Flexural Behavior of Lightweight Sandwich Panels with Rice Husk Bio-Aggregate Concrete Core and Sisal Fiber-Reinforced Foamed Cementitious Faces

Abstract

1. Introduction

2. Materials and Methods

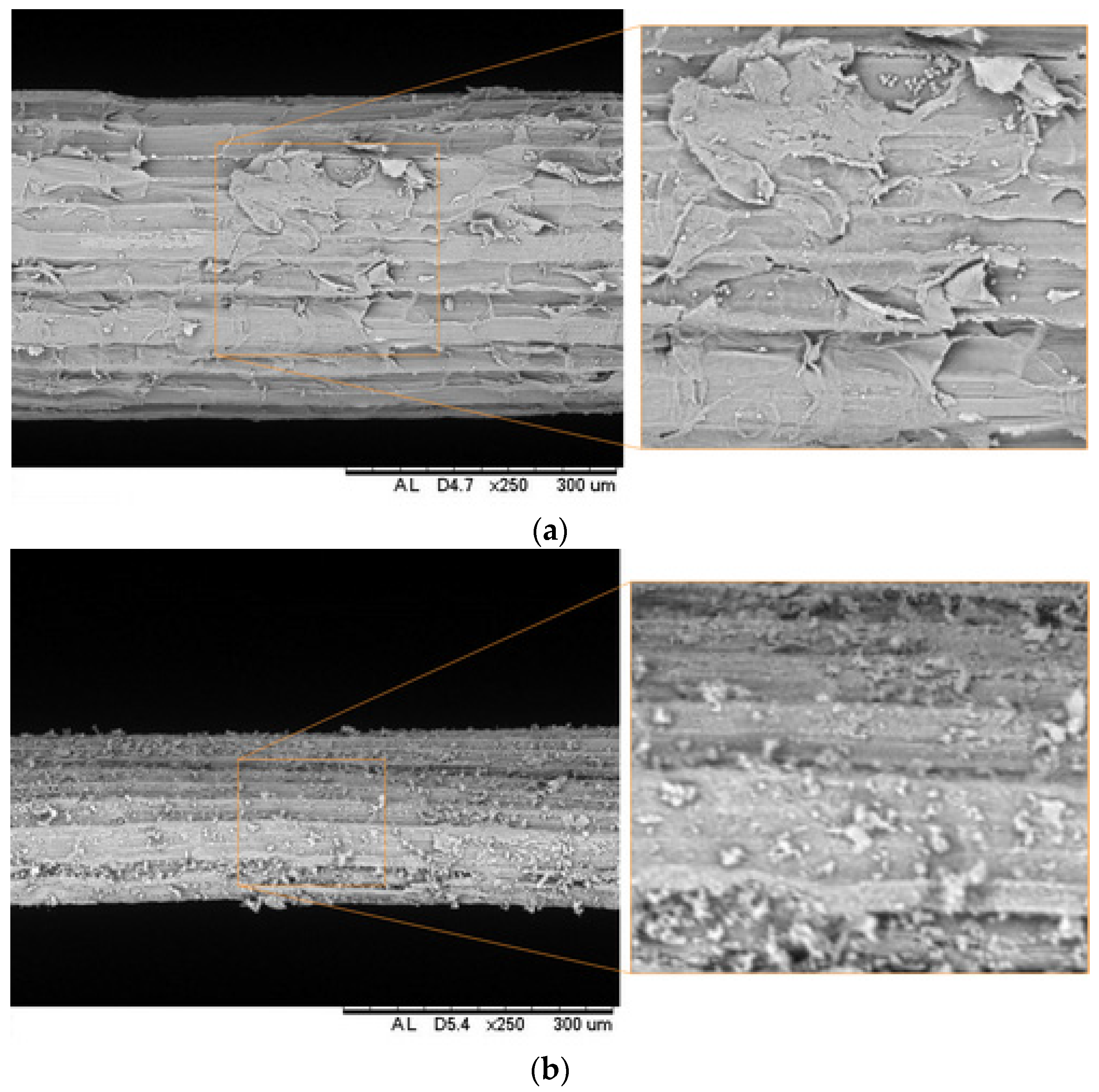

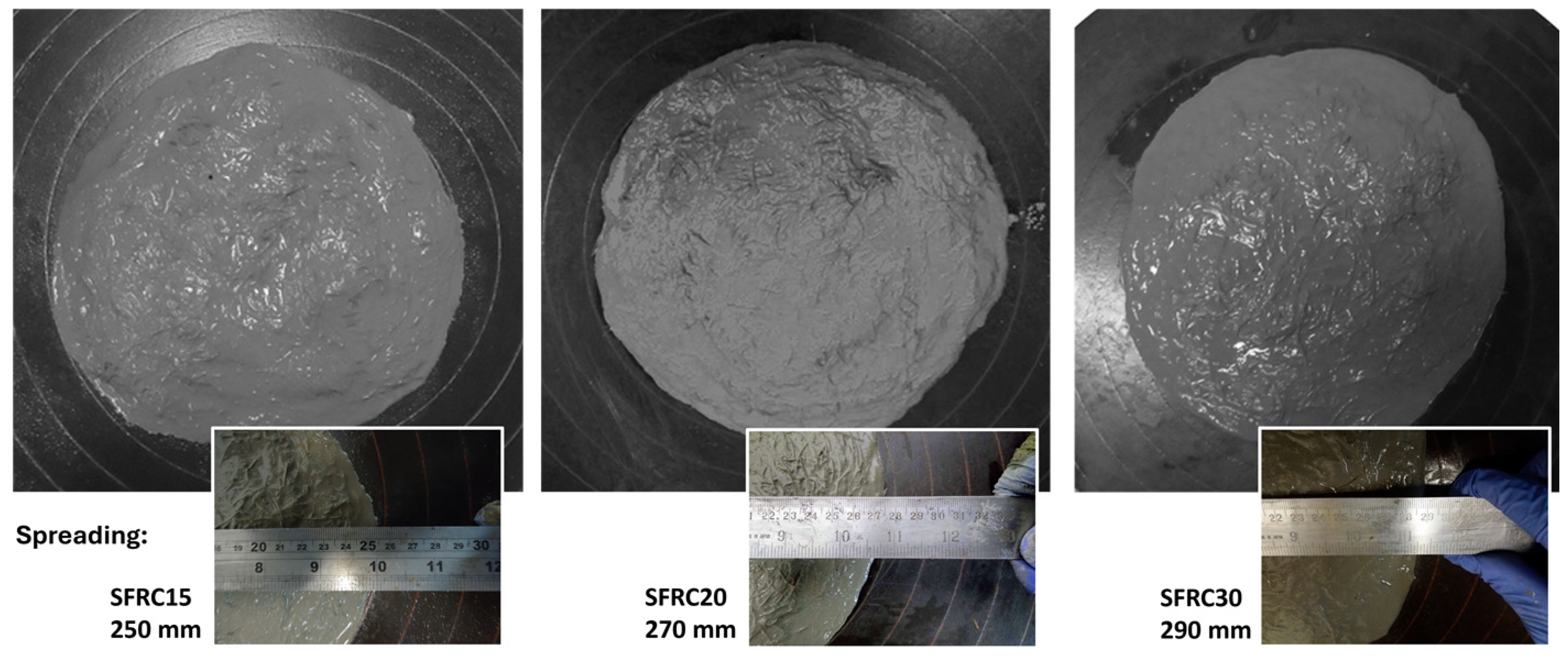

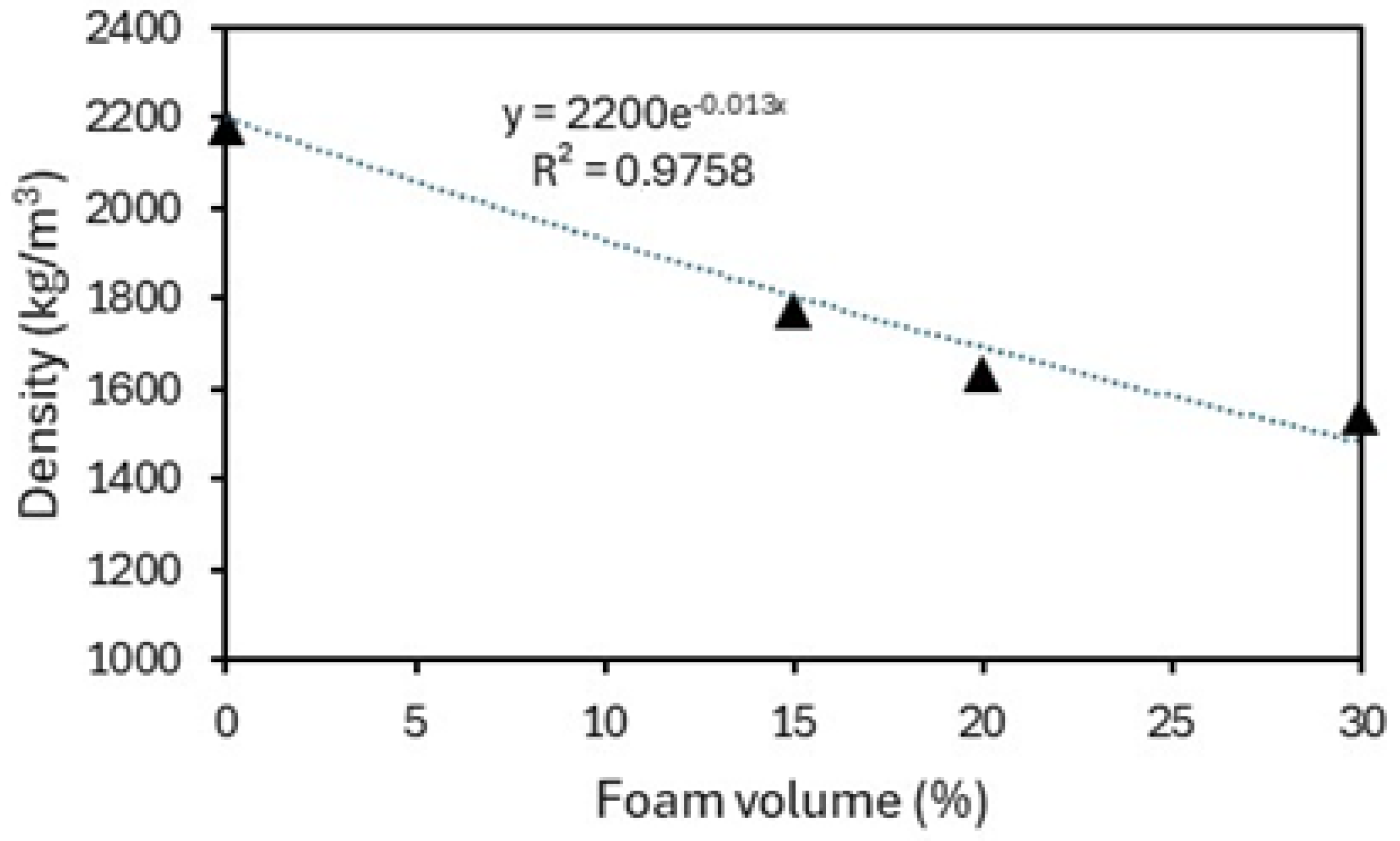

2.1. Sisal Fiber-Reinforced Foamed Cement Composite (SFRFCC)

2.2. Rice Husk Bio-Agreggate Concrete (RHBC)

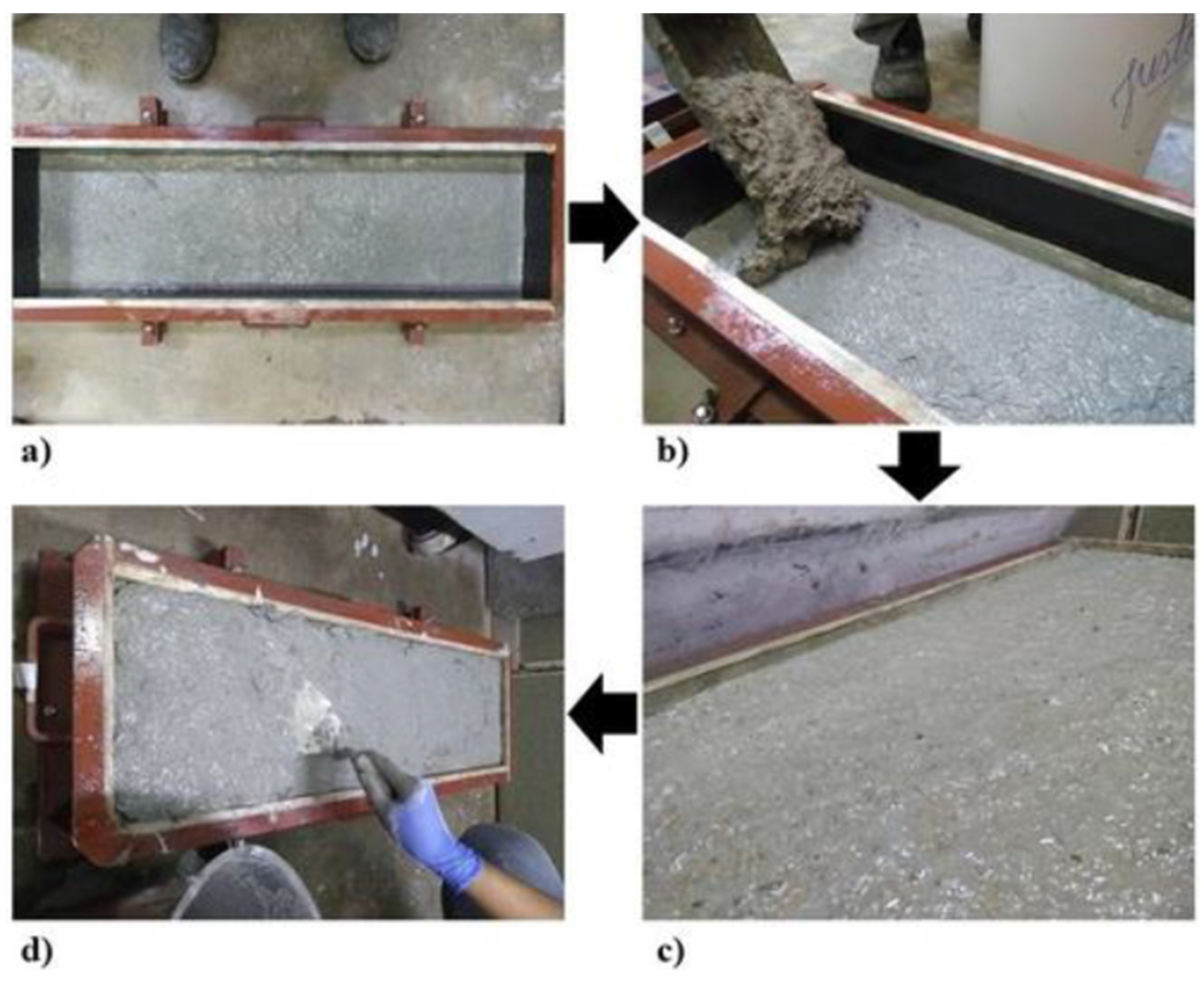

2.3. Lightweight Sandwich Panels (LSP)

3. Results

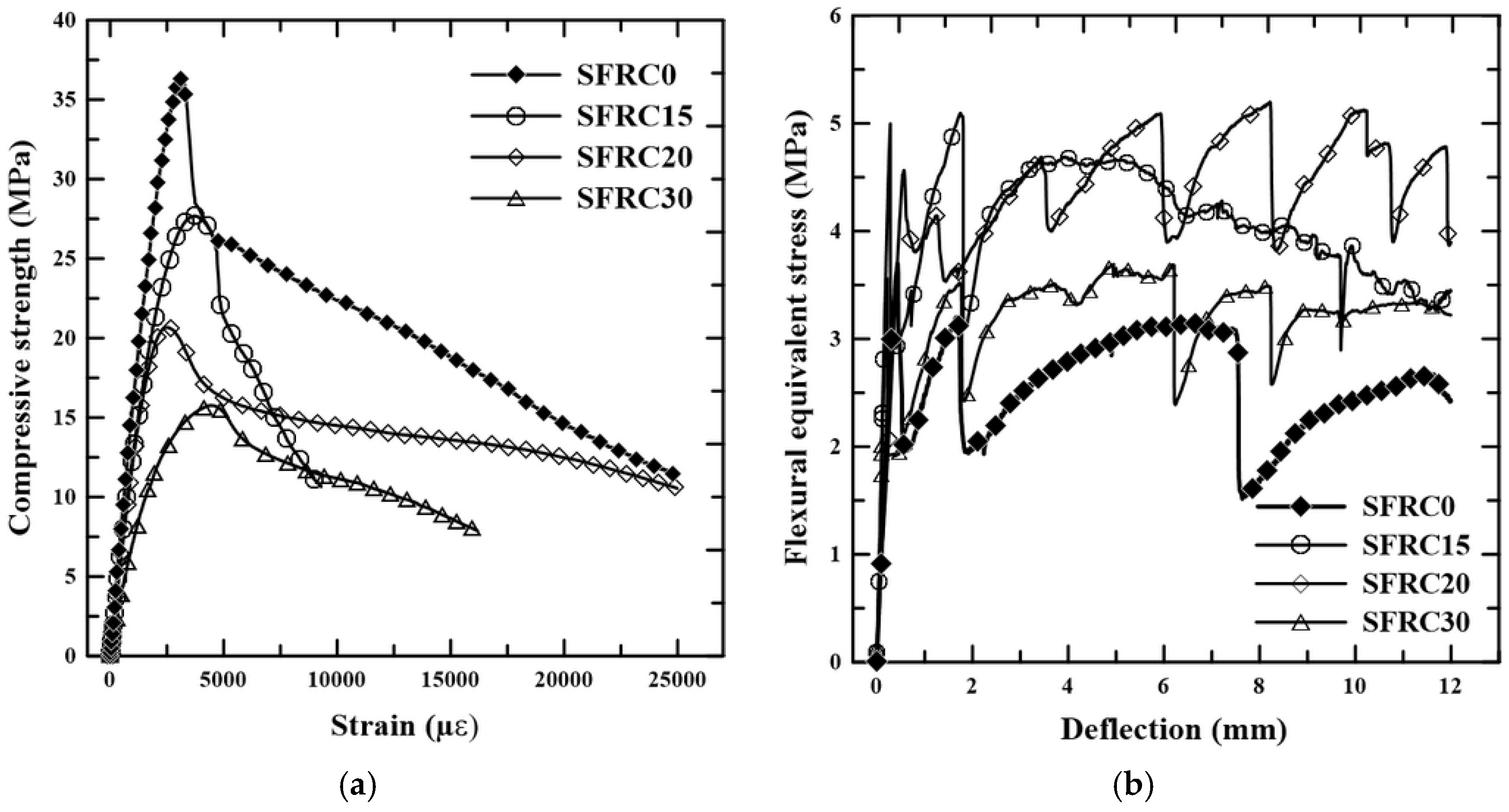

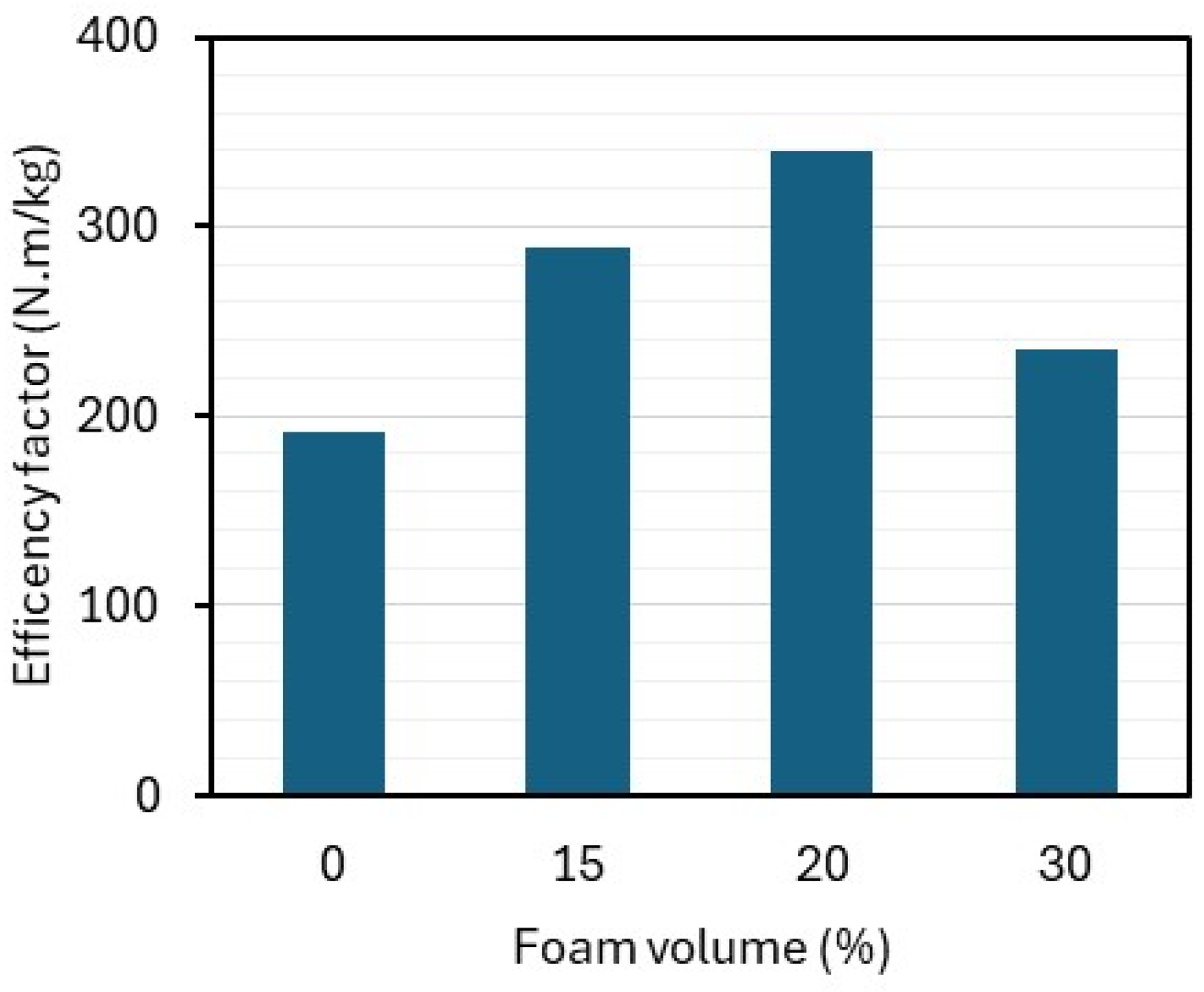

3.1. Characterization of Sisal Fiber Reinforced Foamed Cement Composite

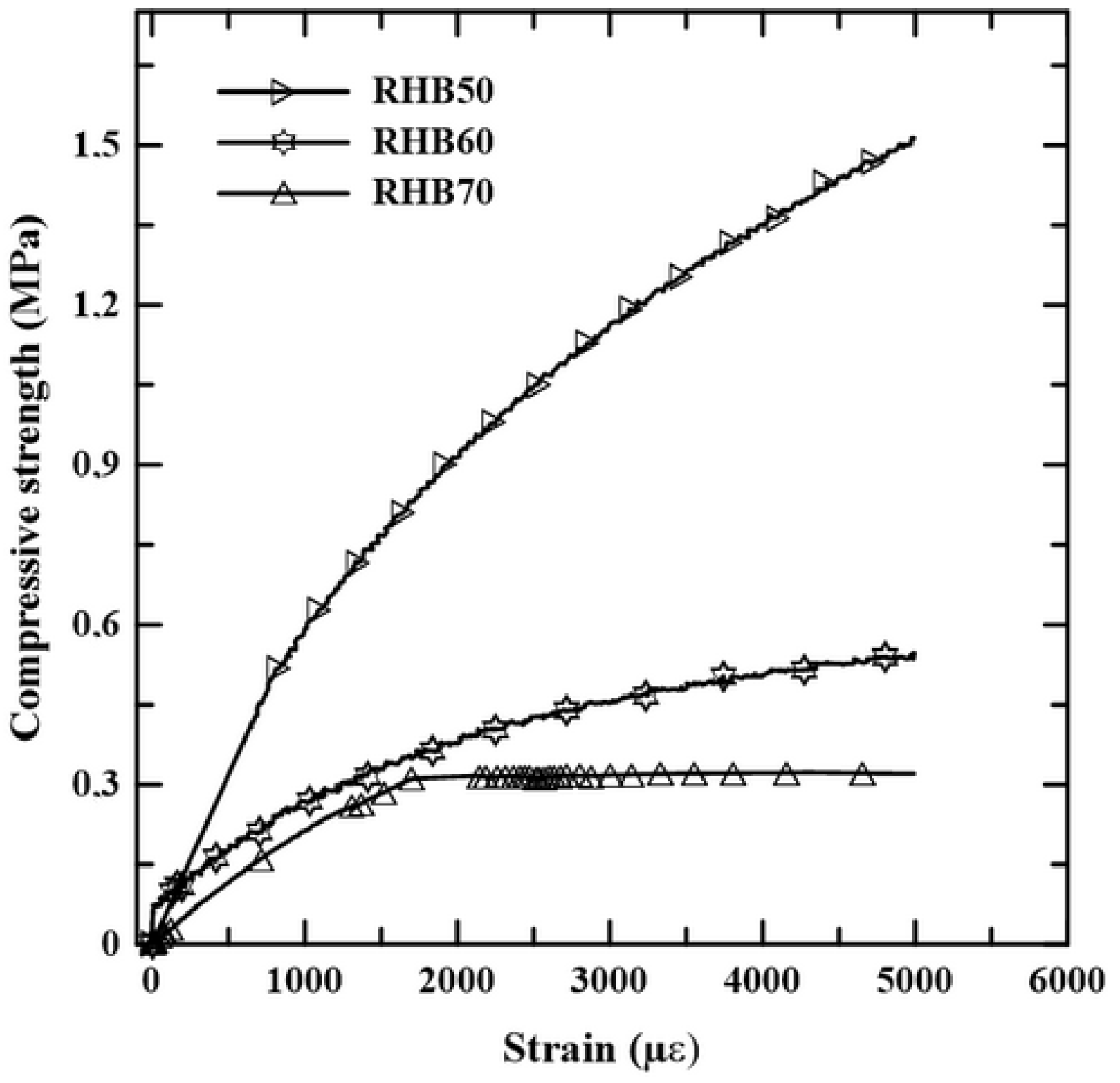

3.2. Characterization of Rice Husk Bio-Agreggate Concrete (RHBC)

3.3. Mechanical Performance and Failure Mode of Lightweight Sandwich Panel (LSP)

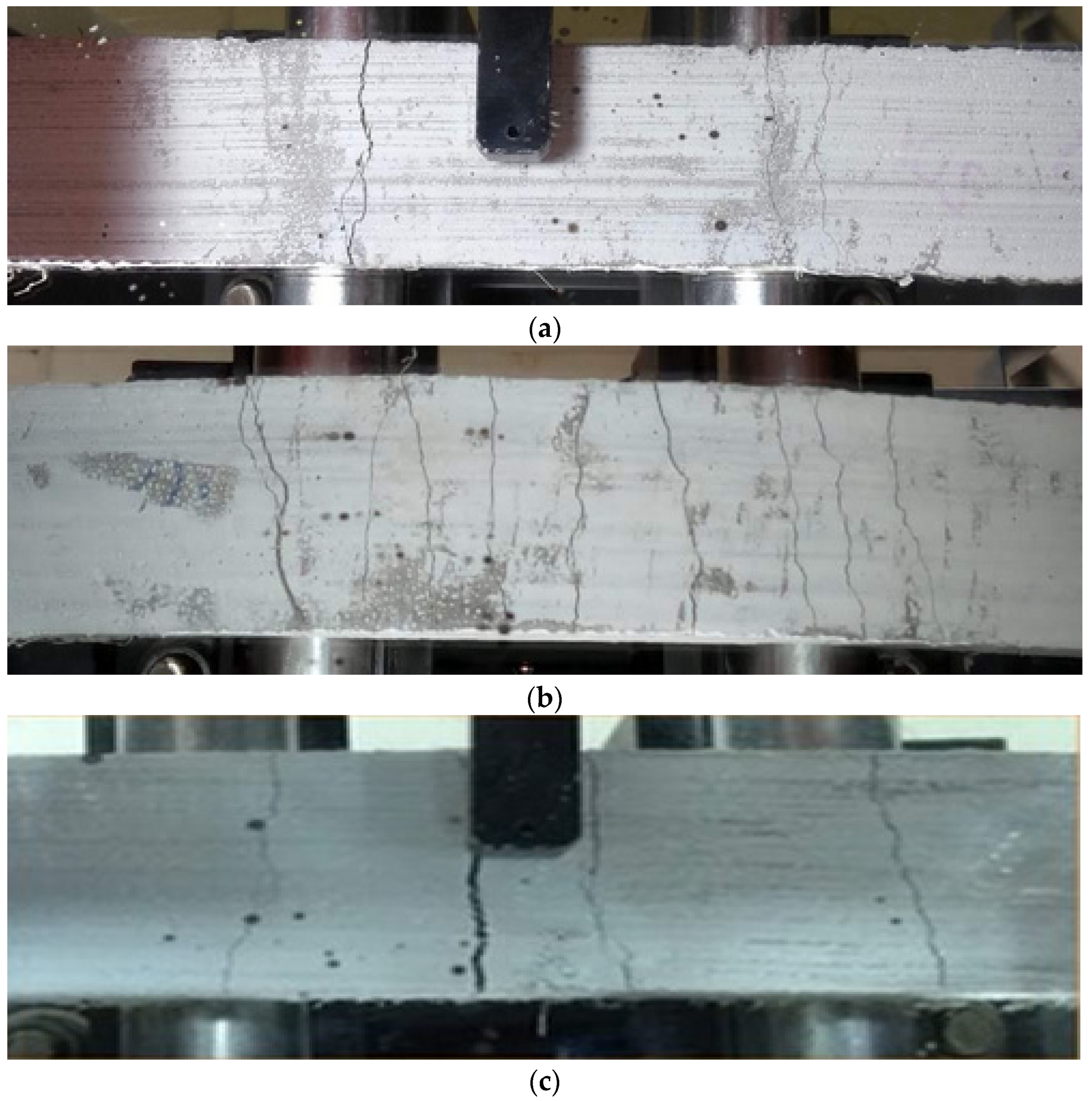

3.3.1. Evaluation of the Facing Properties of LSP by Long Beam Flexure

3.3.2. Evaluation of the Core Shear Properties of LSP by Beam Flexure

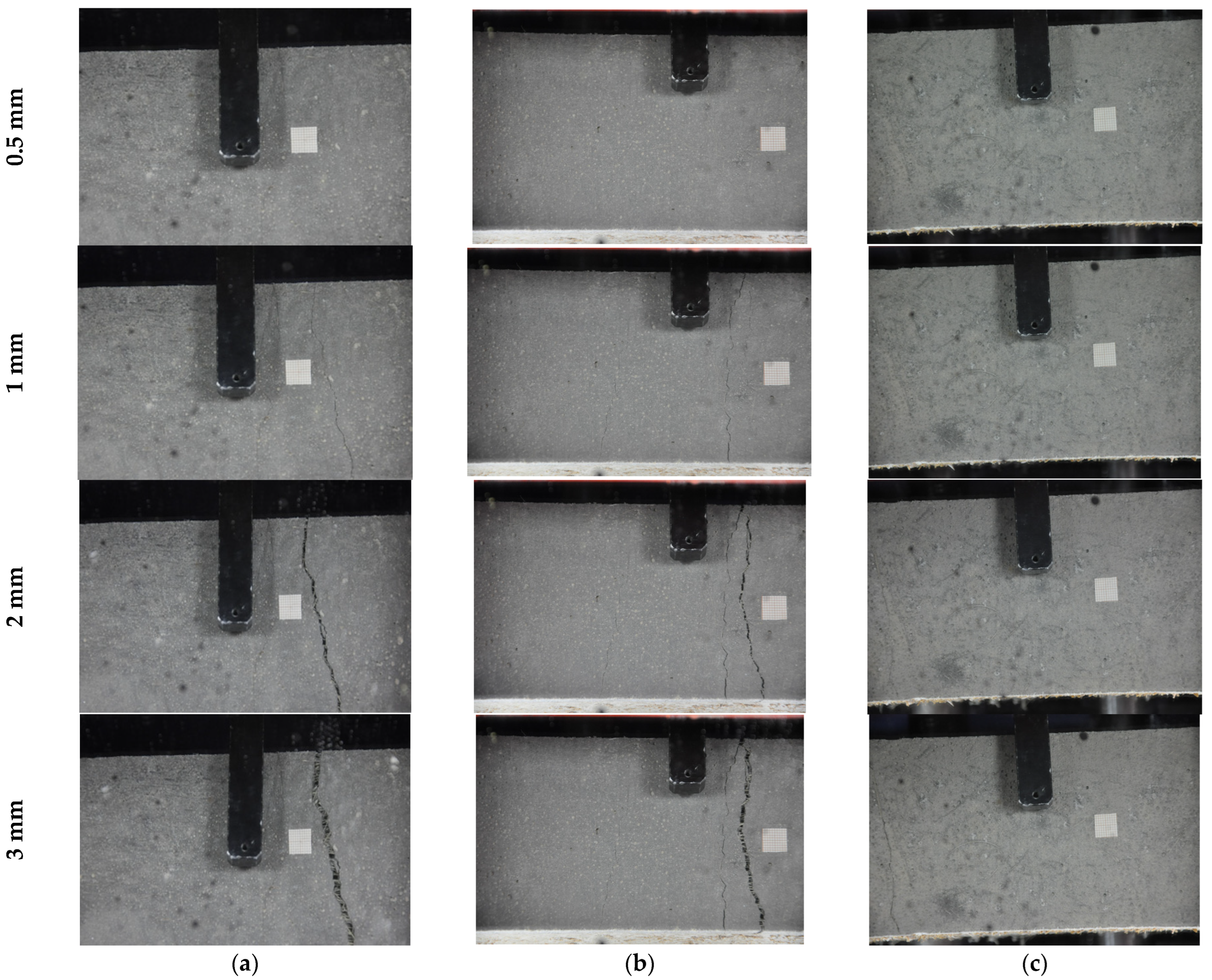

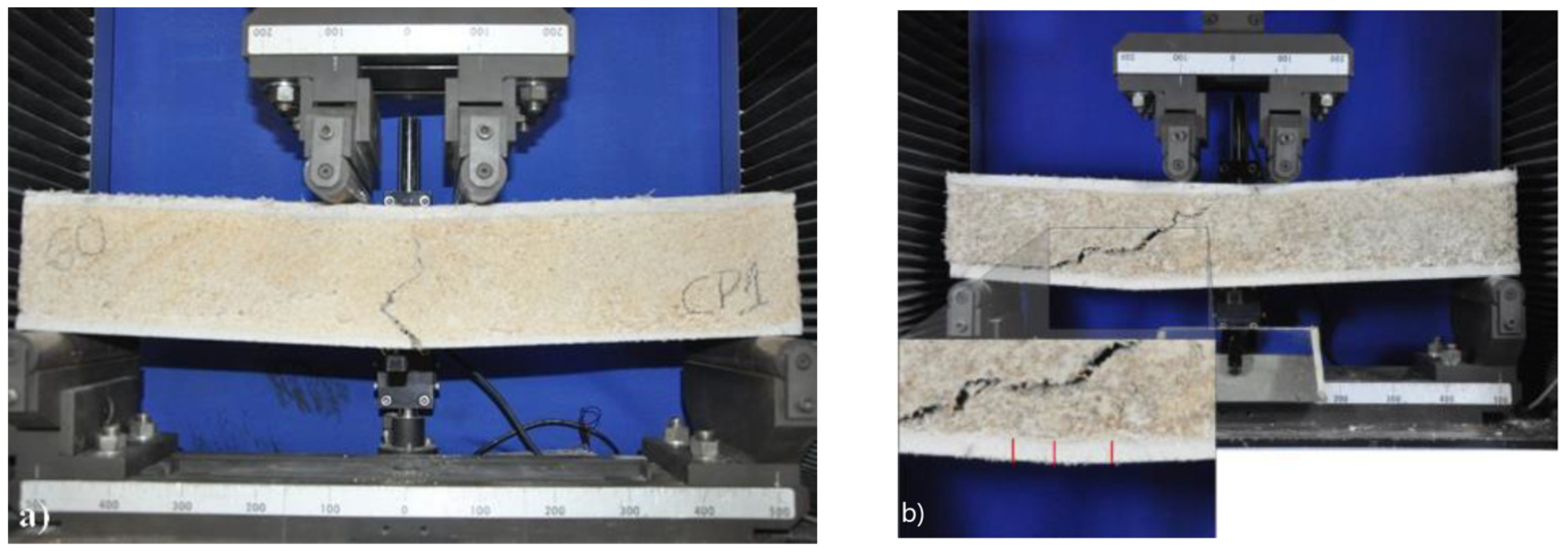

3.3.3. Failure Mode of Lightweight Sandwich Panels

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Yang, L.; Yan, H.; Lam, J.C. Thermal comfort and building energy consumption implications—A review. Appl. Energy 2014, 115, 164–173. [Google Scholar] [CrossRef]

- Huang, Y.; Yang, C.; Ji, X.; Lu, D.; Song, Q. Seismic response of expanded polystyrene (EPS) sandwiched concrete panels system in buildings: Damage distribution and correlation analysis of parameters. J. Build. Eng. 2024, 91, 109608. [Google Scholar] [CrossRef]

- Alavez-Ramirez, R.; Chiñas-Castillo, F.; Morales-Dominguez, V.J.; Ortiz-Guzman, M. Thermal conductivity of coconut fibre filled ferrocement sandwich panels. Constr. Build. Mater. 2012, 37, 425–431. [Google Scholar] [CrossRef]

- Sukontasukkul, P.; Sangpet, T.; Newlands, M.; Tangchirapat, W.; Limkatanyu, S.; Chindaprasirt, P. Thermal behaviour of concrete sandwich panels incorporating phase change material. Adv. Build. Energy Res. 2020, 16, 64–88. [Google Scholar] [CrossRef]

- Castillo-Lara, J.F.; Flores-Johnson, E.A.; Valadez-Gonzalez, A.; Herrera-Franco, P.J.; Carrillo, J.G.; Gonzalez-Chi, P.I.; Li, Q.M. Mechanical properties of natural fiber reinforced foamed concrete. Materials 2020, 13, 3060. [Google Scholar] [CrossRef]

- Cintura, E.; Faria, P.; Molari, L.; Barbaresi, L.; D’Orazio, D.; Nunes, L. A feasible re-use of an agro-industrial by-product: Hazelnut shells as high-mass bio-aggregate in boards for indoor applications. J. Clean. Prod. 2024, 434, 140297. [Google Scholar] [CrossRef]

- Gloria, M.Y.R.; Toledo Filho, R.D. Innovative sandwich panels made of wood bio-concrete and sisal fiber reinforced cement composites. Constr. Build. Mater. 2021, 272, 121636. [Google Scholar] [CrossRef]

- Ratiarisoa, R.V.; Magniont, C.; Ginestet, S.; Oms, C.; Escadeillas, G. Assessment of distilled lavender stalks as bioaggregate for building materials: Hygrothermal properties, mechanical performance and chemical interactions with mineral pozzolanic binder. Constr. Build. Mater. 2016, 124, 801–815. [Google Scholar] [CrossRef]

- Pokorný, J.; Ševčík, R.; Šál, J.; Fiala, L.; Zárybnická, L.; Podolka, L. Bio-based aggregate in the production of advanced thermal-insulating concrete with improved acoustic performance. Constr. Build. Mater. 2022, 358, 19436. [Google Scholar] [CrossRef]

- Moussa, T.; Maalouf, C.; Bliard, C.; Abbes, B.; Badouard, C.; Lachi, M.; do Socorro Veloso Sodré, S.; Bufalino, L.; Bogard, F.; Beaumont, F.; et al. Spent Coffee Grounds as Building Material for Non-Load-Bearing Structures. Materials 2022, 15, 1689. [Google Scholar] [CrossRef]

- Barbieri, V.; Lassinantti, G.M.; Manfredini, T.; Siligardi, C. Lightweight concretes based on wheat husk and hemp hurd as bio-aggregates and modified magnesium oxysulfate binder: Microstructure and technological performances. Constr. Build. Mater. 2021, 284, 122751. [Google Scholar]

- Della, V.P.; Kühn, I.; Hotza, D. Reciclagem de Resíduos Agro-Industriais: Cinza de Casca de Arroz como Fonte Alternativa de Sílica. Cerâmica Ind. 2005, 10, 22–25. [Google Scholar]

- Kazemi, R.; Emamian, S.A.; Arashpour, M. Assessing the compressive strength of eco-friendly concrete made with rice husk ash: A hybrid artificial intelligence-aided technique. Structures 2024, 68, 107050. [Google Scholar] [CrossRef]

- Amantino, G.M.; Hasparyk, N.P.; Tiecher, F.; Toledo Filho, R.D. Assessment of bio-aggregate concretes’ properties with rice residue. Build. Eng. 2022, 52, 104348. [Google Scholar]

- Chabannes, M.; Bénézet, J.C.; Clerc, L.; Garcia-Diaz, E. Use of raw rice husk as natural aggregate in a lightweight insulating concrete: An innovative application. Constr. Build. Mater. 2014, 70, 428–438. [Google Scholar]

- Caldas, L.R.; Araujo, A.F.D.; Hasparyk, N.P.; Tiecher, F.; Amantino, G.; Toledo Filho, R.D. Circular economy in concrete production: Greenhouse Gas (GHG) emissions assessment of rice husk bio-concretes. Rev. IBRACON Estrut. Mater. 2022, 15, e15602. [Google Scholar]

- Garhwal, A.; Sharma, S.; Danie Roy, A.B. Corrosion effects on flexural behaviour of EPS sandwich concrete panels: A study using acoustic emission technique. Can. J. Civ. Eng. 2024, 52, 213–227. [Google Scholar] [CrossRef]

- Yang, T.; Zhu, D.; Chen, C. Mechanical properties and failure patterns of sandwich panels with AR-glass textile reinforced concrete face sheets subjected to quasi-static load. Thin-Walled Struct. 2023, 193, 111286. [Google Scholar]

- Priyanga, R.; Muthadhi, A. Bending analysis of textile reinforced concrete sandwich panels: Experimental and numerical evaluation. Constr. Build. Mater. 2024, 439, 137213. [Google Scholar] [CrossRef]

- Sudhakar, A.J.; Muthusubramanian, B. Flexural response of textile-reinforced sandwich slab with modified polymeric core. Structures 2024, 59, 105679. [Google Scholar] [CrossRef]

- Pennarasi, G.; Soumya, S.; Gunasekaran, K. Study for the relevance of coconut shell aggregate concrete paver blocks. Mater. Today Proc. 2019, 14, 368–378. [Google Scholar]

- Quintero Garcia, S.L.; Gonzalez Salcedo, L.O. Uso de fibra de estopa de coco para mejorar las propiedades mecánicas del concreto. Ing. Y Desarro. 2006, 20, 135–150. [Google Scholar]

- Frazão, C.; Barros, J.; Toledo Filho, R.D.; Ferreira, S.R.; Gonçalves, D. Development of sandwich panels combining Sisal Fiber-Cement Composites and Fiber-Reinforced Lightweight Concrete. Cem. Concr. Compos. 2018, 86, 206–223. [Google Scholar]

- Mercedes, L.; Bernat-Maso, E.; Gil, L. Bending and compression performance of full-scale sandwich panels of hemp fabric reinforced cementitious matrix. Eng. Struct. 2023, 275, 115241. [Google Scholar]

- Lima, P.R.L.; Barros, J.A.O.; Roque, A.B.; Fontes, C.M.A.; Lima, J.M.F. Short sisal fiber reinforced recycled concrete block for one-way precast concrete slabs. Constr. Build. Mater. 2018, 187, 620–634. [Google Scholar]

- Amran, M.; Fediuk, R.; Vatin, N.; Huei Lee, Y.; Murali, G.; Ozbakkaloglu, T.; Klyuev, S.; Alabduljabber, H. Fibre-reinforced foamed concretes: A review. Materials 2020, 13, 4323. [Google Scholar] [CrossRef]

- Jaramillo, H.Y.; Vasco-Echeverri, O.H.; Moreno-Pacheco, L.A.; García-León, R.A. Biomaterials in Concrete for Engineering Applications: A Bibliometric Review. Infrastructure 2023, 8, 161. [Google Scholar] [CrossRef]

- Ballester Olmos, J.F. Agave Are Succulents Plants; Floraprint: Spain, 1995; p. 144. [Google Scholar]

- Fidelis, M.E.A.; Pereira, T.V.C.; Gomes, O.D.F.M.; de Andrade Silva, F.; Toledo Filho, R.D. The effect of fiber morphology on the tensile strength of natural fibers. J. Mater. Res. Technol. 2013, 2, 149–157. [Google Scholar]

- Rosa, M.F.; Chiou, B.; Medeiros, E.S.; Wood, D.F.; Williams, T.G.; Mattoso, L.H.C.; Orts, W.J.; Imama, S.H. Effect of fiber treatment on tensile and thermal properties of starch/ethylene vinyl copolymers/coir biocomposites. Bioresour. Technol. 2009, 100, 5196–5202. [Google Scholar] [CrossRef]

- Saha, P.; Manna, S.; Chowdhury, S.R.; Sen, R.; Roy, D.; Adhikari, B. Enhancement of tensile strength of lignocellulosic jute fibers by alkali-steam treatment. Bioresour. Technol. 2010, 101, 3182–3187. [Google Scholar] [CrossRef]

- Ferreira, S.R. The Effect of Surface Treatments on the Structure, Durability and Bond Behavior of Vegetable Fibers for Cementitious Composites. Ph.D. Thesis, Federal University of Rio de Janeiro, Rio de Janeiro, Brazil, 2016. (In Portuguese). [Google Scholar]

- Othman, R.; Jaya, R.P.; Muthusamy, K.; Sulaiman, M.; Duraisamy, Y.; Abdullah, M.M.A.B.; Przybył, A.; Sochacki, W.; Skrzypczak, T.; Vizureanu, P.; et al. Relation between density and compressive strength of foamed concrete. Materials 2021, 14, 2967. [Google Scholar] [CrossRef] [PubMed]

- Batool, F.; Bindiganavile, V. Microstructural parameters of fiber reinforced cement-based foam and their influence on compressive and thermal properties. J. Build. Eng. 2020, 31, 101320. [Google Scholar]

- Gencel, O.; Nodehi, M.; Bayraktar, O.Y.; Kaplan, G.; Benli, A.; Gholampour, A.; Ozbakkaloglu, T. Basalt fiber-reinforced foam concrete containing silica fume: An experimental study. Constr. Build. Mater. 2022, 326, 126861. [Google Scholar]

- He, S.; Chen, Y.; Liang, M.; Yang, E.H.; Schlangen, E. Distribution of porosity surrounding a microfiber in cement paste. Cem. Concr. Compos. 2023, 142, 105188. [Google Scholar]

- Rasheed, M.A.; Prakash, S.S. Behavior of hybrid-synthetic fiber reinforced cellular lightweight concrete under uniaxial tension—Experimental and analytical studies. Constr. Build. Mater. 2018, 162, 857–870. [Google Scholar]

- Moravia, W.G.; Gumieri, A.G.; Vasconcelos, W.L. Efficiency Factor and Modulus of Elasticity of Lightweight Concrete with Expanded Clay Aggregate. Rev. IBRACON De Estrut. E Mater. 2010, 3, 195–204. [Google Scholar]

- Yuzer, N.; Cinar, Z.; Akoz, F.; Biricik, H.; Gurkan, Y.Y.; Kabay, N.; Kizilkanat, A.B. Influence of raw rice husk addition on structure and properties of concrete. Constr. Build. Mater. 2013, 44, 54–62. [Google Scholar]

- Lima, P.R.L.; Leite, M.B.; Santiago, E.Q.R. Recycled lightweight concrete made from footwear industry waste and CDW. Waste Manag. 2010, 30, 1107–1113. [Google Scholar] [CrossRef]

- Peng, S.L.; Chen, Y.L.; Dai, Y.S. Composite Building Materials Prepared from Bioresources: Use of Rice Husk for Autoclaved Lightweight Concrete Production. J. Compos. Sci. 2024, 8, 359. [Google Scholar] [CrossRef]

- Losch, E.D.; Hynes, P.W.; Andrews, R., Jr.; Browning, R.; Cardone, P.; Devalapura, R.; Donahey, R.; Freedman, S.; Gleich, H.A.; Yan, L.; et al. State of the art of precast/prestressed concrete sandwich wall panels. PCI J. 2011, 56, 131–176. [Google Scholar]

- Dey, V.; Zani, G.; Colombo, M.; Di Prisco, M.; Mobasher, B. Flexural impact response of textile-reinforced aerated concrete sandwich panels. Mater. Des. 2015, 86, 187–197. [Google Scholar]

- Richard, O.; West, R.; Reilly, A.; Kinnane, O. Composite behaviour of fibre-reinforced concrete sandwich panels with FRP shear connectors. Eng. Struct. 2019, 198, 109475. [Google Scholar]

- Vitale, J.P.; Francucci, G.; Xiong, J.; Stocchi, A. Failure mode maps of natural and synthetic fiber reinforced composite sandwich panels. Compos. Part A Appl. Sci. Manuf. 2017, 94, 217–225. [Google Scholar]

- Bai, F.; Davidson, J.S. Analysis of partially composite foam insulated concrete sandwich structures. Eng. Struct. 2015, 91, 197–209. [Google Scholar]

- Benayoune, A.; Samad, A.A.; Trikha, D.N.; Ali, A.A.; Ellinna, S.H.M. Flexural behaviour of pre-cast concrete sandwich composite panel–experimental and theoretical investigations. Constr. Build. Mater. 2008, 22, 580–592. [Google Scholar]

- Kandil, M.A.E.N.; Mahdy, M.; Raheem, A.H.A.; Tahwia, A.M. Effect of shear connectors on strength of structural sandwich panels. SN Appl. Sci. 2020, 2, 1–10. [Google Scholar]

- Gdoutos, E.; Daniel, I. Failure modes of composite sandwich beams. Theor. Appl. Mech. 2008, 35, 105–118. [Google Scholar]

- Steeves, C.A.; Fleck, N.A. Collapse mechanisms of sandwich beams with composite faces and a foam core, loaded in three-point bending. Part II: Experimental investigation and numerical modelling. Int. J. Mech. Sci. 2004, 46, 585–608. [Google Scholar]

- Ghazy, M.F.; Abd Elaty, M.A.A.; Sakr, M.A.E.; Arafa, E.M. Thermo-Mechanical Performance of Sustainable Lightweight Sandwich Panels Utilizing Ultra-High-Performance Fiber-Reinforced Concrete. Buildings 2025, 15, 593. [Google Scholar] [CrossRef]

- Colombo, I.G.; Colombo, M.; Di Prisco, M. Bending behaviour of Textile Reinforced Concrete sandwich beams. Constr. Build. Mater. 2015, 95, 675–685. [Google Scholar] [CrossRef]

| Mix | C | MK | FA | RHB | W | WC | VMA | CaCl2 |

|---|---|---|---|---|---|---|---|---|

| RHB50 | 320.5 | 160.2 | 53.4 | 150.0 | 438.1 | 171.0 | 0.53 | 16.0 |

| RHB60 | 256.4 | 128.2 | 42.7 | 180.0 | 418.9 | 205.2 | 0.42 | 12.8 |

| RHB70 | 192.3 | 96.1 | 32.0 | 210.0 | 400.0 | 239.4 | 0.32 | 9.61 |

| Mix | Foam Volume (%) | Compressive Strength (MPa) | Elastic Modulus (GPa) | Flexural Strength (MPa) |

|---|---|---|---|---|

| SFRC0 | 0 | 33.53 (3.4) | 15.76 (1.7) | 4.16 (3.0) |

| SFRC15 | 15 | 27.68 (2.8) | 12.77 (9.0) | 5.12 (2.7) |

| SFRC20 | 20 | 20.81 (5.6) | 11.50 (8.1) | 5.54 (4.0) |

| SFRC30 | 30 | 15.37 (8.9) | 7.70 (4.1) | 3.60 (4.6) |

| Panel | Bio-Aggregate Content (%) | Ffcr (kN) | Fmax (kN) | δmax (mm) | Fu (MPa) | Toughness (kN·mm) | Failure Mode |

|---|---|---|---|---|---|---|---|

| LSP50 | 50 | 1.08 (4.6) | 2.21 (5.3) | 0.75 (11.03) | 3.07 (5.3) | 5.45 (14.0) | Face yield |

| LSP60 | 60 | 0.90 (9.4) | 1.62 (1.7) | 0.97 (7.13) | 2.25 (1.7) | 4.80 (28.4) | Face yield |

| LSP70 | 70 | 0.28 (10.0) | 0.31 (6.1) | 0.41 (13.21) | 0.43 (6.1) | 1.29 (15.3) | Shear core |

| Panel | Bio Aggregate Content (%) | Fmax (kN) | δmax (mm) | Fs (MPa) | Toughness (kN·mm) | Failure Mode |

|---|---|---|---|---|---|---|

| LSP50 | 50 | 5.40 (6.3) | 0.27 (7.9) | 0.37 (6.3) | 17.81 (10.2) | Shear core |

| LSP60 | 60 | 2.72 (11.8) | 0.78 (10.5) | 0.18 (11.8) | 10.67 (11.9) | Shear core |

| LSP70 | 70 | 0.67 (9.0) | 0.80 (6.0) | 0.05 (9.0) | 2.95 (11.9) | Crushing core |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

dos Santos, D.O.J.; Lima, P.R.L.; Toledo Filho, R.D. Flexural Behavior of Lightweight Sandwich Panels with Rice Husk Bio-Aggregate Concrete Core and Sisal Fiber-Reinforced Foamed Cementitious Faces. Materials 2025, 18, 1850. https://doi.org/10.3390/ma18081850

dos Santos DOJ, Lima PRL, Toledo Filho RD. Flexural Behavior of Lightweight Sandwich Panels with Rice Husk Bio-Aggregate Concrete Core and Sisal Fiber-Reinforced Foamed Cementitious Faces. Materials. 2025; 18(8):1850. https://doi.org/10.3390/ma18081850

Chicago/Turabian Styledos Santos, Daniele Oliveira Justo, Paulo Roberto Lopes Lima, and Romildo Dias Toledo Filho. 2025. "Flexural Behavior of Lightweight Sandwich Panels with Rice Husk Bio-Aggregate Concrete Core and Sisal Fiber-Reinforced Foamed Cementitious Faces" Materials 18, no. 8: 1850. https://doi.org/10.3390/ma18081850

APA Styledos Santos, D. O. J., Lima, P. R. L., & Toledo Filho, R. D. (2025). Flexural Behavior of Lightweight Sandwich Panels with Rice Husk Bio-Aggregate Concrete Core and Sisal Fiber-Reinforced Foamed Cementitious Faces. Materials, 18(8), 1850. https://doi.org/10.3390/ma18081850