Optimization of L-PBF Process Parameters for Defect Reduction and Mechanical Strength of Ni-Cr-Mo-Nb Superalloy Using Multi-Objective Methods

Abstract

1. Introduction

2. Materials and Methods

2.1. Experimental Design and Sample Preparation

2.2. Microstructural Characterization and Mechanical Property Tests

2.3. Multi-Objective Optimization—Grey Correlation Analysis

3. Results

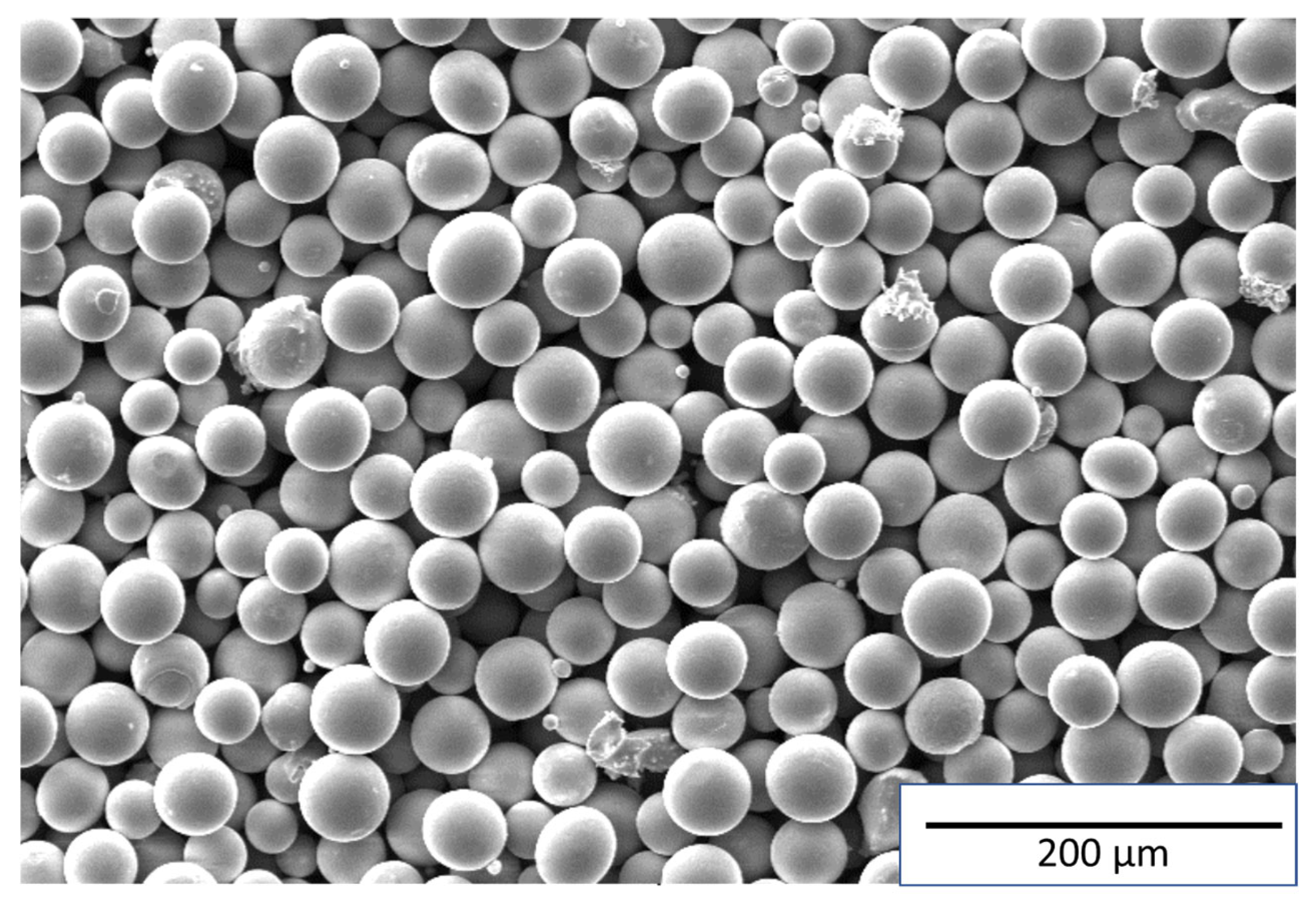

3.1. Powder Characterization and Chemical Analysis

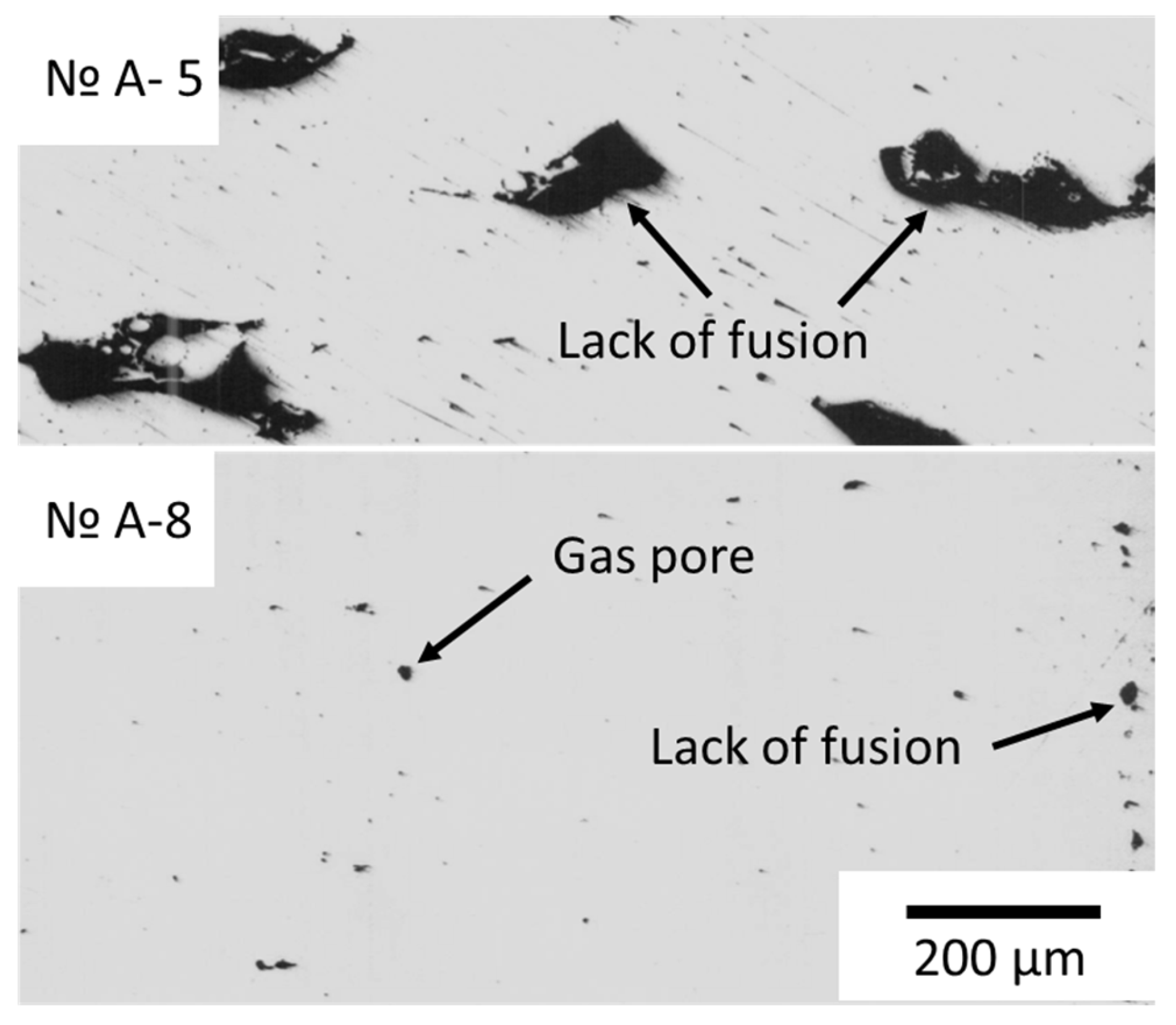

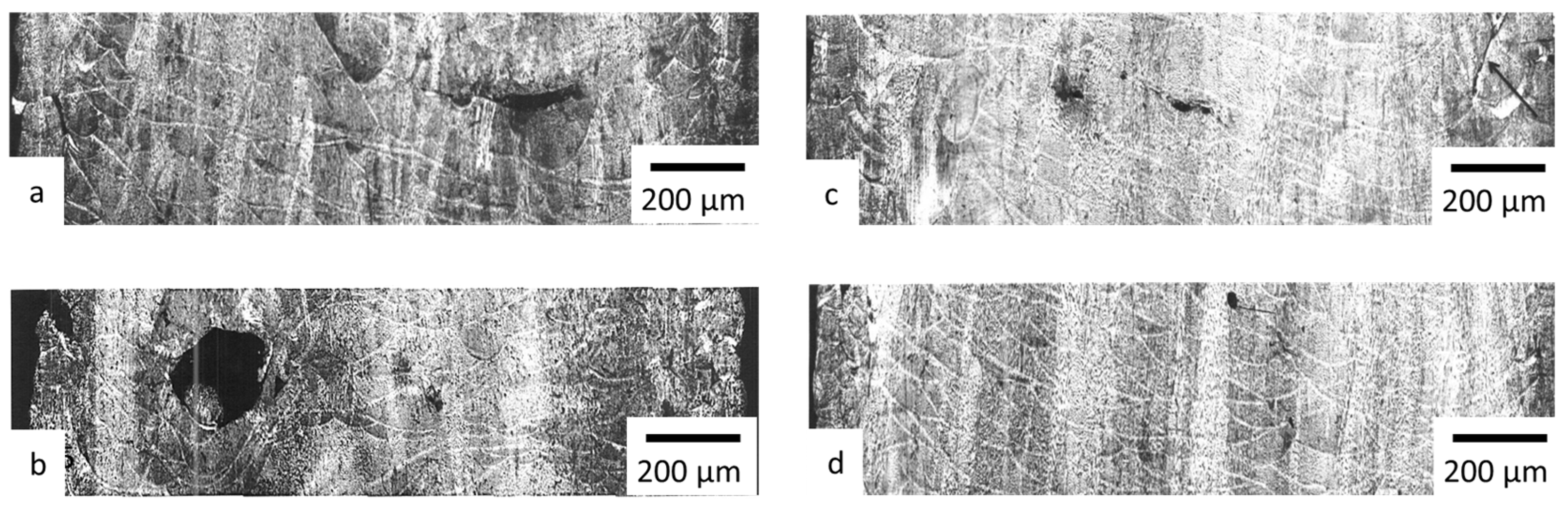

3.2. Microstructure and Mechanical Properties

3.3. Stage A: Optimization of L-PBF Parameters Using GRA

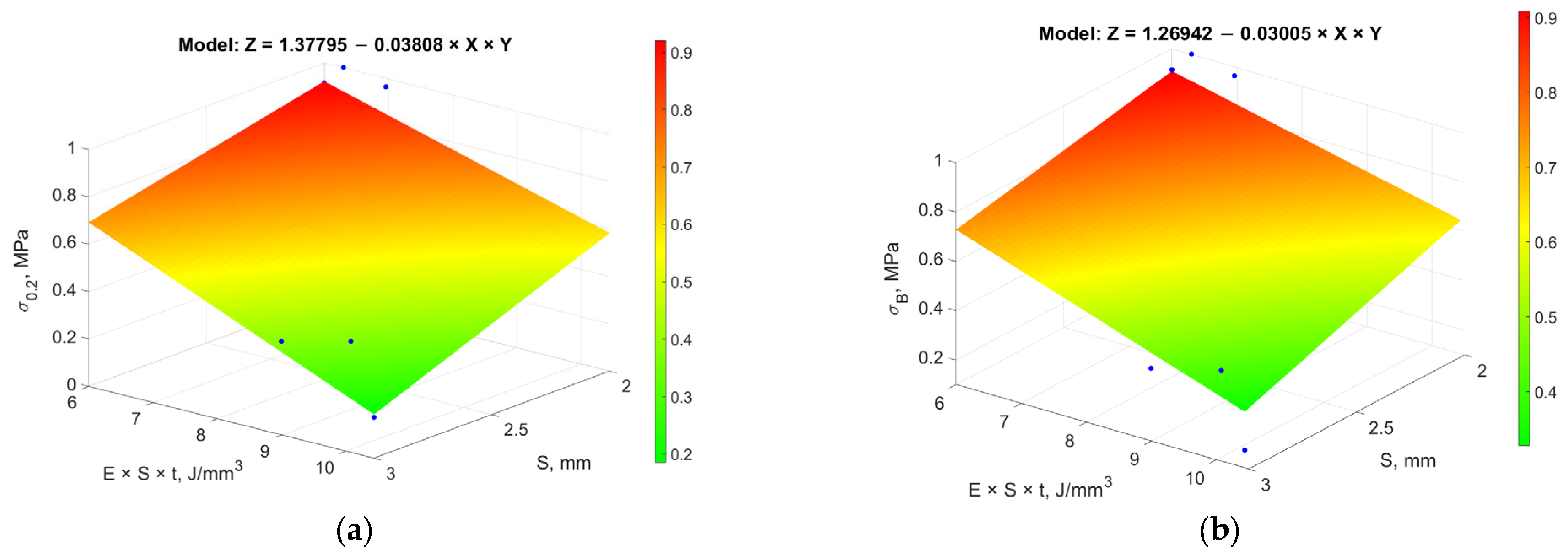

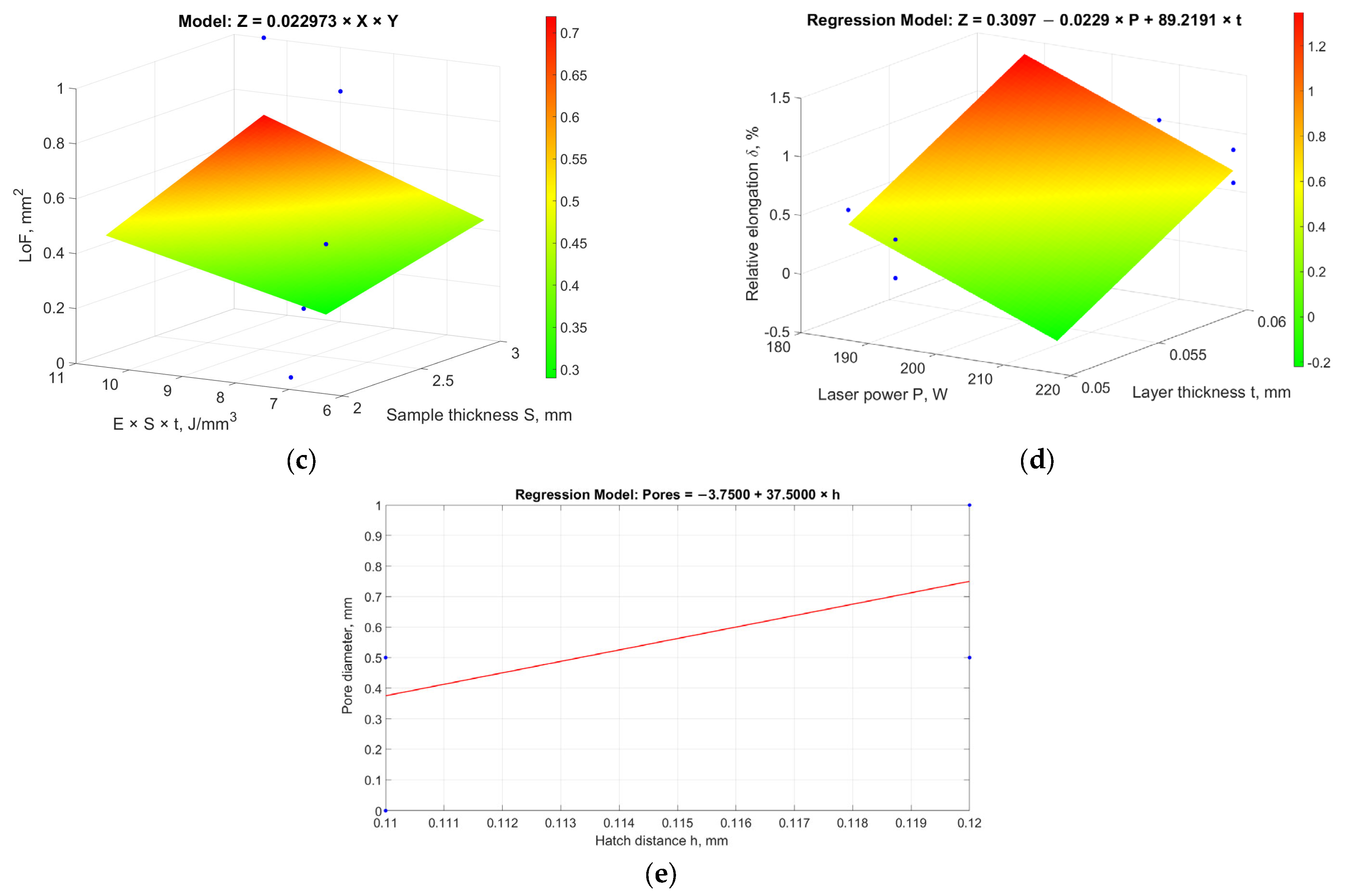

3.4. Stage B: Optimization of L-PBF Parameters Using RSM

- −

- σ0.2 = F1 (EV×S×t, S);

- −

- σB = F2 (EV×S×t, S);

- −

- δ = F3 (P, t);

- −

- LoF = F4 (EV×S×t, S);

- −

- d = F5 (h).

- P—laser power;

- —sample thickness normalized by scanning speed, characterizing the exposure time of the specimen to the melt front;

- —number of heat front passes within the layer, determining the heating non-uniformity in the layer perpendicular to the scanning speed.

- δ0—baseline elongation at break;

- —coefficients determining the influence of the reduced laser power P and layer thickness t.

- —baseline gas pore diameter;

- —coefficient determining the influence of hatch distance (h).

3.5. Stage C: Optimization of L-PBF Parameters Using the Gradient Ascent Method

- —significance coefficients for each quality characteristic;

- —normalized values of the corresponding quality indicators.

4. Discussion

5. Conclusions

- 1.

- Multi-Objective Optimization Using GRA (Stage A): Due to the complex and multi-parameter nature of interactions between process parameters and material characteristics, Grey Relational Analysis was applied. This approach allowed for the simultaneous optimization of characteristics with conflicting criteria (“larger is better” and “smaller is better”). The highest relational quality scores were achieved with parameter sets A-13 (0.776) and A-16 (0.730).

- 2.

- Development of Regression Models Using RSM (Stage B): Response Surface Methodology enabled the development of regression models describing the relationships between process parameters and material characteristics. Introducing the specific energy of layer fusion (EV×S×t) as a key factor significantly improved the models’ accuracy. The analysis showed that σ0.2 and σβ depend primarily on EV×S×t and sample thickness (S), while elongation at break (δ) is influenced by laser power (P) and layer thickness (t), and gas pore diameter depends on hatch distance (h).

- 3.

- Global Optimization Using the Gradient Ascent Method (Stage C): The Gradient Ascent Method was applied to identify the global optimum using a desirability function. The best results were obtained at the second ascent step (C-2), achieving a yield strength of 774.73 ± 4.94 MPa, tensile strength of 1022.83 ± 5.19 MPa, and elongation at break of 23.1 ±0.70%, with minimal LoF area (0.003 mm2) and gas pore diameter (0.02 mm). The subsequent steps led to a decrease in optimization performance, indicating that the global optimum was reached at C-2.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| Abbreviations: | |

| AM | Additive Manufacturing |

| L-PBF | Laser Powder Bed Fusion |

| SLM | Selective Laser Melting |

| DMLS | Direct Metal Laser Sintering |

| DoE | Design of Experiments |

| GRA | Grey Relational Analysis |

| RSM | Response Surface Methodology |

| HIP | Hot Isostatic Pressing |

| LIH | Liquid-Induced Healing |

| Symbols and Units: | |

| P (W) | Laser power |

| V (mm/s) | Scanning speed |

| h (mm) | Hatch distance |

| t (mm) | Layer thickness |

| EV (J/mm3) | Volume energy density |

| S (mm) | Sample thickness |

| σ0.2 (MPa) | Yield strength |

| σB (MPa) | Ultimate tensile strength |

| δ (%) | Elongation at break |

| LoF (mm2) | Lack of fusion area |

| Rank | Microstructure desirability rank |

| d (mm) | Gas pore diameter |

References

- Ghidini, T.; Grasso, M.; Gumpinger, J.; Makaya, A.; Colosimo, B.M. Additive manufacturing in the new space economy: Current achievements and future perspectives. Prog. Aerosp. Sci. 2023, 142, 100959. [Google Scholar] [CrossRef]

- Thryft, A.R. Space X Reveals 3D-Printed Rocket Engine Parts. Available online: https://www.designnews.com/3d-printing-software/spacex-reveals-3d-printed-rocket-engine-parts (accessed on 14 December 2024).

- Rocket Lab to Use Pre-Flown Additively Manufactured Rutherford Engine in Electron Rocket. Available online: https://www.metal-am.com/rocket-lab-to-use-pre-flown-additively-manufactured-rutherford-engine-in-electron-rocket/ (accessed on 14 December 2024).

- GE Aviation invests in EBM. Met. Powder Rep. 2019, 74, 272. [CrossRef]

- Rolls-Royce invests in AM. Met. Powder Rep. 2019, 74, 269. [CrossRef]

- Bihr, M.; Allaire, G.; Betbeder-Lauque, X.; Bogosel, B.; Bordeu, F.; Querois, J. Part and supports optimization in metal powder bed additive manufacturing using simplified process simulation. Comput. Methods Appl. Mech. Eng. 2022, 395, 114975. [Google Scholar] [CrossRef]

- Gasman, L. Additive aerospace considered as a business. In Additive Manufacturing for the Aerospace Industry; Elsevier: Amsterdam, The Netherlands, 2019; pp. 327–340. [Google Scholar] [CrossRef]

- Marques, A.; Cunha, Â.; Silva, M.R.; Osendi, M.I.; Silva, F.S.; Carvalho, Ó.; Bartolomeu, F. Inconel 718 produced by laser powder bed fusion: An overview of the influence of processing parameters on microstructural and mechanical properties. Int. J. Adv. Manuf. Technol. 2022, 121, 5651–5675. [Google Scholar] [CrossRef]

- Mazur, M.; Selvakannan, P.R. Laser Powder Bed Fusion—Principles, Challenges, and Opportunities. In Additive Manufacturing for Chemical Sciences and Engineering; Springer Nature: Singapore, 2022; pp. 77–108. [Google Scholar] [CrossRef]

- Wang, D.; Yang, Y.; Liu, Y.; Bai, Y.; Tan, C. Factors Affecting the Manufacturing Quality of Laser Powder Bed Fusion. In Laser Powder Bed Fusion of Additive Manufacturing Technology; Additive Manufacturing Technology; Springer: Singapore, 2024; pp. 35–58. [Google Scholar] [CrossRef]

- Gatto, A.; Gatto, M.L.; Groppo, R.; Munteanu, D.; Mengucci, P. Influence of laser powder bed fusion process parameters on the properties of CuZn42 components: Case study of the laser surface energy density. Prog. Addit. Manuf. 2023, 8, 843–855. [Google Scholar] [CrossRef]

- Buhairi, M.A.; Foudzi, F.M.; Jamhari, F.I.; Sulong, A.B.; Radzuan, N.A.M.; Muhamad, N.; Mohamed, I.F.; Azman, A.H.; Harun, W.S.W.; Al-Furjan, M.S.H. Review on volumetric energy density: Influence on morphology and mechanical properties of Ti6Al4V manufactured via laser powder bed fusion. Prog. Addit. Manuf. 2023, 8, 265–283. [Google Scholar] [CrossRef]

- Kan, W.H.; Chiu, L.N.S.; Lim, C.V.S.; Zhu, Y.; Tian, Y.; Jiang, D.; Huang, A. A critical review on the effects of process-induced porosity on the mechanical properties of alloys fabricated by laser powder bed fusion. J. Mater. Sci. 2022, 57, 9818–9865. [Google Scholar] [CrossRef]

- Templeton, W.F.; Hinnebusch, S.; Strayer, S.T.; To, A.C.; Pistorius, P.C.; Narra, S.P. A mechanistic explanation of shrinkage porosity in laser powder bed fusion additive manufacturing. Acta Mater. 2024, 266, 119632. [Google Scholar] [CrossRef]

- Cao, S.; Zou, Y.; Lim, C.V.S.; Wu, X. Review of laser powder bed fusion (LPBF) fabricated Ti-6Al-4V: Process, post-process treatment, microstructure, and property. Light Adv. Manuf. 2021, 2, 1. [Google Scholar] [CrossRef]

- Kan, W.H.; Gao, M.; Zhang, X.; Liang, E.; Chiu, N.S.L.; Lim, C.V.S.; Huang, A. The influence of porosity on Ti-6Al-4V parts fabricated by laser powder bed fusion in the pursuit of process efficiency. Int. J. Adv. Manuf. Technol. 2022, 119, 5417–5438. [Google Scholar] [CrossRef]

- Koutiri, I.; Pessard, E.; Peyre, P.; Amlou, O.; De Terris, T. Influence of SLM process parameters on the surface finish, porosity rate and fatigue behavior of as-built Inconel 625 parts. J. Mater. Process. Technol. 2018, 255, 536–546. [Google Scholar] [CrossRef]

- Read, N.; Wang, W.; Essa, K.; Attallah, M.M. Selective laser melting of AlSi10Mg alloy: Process optimisation and mechanical properties development. Mater. Des. 2015, 65, 417–424. [Google Scholar] [CrossRef]

- Ahmed, N.; Barsoum, I.; Haidemenopoulos, G.; Al-Rub, R.K.A. Process parameter selection and optimization of laser powder bed fusion for 316L stainless steel: A review. J. Manuf. Process. 2022, 75, 415–434. [Google Scholar] [CrossRef]

- Giorgetti, A.; Baldi, N.; Palladino, M.; Ceccanti, F.; Arcidiacono, G.; Citti, P. A Method to Optimize Parameters Development in L-PBF Based on Single and Multitracks Analysis: A Case Study on Inconel 718 Alloy. Metals 2023, 13, 306. [Google Scholar] [CrossRef]

- Wen, S.; Wang, C.; Zhou, Y.; Duan, L.; Wei, Q.; Yang, S.; Shi, Y. High-density tungsten fabricated by selective laser melting: Densification, microstructure, mechanical and thermal performance. Opt. Laser Technol. 2019, 116, 128–138. [Google Scholar] [CrossRef]

- Nahr, F.; Rasch, M.; Burkhardt, C.; Renner, J.; Baumgärtner, B.; Hausotte, T.; Körner, C.; Steinmann, P.; Mergheim, J.; Schmidt, M.; et al. Geometrical influence on material properties for Ti6Al4V parts in powder bed fusion. J. Manuf. Mater. Process. 2023, 7, 82. [Google Scholar] [CrossRef]

- Munk, J.; Breitbarth, E.; Siemer, T.; Pirch, N.; Häfner, C. Geometry effect on microstructure and mechanical properties in laser powder bed fusion of Ti-6Al-4V. Metals 2022, 12, 482. [Google Scholar] [CrossRef]

- Aarab, M.; Dorussen, B.J.A.; Poelsma, S.S.; Remmers, J.J.C. Development of optimal L-PBF process parameters using an accelerated discrete element simulation framework. Granul. Matter 2024, 26, 69. [Google Scholar] [CrossRef]

- Shina, S. DoE Error Handling, Significance, and Goal Setting. In Industrial Design of Experiments; Springer International Publishing: Cham, Switzerland, 2022; pp. 217–246. [Google Scholar] [CrossRef]

- Sohrabpoor, H.; Negi, S.; Shaiesteh, H.; Ahad, I.; Brabazon, D. Optimizing selective laser sintering process by grey relational analysis and soft computing techniques. Optik 2018, 174, 185–194. [Google Scholar] [CrossRef]

- Acherjee, B.; Kuar, A.S.; Mitra, S.; Misra, D. Application of grey-based Taguchi method for simultaneous optimization of multiple quality characteristics in laser transmission welding process of thermoplastics. Int. J. Adv. Manuf. Technol. 2011, 56, 995–1006. [Google Scholar] [CrossRef]

- Agapovichev, A.V.; Khaimovich, A.I.; Smelov, V.G.; Kokareva, V.V.; Zemlyakov, E.V.; Babkin, K.D.; Kovchik, A.Y. Multiresponse Optimization of Selective Laser Melting Parameters for the Ni-Cr-Al-Ti-Based Superalloy Using Gray Relational Analysis. Materials 2023, 16, 2088. [Google Scholar] [CrossRef] [PubMed]

- ASTM E8/E8M-13a; Standard Test Methods for Tension Testing of Metallic Materials. ASTM International: West Conshohocken, PA, USA, 2013.

- Kassym, K.; Perveen, A. Atomization processes of metal powders for 3D printing. Mater. Today Proc. 2020, 26, 1727–1733. [Google Scholar] [CrossRef]

- Chua, C.K.; Leong, K.F. 3D Printing and Additive Manufacturing, 4th ed.; World Scientific: Singapore, 2017. [Google Scholar] [CrossRef]

- Traore, S.; Schneider, M.; Koutiri, I.; Coste, F.; Fabbro, R.; Charpentier, C.; Lefebvre, P.; Peyre, P. Influence of gas atmosphere (Ar or He) on the laser powder bed fusion of a Ni-based alloy. J. Mater. Process. Technol. 2021, 288, 116851. [Google Scholar] [CrossRef]

- Gardiner, W.P.; Gettinby, G. Response Surface Methods. In Experimental Design Techniques in Statistical Practice; Elsevier: Amsterdam, The Netherlands, 1998; pp. 322–354. [Google Scholar] [CrossRef]

- Köhnen, P.; Létang, M.; Voshage, M.; Schleifenbaum, J.H.; Haase, C. Understanding the process-microstructure correlations for tailoring the mechanical properties of L-PBF produced austenitic advanced high strength steel. Addit. Manuf. 2019, 30, 100914. [Google Scholar] [CrossRef]

- Wang, Y.; Guo, W.; Xu, C.; Zhang, Y.; Ji, Q.; Feng, X.; Han, R.; Zhang, Y.; Wang, C.; Lu, B. Defects, microstructure, and properties in laser powder bed fusion IN718: Power density effects and feature maps. J. Manuf. Process. 2025, 135, 240–252. [Google Scholar] [CrossRef]

- Wang, Y.; Guo, W.; Li, H.; Xie, Y.; Shi, J.; Liang, Z.; Han, P.; Li, S.; Zhang, H. Nano-scale microstructural evolution and mechanical property enhancement mechanism during crack inhibition in nickel-based superalloys fabricated by laser powder bed fusion. Addit. Manuf. 2025, 100, 104685. [Google Scholar] [CrossRef]

- Hu, X.; Guo, C.; Huang, Y.; Xu, Z.; Shi, Z.; Zhou, F.; Li, G.; Zhou, Y.; Li, Y.; Li, Z.; et al. Liquid-induced healing of cracks in nickel-based superalloy fabricated by laser powder bed fusion. Acta Mater. 2024, 267, 119731. [Google Scholar] [CrossRef]

- Sotov, A.V.; Agapovichev, A.V.; Smelov, V.G.; Kokareva, V.V.; Dmitrieva, M.O.; Melnikov, A.A.; Golanov, S.P.; Anurov, Y.M. Investigation of the IN-738 superalloy microstructure and mechanical properties for the manufacturing of gas turbine engine nozzle guide vane by selective laser melting. Int. J. Adv. Manuf. Technol. 2020, 107, 2525–2535. [Google Scholar] [CrossRef]

| Experiment Number | P, W | EV, J/mm3 | V, mm/s | h, mm | t, mm | S, mm |

|---|---|---|---|---|---|---|

| A-1 | 148 | 56 | 480 | 0.11 | 0.05 | 3 |

| A-2 | 215 | 69 | 480 | 0.13 | 0.05 | 2 |

| A-3 | 306 | 76 | 480 | 0.14 | 0.06 | 2 |

| A-4 | 218 | 63 | 480 | 0.12 | 0.06 | 3 |

| A-5 | 262 | 56 | 600 | 0.13 | 0.06 | 3 |

| A-6 | 273 | 69 | 600 | 0.11 | 0.06 | 2 |

| A-7 | 274 | 76 | 600 | 0.12 | 0.05 | 2 |

| A-8 | 265 | 63 | 600 | 0.14 | 0.05 | 3 |

| A-9 | 259 | 56 | 660 | 0.14 | 0.05 | 2 |

| A-10 | 273 | 69 | 660 | 0.12 | 0.05 | 3 |

| A-11 | 331 | 76 | 660 | 0.11 | 0.06 | 3 |

| A-12 | 299 | 63 | 660 | 0.12 | 0.06 | 2 |

| A-13 | 218 | 56 | 540 | 0.12 | 0.06 | 2 |

| A-14 | 313 | 69 | 540 | 0.14 | 0.06 | 3 |

| A-15 | 267 | 76 | 540 | 0.13 | 0.05 | 3 |

| A-16 | 187 | 63 | 540 | 0.11 | 0.05 | 2 |

| Characteristic | Quantitative/Qualitative Characteristic | Desirability Rank “More Is Better” |

|---|---|---|

| Grain structure type | Elongated grains | 1–4 |

| Formation of “fish scale” structure (length-to-height ratio not exceeding 1.8) | 4–8 | |

| Lack of interlayer bonding | Significant areas of non-penetration observed | 1–2 |

| None | 9–10 | |

| Pores | More than 3 within 500 mm2 | 6–8 |

| Less than 3 within 500 mm2 | 8–10 |

| Spectrum | Ni | C | Si | Mn | S | P | Cr | Mo | Nb | Al | Fe | N | O |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| wt.% | Base | 0.041 | 0.73 | 0.24 | 0.005 | 0.004 | 27.1 | 7.2 | 3.1 | 1.53 | 1.95 | 0.2 | 0.017 |

| vol.% | Base | 0.143 | 2.469 | 0.262 | 0.019 | 0.017 | 29.7 | 5.52 | 2.85 | 4.465 | 1.95 | 1.261 | 0.094 |

| Experiment Number | Yield Stress σ0.2, MPa | Tensile Strength σβ, MPa | Relative Elongation δ, % | Rank | LoF, mm2 | d, mm |

|---|---|---|---|---|---|---|

| A-1 | 858.08 | 1015.97 | 21.1 | 8 | 0.0189 | 0.08 |

| A-2 | 719.81 | 1015.97 | 19.9 | 5 | 0.008 | 0.017 |

| A-3 | 775.71 | 1000.28 | 16.2 | 8 | 0.008 | 0.04 |

| A-4 | 710.00 | 991.45 | 24.3 | 5 | 0.015 | 0.05 |

| A-5 | 667.83 | 943.40 | 20.1 | 5 | 0.161 | 0.04 |

| A-6 | 768.84 | 1004.20 | 19.6 | 8 | 0.0024 | 0.04 |

| A-7 | 744.32 | 1005.18 | 21.2 | 1 | 0.006 | 0.03 |

| A-8 | 725.69 | 993.41 | 25.1 | 1 | 0.005 | 0.03 |

| A-9 | 755.11 | 1030.68 | 20.8 | 5 | 0.0024 | 0.025 |

| A-10 | 736.48 | 1004.20 | 23 | 5 | 0.0013 | 0.02 |

| A-11 | 716.87 | 978.70 | 22.5 | 1 | 0.002 | 0.03 |

| A-12 | 774.73 | 993.41 | 17.3 | 8 | 0.0015 | 0.02 |

| A-13 | 803.16 | 1034.60 | 15.9 | 10 | 0.0002 | 0.02 |

| A-14 | 719.81 | 961.05 | 19.6 | 1 | 0.0003 | 0.02 |

| A-15 | 738.44 | 1004.20 | 23.1 | 1 | 0.0024 | 0.02 |

| A-16 | 761.00 | 1060.10 | 19.85 | 7 | 0.001 | 0.03 |

| Process Parameters/ Material Characteristics | P, W | EV, J/mm3 | V, mm/c | h, mm | t, mm | S, mm | σ0.2, MPa | σΒ, MPa | δ, % | Rank | LoF, mm2 | d, mm |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| P, W | 1.00 | 0.58 | 0.54 | 0.35 | 0.44 | 0.15 | −0.58 | −0.45 | −0.06 | −0.44 | −0.05 | −0.50 |

| EV, J/mm3 | 0.58 | 1.00 | 0 | 0.02 | 0 | −0.17 | −0.16 | −0.23 | 0.12 | −0.50 | −0.37 | −0.30 |

| V, mm/c | 0.54 | 0 | 1.00 | −0.08 | −0.03 | −0.17 | −0.17 | −0.24 | 0.15 | −0.23 | 0.03 | −0.41 |

| h, mm | 0.35 | 0.02 | −0.08 | 1.00 | −0.06 | −0.22 | −0.29 | −0.35 | −0.02 | −0.33 | 0.11 | −0.35 |

| t, mm | 0.44 | 0 | −0.03 | −0.06 | 1.00 | 0.88 | −0.52 | −0.15 | −0.45 | 0.27 | 0.24 | 0.03 |

| S, mm | 0.15 | −0.17 | −0.17 | −0.22 | 0.88 | 1.00 | −0.46 | −0.15 | −0.43 | 0.40 | 0.25 | 0.42 |

| σ0.2, MPa | −0.58 | −0.16 | −0.17 | −0.29 | −0.52 | −0.46 | 1.00 | 0.59 | −0.18 | 0.44 | −0.56 | −0.05 |

| σΒ, MPa | −0.45 | −0.23 | −0.24 | −0.35 | −0.15 | −0.15 | 0.59 | 1.00 | −0.41 | 0.61 | −0.45 | 0.42 |

| δ, % | −0.06 | 0.12 | 0.15 | −0.02 | −0.45 | −0.43 | −0.18 | −0.41 | 1.00 | −0.67 | −0.02 | 0.14 |

| Rank | −0.44 | −0.50 | −0.23 | −0.33 | 0.27 | 0.40 | 0.44 | 0.61 | −0.67 | 1.00 | 0.03 | 0.28 |

| LoF, mm2 | −0.05 | −0.37 | 0.03 | 0.11 | 0.24 | 0.25 | −0.56 | −0.45 | −0.02 | 0.03 | 1.00 | 0.25 |

| d, mm | −0.50 | −0.30 | −0.41 | −0.35 | 0.03 | 0.42 | −0.05 | 0.42 | 0.14 | 0.28 | 0.25 | 1.00 |

| Experiment Number | P, W | EV, J/mm3 | V, mm/c | h, mm | t, mm | S, mm | EV×S×t, J/mm | σ0.2, MPa | σΒ, MPa | δ, % | LoF, mm2 | d, mm |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| B-1 | 218 | 56 | 540 | 0.12 | 0.06 | 2 | 6.72 | 727.65 | 1017.93 | 23.7 | 0.0156 | 0.03 |

| B-2 | 207 | 58 | 540 | 0.11 | 0.06 | 2 | 6.96 | 750.21 | 1007.14 | 22.9 | 0.007 | 0.03 |

| B-3 | 194 | 60 | 540 | 0.12 | 0.05 | 2 | 6.00 | 746.29 | 981.65 | 17.3 | 0.0055 | 0.03 |

| B-4 | 187 | 63 | 540 | 0.11 | 0.05 | 2 | 6.30 | 753.15 | 1014.01 | 16.5 | 0.0238 | 0.03 |

| B-5 | 218 | 56 | 540 | 0.12 | 0.06 | 3 | 10.08 | 710.98 | 987.53 | 21.3 | 0.0238 | 0.04 |

| B-6 | 207 | 58 | 540 | 0.11 | 0.06 | 3 | 10.44 | 687.45 | 935.55 | 25 | 0.039 | 0.02 |

| B-7 | 194 | 60 | 540 | 0.12 | 0.05 | 3 | 9.00 | 705.1 | 942.42 | 20.1 | 0.0336 | 0.04 |

| B-8 | 187 | 63 | 540 | 0.11 | 0.05 | 3 | 9.45 | 673.72 | 893.39 | 21.7 | 0.02 | 0.03 |

| Factors/ Experiment Response Characteristics | σ0.2, MPa | σΒ, MPa | δ, % | LoF, mm2 | d, mm |

|---|---|---|---|---|---|

| P, W | 0.03 | 0.43 | 0.64 | −0.02 | 0.06 |

| EV, J/mm3 | −0.06 | −0.41 | −0.60 | 0.04 | −0.10 |

| h, mm | 0.11 | 0.24 | −0.17 | −0.13 | 0.63 |

| t, mm | −0.01 | 0.35 | 0.78 | 0.03 | −0.21 |

| S, mm | −0.89 | −0.79 | 0.35 | 0.73 | 0.21 |

| EV×S×t, J/mm | −0.87 | −0.69 | 0.53 | 0.73 | 0.06 |

| σ0.2, MPa | 1.00 | 0.88 | −0.51 | −0.46 | 0.11 |

| σΒ, MPa | 0.88 | 1.00 | −0.22 | −0.62 | 0.07 |

| δ, % | −0.51 | −0.22 | 1.00 | 0.26 | −0.35 |

| LoF, mm2 | −0.62 | −0.46 | 0.26 | 1.00 | −0.05 |

| d, mm | 0.07 | 0.11 | −0.35 | −0.05 | 1.00 |

| 1 | 0.7 | 1 | 1 |

| Step | P, W | EV, J/mm3 | V, mm/c | h, mm | t, mm | S, mm | Δh | ΔP | σ0.2, MPa | σΒ, MPa | δ, % | LoF, mm2 | d, mm |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| C-1 | 218 | 56 | 540 | 0.12 | 0.06 | 2 | 0 | 0 | 737.46 | 1014.01 | 22.4 | 0.0112 | 0.03 |

| C-2 | 207 | 58 | 540 | 0.11 | 0.06 | 2 | −0.01 | −10 | 774.73 | 1022.83 | 23.1 | 0.003 | 0.02 |

| C-3 | 194 | 60 | 540 | 0.10 | 0.05 | 2 | −0.01 | −10 | 731.58 | 1010.08 | 23.4 | 0.0117 | 0.02 |

| C-4 | 187 | 63 | 540 | 0.09 | 0.05 | 3 | −0.01 | −10 | 730.60 | 991.45 | 23.1 | 0.014 | 0.03 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Agapovichev, A.V.; Khaimovich, A.I.; Smelov, V.G.; Kokareva, V.V.; Alekseev, V.P.; Zemlyakov, E.V.; Kovchik, A.Y. Optimization of L-PBF Process Parameters for Defect Reduction and Mechanical Strength of Ni-Cr-Mo-Nb Superalloy Using Multi-Objective Methods. Materials 2025, 18, 1743. https://doi.org/10.3390/ma18081743

Agapovichev AV, Khaimovich AI, Smelov VG, Kokareva VV, Alekseev VP, Zemlyakov EV, Kovchik AY. Optimization of L-PBF Process Parameters for Defect Reduction and Mechanical Strength of Ni-Cr-Mo-Nb Superalloy Using Multi-Objective Methods. Materials. 2025; 18(8):1743. https://doi.org/10.3390/ma18081743

Chicago/Turabian StyleAgapovichev, Anton V., Alexander I. Khaimovich, Vitaliy G. Smelov, Viktoriya V. Kokareva, Vyacheslav P. Alekseev, Evgeny V. Zemlyakov, and Anton Y. Kovchik. 2025. "Optimization of L-PBF Process Parameters for Defect Reduction and Mechanical Strength of Ni-Cr-Mo-Nb Superalloy Using Multi-Objective Methods" Materials 18, no. 8: 1743. https://doi.org/10.3390/ma18081743

APA StyleAgapovichev, A. V., Khaimovich, A. I., Smelov, V. G., Kokareva, V. V., Alekseev, V. P., Zemlyakov, E. V., & Kovchik, A. Y. (2025). Optimization of L-PBF Process Parameters for Defect Reduction and Mechanical Strength of Ni-Cr-Mo-Nb Superalloy Using Multi-Objective Methods. Materials, 18(8), 1743. https://doi.org/10.3390/ma18081743