Microstructure and Wear Behavior of WMoTaNbV Refractory High-Entropy Alloy Coating on Ti6Al4V Alloy Surface Prepared by Laser Cladding

Abstract

1. Introduction

2. Materials and Methods

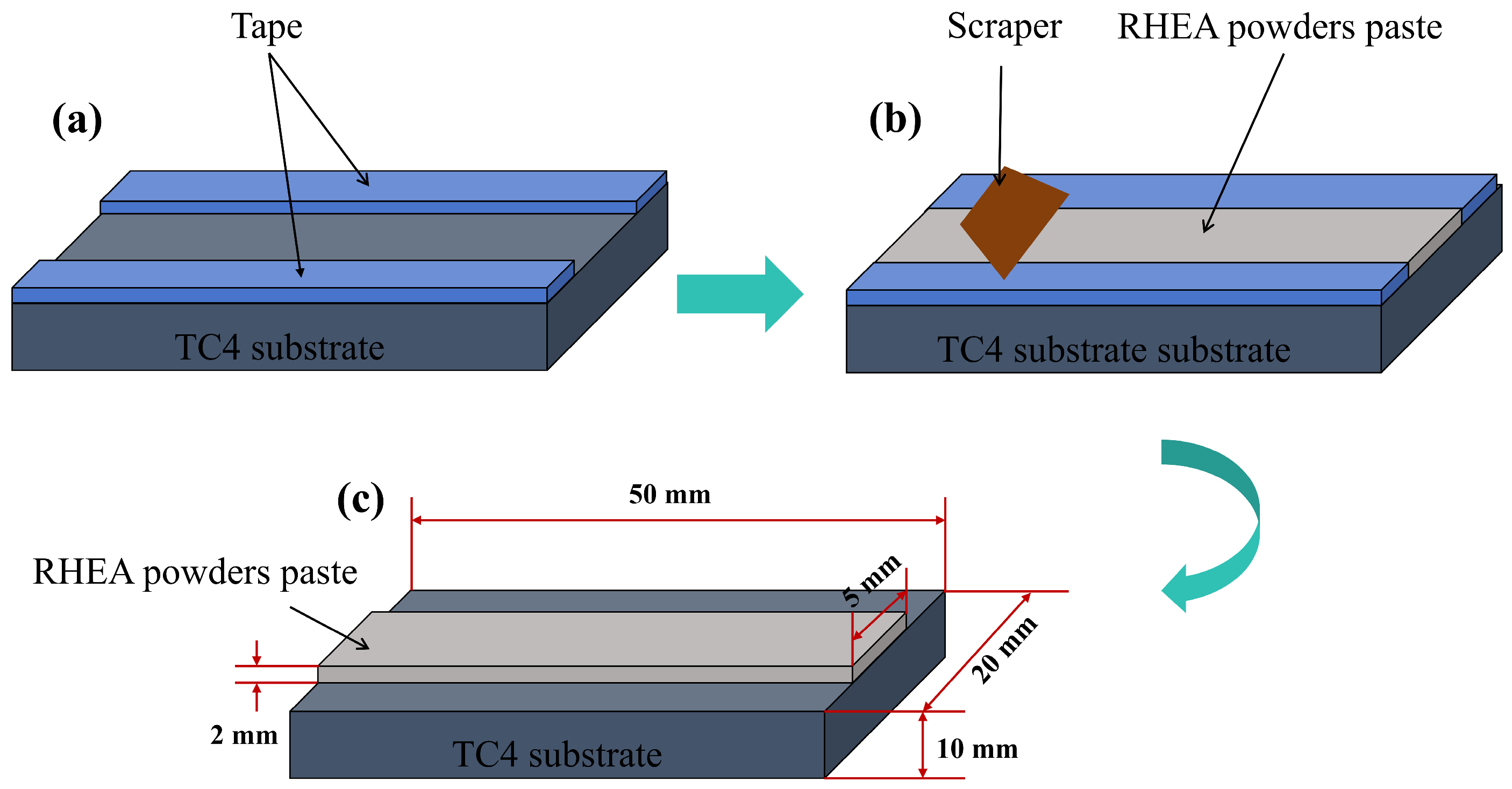

2.1. Experimental Materials and Preparation of Coating

2.2. Microstructure Characterization and Performance Test of RHEA Coating

3. Results

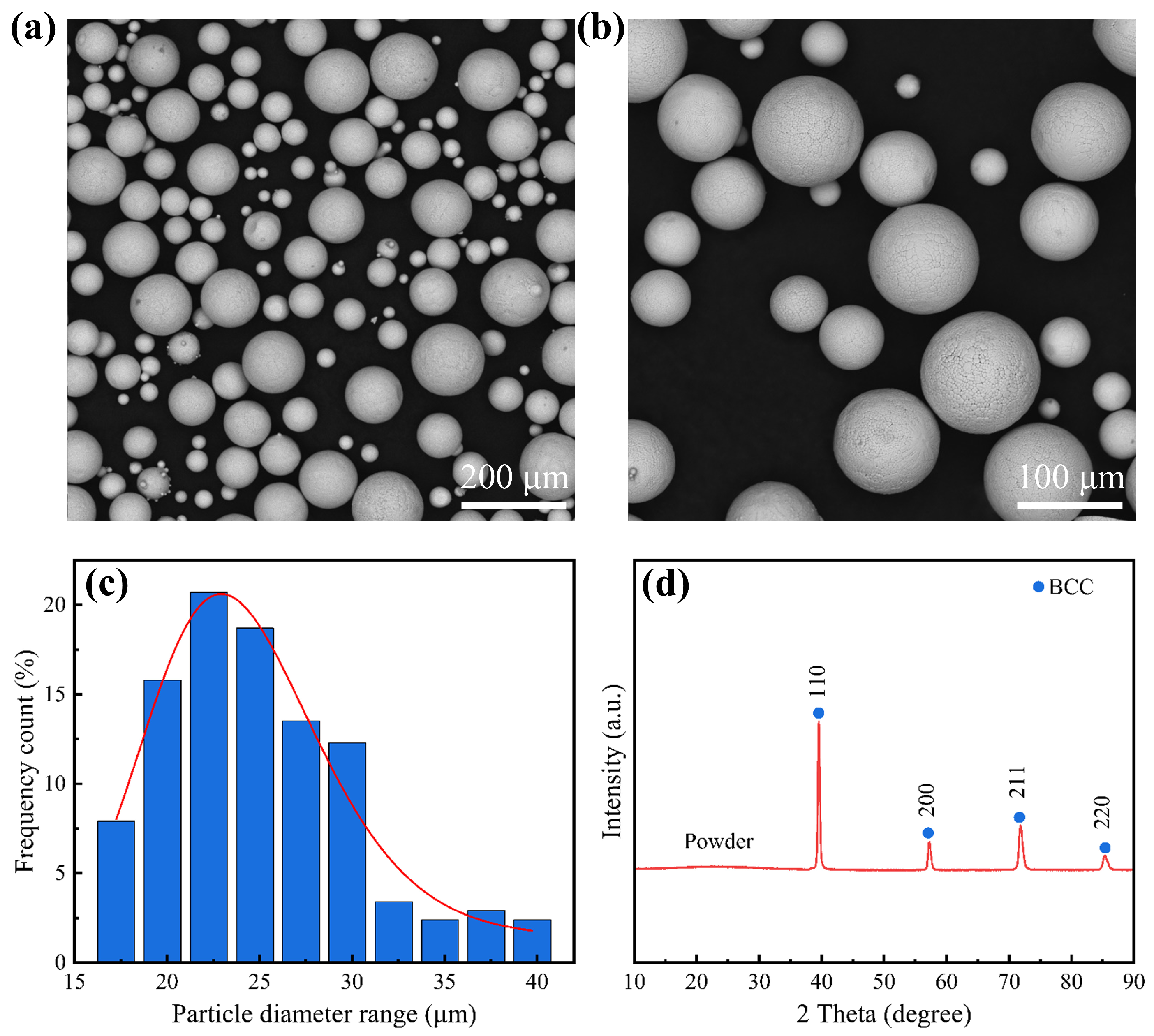

3.1. Microstructure of the Powders

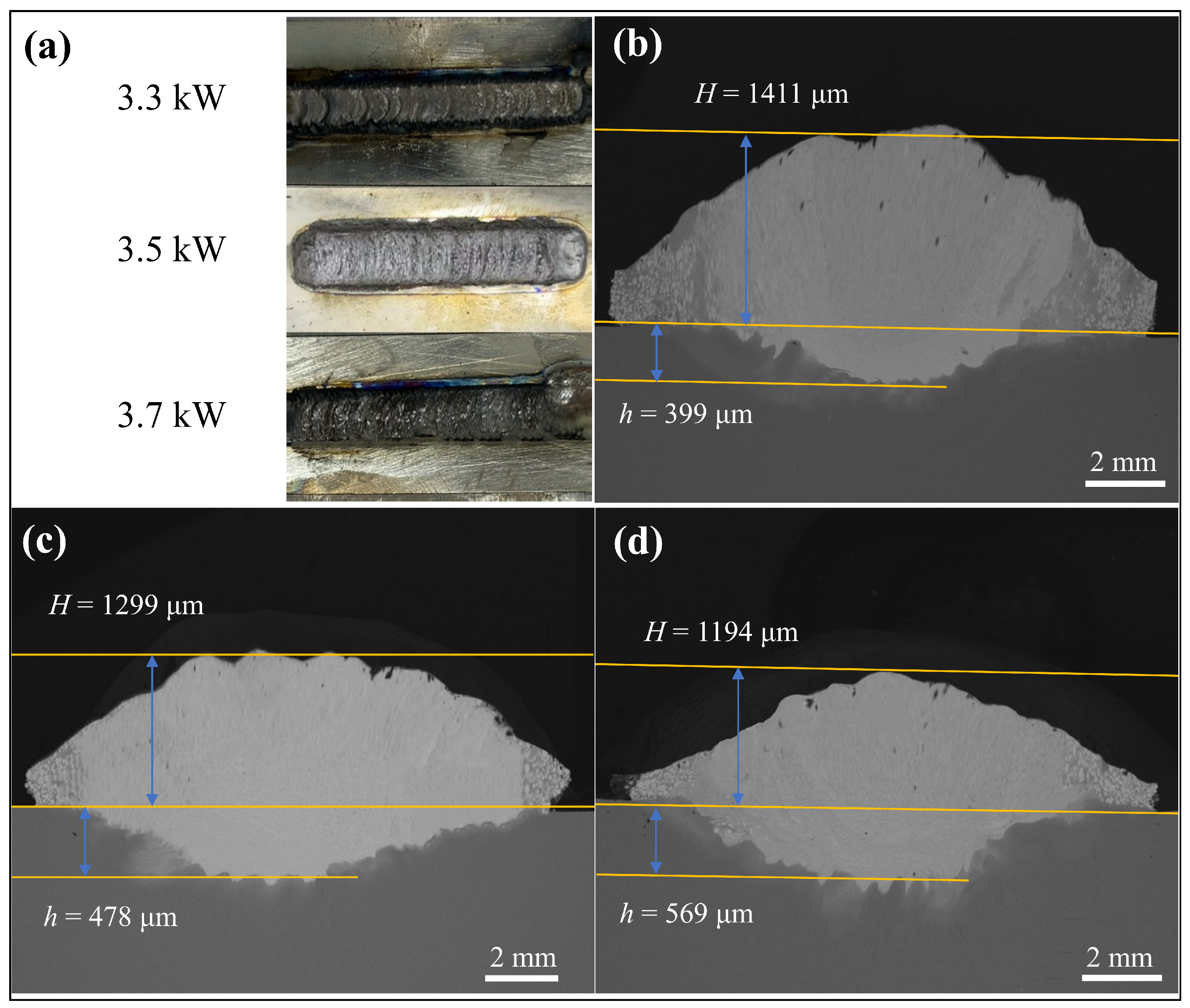

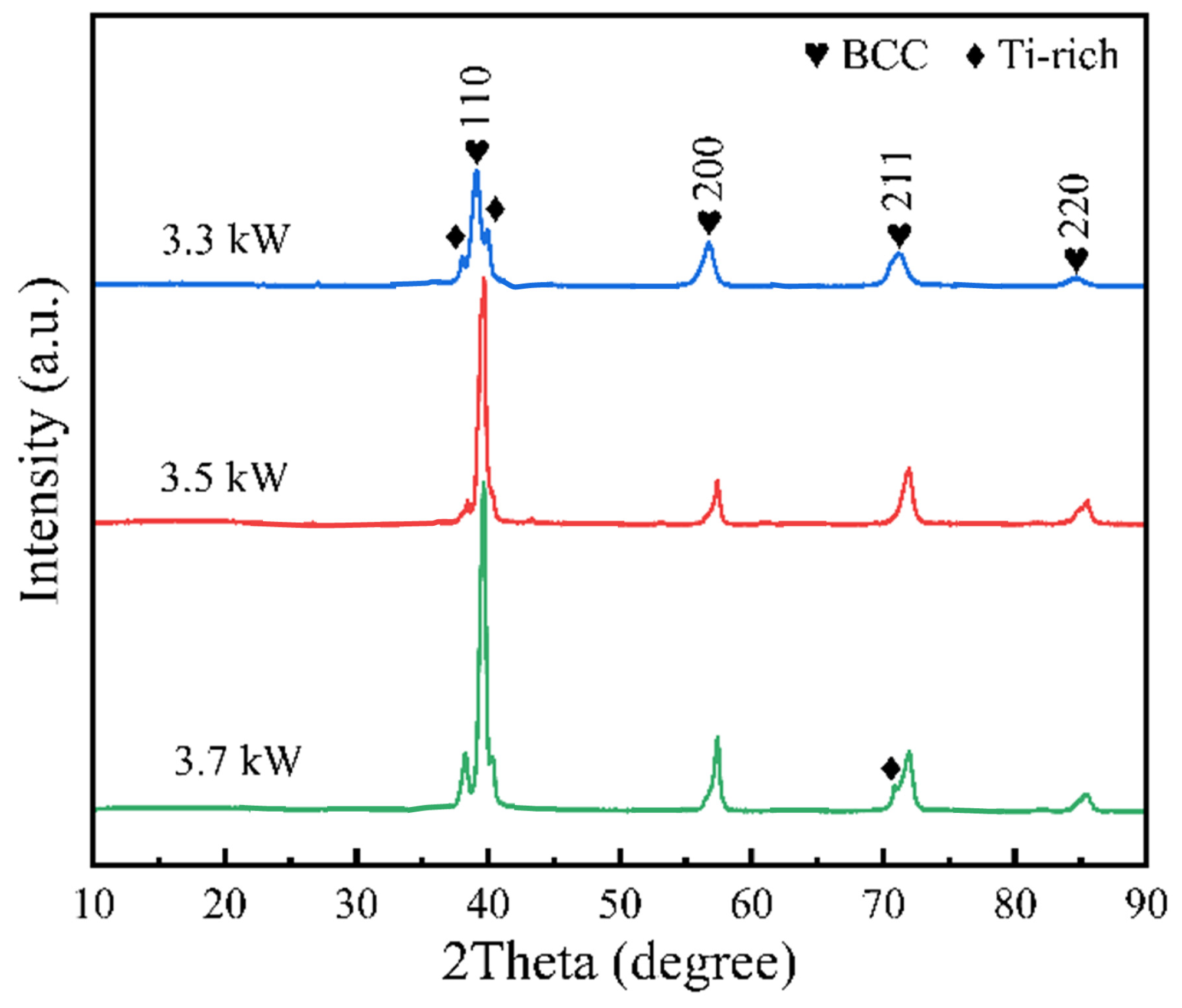

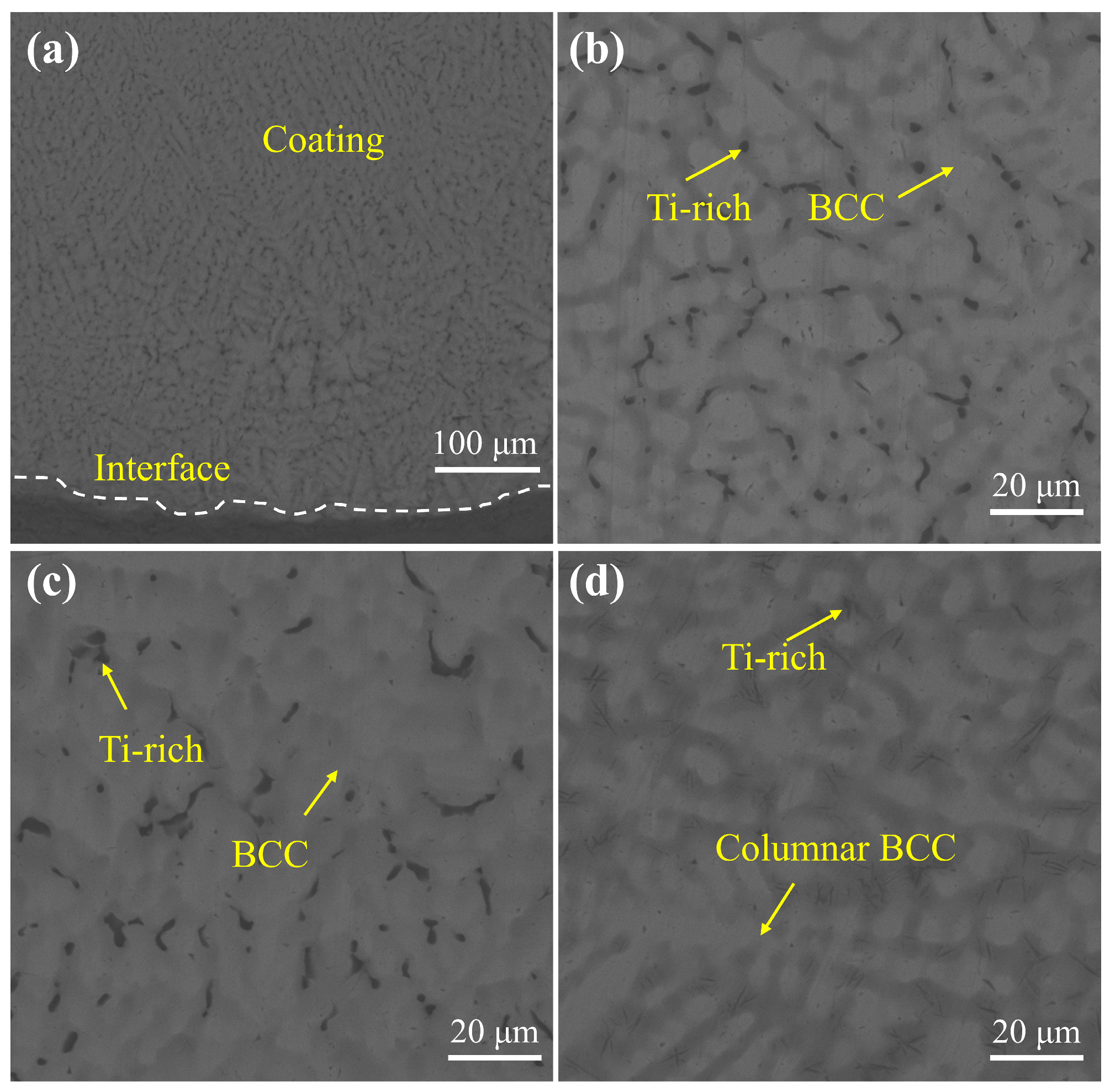

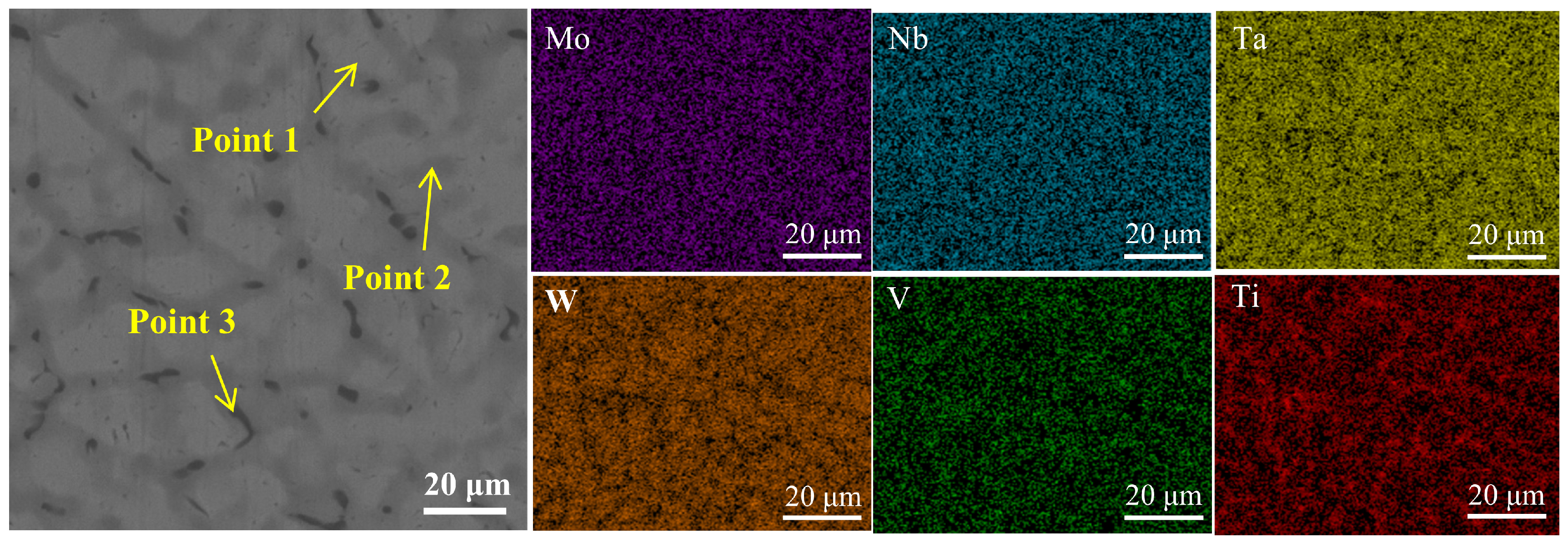

3.2. Surface Morphology and Microstructure of Coating

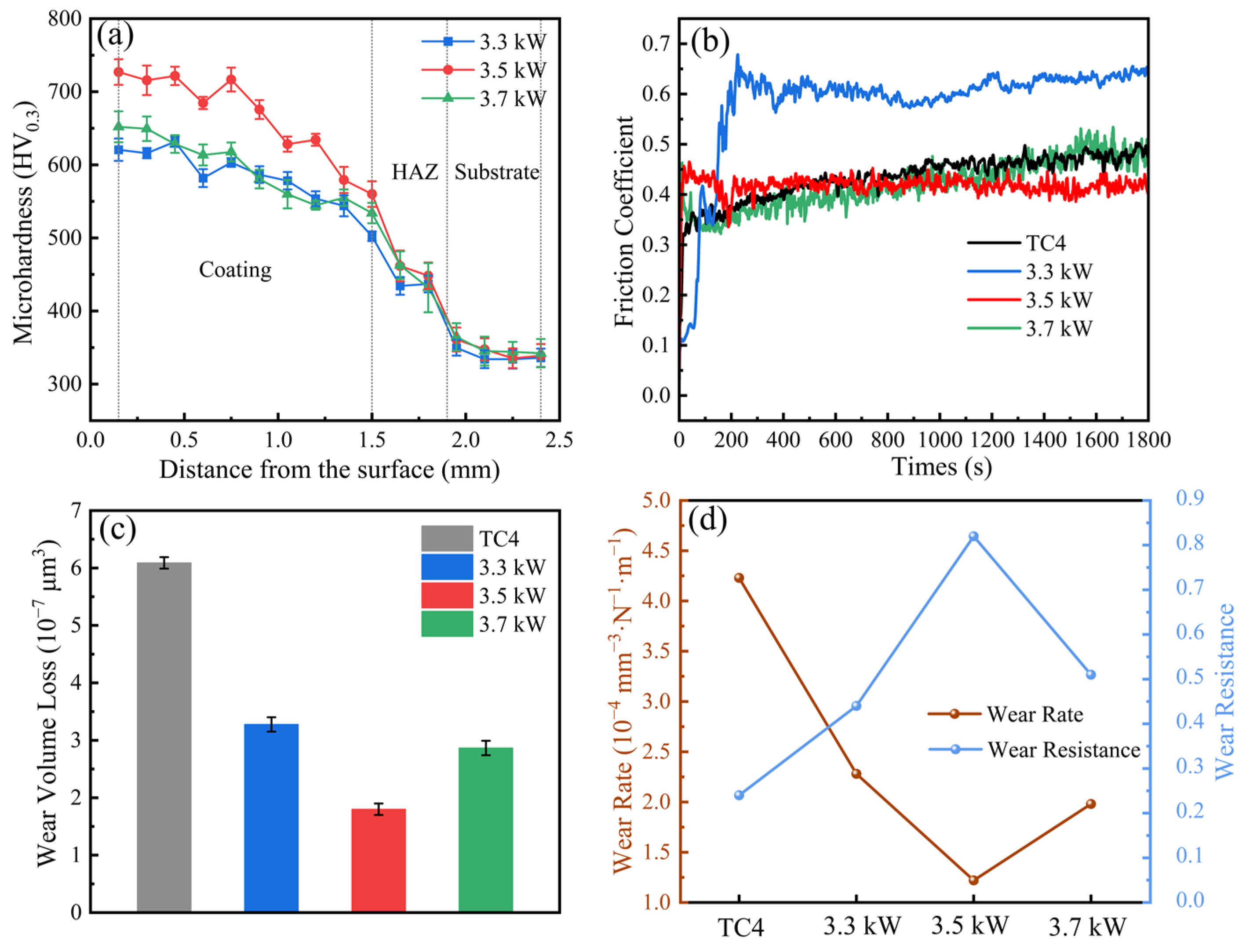

3.3. Microhardness and Wear of Coating

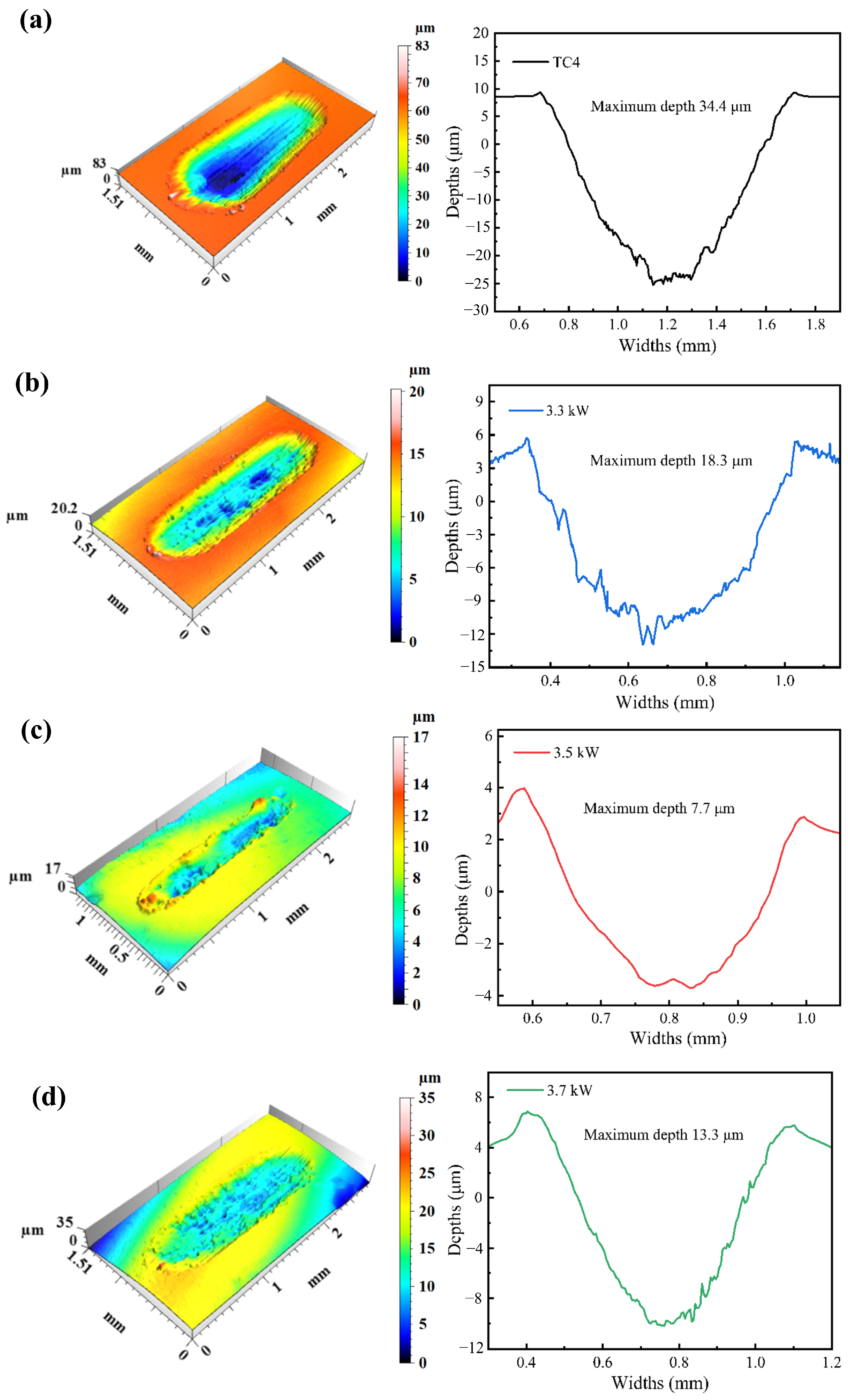

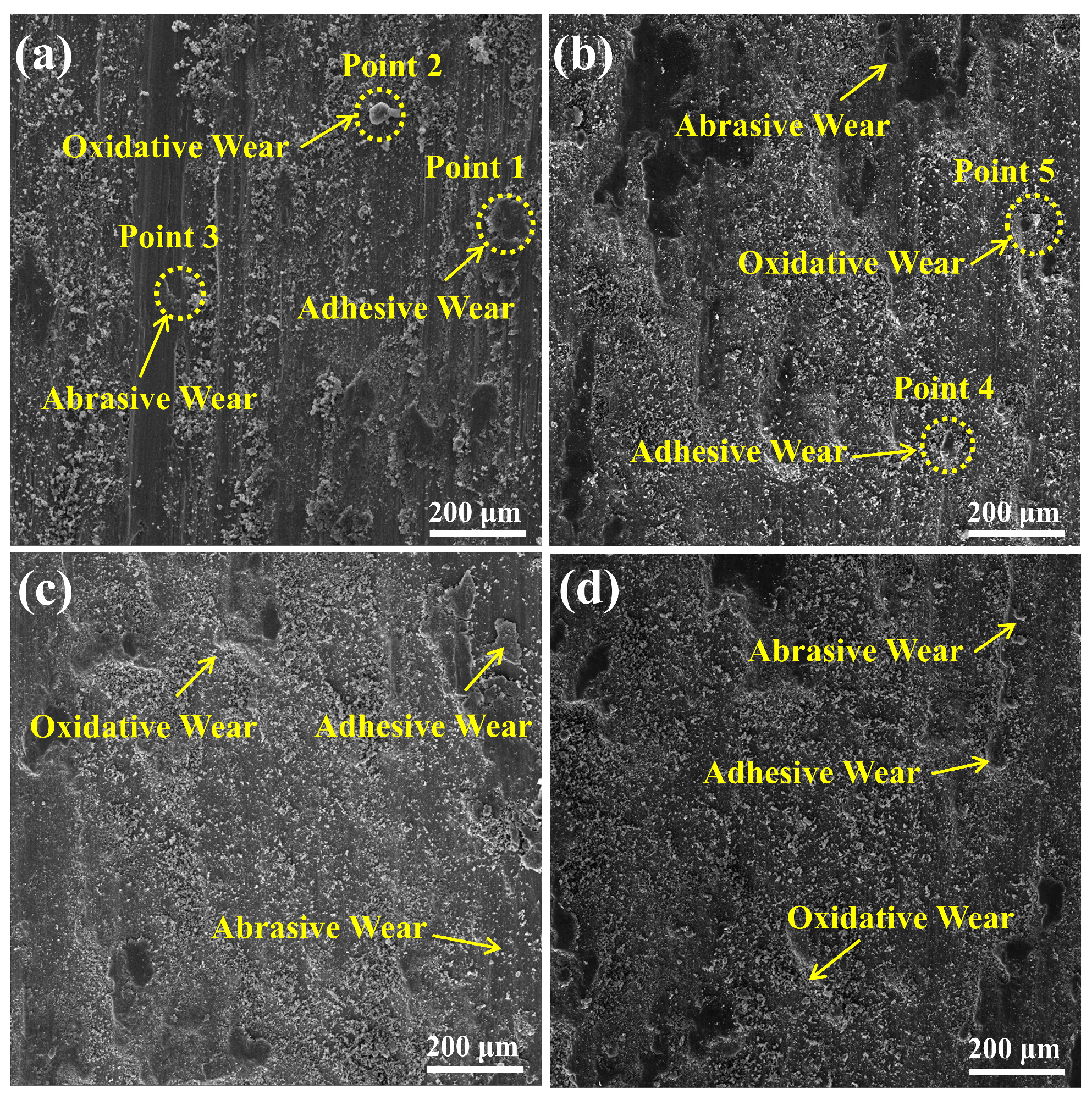

3.4. Wear Mechanisms

4. Conclusions

- The parameter settings of binder, radiofrequency power, and sheath gas are very important when preparing WNbMoTaV RHEA spherical alloy powder. Through the optimization of process parameters, the granulated powder showed high homogeneity; the binder system effectively ensured the integrity of the particles, and the alloy powder had excellent sphericity without any fragmentation or oxidation; the particle size distribution of the alloy powder was 15–45 μm, and the alloy showed a single BCC solid solution structure.

- For the prepared WNbMoTaV RHEA coatings, the macroscopic organization of the coatings showed no obvious defects. The percentage of unfused alloy powder coated with laser powers of 3.3 kW, 3.5 kW, and 3.7 kW was 19.3%, 11.2%, and 7.8%, respectively, and the dilution rates were 22.04%, 26.90%, and 32.27%, respectively. The coating is mainly composed of BCC phase and a Ti-rich phase. At a laser power of 3.7 kW, more Ti-rich phases are generated in the coating, and the crystallinity of the coating increases with the increase in laser power. The grain sizes of the coatings with laser powers of 3.3 kW, 3.5 kW, and 3.7 kW are 21.55 nm, 16.48 nm, and 16.17 nm, respectively. Higher laser power results in smaller grain sizes.

- The hardness of the coatings with 3.3 kW, 3.5 kW, and 3.7 kW was 1.72, 1.97, and 1.76 times higher than that of the substrate, respectively. In addition, the abrasion resistance of the coatings with laser powers of 3.3 kW, 3.5 kW, and 3.7 kW was 1.83, 3.42, and 2.13 times higher than that of the TC4 substrate, respectively. The main mechanisms of coating wear are oxidative wear, minor abrasive wear, and adhesive wear. The coating with the highest hardness and wear resistance is the 3.5 kW coating. Precise control of the laser power inhibits plastic deformation of the coating, thus increasing the wear resistance of the coating. This has a positive effect on the future application of TC4 titanium alloys in various wear parts in the field of precision military and aerospace.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Li, Y.; Zhou, Z.; He, Y. Tribocorrosion and Surface Protection Technology of Titanium Alloys: A Review. Materials 2024, 17, 65. [Google Scholar] [CrossRef] [PubMed]

- Luo, H.; Li, J.b.; Ye, J.L.; Tan, J.; Rashad, M.; Chen, X.H.; Han, S.L.; Zheng, K.H.; Zhao, T.T.; Pan, F.S. Effect of Ti-6Al-4V particle reinforcements on mechanical properties of Mg-9Al-1Zn alloy. Trans. Nonferrous Met. Soc. China 2022, 32, 3238–3249. [Google Scholar] [CrossRef]

- Shi, Z.M.; Pang, M. Study on the performance of laser nitriding in situ enhanced Co12/TC4 composite Ag self-lubricating coating on TC4 surface. J. Mater. Sci. 2023, 58, 18207–18227. [Google Scholar] [CrossRef]

- Liu, K.; Yan, H.; Zhang, P.; Zhao, J.; Yu, Z.; Lu, Q. Wear Behaviors of TiN/WS2 + hBN/NiCrBSi Self-Lubricating Composite Coatings on TC4 Alloy by Laser Cladding. Coatings 2020, 10, 747. [Google Scholar] [CrossRef]

- Gangwar, K.; Ramulu, M. Friction stir welding of titanium alloys: A review. Mater. Des. 2018, 141, 230–255. [Google Scholar] [CrossRef]

- Jin, L.; Li, P.; Zhou, H.; Zhang, W.; Zhou, G.; Wang, C. Improving thermal insulation of TC4 using YSZ-based coating and SiO2 aerogel. Prog. Nat. Sci. 2015, 25, 141–146. [Google Scholar] [CrossRef]

- Almonti, D.; Salvi, D.; Ucciardello, N.; Vesco, S. Enhanced Wear Resistance and Thermal Dissipation of Copper-Graphene Composite Coatings via Pulsed Electrodeposition for Circuit Breaker Applications. Materials 2024, 17, 6017. [Google Scholar] [CrossRef]

- Almonti, D.; Baiocco, G.; Millia, M.D.; Mingione, E.; Menna, E.; Rubino, G.; Salvi, D.; Stamopoulos, A.; Ucciardello, N. Morphological and functional characterization of electroplated Ni-graphene composite coatings. J. Phys. Conf. Ser. 2024, 2692, 012008. [Google Scholar] [CrossRef]

- Peta, K.; Bartkowiak, T.; Rybicki, M.; Galek, P.; Mendak, M.; Wieczorowski, M.; Brown, C.A. Scale-dependent wetting behavior of bioinspired lubricants on electrical discharge machined Ti6Al4V surfaces. Tribol. Int. 2024, 194, 109562. [Google Scholar] [CrossRef]

- Atroshenko, S.A.; Valiev, R.Z.; Morozov, N.F.; Valiev, R.R.; Savina, Y.N.; Antonova, M.N.; Evstifeev, A.D. Wear and failure analysis of Ti-6Al-4V titanium alloy with a protective coating during high-speed erosion. Phys. Mesomech. 2024, 27, 387–397. [Google Scholar] [CrossRef]

- Lv, Y.H.; Li, J.; Tao, Y.F.; Hu, L.F. Oxidation behaviors of the TiNi/Ti2Ni matrix composite coatings with different contents of TaC addition fabricated on Ti6Al4V by laser cladding. J. Alloys Compd. 2016, 679, 202–212. [Google Scholar] [CrossRef]

- Li, W.; Liu, P.; Liaw, P.K. Microstructures and properties of high-entropy alloy films and coatings: A review. Mater. Res. Lett. 2018, 6, 199–229. [Google Scholar] [CrossRef]

- Weng, F.; Chen, C.; Yu, H. Research status of laser cladding on titanium and its alloys: A review. Mater. Des. 2014, 58, 412–425. [Google Scholar] [CrossRef]

- Candel, J.J.; Amigó, V.; Ramos, J.A. Sliding wear resistance of TiCp reinforced titaniumcomposite coating produced by laser cladding. Surf. Coat. Technol. 2010, 204, 3161–3166. [Google Scholar] [CrossRef]

- Yeh, J.W.; Chen, S.K.; Lin, S.J.; Gan, J.Y.; Chin, T.S.; Shun, T.T.; Tsau, C.H.; Chang, S.Y. Nanostructured high-entropy alloys with multiple principal elements: Novel alloy design concepts and outcomes. Adv. Eng. Mater. 2004, 6, 299–303. [Google Scholar] [CrossRef]

- Cui, K.; Zhang, Y. High-entropy alloy films. Coatings 2023, 13, 635. [Google Scholar] [CrossRef]

- Wang, Y.; Yang, Y.; Yang, H. Microstructure and wear properties of nitrided AlCoCrFeNi high-entropy alloy. Mater. Chem. Phys. 2018, 210, 233–239. [Google Scholar] [CrossRef]

- Li, J.H.; Tsai, M.H. Theories for predicting simple solid solution high-entropy alloys: Classification, accuracy, and important factors impacting accuracy. Scr. Mater. 2020, 188, 80–87. [Google Scholar] [CrossRef]

- Xie, X.; Li, N.; Liu, W. Research progress of refractory high entropy alloys: A review. Chin. J. Mech. Eng. 2022, 35, 142. [Google Scholar] [CrossRef]

- Zhang, B.; Huang, Y.; Dou, Z.; Wang, J.; Huang, Z. Refractory high-entropy alloys fabricated by powder metallurgy: Progress, challenges and opportunities. J. Sci. 2024, 9, 100688. [Google Scholar] [CrossRef]

- Miracle, D.B.; Senkov, O.N. A critical review of high entropy alloys and related concepts. Acta Mater. 2017, 122, 448–511. [Google Scholar] [CrossRef]

- Jiang, L.; Hu, Y.J.; Sun, K. Irradiation-induced extremes create hierarchical face-/body-centered-cubic phases in nanostructured high entropy alloys. Adv. Mater. 2020, 32, 2002652. [Google Scholar] [CrossRef] [PubMed]

- Ren, Z.Y.; Hu, Y.L.; Tong, Y. Wear-resistant NbMoTaWTi high entropy alloy coating prepared by laser cladding on TC4 titanium alloy. Tribol. Int. 2023, 182, 108366. [Google Scholar] [CrossRef]

- Hao, X.; Liu, H.; Zhang, X.; Tao, J.; Wang, Y.; Yang, C.; Liu, Y. Microstructure and wear resistance of in-situ TiN/(Nb, Ti)5Si3 reinforced MoNbTaWTi-based refractory high entropy alloy composite coatings by laser cladding. Appl. Surf. Sci. 2023, 626, 157240. [Google Scholar] [CrossRef]

- Senkov, O.N.; Wilks, G.B.; Scott, J.M.; Miracle, D.B. Mechanical properties of Nb25Mo25Ta25W25 and V20Nb20Mo20Ta20W20 refractory high entropy alloys. Intermetallics 2011, 19, 698–706. [Google Scholar] [CrossRef]

- Liu, B.; Duan, H.; Li, L. Microstructure and mechanical properties of ultra-hard spherical refractory high-entropy alloy powders fabricated by plasma spheroidization. Powder Technol. 2021, 382, 550–555. [Google Scholar] [CrossRef]

- Na, T.W.; Park, K.B.; Lee, S.Y. Preparation of spherical TaNbHfZrTi high-entropy alloy powders by a hydrogenation-dehydrogenation reaction and thermal plasma treatment. J. Alloys Compd. 2020, 817, 152757. [Google Scholar] [CrossRef]

- Xia, M.; Chen, Y.; Chen, K. Synthesis of WTaMoNbZr refractory high-entropy alloy powder by plasma spheroidization process for additive manufacturing. J. Alloys Compd. 2022, 917, 165501. [Google Scholar] [CrossRef]

- Jiang, Y.Q.; Li, J.; Juan, Y.F. Evolution in microstructure and corrosion behavior of AlCoCrxFeNi high-entropy alloy coatings fabricated by laser cladding. J. Alloys Compd. 2019, 775, 1–14. [Google Scholar] [CrossRef]

- Lipson, H. Elements of X-ray diffraction. Contemp. Phys. 1979, 20, 87–88. [Google Scholar] [CrossRef]

- Shao, J.Z.; Li, J.; Song, R.; Bai, L.L.; Chen, J.L.; Qu, C.C. Microstructure and wear behaviors of TiB/TiC reinforced Ti2Ni/α(Ti) matrix coating produced by laser cladding. Rare Metals 2020, 39, 304–315. [Google Scholar] [CrossRef]

- Zhao, Y.; Ma, M.; Huang, C.; Lin, M.; Tu, J.; Wang, H.; Zhan, Z.; Liu, H.; Chang, X.; Duan, H.; et al. Microstructure, high temperature wear resistance and corrosion behaviour of NiCrCoNbMox high-entropy alloy coatings on 15CrMoG alloy by laser cladding. Mater. Today Commun. 2024, 39, 109186. [Google Scholar] [CrossRef]

- Wang, C.; Gao, Y.; Wang, R.; Wei, D.; Cai, M.; Fu, Y. Microstructure of laser-clad Ni60 cladding layers added with different amounts of rare-earth oxides on 6063 Al alloys. J. Alloys Compd. 2018, 740, 1099–1107. [Google Scholar] [CrossRef]

- Archard, J.F. Contact and rubbing of flat surfaces. J. Appl. Phys. 1953, 24, 981–988. [Google Scholar] [CrossRef]

| Ta | W | Mo | Nb | V |

|---|---|---|---|---|

| 31.7 | 29.2 | 16.3 | 16.2 | 6.6 |

| Point | Mo | Nb | Ta | W | V | Ti |

|---|---|---|---|---|---|---|

| 1 | 9.8 | 19.6 | 29.7 | 29.2 | 4.2 | 7.5 |

| 2 | 13.2 | 14.4 | 25.6 | 26.2 | 6.0 | 14.6 |

| 3 | 8.0 | 11.4 | 17.3 | 8.6 | 5.2 | 49.4 |

| Point | Ti | O | Al | Si | N | W | Mo | Nb | Ta | V |

|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 28.5 | 50.5 | 2.5 | 12.6 | 4.8 | - | - | - | - | 1.1 |

| 2 | 60.8 | 31.2 | 5.5 | - | - | - | - | - | - | 2.5 |

| 3 | 87.0 | 6.2 | 4.8 | - | - | - | - | - | - | 2.0 |

| 4 | 3.7 | 28.4 | - | 5.2 | 12.2 | 15.3 | 7.9 | 7.2 | 17.4 | 2.7 |

| 5 | 2.1 | 52.6 | - | 4.3 | 1.6 | 12.2 | 5.9 | 5.7 | 14.8 | 0.8 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liang, J.; Liu, H.; Zhang, Q.; Zhou, L.; Peng, Y. Microstructure and Wear Behavior of WMoTaNbV Refractory High-Entropy Alloy Coating on Ti6Al4V Alloy Surface Prepared by Laser Cladding. Materials 2025, 18, 1770. https://doi.org/10.3390/ma18081770

Liang J, Liu H, Zhang Q, Zhou L, Peng Y. Microstructure and Wear Behavior of WMoTaNbV Refractory High-Entropy Alloy Coating on Ti6Al4V Alloy Surface Prepared by Laser Cladding. Materials. 2025; 18(8):1770. https://doi.org/10.3390/ma18081770

Chicago/Turabian StyleLiang, Jiazhu, Hongxi Liu, Qinghua Zhang, Ling Zhou, and Yuanrun Peng. 2025. "Microstructure and Wear Behavior of WMoTaNbV Refractory High-Entropy Alloy Coating on Ti6Al4V Alloy Surface Prepared by Laser Cladding" Materials 18, no. 8: 1770. https://doi.org/10.3390/ma18081770

APA StyleLiang, J., Liu, H., Zhang, Q., Zhou, L., & Peng, Y. (2025). Microstructure and Wear Behavior of WMoTaNbV Refractory High-Entropy Alloy Coating on Ti6Al4V Alloy Surface Prepared by Laser Cladding. Materials, 18(8), 1770. https://doi.org/10.3390/ma18081770