Recycling of Clay Sediments for Geopolymer Binder Production. A New Perspective for Reservoir Management in the Framework of Italian Legislation: The Occhito Reservoir Case Study

Abstract

:1. Introduction

1.1. Italian Legislation Framework

- 1.5% of the dams were almost completely filled by sediments;

- 17.5% showed a reservoir capacity reduction of more than 50%;

- 4.5% showed a reservoir capacity reduction of approximately 20%.

- (a)

- excavation soils result from the completing of a work and are part of a production process whose primary purpose is not the production of such material;

- (b)

- excavation soils are used in accordance to the Use Plan;

- (c)

- the excavation soils can be directly used without any further processing other than normal industrial practice (Annex 3 to the Ministerial Decree, 161/2012) [16];

- (d)

- for the specific use to which Point (c) is refers, the excavation soils fulfil the environmental protection requirements specified in Annex 4 to [16].

1.2. Geopolymer Binders as an Innovative Management Strategy

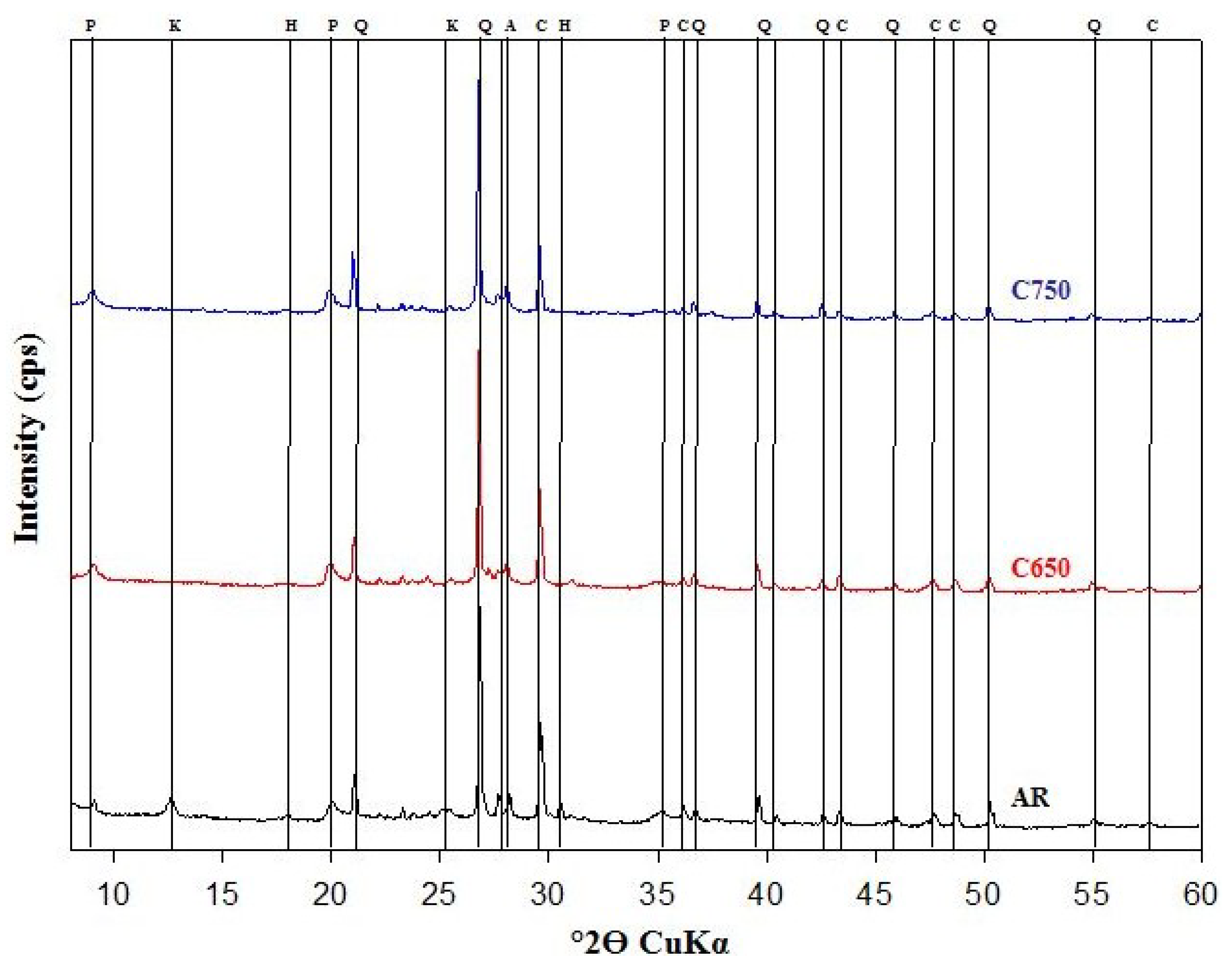

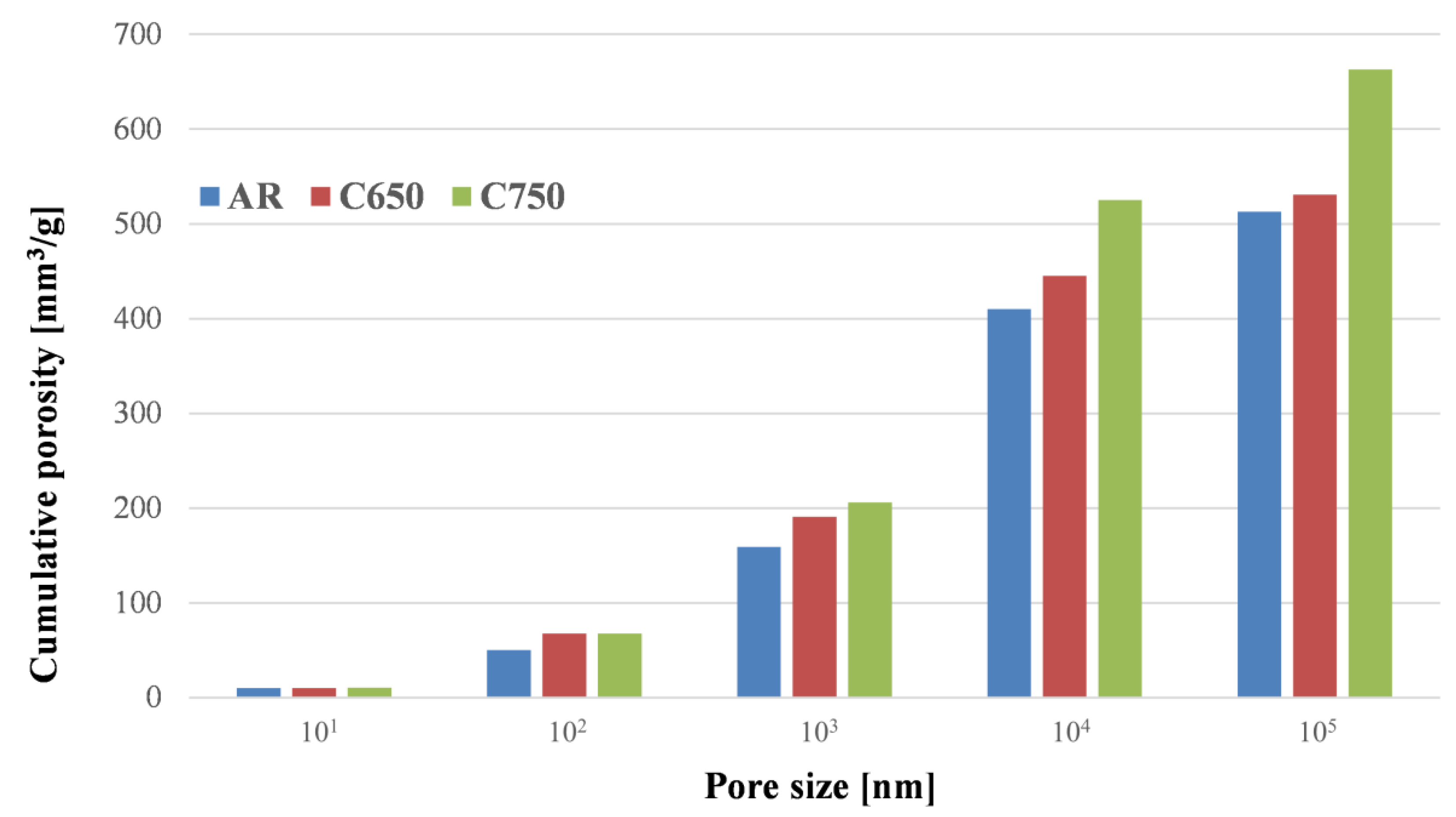

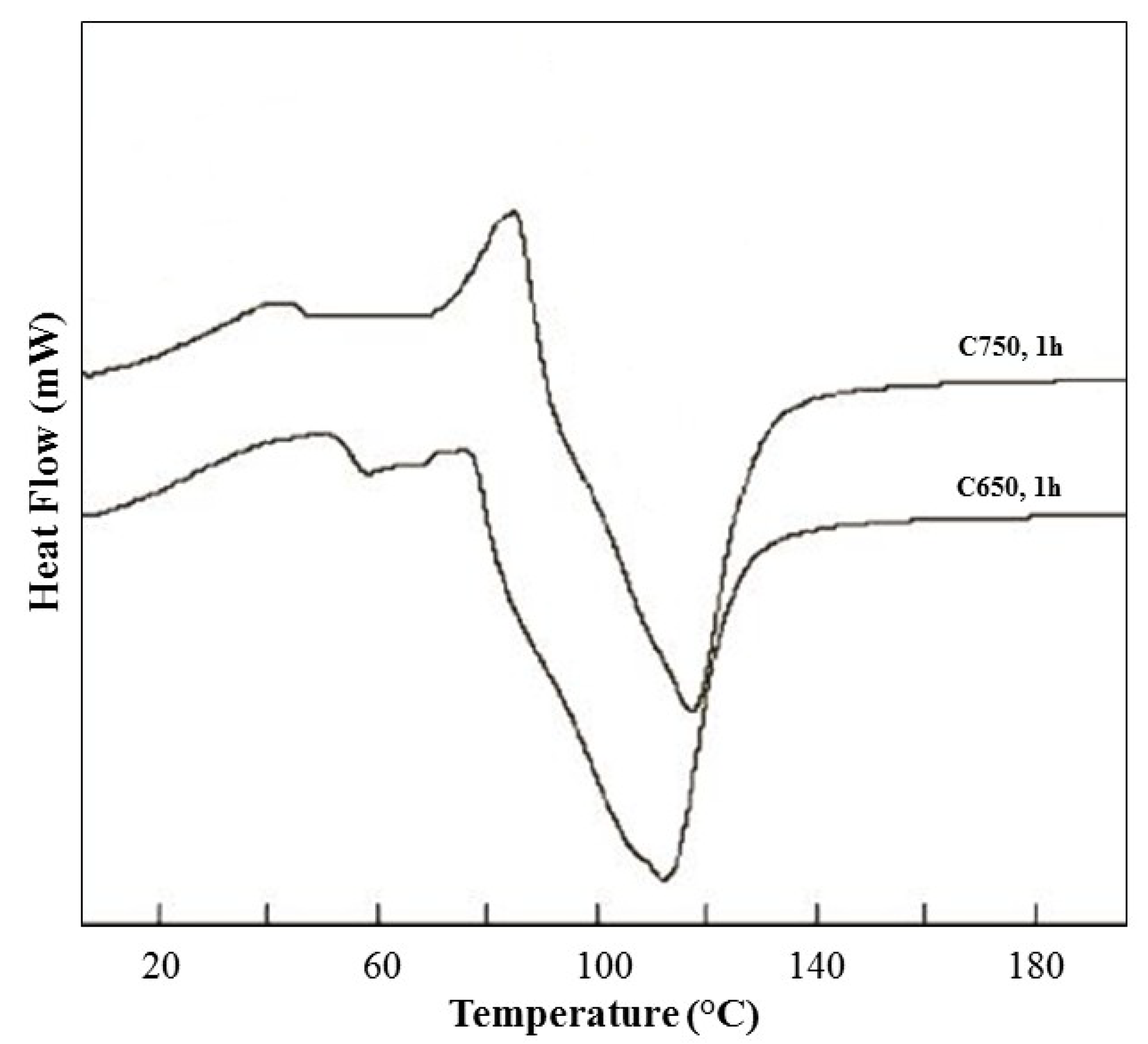

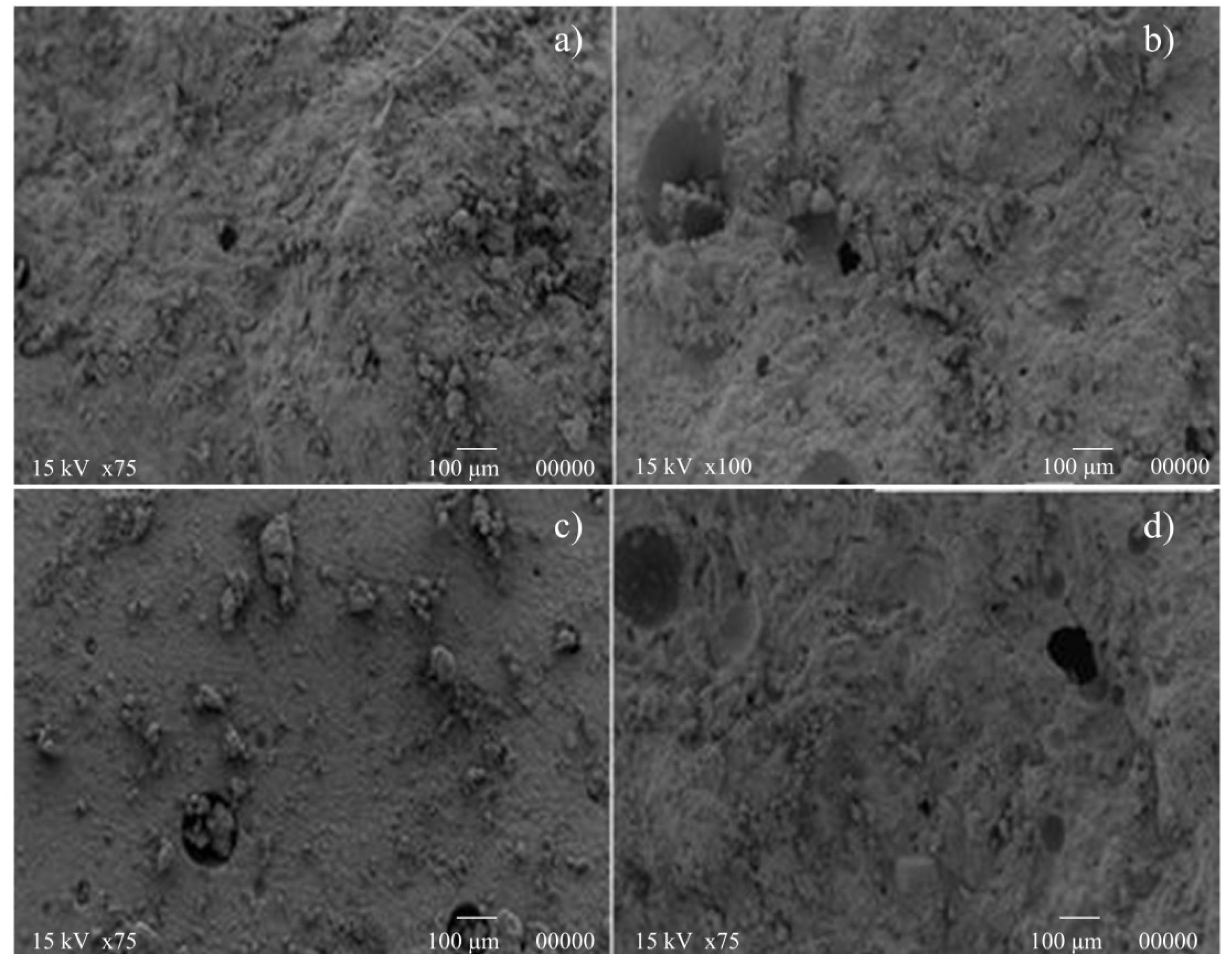

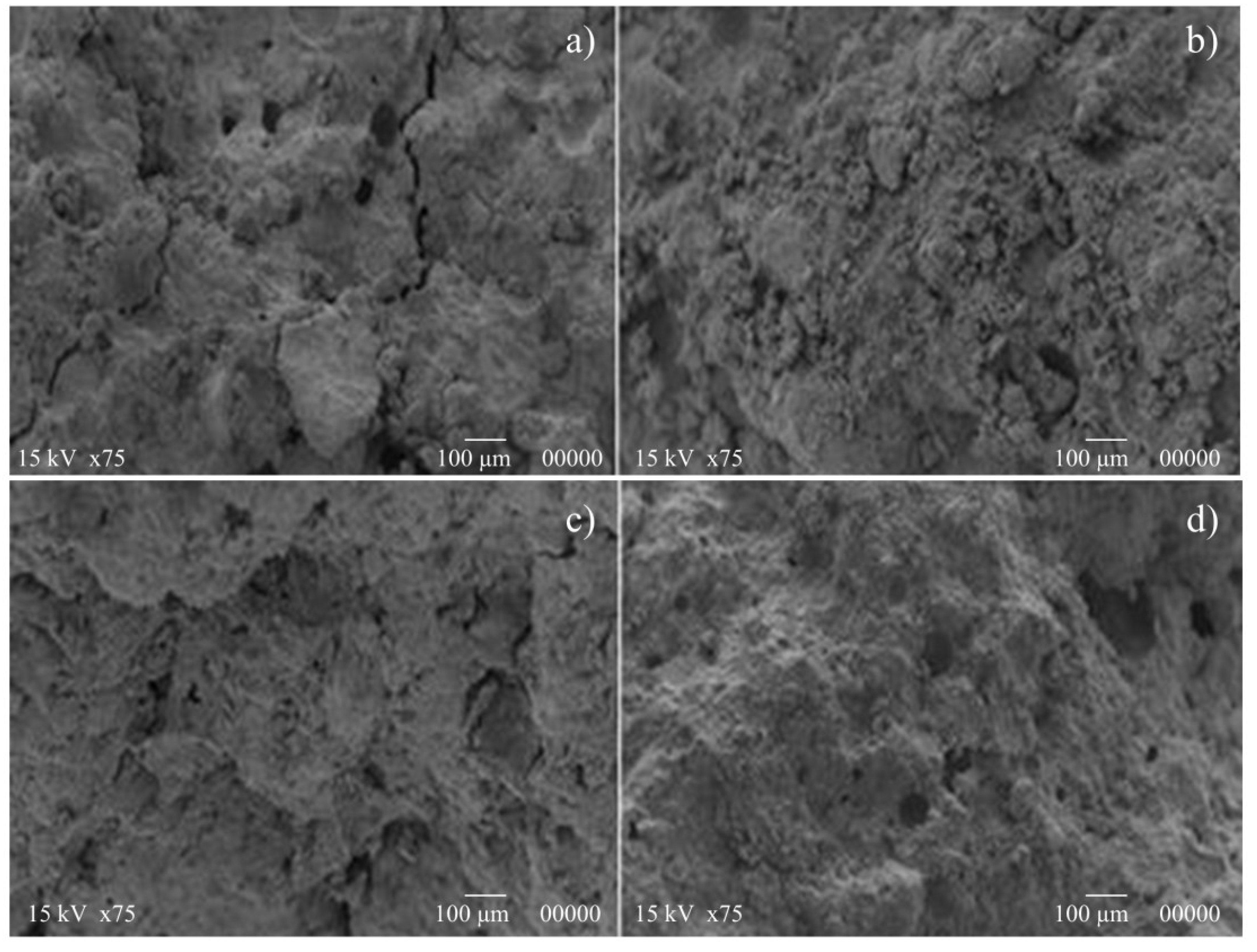

2. Results and Discussion

| Oxides | SiO2 | Al2O3 | CaO | Fe2O3 | MgO | K2O | TiO2 | Na2O | MnO | P2O5 |

|---|---|---|---|---|---|---|---|---|---|---|

| Occhito | 57.13 | 16.33 | 12.5 | 6.94 | 2.97 | 2.4 | 0.88 | 0.37 | 0.15 | 0.15 |

| MK1 | 51.2 | 43.98 | - | 1.12 | - | 0.54 | 1.67 | - | - | - |

| MK2 | 52.9 | 41.9 | 0.17 | 1.6 | 0.19 | 0.77 | 1.8 | - | - | - |

3. Experimental Section

species [47]. Hajimohammadi et al. [48] studied a one-part geopolymer composition obtained by adding water to a solid geothermal silica and sodium aluminate blend, but engineering characterization was not carried out. In [49], many binding mixtures were studied and, among those, sodium aluminate activated kaolinite, slag, K-feldspar and fly ash mixtures. The alumina content obtained by means of XRF analysis was equal to 28.6, 17.6, 14.1 and 27.1 wt% for kaolinite, k-feldspar, slag and fly ash, respectively. Compressive strength values after 7 days of curing ranged from 3.3 to 26.6 MPa when only sodium aluminate was used and from 23.0 to 86.5 MPa when a binary aluminosilicate alkaline solution was used [49]. Recently, other works have demonstrated the interest of research in aluminate activation. Rickard et al. investigated the thermal properties of fly ash-based geopolymers activated by means of sodium silicate and sodium aluminate solutions [50]. Van Riessen et al. obtained average performance geopolymers (compressive strength in the range 33–43 MPa) activating fly ash by means of industrial liquors coming from the Bayer process [51]. All of these considerations reasonably push research toward the further development of aluminate activation, which could bring not just average performance composites for the construction sector, but also high performance ones.

species [47]. Hajimohammadi et al. [48] studied a one-part geopolymer composition obtained by adding water to a solid geothermal silica and sodium aluminate blend, but engineering characterization was not carried out. In [49], many binding mixtures were studied and, among those, sodium aluminate activated kaolinite, slag, K-feldspar and fly ash mixtures. The alumina content obtained by means of XRF analysis was equal to 28.6, 17.6, 14.1 and 27.1 wt% for kaolinite, k-feldspar, slag and fly ash, respectively. Compressive strength values after 7 days of curing ranged from 3.3 to 26.6 MPa when only sodium aluminate was used and from 23.0 to 86.5 MPa when a binary aluminosilicate alkaline solution was used [49]. Recently, other works have demonstrated the interest of research in aluminate activation. Rickard et al. investigated the thermal properties of fly ash-based geopolymers activated by means of sodium silicate and sodium aluminate solutions [50]. Van Riessen et al. obtained average performance geopolymers (compressive strength in the range 33–43 MPa) activating fly ash by means of industrial liquors coming from the Bayer process [51]. All of these considerations reasonably push research toward the further development of aluminate activation, which could bring not just average performance composites for the construction sector, but also high performance ones.- (1)

- 5 M NaOH in an amount so as to have a Na/Al ratio at most equal to 1:1; this is possible by assuming the hypothesis that all of the alumina is available for polycondensation reactions;

- (2)

- sodium aluminate solution obtained by dissolving pure Al(OH)3 in NaOH solutions in an amount so as to have a molar Al/Na ratio equal to 0.65 (maximum solubility);

- (3)

- potassium aluminate solution obtained by dissolving pure Al(OH)3 in KOH solutions in an amount so as to have a molar Al/K ratio equal to 0.53 (maximum solubility).

4. Conclusions and Further Developments

Author Contributions

Conflicts of Interest

References

- Law No. 584, Italy, 21 October 1994.

- Bazzoffi, P.; Vanino, S. L’interrimento degli invasi ad uso irriguo nelle regioni meridionali: Rilievi diretti metodologie e modellistica. In Rapporto; Istituto Nazionale di Economia Agraria: Rome, Italy, 2009. (In Italian) [Google Scholar]

- Barbagallo, S.; Tamburino, V. Valutazione dei deflussi in alcuni bacini siciliani mediante il bilancio idrico dei serbatoi. Idrotecnica 1989, 1, 5–12. (In Italian) [Google Scholar]

- Tamburino, V.; Barbagallo, S.; Vella, P. Indagine sull’interrimento dei serbatoi artificiali siciliani. Ing. Agrar. 1989, 3, 156–164. (In Italian) [Google Scholar]

- Tomasi, L. Operation and maintenance problems due to sedimentation in reservoir. In Proceedings of the International Conference on Reservoir Sedimentation, Fort Collins, CO, USA, 9–13 September 1996; Colorado State University Press: Fort Collins, CO, USA, 1996; pp. 15–28. [Google Scholar]

- Barko, J.W.; Adams, M.S.; Clesceri, N.L. Environmental factors and their considerations in the managements of submersed aquatic vegetations: A review. J. Aquat. Plant Manag. 1986, 24, 1–10. [Google Scholar]

- Nichols, S.A. Depth, substrate, and turbidity relationships of some Wisconsin lake plants. Trans. Wis. Acad. Sci. Arts Lett. 1992, 80, 97–118. [Google Scholar]

- Article 114, Legislative Decree No. 152, Italy, 2006.

- Legislative Decree No. 152, Italy, 1999.

- Ministerial Decree, Italy, 30 June 2004.

- Article 43, Decree Law No. 201, Italy, 2011.

- Decree of the President of the Italian Republic No. 1363, Italy, 1959.

- Ministerial Decree, Italy, 27 September 2011.

- Ministerial Decree, Italy, 5 February 1998.

- Legislative Decree No. 205, Italy, 2010.

- Ministerial Decree No. 161, Italy, 2012.

- Decree No. 3159, Italy, 1 February 2013.

- Decree No. 179, Italy, 11 February 2013.

- Magri, M. Profili giuridici del riuso dei materiali. Quarry Constr. 2009, 9, 13–20. (In Italian) [Google Scholar]

- Molino, B. Combined reservoir rehabilitation and sediment utilization: Economic defence. In Proceedings of the International Conference on Trends in Water and Environmental Engineering for Safety and Life, Capri, Italy, 3–7 July 2000.

- Molino, B.; Sole, A.; Zuccaro, G. Rehabilitation of artificial reservoir and environmental reuse of sediment. In Proceedings of the 3rd International Conference on Management Information System, Halkidiki, Greece, 24–26 April 2002.

- Molino, B. Environmental protection in processes of reservoir restoration and use of sediments. In Proceedings of the International Workshop from Watersheds Slopes to Coastal Areas: Sedimentation Processes at Different Scales, Venice, Italy, 3–6 December 2003.

- Chiang, K.Y.; Chien, K.L.; Hwang, S.J. Study on the characteristics of building bricks produced from reservoir sediment. J. Hazard. Mater. 2008, 159, 499–504. [Google Scholar] [CrossRef] [PubMed]

- Hamer, K.; Karius, V. Brick production with dredged harbour sediments. An industrial-scale experiment. Waste Manag. 2002, 22, 521–530. [Google Scholar]

- Samara, M.; Lafhaj, Z.; Chapiseau, C. Valorization of stabilized river sediments in fired clay bricks: Factory scale experiment. J. Hazard. Mater. 2009, 163, 701–710. [Google Scholar] [CrossRef] [PubMed]

- Liao, Y.C.; Huang, C.Y. Effects of heat treatment on the physical properties of lightweight aggregate from water reservoir sediment. Ceram. Int. 2011, 37, 3723–3730. [Google Scholar] [CrossRef]

- Liao, Y.C.; Huang, C.Y. Effects of CaO addition on lightweight aggregates produced from water reservoir sediment. Constr. Build. Mater. 2011, 25, 2997–3002. [Google Scholar] [CrossRef]

- Tang, C.W.; Chen, H.J.; Wang, S.Y.; Spaulding, J. Production of synthetic lightweight aggregate using reservoir sediments for concrete and masonry. Cem. Concr. Compos. 2011, 33, 292–300. [Google Scholar] [CrossRef]

- Wei, Y.L.; Yang, J.C.; Lin, Y.Y.; Chuang, S.Y.; Wang, H.P. Recycling of harbor sediment as lightweight aggregate. Mar. Pollut. Bull. 2008, 57, 867–872. [Google Scholar] [CrossRef] [PubMed]

- Wei, Y.L.; Lin, Y.Y. Role of Fe compounds in light aggregate formation from a reservoir sediment. J. Hazard. Mater. 2009, 171, 111–115. [Google Scholar] [CrossRef] [PubMed]

- Wei, Y.L.; Lin, C.Y.; Ko, K.W.; Wang, H.P. Preparation of low water-sorption lightweight aggregates from harbor sediment added with waste glass. Mar. Pollut. Bull. 2011, 63, 135–140. [Google Scholar] [CrossRef] [PubMed]

- Valenti, G.; Bernardo, G.; Marroccoli, M.; Molino, B. Beneficial reuse of reservoir sediment in the cement industry. In Proceedings of the International Conference on Remediation of Contaminated Sediments, Venice, Italy, 30 September–3 October 2003.

- De Vincenzo, A.; Molino, B.; Viparelli, R.; Albergo, G. Silting-up in reservoir: A risk and a resource. In Proceedings of the 32nd IAHR World Congress, Venice, Italy, 1–6 July 2007; pp. 2–10.

- Molino, B. L’interrimento degli invasi e utilizzo dei sedimenti per la tutela dell’ambiente costiero. Geol. Ambient. 2008, 2, 77–86. (In Italian) [Google Scholar]

- Ferone, C.; Colangelo, F.; Messina, F.; Iucolano, F.; Liguori, B.; Cioffi, R. Coal combustion wastes reuse in low energy artificial aggregates manufacturing. Materials 2013, 6, 5000–5015. [Google Scholar] [CrossRef]

- Bakharev, T. Resistance of geopolymer materials to acid attack. Cem. Concr. Res. 2005, 35, 658–670. [Google Scholar] [CrossRef]

- Bakharev, T. Durability of geopolymer materials in sodium and magnesium sulfate solutions. Cem. Concr. Res. 2005, 35, 1233–1246. [Google Scholar] [CrossRef]

- Bakharev, T. Thermal behaviour of geopolymers prepared using class F fly ash and elevated temperature curing. Cem. Concr. Res. 2006, 36, 1134–1147. [Google Scholar] [CrossRef]

- Davidovits, J. Geopolymers and geopolymeric materials. J. Therm. Anal. Calorim. 1989, 35, 429–441. [Google Scholar] [CrossRef]

- Provis, J.L.; Brice, D.G.; Buchwald, A.; Duxson, P.; Kavalerova, E.; Krivenko, P.V.; Shi, C.; van Deventer, J.S.J.; Wiercx, J.A.L.M. Demonstration projects and applications in building and civil infrastructure. In Alkali-Activated Materials: State-of-the-Art Report; Springer: Berlin, Germany, 2014; pp. 309–338. [Google Scholar]

- Migliaccio, M.; Ferrara, G.; Gifuni, A.; Sorrentino, A.; Colangelo, F.; Ferone, C.; Cioffi, R.; Messina, F. Shielding effectiveness tests of low-cost civil engineering materials in a reverberating chamber. Prog. Electromagn. Res. B 2013, 54, 227–243. [Google Scholar] [CrossRef]

- Ferone, C.; Colangelo, F.; Messina, F.; Santoro, L.; Cioffi, R. Recycling of pre-washed municipal solid waste incinerator fly ash in the manufacturing of low temperature setting geopolymer materials. Materials 2013, 6, 3420–3437. [Google Scholar] [CrossRef]

- Menna, C.; Asprone, D.; Ferone, C.; Colangelo, F.; Balsamo, A.; Prota, A.; Cioffi, R.; Manfredi, G. Use of geopolymers for composite external reinforcement of RC members. Compos. Part B Eng. 2013, 45, 1667–1676. [Google Scholar] [CrossRef]

- Ferone, C.; Colangelo, F.; Cioffi, R.; Montagnaro, F.; Santoro, L. Mechanical performances of weathered coal fly ash based geopolymer bricks. Proc. Eng. 2011, 21, 745–752. [Google Scholar] [CrossRef]

- Ferone, C.; Colangelo, F.; Cioffi, R.; Montagnaro, F.; Santoro, L. Use of reservoir clay sediments as raw materials for geopolymer binders. Adv. Appl. Ceram. 2013, 112, 184–189. [Google Scholar] [CrossRef]

- Brew, D.R.M.; MacKenzie, K.J.D. Geopolymer synthesis using silica fume and sodium aluminate. J. Mater. Sci. 2007, 42, 3990–3993. [Google Scholar] [CrossRef]

- Hajimohammadi, A.; Provis, J.L.; van Deventer, J.S. One-part geopolymer mixes from geothermal silica and sodium aluminate. Ind. Eng. Chem. Res. 2008, 47, 9396–9405. [Google Scholar] [CrossRef]

- Phair, J.W.; van Deventer, J.S.J. Characterization of fly-ash-based geopolymeric binders activated with sodium aluminate. Ind. Eng. Chem. Res. 2002, 41, 4242–4251. [Google Scholar] [CrossRef]

- Garcia-Lodeiro, I.; Palomo, A.; Fernández-Jiménez, A.; Macphee, D.E. Compatibility studies between N-A-S-H and C-A-S-H gels. Study in the ternary diagram Na2O–CaO–Al2O3–SiO2–H2O. Cem. Concr. Res. 2011, 41, 923–931. [Google Scholar]

- Rickard, W.D.; Temuujin, J.; van Riessen, A. Thermal analysis of geopolymer pastes synthesised from five fly ashes of variable composition. J. Non Cryst. Solids 2012, 358, 1830–1839. [Google Scholar] [CrossRef]

- Van Riessen, A.; Jamieson, E.; Kealley, C.S.; Hart, R.D.; Williams, R.P. Bayer-Geopolymers: An exploration of synergy between the alumina and geopolymer industries. Cem. Conc. Compos. 2013, 41, 29–33. [Google Scholar] [CrossRef]

© 2014 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/3.0/).

Share and Cite

Molino, B.; De Vincenzo, A.; Ferone, C.; Messina, F.; Colangelo, F.; Cioffi, R. Recycling of Clay Sediments for Geopolymer Binder Production. A New Perspective for Reservoir Management in the Framework of Italian Legislation: The Occhito Reservoir Case Study. Materials 2014, 7, 5603-5616. https://doi.org/10.3390/ma7085603

Molino B, De Vincenzo A, Ferone C, Messina F, Colangelo F, Cioffi R. Recycling of Clay Sediments for Geopolymer Binder Production. A New Perspective for Reservoir Management in the Framework of Italian Legislation: The Occhito Reservoir Case Study. Materials. 2014; 7(8):5603-5616. https://doi.org/10.3390/ma7085603

Chicago/Turabian StyleMolino, Bruno, Annamaria De Vincenzo, Claudio Ferone, Francesco Messina, Francesco Colangelo, and Raffaele Cioffi. 2014. "Recycling of Clay Sediments for Geopolymer Binder Production. A New Perspective for Reservoir Management in the Framework of Italian Legislation: The Occhito Reservoir Case Study" Materials 7, no. 8: 5603-5616. https://doi.org/10.3390/ma7085603

APA StyleMolino, B., De Vincenzo, A., Ferone, C., Messina, F., Colangelo, F., & Cioffi, R. (2014). Recycling of Clay Sediments for Geopolymer Binder Production. A New Perspective for Reservoir Management in the Framework of Italian Legislation: The Occhito Reservoir Case Study. Materials, 7(8), 5603-5616. https://doi.org/10.3390/ma7085603