Evaluation of Selected Properties of Ti Coatings Deposited on MED610 for Medical Applications

Abstract

1. Introduction

2. Materials and Methods

2.1. Research Methodology

2.2. Sample Preparation

- -

- Isobornyl acrylate, 15–30 wt %;

- -

- Acrylic monomer, 15–30 wt %;

- -

- Urethane acrylate, 10–30 wt %;

- -

- Acrylic monomer, 5–15 wt %;

- -

- Epoxy acrylate, 5–15 wt %;

- -

- Acrylate oligomer, 5–15 wt %;

- -

- Photoinitiator, 0.1–2 wt %.

2.3. Coating Deposition

3. Results

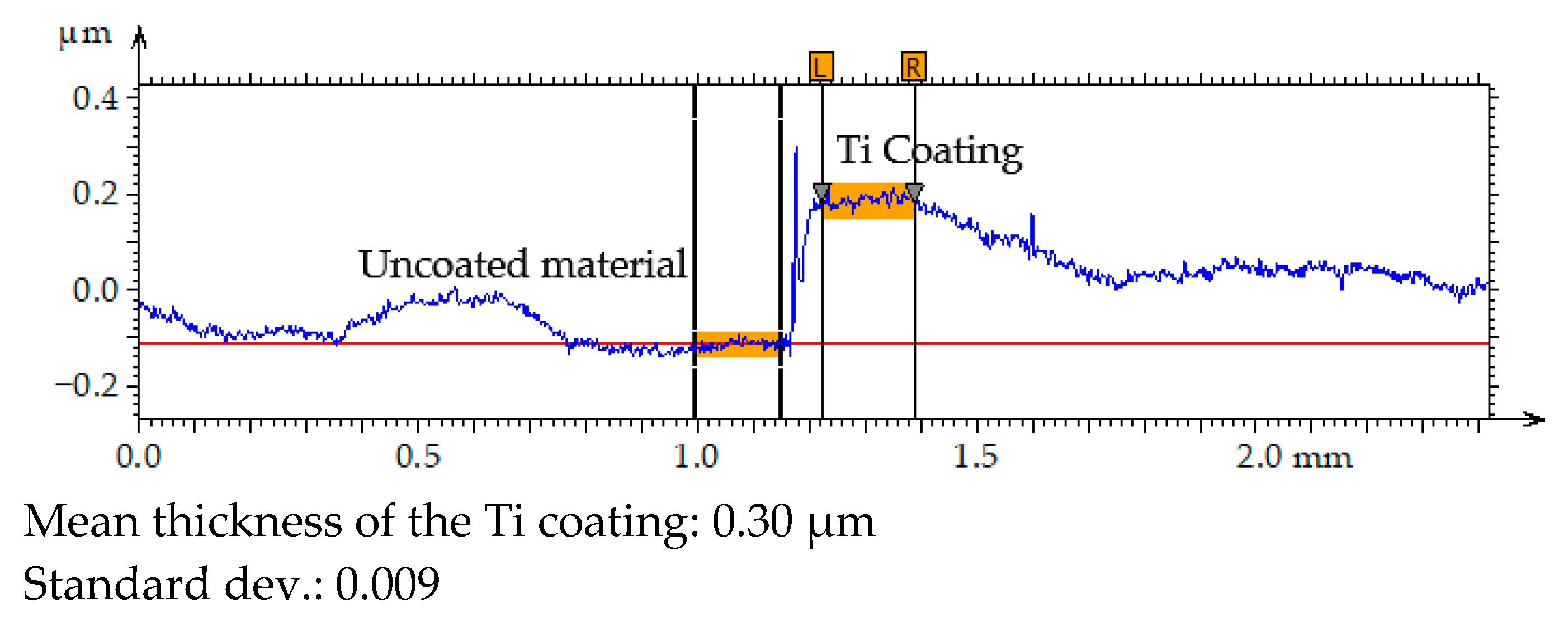

3.1. Coatings Thickness

3.2. Surface Texture

3.3. Wettability and Adhesion

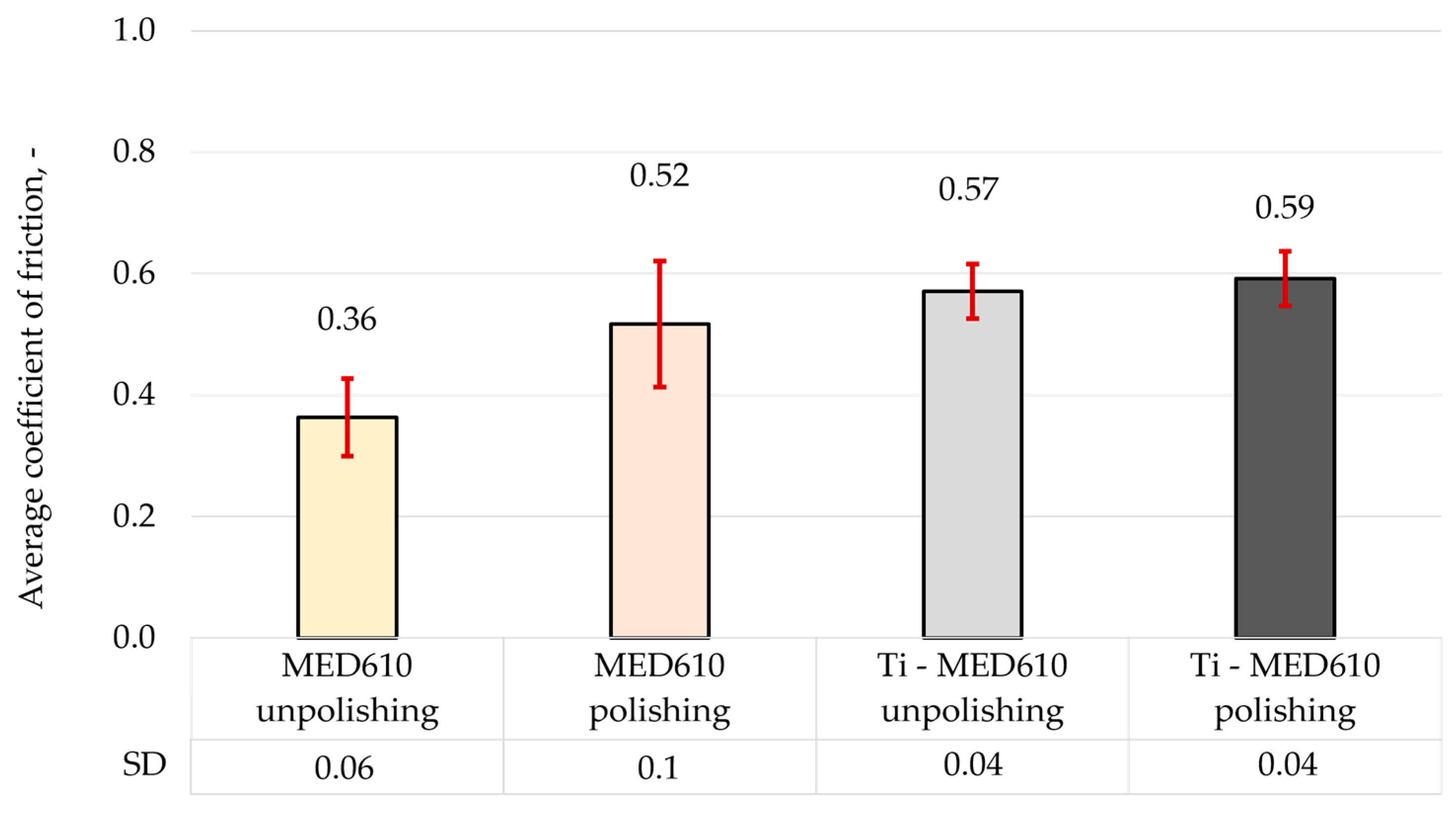

3.4. Tribological Test and Wear Analysis of Samples After Testing

4. Conclusions

- The PVD process enabled the deposition of a uniform ~300 nm titanium coating with good adhesion to the MED610 substrate.

- Surface topography measurements showed that the Ti coating reduced the characteristic roughness of PJM-manufactured components, lowering amplitude parameters by 20–45%.

- Wettability tests demonstrated that unpolished samples exhibited lower contact angles, while polishing increased the contact angle and shifted the surface character from hydrophilic to hydrophobic.

- Tribological measurements revealed that polishing increased the friction coefficient of MED610 by approximately 31%, likely due to reduced lubricant retention, while Ti-coated samples exhibited similar friction values (~0.57–0.59), indicating stabilisation of frictional behaviour by the coating. Wear analyses showed that polishing significantly decreased volumetric wear (by ~75% for uncoated and ~44% for Ti-coated samples). Ti deposition reduced wear by ~40% on unpolished surfaces, whereas on polished surfaces it caused a slight wear increase of about 27%.

- Overall, the results confirm that both surface roughness and the titanium coating substantially affect the tribological behaviour and wettability of MED610. Improved wear resistance and favourable wettability in artificial saliva highlight the potential of this surface modification for medical devices intended for contact with mucous membranes, and provide a basis for further studies on enhancing the biocompatibility and durability of 3D-printed polymer materials.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Schneider, K.H.; Oberoi, G.; Unger, E.; Janjic, K.; Rohringer, S.; Heber, S.; Agis, H.; Schedle, A.; Kiss, H.; Podesser, B.K.; et al. Medical 3D Printing with Polyjet Technology: Effect of Material Type and Printing Orientation on Printability, Surface Structure and Cytotoxicity. 3D Print. Med. 2023, 9, 27. [Google Scholar] [CrossRef] [PubMed]

- Hamza, A.; Bousnina, K.; Dridi, I.; Ben Yahia, N. Revolutionizing Automotive Design: The Impact of Additive Manufacturing. Vehicles 2025, 7, 24. [Google Scholar] [CrossRef]

- Khorasani, M.; Ghasemi, A.; Rolfe, B.; Gibson, I. Additive manufacturing a powerful tool for the aerospace industry. Rapid Prototyp. J. 2022, 28, 87–100. [Google Scholar] [CrossRef]

- Szczygieł, P.; Radoń-Kobus, K.; Madej, M.; Kozior, T. Tribological Properties of MED610 Medical Material Used in PolyJet Matrix 3D Printing Technology. Tribologia 2023, 4, 65–77. [Google Scholar] [CrossRef]

- Tanzli, E.; Kozior, T.; Hajnys, J.; Mesicek, J.; Brockhagen, B.; Grothe, T.; Ehrmann, A. Improved Cell Growth on Additively Manufactured Ti64 Substrates with Varying Porosity and Nanofibrous Coating. Heliyon 2024, 10, e25576. [Google Scholar] [CrossRef]

- Paxton, N.C. Navigating the Intersection of 3D Printing, Software Regulation and Quality Control for Point-of-Care Manufacturing of Personalized Anatomical Models. 3D Print. Med. 2023, 9, 9. [Google Scholar] [CrossRef]

- Zhao, C.X.; Yam, M. 3D Printing for Preoperative Planning and Intraoperative Surgical Jigs—A Prospective Study on Surgeon Perception. J. Orthop. Rep. 2024, 3, 100305. [Google Scholar] [CrossRef]

- l’Alzit, F.R.; Cade, R.; Naveau, A.; Babilotte, J.; Meglioli, M.; Catros, S. Accuracy of Commercial 3D Printers for the Fabrication of Surgical Guides in Dental Implantology. J. Dent. 2022, 117, 103909. [Google Scholar] [CrossRef]

- Cozzolino, E.; Risco, G.D.; von Windheim, N.; Gygi, C.; Astarita, A.; Ames, N. Scaling up the 3D Printing of Surgical Guides: Repeatability and Energy Efficiency. Rapid Prototyp. J. 2025, 31, 148–159. [Google Scholar] [CrossRef]

- Labakoum, B.; Farhan, A.; El Malali, H.; Mouhsen, A.; Lyazidi, A. Development of a Personalized and Low-Cost 3D-Printed Liver Model for Preoperative Planning of Hepatic Resections. Appl. Sci. 2025, 15, 9033. [Google Scholar] [CrossRef]

- Tappa, K.; Jammalamadaka, U.; Weisman, J.A.; Ballard, D.H.; Wolford, D.D.; Pascual-Garrido, C.; Wolford, L.M.; Woodard, P.K.; Mills, D.K. 3D Printing Custom Bioactive and Absorbable Surgical Screws, Pins, and Bone Plates for Localized Drug Delivery. J. Funct. Biomater. 2019, 10, 17. [Google Scholar] [CrossRef]

- Hari Raj, K.; Gnanavel, S.; Ramalingam, S. Investigation of 3D Printed Biodegradable PLA Orthopedic Screw and Surface Modified with Nanocomposites (Ti–Zr) for Biocompatibility. Ceram. Int. 2023, 49, 7299–7307. [Google Scholar] [CrossRef]

- Saleh-Bey-Kinj, Z.; Heller, Y.; Socratous, G.; Christodoulou, P. 3D Printing in Oral Drug Delivery: Technologies, Clinical Applications and Future Perspectives in Precision Medicine. Pharmaceuticals 2025, 18, 973. [Google Scholar] [CrossRef]

- Sim, L. Novel application of 3D printing in brachytherapy using MED610 3D printed insert for I-125 ROPES eye plaque. Australas. Phys. Eng. Sci. Med. 2016, 39, 863–870. [Google Scholar] [CrossRef]

- Gong, X.; Dang, R.; Xu, T.; Yu, Q.; Zheng, J. Full Digital Workflow of Nasoalveolar Molding Treatment in Infants With Cleft Lip and Palate. J. Craniofacial Surg. 2020, 31, 367–371. [Google Scholar] [CrossRef] [PubMed]

- Kitamori, H.; Sumida, I.; Tsujimoto, T.; Shimamoto, H.; Murakami, S.; Ohki, M. Evaluation of mouthpiece fixation devices for head and neck radiotherapy patients fabricated in PolyJet photopolymer by a 3D printer. Phys. Medica 2019, 58, 90–98. [Google Scholar] [CrossRef]

- Chen, Y.-W.; Fang, H.-Y.; Shie, M.-Y.; Shen, Y.-F. The Mussel-Inspired Assisted Apatite Mineralized on PolyJet Material for Artificial Bone Scaffold. Int. J. Bioprint. 2019, 5, 197. [Google Scholar] [CrossRef]

- Rudnik, M.; Hanon, M.; Szot, W.; Beck, K.; Gogolewski, D.; Zmarzły, P.; Kozior, T. Tribological Properties of Medical Material (MED610) Used in 3D Printing PJM Technology. Teh. Vjesn. 2022, 29, 1100–1108. [Google Scholar] [CrossRef]

- Studeny, Z.; Krbata, M.; Dobrocky, D.; Eckert, M.; Ciger, R.; Kohutiar, M.; Mikus, P. Analysis of Tribological Properties of Powdered Tool Steels M390 and M398 in Contact with Al2O3. Materiały 2022, 15, 7562. [Google Scholar] [CrossRef]

- Bartosova, L.; Kohutiar, M.; Krbaťa, M.; Escherová, J.; Eckert, M.; Jus, M. The Influence of Accelerated Electron Irradiation on the Change of Tribological Behavior of Polymeric Materials PET, PTFE & PE2000C. Manuf. Technol. 2023, 23, 589–596. [Google Scholar] [CrossRef]

- Cyphert, E.L.; von Recum, H.A. Emerging Technologies for Long-Term Antimicrobial Device Coatings: Advantages and Limitations. Exp. Biol. Med. 2017, 242, 788–798. [Google Scholar] [CrossRef]

- Rautray, T.R.; Narayanan, R.; Kim, K.H. Ion implantation of titanium based biomaterials. Prog. Mater. Sci. 2011, 56, 1137–1177. [Google Scholar] [CrossRef]

- Marciniak, J. Biomaterials; Silesian University of Technology: Gliwice, Poland, 2002. [Google Scholar]

- Jung, H.-D. Titanium and Its Alloys for Biomedical Applications. Materials 2021, 11, 1945. [Google Scholar] [CrossRef]

- Rodrigues, M.M.; Fontoura, C.P.; Maddalozzo, A.E.D.; Leidens, L.M.; Quevedo, H.G.; dos Santos Souza, K.; da Silva Crespo, J.; Michels, A.F.; Figueroa, C.A.; Aguzzoli, C. Ti, Zr and Ta Coated UHMWPE Aiming Surface Improvement for Biomedical Purposes. Compos. Part B Eng. 2020, 189, 107909. [Google Scholar] [CrossRef]

- Yao, C.; Storey, D.; Webster, T.-J. Nanostructured metal coatings on polymers increase osteoblast attachment. Int. J. Nanomed. 2007, 2, 487–492. [Google Scholar] [PubMed Central]

- Breme, F.; Buttstaedt, J.; Emig, G. Coating of polymers with titanium-based layers by a novel plasma-assisted chemical vapor deposition process. Thin Solid Films 2000, 377, 755–759. [Google Scholar] [CrossRef]

- ISO 10993-15; Biological Evaluation of Medical Devices—Part 15: Identification and Quantification of Degradation Products of Metals and Alloys. International Organization for Standardization: Geneva, Switzerland, 2024.

- Stratasys. Biocompatible Clear MED610: 2018. Available online: https://support.stratasys.com/en/Materials/PolyJet/MED610 (accessed on 20 December 2025).

- EN ISO 10993-10; Biological Evaluation of Medical Devices—Part 10: Tests for Irritation and Skin Sensitization. International Organization for Standardization: Geneva, Switzerland, 2013.

- EN ISO 10993-5; Biological Evaluation of Medical Devices—Part 5: Tests for In Vitro Cytotoxicity. International Organization for Standardization: Geneva, Switzerland, 2009.

- EN ISO 10993-3; Biological Evaluation of Medical Devices—Part 3: Tests for Genotoxicity, Carcinogenicity and Reproductive Toxicit. International Organization for Standardization: Geneva, Switzerland, 2014.

- EN ISO 10993-18; Biological Evaluation of Medical Devices—Part 18: Chemical Characterization of Materials. International Organization for Standardization: Geneva, Switzerland, 2009.

- Stratasys MSDS Clear Bio-Compatible MED610. Available online: https://www.sys-uk.com/wp-content/uploads/2016/01/MSDS-Clear-Bio-Compatible-MED610-English-US-1.pdf (accessed on 20 December 2025).

- Jeon, D.-M.; An, J.-S.; Lim, B.-S.; Ahn, S.-J. Orthodontic Bonding Procedures Significantly Influence Biofilm Composition. Prog. Orthod. 2020, 21, 14. [Google Scholar] [CrossRef]

- Ahn, H.-B.; Ahn, S.-J.; Lee, S.-J.; Kim, T.-W.; Nahm, D.-S. Analysis of Surface Roughness and Surface Free Energy Characteristics of Various Orthodontic Materials. Am. J. Orthod. Dentofac. Orthop. 2009, 136, 668–674. [Google Scholar] [CrossRef]

- Martínez Gil-Ortega, A.; Paz-Cortés, M.M.; Viñas, M.J.; Cintora-López, P.; Martín-Vacas, A.; Gil, J.; Aragoneses, J.M. Effect of Surface Wettability and Energy on Bacterial Adhesion to Dental Aligners: A Comparative In Vitro Study. Bioengineering 2025, 12, 898. [Google Scholar] [CrossRef] [PubMed]

- Oliveira, A.S.; Kaizer, M.R.; Azevedo, M.S.; Ogliari, F.A.; Cenci, M.S.; Moraes, R.R. (Super)Hydrophobic Coating of Orthodontic Dental Devices and Reduction of Early Oral Biofilm Retention. Biomed. Mater. 2015, 10, 065004. [Google Scholar] [CrossRef]

- Rupp, F.; Gittens, R.A.; Scheideler, L.; Marmur, A.; Boyan, B.D.; Schwartz, Z.; Geis-Gerstorfer, J. A Review on the Wettability of Dental Implant Surfaces I: Theoretical and Experimental Aspects. Acta Biomater. 2014, 10, 2894–2906. [Google Scholar] [CrossRef]

- Liber-Kneć, A.; Łagan, S. Surface Testing of Dental Biomaterials—Determination of Contact Angle and Surface Free Energy. Materials 2021, 14, 2716. [Google Scholar] [CrossRef]

- Valli, J. A review of adhesion test methods for thin hard coatings. J. Vac. Sci. Technol. A Vac. Surf. Film. 1986, 4, 3007–3014. [Google Scholar] [CrossRef]

- Grzesik, W. Effect of the machine parts surface topography features on the machine service. Mechanik 2015, 88, 587–593. [Google Scholar] [CrossRef]

- Al-Samarai, R.A.; Haftirman, K.R.A.; Al-Douri, Y. The Influence of Roughness on the Wear and Fric-Tion Coefficient under Dry and Lubricated Sliding. Int. J. Sci. Eng. Res. 2012, 3, 1–6. [Google Scholar]

- Bayer, R.G.; Sirico, J.L. The Influence of Surface Roughness on Wear. Wear 1975, 35, 251–260. [Google Scholar] [CrossRef]

- Barrett, T.S.; Stachowiak, G.W.; Batchelor, A.W. Effect of Roughness and Sliding Speed on the Wear and Friction of Ultra-High Molecular Weight Polyethylene. Wear 1992, 153, 331–350. [Google Scholar] [CrossRef]

| Artifical Saliva, g/dm3 | |||||

|---|---|---|---|---|---|

| NaCl | KCl | CaCl2 ∗ 2H2O | NaH2PO4 ∗ 2H2O | Na2S ∗ 9H2O | Urea |

| 0.4 | 0.4 | 0.795 | 0.780 | 0.005 | 1.0 |

| Cleaning | Coating | ||||

|---|---|---|---|---|---|

| Ar, sccm | Time, min | RF, W | Ar, sccm | Time, min | DC, W |

| 30 | 20 | 100 | 30 | 180 | 100 |

| Sa | Sq | Sv | Sp | Ssk | Sku | |

|---|---|---|---|---|---|---|

| µm | µm | µm | µm | - | ||

| MED610 unpolished | 2.8 | 3.5 | 31.1 | 28.3 | 0.002 | 3.3 |

| MED610 polished | 1.2 | 1.6 | 11.6 | 16.0 | −0.24 | 4.0 |

| Ti-MED610 unpolished | 2.0 | 2.9 | 23.1 | 15.3 | −0.4 | 4.8 |

| Ti-MED610 polished | 1.7 | 2.3 | 26.2 | 18.5 | −1.0 | 4.5 |

| Surface Condition | Coating | Avg. Contact Angle (°) | Avg. Coefficient of Friction | Volume of Wear Track (×106) |

|---|---|---|---|---|

| Unpolished | Without Ti | 68 ± 6 | 0.36 ± 0.06 | 23.4 ± 0.9 |

| Polished | 85 ± 2.4 ** | 0.52 ± 0.1 * | 5.9 ± 0.2 *** | |

| Unpolished | With Ti | 51 ± 6.7 * | 0.57 ± 0.04 ** | 14.4 ± 2.6 ** |

| Polished | 99 ± 6.4 ** | 0.59 ± 0.04 ** | 8.1 ± 0.3 *** |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license.

Share and Cite

Piotrowska, K.; Kowalczyk, J.; Kozior, T. Evaluation of Selected Properties of Ti Coatings Deposited on MED610 for Medical Applications. Materials 2026, 19, 60. https://doi.org/10.3390/ma19010060

Piotrowska K, Kowalczyk J, Kozior T. Evaluation of Selected Properties of Ti Coatings Deposited on MED610 for Medical Applications. Materials. 2026; 19(1):60. https://doi.org/10.3390/ma19010060

Chicago/Turabian StylePiotrowska, Katarzyna, Joanna Kowalczyk, and Tomasz Kozior. 2026. "Evaluation of Selected Properties of Ti Coatings Deposited on MED610 for Medical Applications" Materials 19, no. 1: 60. https://doi.org/10.3390/ma19010060

APA StylePiotrowska, K., Kowalczyk, J., & Kozior, T. (2026). Evaluation of Selected Properties of Ti Coatings Deposited on MED610 for Medical Applications. Materials, 19(1), 60. https://doi.org/10.3390/ma19010060