3.2. Effects of Pressure Levels on the Corner Filling Process and Thickness Distribution

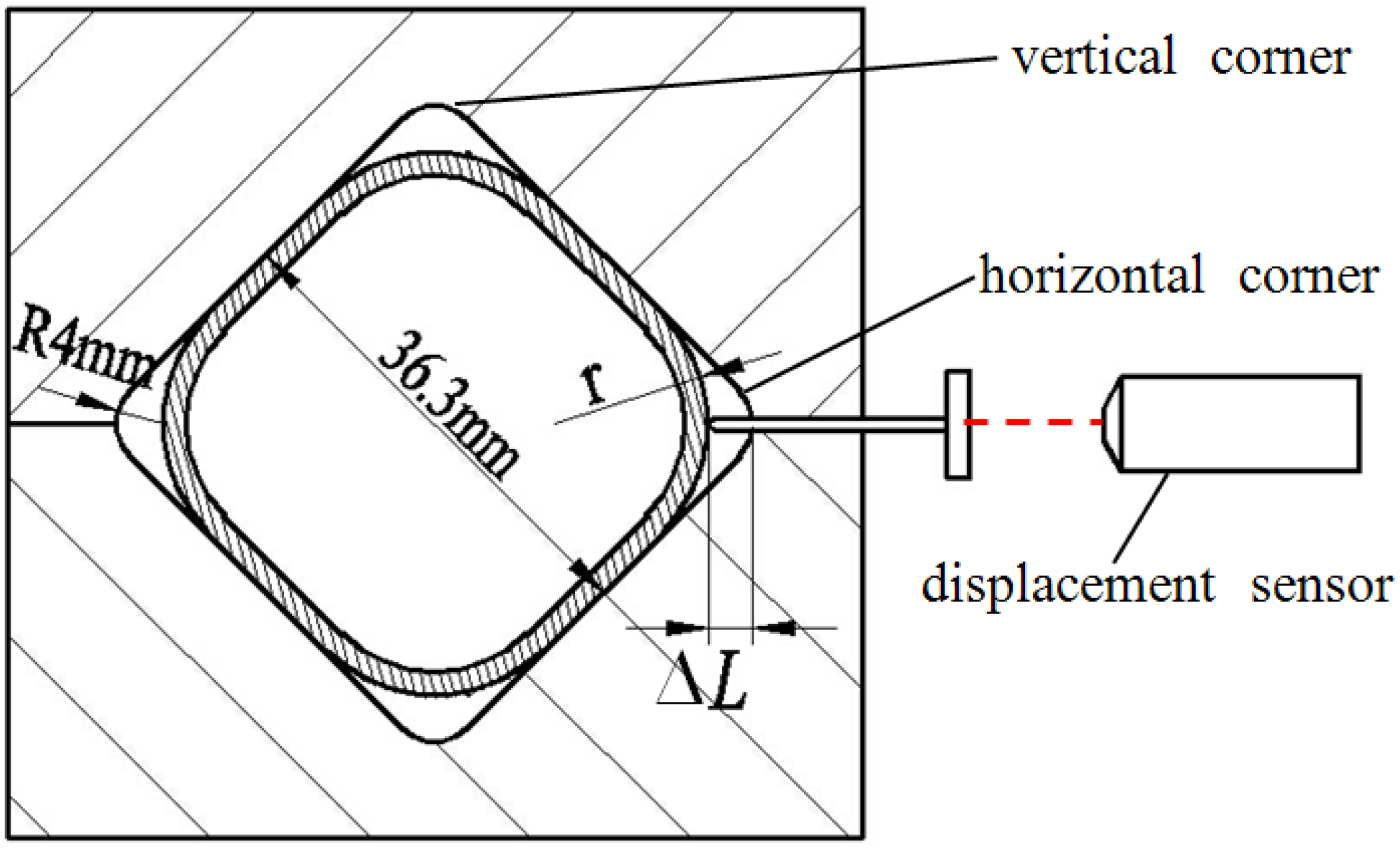

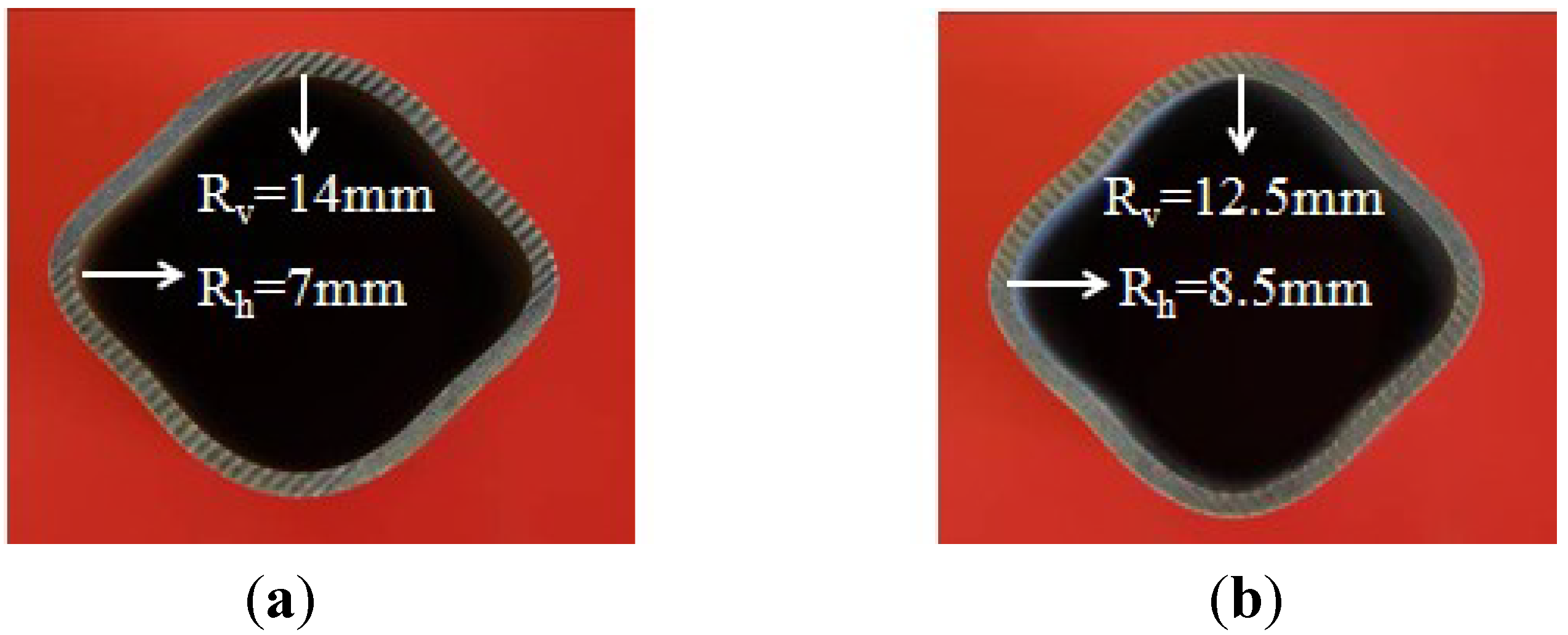

After forming at 850 °C and using four different pressure levels, tubular components with an outer radius of 4 mm were all fully formed and one of the fully formed components is shown in

Figure 4. The corner filling process is shown in

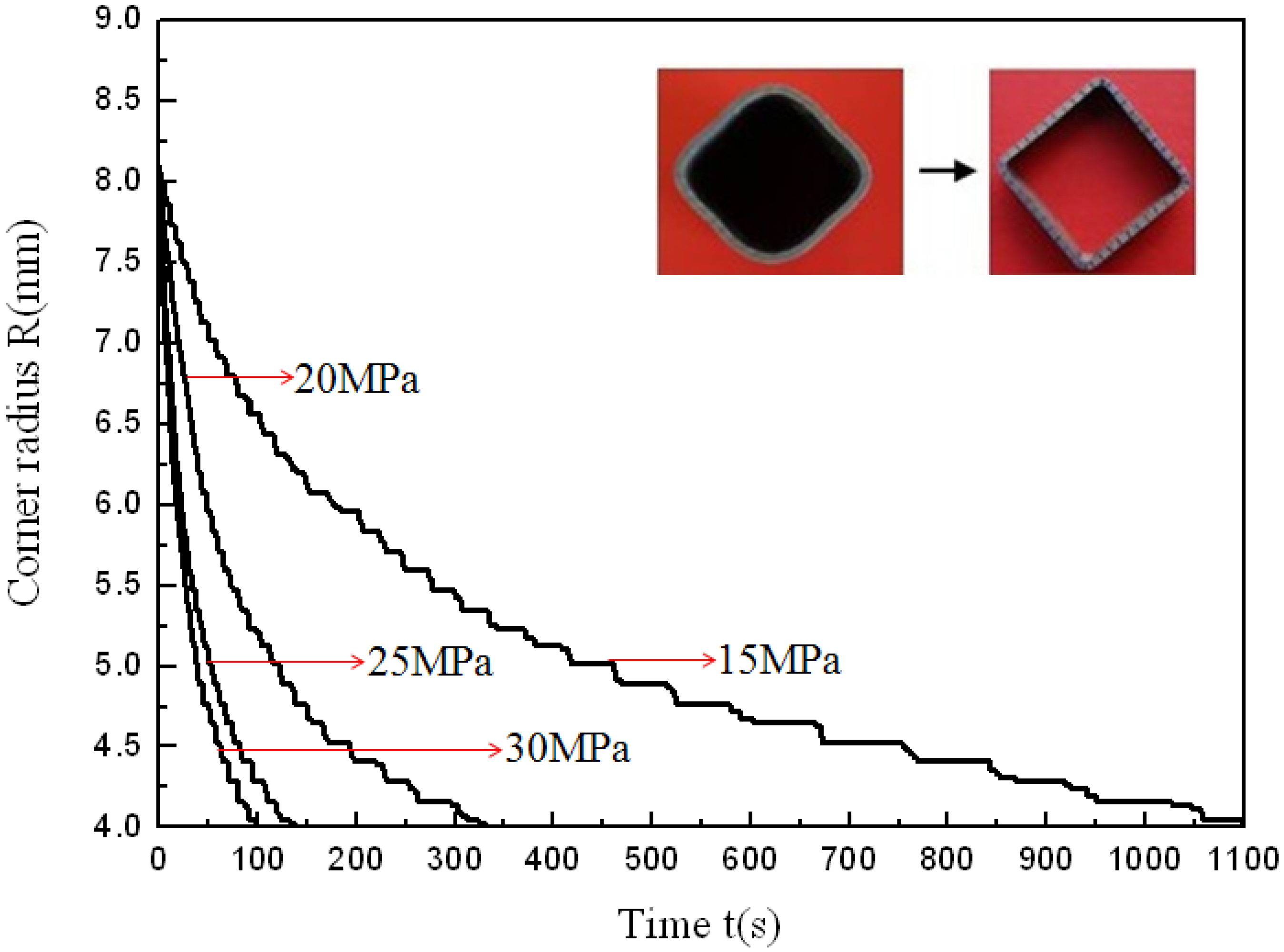

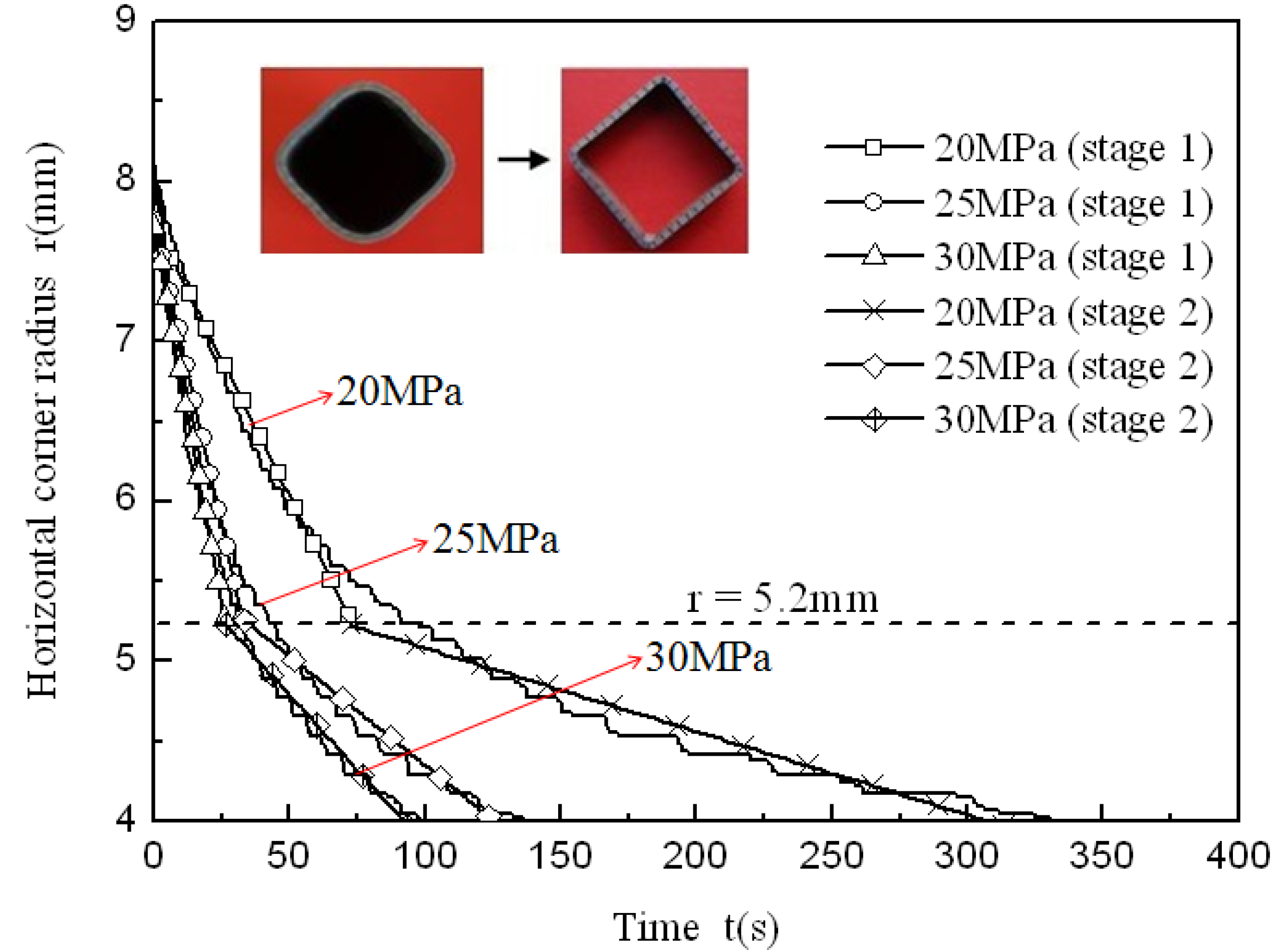

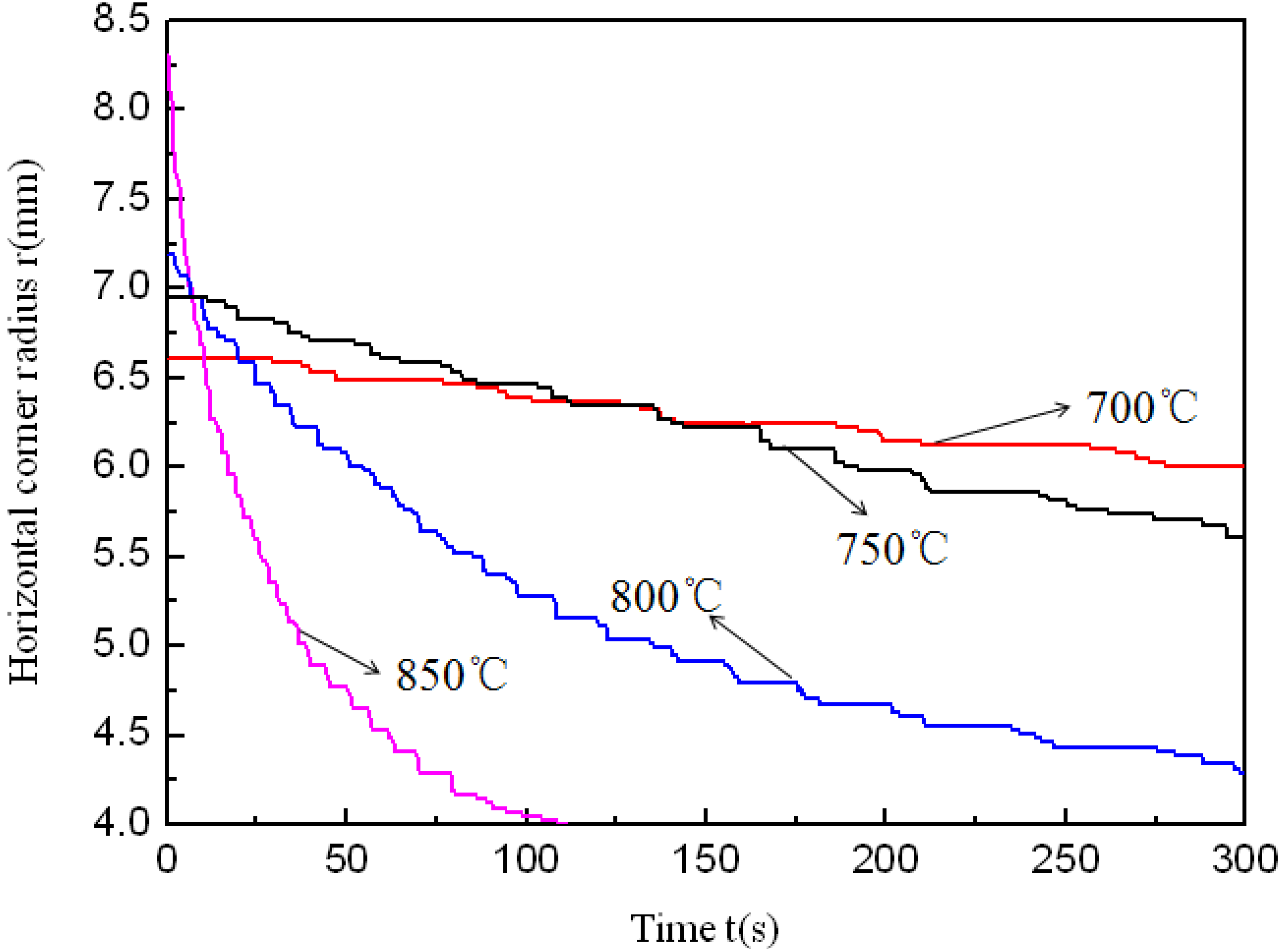

Figure 5. During the preforming process, the corner areas of the tube do not contact with the die so that the preforming corner radii are not controlled precisely. Therefore, there is a slight difference in the corner radius of the preformed tubes. Besides, 8 mm is the value at which the four corner filling curves all start to change steadily. So the data of radii from 8 and 4 mm are analyzed to reduce errors caused by the preforming process and measuring. Because of the strain rate sensitivity at elevated temperature, the corner radii of the forming tubes depend on the internal pressure levels and forming time. This is different from corner filling at room temperature in which the corner radii of the forming tube depend only on the internal pressure levels. As is well known, forming a smaller corner needs a higher pressure in the hydroforming process. At room temperature and with a constant pressure level, as the radius reaches a certain value, the corner filling process stops because of the work hardening effect and the smaller radius. At elevated temperature and with a constant pressure level, as the radius gets smaller and smaller, the corner filling does not stop although it becomes slower and slower. This results from the strain rate sensitivity at elevated temperature. When the strain rate decreases, the flow stress also decreases to permit continuous deformation.

Figure 5 shows that the same corner radius could be achieved with different pressure levels at the identical forming temperature, indicating that pressure levels might not be one of the major factors influencing formability but can notably affect the forming time. The corner radius changing from 8 to 4 mm needs 100 s at a pressure level of 30 MPa, but needs 1100 s at a pressure level of 15 MPa. In order to better understand the effect of pressure levels on the corner filling rate, the corner filling curves at different pressure levels were divided into two stages, then the curves at stage 1 and stage 2 were linearly fitted where the absolute values of the slopes refer to the average filling rate. Through the variation trend of the corner filling curves, it is found that values between 5 and 5.5 mm divide the whole curve clearly into two stages. When 5.2 mm is the value at which the first stage ends and the second one begins, every stage of the corner filling curves at different pressure levels can be linearly fitted and can be used for comparing corner filling rates between two stages. Therefore, 5.2 mm is chosen as the point of division. Besides, the corner filling time at 15 MPa is too prolonged for the HPPF process and the corner filling curve for 15 MPa is not considered. So corner filling curves at 20, 25 and 30 MPa are chosen for the analysis, as shown in

Figure 6.

Table 2 shows the average filling rate of stage 1 and stage 2 at three different pressure levels, in which ∆r

1 refers to the average filling rate of stage 1 and ∆r

2 refers to the average filling rate of stage 2. It is found that ∆r

2 is much smaller than ∆r

1 at the same pressure level. As the pressure level is increased, both ∆r

1 and ∆r

2 increase while ∆r

1/∆r

2 decreases. This indicates that the higher pressure level can not only increase the average filling rate but also decreases the descent gradient of the filling rate.

Figure 4.

(a) Fully formed component with outer radius of 4 mm; (b) middle cross-section of the fully formed component.

Figure 4.

(a) Fully formed component with outer radius of 4 mm; (b) middle cross-section of the fully formed component.

Figure 5.

Corner filling process at 850 °C and four different pressure levels.

Figure 5.

Corner filling process at 850 °C and four different pressure levels.

Figure 6.

Corner filling curves at three different pressure levels which are linearly fitted.

Figure 6.

Corner filling curves at three different pressure levels which are linearly fitted.

Table 2.

The average filling rate of stage 1 and stage 2 at different pressure levels.

Table 2.

The average filling rate of stage 1 and stage 2 at different pressure levels.

| Pressure (MPa) | ∆r1 (mm·s−1) | ∆r2 (mm·s−1) | ∆r1/∆r2 |

|---|

| 20 | 0.034 | 0.005 | 6.80 |

| 25 | 0.076 | 0.014 | 5.43 |

| 30 | 0.094 | 0.019 | 4.95 |

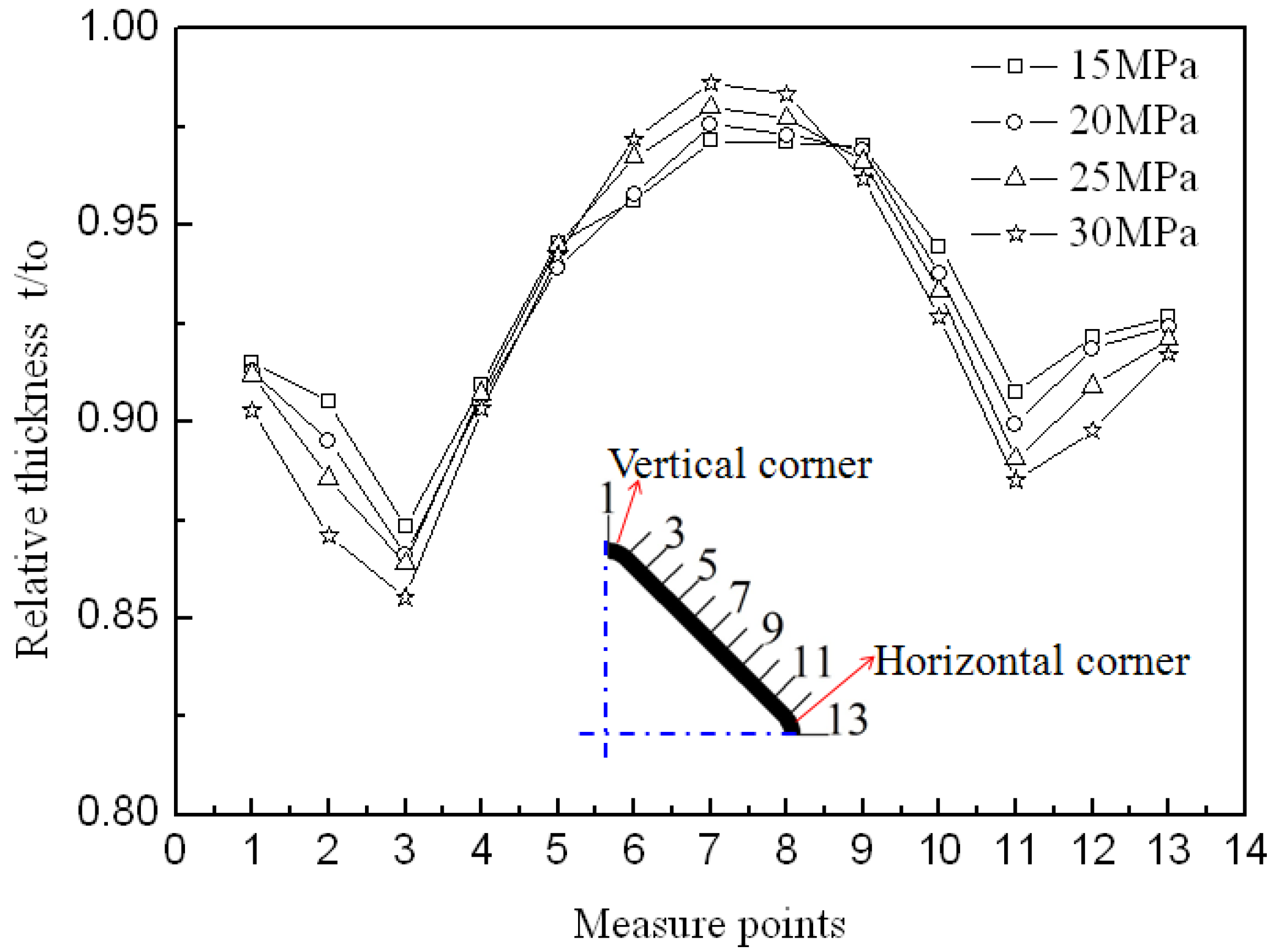

Figure 7 illustrates the circumferential thickness distribution of tubular components at 850 °C and four different pressure levels. It can be seen that the minimum thickness occurs at the transition zone between the straight wall area and the vertical corner area and the maximum thickness occurs at the middle of the straight wall area. Because the horizontal corner radius is smaller than the vertical corner radius after the preforming process, the thickness from the horizontal corner to the middle of the straight wall area is slightly greater than that from the vertical corner to the middle of the straight wall area after the expanding process. The maximum thinning ratio does not significantly change and is 12.86%, 13.38%, 13.62%, 14.48% at the pressure levels of 15, 20, 25, 30 MPa, respectively. However, higher pressure induces a little more thinning at the transition zone between the straight wall area and the vertical corner area (

Figure 7, point 3). This is because the smaller friction force at lower pressure makes the deformation in the straight wall area easier once the tube is in contact with the die. Besides, the strain rate sensitivity index is affected by the strain rate and it is related to the thinning behavior of the material. Li

et al. [

18] studied the effects of strain rate on the formability of Ti-6Al-4V alloy sheet and found that the strain rate sensitivity index decreased with increasing the strain rate. Salam [

19] studied the flow stress-strain rate behavior of Ti-3Al-2.5V alloy and also found that the strain rate sensitivity index decreased with increasing the strain rate. According to these results, lower pressure induces smaller flow stress and lower strain rate in HPPF experiments, so the strain rate sensitivity index is probably larger and this can result in more uniform deformation. In the future, much more work will be done to verify this inference. The reason for the occurrance of the minimum thickness at the transition zone instead of at the middle part of the corner is probably because the stress states are different at different areas during the corner filling process. Through the HPPF process, the maximum thinning ratio of the cross section is smaller than 15%, which can meet the demand of most applications and correct lubrication improves the thickness uniformity.

Figure 7.

Thickness distribution at 850 °C and at different pressure levels.

Figure 7.

Thickness distribution at 850 °C and at different pressure levels.

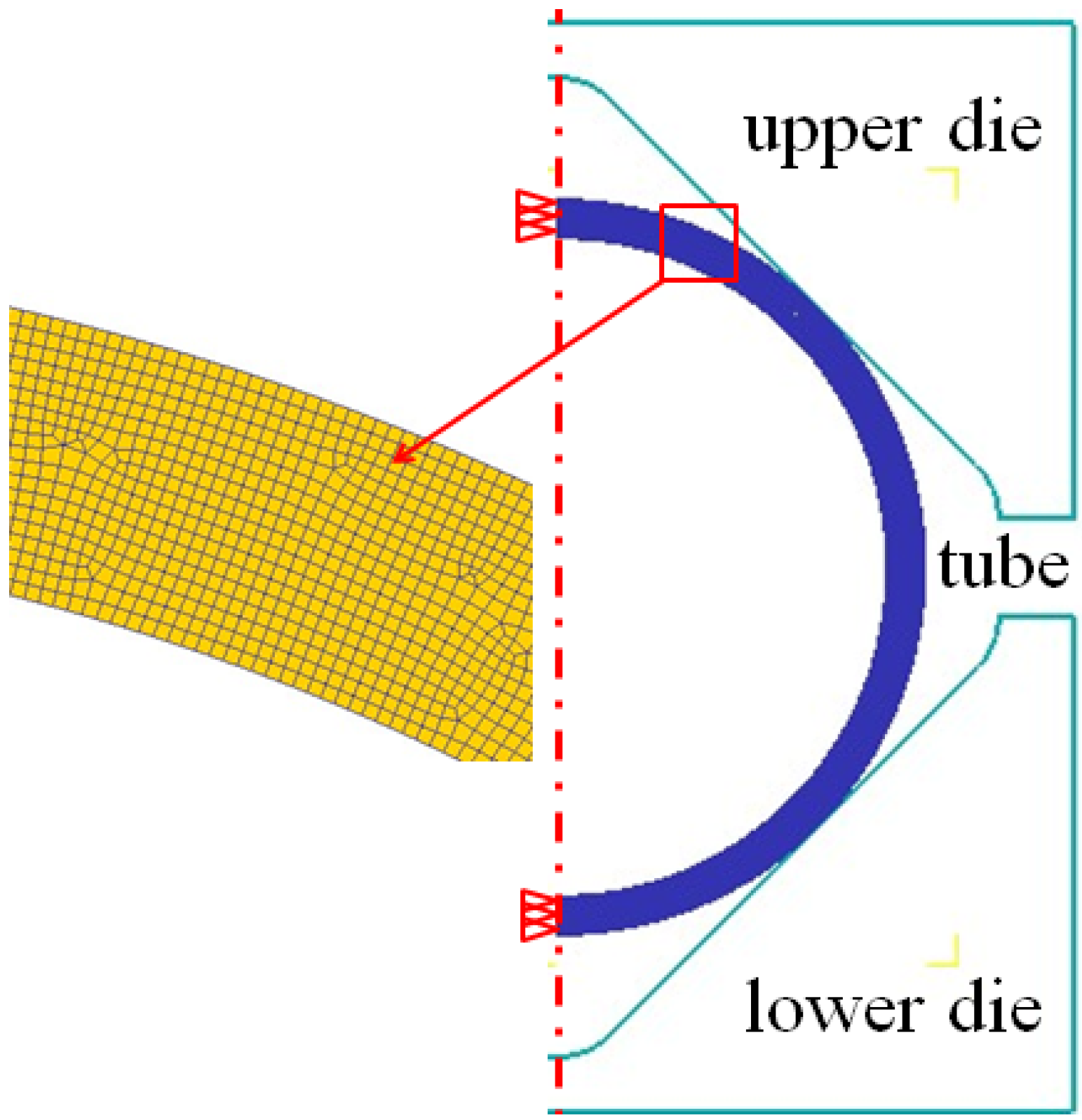

3.4. Finite Element Method Analysis of Corner Filling Process

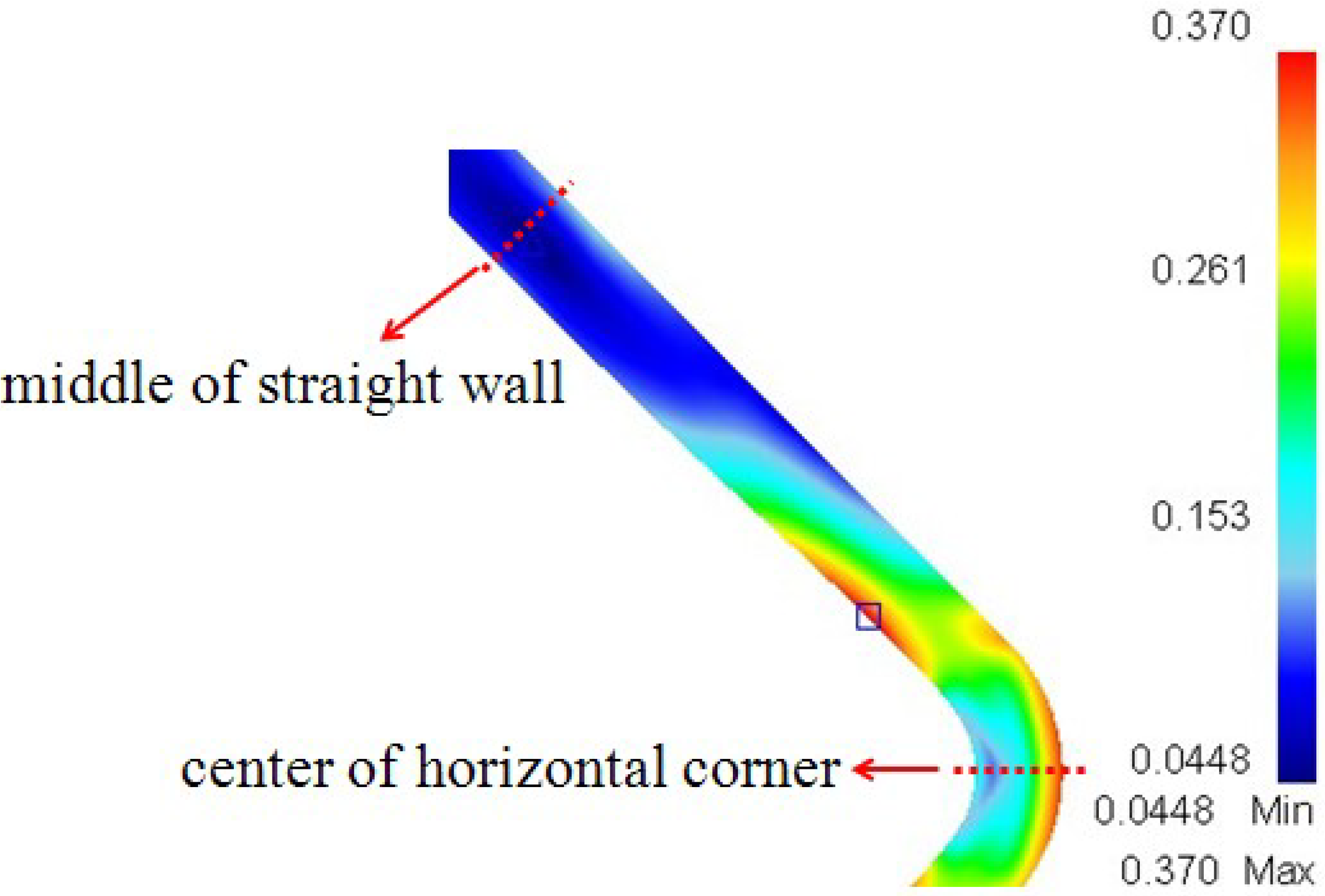

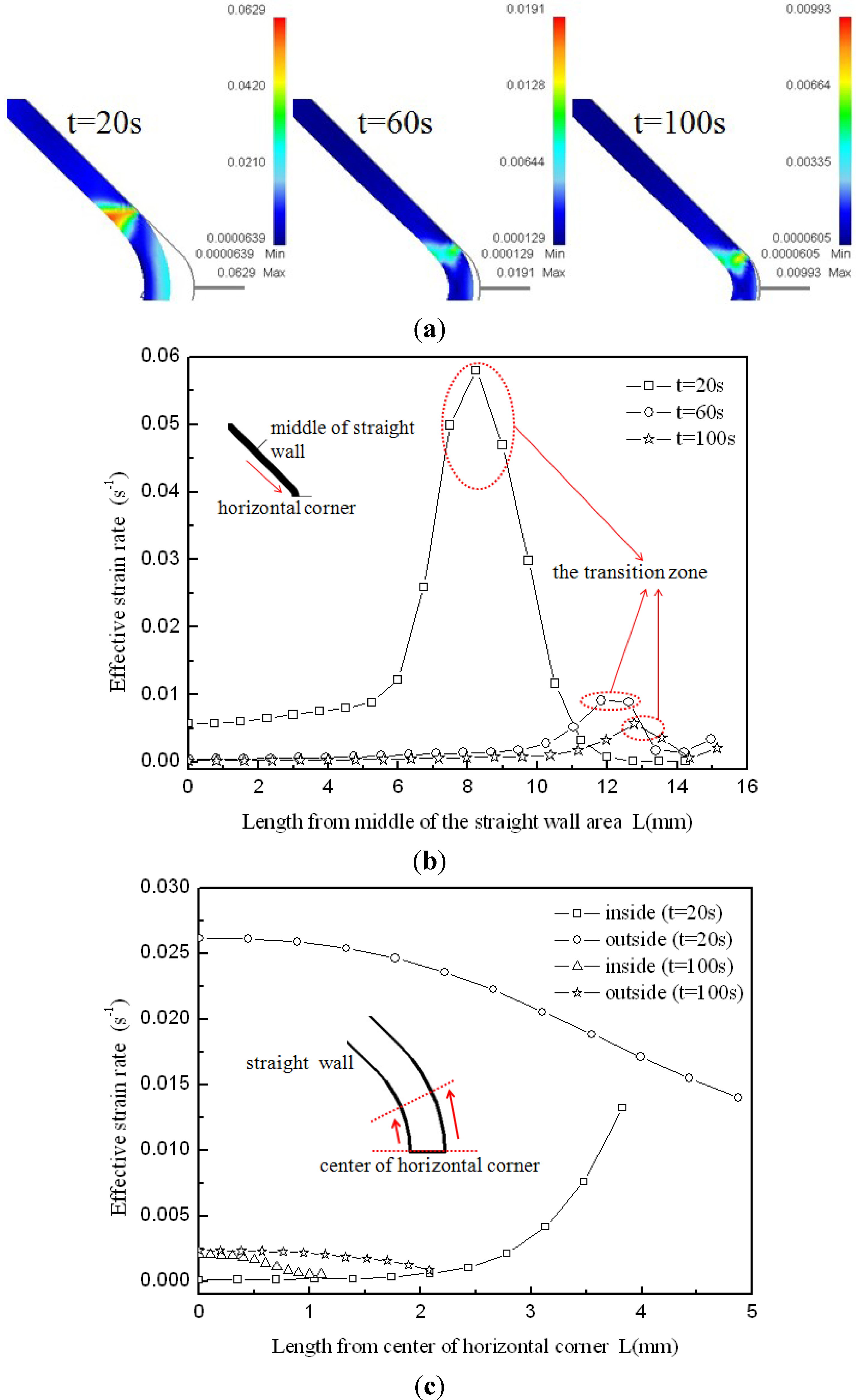

At the end of the corner filling process, the effective strain distribution at the cross-section is shown in

Figure 9. From the thickness distribution in

Figure 7, it is found that the thickness difference between the vertical corner and horizontal corner is very small, therefore only the horizontal corner radius is measured during the HPPF process and analyzed in the following context. It can be seen that between the straight wall area and horizontal corner area the maximum effective strain of 0.37 is located at the inside of the transition zone, but the effective strain is different along the thickness direction, especially at the corner area. The effective strain just achieves 0.116 at the inside of the horizontal corner, while it achieves 0.330 at the outside of the horizontal corner. This is probably because of different stress states at the inside and outside of the corner. The effective strain rate distribution at different moments is given in

Figure 10a, the values of effective strain rate from the middle of the straight wall area to the center of the horizontal corner area at the inside of the component are given in

Figure 10b, and the values of the effective strain rate at the inside and outside of the horizontal corner are given in

Figure 10c. As shown in

Figure 10a,b, the maximum effective strain rate always occurs at the transition zone during the corner filling process and it nearly achieves 0.06 s

−1 at the time of

t = 20 s, but the effective strain rate at the straight wall area and corner area are much smaller. As a result, deformation at the transition zone is much larger than other areas. It is also found that the effective strain rate at the transition zone becomes slower clearly during the corner filling process and this is the main reason for the corner filling rate becoming slower at constant pressure levels. For the straight wall area, the effective strain rate is 0.0065 s

−1 at the time of 20 s, but it is nearly zero at the moment of

t = 60 s. This indicates that small deformation at the straight wall area mainly occurs at the beginning of corner filling. For the corner area, it can bulge freely during the corner filling process and the situation is much more complicated. As shown in

Figure 10c, the effective strain rates at the inside and outside of the corner are very different at the time of

t = 20 s: for the outside of the corner, the effective strain rate can be above 0.025 s

−1 at the center of the corner and decreases to 0.014 s

−1 gradually far away from the center; for the inside of the corner, the effective strain rate is nearly 0 at the center and increases to 0.014 s

−1 gradually far away from the center. However, the effective strain rates at the inside and outside of the corner become very close at the time of 100 s and the effective strain rate at the center of the inside corner can achieve 0.002 s

−1. This indicates that a small deformation around the center of the inside corner mainly occurs at the end of the corner filling. Besides, the effective strain rate at the outside of the corner is always higher than that at the inside of the corner during the corner filling process. Hwang and Chen [

20] indicated that the tube at the transition zone was subjected simultaneously to a tensile stress and a compressive stress. Because of this, material at the transition zone flows more easily and this leads to a higher strain rate. However, the stress states at other areas are also very important with respect to their deformation during the corner filling process and need to be further discussed.

Figure 9.

Effective strain distribution at the cross-section.

Figure 9.

Effective strain distribution at the cross-section.

Figure 10.

(a) Finite Element Method results of effective strain rate distribution; (b) values of effective strain rate at the inside of the component; (c) values of effective strain rate at the inside and outside of the horizontal corner.

Figure 10.

(a) Finite Element Method results of effective strain rate distribution; (b) values of effective strain rate at the inside of the component; (c) values of effective strain rate at the inside and outside of the horizontal corner.

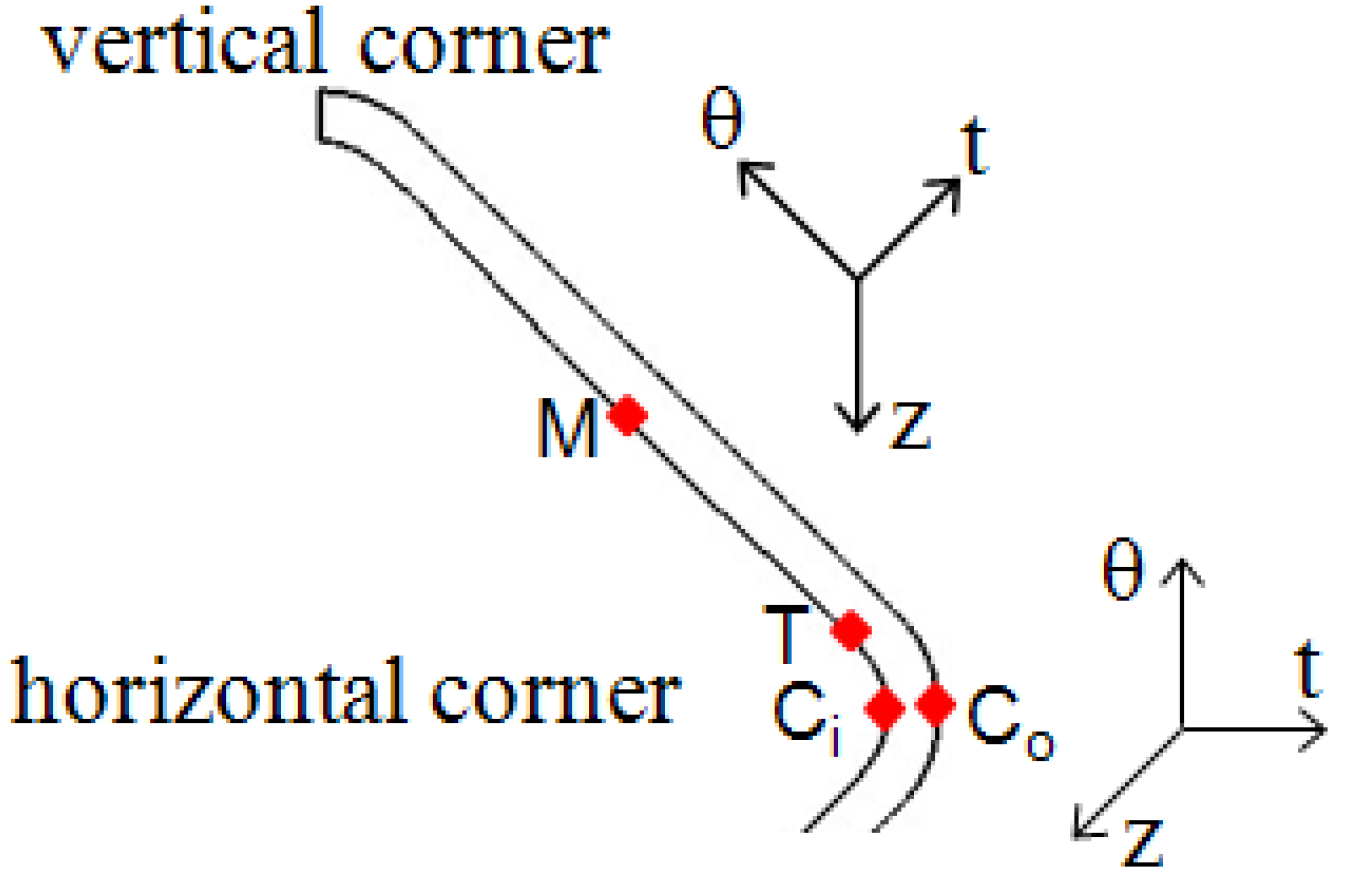

With the simulation results, the stress states of typical feature points during the corner filling process are obtained, including the middle point of the straight wall at the inside of the tube (

Figure 11, point M), the transition point at the inside of the tube (

Figure 11, point T), and the central points of the horizontal corner at the inside and outside of the tube (

Figure 11, point C

i and point C

o). The positions of these points are shown in

Figure 11 and the stress states during corner filling process of these points are shown in

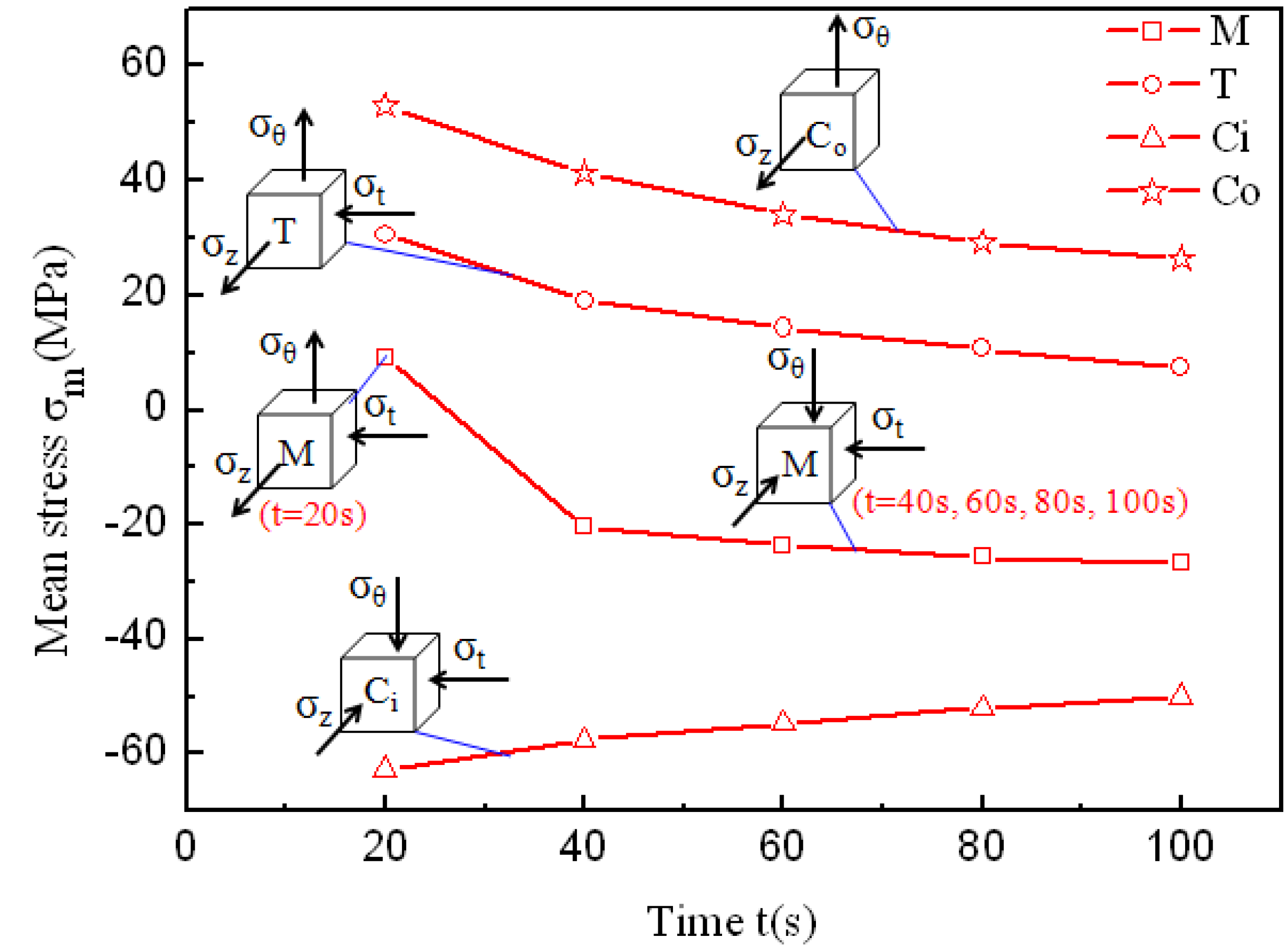

Figure 12. For a tubular component, σ

θ refers to the stress in the hoop direction; σ

t refers to the stress in the thickness direction; and σ

z refers to the stress in the axis direction. In order to facilitate analysis, the stress states at the times of

t = 20 s,

t = 40 s,

t = 60 s,

t = 80 s, and

t = 100 s are chosen to refer to the whole corner filling process. In

Figure 12, it is found that point M is subjected to tensile stresses in the hoop and axis direction and a compressive stress in the thickness direction at the beginning of the corner filling, but as the corner gets smaller and the tube contacts the die better, the tensile stresses turn into compressive stresses and then point M is subjected to a three-compressive stress state. As a result, the deformation of the middle area of the straight wall mainly occurs at the beginning of corner filling. However, point T is always subjected to tensile stresses in the hoop and axis direction and a compressive stress in the thickness direction. It is conducive to deformation and the maximum effective strain and strain rate all occur at the transition zone. Point C

i is subjected to three compressive stresses, while point C

o is subjected to tensile stresses in the hoop and axis direction, which denotes a plane-stress state. As a result, the outside of the corner can deform more easily than the inside of the corner and the strain is very different along the thickness direction.

Figure 11.

Position of typical feature points.

Figure 11.

Position of typical feature points.

Figure 12.

The stress states and mean stresses at the typical feature points during the corner filling process.

Figure 12.

The stress states and mean stresses at the typical feature points during the corner filling process.

The mean stresses at the typical feature points during the corner filling process are also shown in

Figure 12. For point M, the algebraic value of the mean stress changes from a positive number to a negative number and then decreases gradually. This indicates that the tensile stress in the hoop direction is large at the beginning of the corner filling, but it decreases and turns into compressive stress as the tube contacts the die better. Then the hydrostatic pressure increases gradually to a constant value of 30 MPa due to the corner filling process at 30 MPa. But the middle area of the straight wall can hardly deform due to the constraints of the die and the material around. For point T, although the stress state of two-tensional and one-compressive makes the transition zone deform easily, the mean stress decreases gradually during the corner filling process. As a result, the corner filling rate decreases gradually at constant pressure levels. The strain types are both plane strain type at points C

i and C

o, but the loading locus of the mean stress at point C

i is very different from that at point C

o. The mean stress is always positive at point C

o and negative at point C

i. This also indicates that the outside of the corner can deform more easily than the inside of the corner during the corner filling process. The absolute values of mean stresses at points C

i and C

o both decrease gradually during the corner filling process, which are similar to point T. During the corner filling process, although their strain types are all plane strain type, different areas of the cross-section are subjected to different stress states and this results in different strain and strain rates.

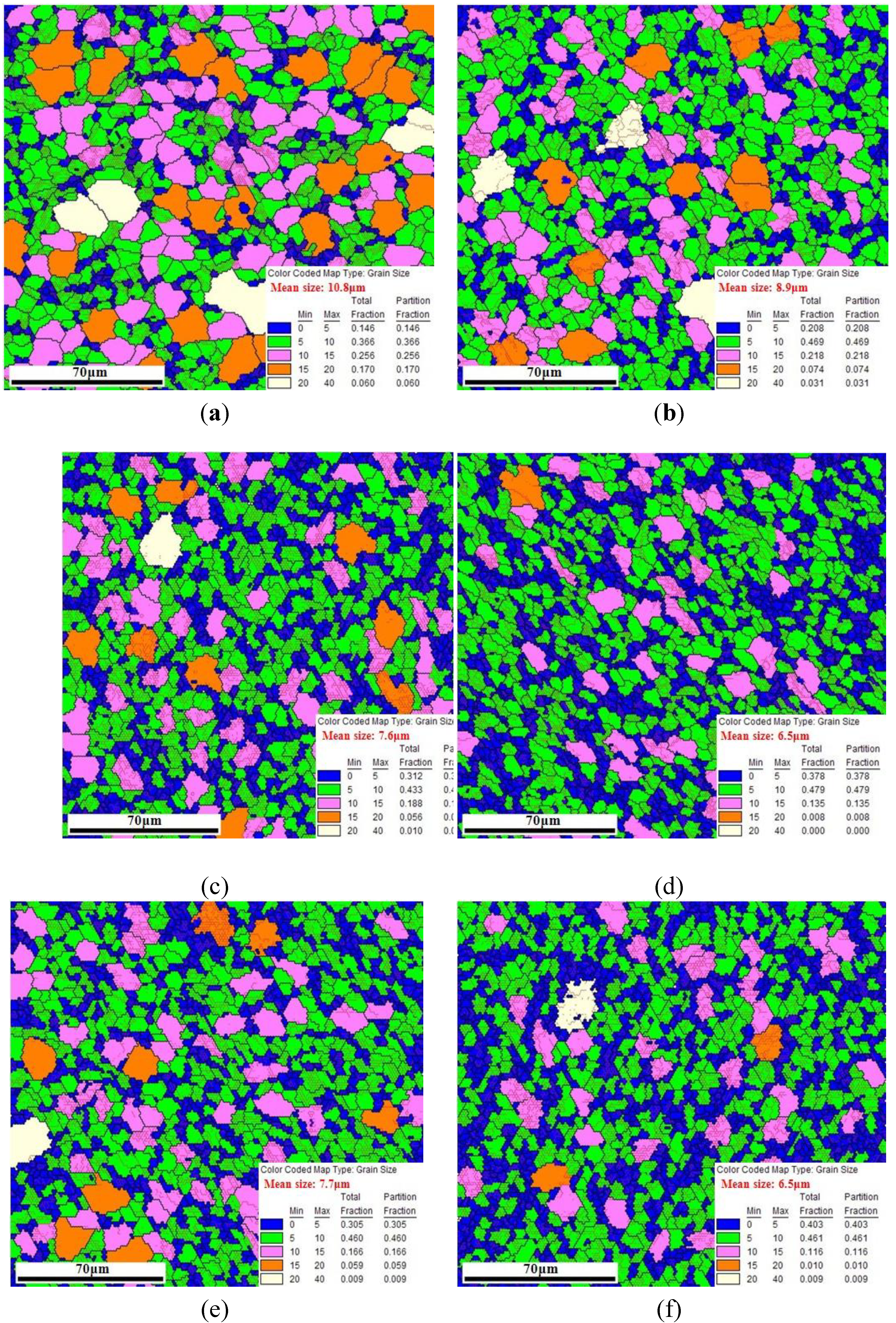

3.5. Microstructure Evolution during the Corner Filling Process

From the results of FEM simulation above, it was evident that different regions at the cross-section of the tube are subjected to different stress states during the corner filling process and this results in different strains, so the microstructure at typical regions formed at 850 °C and 30 MPa were analyzed using EBSD. As for the FEM analysis, the areas between the middle of the straight wall area and the horizontal corner area were chosen to be analyzed. Besides, the same region formed at 850 °C and different pressure levels was also analyzed to investigate the effect of forming time on the microstructure. As shown in

Figure 13, regions M, T, C

i and C

o are typical regions and refer to the middle region at the inside of straight wall area, the region at the inside of the transition zone, the central region at the inside of the corner and the central region at the outside of the corner respectively.

Figure 14a depicts the EBSD result showing the microstructure of the as-received tube. The initial grain size in the scanned area varies over a wide range with the mean size of 10.8 μm. The microstructures of typical regions formed at 850 °C and 30 MPa are shown in

Figure 14c–f: overall, the grains of four regions are all refined to a certain extent, but the refining effect is more obvious with larger deformation; the grains are refined with mean size of 6.5 μm at regions T and C

o, and the grains are refined with mean size of 7.6 and 7.7 μm at regions M and C

i respectively. As shown in

Figure 9, the effective strain is larger and similar at regions T and C

o, and it is smaller and similar at regions M and C

i, thus the results above occur. For regions T and C

o, the proportion of the grains with size smaller than 5 μm is 37.8% and 40.3% respectively, but for regions M and C

i, it is 31.2% and 30.5% respectively. It is probably because a larger deformation can strengthen the dynamic recrystallization at high temperature. As shown in

Figure 14b, the grains are refined with mean size of 8.9 μm at region T formed at 850 °C and 15 MPa. Compared with region T formed at 850 °C and 30 MPa, the refining effect is less significant. It is also found that the proportion of the grains with size smaller than 5 μm is 37.8% at 30 MPa but only 20.8% at 15 MPa. This is probably because some fine grains after dynamic recrystallization grow due to the much longer forming time at 15 MPa. The results illustrate that the HPPF at high pressure has advantages both for efficiency and microstructure. Although the grain size of the formed components at high pressure is not as uniform as the original tube blank, the difference is acceptable.

Figure 13.

Regions for electron back scattering diffraction (EBSD) analysis.

Figure 13.

Regions for electron back scattering diffraction (EBSD) analysis.

Figure 14.

(a) Cross-sectional EBSD result of as-received tube; (b) cross-sectional EBSD result at region T formed at 850°C and 15MPa; (c) cross-sectional EBSD result at region M formed at 850 °C and 30 MPa; (d) cross-sectional EBSD result at region T formed at 850 °C and 30 MPa; (e) cross-sectional EBSD result at region Ci formed at 850 °C and 30 MPa; (f) cross-sectional EBSD result at region Co formed at 850 °C and 30 MPa.

Figure 14.

(a) Cross-sectional EBSD result of as-received tube; (b) cross-sectional EBSD result at region T formed at 850°C and 15MPa; (c) cross-sectional EBSD result at region M formed at 850 °C and 30 MPa; (d) cross-sectional EBSD result at region T formed at 850 °C and 30 MPa; (e) cross-sectional EBSD result at region Ci formed at 850 °C and 30 MPa; (f) cross-sectional EBSD result at region Co formed at 850 °C and 30 MPa.