Modified Powder-in-Tube Technique Based on the Consolidation Processing of Powder Materials for Fabricating Specialty Optical Fibers

Abstract

:1. Introduction

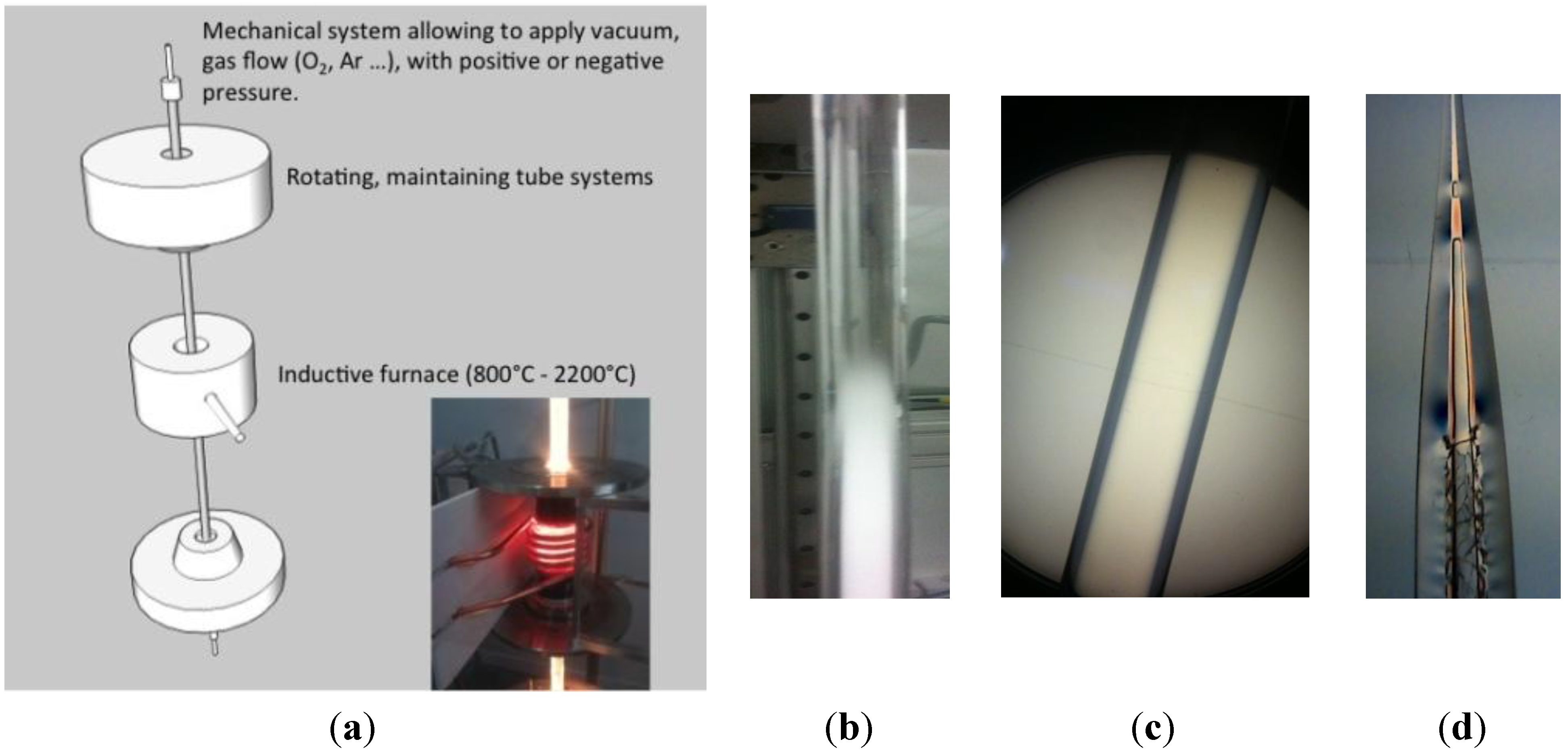

2. The Powder Consolidation Process

2.1. Description of the Fabrication Process

- For TG < T < TSOFT (with TSOFT the glass softening temperature), the glass grains initiate a molten state and are able to deform. Primary vacuum ensures slight air elimination and granulates tend to agglomerate. After cooling, the final aspect of the preform is a spongious-like solid rod in the surrounding glass tube. This process is called preform consolidation.

- For TSOFT < T, the glass powder material is softening and air can evacuate by natural bubbles collapsing that is enhanced by vacuum pumping. After cooling, the preform is a dense glassy rod. This process is called preform vitrification (see Figure 1b,c).

2.2. Processing Features

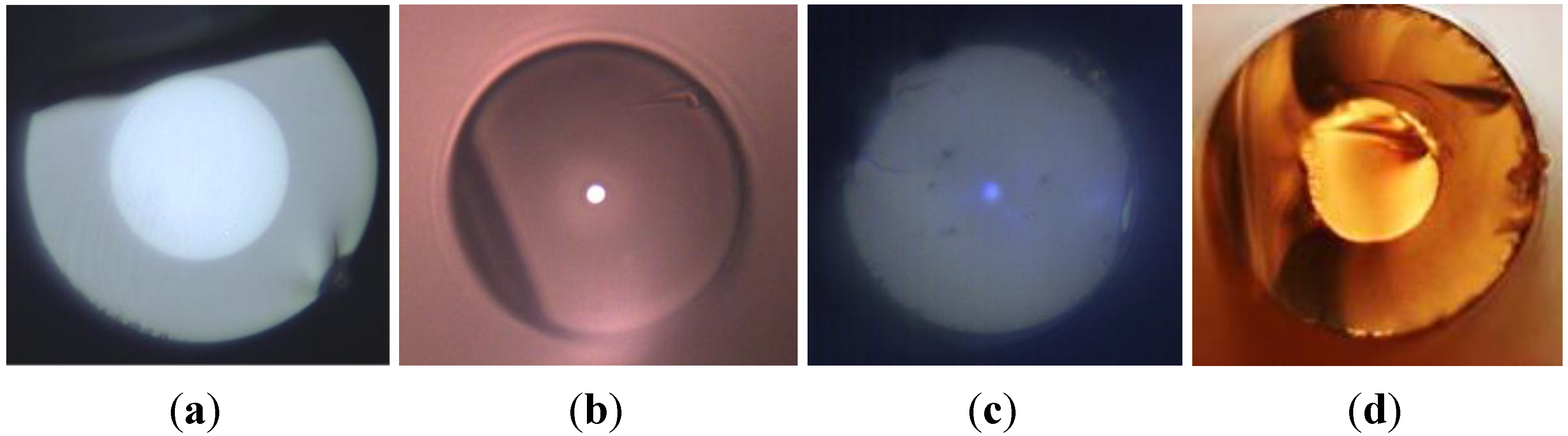

2.2.1. Thermo-Mechanical Property Mismatches between Fiber Materials

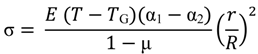

- In the case of a low TG mismatch between the glass core and pure silica cladding (TG(SiO2) ~ 1200 °C), the consolidation of the powder leads to rearrangements of macroscopic defects (reduction of the air fraction, annealing of glass powder materials…).

- In the case of a large TG mismatch between the glass core and pure silica cladding, the consolidation process leads to an all-solid preform by softening only the core glass material.

2.2.2. Thermal Consolidation under Controlled Reducing or Oxidizing Atmospheres

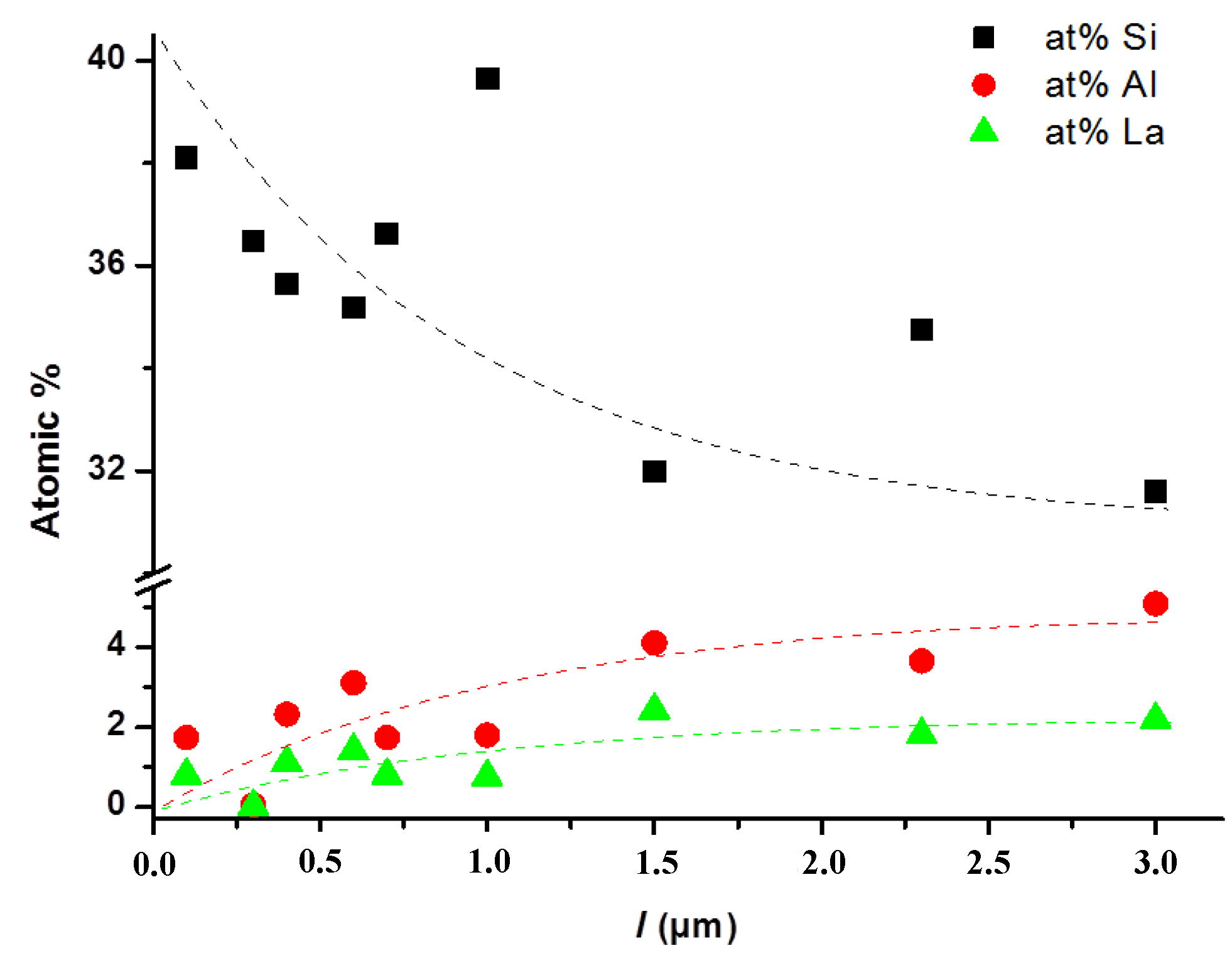

2.2.3. Chemical Diffusion between the Core/Cladding Materials

3. Examples of Specialty Optical Fibers Fabricated with the Modified Powder in Tube Technique

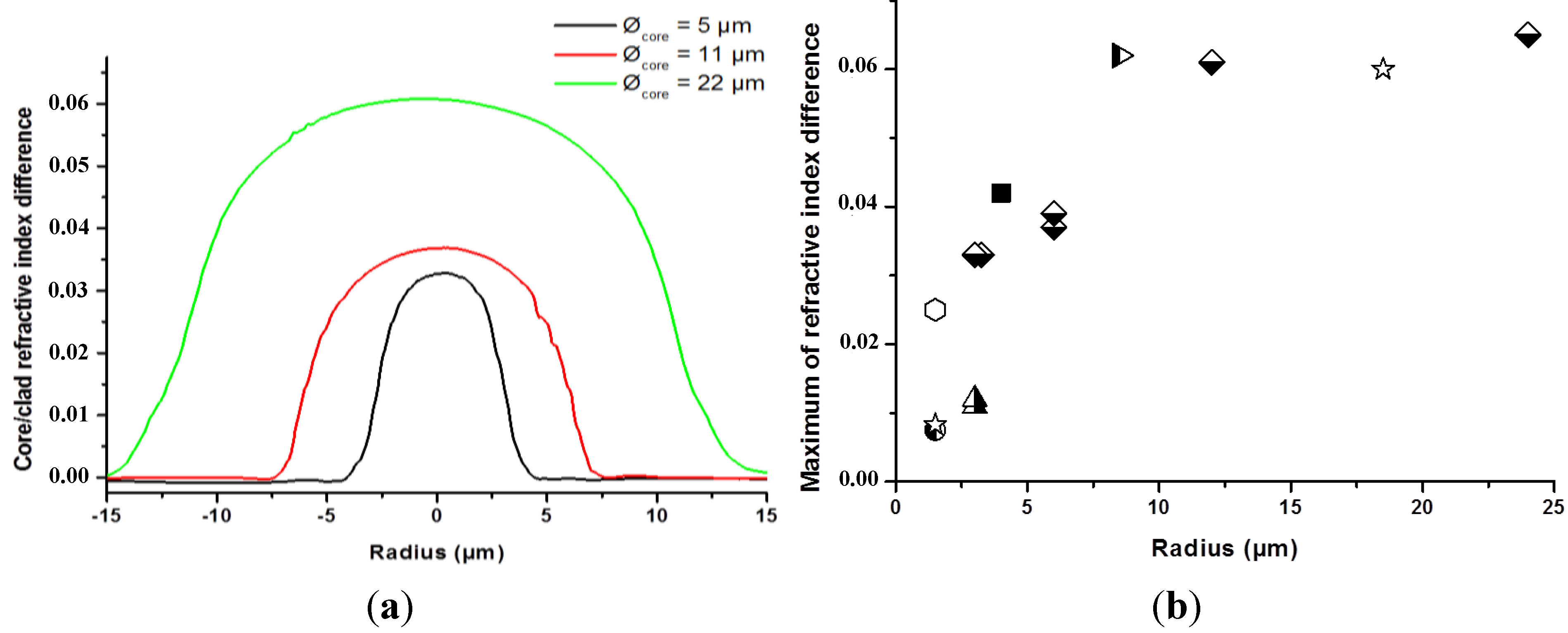

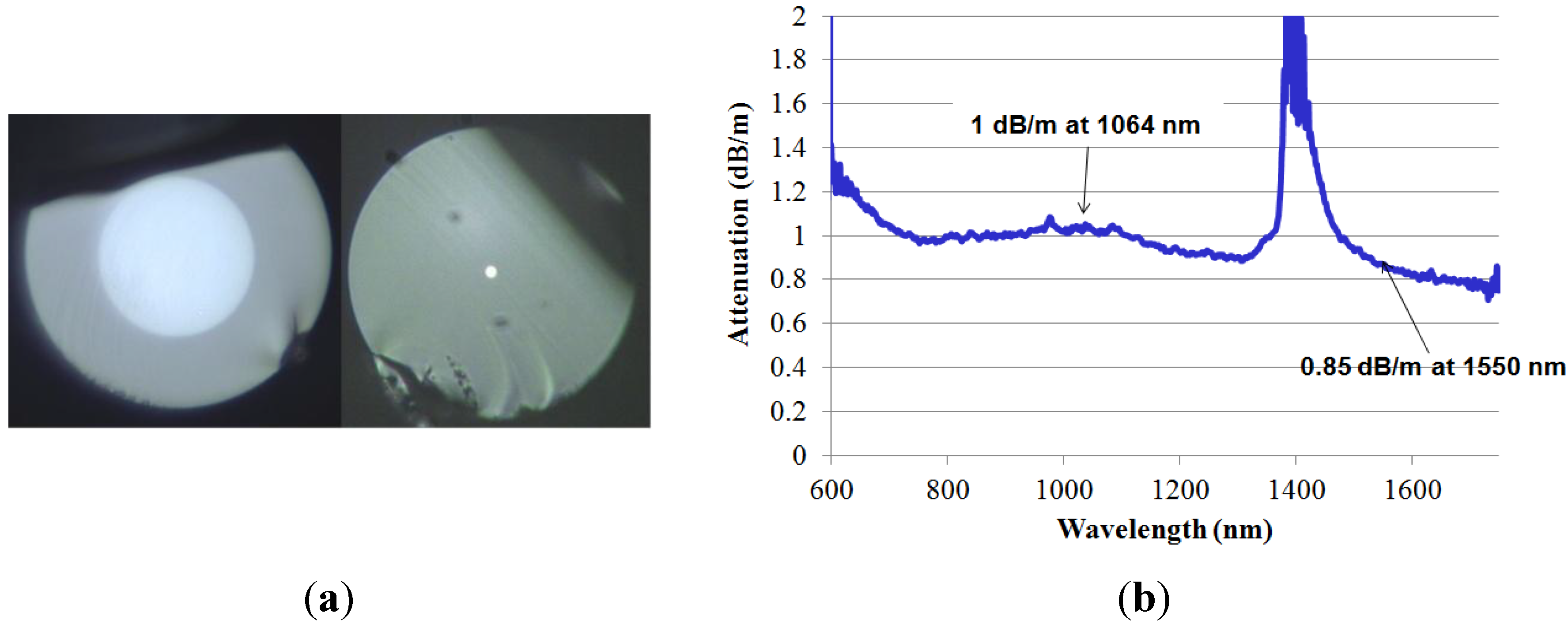

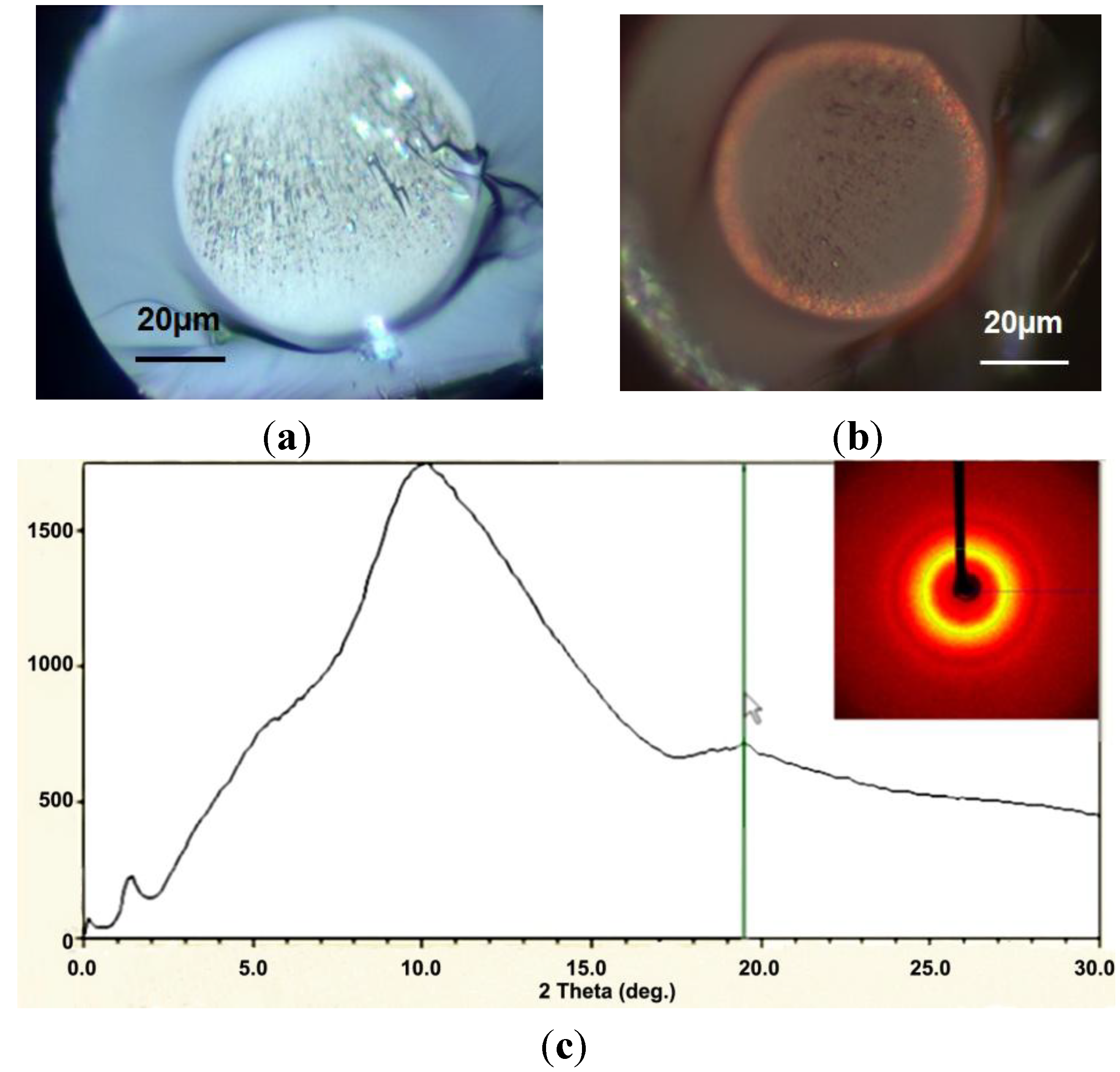

3.1. Lanthano-Aluminosilicate Glass Core/Silica Cladding Optical Fibers

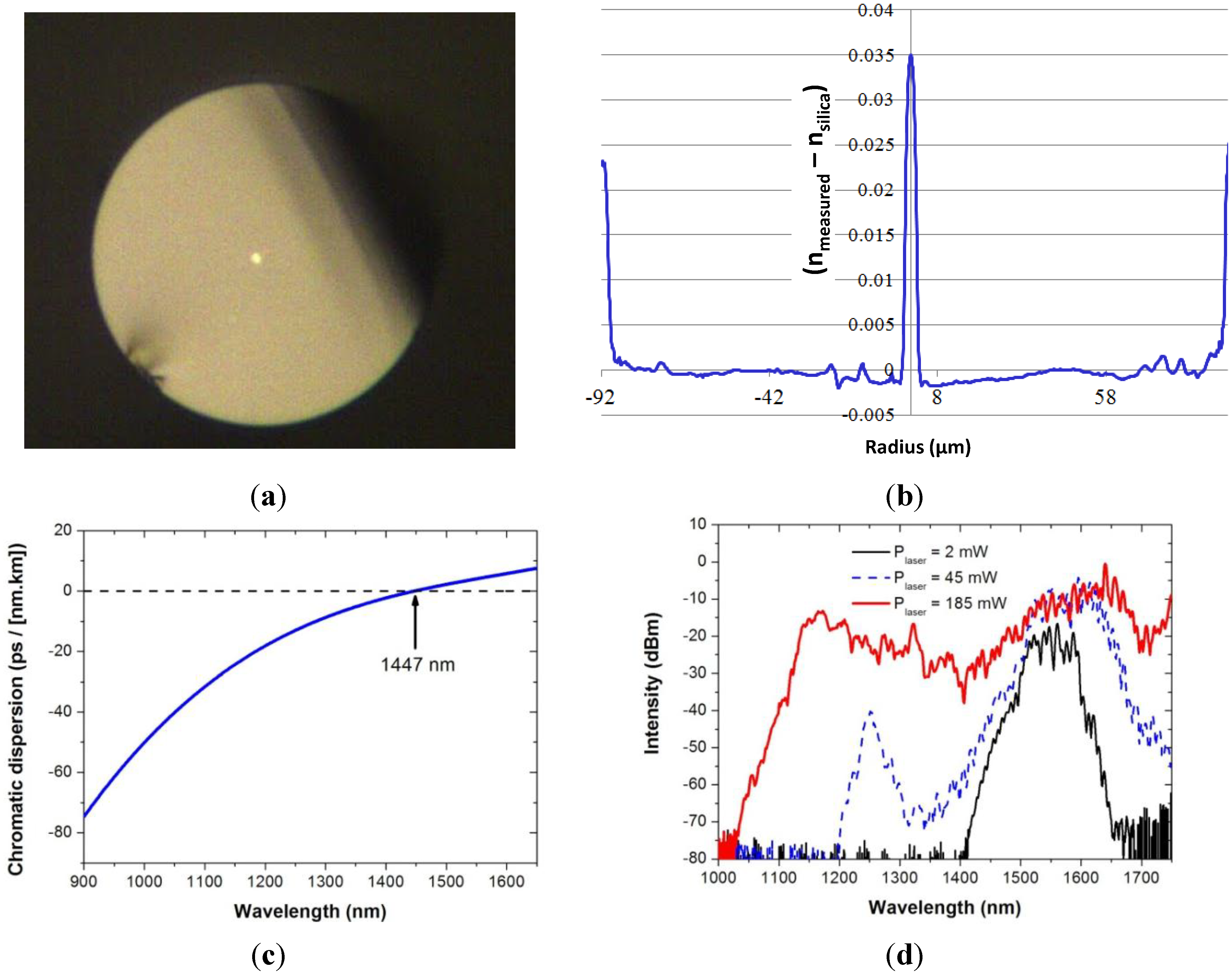

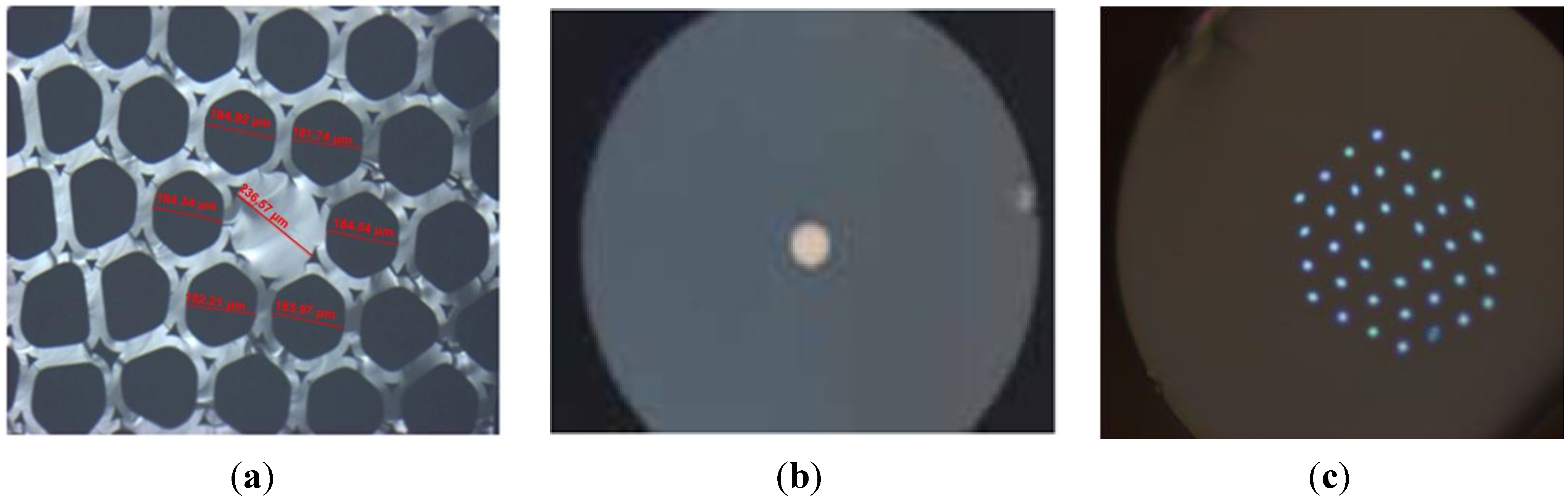

3.2. Multi Glasses Microstructured Optical Fibers

3.3. Metal–Silica Optical Fibers

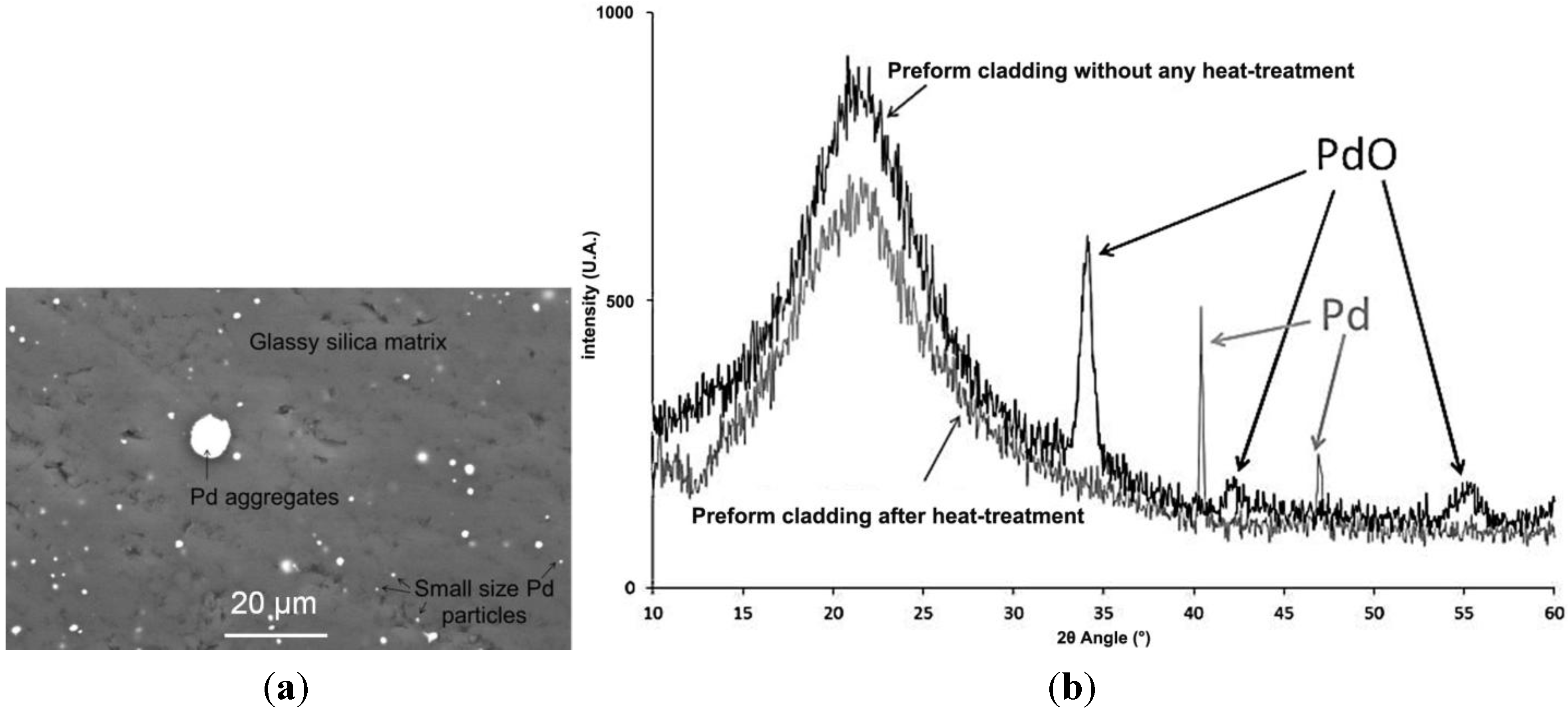

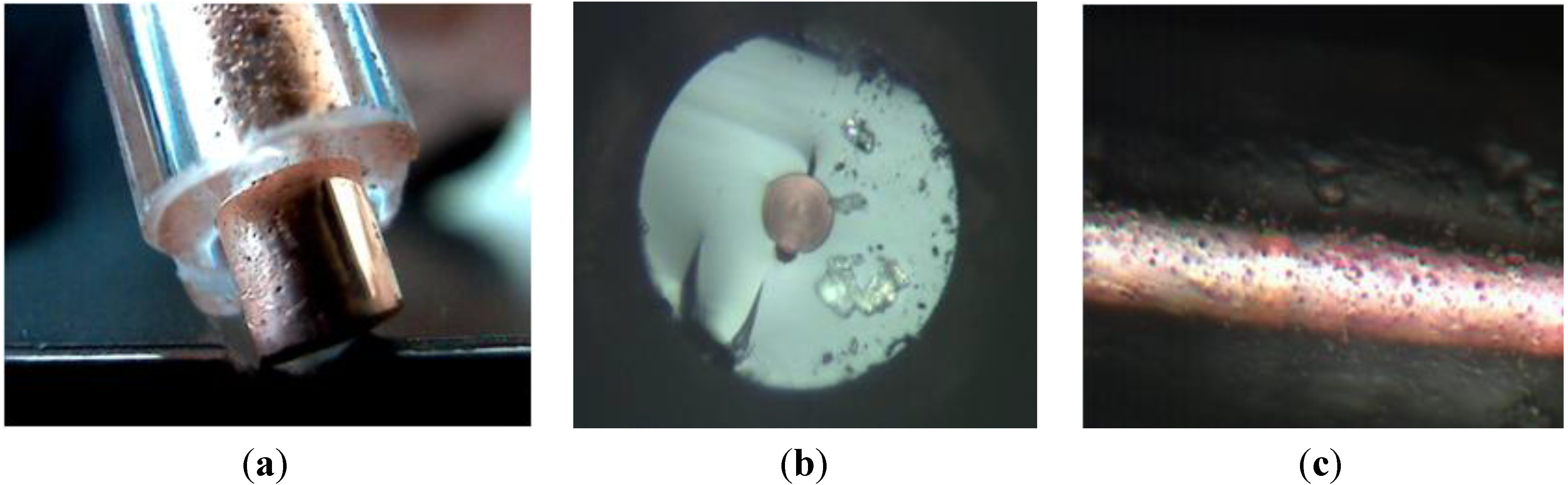

3.3.1. Optical Fibers with Metallic Ions and Particles Embedded into the Core

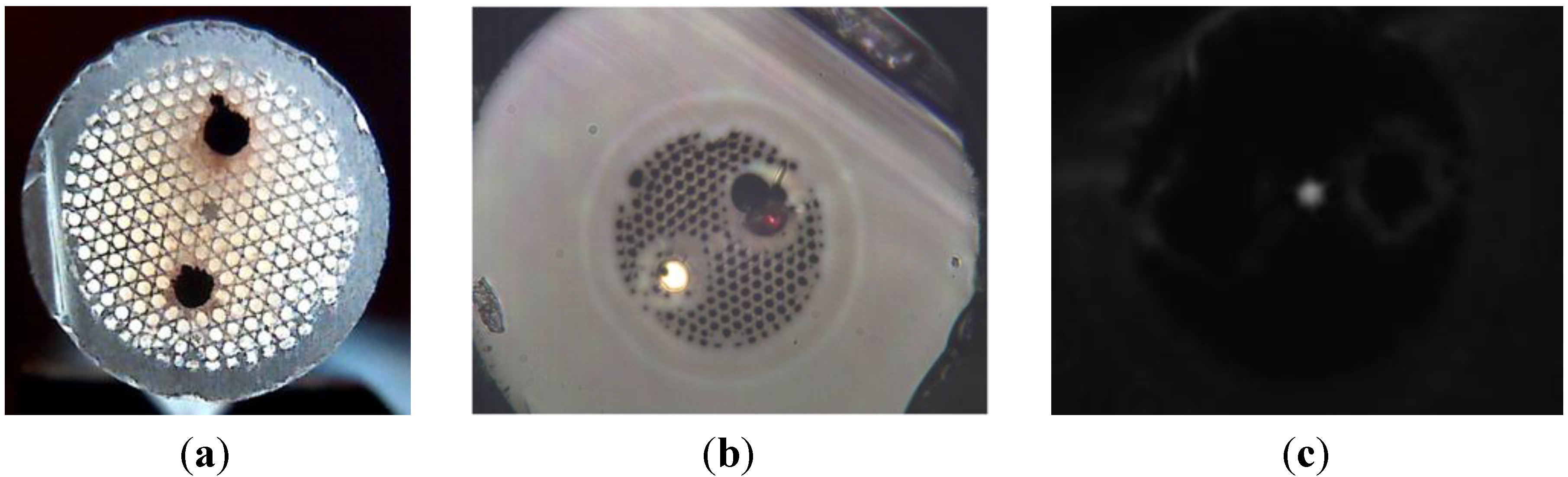

3.3.2. Long Metallic Wires Distributed in Optical Fibers

4. Conclusions

Acknowledgments

Conflicts of Interest

References

- Knight, J.C.; Birks, T.A.; Russell, P.; Atkin, D.M. All-silica single-mode fiber with photonic crystal cladding. Opt. Lett. 1997, 22, 484–485. [Google Scholar] [CrossRef]

- Russell, P. Photonic crystal fibers. Science 2003, 299, 358–362. [Google Scholar] [CrossRef]

- Russell, P. Photonic-crystal fibers. J. Lightwave Technol. 2006, 24, 4729–4749. [Google Scholar] [CrossRef]

- Gérôme, F.; Auguste, J.L.; Maury, J.; Blondy, J.M.; Marcou, J. Theoretical and experimental analysis of a chromatic dispersion compensating module using a dual concentric core fiber. J. Lightwave Technol. 2006, 24, 442–448. [Google Scholar] [CrossRef]

- Goel, N.K.; Stolen, R.H.; Morgan, S.; Kim, J.K.; Kominsky, D.; Pickrell, G. Core-suction technique for the fabrication of optical fiber preforms. Opt. Lett. 2006, 31, 438–440. [Google Scholar] [CrossRef]

- Schmidt, M.; Wondraczek, L.; Russell, P. Pressure-assisted flow of glass melts in narrow capillaries. In Proceedings of the GOMD Conference, Corning, NY, USA, 1–4 October 2010. SII-035-2010.

- Ballato, J.; Hawkins, T.; Foy, P.; Stolen, R.; Kokuoz, B.; Ellison, M.; McMillen, C.; Reppert, J.; Rao, A.M.; Daw, M.; et al. Silicon optical fiber. Opt. Express 2008, 16, 18675–18683. [Google Scholar] [CrossRef]

- Ballato, J.; Snitzer, E. Fabrication of fibers with high rare-earth concentrations for Faraday isolator applications. Appl. Opt. 1995, 34, 6848–6854. [Google Scholar] [CrossRef]

- Van Uitert, L.G.; Pinnow, D.A.; Williams, J.C.; Rich, T.C.; Jaeger, R.E.; Grodkiewicz, W.H. Borosilicate glasses for fiber optical waveguide. Mater. Results Bull. 1973, 8, 469–476. [Google Scholar] [CrossRef]

- Pedrido, C. Method for Fabricating an Optical Fiber, Preform for Fabricating an Optical Fiber, Optical Fiber and Apparatus. Dätwyler Fiber Optics SA. Patent WO 2005/102946 A1 and WO 2005/102947 A, 3 November 2005. [Google Scholar]

- Clare, A.G.; Parker, J.M. The effect of refractive index modifiers on the thermal expansion coefficient of fluoride glasses. Phys. Chem. Glasses 1989, 30, 205–210. [Google Scholar]

- Litzkendorf, D.; Grimm, S.; Schuster, K.; Kobelke, J.; Schwuchow, A.; Ludwig, A.; Kirchhof, J.; Leich, M.; Jetschke, S.; Dellith, J.; et al. Study of lanthanum aluminum silicate glasses for passive and active optical fibers. Int. J. Appl. Glass Sci. 2012, 3, 321–331. [Google Scholar] [CrossRef]

- Leparmentier, S.; Auguste, J.L.; Humbert, G.; Delaizir, G.; Delepine Lesoille, S.; Bertrand, J.; Buschaert, S.; Perisse, J.; Mace, J.R. Palladium particles embedded into silica optical fibers for hydrogen gas detection. In Proceedings of the SPIE Photonics Europe, Bruxelles, Belgium, 2 May 2014; Volume 9128.

- Lemaire, P.J. Reliability of optical fibers exposed to hydrogen: Prediction of long-term loss increases. Opt. Eng. 1991, 30, 780–790. [Google Scholar] [CrossRef]

- Lee, K.G.; Oh, C.H.; Ryu, K.S.; Kang, H.J. Mass-production of zero water peak fiber by VAD process. In Proceedings of the Asia-Pacific Optical Communications Conference, Shanghai, China, 7–10 November 2005.

- Dianov, E.M.; Mashinsky, V.M.; Neustruev, V.B.; Sazhin, O.D. Origin of excess loss in singlemode optical fibers with high GeO2 doped silica core. Opt. Fiber Technol. 1997, 3, 77–86. [Google Scholar] [CrossRef]

- Ballato, J.; Hawkins, T.; Foy, P.; Kokuoz, B.; Stolen, R.; McMillen, C.; Daw, M.; Su, Z.; Tritt, T.M.; Dubinskii, M.; et al. On the fabrication of all-glass optical fibers from crystals. J. Appl. Phys. 2009, 105, 053110:1–053110:9. [Google Scholar]

- Kobelke, J.; Schuster, K.; Litzkendorf, D.; Schwuchow, A.; Kirchhof, J.; Bartelt, H.; Tombelaine, V.; Leproux, P.; Couderc, V.; Labruyère, A. Microstructured fibers with high lanthanum oxide glass core for nonlinear applications. SPIE 2009, 7357, 1–12. [Google Scholar]

- Luan, F.; George, A.K.; Hedley, T.D.; Pearce, G.J.; Bird, D.M.; Knight, J.C.; Russell, P. All-solid photonic bandgap fiber. Opt. Lett. 2004, 29, 2369–2371. [Google Scholar] [CrossRef]

- Kelly, K.L.; Coronado, E.; Zhao, L.L.; Schatz, G.C. The optical properties of metal nanoparticles: The influence of size, shape, and dielectric environment. J. Phys. Chem. B 2003, 107, 668–677. [Google Scholar]

- Nikolajsen, T.; Leosson, K.; Bozhevolnyi, S.I. Surface plasmon polariton based modulators and switches operating at telecom wavelengths. Appl. Phys. Lett. 2004, 85, 5833–5835. [Google Scholar] [CrossRef]

- Hochberg, M.; Baehr-Jones, T.; Walker, C.; Scherer, A. Integrated plasmon and dielectric waveguides. Opt. Express 2004, 12, 5481–5486. [Google Scholar] [CrossRef]

- Zia, R.; Selker, M.D.; Brongersma, M.L. Leaky and bound modes of surface plasmon waveguides. Phys. Rev. B 2005, 71, 165431:1–165431:9. [Google Scholar]

- Krasteva, N.; Besnard, I.; Guse, B.; Bauer, R.E.; Mullen, K.; Yasuda, A.; Vossmeyer, T. Composite films for vapor sensing applications. Nano Lett. 2002, 2, 551–555. [Google Scholar] [CrossRef]

- Lin, A.; Kim, B.H.; Moon, D.S.; Chung, Y.; Han, W.-T. Cu2+ doped germano-silicate glass fiber with high resonant nonlinearity. Opt. Express 2007, 15, 3665–3672. [Google Scholar] [CrossRef]

- Huston, A.L.; Justus, B.L.; Falkenstein, P.L.; Miller, R.W.; Ning, H.; Altemus, R. Remote optical fibre dosimetry. Nucl. Instrum. Methods Phys. Res. B 2001, 182, 55–67. [Google Scholar]

- Lenardič, B.; Kveder, M.; Lisjak, D.; Guillon, H.; Bonnafous, S. Novel method for fabrication of metal- or oxide-nanoparticle doped silica-based specialty optical fibers. SPIE 2011, 7934. [Google Scholar] [CrossRef]

© 2014 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/3.0/).

Share and Cite

Auguste, J.-L.; Humbert, G.; Leparmentier, S.; Kudinova, M.; Martin, P.-O.; Delaizir, G.; Schuster, K.; Litzkendorf, D. Modified Powder-in-Tube Technique Based on the Consolidation Processing of Powder Materials for Fabricating Specialty Optical Fibers. Materials 2014, 7, 6045-6063. https://doi.org/10.3390/ma7086045

Auguste J-L, Humbert G, Leparmentier S, Kudinova M, Martin P-O, Delaizir G, Schuster K, Litzkendorf D. Modified Powder-in-Tube Technique Based on the Consolidation Processing of Powder Materials for Fabricating Specialty Optical Fibers. Materials. 2014; 7(8):6045-6063. https://doi.org/10.3390/ma7086045

Chicago/Turabian StyleAuguste, Jean-Louis, Georges Humbert, Stéphanie Leparmentier, Maryna Kudinova, Pierre-Olivier Martin, Gaëlle Delaizir, Kay Schuster, and Doris Litzkendorf. 2014. "Modified Powder-in-Tube Technique Based on the Consolidation Processing of Powder Materials for Fabricating Specialty Optical Fibers" Materials 7, no. 8: 6045-6063. https://doi.org/10.3390/ma7086045

APA StyleAuguste, J.-L., Humbert, G., Leparmentier, S., Kudinova, M., Martin, P.-O., Delaizir, G., Schuster, K., & Litzkendorf, D. (2014). Modified Powder-in-Tube Technique Based on the Consolidation Processing of Powder Materials for Fabricating Specialty Optical Fibers. Materials, 7(8), 6045-6063. https://doi.org/10.3390/ma7086045