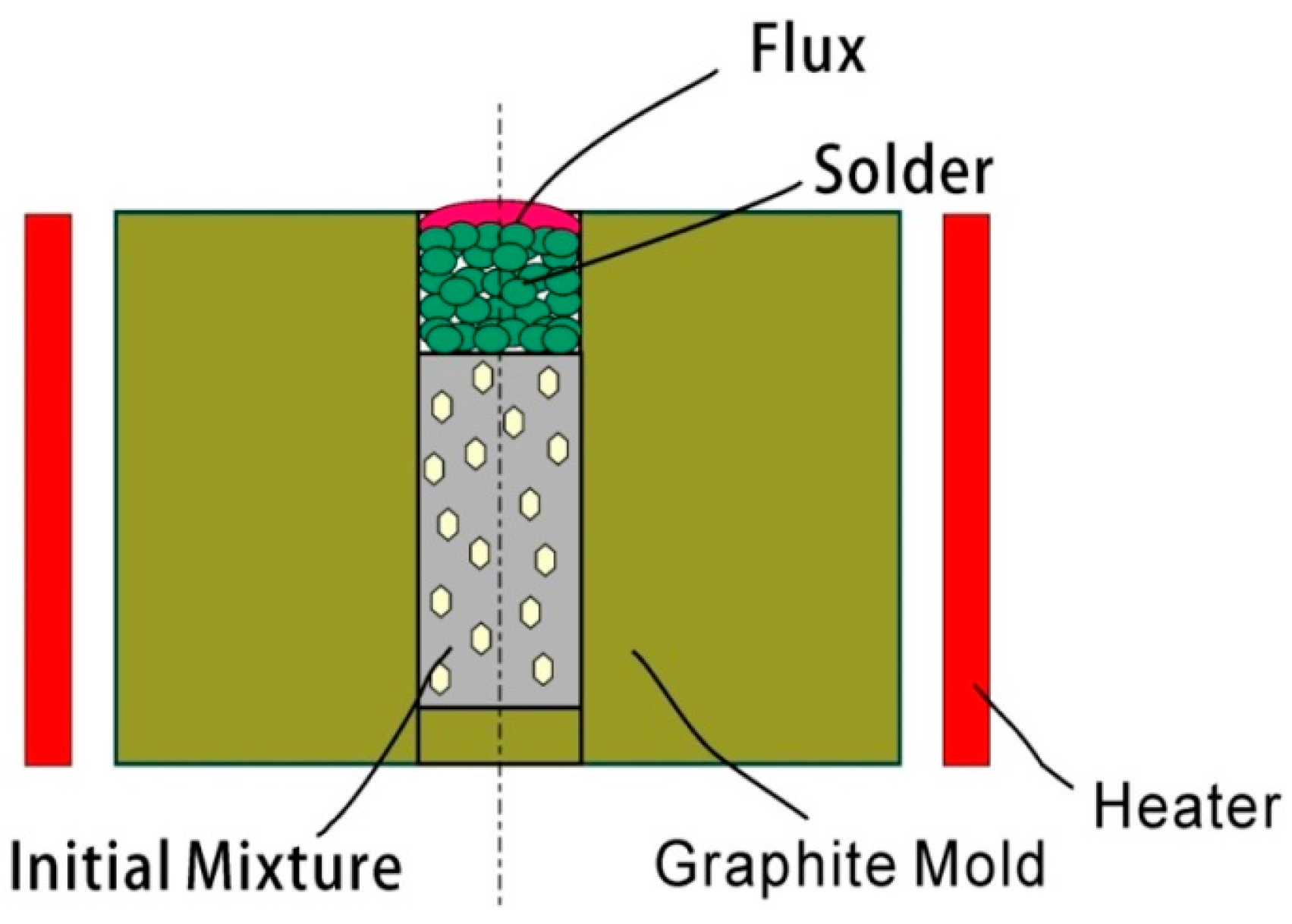

2. Materials and Methods

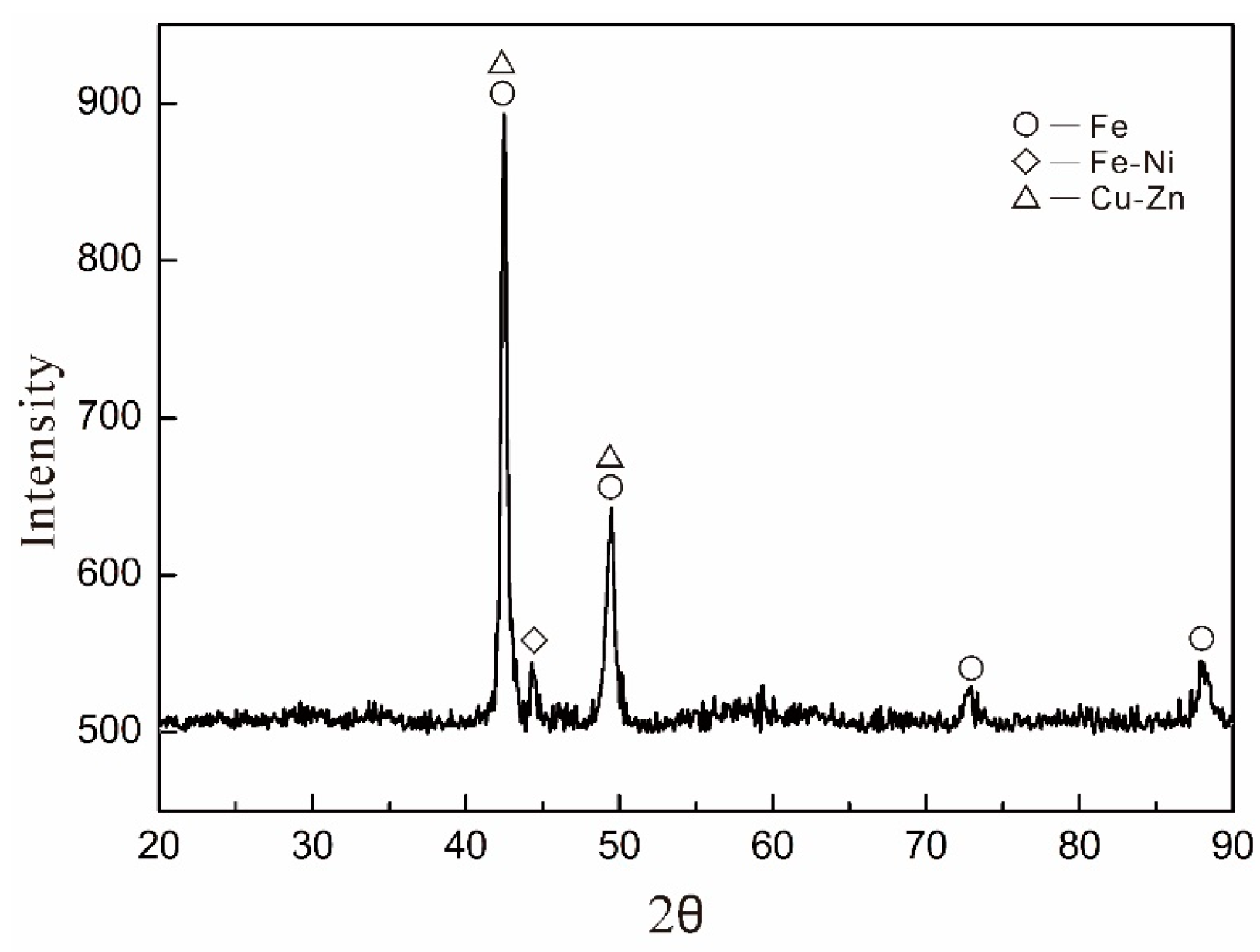

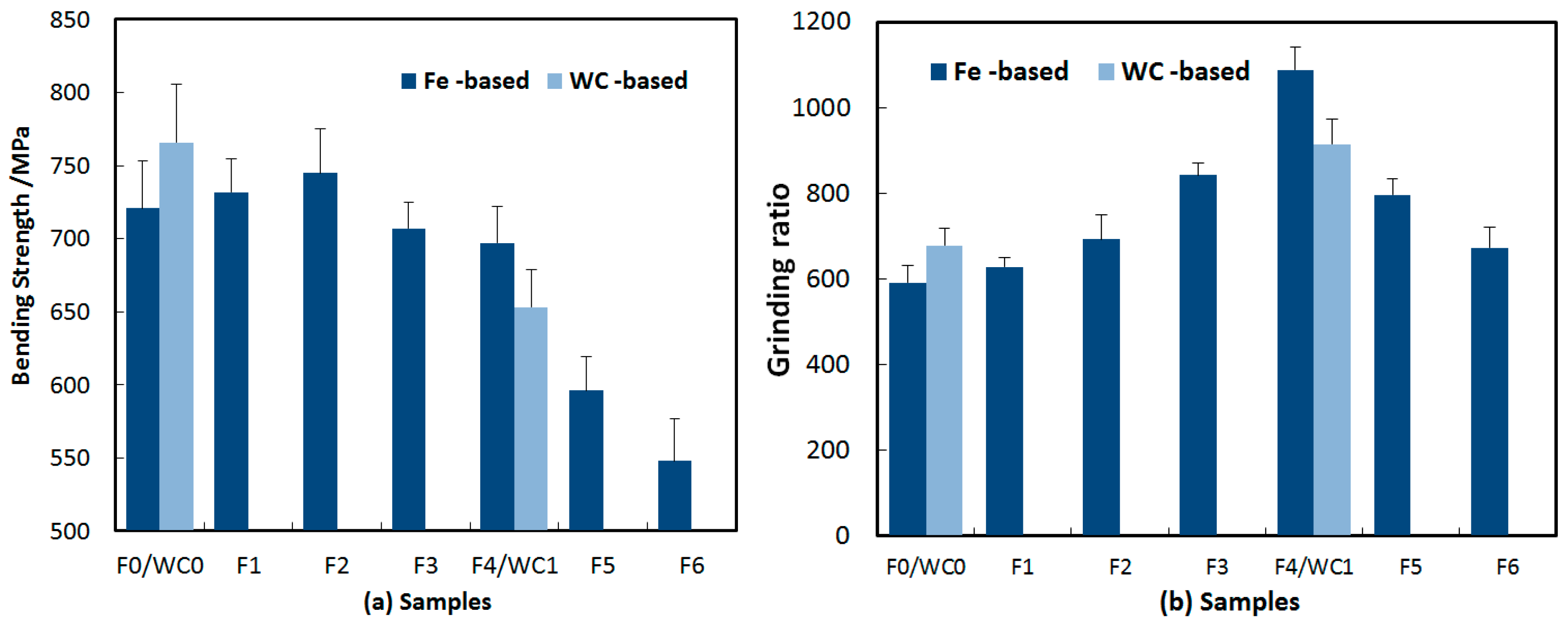

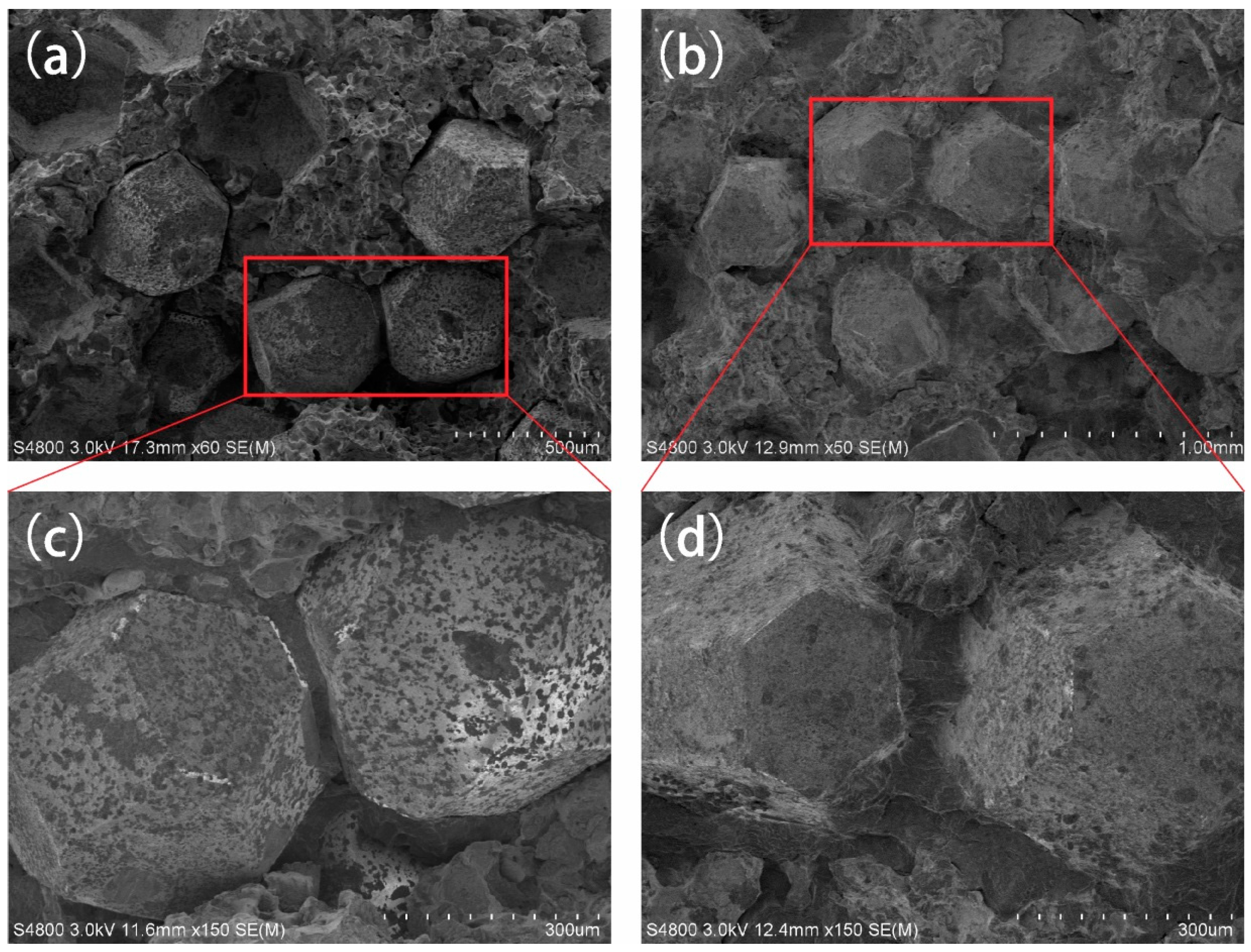

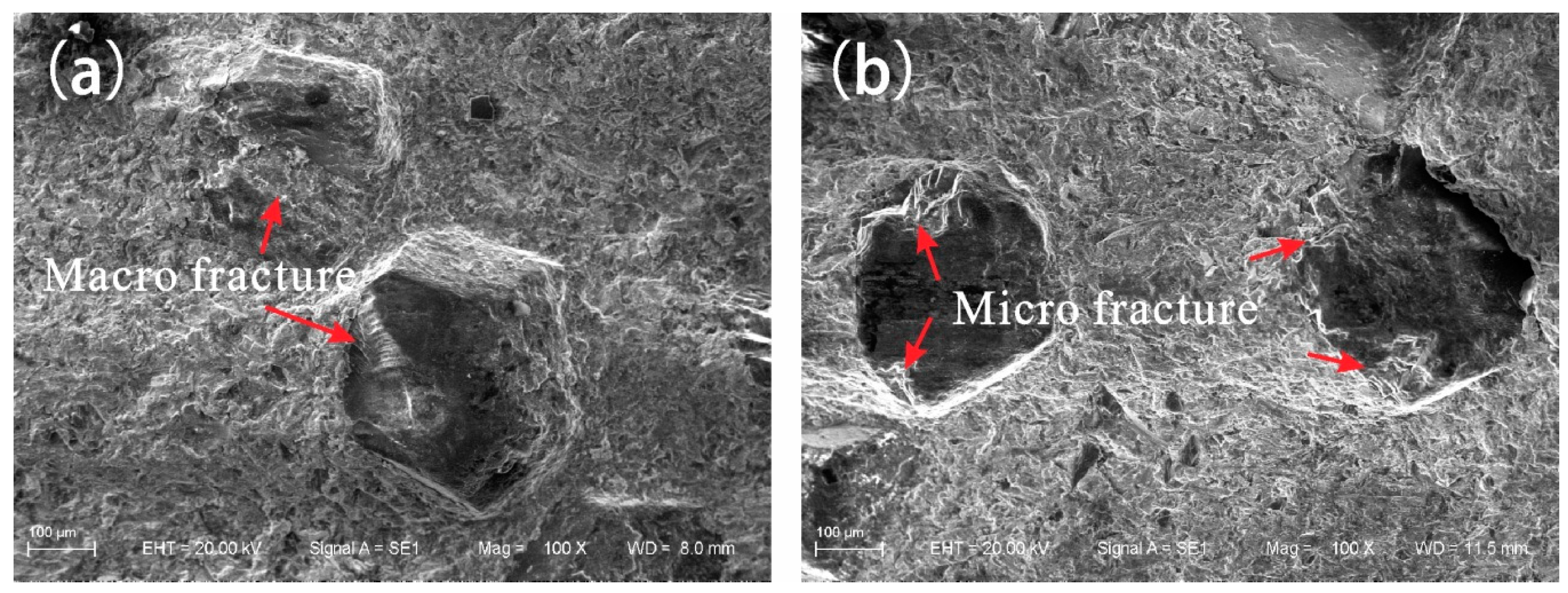

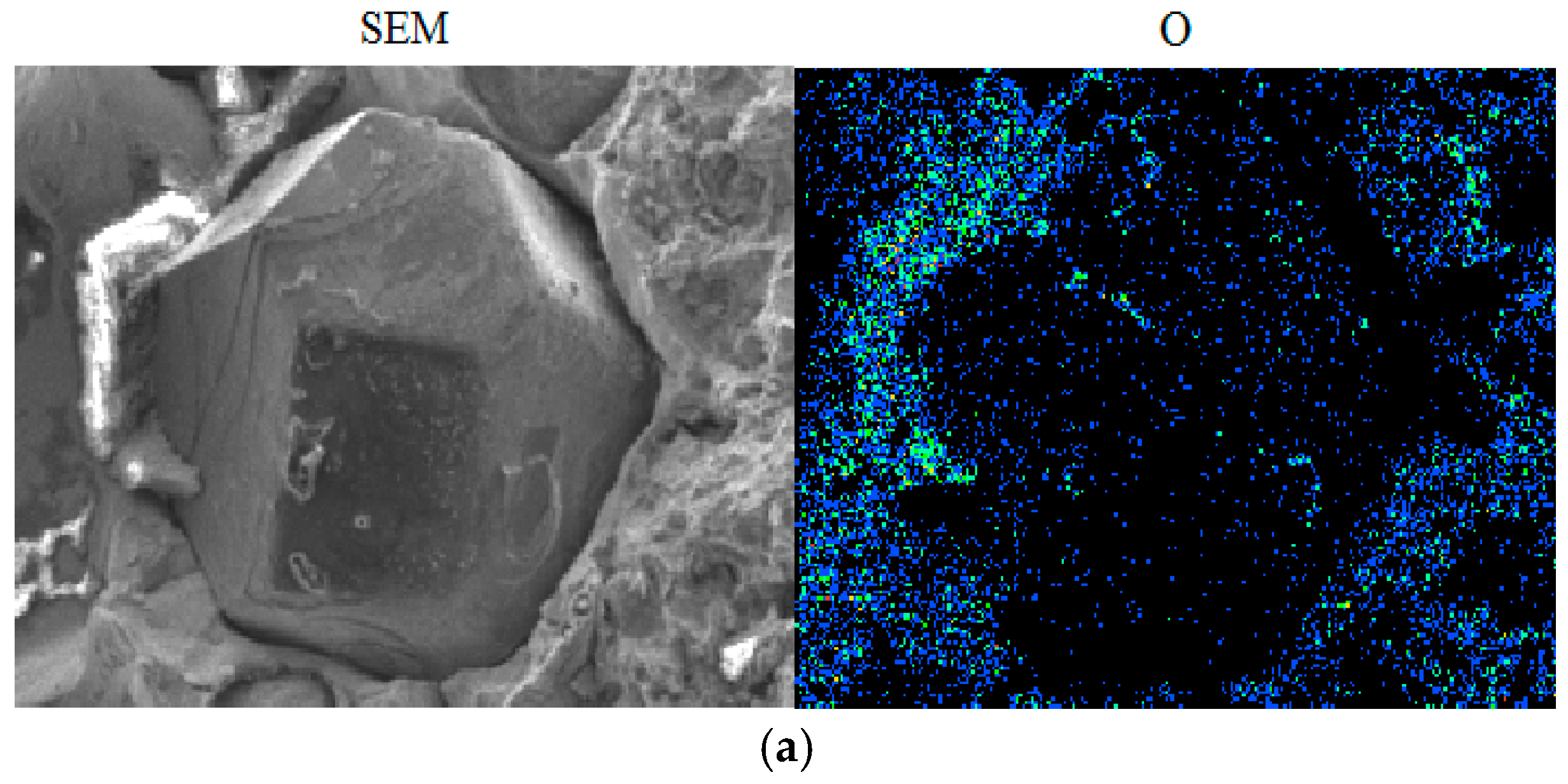

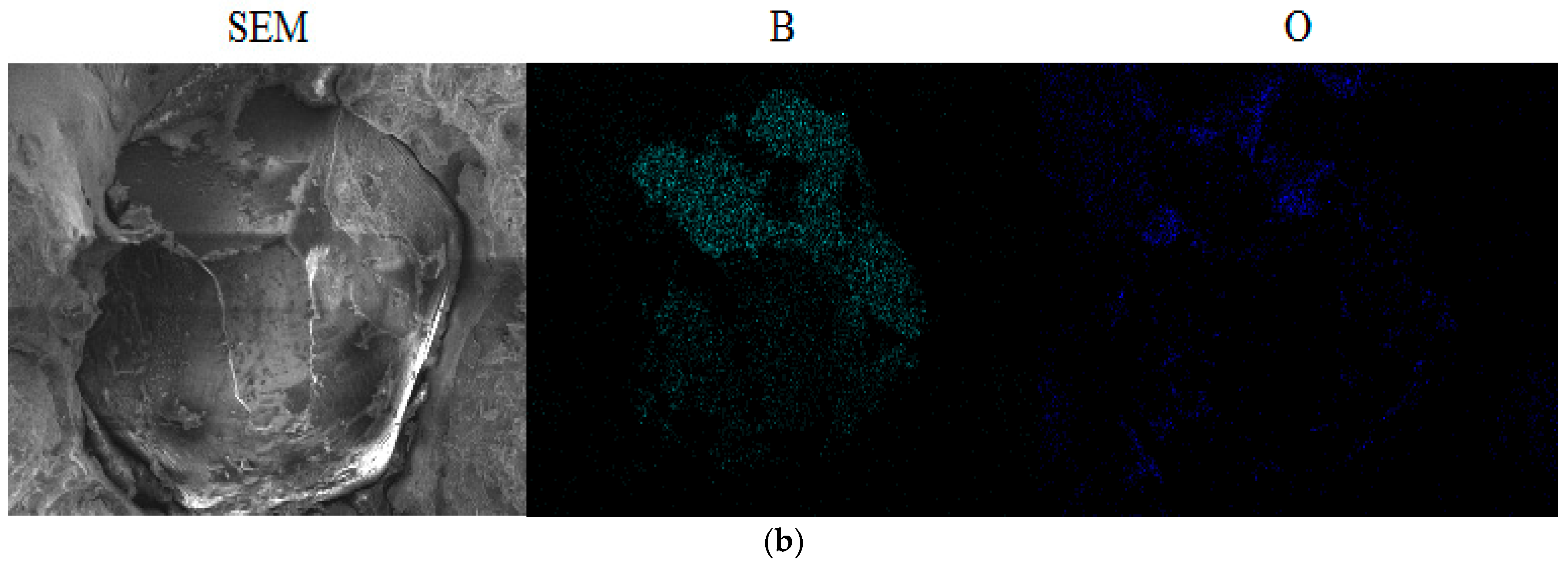

3. Results and Discussion

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Lin, B.; Wang, X.; Zhang, Y.; Zhu, J.; Zhang, H. Interface characterization of a Cu–Ti-coated diamond system. Surf. Coat. Technol. 2015, 278, 163–170. [Google Scholar] [CrossRef]

- Dai, Q.L.; Luo, C.B.; Xu, X.P.; Wang, Y.C. Effect of rare earth and sintering temperature on the transverse rupture strength of Fe-based diamond composites. J. Mater. Process. Technol. 2002, 129, 427–430. [Google Scholar] [CrossRef]

- Nitkiewicz, Z.; Świerzy, M. Tin influence on diamond–metal matrix hot pressed tools for stone cutting. J. Mater. Process. Technol. 2006, 175, 306–315. [Google Scholar] [CrossRef]

- Sun, L.; Pan, J.S.; Lin, C.J. A new approach to improve the performance of diamond sawblades. Mater. Lett. 2002, 57, 1010–1014. [Google Scholar] [CrossRef]

- Ronald, B.A.; Vijayaraghavan, L.; Krishnamurthy, R. Studies on the influence of grinding wheel bond material on the grindability of metal matrix composites. Mater. Des. 2009, 30, 679–686. [Google Scholar] [CrossRef]

- Tan, S.; Fang, X.; Yang, K.; Duan, L. A new composite impregnated diamond bit for extra-hard, compact, and nonabrasive rock formation. Int. J. Refract. Met. Hard Mater. 2014, 43, 186–192. [Google Scholar] [CrossRef]

- Li, M.; Sun, Y.H.; Dong, B.; Wu, H.D.; Gao, K. Study on effects of CNTs on the properties of WC-based impregnated diamond matrix composites. Mater. Res. Innov. 2015, 19, 59–63. [Google Scholar] [CrossRef]

- De Oliveira, L.J.; Cabral, S.C.; Filgueira, M. Study hot pressed Fe-diamond composites graphitization. Int. J. Refract. Met. Hard Mater. 2012, 35, 228–234. [Google Scholar] [CrossRef]

- Li, W.; Zhan, J.; Wang, S.; Dong, H.; Li, Y.; Liu, Y. Characterizations and mechanical properties of impregnated diamond segment using Cu-Fe-Co metal matrix. Rare Met. 2012, 31, 81–87. [Google Scholar] [CrossRef]

- Chung, C.-Y.; Lee, M.-T.; Tsai, M.-Y.; Chu, C.-H.; Lin, S.-J. High thermal conductive diamond/Cu–Ti composites fabricated by pressureless sintering technique. Appl. Ther. Eng. 2014, 69, 208–213. [Google Scholar] [CrossRef]

- Zhao, C.W. Impregnating procedure of diamond drill bit at a low melting point. J. Univ. Pet. Chin. 1996, 2, 65–69. [Google Scholar]

- Xu, S.P. Discussion on non-pressure liquid infiltration theory for diamond bit making. West-Chin. Explor. Eng. 1992, 6, 7–9. [Google Scholar]

- De Oliveira, L.J.; Bobrovnitchii, G.S.; Filgueira, M. Processing and characterization of impregnated diamond cutting tools using a ferrous metal matrix. Int. J. Refract. Met. Hard Mater. 2007, 25, 328–335. [Google Scholar] [CrossRef]

- Xu, X.P.; Tie, X.R.; Yu, Y.Q. The effects of rare earth on the fracture properties of different metal–diamond composites. J. Mater. Process. Technol. 2007, 187, 421–424. [Google Scholar] [CrossRef]

- Islak, S.; Çelik, H. Effect of sintering temperature and boron carbide content on the wear behavior of hot pressed diamond cutting segments. Sci. Sinter. 2015, 47, 131–143. [Google Scholar] [CrossRef]

- Xu, X.; Tie, X.; Wu, H. The effects of a Ti coating on the performance of metal-bonded diamond composites containing rare earth. Int. J. Refract. Met. Hard Mater. 2007, 25, 244–249. [Google Scholar] [CrossRef]

- Sun, Y.C.; Liu, Y.B. Diamond Tool and Metallurgical Technology; China Construction Materials Press: Beijing, China, 1999. [Google Scholar]

- Zhang, Z.; Chen, Y.; Huang, A.; Jiang, Y.; Wu, G. The development study about low Co matrix of stone sawing blade. Diam. Abras. Eng. 1995, 5, 2–4. [Google Scholar]

- Wang, M.; Li, H.; Li, M.; Gong, J.; Tian, B. Effect of Boron Contained in the Catalyst on Thermal Stability of Boron-Doped Diamond Single Crystals. Chin. J. High Press. Phys. 2008, 2, 215–219. [Google Scholar]

- Fan, Y.-M.; Guo, H.; Xu, J.; Chu, K.; Zhu, X.-X.; Jia, C.-C. Effects of boron on the microstructure and thermal properties of Cu/diamond composites prepared by pressure infiltration. Int. J. Refract. Met. Hard Mater. 2011, 18, 472–478. [Google Scholar] [CrossRef]

- Hu, H.; Kong, J. Improved thermal performance of diamond-copper composites with boron carbide coating. J. Mater. Eng. Perform. 2013, 23, 651–657. [Google Scholar] [CrossRef]

- Bai, H.; Ma, N.; Lang, J.; Zhu, C. Effect of a new pretreatment on the microstructure and thermal conductivity of Cu/diamond composites. J. Alloys Comp. 2013, 580, 382–385. [Google Scholar] [CrossRef]

- Li, S.; Zhao, M.; Zhang, L. The B solubility in Fe3 (C1-x, Bx) of Fe-B-C alloy. Trans. Chin. Soc. Agric. Mach. 1993, 4, 91–95. [Google Scholar]

| Designation | Composition | Relative Density (%) | Rockwell Hardness Scale B (HRB) | Rockwell Hardness Scale C (HRC) |

|---|---|---|---|---|

| F0 | Fe-based Matrix | 94 | 56.4 ± 1.5 | – |

| F1 | Fe-based Matrix + 0.25 wt % B | 95 | 58.4 ± 2.1 | – |

| F2 | Fe-based Matrix + 0.5 wt % B | 97 | 59.6 ± 1.6 | – |

| F3 | Fe-based Matrix + 0.75 wt % B | 95 | 62.4 ± 1.2 | – |

| F4 | Fe-based Matrix + 1 wt % B | 96 | 63.5 ± 1.0 | – |

| F5 | Fe-based Matrix + 1.25 wt % B | 96 | 65.0 ± 1.4 | – |

| F6 | Fe-based Matrix + 1.5 wt % B | 95 | 67.2 ± 1.8 | – |

| WC0 | WC-based Matrix | 92 | – | 43 ± 1.0 |

| WC1 | WC-based Matrix + 1 wt % B | 90 | – | 44 ± 0.5 |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, M.; Sun, Y.; Meng, Q.; Wu, H.; Gao, K.; Liu, B. Fabrication of Fe-Based Diamond Composites by Pressureless Infiltration. Materials 2016, 9, 1006. https://doi.org/10.3390/ma9121006

Li M, Sun Y, Meng Q, Wu H, Gao K, Liu B. Fabrication of Fe-Based Diamond Composites by Pressureless Infiltration. Materials. 2016; 9(12):1006. https://doi.org/10.3390/ma9121006

Chicago/Turabian StyleLi, Meng, Youhong Sun, Qingnan Meng, Haidong Wu, Ke Gao, and Baochang Liu. 2016. "Fabrication of Fe-Based Diamond Composites by Pressureless Infiltration" Materials 9, no. 12: 1006. https://doi.org/10.3390/ma9121006

APA StyleLi, M., Sun, Y., Meng, Q., Wu, H., Gao, K., & Liu, B. (2016). Fabrication of Fe-Based Diamond Composites by Pressureless Infiltration. Materials, 9(12), 1006. https://doi.org/10.3390/ma9121006