Developing New Geomaterials: The Case of the Natural Rubber Latex Polymers in Soil Stabilization

Abstract

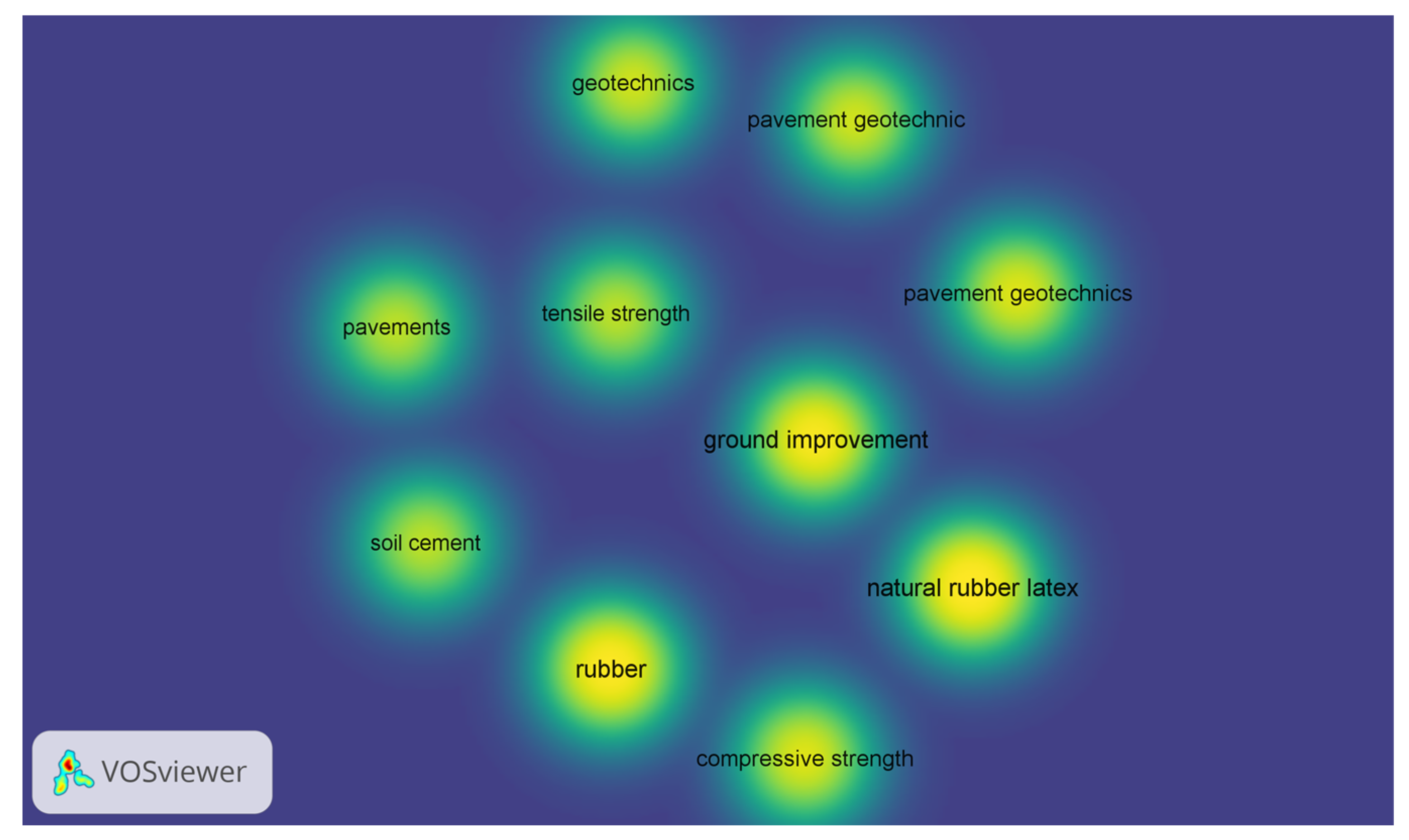

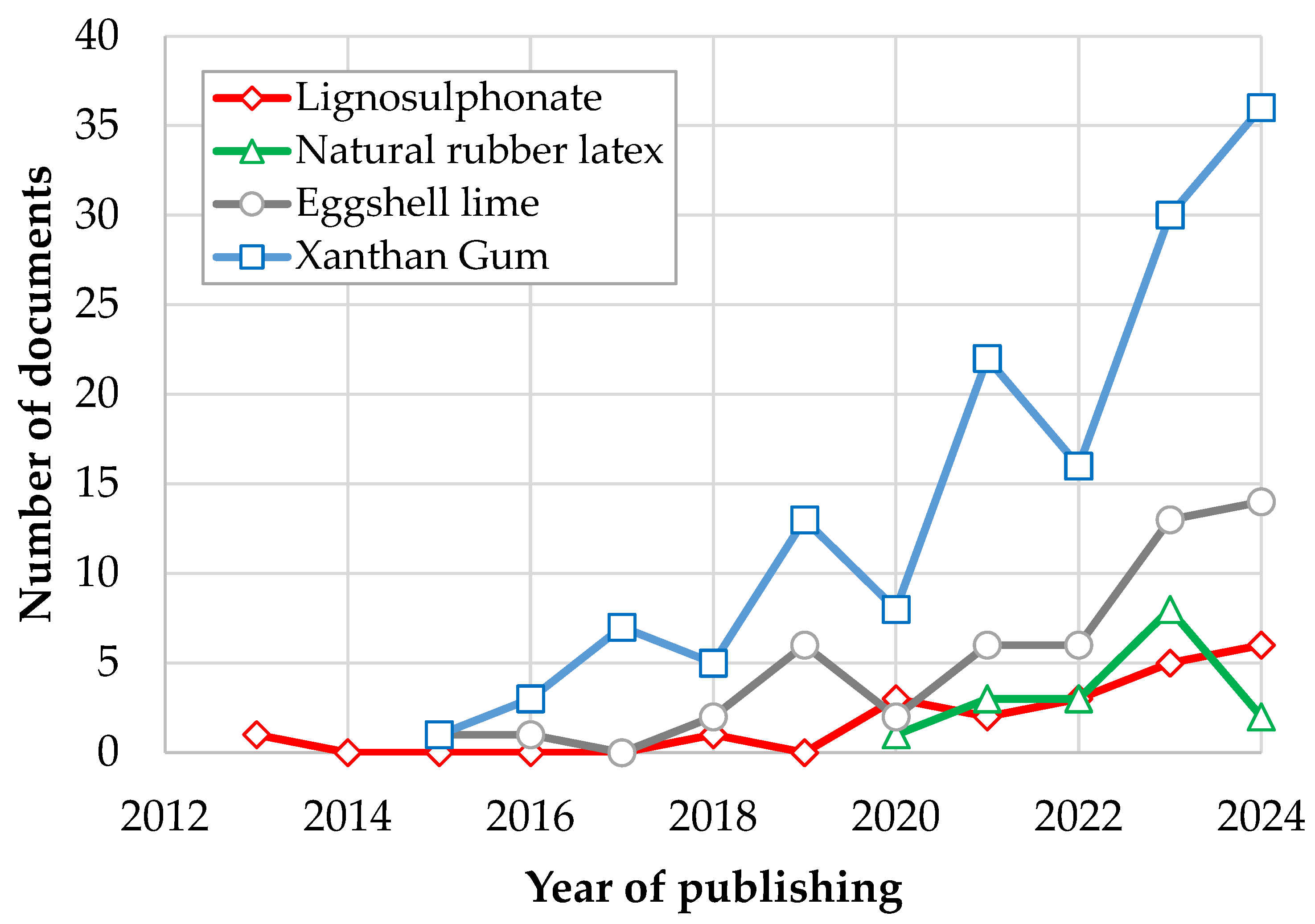

1. Introduction

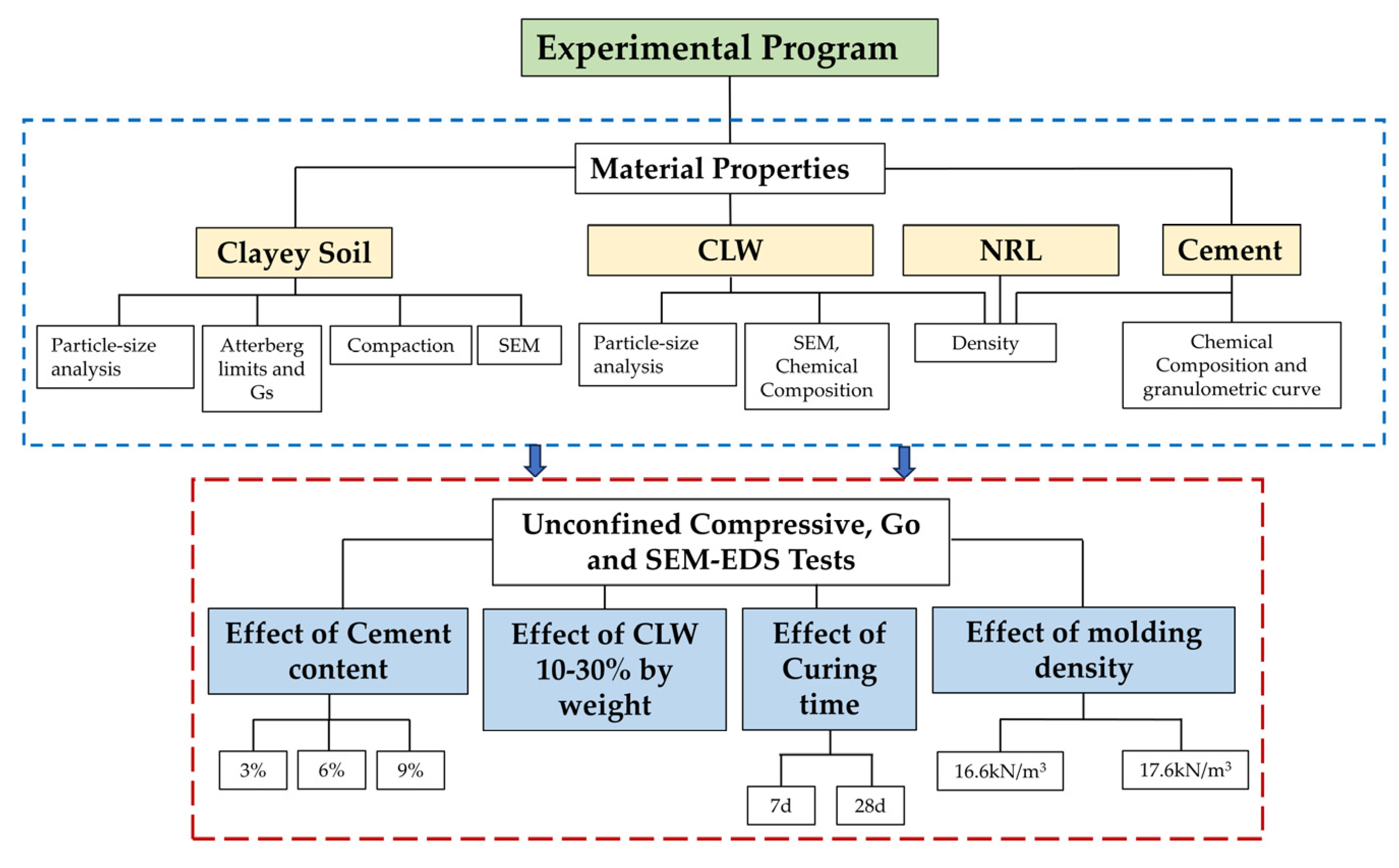

2. Materials and Methods

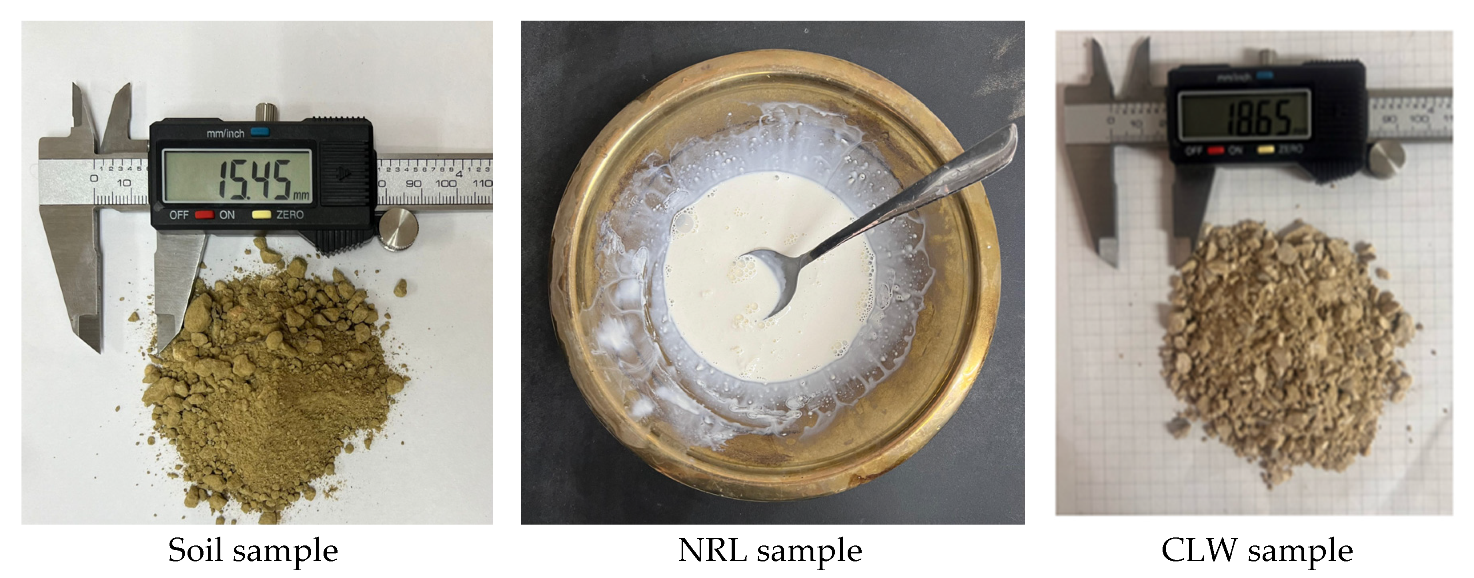

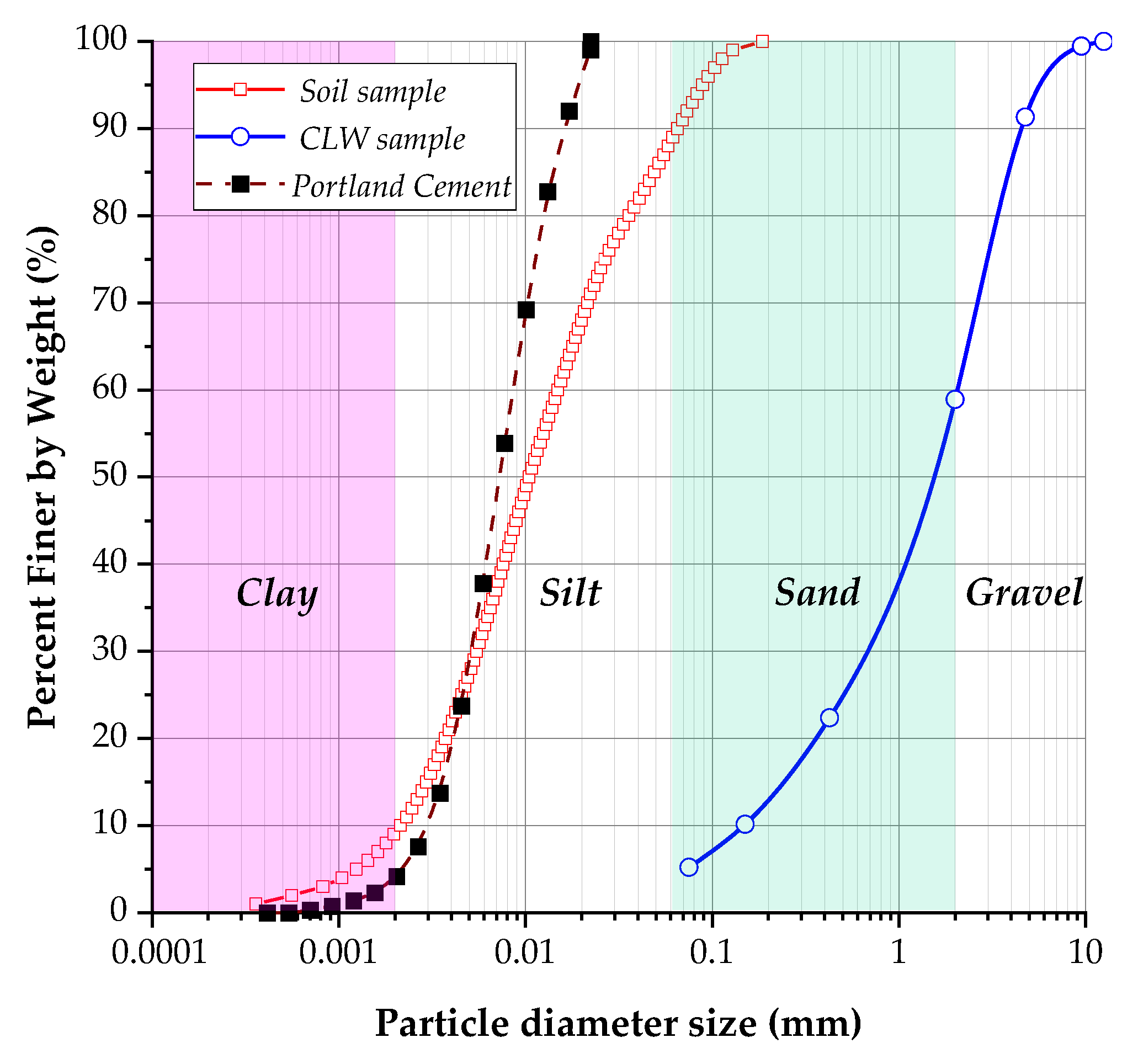

2.1. Materials

2.2. Methods

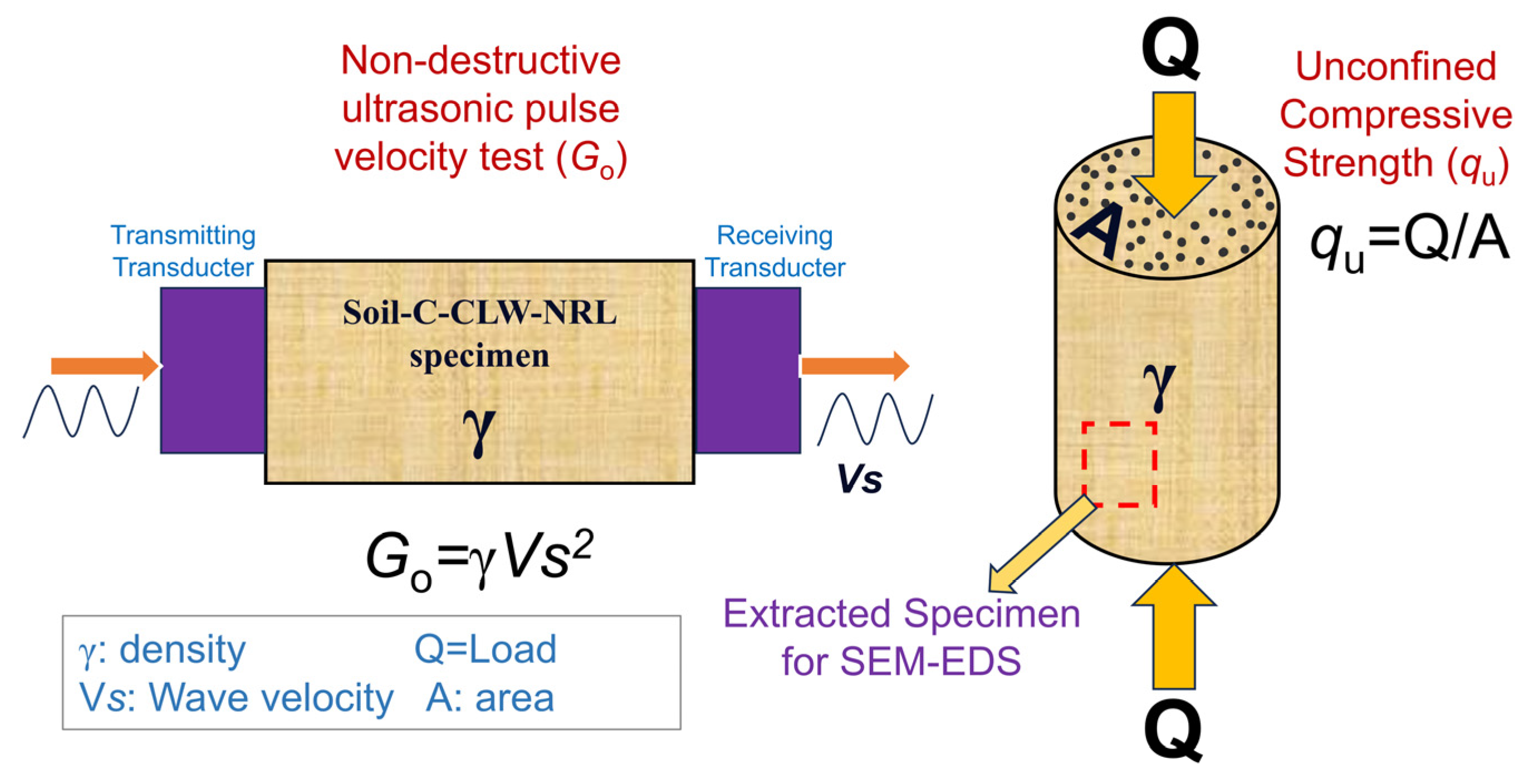

2.3. UCS and Stiffness (Non-Destructive) Program

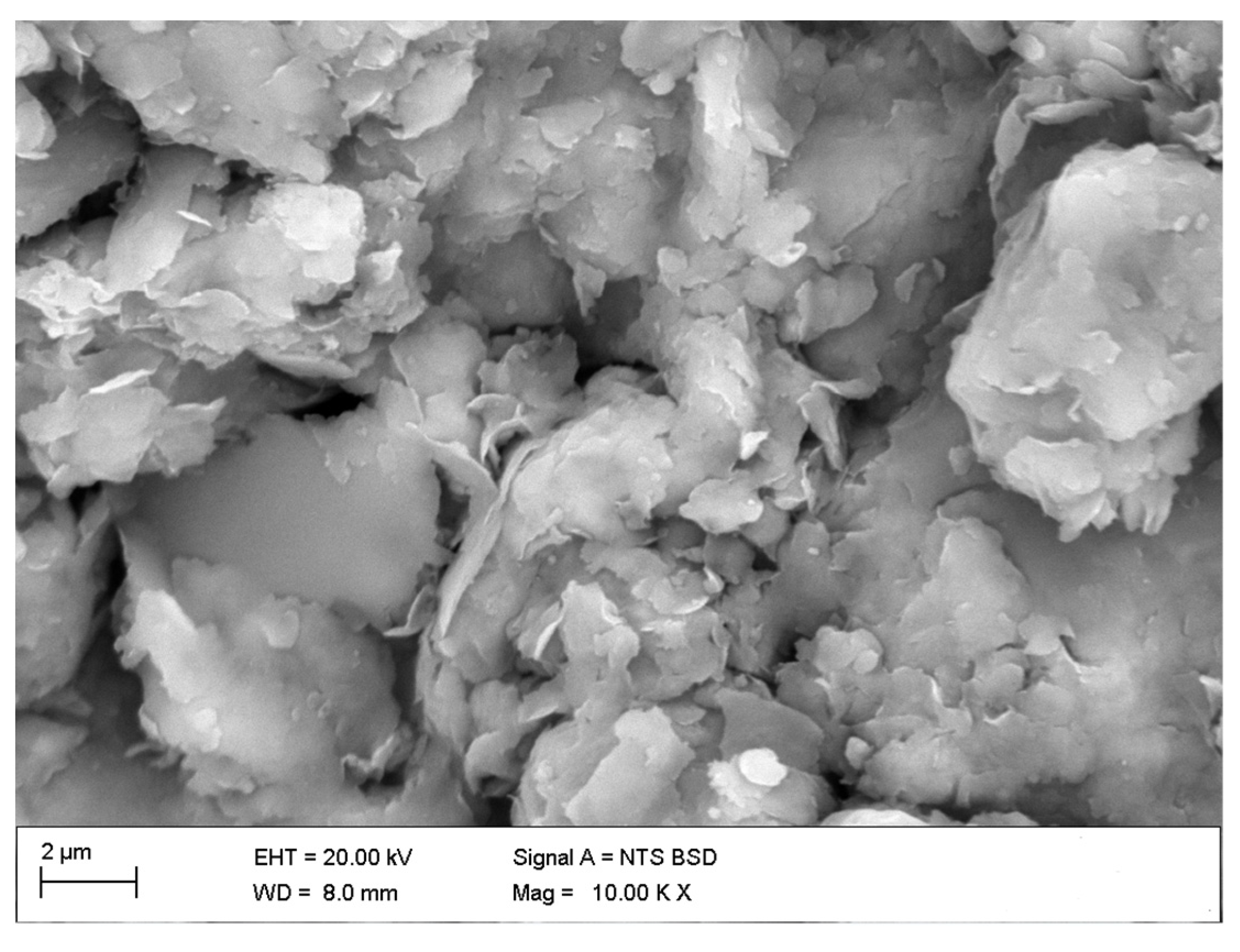

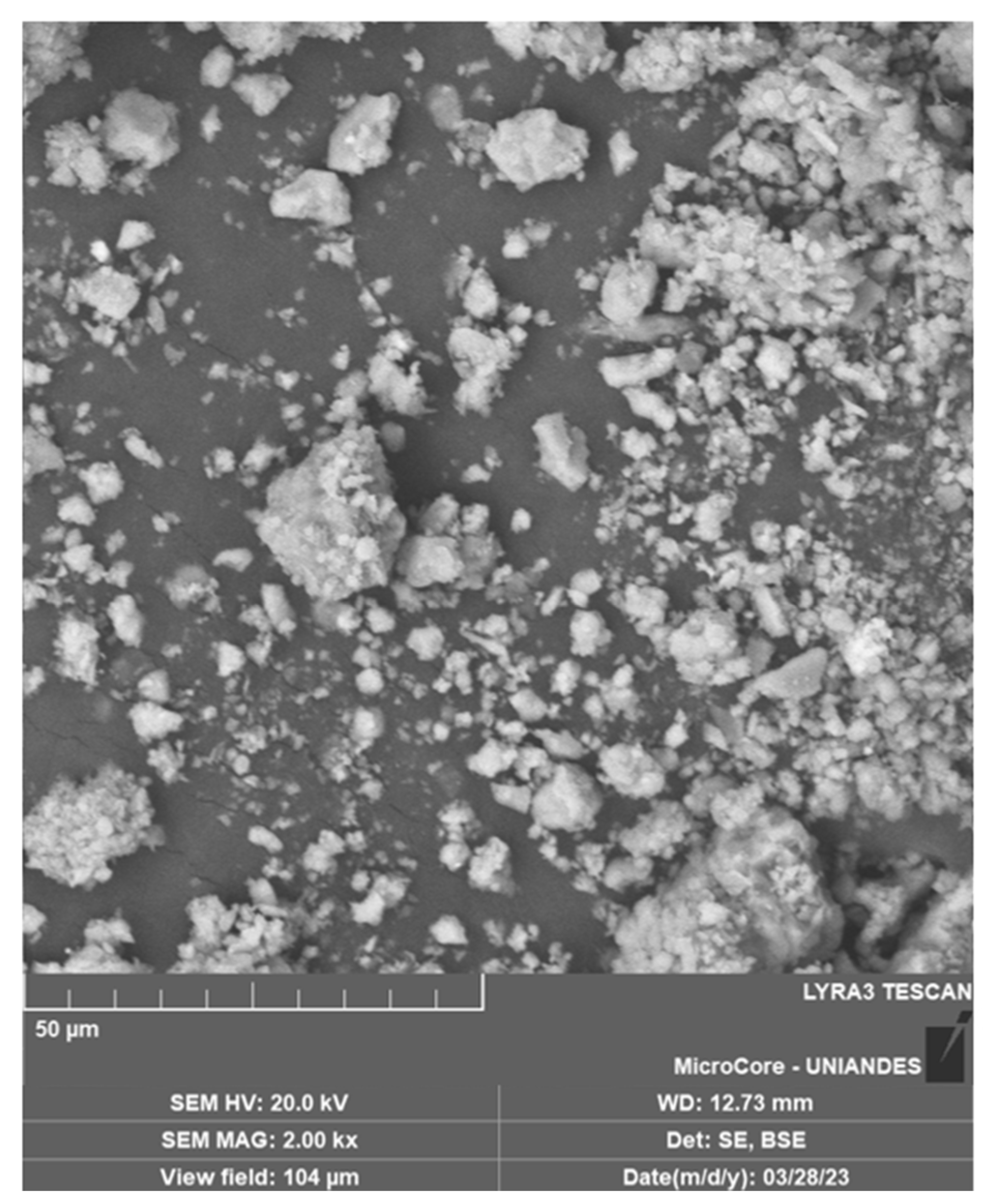

2.4. Microstructural Analysis

2.5. Statistical Analysis

3. Results and Discussions

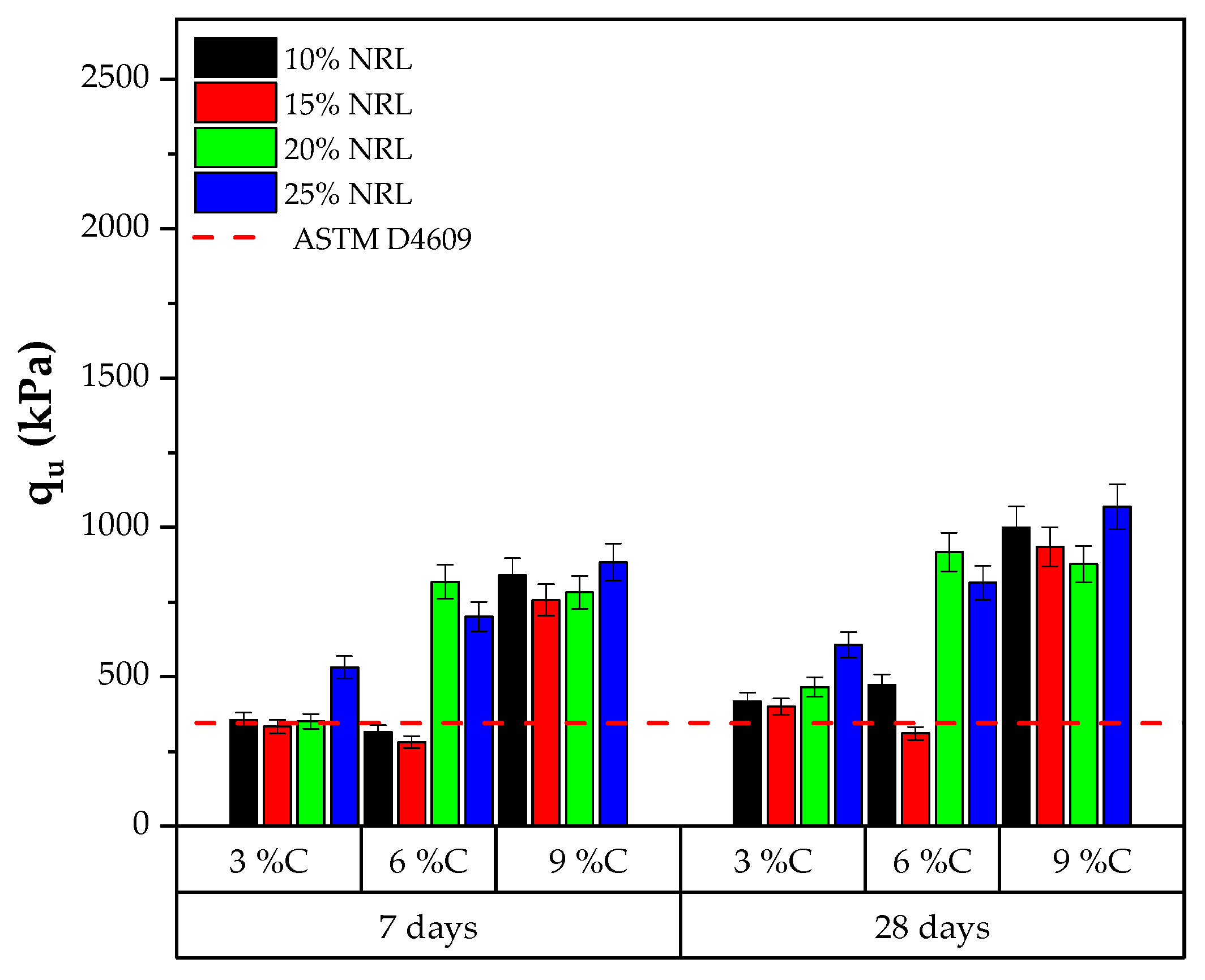

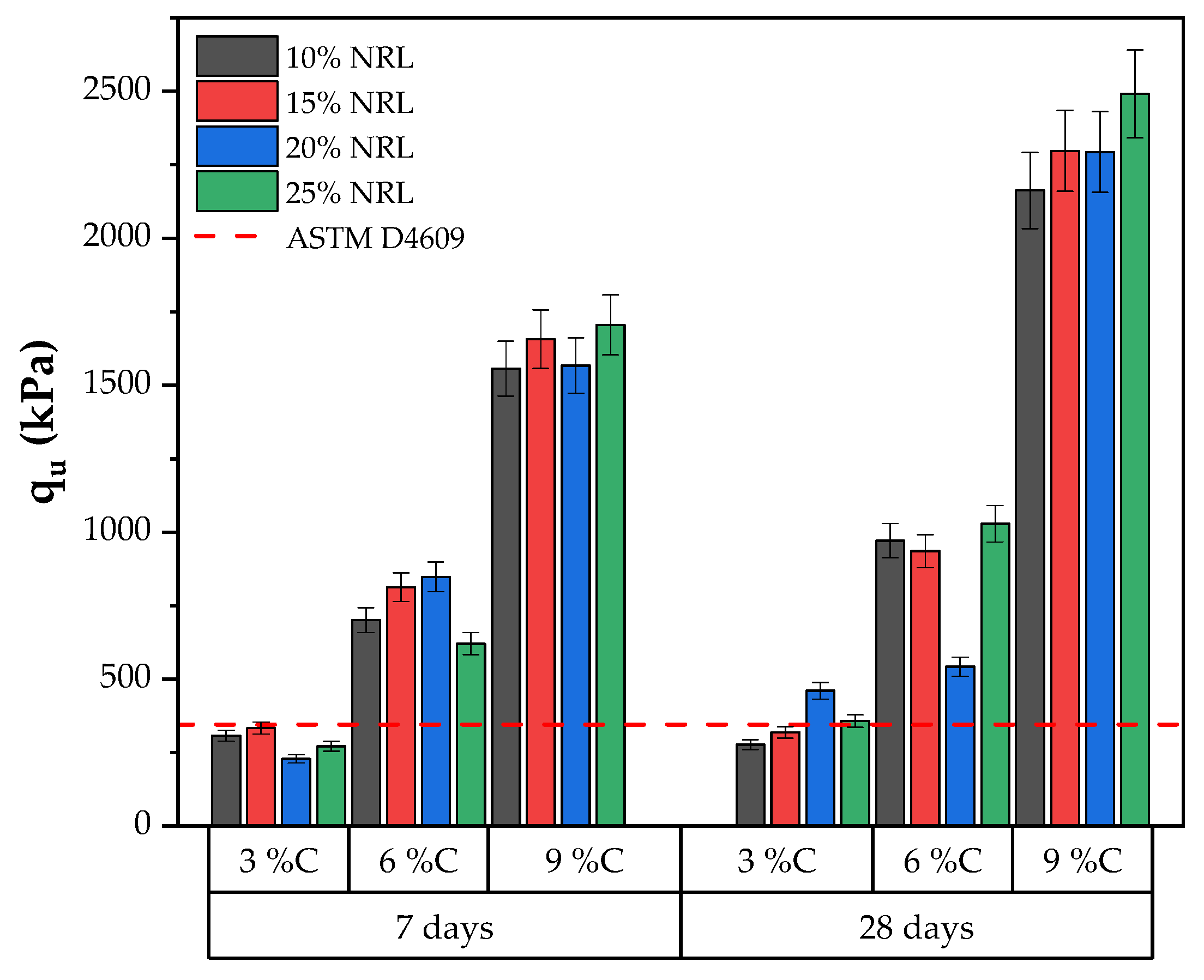

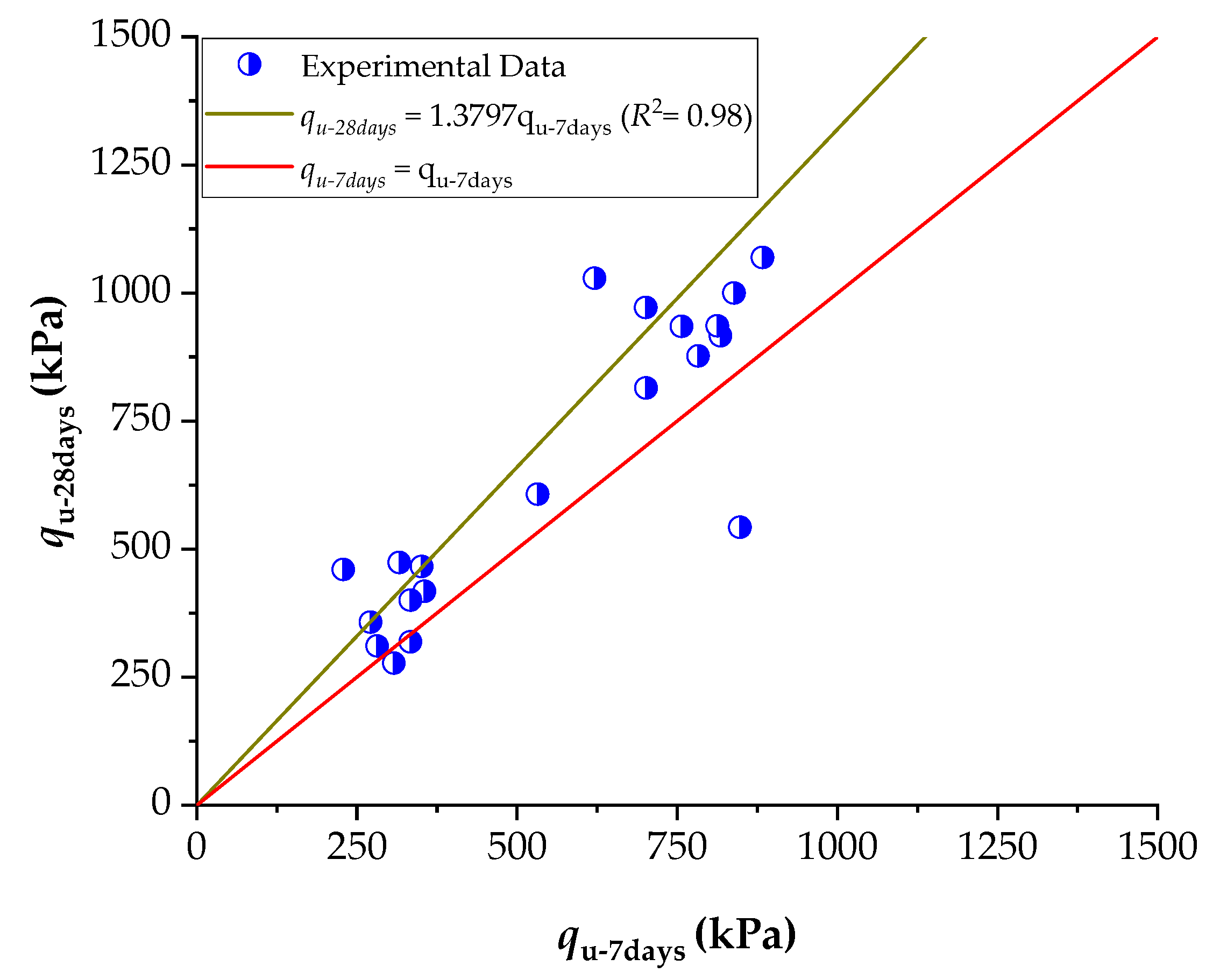

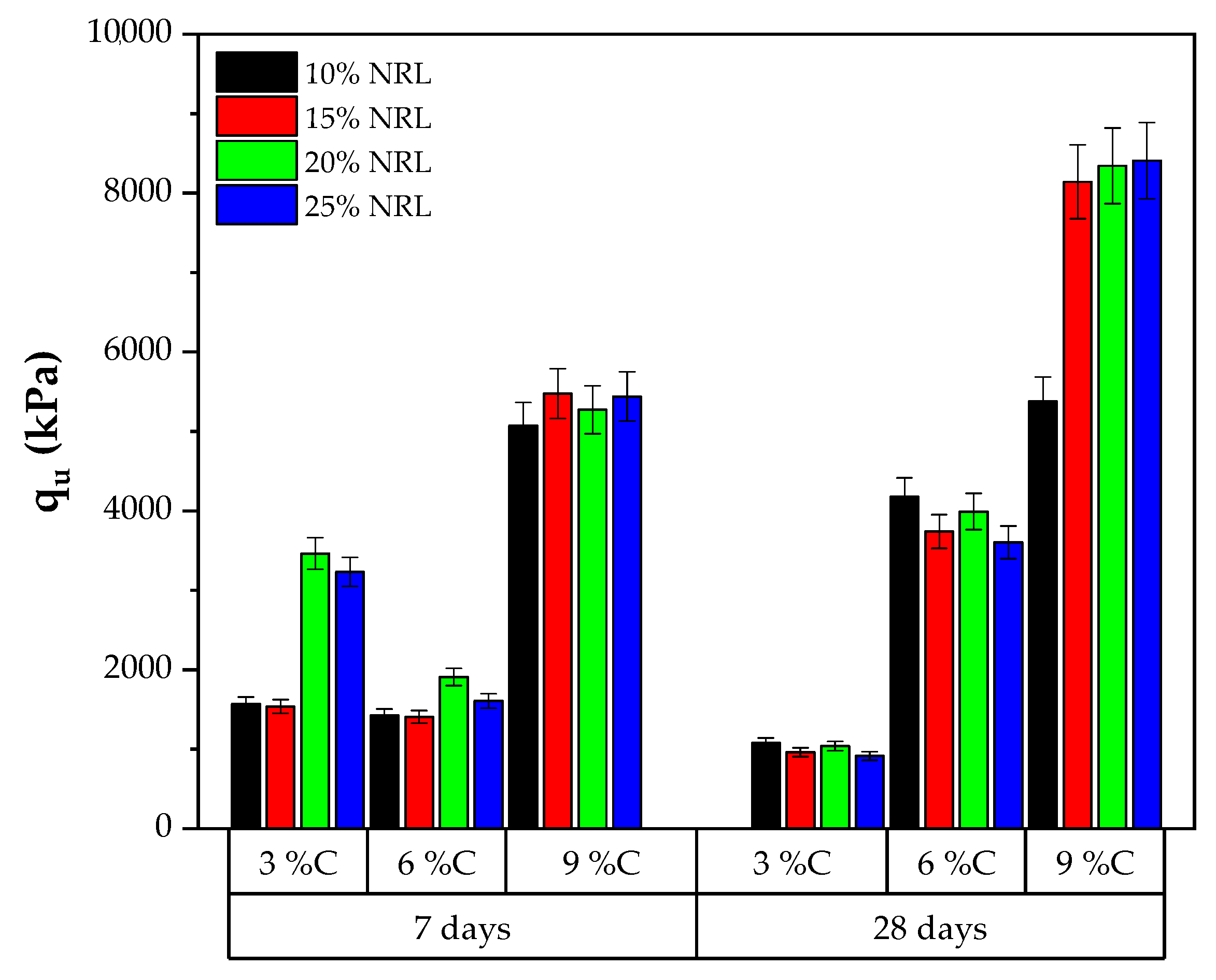

3.1. Effects of NRL on the Unconfined Compressive Strength of Soil–Cement–CLW Compacted Blends

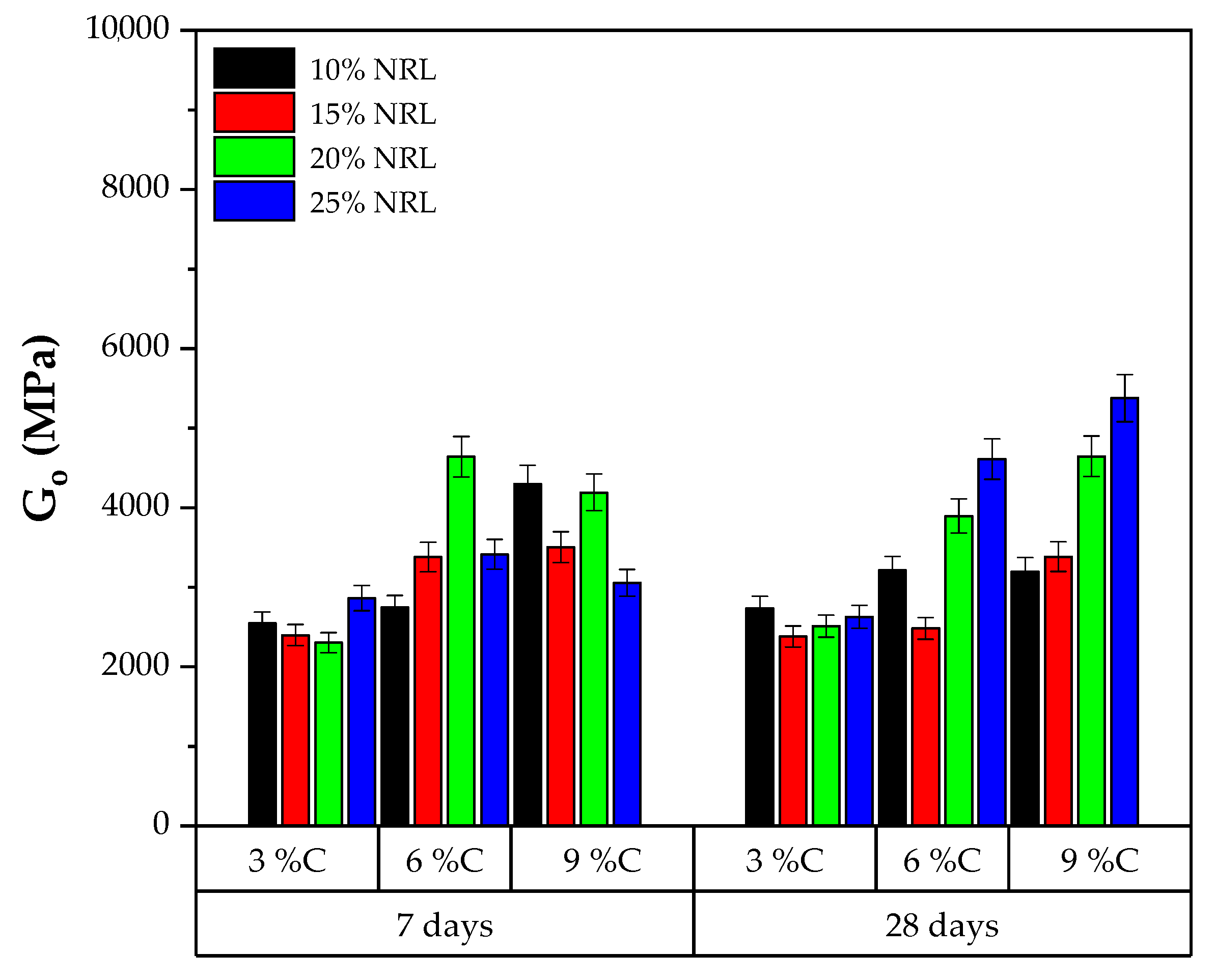

3.2. Effects of NRL on the Stiffness of Soil–Cement–CLW Compacted Blends

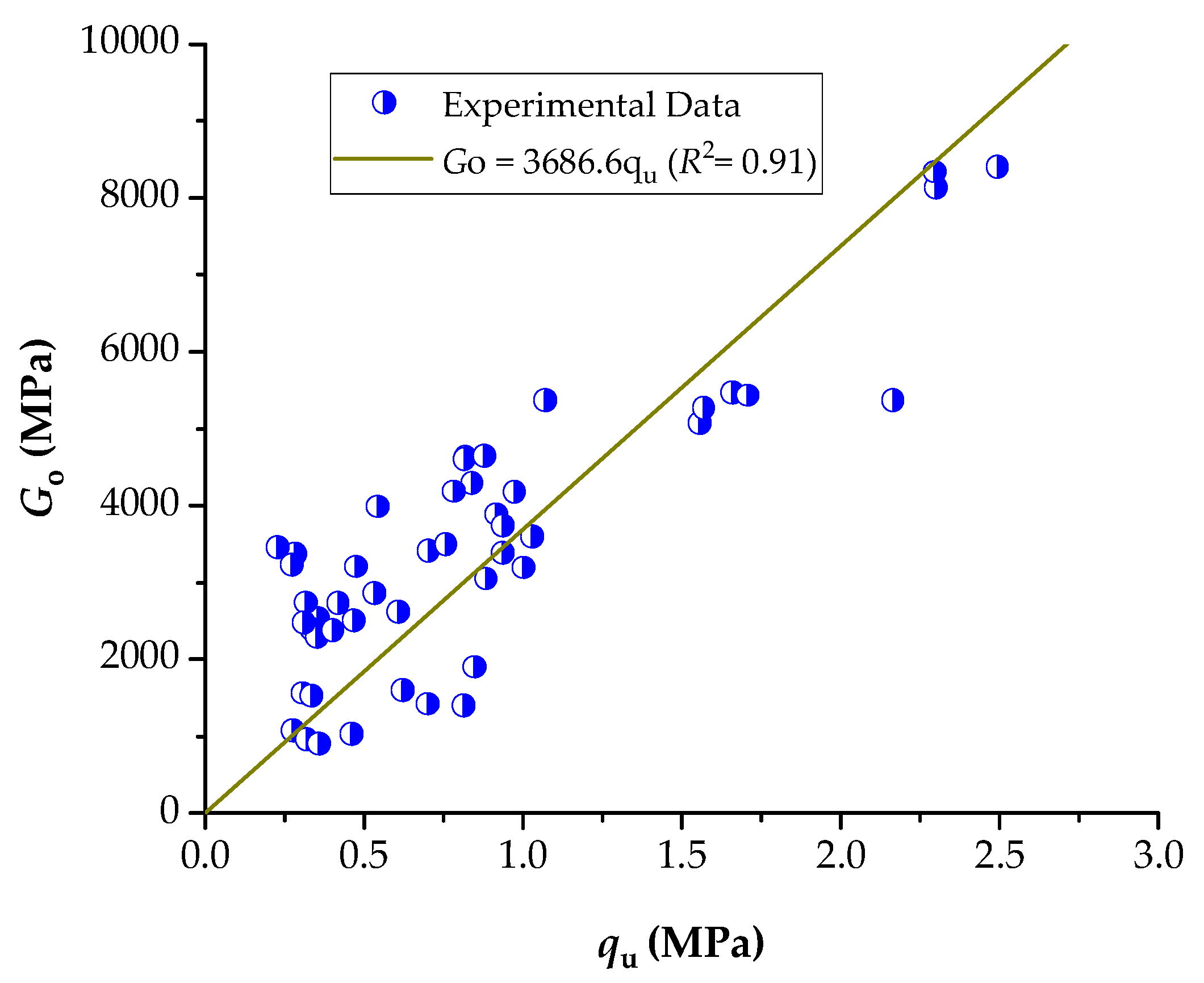

3.3. Relationship Between Stiffness and Unconfined Compressive Strength

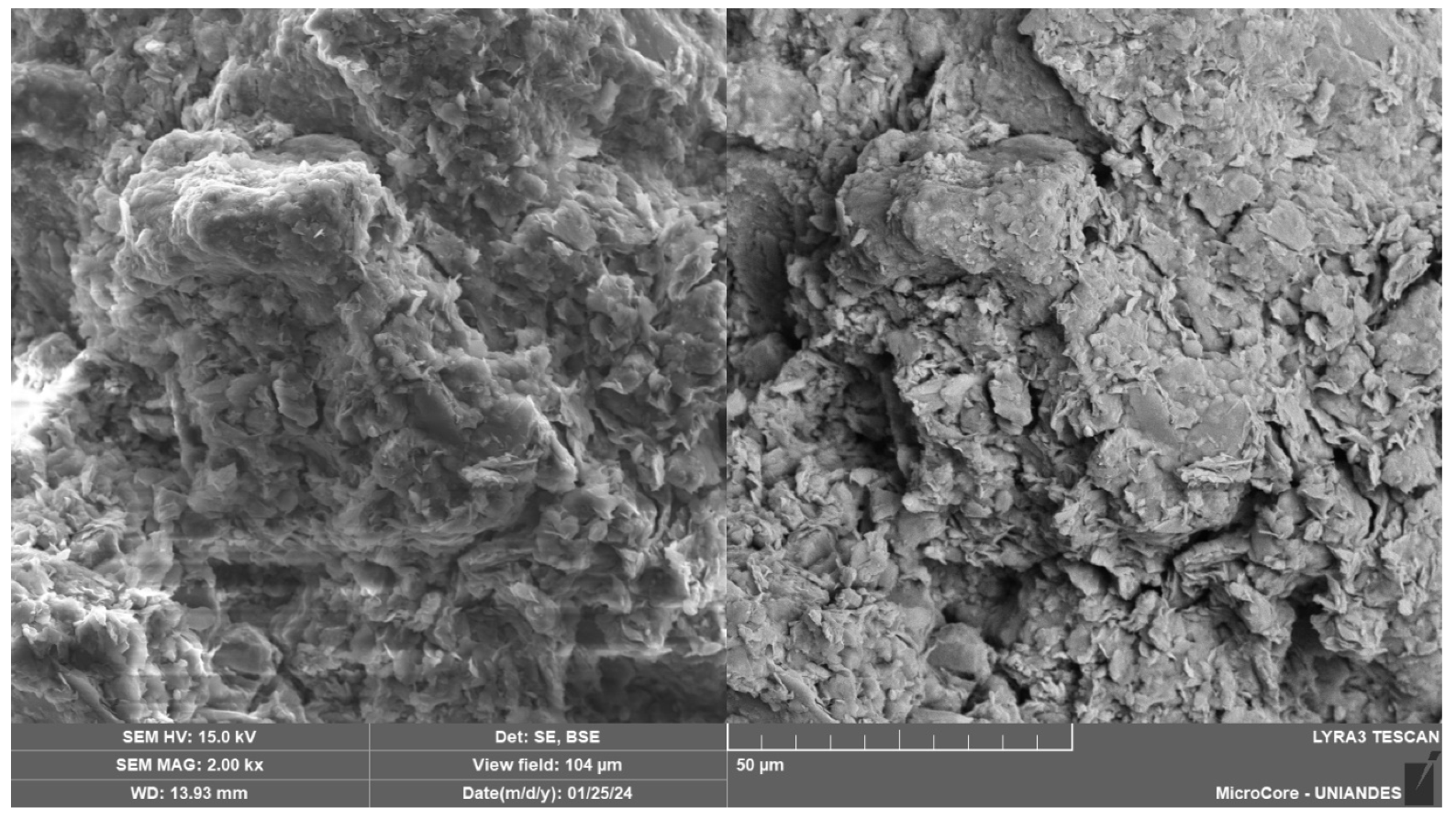

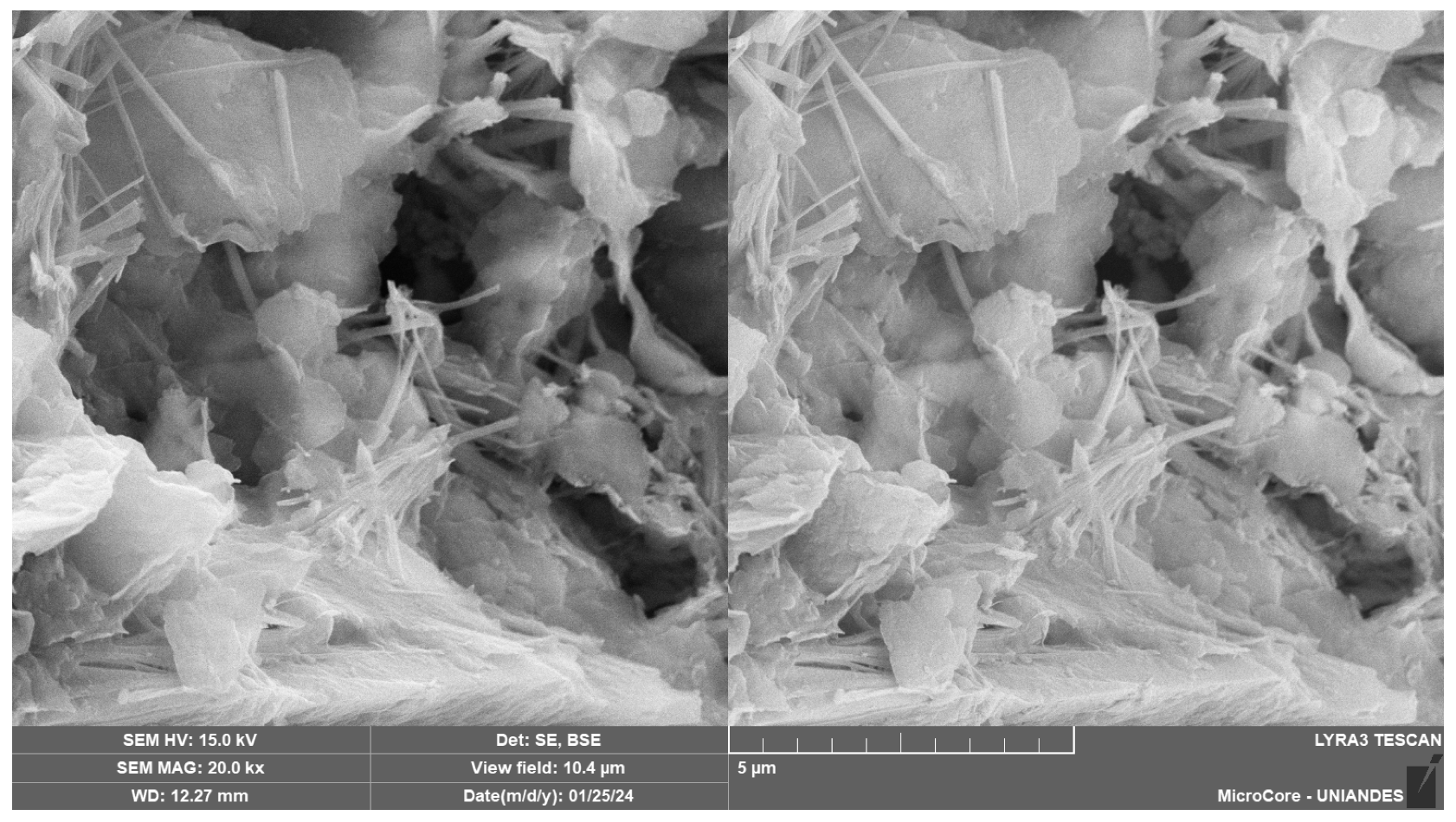

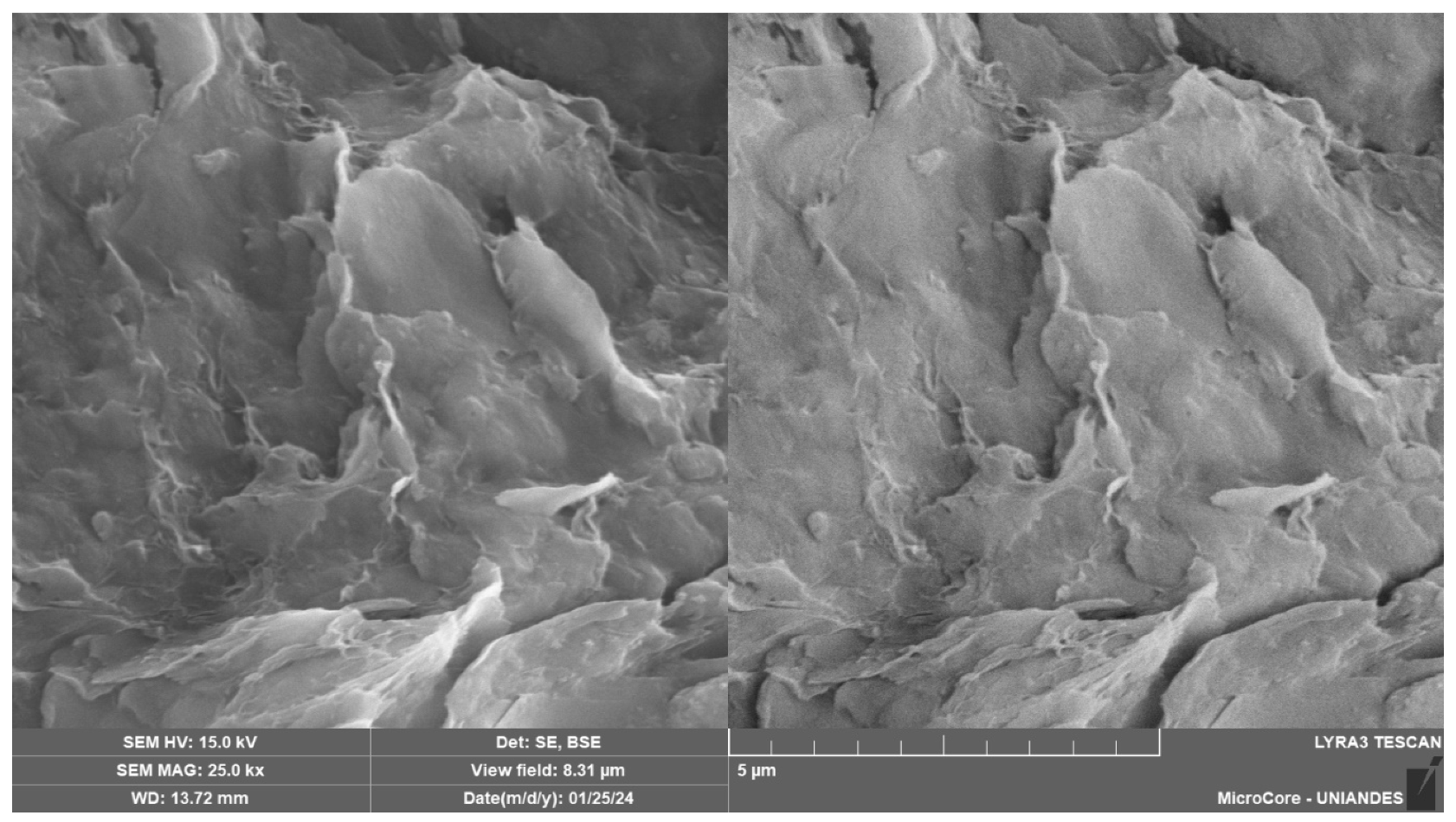

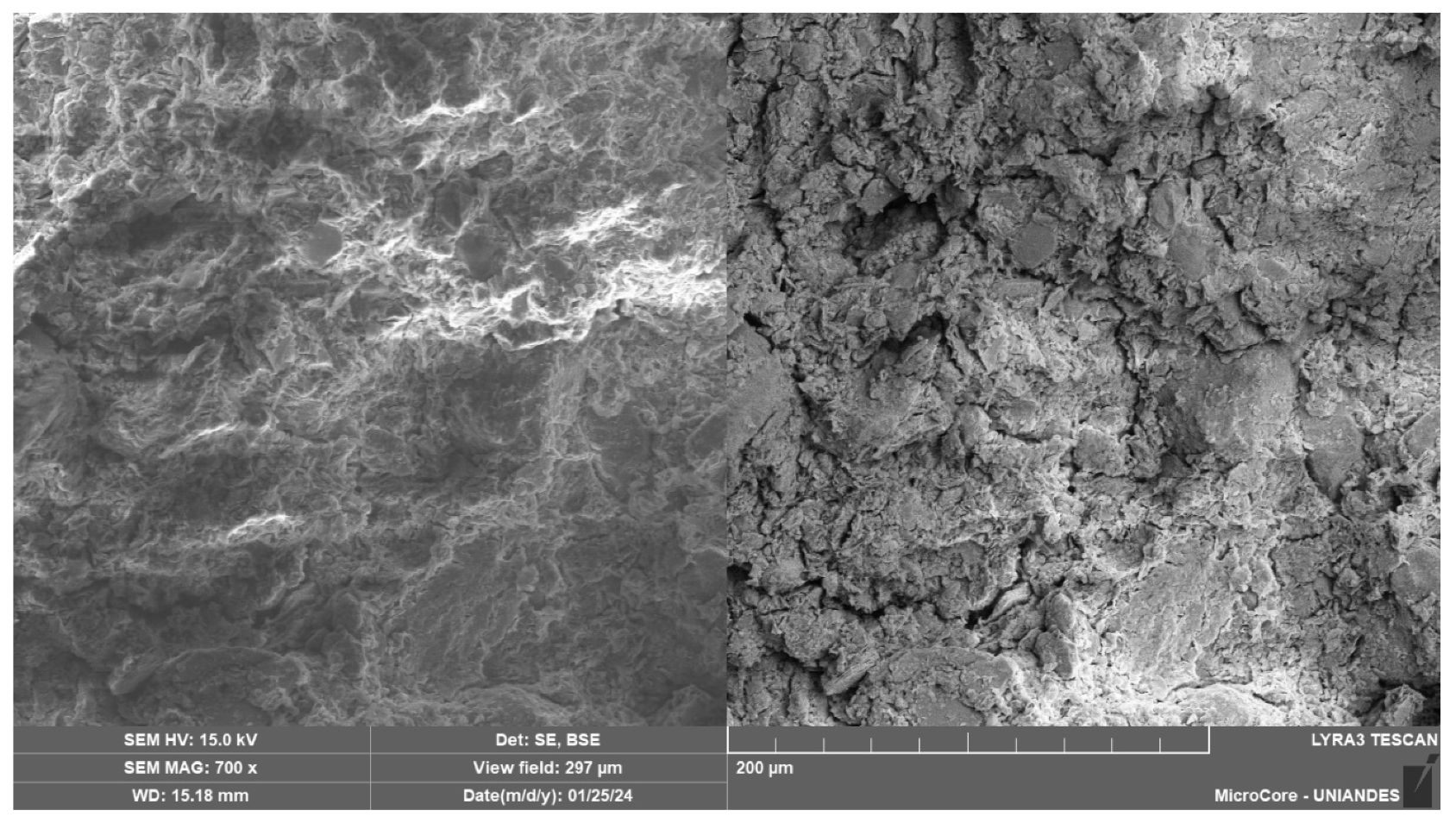

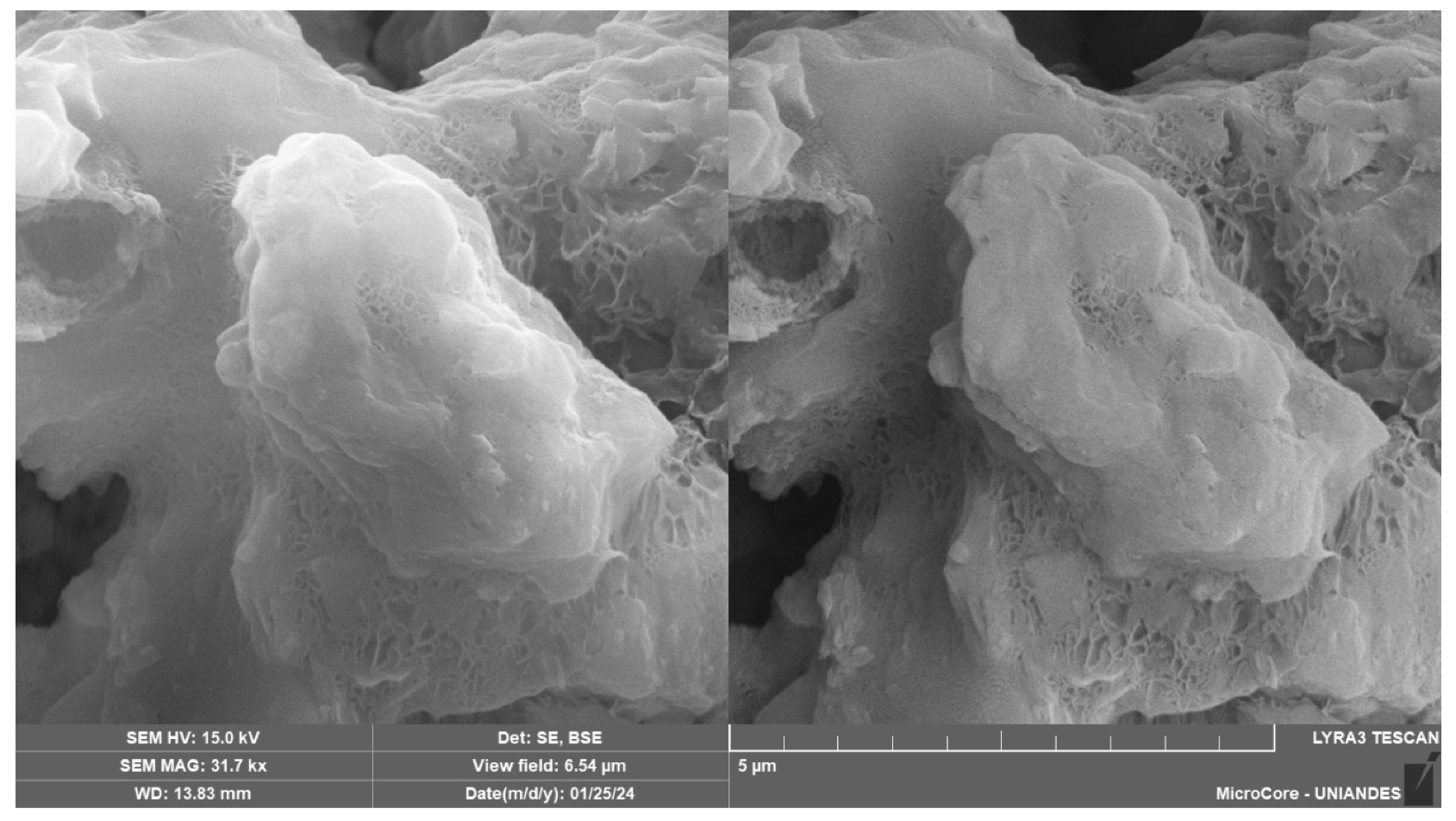

3.4. Microstructure of Compacted Blends

3.5. Statistical Analysis of Influence of Cement and NRL in the Strength and Stiffness of Compacted Blends

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Naseem, S.; Hu, X.; Sarfraz, M.; Mohsin, M. Strategic Assessment of Energy Resources, Economic Growth, and CO2 Emissions in G-20 Countries for a Sustainable Future. Energy Strategy Rev. 2024, 52, 101301. [Google Scholar] [CrossRef]

- Kobayakawa, T. Country Diagnostics for Low Carbon Development: Can Developing Countries Pursue Simultaneous Implementation of the Sustainable Development Goals and the Paris Agreement? Bus. Strategy Dev. 2021, 4, 294–312. [Google Scholar] [CrossRef]

- Ripley, K.M.; Saadi, F.H.; Burke, Z.L. Cost-Motivated Pathways towards near-Term Decarbonization of the Cement Industry. RSC Sustain. 2025, 3, 255–263. [Google Scholar] [CrossRef]

- Shen, W.; Cao, L.; Li, Q.; Zhang, W.; Wang, G.; Li, C. Quantifying CO2 Emissions from China’s Cement Industry. Renew. Sustain. Energy Rev. 2015, 50, 1004–1012. [Google Scholar] [CrossRef]

- Centi, G.; Perathoner, S. The Chemical Engineering Aspects of CO2 Capture, Combined with Its Utilisation. Curr. Opin. Chem. Eng. 2023, 39, 100879. [Google Scholar] [CrossRef]

- Benhelal, E.; Zahedi, G.; Shamsaei, E.; Bahadori, A. Global Strategies and Potentials to Curb CO2 Emissions in Cement Industry. J. Clean. Prod. 2013, 51, 142–161. [Google Scholar] [CrossRef]

- Ordoñez Muñoz, Y.; Villota-Mora, A.J.E.; Perretto, F.; dos Santos Izzo, R.L. Eco-Friendly Stabilization of Clayey Soil with Waste Glass Powder-Based Geopolymer. Geomech. Geoengin. 2024, 1–30. [Google Scholar] [CrossRef]

- Kang, X.; Li, C.; Zhang, M.; Yu, X.; Chen, Y. Mechanical Properties and Stabilization Mechanism of Steel Slag-Rice Husk Ash Solidified High Plasticity Clay. Geotech. Test. J. 2024, 47, 235–253. [Google Scholar] [CrossRef]

- Sreekala, A.G.V.; Nair, S.; Nathan, V.K. Microbially Induced Calcium Carbonate Precipitation Using Lysinibacillus sp.: A Ureolytic Bacterium from Uttarakhand for Soil Stabilization. Curr. Microbiol. 2024, 81, 387. [Google Scholar] [CrossRef]

- Baldovino, J.A.; Nuñez de la Rosa, Y.E.; Namdar, A. Sustainable Cement Stabilization of Plastic Clay Using Ground Municipal Solid Waste: Enhancing Soil Properties for Geotechnical Applications. Sustainability 2024, 16, 5195. [Google Scholar] [CrossRef]

- Baldovino, J.d.J.A.; Palma Calabokis, O.; Saba, M. From Bibliometric Analysis to Experimental Validation: Bibliometric and Literature Review of Four Cementing Agents in Soil Stabilization with Experimental Focus on Xanthan Gum. Sustainability 2024, 16, 5363. [Google Scholar] [CrossRef]

- Buritatun, A.; Takaikaew, T.; Horpibulsuk, S.; Udomchai, A.; Hoy, M.; Vichitcholchai, N.; Arulrajah, A. Mechanical Strength Improvement of Cement-Stabilized Soil Using Natural Rubber Latex for Pavement Base Applications. J. Mater. Civ. Eng. 2020, 32, 3471. [Google Scholar] [CrossRef]

- Yaowarat, T.; Suddeepong, A.; Hoy, M.; Horpibulsuk, S.; Takaikaew, T.; Vichitcholchai, N.; Arulrajah, A.; Chinkulkijniwat, A. Improvement of Flexural Strength of Concrete Pavements Using Natural Rubber Latex. Constr. Build. Mater. 2021, 282, 122704. [Google Scholar] [CrossRef]

- Buritatum, A.; Suddeepong, A.; Horpibulsuk, S.; Udomchai, A.; Arulrajah, A.; Mohammadinia, A.; Horpibulsuk, J.; Hoy, M. Improvement of Tensile Properties of Cement-Stabilized Soil Using Natural Rubber Latex. J. Mater. Civ. Eng. 2022, 34, 4022028. [Google Scholar] [CrossRef]

- Buritatum, A.; Aiamsri, K.; Yaowarat, T.; Suddeepong, A.; Horpibulsuk, S.; Arulrajah, A.; Kou, H. Improved Fatigue Performance and Cost-Effectiveness of Natural Rubber Latex-Modified Cement-Stabilized Pavement Base at Raised Temperatures. J. Mater. Civ. Eng. 2023, 35, 04022461. [Google Scholar] [CrossRef]

- Buritatum, A.; Horpibulsuk, S.; Udomchai, A.; Suddeepong, A.; Takaikaew, T.; Vichitcholchai, N.; Horpibulsuk, J.; Arulrajah, A. Durability Improvement of Cement Stabilized Pavement Base Using Natural Rubber Latex. Transp. Geotech. 2021, 28, 100518. [Google Scholar] [CrossRef]

- Udomchai, A.; Buritatum, A.; Suddeepong, A.; Hoy, M.; Horpibulsuk, S.; Arulrajah, A.; Horpibulsuk, J. Evaluation of Durability against Wetting and Drying Cycles of Cement-Natural Rubber Latex Stabilised Unpaved Road under Cyclic Tensile Loading. Int. J. Pavement Eng. 2022, 23, 4442–4453. [Google Scholar] [CrossRef]

- Tran, N.Q.; Hoy, M.; Suddeepong, A.; Horpibulsuk, S.; Kantathum, K.; Arulrajah, A. Improved Mechanical and Microstructure of Cement-Stabilized Lateritic Soil Using Recycled Materials Replacement and Natural Rubber Latex for Pavement Applications. Constr. Build. Mater. 2022, 347, 128547. [Google Scholar] [CrossRef]

- Nhieu, D.V.; Hoy, M.; Horpibulsuk, S.; Karntatam, K.; Arulrajah, A.; Horpibulsuk, J. Cement–Natural Rubber Latex Stabilised Recycled Concrete Aggregate as a Pavement Base Material. Road Mater. Pavement Des. 2023, 24, 1636–1650. [Google Scholar] [CrossRef]

- Hoy, M.; Vinh Nhieu, D.; Suddeepong, A.; Horpibulsuk, S.; Arulrajah, A.; Deng, Y.; Udomchai, A. Stiffness, Rutting, and Fatigue Performance Evaluation of Cement-Natural Rubber Latex Stabilized Recycled Concrete Aggregate. Int. J. Pavement Eng. 2023, 24, 1636–1650. [Google Scholar] [CrossRef]

- Aiamsri, K.; Buritatum, A.; Suddeepong, A.; Horpibulsuk, S.; Yaowarat, T.; Hoy, M.; Phunpeng, V.; Arulrajah, A.; Udomchai, A. Performance Evaluation of Pre-Vulcanised Rubber Latex Modified Asphalt Concrete with Various Aggregates. Int. J. Pavement Eng. 2024, 25, 2404705. [Google Scholar] [CrossRef]

- Prongmanee, N.; Noulmanee, A.; Dulyasucharit, R.; Horpibulsuk, S.; Chai, J.-C. Durability against Wetting and Drying Cycles and Installation Damage of Water Hyacinth Geotextiles Coated with Natural Rubber Latex. J. Mater. Civ. Eng. 2023, 35, 4023408. [Google Scholar] [CrossRef]

- Veena, U.; James, N. Natural Rubber Latex Treatment of Sand: A Novel Remediation Technique for Soil Liquefaction. Soil. Dyn. Earthq. Eng. 2023, 165, 107661. [Google Scholar] [CrossRef]

- ASTM D4318-10; Stardard Test Methods for Liquid Limit, Plastic Limit and Plasticity Index of Soils. ASTM International: West Conshohocken, PA, USA, 2010.

- ASTM D7928; Standard Test Method for Particle-Size Distribution (Gradation) of Fine-Grained Soils Using the Sedimentation (Hydrometer) Analysis. ASTM International: West Conshohocken, PA, USA, 2021.

- ASTM D854; Standard Test Methods for Specific Gravity of Soil Solids by Water Pycnometer. ASTM International: West Conshohocken, PA, USA, 2014.

- ASTM D698-12; Test Method for Laboratory Compaction Characteristics of Soils Using Standard Effort (12,400 Ft-Lbf/Ft3 (600 KN-m/m3)). ASTM International: West Conshohocken, PA, USA, 2012.

- ASTM D2487-11; Standard Practice for Classification of Soils for Engineering Purposes (Unified Soil Classification System). ASTM International: West Conshohocken, PA, USA, 2017. [CrossRef]

- Román Martínez, C.; Nuñez de la Rosa, Y.E.; Estrada Luna, D.; Baldovino, J.A.; Jordi Bruschi, G. Strength, Stiffness, and Microstructure of Stabilized Marine Clay-Crushed Limestone Waste Blends: Insight on Characterization through Porosity-to-Cement Index. Materials 2023, 16, 4983. [Google Scholar] [CrossRef]

- ASTM C597; Standard Test Method for Pulse Velocity Through Concrete. ASTM International: West Conshohocken, PA, USA, 2016.

- ASTM D2166-03; Standard Test Method for Unconfined Compressive Strength of Cohesive Soil 1. ASTM International: West Conshohocken, PA, USA, 2003.

- Astm D4609-08; Standard Guide for Evaluating Effectiveness of Admixtures for Soil Stabilization. ASTM International: West Conshohocken, PA, USA, 2008.

- López, L.C.S.; Vergara, J.A.A.; de la Rosa, Y.E.N.; Arrieta, A.; Baldovino, J.d.J.A. Effect of Grain Size and Porosity/Binder Index on the Unconfined Compressive Strength, Stiffness and Microstructure of Cemented Colombian Sands. Materials 2024, 17, 5193. [Google Scholar] [CrossRef]

- Consoli, N.C.; Winter, D.; Leon, H.B.; Scheuermann Filho, H.C. Durability, Strength, and Stiffness of Green Stabilized Sand. J. Geotech. Geoenvironmental Eng. 2018, 144, 04018057. [Google Scholar] [CrossRef]

- Consoli, N.C.; da Silva Carretta, M.; Festugato, L.; Leon, H.B.; Tomasi, L.F.; Heineck, K.S. Ground Waste Glass–Carbide Lime as a Sustainable Binder Stabilising Three Different Silica Sands. Géotechnique 2021, 71, 480–493. [Google Scholar] [CrossRef]

- Horpibulsuk, S.; Rachan, R.; Chinkulkijniwat, A.; Raksachon, Y.; Suddeepong, A. Analysis of Strength Development in Cement-Stabilized Silty Clay from Microstructural Considerations. Constr. Build. Mater. 2010, 24, 2011–2021. [Google Scholar] [CrossRef]

- Hoy, M.; Tran, N.Q.; Suddeepong, A.; Horpibulsuk, S.; Buritatum, A.; Yaowarat, T.; Arulrajah, A. Wetting-Drying Durability Performance of Cement-Stabilized Recycled Materials and Lateritic Soil Using Natural Rubber Latex. Constr. Build. Mater. 2023, 403, 133108. [Google Scholar] [CrossRef]

| Stabilizer | Scopus String | Total Results 2023 | Total Results 2024 |

|---|---|---|---|

| Lignosulphonate | (“soil stabilization” OR “soil improvement” OR “ground improvement”) AND (“Lignosulphonate”) | 15 | 21 |

| Natural rubber latex | (“soil stabilization” OR “soil improvement” OR “ground improvement”) AND (“natural rubber latex” OR “natural latex”) | 15 | 17 |

| Eggshell lime | (“soil stabilization” OR “soil improvement” OR “ground improvement”) AND (“eggshell” OR “egg lime”) | 37 | 51 |

| Xanthan Gum | (“soil stabilization” OR “soil improvement” OR “ground improvement”) AND (“xanthan”) | 105 | 141 |

| Property | Unit | Soil | CLW |

|---|---|---|---|

| ASTM D4318 [24] Limit Liquid, L.L. | % | 42.0 | NP |

| ASTM D4318 [24] Plasticity Index, P.I. | % | 15.9 | NP |

| ASTM D854 [26] Specific Gravity, Gs | - | 2.80 | 2.52 |

| ASTM D2487 [28] Gravel (4.75–76.2 mm) | % | 0 | 10 |

| ASTM D2487 [28] Coarse Sand (2.00–4.75 mm) | % | 0 | 30 |

| ASTM D2487 [28] Medium Sand (0.425–2.0 mm) | % | 0 | 38 |

| ASTM D2487 [28] Fine Sand (0.075–0.425 mm) | % | 8 | 17 |

| ASTM D2487 [28] Silt (0.002–0.075 mm) | % | 82 | 15 |

| ASTM D2487 [28] Clay (<0.002 mm) | % | 10 | 0 |

| ASTM D2487 [28] Mean Diameter (d50) | mm | 0.011 | 1.6 |

| ASTM D2487 [28] Effective Diameter (d10) | mm | 0.0021 | 0.15 |

| ASTM D2487 [28] Uniformity Coefficient Cu | - | 7.14 | 13.67 |

| ASTM D2487 [28] Coefficient of Curvature Cc | - | 0.96 | 1.59 |

| Skempton Activity of Clay | - | 1.60 | - |

| USCS Classification | - | CL | SW |

| Color | - | Gray | Gray |

| Compound | Concentration by Weight in % | ||

|---|---|---|---|

| Soil | Cement | CLW | |

| CaO | 3.0 | 62.7 | 72.4 |

| MgO | - | 3.8 | 2.1 |

| SiO2 | 66.0 | 21.1 | 9.0 |

| Al2O3 | 21.1 | 5.2 | 1.3 |

| Fe2O3 | 0.9 | 2.6 | 0.9 |

| TiO2 | 0.3 | - | - |

| K2O | 3.1 | - | - |

| SO3 | 4.0 | 3.5 | - |

| Na2O | - | 0.1 | - |

| MnO | - | 0.2 | 14.3 |

| P2O5 | - | - | 2.1 |

| LOI | 1.6 | 0.8 | 2.1 |

| Molding γd (kN/m3) | Soil | Cement | CLW | NRL Replacement in Water (%) | Curing Times (Days) | Specimens |

|---|---|---|---|---|---|---|

| 16.6 | 100 | 3 | 30 | 10, 15, 20 and 25 | 7, 28 | 24 |

| 100 | 6 | 30 | 10, 15, 20 and 25 | 7, 28 | 24 | |

| 100 | 9 | 30 | 10, 15, 20 and 25 | 7, 28 | 24 | |

| 17.6 | 100 | 3 | 30 | 10, 15, 20 and 25 | 7, 28 | 24 |

| 100 | 6 | 30 | 10, 15, 20 and 25 | 7, 28 | 24 | |

| 100 | 9 | 30 | 10, 15, 20 and 25 | 7, 28 | 24 |

| Type of Compacted Blend | Go/UCS Index | R2 | Reference |

|---|---|---|---|

| Present study | 3686.6 | 0.91 | - |

| Clayey soil–cement–CLW | 4828.8 | 0.96 | [29] |

| Sand–cement | 7465.9 | 0.86 | [34] |

| Clayey soil–xanthan gum | 1915.3 | 0.98 | [11] |

| Clayey soil–glass-powder–cement | 2909.68 | 0.97 | [10] |

| Sand–ground-glass–carbide lime (7 days) | 21,690 | 0.99 | [34] |

| Sand–ground-glass–carbide lime (180 days) | 30,690 | 0.98 | [34] |

| Osorio sand–glass-powder–carbide lime | 2169.49 | 0.94 | [35] |

| Rio Pardo sand–glass-powder–carbide lime | 1785.74 | 0.85 | [35] |

| Porto Alegre sand–glass-powder–carbide lime | 985.34 | 0.82 | [35] |

| Source | Sum of Squares | Degrees of Freedom | Mean Squares | Z | p-Value | Significance (p-Value < 0.05) |

|---|---|---|---|---|---|---|

| Corrected Model | 10,002,384.224 * | 6 | 1,667,064.037 | 11.200 | <0.000 | yes |

| Cement (C) | 9,344,460.009 | 2 | 4,672,230.004 | 31.391 | <0.000 | yes |

| γd | 493,252.683 | 1 | 493,252.683 | 3.314 | 0.076 | no |

| NRL | 164,671.532 | 3 | 54,890.511 | 0.369 | 0.776 | no |

| Error | 6,102,492.353 | 41 | 148,841.277 | |||

| Total | 49,411,208.833 | 48 |

| Source | Sum of Squares | Degrees of Freedom | Mean Squares | Z | p-Value | Significance (p-Value < 0.05) |

|---|---|---|---|---|---|---|

| Corrected Model | 87,108,980.020 a | 6 | 14,518,163.337 | 9.120 | 0.000 | yes |

| Cement (C) | 78,074,538.949 | 2 | 39,037,269.474 | 24.522 | 0.000 | yes |

| γd | 4,142,980.079 | 1 | 4,142,980.079 | 2.603 | 0.114 | no |

| NRL | 4,891,460.993 | 3 | 1,630,486.998 | 1.024 | 0.392 | no |

| Error | 65,268,720.310 | 41 | 1,591,920.008 | |||

| Total | 737,724,685.315 | 48 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Baldovino, J.A.; Diaz, K.C.; Royero, J.M.; Sierra, R.S.; Nuñez de la Rosa, Y.E. Developing New Geomaterials: The Case of the Natural Rubber Latex Polymers in Soil Stabilization. Materials 2025, 18, 1720. https://doi.org/10.3390/ma18081720

Baldovino JA, Diaz KC, Royero JM, Sierra RS, Nuñez de la Rosa YE. Developing New Geomaterials: The Case of the Natural Rubber Latex Polymers in Soil Stabilization. Materials. 2025; 18(8):1720. https://doi.org/10.3390/ma18081720

Chicago/Turabian StyleBaldovino, Jair Arrieta, Kevin Cardenas Diaz, Jorge Martínez Royero, Rohonal Serrano Sierra, and Yamid E. Nuñez de la Rosa. 2025. "Developing New Geomaterials: The Case of the Natural Rubber Latex Polymers in Soil Stabilization" Materials 18, no. 8: 1720. https://doi.org/10.3390/ma18081720

APA StyleBaldovino, J. A., Diaz, K. C., Royero, J. M., Sierra, R. S., & Nuñez de la Rosa, Y. E. (2025). Developing New Geomaterials: The Case of the Natural Rubber Latex Polymers in Soil Stabilization. Materials, 18(8), 1720. https://doi.org/10.3390/ma18081720