Influence of Blended Cements with Calcareous Fly Ash on Chloride Ion Migration and Carbonation Resistance of Concrete for Durable Structures

Abstract

:1. Introduction

2. Experimental Section

2.1. Materials

| Constituent | LOI | SiO2 | Al2O3 | Fe2O3 | CaO | MgO | SO3 | K2O | Na2O | CaOfree |

|---|---|---|---|---|---|---|---|---|---|---|

| Calcareous fly ash (W) | 2.12 | 40.88 | 19.00 | 4.25 | 25.97 | 1.73 | 3.94 | 0.14 | 0.13 | 1.07 |

| Siliceous fly ash (V) | 2.31 | 53.54 | 26.64 | 5.75 | 2.91 | 2.68 | 0.23 | 3.31 | 0.84 | 0.1 |

| Blast furnace slag * (S) | 1.06 | 1.30 | 6.79 | 1.21 | 45.79 | 5.16 | 2.09 | 0.39 | 0.53 | - |

| Type of Cement | Main constituents, % | Properties | ||||||

|---|---|---|---|---|---|---|---|---|

| Cement Clinker | Fly Ash | Slag S | Specific Gravity, (g/cm3) | Surface Area (Blaine), (cm2/g) | SO3 Content, (%) | Strength fc28 *) (MPa) | ||

| Calcareous W | Siliceous V | |||||||

| CEM I | 94.5 | - | - | - | 3.10 | 3850 | 2.82 | 52.5 |

| CEM II/A-W | 80.9 | 14.3 | - | - | 3.05 | 3840 | 3.11 | 47.0 |

| CEM II/B-W | 67.4 | 28.9 | - | - | 2.98 | 3750 | 3.13 | 38.1 |

| CEM II/B-M(V-W) | 66.6 | 14.3 | 14.3 | - | 2.93 | 3750 | 3.13 | 30.9 |

| CEM II/B-M(S-W) | 66.6 | 14.3 | - | 14.3 | 3.03 | 3720 | 3.33 | 41.5 |

| CEM V/A(S-W) **) | 47.9 | 23.9 | - | 23.9 | 2.97 | 3800 | 3.33 | 31.8 |

| Concrete Series Designation | Cement | Sand 0–2 mm | Coarse Aggregate | Water | HRWR | |

|---|---|---|---|---|---|---|

| 1G | CEM I | 320 | 630 | 1325 *) | 176 | - |

| 2G | CEM II/A-W | 0.36 | ||||

| 3G | CEM II/B-W | 0.36 | ||||

| 4G | CEM II/B-M(V-W) | 0.36 | ||||

| 5G | CEM II/B-M(S-W) | 0.36 | ||||

| 6G | CEM V/A(S-W) | 0.36 | ||||

| 1D | CEM I | 320 | 630 | 1325 **) | 176 | - |

| 2D | CEM II/A-W | 0.36 | ||||

| 3D | CEM II/B-W | 0.36 | ||||

| 4D | CEM II/B-M(V-W) | 0.36 | ||||

| 5D | CEM II/B-M(S-W) | 0.36 | ||||

| 6D | CEM V/A(S-W) | 0.36 | ||||

2.2. Test Methods

2.2.1. Chloride Migration Coefficient

2.2.2. Carbonation Depth

2.2.3. Compressive Strength

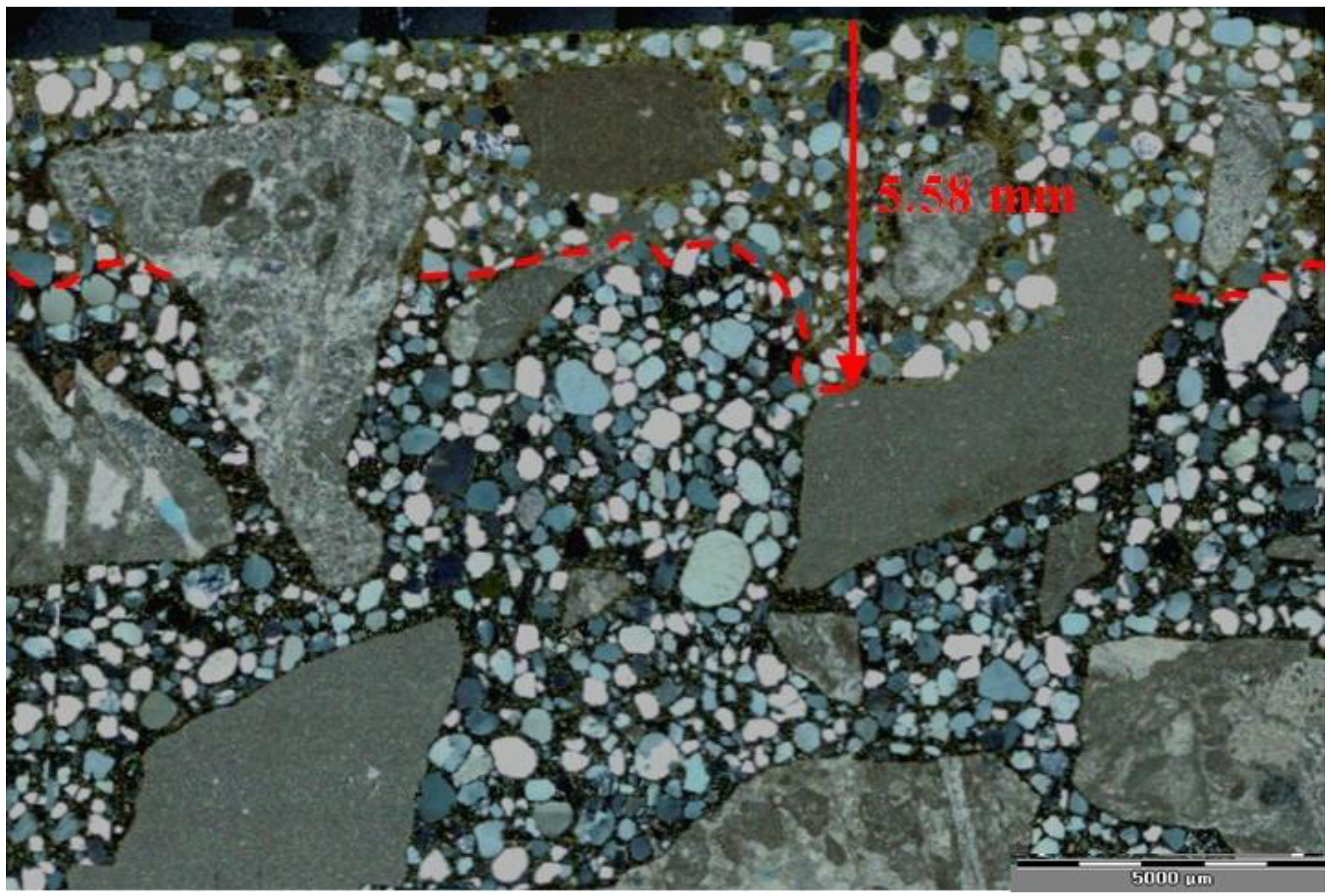

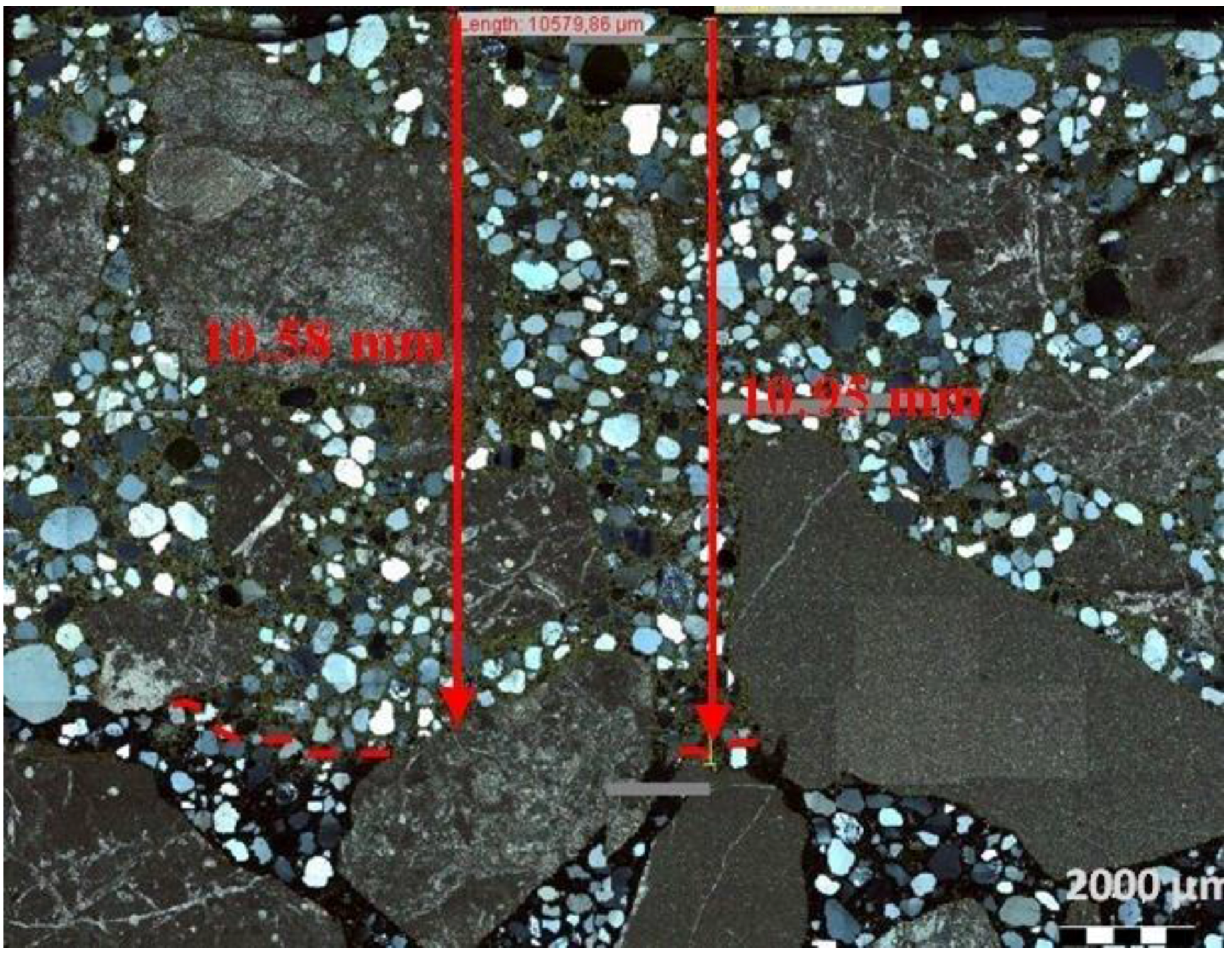

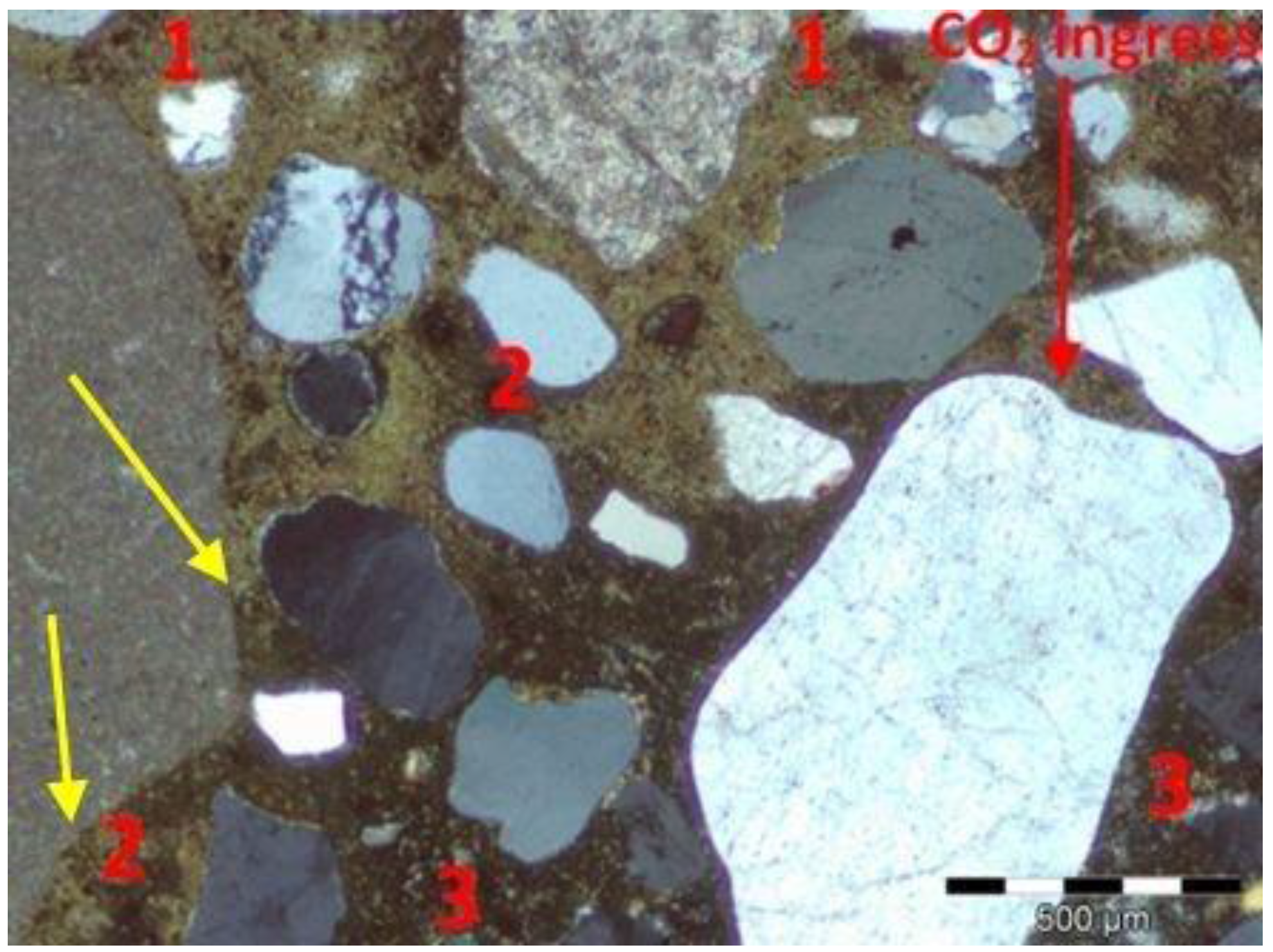

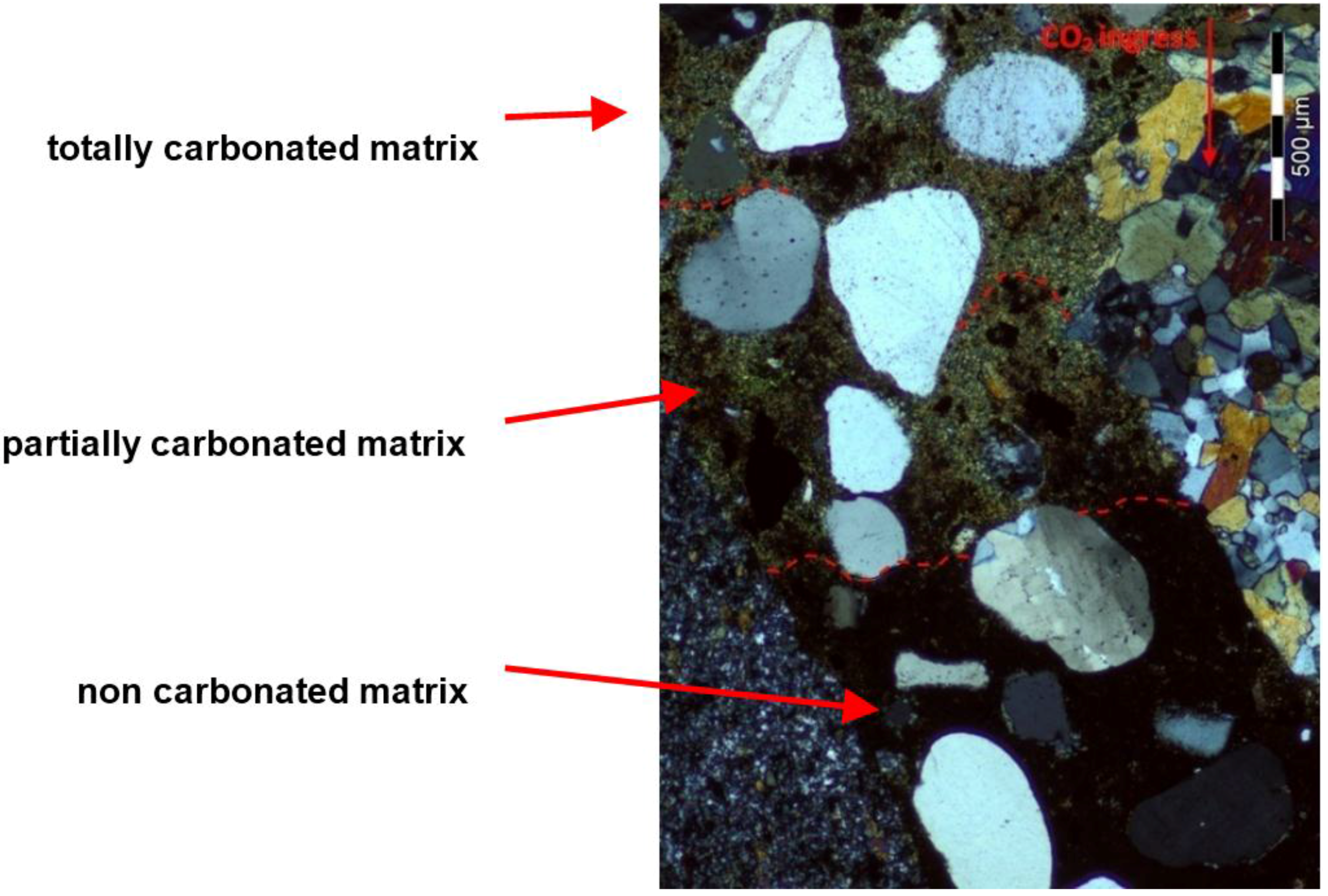

2.2.4. Thin Section Analysis

3. Test Results

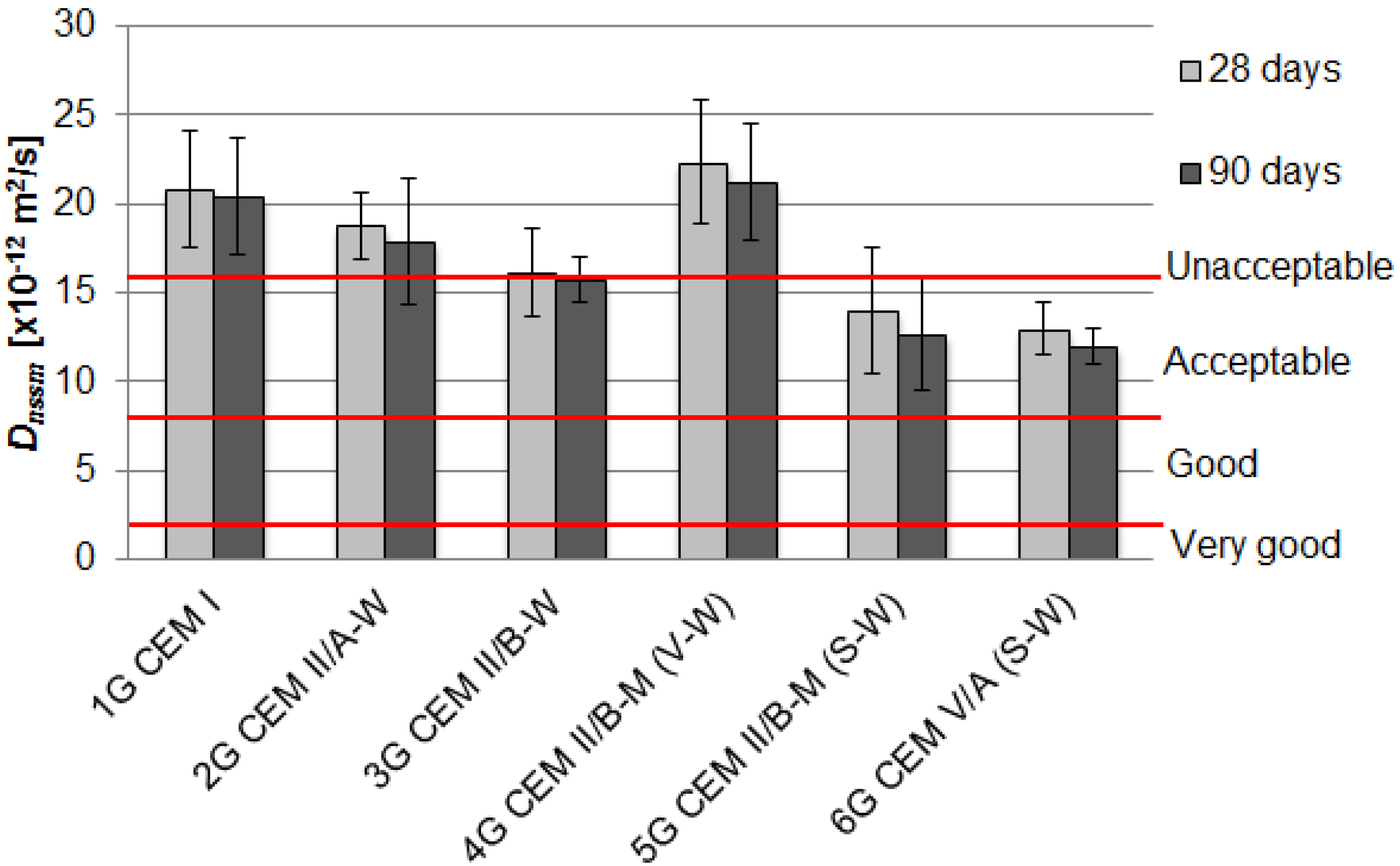

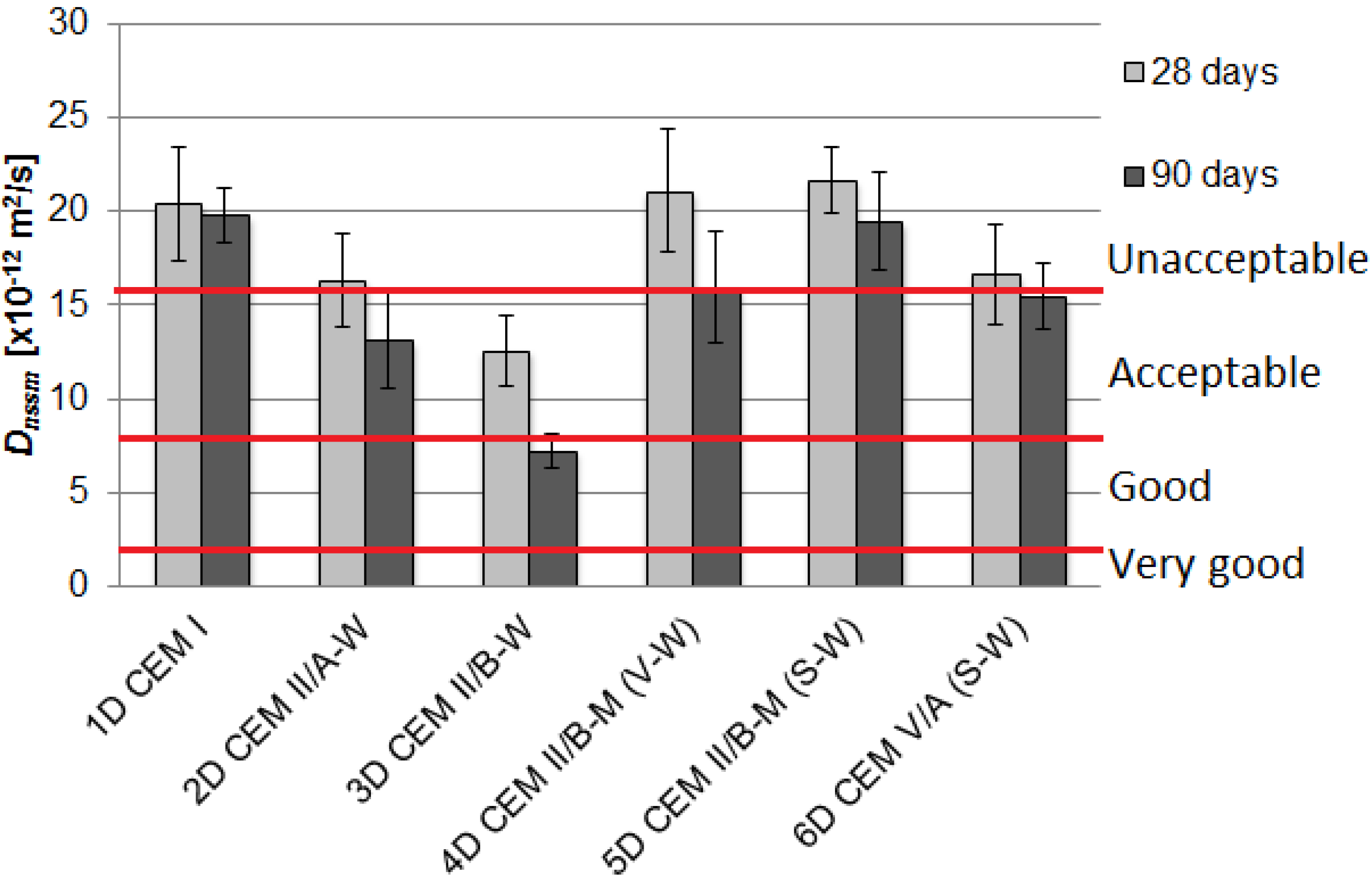

3.1. Compressive Strength and Chloride Permeability

| Cement Type | Compressive Strength, fc28 (MPa) | |

|---|---|---|

| Granodiorite Aggregate | Limestone Aggregate | |

| CEM I | 48.5 | 46.8 |

| CEM II/A-W | 52.1 | 52.4 |

| CEM II/B-W | 47.1 | 48.6 |

| CEM II/B-M(V-W) | 41.5 | 34.3 |

| CEM II/B-M(S-W) | 50.0 | 43.5 |

| CEM V/A(S-W) | 39.6 | 36.7 |

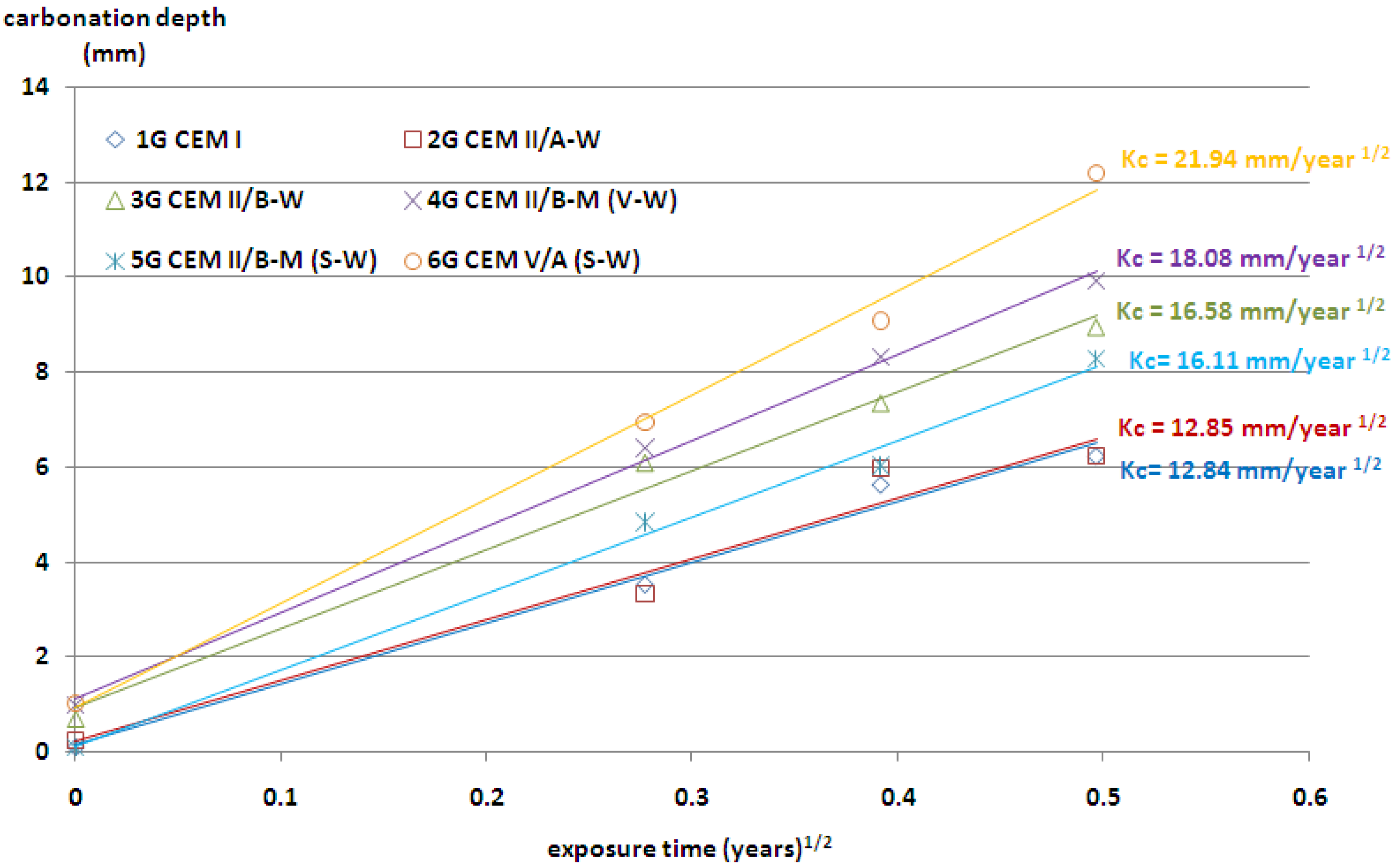

3.2. Rate of Carbonation

| Cement Type | Carbonation Coefficient Kc (mm/y1/2), Natural Conditions, CO2 = 0.03% | |

|---|---|---|

| Granodiorite Aggregate | Limestone Aggregate | |

| CEM I | 2.24 | 2.09 |

| CEM II/A-W | 2.24 | 2.06 |

| CEM II/B-W | 2.89 | 2.84 |

| CEM II/B-M(V-W) | 3.15 | 3.73 |

| CEM II/B-M(S-W) | 2.81 | 2.66 |

| CEM V/A(S-W) | 3.92 | 2.77 |

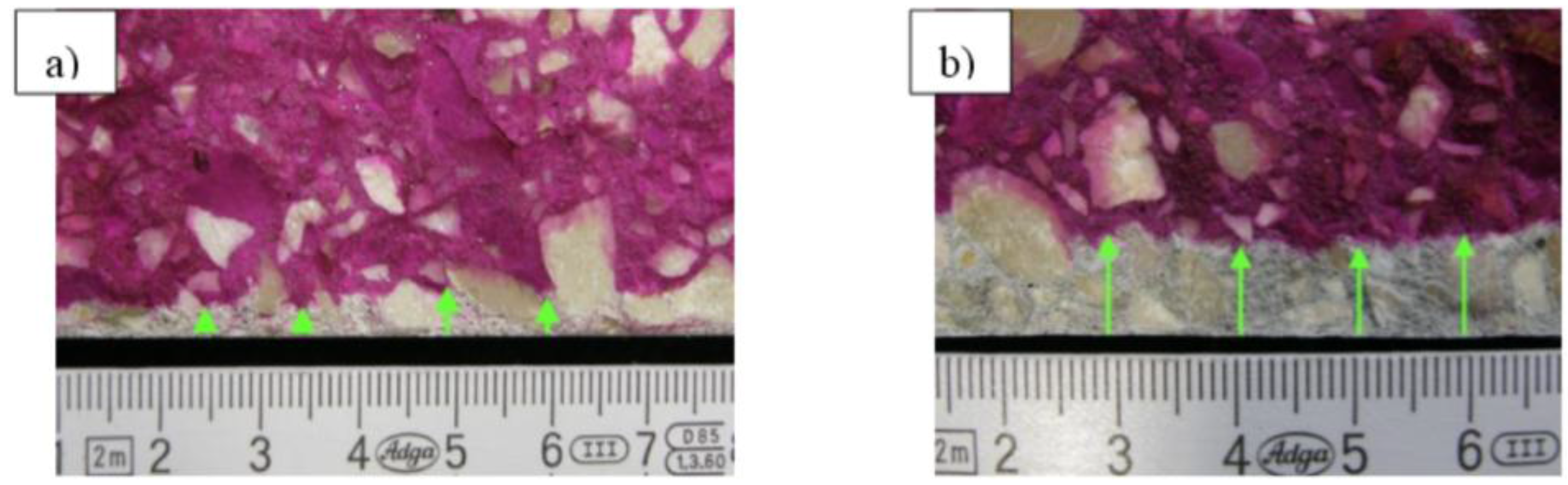

3.3. Microscopic Evaluation of the Carbonation Depth

4. Discussion

5. Conclusions

- 1

- Due to pozzolanic and hydraulic activity of calcareous fly ash, the compressive strength of concrete containing blended binary cements was improved by 7% or 12% at the age of 28 days for granodiorite or limestone aggregate concrete, respectively. Increased clinker replacement levels resulted in a decrease in strength of 3%–19% or 25% for granodiorite or limestone aggregate concrete, respectively.

- 2

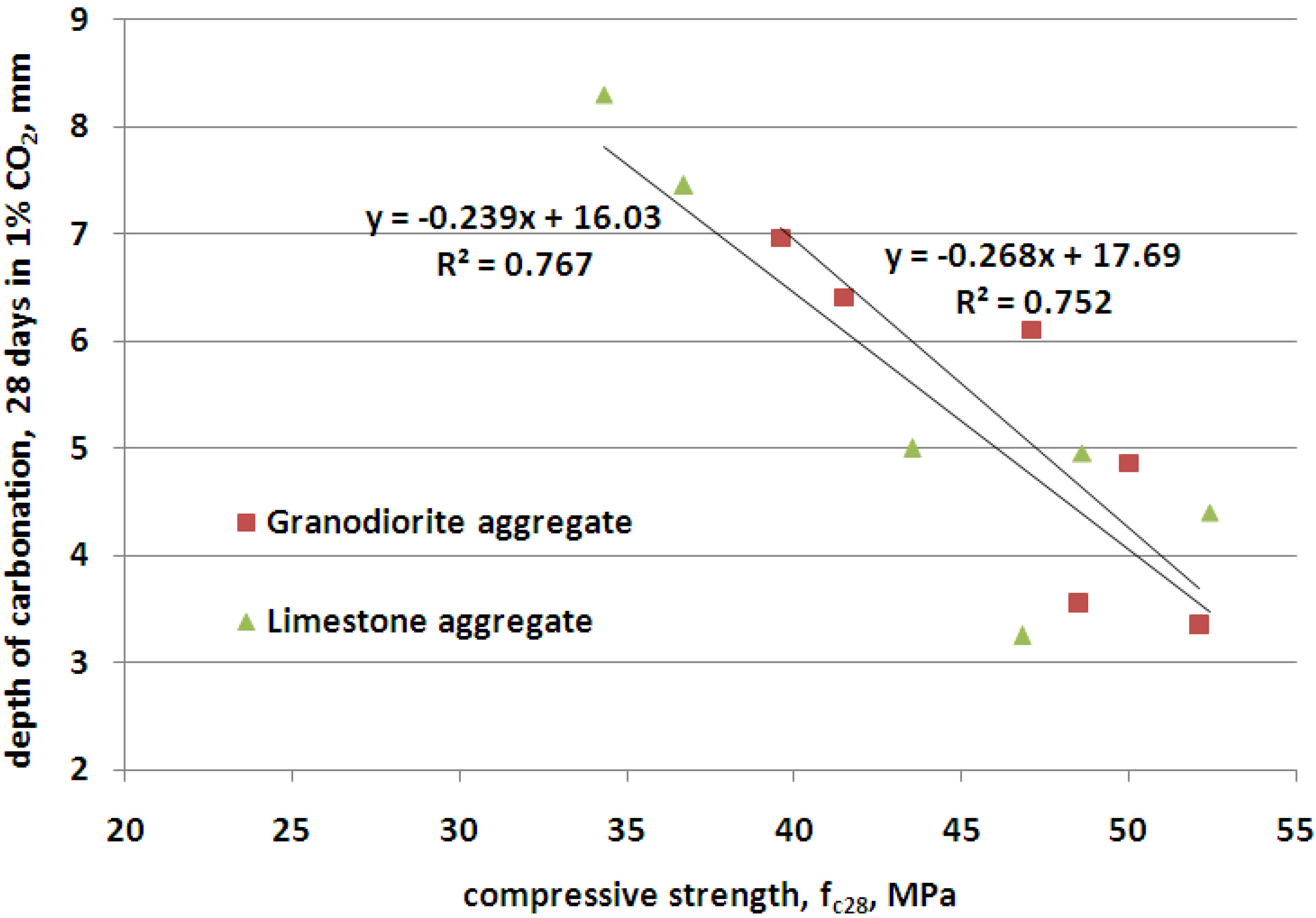

- The carbonation resistance of concrete with blended cements containing calcareous fly ash increased linearly with an increase in the compressive strength of the concrete.

- 3

- The carbonation resistance of concrete decreased with clinker replacement level, however, the depth of carbonation was low. Concrete containing Portland-calcareous fly ash cement (14.3% of calcareous fly ash) exhibited an equal carbonation resistance to a reference concrete containing CEM I.

- 4

- The type of coarse aggregate did not affect the concrete resistance to carbonation except in the case of cement CEM II/B-M(V-W). Here, the carbonation depth of concrete containing limestone aggregate was higher by 17%–33% than for concrete containing granodiorite aggregate.

- 5

- The concrete microstructure analysis performed on thin section confirmed the results obtained from phenoloftalein test and also revealed that the carbonation front was gradual, not sharp as previously assumed.

- 6

- The use of cements CEM V/A(S-W) and CEM II/B-M(S-W) in concrete mixes with granodiorite aggregate resulted in the reduction of the chloride migration coefficient Dnssm by 38%–41% after 90 days of curing, corresponding to an increased penetration resistance level from “unacceptable” to “acceptable”.

- 7

- Chloride migration coefficient of concrete with limestone aggregate made with CEM II/A-W and CEM II/B-W cements decreased by 34%–64% in relation to CEM I reference concrete. The highest chloride penetration resistance, Dnssm = 7.2 × 10−12 m2/s, corresponding to “good” penetration resistance, was found in the case of concrete with CEM II/B-W.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- American Concrete Institute Committee. Evaluation of Existing Nuclear Safety-Related Concrete Structures; ACI 349.3R-02; ACI Committee: Farmington Hills, MI, USA, 2010; p. 20. [Google Scholar]

- Bamonte, P.; Gambarova, P.G. Properties of concrete required in nuclear power plants. In Infrastructure Systems for Nuclear Energy; Hsu, T.T.C., Wu, C.-L., Lin, J.-L., Eds.; John Wiley & Sons: Hobokon, NJ, USA, 2014; pp. 409–438. [Google Scholar]

- Mazars, J.; Capra, B.; Rouquand, A.; Pontiroli, C. Concrete properties, safety, and sustainability of nuclear power plant infrastructures: New tools and themes for future research. In Infrastructure Systems for Nuclear Energy; Hsu, T.T.C., Wu, C.-L., Lin, J.-L., Eds.; John Wiley & Sons: Hobokon, NJ, USA, 2014; pp. 103–125. [Google Scholar]

- Thomas, M. Supplementary Cementing Materials in Concrete; CRC Press, Taylor and Francis Group: New York, NY, USA, 2014. [Google Scholar]

- Fly Ash for Concrete. Definition, Specifications and Conformity Criteria; PN-EN 450-1; Polski Komitet Normalizacyjny: Warszawa, Poland, 2012.

- Papadakis, V.G. Effect of fly ash on Portland cement systems Part II. High calcium fly ash. Cem. Concr. Res. 2002, 30, 1647–1654. [Google Scholar] [CrossRef]

- Antiohos, S.; Maganari, K.; Tsimas, S. Evaluation of blends of high and low calcium fly ashes for use as supplementary cementing materials. Cem. Concr. Compos. 2005, 27, 349–356. [Google Scholar] [CrossRef]

- Felekoglu, B.; Türkel, S.; Kalyoncu, H. Optimization of fineness to maximize the strength activity of high calcium ground fly ash—Portland cement composites. Constr. Build. Mater. 2009, 23, 2053–2061. [Google Scholar] [CrossRef]

- Standard Specification for Coal Fly Ash and Raw or Calcined Natural Pozzolan for Use in Concrete; ASTM C618-12a; American Society for Testing of Materials: Philadelphia, PA, USA, 2012.

- Radlinski, M.; Olek, J. Effects of curing conditions on the properties of ternary (ordinary portland cement/fly ash/silica fume) concrete. ACI Mater. J. 2015, 112, 49–58. [Google Scholar] [CrossRef]

- Cement Composition, Specifications and Conformity Criteria for Common Cements; PN-EN 197-1; Polski Komitet Normalizacyjny: Warszawa, Poland, 2011.

- Vizcaíno-Andrés, L.M.; Sánchez-Berriel, S.; Damas-Carrera, S.; Pérez-Hernández, A.; Scrivener, K.L.; Martirena-Hernández, J.F. Industrial trial to produce a low clinker, low carbon cement. Mater. Construcc. 2015, 65, 317. [Google Scholar] [CrossRef]

- Bonavetti, V.L.; Castellano, C.; Donza, H.; Rahhal, V.F.; Irassar, E.F. Cement with silica fume and granulated blast-furnace slag: strength behavior and hydration. Mater. Construcc. 2014, 64, 315. [Google Scholar] [CrossRef]

- Lothenbach, B.; Scrivener, K.L.; Hooton, R.D. Supplementary cementitious materials. Cem. Concr. Res. 2011, 41, 1244–1256. [Google Scholar] [CrossRef]

- Schneider, M.; Romer, M.; Tschudin, M.; Boli, H. Sustainable cement production—Present and future. Cem. Concr. Res. 2011, 41, 642–650. [Google Scholar] [CrossRef]

- Gołaszewski, J.; Giergiczny, Z.; Cygan, G.; Dziuk, D. The effect of high calcium fly ash on the formation of cement properties with its participation. In Proceedings of the XII ICCC International Congress on the Chemistry of Cement 2011, Madrid, Spain, 3–8 July 2011; Palomo, A., Zaragoza, A., Lopez Agui, J.C., Eds.; Instituto de Ciencias de la Construcción: Madrid, Spain, 2011; p. 119. [Google Scholar]

- Dąbrowska, M.; Giergiczny, Z. Chemical resistance of mortars made of cements with calcareous fly ash. Roads Bridges-Drogi i Mosty 2013, 12, 131–146. [Google Scholar]

- Glinicki, M.A.; Nowowiejski, G. Strength and permeability of concrete with CEM II and “CEM V” cements containing high calcium fly ash. In Proceedings of the 3rd International Conference on Sustainable Materials and Technologies SMCT3 2013, Kyoto, Japan, 2–13 August 2013; Coventry University and The University of Wisconsin Milwaukee Centre for By-products Utilization: Kyoto, Japan, 2013; pp. 43–50. [Google Scholar]

- Concrete, Mortar and Cement-Based Repair Materials: Chloride Migration Coefficient from Non-Steady-State Migration Experiments; Nordtest Method NT Build 492; Nordtest: Espoo, Finland, 1999.

- Gibas, K.; Glinicki, M.A. Influence of calcerous fly ash on concrete resistance to migration of chlorides. In Proceedings of the International Symposium Brittle Matrix Composites BMC-10, Warsaw, Poland, 15–17 October 2012; Brandt, A.M., Olek, J., Glinicki, M.A., Leung, C.K.Y., Eds.; IPPT PAN: Warsaw, Poland, 2012; pp. 367–376. [Google Scholar]

- Products and Systems for the Protection and Repair of Concrete Structures—Test Methods—Determination of Resistance to Carbonation; PN-EN 13295; Polski Komitet Normalizacyjny: Warszawa, Poland, 2005.

- Jóźwiak-Niedźwiedzka, D. Influence of blended cements on the concrete resistance to carbonation. In Proceedings of the International Symposium Brittle Matrix Composites BMC-10, Warsaw, Poland, 15–17 October 2012; Brandt, A.M., Olek, J., Glinicki, M.A., Leung, C.K.Y., Eds.; IPPT PAN: Warsaw, Poland, 2012; pp. 125–134. [Google Scholar]

- Tang, L. Chloride Transport in Concrete—Measurement and Prediction. Ph.D. Thesis, Chalmers University of Technology, Göteborg, Sweden, 1996. [Google Scholar]

- Papadakis, V.G. Effect of supplementary cementing materials on concrete resistance against carbonation and chloride ingress. Cem. Concr. Res. 2000, 30, 291–299. [Google Scholar] [CrossRef]

- Sisomphon, K.; Franke, L. Carbonation rates of concretes containing high volume of pozzolanic materials. Cem. Concr. Res. 2007, 37, 1647–1653. [Google Scholar] [CrossRef]

- Bertolini, L.; Elsener, B.; Pedeferri, P.; Polder, R.B. Corrosion of Steel in Concrete: Prevention, Diagnosis, Repair; WILEY-VCH Verlag GmbH & Co. KGaA: Weinheim, Germany, 2004; p. 401. [Google Scholar]

- Khunthongkeaw, J.; Tangtermsirikul, S.; Leelawat, T. A study on carbonation depth prediction for fly ash concrete. Constr. Build. Mater. 2006, 20, 744–753. [Google Scholar] [CrossRef]

- Jóźwiak-Niedźwiedzka, D.; Gibas, K.; Glinicki, M.A.; Nowowiejski, G. Influence of high calcium fly ash on permeability of concrete in respect to aggressive media. Roads Bridges-Drogi i Mosty 2011, 10, 39–61. [Google Scholar]

- Gibas, K.; Glinicki, M.A.; Nowowiejski, G. Evaluation of impermeability of concrete containing calcareous fly ash in respect to environmental media. Roads Bridges-Drogi i Mosty 2013, 12, 159–171. [Google Scholar]

- Glinicki, M.A.; Krzywobłocka-Laurów, R.; Ranachowski, Z.; Dąbrowski, M.; Wołowicz, J. Microstructure analysis of concrete modified with addition of calcareous fly ash. Roads Bridges-Drogi i Mosty 2013, 12, 173–189. [Google Scholar]

- Jackiewicz-Rek, W.; Woyciechowski, P. Carbonation rate of air-entrained fly ash concretes. Cem. Wapno Beton 2011, 16, 249–256. [Google Scholar]

- Papadakis, V.G.; Vayenas, C.G.; Fardis, M.N. Fundamental modeling and experimental investigation of concrete carbonation. ACI Mater. J. 1991, 88, 363–373. [Google Scholar]

- Thiery, M.; Villain, G.; Dangla, P.; Platret, G. Investigation of the carbonation front shape on cementitious materials: Effects of the chemical kinetics. Cem. Concr. Res. 2007, 37, 1047–1058. [Google Scholar] [CrossRef]

- Nuclear Energy Agency, Committee on the Safety of Nuclear Installations. NEA/CSNI/R(2002)7/VOL1. In Proceedings of the OECD-NEA Workshop on the Evaluation of Defects, Repair Criteria and Methods of Repair for Concrete Structures on Nuclear Power Plants, Berlin, Germany, 10–11 April 2012; p. 167.

- The Federal Agency for Nuclear Control, National Report. In Proceedings of the 6th Meeting of the Contracting Parties of the Convention on Nuclear Safety, Brussels, Belgium, 16 August 2013; p. 129.

- Glinicki, M.A.; Dąbrowski, M.; Jaskulski, R.; Ranachowski, Z. Determination of thermal properties of hardening concrete for massive nuclear shielding structures. In Proceedings of the 4th International Conference on Sustainable Construction Materials and Technologies (SCMT4), Las Vegas, NV, USA, 7–11 August 2016.

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons by Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Glinicki, M.A.; Jóźwiak-Niedźwiedzka, D.; Gibas, K.; Dąbrowski, M. Influence of Blended Cements with Calcareous Fly Ash on Chloride Ion Migration and Carbonation Resistance of Concrete for Durable Structures. Materials 2016, 9, 18. https://doi.org/10.3390/ma9010018

Glinicki MA, Jóźwiak-Niedźwiedzka D, Gibas K, Dąbrowski M. Influence of Blended Cements with Calcareous Fly Ash on Chloride Ion Migration and Carbonation Resistance of Concrete for Durable Structures. Materials. 2016; 9(1):18. https://doi.org/10.3390/ma9010018

Chicago/Turabian StyleGlinicki, Michał A., Daria Jóźwiak-Niedźwiedzka, Karolina Gibas, and Mariusz Dąbrowski. 2016. "Influence of Blended Cements with Calcareous Fly Ash on Chloride Ion Migration and Carbonation Resistance of Concrete for Durable Structures" Materials 9, no. 1: 18. https://doi.org/10.3390/ma9010018

APA StyleGlinicki, M. A., Jóźwiak-Niedźwiedzka, D., Gibas, K., & Dąbrowski, M. (2016). Influence of Blended Cements with Calcareous Fly Ash on Chloride Ion Migration and Carbonation Resistance of Concrete for Durable Structures. Materials, 9(1), 18. https://doi.org/10.3390/ma9010018