Sustainable Material Selection for Interior Design Furniture: A Simple Procedure Based on Environmental Analysis and Structural Optimization

Abstract

1. Introduction

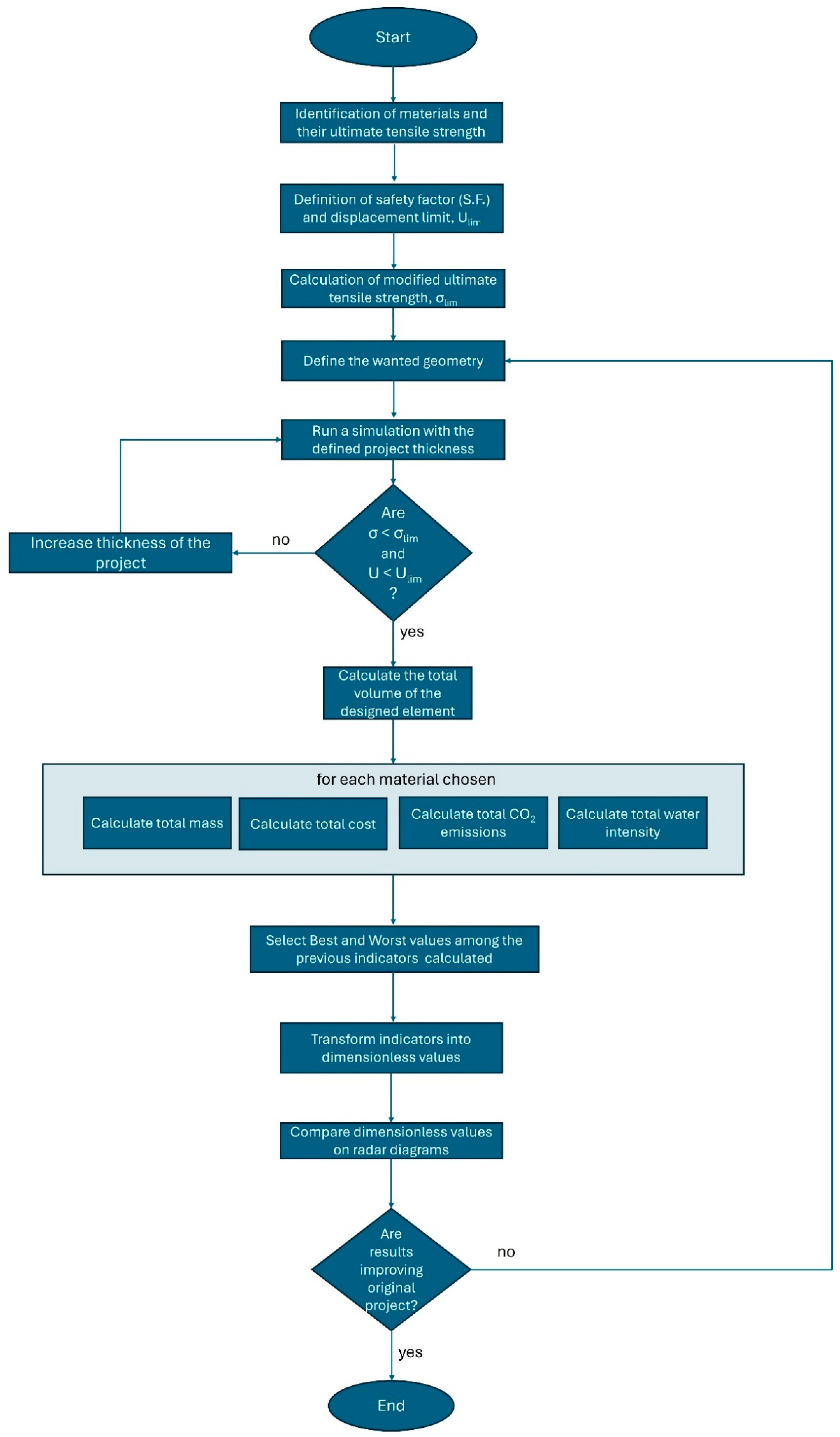

2. Proposed Approach to Sustainable Design

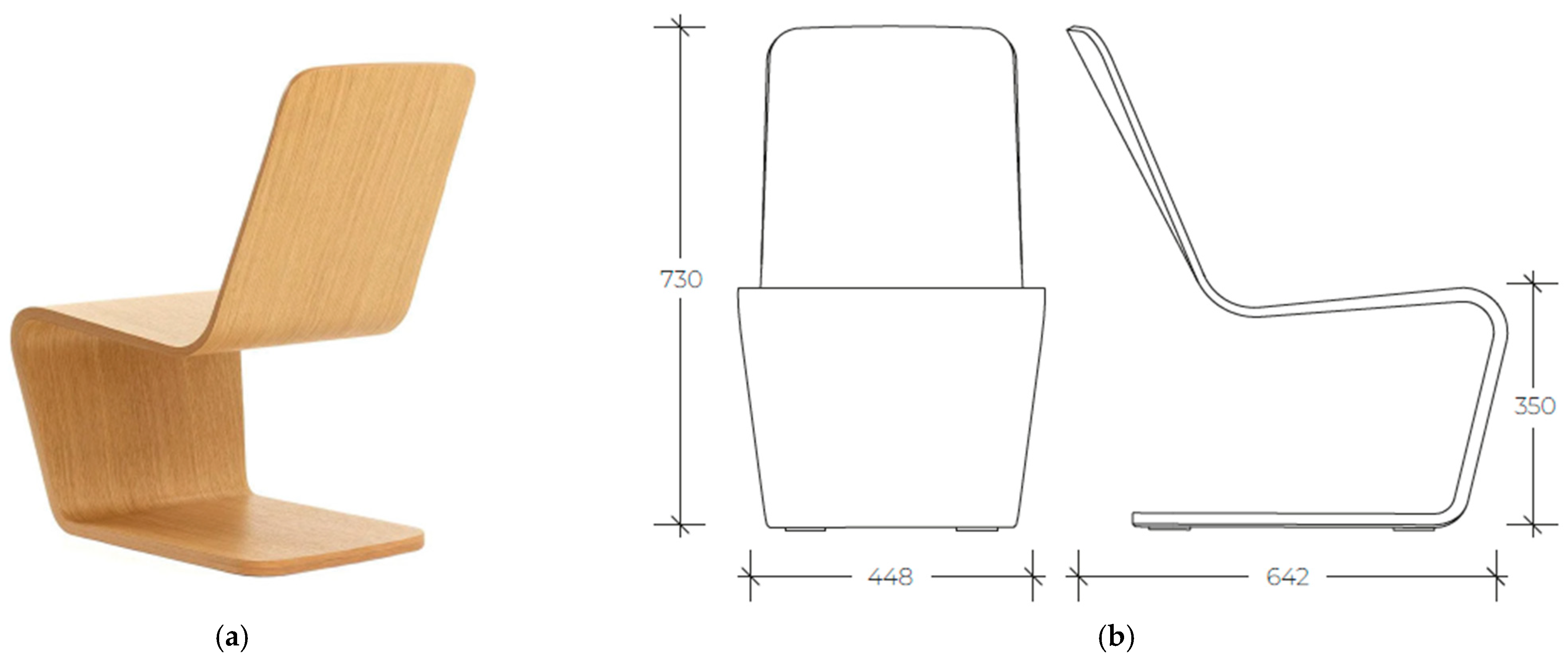

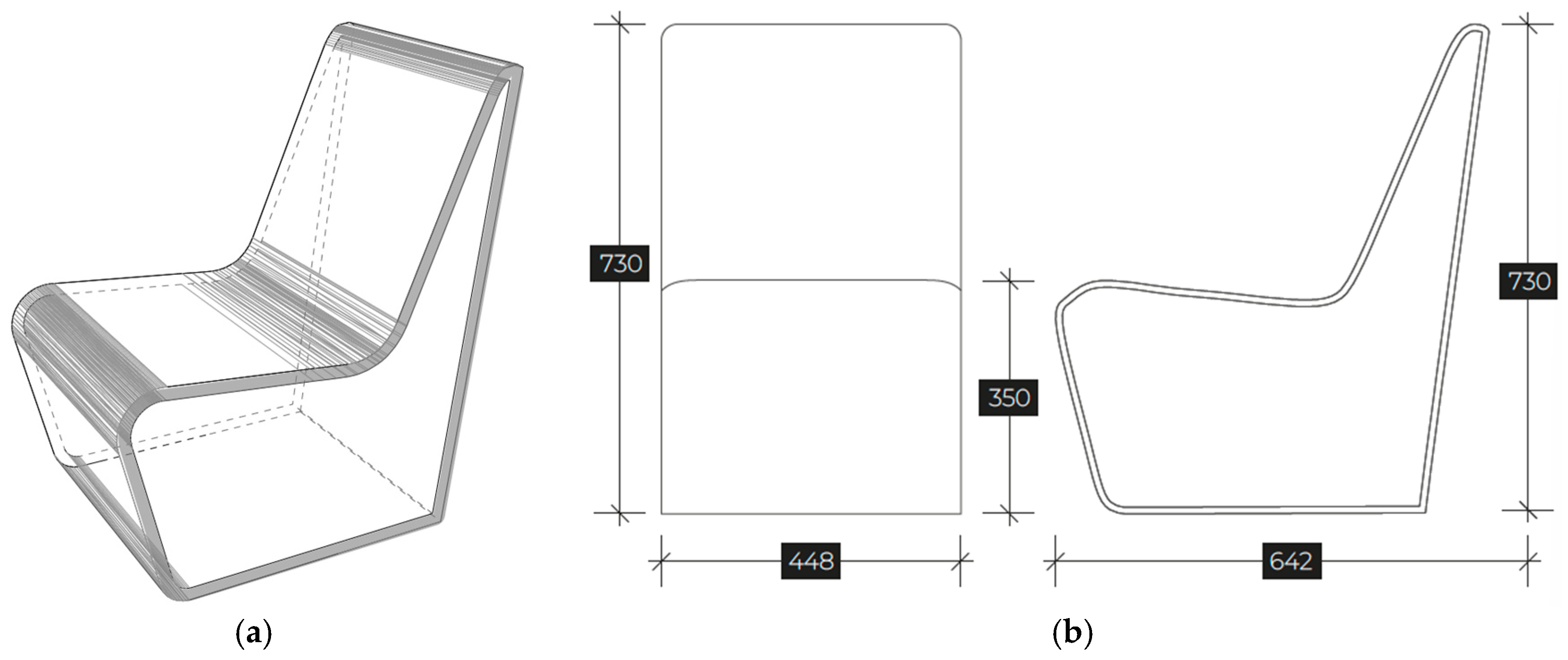

3. The Case Study

4. Materials and Methods

4.1. Plywood

4.2. Polypropylene

4.3. Polycarbonate

4.4. The Finite Element Model

4.5. Sustainability Indicators Calculations

5. Results

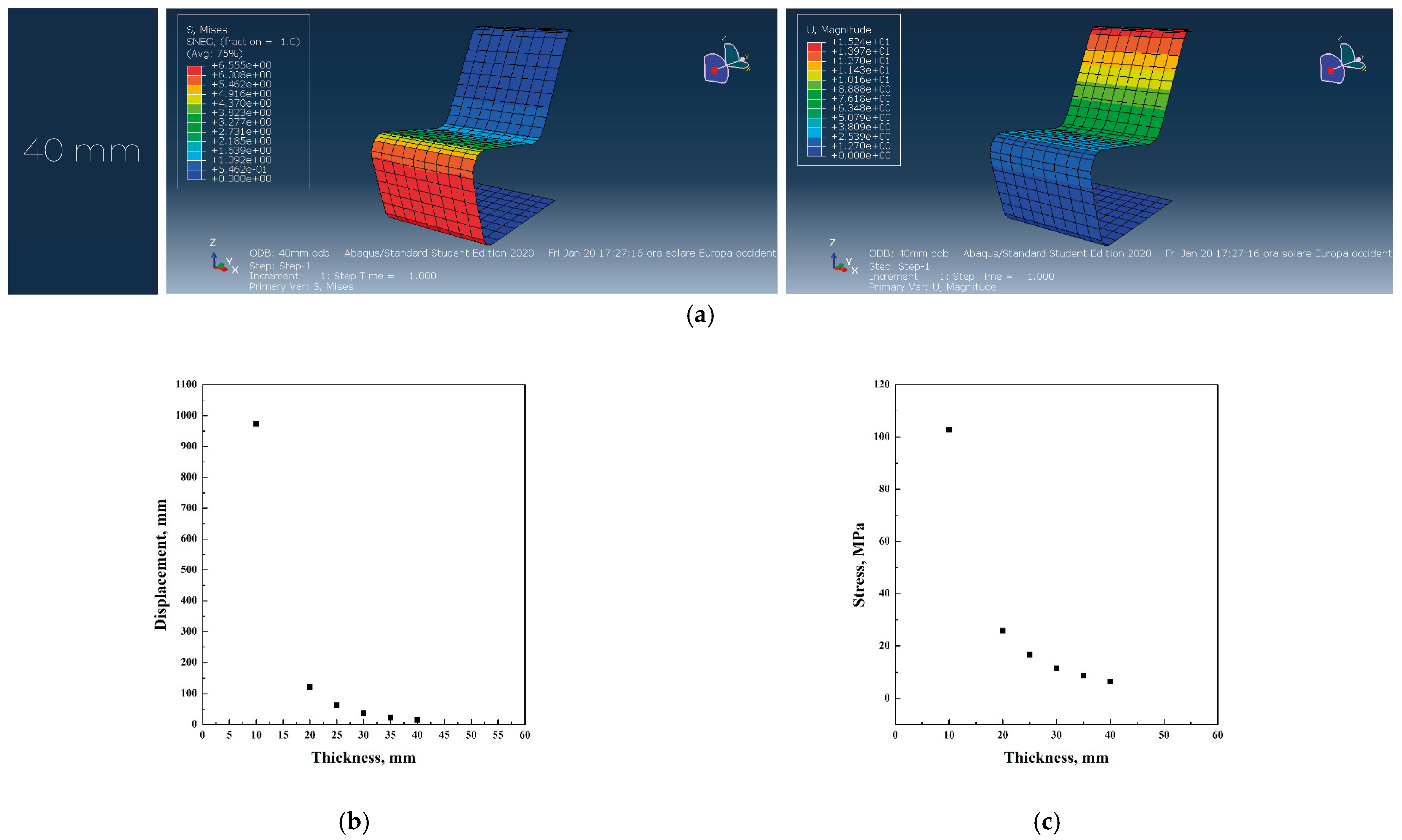

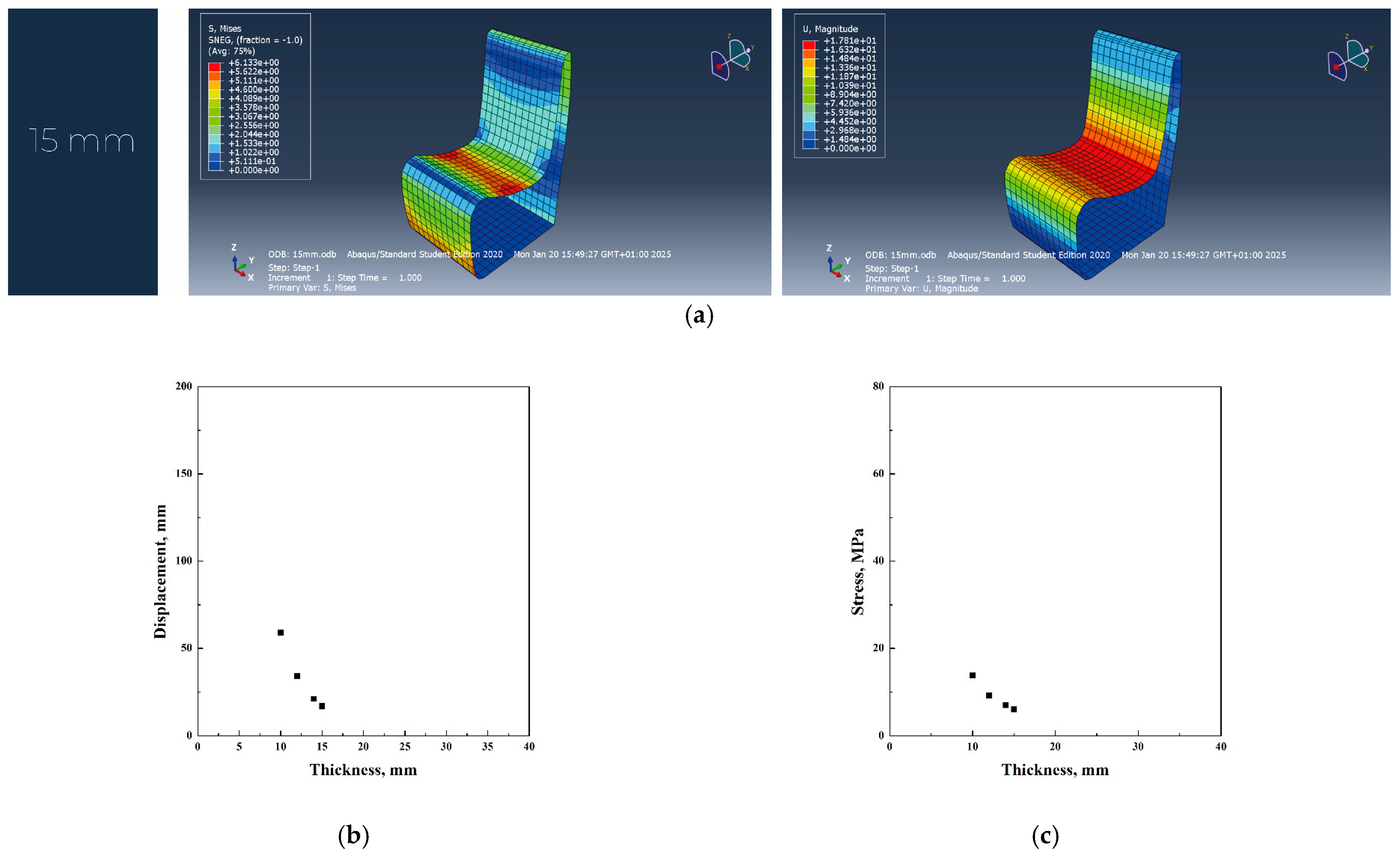

5.1. Original Project: Use of Plywood

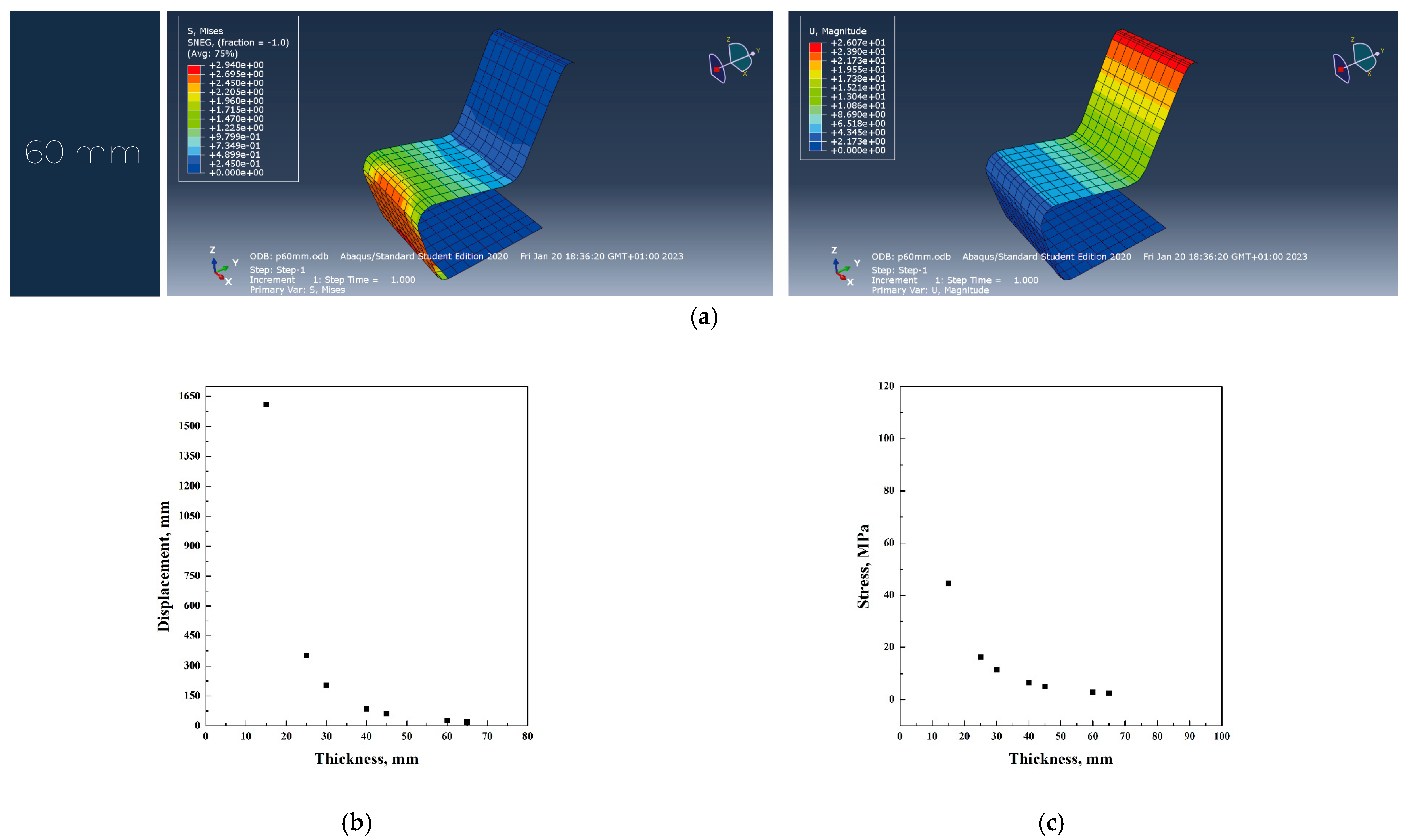

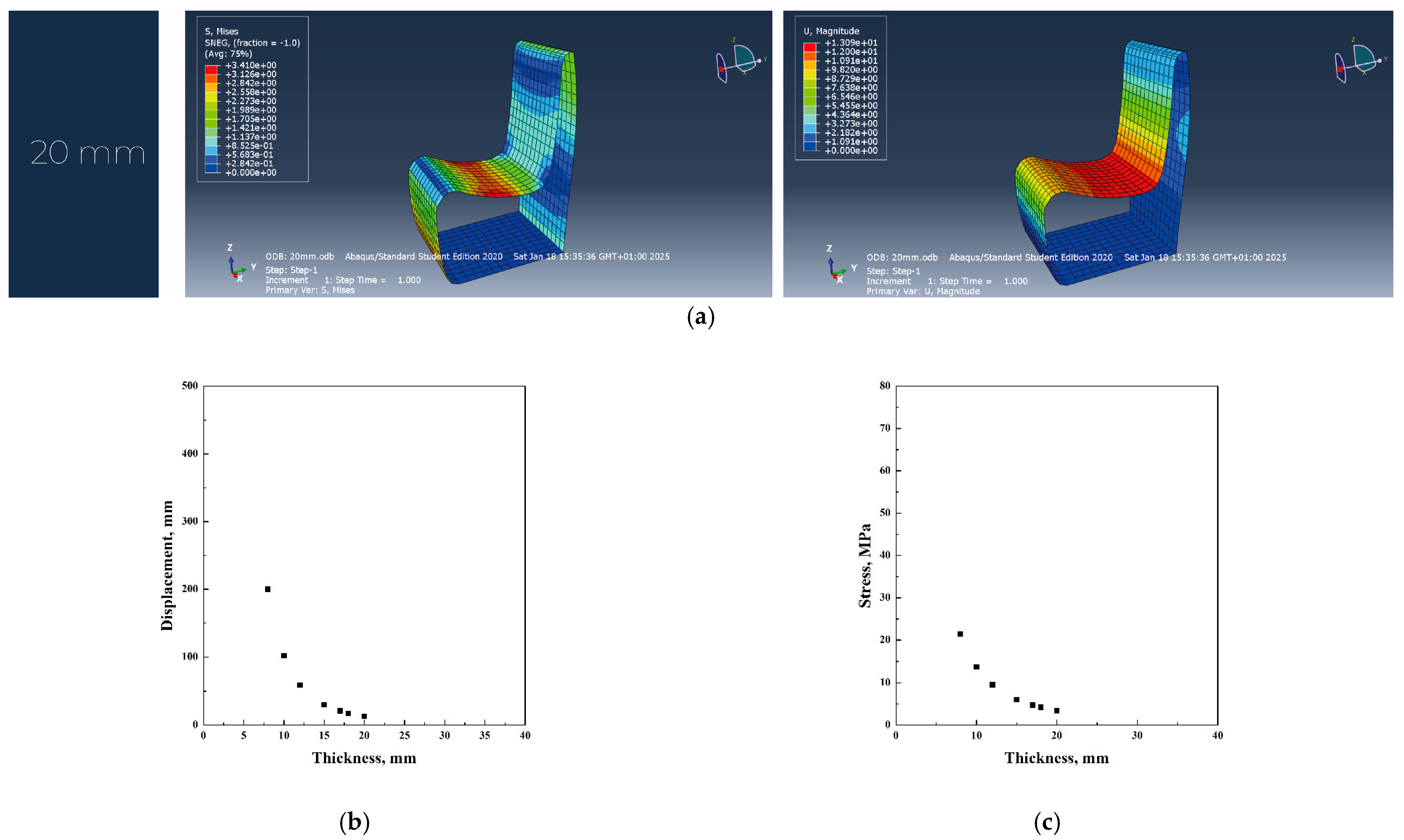

5.2. Original Project: Use of Polypropylene

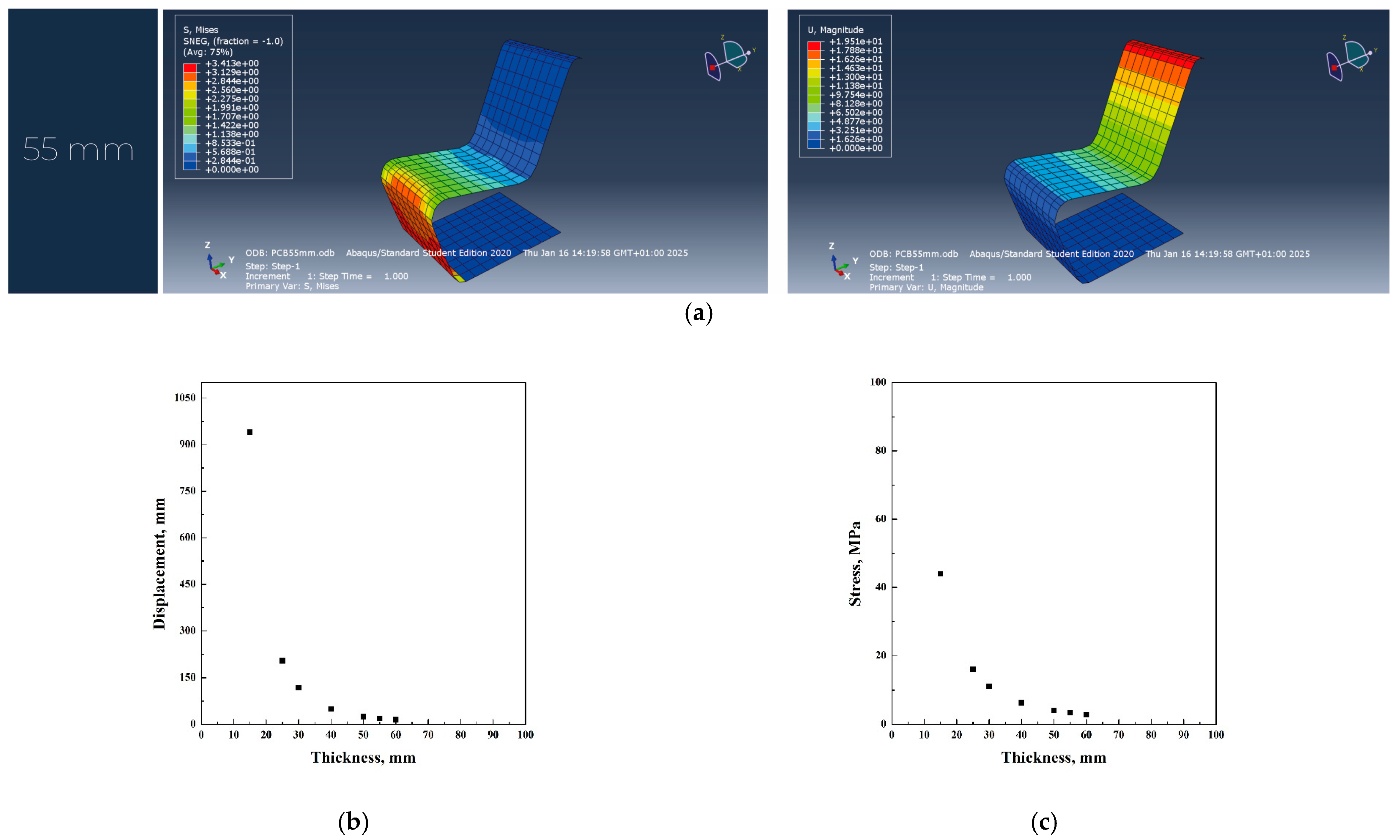

5.3. Original Project: Use of Polycarbonate

5.4. Discussion

6. Redesign Results

6.1. Redesigned Project: Use of Plywood

6.2. Redesigned Project: Use of Polypropylene

6.3. Redesigned Project: Use of Polycarbonate

7. Calculation of Sustainability Analysis and Comparison

| Material | T, mm | Volume, m3 | Mass, kg | Cost, € | CO2, kg | Stiffness, MPa | Y. S., MPa | W.I., L/kg | Rec. Energy, % | Mech Rec., % |

|---|---|---|---|---|---|---|---|---|---|---|

| PW | 40 | 0.0314 | 22.13 | 15.49 | 110.65 | 8600 | 41.8 | 645 | 75 | 80 |

| PW redesign | 15 | 0.0249 | 17.49 | 12.24 | 87.45 | 8600 | 41.8 | 645 | 75 | 80 |

| PP | 60 | 0.0314 | 45.98 | 50.57 | 125.30 | 1325 | 24 | 5.2 | 92.5 | 50 |

| PP redesign | 20 | 0.0447 | 40.25 | 44.28 | 109.68 | 1325 | 24 | 5.2 | 92.5 | 50 |

| PC | 55 | 0.0432 | 51.81 | 113.98 | 307.54 | 2380 | 18 | 320 | 87.5 | 60 |

| PC redesign | 15 | 0.0373 | 44.73 | 98.40 | 265.51 | 2380 | 18 | 320 | 87.5 | 60 |

| Material | T, % | Mass, % | Cost, % | CO2, % | Stiffness, MPa | Y.S., MPa | W.I., % | Rec. Energy, % | Mech Rec., % |

|---|---|---|---|---|---|---|---|---|---|

| PW | 60.00 | 77.87 | 89.67 | 77.87 | 85.86 | 41.21 | 35.54 | 75.00 | 80.00 |

| PW redesign | 85.00 | 82.51 | 91.84 | 82.51 | 85.86 | 41.21 | 35.54 | 75.00 | 80.00 |

| PP | 40.00 | 54.02 | 66.29 | 74.94 | 12.37 | 23.23 | 99.58 | 92.50 | 50.00 |

| PP redesign | 80.00 | 59.75 | 70.48 | 78.06 | 12.37 | 23.23 | 99.58 | 92.50 | 50.00 |

| PC | 45.00 | 48.19 | 24.01 | 38.49 | 23.03 | 17.17 | 68.07 | 87.50 | 60.00 |

| PC redesign | 85.00 | 55.27 | 34.40 | 46.90 | 23.03 | 17.17 | 68.07 | 87.50 | 60.00 |

8. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| FEA | Finite Element Analysis |

| PC | Polycarbonate |

| PP | Polypropylene |

| MPa | Megapascal (unit of pressure or stress) |

| FEAS | Finite Element Analysis Software |

| ISO | International Organization for Standardization |

| T | Thickness |

| V | Volume |

| ρ | Density |

| M | Mass |

| C | Cost |

| EBD | Evidence-Based Design |

| SF | Safety Factor |

| UTS | Ultimate Tensile Strength |

References

- Anjum, N.; Paul, J.; Ashcroft, R. The changing environment of offices: A challenge for furniture design. Des. Stud. 2005, 26, 73–95. [Google Scholar] [CrossRef]

- Suchy, A. Product Instability or Tip-Over Injuries and Fatalities Associated with Televisions, Furniture, and Appliances: 2020 Report; US Consumer Product Safety Commission: Bethesda, MD, USA, 2021.

- Bijalwan, A.; Misra, A. Design and Structural Analysis of Flexible Wearable Chair Using Finite Element Method. Open J. Appl. Sci. 2016, 6, 465–477. [Google Scholar] [CrossRef]

- Hall-Andersen, L.B.; Broberg, O. Integrating ergonomics into engineering design: The role of objects. Appl. Ergon. 2014, 45, 647–654. [Google Scholar] [CrossRef] [PubMed]

- Duarte, F.; Silva, G.; Lima, F.; Maia, N. Ergonomics guidelines for the design process. In Proceedings of the Society of Petroleum Engineers—SPE International Conference on Health, Safety and Environment in Oil and Gas Exploration and Production, Rio de Janeiro, Brazil, 12–14 April 2010. [Google Scholar]

- Likotiko, E.D.; Nyambo, D.; Mwangoka, J. Multi-agent based IoT smart waste monitoring and collection architecture. arXiv 2017, arXiv:1711.03966. [Google Scholar] [CrossRef]

- Utama, D.M.; Ardiyanti, N.; Putri, A.A. A new hybrid method for manufacturing sustainability performance assessment: A case study in furniture industry. Prod. Manuf. Res. 2022, 10, 760–783. [Google Scholar] [CrossRef]

- Hartini, S.; Ciptomulyono, U.; Anityasari, M.; Sriyanto, M. Manufacturing sustainability assessment using a lean manufacturing tool: A case study in the Indonesian wooden furniture industry. Int. J. Lean Six Sigma 2020, 11, 943–971. [Google Scholar] [CrossRef]

- Daian, G.; Ozarska, B. Wood waste management practices and strategies to increase sustainability standards in the Australian wooden furniture manufacturing sector. J. Clean. Prod. 2009, 17, 1594–1602. [Google Scholar] [CrossRef]

- EN 1022; Furniture—Seating—Determination of Stability. European Committee for Standardization (CEN): Brussels, Belgium, 2023.

- EN 1728; Furniture—Seating—Test Methods for the Determination of Strength and Durability. European Committee for Standardization (CEN): Brussels, Belgium, 2012.

- Beer, P.; Olenska, S.; Podobas, I.; Zbiec, M. Design for AAL integrated furniture for the care and support of elderly and disabled people. Drv. Ind. 2017, 68, 185–193. [Google Scholar] [CrossRef]

- Cacciabue, P.C.; Vella, G. Human factors engineering in healthcare systems: The problem of human error and accident management. Int. J. Med. Inform. 2010, 79, e1–e17. [Google Scholar] [CrossRef]

- Bhardwaj, P. Furniture Design Features and Healthcare Outcomes. In Latest in Healthcare Management; Jaypee Digital: New Delhi, India, 2015. [Google Scholar]

- Malone, E.B.; Dellinger, B.A. Furniture Design Features and Healthcare Outcomes; The Center for Health Design: Concord, CA, USA, 2011. [Google Scholar]

- Safin, S.; Pintus, P.; Elsen, C. Ergonomics in design and design in ergonomics: Issues and experience in education. Work 2020, 66, 917–931. [Google Scholar] [CrossRef]

- Song, L.; Yang, M.; Shen, D. Structural design and experimental verification of a thin-walled plastic chairs based on the finite element method. Sci. Rep. 2024, 14, 22285. [Google Scholar] [CrossRef] [PubMed]

- Mahantesh, M.M.; Rao, K.V.S.R.; Chandra, A.C.P.; Vijayakumar, M.N.; Nandini, B.; Prasad, C.D.; Vasudev, H. Design and modeling using finite element analysis for the sitting posture of computer users based on ergonomic perspective. Int. J. Interact. Des. Manuf. 2023, 18, 5875–5891. [Google Scholar] [CrossRef]

- Suarez, B.; Muneta, L.M.; Romero, G.; Sanz-Bobi, J.D. Efficient design of thin wall seating made of a single piece of heavy-duty corrugated cardboard. Materials 2021, 14, 6645. [Google Scholar] [CrossRef]

- Trucillo, P.; Rizzo, M.; Errico, D.; Di Maio, E. Social, Economic, and Environmental Impacts of Bio-Based Versus Fossil-Derived Polyethylene Production. Advanced Sustainable Systems. Adv. Sustain. Syst. 2025, 9, 2400392. [Google Scholar] [CrossRef]

- Trucillo, P.; Erto, A. Sustainability Indicators for Materials and Processes. Sustainability 2023, 15, 6689. [Google Scholar] [CrossRef]

- Kolář, T.; Rybníček, M. Physical and mechanical properties of Subfossil Oak (Quercus, SP.) wood. Acta Univ. Agric. Silvic. Mendel. Brun. 2010, 58, 123–134. [Google Scholar] [CrossRef]

- Büyüksari, Ü.; As, N.; Dündar, T.; Korkmaz, O. Micro-mechanical properties of Oak wood and comparison with standard-sized samples. Maderas Cienc. Tecnol. 2017, 19, 481–494. [Google Scholar] [CrossRef]

- Konnerth, J.; Eiser, M.; Jäger, A.; Bader, T.K.; Hofstetter, K.; Follrich, J.; Ters, T.; Hansmann, C.; Wimmer, R. Macro- and micro-mechanical properties of red oak wood (Quercus rubra L.) treated with hemicellulases. Holzforschung 2010, 64, 447–453. [Google Scholar] [CrossRef]

- Uzcategui, M.G.C.; Seale, R.D.; França, F.J.N. Physical and mechanical properties of clear wood from red oak and white oak. Bioresources 2020, 15, 4960. [Google Scholar] [CrossRef]

- Sonderegger, W.; Kránitz, K.; Bues, C.T.; Niemz, P. Aging effects on physical and mechanical properties of spruce, fir and oak wood. J. Cult. Herit. 2015, 16, 883–889. [Google Scholar] [CrossRef]

- Schyns, J.F.; Booij, M.J.; Hoekstra, A.Y. The water footprint of wood for lumber, pulp, paper, fuel and firewood. Adv. Water Resour. 2017, 107, 490–501. [Google Scholar] [CrossRef]

- Franklin Associates: Cradle-to-Gate Life Cycle Inventory of Nine Plastic Resins and Four Polyurethane Precursors. Report. 1. 2010. Available online: https://www.researchgate.net/publication/297268002_Cradle-to-Gate_Life_Cycle_Inventory_of_Nine_Plastic_Resins_and_Four_Polyurethane_Precursors (accessed on 15 January 2025).

- Boustead, I. Eco-Profiles of the European Plastics Industry: Polypropylene (PP). PlasticsEurope. 2005. Available online: https://www.researchgate.net/publication/318864901_Eco-profiles_and_Environmental_Product_Declarations_of_the_European_Plastics_Manufacturers_-_Polypropylene_PP (accessed on 15 January 2025).

- Korol, J.; Hejna, A.; Burchart-Korol, D.; Wachowicz, J. Comparative analysis of carbon, ecological, and water footprints of polypropylene-based composites filled with cotton, jute and kenaf fibers. Materials 2020, 13, 3541. [Google Scholar] [CrossRef] [PubMed]

- Ferraro, A.; Camurati, I.; Dall’Occo, T.; Piemontesi, F.; Cecchin, G. Advances in Ziegler-Natta catalysts for polypropylene. Kinet. Catal. 2006, 47, 176–185. [Google Scholar] [CrossRef]

- Hossain, M.T.; Shahid, M.A.; Mahmud, N.; Habib, A.; Rana, M.M.; Khan, S.A.; Hossain, M.D. Research and application of polypropylene: A review. Discov. Nano 2024, 19, 2. [Google Scholar] [CrossRef]

- Maddah, H.A. Polypropylene as a Promising Plastic: A Review New organic semiconductor thin film derived from p-toluidine monomer View project Polypropylene as a Promising Plastic: A Review. Am. J. Polym. Sci. 2016, 6, 1–11. [Google Scholar]

- Kissel, W.J.; Han, J.H.; Meyer, J. Polypropylene: Structure, Properties, Manufacturing Processes, and Applications. In Handbook of Polypropylene and Polypropylene Composites; Marcel Dekker Inc.: New York, NY, USA, 2003; pp. 11–34. [Google Scholar]

- Bal, B.C.; Altuntaş, E.; Narlıoğlu, N. Some selected properties of composite material produced from plastic furniture waste and wood flour. Mobilya Ve Ahşap Malzeme Araştırmaları Dergisi 2023, 6, 233–244. [Google Scholar] [CrossRef]

- Shahruzzaman, M.; Biswas, S.; Islam, M.M.; Islam, M.S.; Rahman, M.M. Furniture: Eco-Friendly Polymer Composites Applications. In Encyclopedia of Polymer Applications, 1st ed.; CRC Press: Boca Raton, FL, USA, 2019; pp. 1517–1547. [Google Scholar]

- Ichim, M.; Filip, I.; Stelea, L.; Lisa, G.; Muresan, E.I. Recycling of Nonwoven Waste Resulting from the Manufacturing Process of Hemp Fiber-Reinforced Recycled Polypropylene Composites for Upholstered Furniture Products. Sustainability 2023, 15, 3635. [Google Scholar] [CrossRef]

- Isaeva, V.I.; Aizenshtein, É.M.; Soboleva, O.N. World production and use of polypropylene fibres and thread. A review. Fibre Chem. 1997, 29, 269–281. [Google Scholar] [CrossRef]

- Kausar, A. A review of filled and pristine polycarbonate blends and their applications. J. Plast. Film Sheeting 2018, 34, 60–97. [Google Scholar] [CrossRef]

- Bendler, J.T. Handbook of Polycarbonate Science and Technology; CRC Press: Boca Raton, FL, USA, 1999. [Google Scholar]

- Hafad, S.A.; Hamood, A.F.; Alsalihi, H.A.; Ibrahim, S.I.; Abdullah, A.A.; Radhi, A.A.; Al-Ghezi, M.K.; Alogaidi, B.R. Mechanical properties study of polycarbonate and other thermoplastic polymers. J. Phys. Conf. Ser. 2021, 1973, 012001. [Google Scholar] [CrossRef]

- Song, P.; Trivedi, A.R.; Siviour, C.R. Mechanical response of four polycarbonates at a wide range of strain rates and temperatures. Polym. Test. 2023, 121, 107986. [Google Scholar] [CrossRef]

- Chang, Y.W.; Cheng, J.H. Material characterization of polycarbonate near glass transition temperature. J. Chin. Inst. Eng. 2012, 35, 967–978. [Google Scholar] [CrossRef]

- Rosato, D.V. Consumer Products End Use Applications. Plastics End Use Applications; Springer: New York, NY, USA, 2011; pp. 65–83. [Google Scholar] [CrossRef]

- Antonenko, J.S.; Zhdanova, N.S.; Mishukovskaya, J.I. Research Results of Possibility of Using Non-Traditional Materials in Design of Furniture for Children. IOP Conf. Ser. Mater. Sci. Eng. 2021, 1079, 022026. [Google Scholar] [CrossRef]

- EN 1729-2; Furniture—Chairs and Tables for Educational Institutions Part 2: Safety Requirements and Test Methods. European Committee for Standardization (CEN): Brussels, Belgium, 2012.

- Ruiz-Mercado, G.J.; Smith, R.L.; Gonzalez, M.A. Sustainability indicators for chemical processes: I. Taxonomy. Ind. Eng. Chem. Res. 2012, 51, 2309–2328. [Google Scholar] [CrossRef]

- Ruiz-Mercado, G.J.; Smith, R.L.; Gonzalez, M.A. Sustainability Indicators for chemical processes: II. Data needs. Ind. Eng. Chem. Res. 2012, 51, 2329–2353. [Google Scholar] [CrossRef]

- Schyns, Z.O.; Shaver, M.P. Mechanical recycling of packaging plastics: A review. Macromol. Rapid Commun. 2021, 42, 2000415. [Google Scholar] [CrossRef]

- Coates, G.W.; Getzler, Y.D. Chemical recycling to monomer for an ideal, circular polymer economy. Nat. Rev. Mater. 2020, 5, 501–516. [Google Scholar] [CrossRef]

| Material | Elastic Modulus, MPa | Density, kg/m3 | Unitary Cost, €/kg | CO2 Emissions, kgCO2/kg | Water Intensity, L/kg |

|---|---|---|---|---|---|

| Plywood | 8600 | 704 | 0.7 | 5.00 | 645 |

| Polypropylene | 1325 | 900 | 1.1 | 2.72 | 5.2 |

| Polycarbonate | 2380 | 1200 | 2.2 | 5.94 | 320 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Trucillo, P.; Chaouali, F.; Portioli, F.P.A. Sustainable Material Selection for Interior Design Furniture: A Simple Procedure Based on Environmental Analysis and Structural Optimization. Materials 2025, 18, 2023. https://doi.org/10.3390/ma18092023

Trucillo P, Chaouali F, Portioli FPA. Sustainable Material Selection for Interior Design Furniture: A Simple Procedure Based on Environmental Analysis and Structural Optimization. Materials. 2025; 18(9):2023. https://doi.org/10.3390/ma18092023

Chicago/Turabian StyleTrucillo, Paolo, Farah Chaouali, and Francesco Paolo Antonio Portioli. 2025. "Sustainable Material Selection for Interior Design Furniture: A Simple Procedure Based on Environmental Analysis and Structural Optimization" Materials 18, no. 9: 2023. https://doi.org/10.3390/ma18092023

APA StyleTrucillo, P., Chaouali, F., & Portioli, F. P. A. (2025). Sustainable Material Selection for Interior Design Furniture: A Simple Procedure Based on Environmental Analysis and Structural Optimization. Materials, 18(9), 2023. https://doi.org/10.3390/ma18092023