Advances in the Application and Mechanism of Admixtures and Industrial By-Products in Cement-Based Self-Leveling Mortar: A Comprehensive Review

Abstract

1. Introduction

2. CSL Test Methods and Standards

3. CSL Component Material Types and Characteristics

3.1. Cementitious Materials

3.2. Aggregate

3.3. Filling Material

3.4. Types of Admixtures in CSL

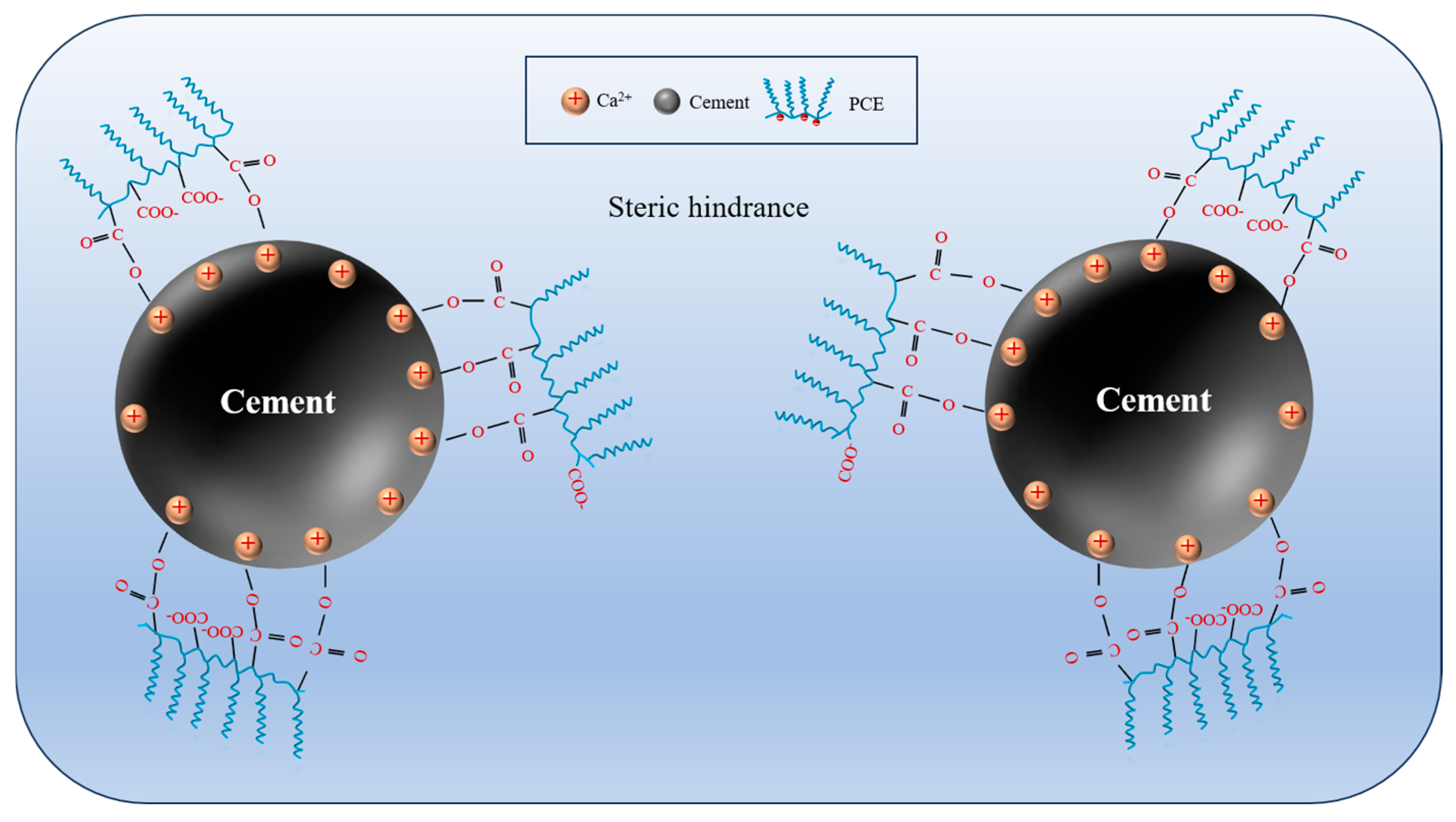

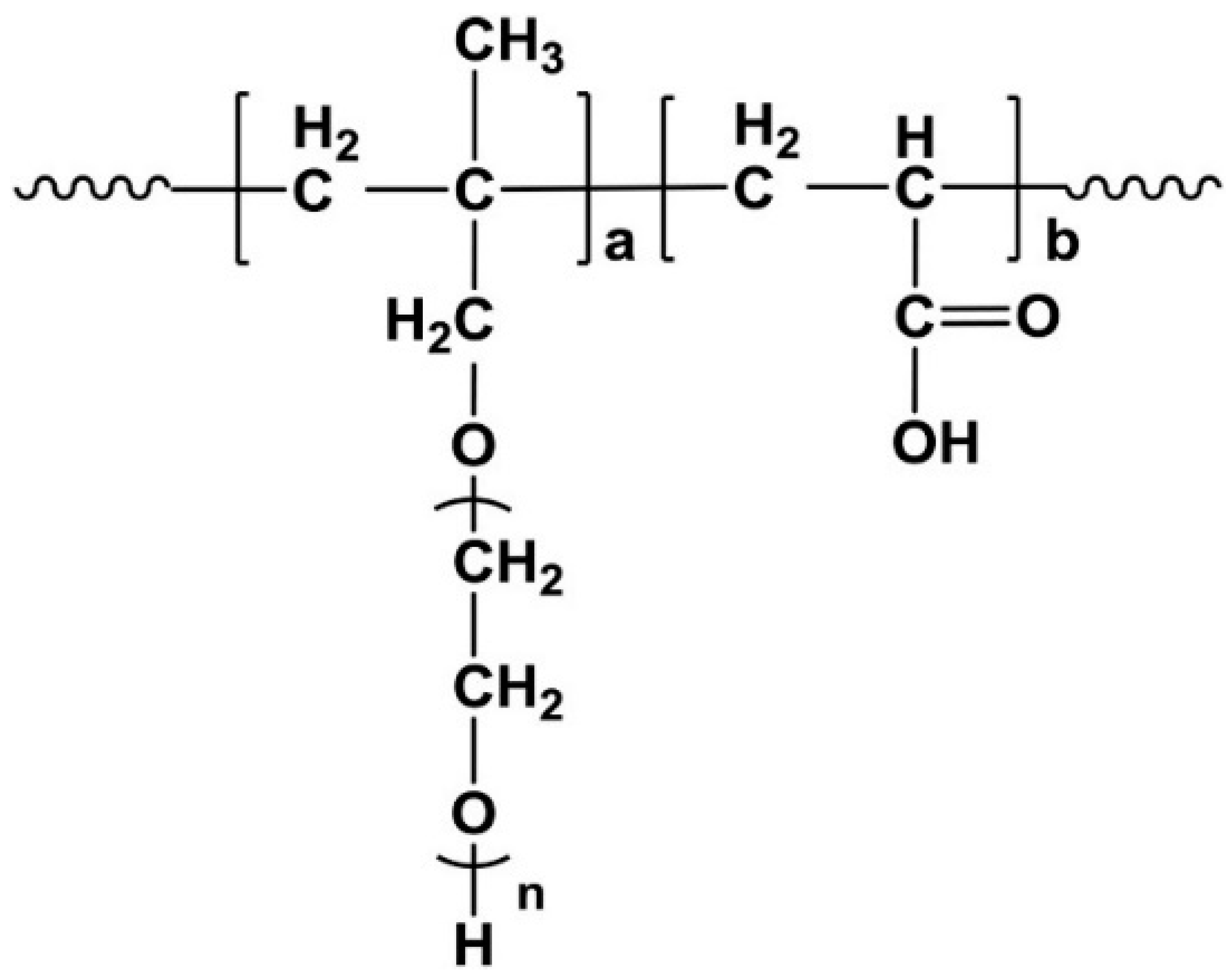

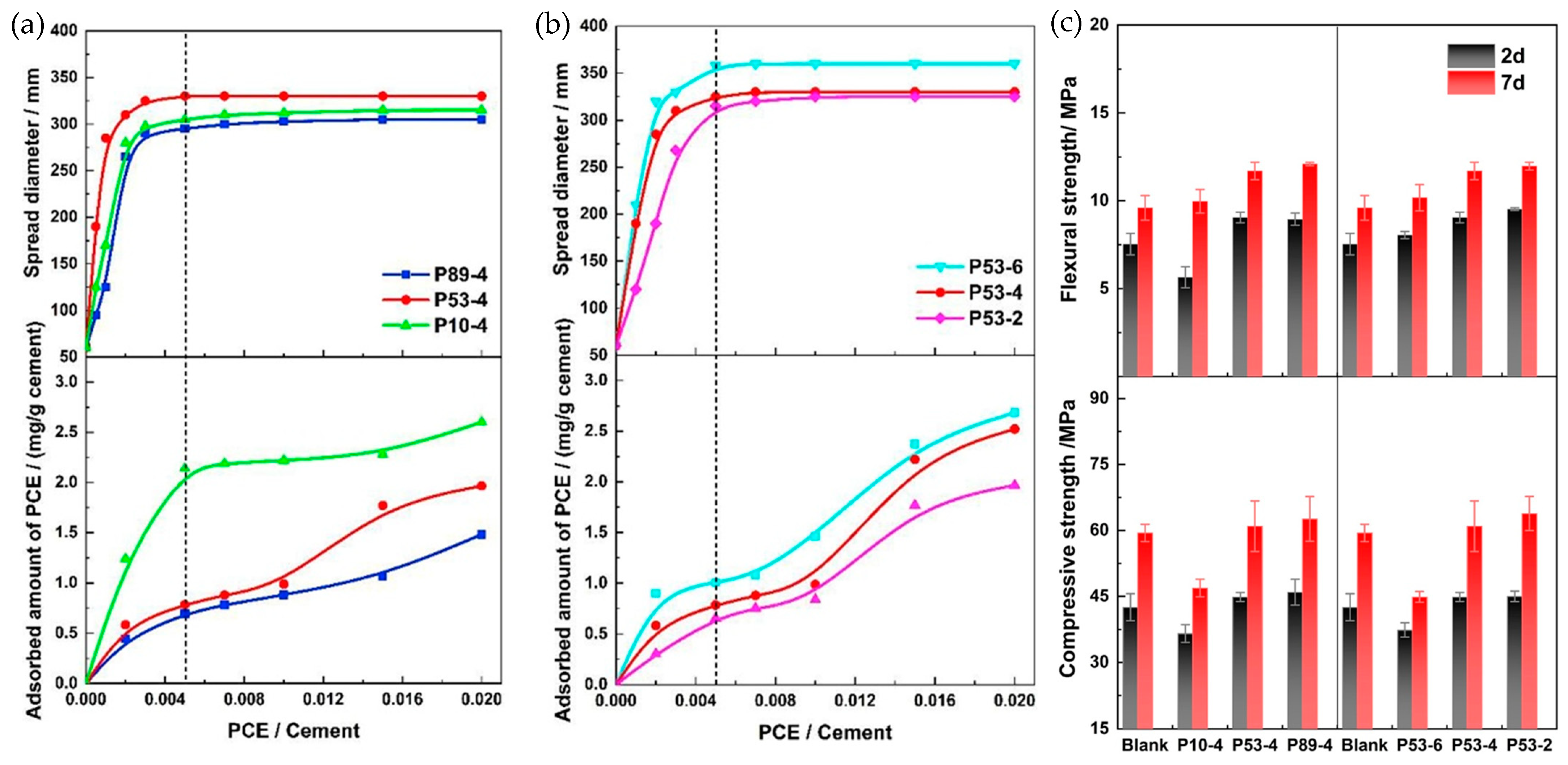

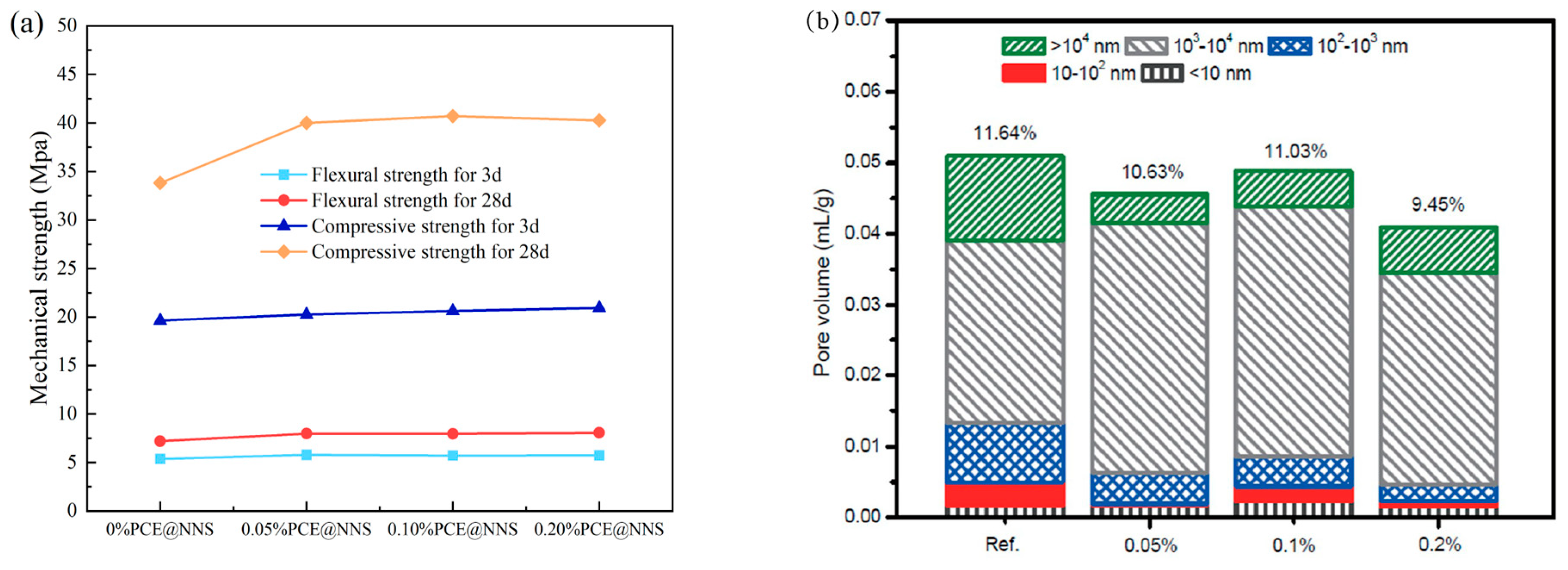

3.4.1. Water Reducing Agent

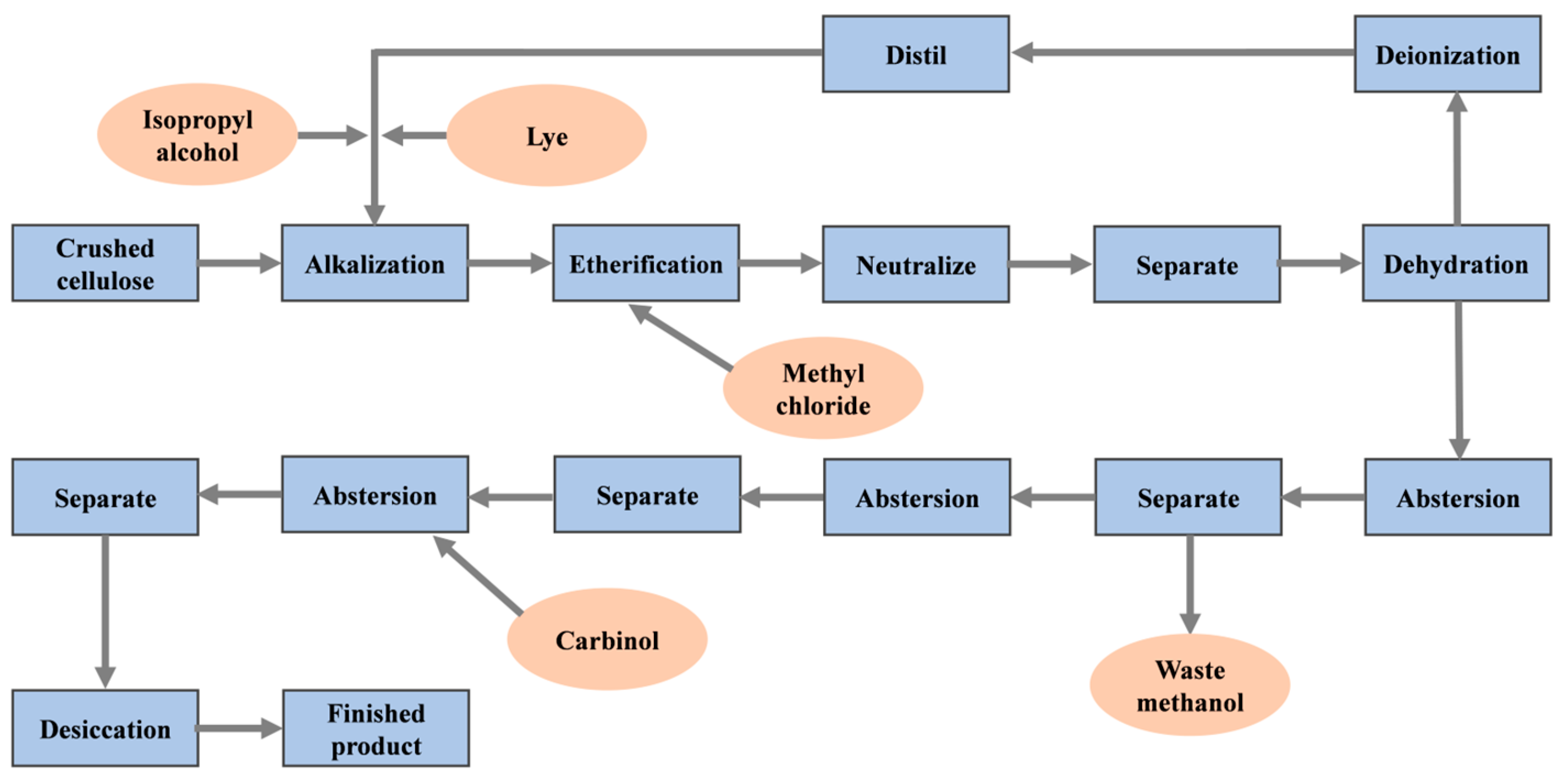

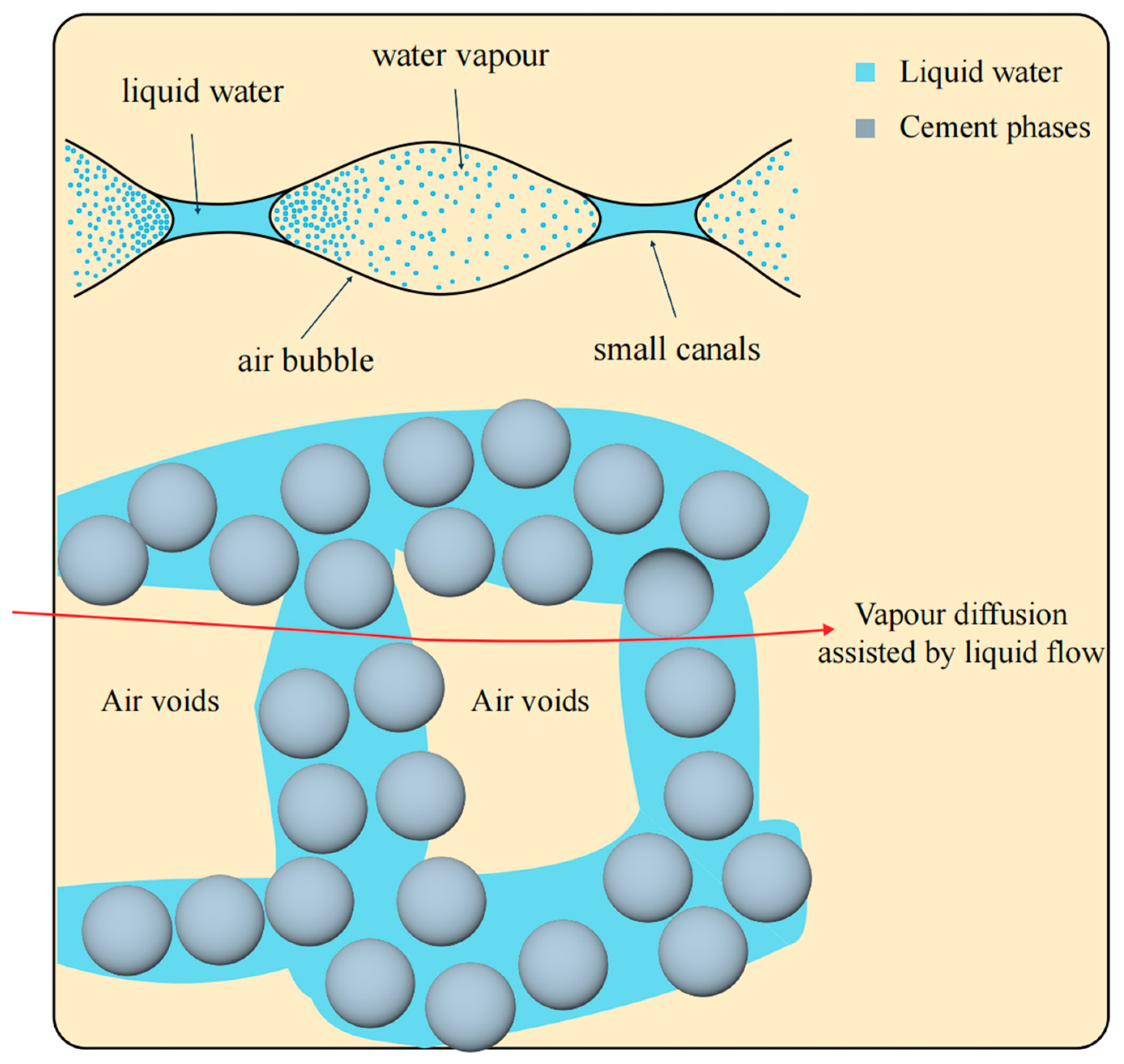

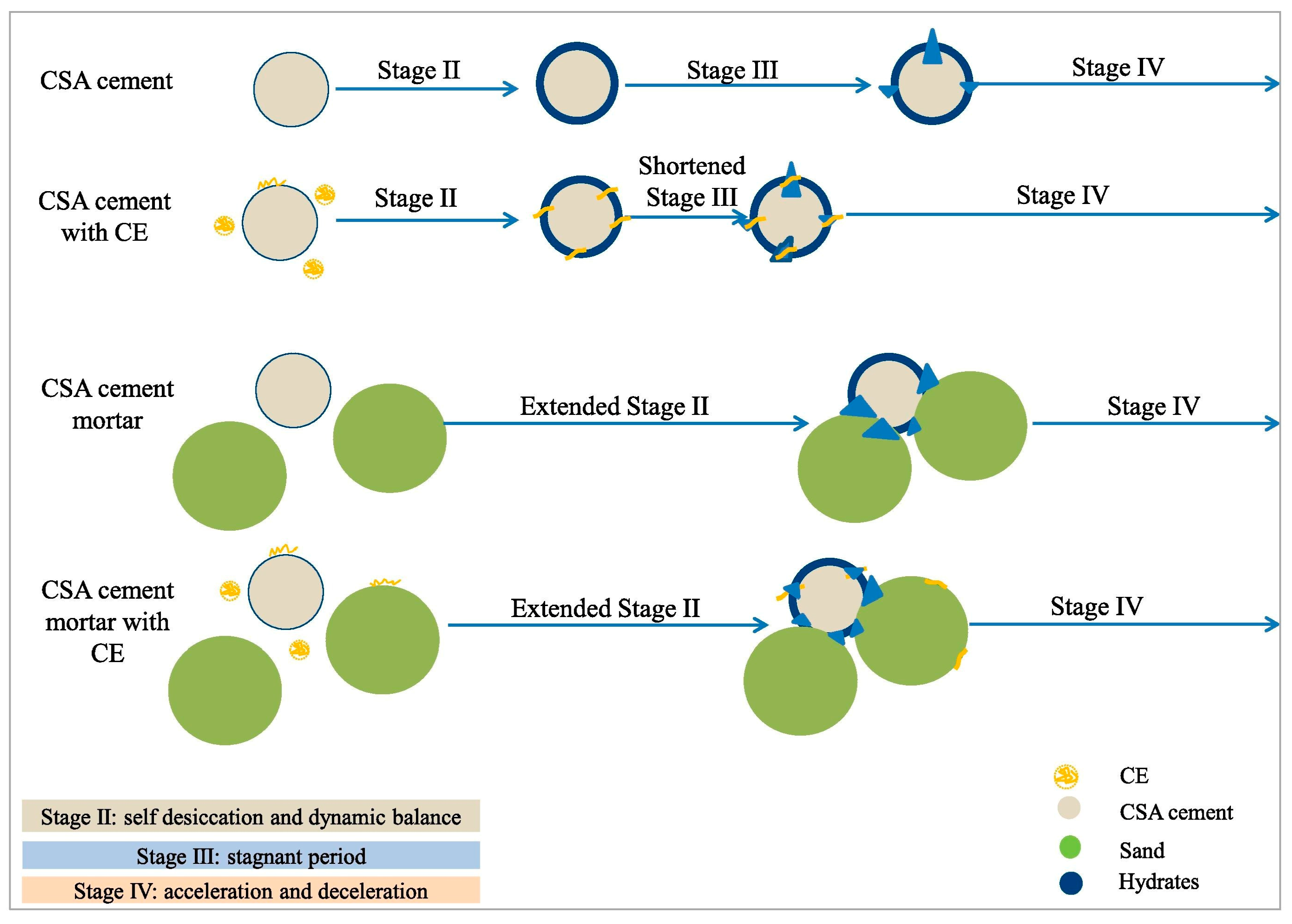

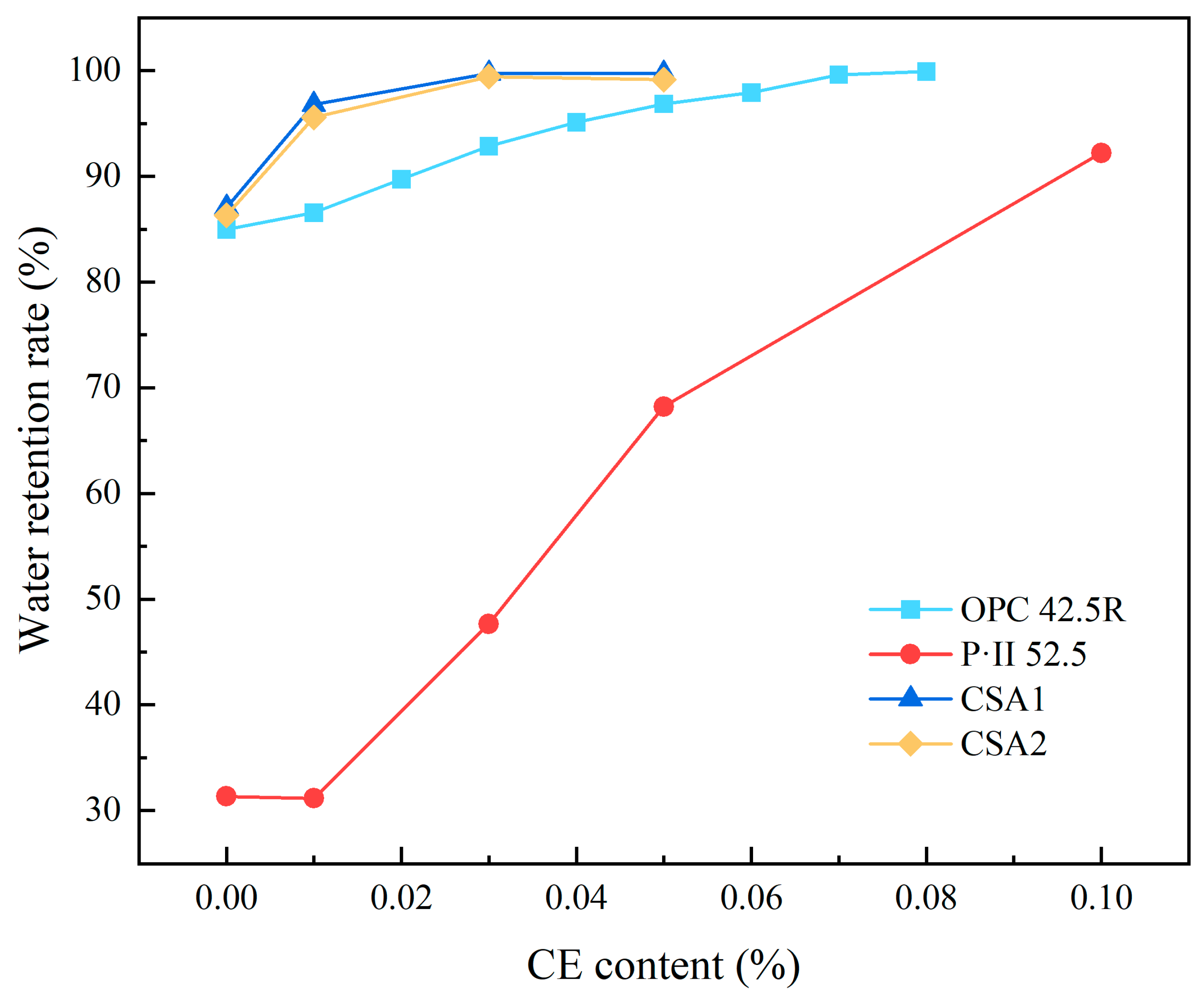

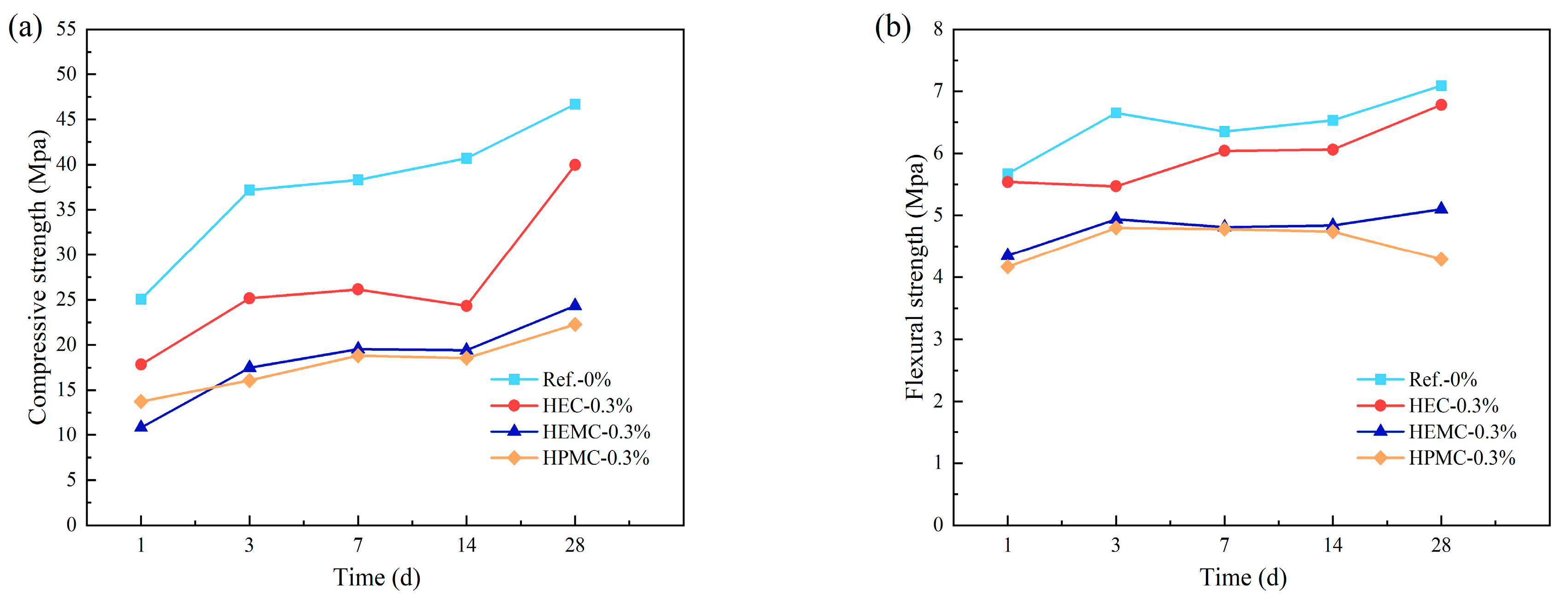

3.4.2. Water Retention Agent

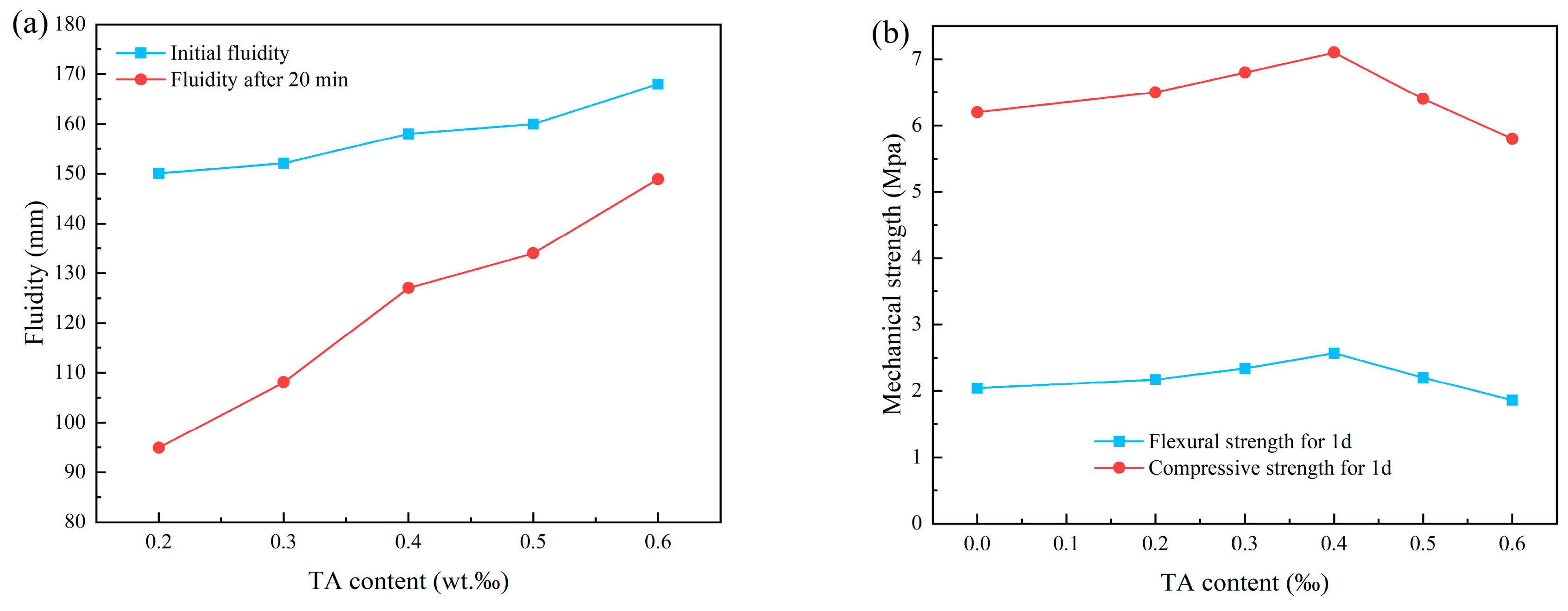

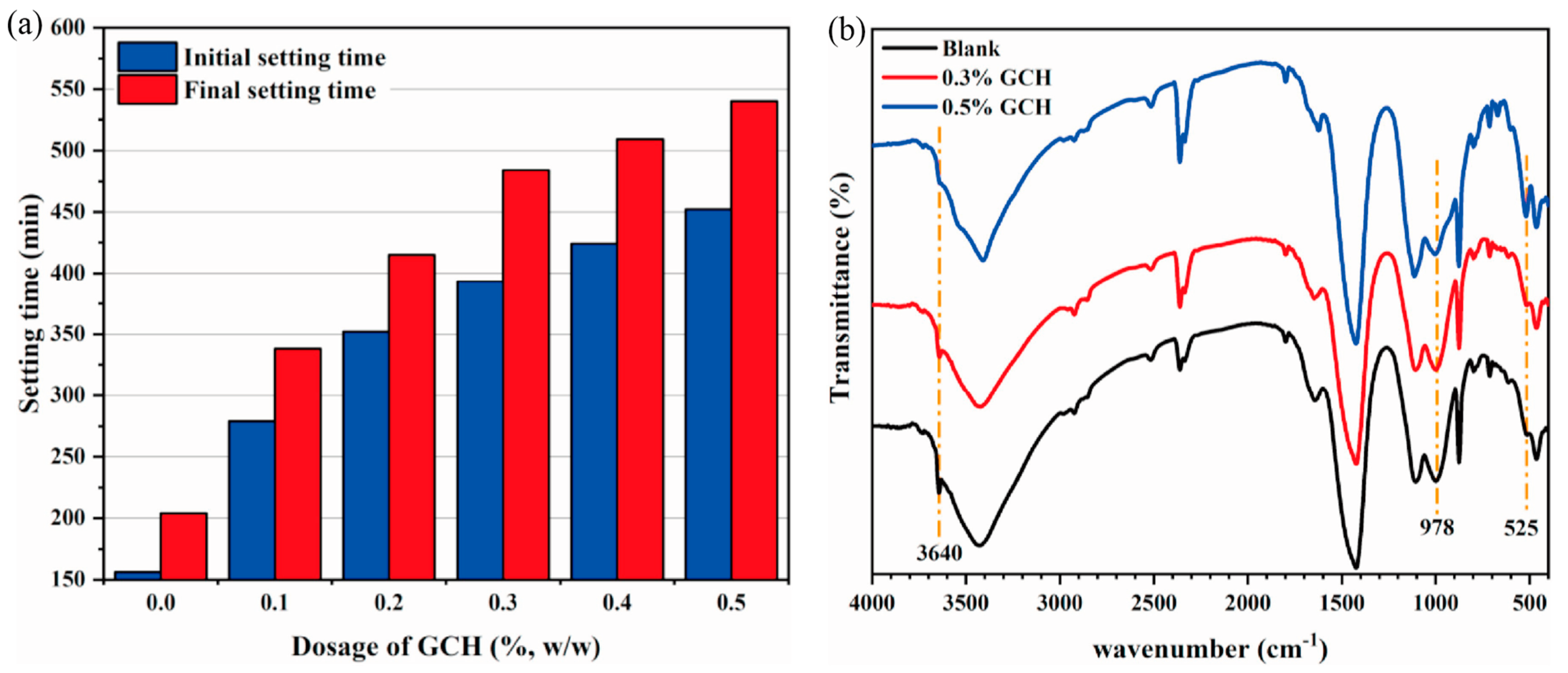

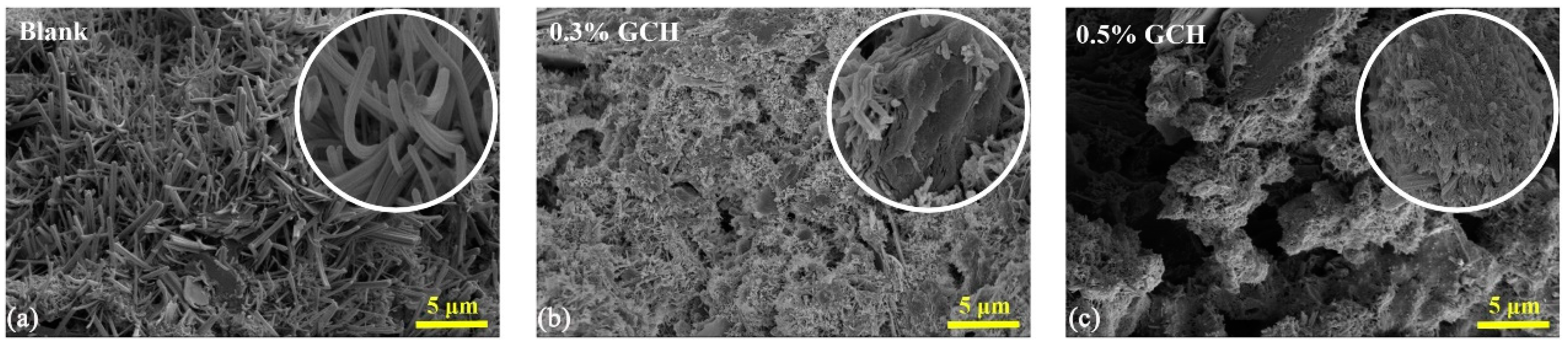

3.4.3. Retarder

3.4.4. Other Admixtures

4. New Green CSL

4.1. Recycling Industrial Waste and By-Products During CSL Production

4.2. Historical Research on and Latest Engineering Applications of Industrial By-Products in CSL Production

| Year | Green Binder | Other Material | Dosage | Mortar Property | Ref. | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| A | B | C | D | E | F | G | H | I | |||||

| 2010 | GS | PC, Sand | GS: 0–45 total wt. % | √ | X | X | X | X | √ | [129] | |||

| 2013 | PW | PC, Sand, LP | PW: 0–50 total wt. % | √ | X | X | √ | √ | [27] | ||||

| 2016 | PG | PC, CSA, Sand | PG: 45–55 total wt. % | √ | √ | X | X | [5] | |||||

| 2017 | PG | PC, CSA, Sand | PG: 19.80 total wt. % | √ | √ | X | X | X | [6] | ||||

| 2017 | NA | CSA, Sand, LP | NA: 0–35 total wt. % | √ | √ | √ | √ | √ | [11] | ||||

| 2018 | P, C | PC, Sand | P: 15–50 PC wt. % | √ | √ | √ | X | [126] | |||||

| 2018 | P, C | PC, Sand | C: 15–50 PC wt. % | √ | √ | X | X | [126] | |||||

| 2019 | PBG | CSA, PC, Granulated blast furnace slags, Sand | PBG: 50 total wt. % | √ | √ | √ | √ | √ | √ | [127] | |||

| 2020 | Marble and granite cutting waste (MGCW) | PC, Sand | MGCW: 40–50 total wt. % | √ | √ | √ | √ | √ | √ | √ | [131] | ||

| 2020 | SCBA | PC, Sand, LP | SCBA: 0–30 total wt. % | X | √ | √ | √ | √ | X | [128] | |||

| 2021 | FGDG | PC, Mechanochemical Syngenite, Sand, Quartz flour | FGDG: 35 total wt. % | X | X | √ | √ | √ | √ | [130] | |||

| 2023 | fluorogypsum (FLG) | PC, Sand | FLG: 92 total wt. % | √ | √ | √ | √ | √ | √ | [19] | |||

| 2024 | FGDG, PG | CSA, Sand | PG: 90 total wt. % | √ | √ | √ | √ | [21] | |||||

| 2024 | FGDG, PG | CSA, Sand | FGDG: 90–100 total wt. % | √ | √ | √ | √ | [21] | |||||

| 2024 | Red mud (RM) | PG, FA, Sand, Quicklime, PC | RM: 11–26 total wt. % | √ | √ | √ | √ | [132] | |||||

| 2024 | PG | RM, FA, Sand, Quicklime, PC | PG: 11–26 total wt. % | √ | √ | X | X | [132] | |||||

| 2024 | PG, CB, PN | PC, Sand | PG: 474.09 kg/m3 | √ | √ | X | √ | X | √ | [26] | |||

| 2024 | PG, CB, PN | PC, Sand | CB: 474.09 kg/m3 | √ | √ | √ | √ | √ | √ | [26] | |||

| 2024 | PG, CB, PN | PC, Sand | PN: 474.09 kg/m3 | √ | X | X | √ | X | √ | [26] | |||

5. Conclusions

- The rapid popularization of CSL is directly related to the standardization framework established by current standards (such as JC/T 985, ISO). These standards provide a clear benchmark for the normative application of CSL through quantitative indicators.

- The performance of CSL is mainly affected by the composition of cementitious materials, aggregates, and fillers. Through the performance analysis of different CSLs, it can be seen that the addition of CSA instead of PC can optimize the formation of ettringite, thereby increasing the compressive strength of 28 days and reducing carbon dioxide emissions by 30% to 50%. The fine sand with a particle size of 0–1 mm has the best performance in CSL. Fly ash can enhance the fluidity and stability of CSL and improve its compactness and mechanical properties.

- Water reducers, water retainers, and retarders significantly enhance the fluidity, mechanical properties, and durability of CSL by optimizing the water–cement ratio, regulating the hydration process, and improving the microstructure. Among these additives, the molecular structure of PCE (side chain length and density) directly influences its adsorption characteristics and early strength development; cellulose ether improves water retention by forming a three-dimensional network; however, excessive use of these admixtures may delay hydration and diminish early strength.

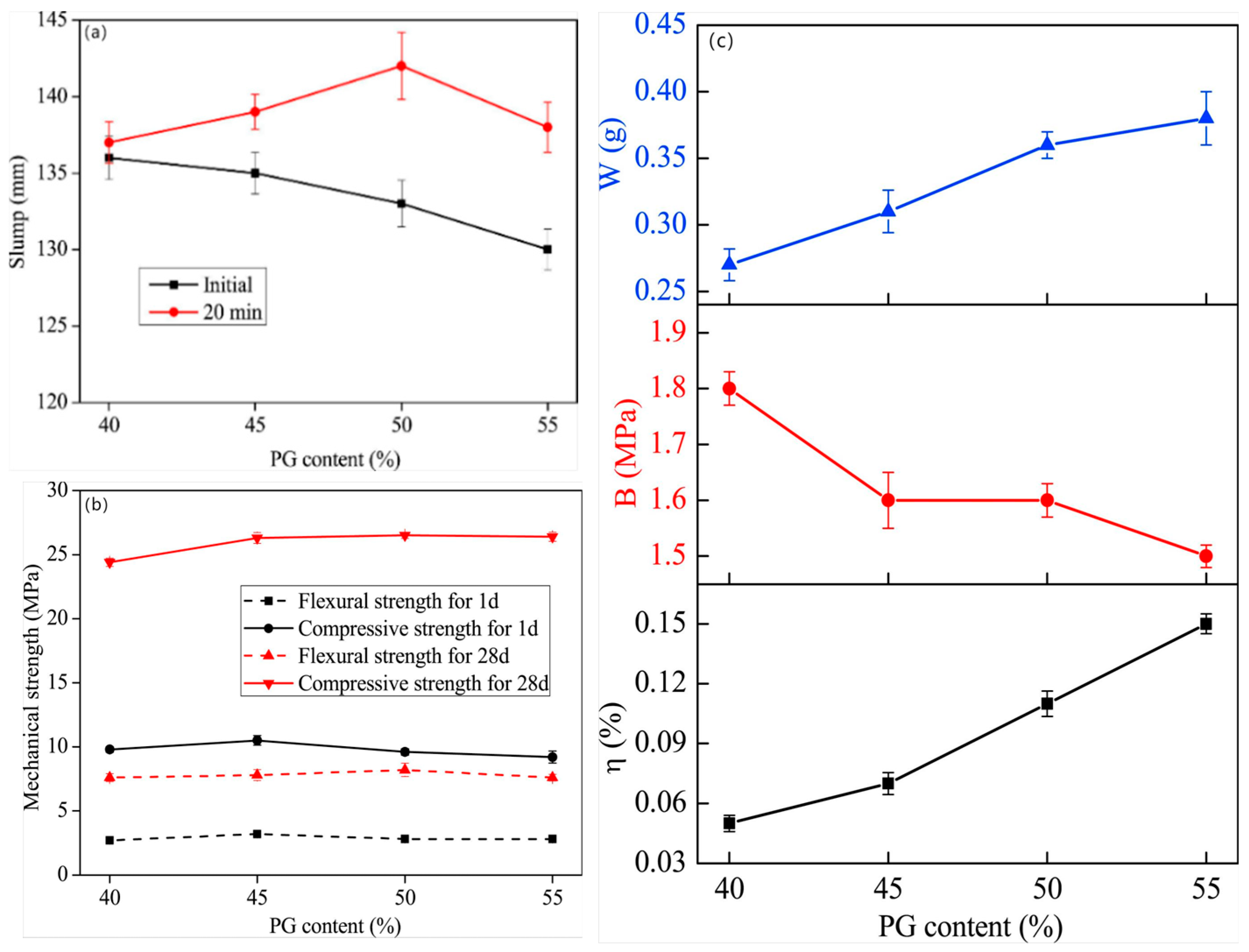

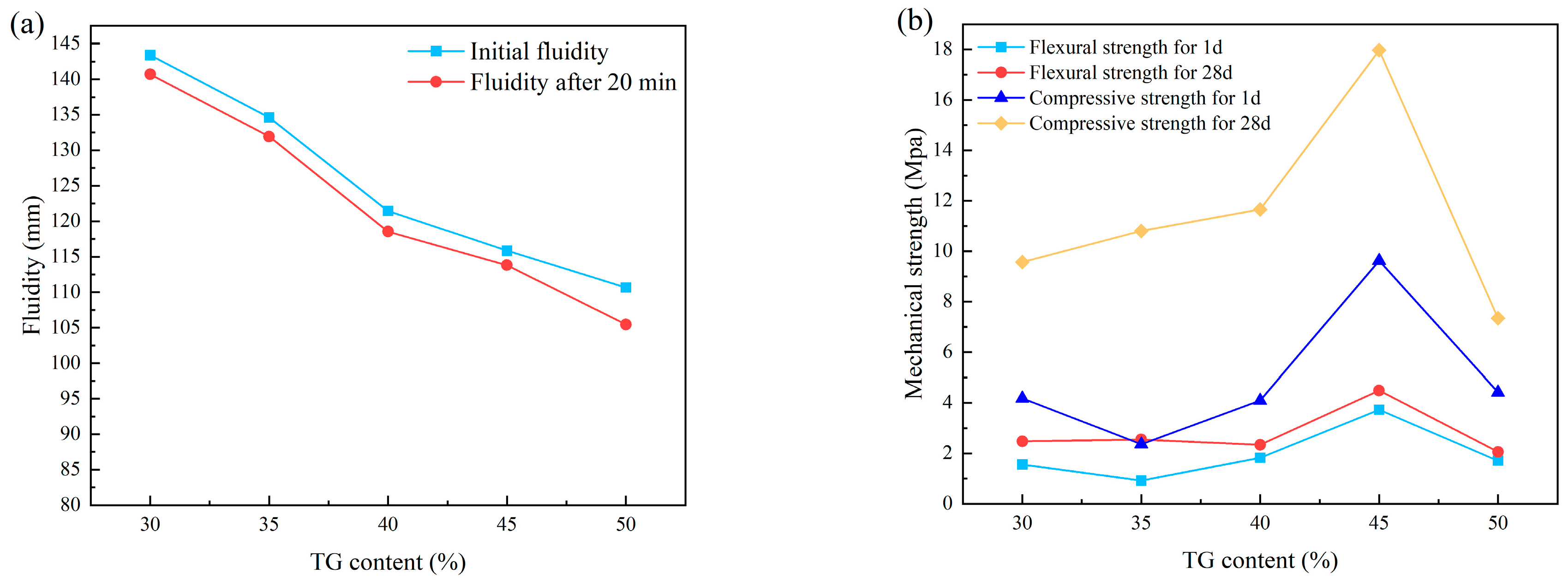

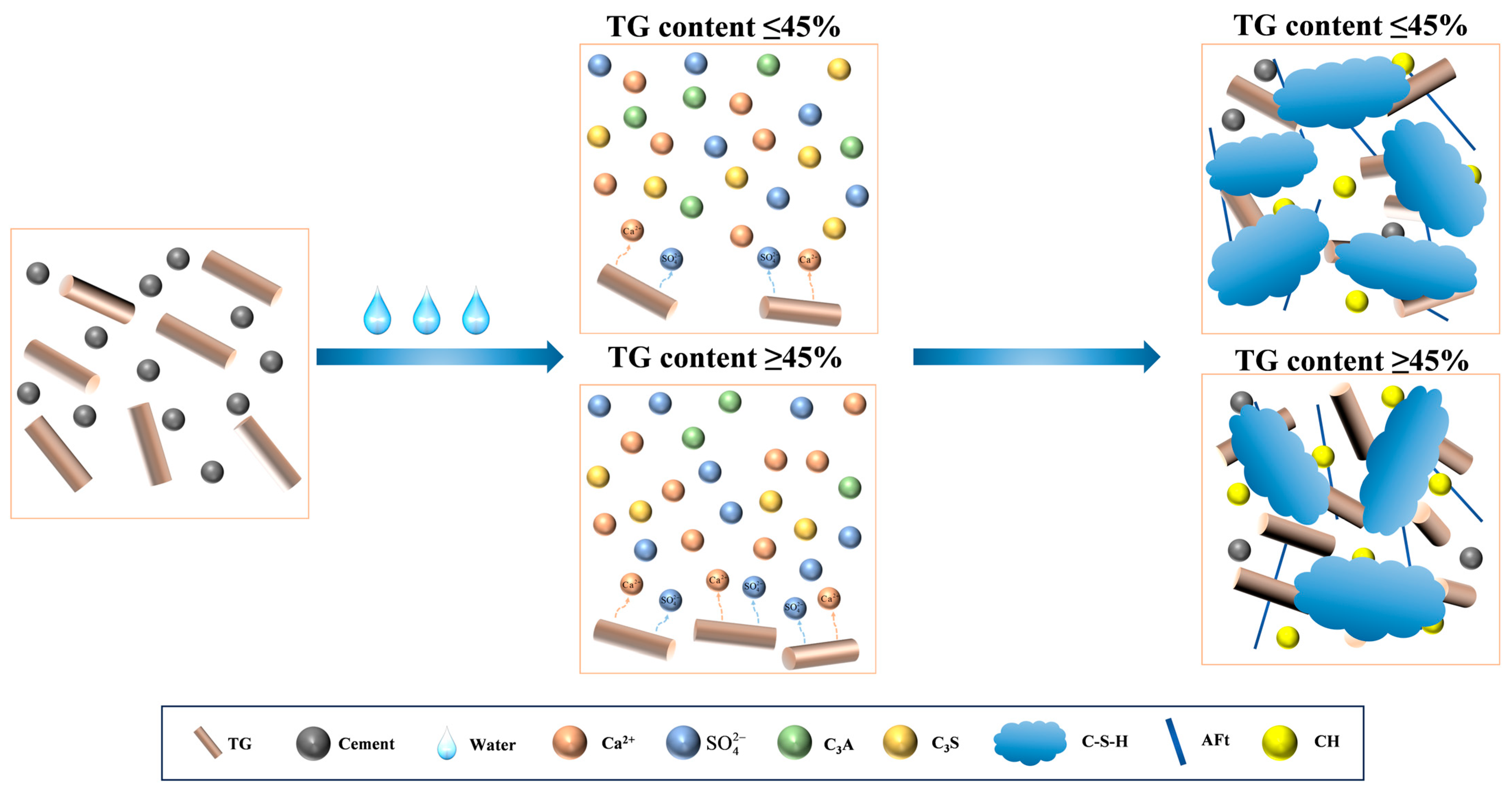

- Industrial by-products such as PG, TG, ceramic waste, and limestone powder can partially replace traditional cementitious materials or aggregates, thereby reducing the environmental impact of CSL. When PG is added to the CSL system at a concentration of 55% or less, the performance of the mortar can be improved, and carbon emissions can be reduced. The incorporation of ceramic waste at 55% can enhance compressive strength, reduce shrinkage, and prolong setting time. By controlling the incorporation ratio of industrial by-products, various green CSLs can meet the requirements of mechanical properties and workability in relevant standards (JC/T 985-2017).

- The use of a single admixture or by-product presents certain limitations, including the negative impact of PCE on early strength and the interference of impurities found in industrial waste with workability. To enhance overall performance, it is essential to utilize combinations of multiple admixtures or to implement synergistic modifications using by-products, such as a composite system that incorporates both fly ash and limestone powder. Additionally, the environmental risks related to the toxicity and heavy metal leaching of industrial by-products necessitate a systematic evaluation.

6. Outlook and Prospect

- Future aims should be to advance the research and development of high-durability CSL materials that incorporate integrated functionalities, including waterproofing, fire resistance, and antimicrobial properties, as well as establish a comprehensive lifecycle performance evaluation system that encompasses flatness retention rate, crack resistance coefficient, and color difference stability, while ensuring the functional stability of the materials under extreme temperature and humidity conditions.

- In subsequent research, fiber materials and nano-mineral additives can be incorporated into mortar to enhance its strength, toughness, and durability. Simultaneously, the balance between compressive strength and initial fluidity was optimized through orthogonal testing.

- While evaluating the performance of admixtures, it is essential to consider their potential negative effects on CSL properties. Addressing the issue of crystal structure alteration caused by admixtures represents a crucial direction for the future advancement of CSL technology. Furthermore, the development of new admixtures must also fully leverage the unique chemical structures and mechanisms of action of existing admixtures.

- There are still many areas that require further investigation regarding the influence of gypsum on the performance of CSL. Future research will focus on conducting pre-treatments, such as dehydration, alkalization, ball milling, and calcination, on various industrial by-product gypsum to enhance the compatibility between gypsum crystals and cement paste.

- Various combinations of industrial by-products can be utilized to produce CSL, leveraging the synergistic effects of these by-products to enhance both the fresh and hardening performance of CSL. Materials exhibiting performance deficiencies can be compensated for by incorporating alternative materials. Furthermore, it is essential to explore the potential of other environmentally friendly adhesives in CSL, as many remain underutilized and have not been fully developed. This category of industrial waste and by-products includes polymer resins, pollutants from tannery wastewater, ash from Prosopis juliflora, thermosetting plastic waste, waste glass, eggshells, sludge from sewage treatment plants, ground concrete waste powder, and undeveloped waste from the paper and pulp industry, among others.

- When utilizing industrial by-products, it is essential not only to consider the properties of the materials themselves but also to assess their environmental impact, including factors such as toxicity, corrosiveness, leaching rates of heavy metals, flammability, and reactivity. The integration of mass spectrometry with gas chromatography or liquid chromatography is facilitated by a comprehensive four-stage evaluation framework. This framework includes screening, mechanism analysis, process simulation, and engineering validation, enabling full-chain risk management of industrial by-products from laboratory research to engineering applications.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- JC/T 985-2017; Cementitious Self-Levelling Compound for Floor. Ministry of Industry and Information Technology of the People’s Republic of China: Beijing, China, 2007; pp. 1–13. Available online: http://www.weboos.cn/assets/basicStandard/std_1361508.pdf (accessed on 7 September 2024).

- Zhi, Z.; Huang, J.; Guo, Y.; Lu, S.; Ma, B. Effect of chemical admixtures on setting time, fluidity and mechanical properties of phosphorus gypsum based self-leveling mortar. KSCE J. Civ. Eng. 2016, 21, 1836–1843. [Google Scholar] [CrossRef]

- Wu, M.; Zhao, Q.; Shen, W.; Zhao, J.; Xu, G.; Zhao, D.; Xiong, X. Mix design of self-levelling mortar prepared by curshed sand with high flowability and early strengthening. Constr. Build. Mater. 2021, 283, 122679. [Google Scholar] [CrossRef]

- Onishi, K.; Bier, T.A. Investigation into relations among technological properties, hydration kinetics and early age hydration of self-leveling underlayments. Cem. Concr. Res. 2010, 40, 1034–1040. [Google Scholar] [CrossRef]

- Lin, Y.; Yunsheng, Z.; Yun, Y. Utilization of original phosphogypsum as raw material for the preparation of self-leveling mortar. J. Clean. Prod. 2016, 127, 204–213. [Google Scholar] [CrossRef]

- Schaefer, C.O.; Cheriaf, M.; Rocha, J.C. Production of Synthetic Phosphoanhydrite and Its Use as a Binder in Self-Leveling Underlayments (SLU). Materials 2017, 10, 958. [Google Scholar] [CrossRef]

- Gutiérrez-González, S.; Alonso, M.M.; Gadea, J.; Rodríguez, A.; Calderón, V. Rheological behaviour of gypsum plaster pastes with polyamide powder wastes. Constr. Build. Mater. 2013, 38, 407–412. [Google Scholar] [CrossRef]

- Aranda, B.; Guillou, O.; Lanos, C.; Daiguebonne, C.; Freslon, S.; Tessier, C.; Laurans, M.; Baux, C. Effect of multiphasic structure of binder particles on the mechanical properties of a gypsum-based material. Constr. Build. Mater. 2016, 102, 175–181. [Google Scholar] [CrossRef]

- Arikan, M.; Sobolev, K. The optimization of a gypsum-based composite material. Cem. Concr. Res. 2002, 32, 1725–1728. [Google Scholar] [CrossRef]

- Zhang, S.; Xu, X.; Memon, S.A.; Dong, Z.; Li, D.; Cui, H. Effect of calcium sulfate type and dosage on properties of calcium aluminate cement-based self-leveling mortar. Constr. Build. Mater. 2018, 167, 253–262. [Google Scholar] [CrossRef]

- Xu, L.; Li, N.; Wang, R.; Wang, P. A comprehensive study on the relationship between mechanical properties and microstructural development of calcium sulfoaluminate cement based self-leveling underlayments. Constr. Build. Mater. 2018, 163, 225–234. [Google Scholar] [CrossRef]

- Yang, J.; Liu, L.; Liao, Q.; Wu, J.; Li, J.; Zhang, L. Effect of superabsorbent polymers on the drying and autogenous shrinkage properties of self-leveling mortar. Constr. Build. Mater. 2019, 201, 401–407. [Google Scholar] [CrossRef]

- Wang, Y.; Wu, J.; Su, L.; Zhang, Z.; Wang, Z.; Lei, T.; Lu, X.; Ye, Z. Effect of Chemical Admixtures on the Working Performance and Mechanical Properties of Cement-Based Self-Leveling Mortar. Buildings 2023, 13, 2248. [Google Scholar] [CrossRef]

- Ge, H.; Sun, Z.; Lu, Z.; Yang, H.; Zhang, T.; He, N. Influence and mechanism analysis of different types of water reducing agents on volume shrinkage of cement mortar. J. Build. Eng. 2024, 82, 108204. [Google Scholar] [CrossRef]

- Patural, L.; Marchal, P.; Govin, A.; Grosseau, P.; Ruot, B.; Devès, O. Cellulose ethers influence on water retention and consistency in cement-based mortars. Cem. Concr. Res. 2011, 41, 46–55. [Google Scholar] [CrossRef]

- Li, N.; Xu, L.; Wang, R.; Li, L.; Wang, P. Experimental study of calcium sulfoaluminate cement-based self-leveling compound exposed to various temperatures and moisture conditions: Hydration mechanism and mortar properties. Cem. Concr. Res. 2018, 108, 103–115. [Google Scholar] [CrossRef]

- Şahmaran, M.; Christianto, H.A.; Yaman, İ.Ö. The effect of chemical admixtures and mineral additives on the properties of self-compacting mortars. Cem. Concr. Compos. 2006, 28, 432–440. [Google Scholar] [CrossRef]

- Pan, J.; Feng, K.; Wang, P.; Chen, H.; Yang, W. Retardation and compressive strength enhancement effect of upcycling waste carrot as bio-admixture for cement mortars. J. Build. Eng. 2022, 62, 105402. [Google Scholar] [CrossRef]

- Fan, L.; Xiong, S.; Wang, W.; Zhang, J.; Zeng, L. Effect of Polycarboxylate Admixture on the Performance of Fluorogypsum-Based Self-Leveling Material. Appl. Sci. 2023, 13, 12802. [Google Scholar] [CrossRef]

- Guan, Q.; Sui, Y.; Zhang, F.; Yu, W.; Bo, Y.; Wang, P.; Peng, W.; Jin, J. Preparation of α-calcium sulfate hemihydrate from industrial by-product gypsum: A review. Physicochem. Probl. Miner. Process. 2020, 57, 168–181. [Google Scholar] [CrossRef]

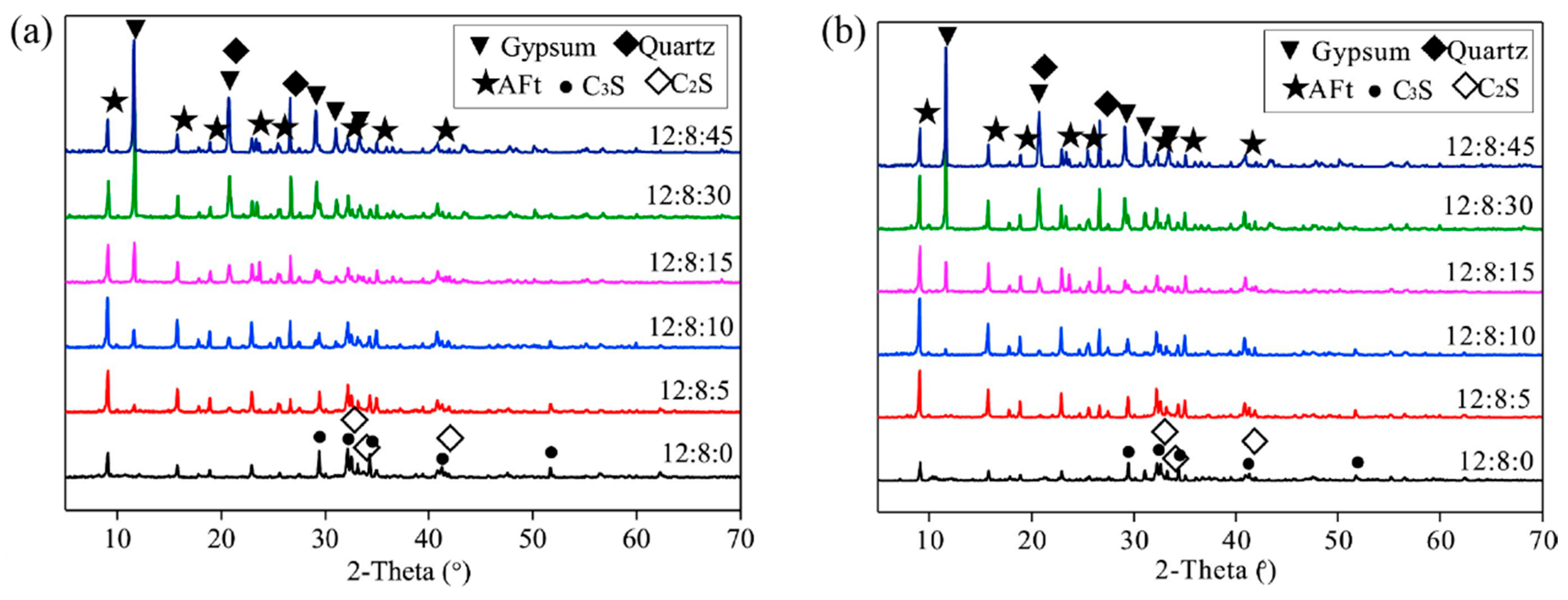

- Xiao, X.; Li, J.; Meng, Q.; Hou, X.; Liu, Y.; Wang, X.; Wang, W.; Lu, S.; Li, Y.; Mao, Y.; et al. Reuse of by-product gypsum with solid wastes-derived sulfoaluminate cement modification for the preparation of self-leveling mortar and influence mechanism of H3PO4. Constr. Build. Mater. 2024, 411, 134298. [Google Scholar] [CrossRef]

- Qi, J.; Zhu, H.; Zhou, P.; Wang, X.; Wang, Z.; Yang, S.; Yang, D.; Li, B. Application of phosphogypsum in soilization: A review. Int. J. Environ. Sci. Technol. 2023, 20, 10449–10464. [Google Scholar] [CrossRef]

- Wang, G.; Zong, H.; Zhang, Z.; Sun, J.; Wang, F.; Feng, Y.; Huang, S.; Li, Q. Application of titanium gypsum as raw materials in cement-based self-leveling mortars. Case Stud. Constr. Mater. 2023, 19, e02536. [Google Scholar] [CrossRef]

- Silva, D.B.P.; Lima, N.B.; Lima, V.M.E.; Estolano, A.M.L.; Nascimento, H.C.B.; Vilemen, P.; Padron-Hernández, E.; Carneiro, A.M.P.; Lima, N.B.D.; Povoas, Y.V. Producing a gypsum-based self-leveling mortar for subfloor modified by polycarboxylate admixture (PCE). Constr. Build. Mater. 2023, 364, 130007. [Google Scholar] [CrossRef]

- Halicka, A.; Ogrodnik, P.; Zegardlo, B. Using ceramic sanitary ware waste as concrete aggregate. Constr. Build. Mater. 2013, 48, 295–305. [Google Scholar] [CrossRef]

- Gruber, E.T.; Effting, C.; Schackow, A.; Mendes, G.A. Performance evaluation of self-leveling mortars using phosphogypsum and white ceramic waste. Rev. IBRACON Estrut. Mater. 2024, 17, e17103. [Google Scholar] [CrossRef]

- Safi, B.; Saidi, M.; Aboutaleb, D.; Maallem, M. The use of plastic waste as fine aggregate in the self-compacting mortars: Effect on physical and mechanical properties. Constr. Build. Mater. 2013, 43, 436–442. [Google Scholar] [CrossRef]

- ISO 9597:2008; Cement—Test Methods—Determination of Setting Time and Soundness. International Organization for Standardization: Geneva, Switzerland, 2008; pp. 1–10. Available online: https://www.iso.org/standard/45571.html (accessed on 13 September 2024).

- ISO 679:2009; Cement—Test Methods—Determination of Strength. International Organization for Standardization: Geneva, Switzerland, 2009; pp. 6–11. Available online: https://www.iso.org/standard/45568.html (accessed on 13 September 2024).

- ISO 13007-2:2013; Ceramic Tiles—Grouts and Adhesives—Part 2: Test Methods for Adhesives. International Organization for Standardization: Geneva, Switzerland, 2013; pp. 1–21. Available online: https://www.iso.org/standard/60881.html (accessed on 13 September 2024).

- ISO 10545-6:2010; Ceramic Tiles—Part 6: Determination of Resistance to Deep Abrasion for Unglazed Tiles. International Organization for Standardization: Geneva, Switzerland, 2010; pp. 1–3. Available online: https://www.iso.org/standard/51089.html (accessed on 13 September 2024).

- JGJ/T 70-2009; Standard for Test Method of Performance on Building Mortar. Ministry of Housing and Urban-Rural Development of the People’s Republic of China: Beijing, China, 2009; pp. 11–12. Available online: https://www.ebiaozhun.com/std/e548168f81d340d7b335fa9ffb4ee28a.html (accessed on 7 September 2024).

- Silva, D.B.P.D.; Pontes, I.D.O.C.; Rodrigues, M.T.J.; Lima, N.B.D.; Póvoas, Y.V. Pasta autonivelante de gesso para utilização como camada de contrapiso. Ambiente Construído 2021, 21, 311–329. [Google Scholar] [CrossRef]

- Padilla, A.; Panama, I.; Toledo, A.; Flores, A. Development of low weight self-levelling mortars. J. Phys. Conf. Ser. 2015, 582, 012030. [Google Scholar] [CrossRef]

- Ma, Y.; Jin, M.; Wang, F.; Jacques, D.; Shen, X.; Zhang, J.; Gao, C.; Zeng, H.; Liu, J.; Liu, J. Heating-induced transformations in calcium silicate hydrate (C-S-H): In-situ investigations of composition, structure, and morphology. Cem. Concr. Res. 2025, 190, 107819. [Google Scholar] [CrossRef]

- Scolaro, T.P.; Rocha, J.C. Influence of the physical characteristics of sand and the crushed filler content on the properties of self-leveling mortars. Cerâmica 2021, 67, 179–187. [Google Scholar] [CrossRef]

- Zeng, L.; Zhu, J.; Ye, J.; Cai, W.; Zhang, J.; Wang, S. Study on the influence mechanism of water reducing agent on the properties of anhydrite-based self-leveling mortar. Case Stud. Constr. Mater. 2023, 19, e02308. [Google Scholar] [CrossRef]

- Tran, T.Q.; Kim, Y.-S.; Dang, L.C.; Do, T.M. A state-of-the-art review on the utilization of new green binders in the production of controlled low-strength materials. Constr. Build. Mater. 2023, 393, 132078. [Google Scholar] [CrossRef]

- Sharp, J.H.; Lawrence, C.D.; Yang, R. Calcium sulfoaluminate cements—Low-energy cements, special cements or what? Adv. Cem. Res. 1999, 11, 3–13. [Google Scholar] [CrossRef]

- Gartner, E. Industrially interesting approaches to “low-CO2” cements. Cem. Concr. Res. 2004, 34, 1489–1498. [Google Scholar] [CrossRef]

- Damtoft, J.S.; Lukasik, J.; Herfort, D.; Sorrentino, D.; Gartner, E.M. Sustainable development and climate change initiatives. Cem. Concr. Res. 2008, 38, 115–127. [Google Scholar] [CrossRef]

- Gartner, E.M.; Macphee, D.E. A physico-chemical basis for novel cementitious binders. Cem. Concr. Res. 2011, 41, 736–749. [Google Scholar] [CrossRef]

- Juenger, M.C.G.; Winnefeld, F.; Provis, J.L.; Ideker, J.H. Advances in alternative cementitious binders. Cem. Concr. Res. 2011, 41, 1232–1243. [Google Scholar] [CrossRef]

- He, X.; Fang, Y.; Peng, Y.; Shen, W.; Qiao, D.; Wang, M. Mortar’s rheological property and workability investigation based on morphology impact factor for graded sand particles. Constr. Build. Mater. 2022, 328, 126987. [Google Scholar] [CrossRef]

- Zhang, D.; Zhang, S.; Yang, Q. Effect of Replacing Fine Aggregate with Fly Ash on the Performance of Mortar. Materials 2023, 16, 4292. [Google Scholar] [CrossRef]

- Canbaz, M.; Topçu, İ.B.; Ateşin, Ö. Effect of admixture ratio and aggregate type on self-leveling screed properties. Constr. Build. Mater. 2016, 116, 321–325. [Google Scholar] [CrossRef]

- Zhang, J.; Jin, C.; Wang, B.; Han, J.; Guo, L.; Tang, N. Study on the micro-rheological properties of fly ash-based cement mortar. Constr. Build. Mater. 2024, 442, 137664. [Google Scholar] [CrossRef]

- Mao, Y.; Wu, H.; Wang, W.; Jia, M.; Che, X. Pretreatment of municipal solid waste incineration fly ash and preparation of solid waste source sulphoaluminate cementitious material. J. Hazard. Mater. 2020, 385, 121580. [Google Scholar] [CrossRef] [PubMed]

- Du, C.; Jiang, X.; Wang, L.; Yi, F.; Niu, B. Experimental study on dynamic characteristics of tailings under different consolidation conditions. Sci. Rep. 2024, 14, 735. [Google Scholar] [CrossRef] [PubMed]

- Cheng, X.; Tian, W.; Gao, J.; Gao, Y. Performance evaluation and lifetime prediction of steel slag coarse aggregate concrete under sulfate attack. Constr. Build. Mater. 2022, 344, 128203. [Google Scholar] [CrossRef]

- López-Uceda, A.; Cantador-Fernández, D.; Da Silva, P.R.; de Brito, J.; Fernández-Rodríguez, J.M.; Jiménez, J.R. Mechanical and durability performance of self-compacting mortars made with different industrial by-products as fillers. Constr. Build. Mater. 2024, 431, 136536. [Google Scholar] [CrossRef]

- Dong, C.R.; Zhang, Q.Y.; Chen, C.; Jiang, T.X.; Guo, Z.G.; Liu, Y.; Lin, S.L. Fresh and hardened properties of recycled plastic fiber reinforced self-compacting concrete made with recycled concrete aggregate and fly ash, slag, silica fume. J. Build. Eng. 2022, 62, 105384. [Google Scholar] [CrossRef]

- Zheng, D.D.; Ji, T.; Wang, C.Q.; Sun, C.J.; Lin, X.J.; Hossain, K.M.A. Effect of the combination of fly ash and silica fume on water resistance of Magnesium-Potassium Phosphate Cement. Constr. Build. Mater. 2016, 106, 415–421. [Google Scholar] [CrossRef]

- Su, N.; Hsu, K.-C.; Chai, H.-W. A simple mix design method for self-compacting concrete. Cem. Concr. Res. 2001, 31, 1799–1807. [Google Scholar] [CrossRef]

- Esping, O. Effect of limestone filler BET(H2O)-area on the fresh and hardened properties of self-compacting concrete. Cem. Concr. Res. 2008, 38, 938–944. [Google Scholar] [CrossRef]

- Avet, F.; Li, X.; Scrivener, K. Determination of the amount of reacted metakaolin in calcined clay blends. Cem. Concr. Res. 2018, 106, 40–48. [Google Scholar] [CrossRef]

- Navrátilová, E.; Rovnaníková, P. Pozzolanic properties of brick powders and their effect on the properties of modified lime mortars. Constr. Build. Mater. 2016, 120, 530–539. [Google Scholar] [CrossRef]

- Zhao, Z.; Grellier, A.; El Karim Bouarroudj, M.; Michel, F.; Bulteel, D.; Courard, L. Substitution of limestone filler by waste brick powder in self-compacting mortars: Properties and durability. J. Build. Eng. 2021, 43, 102898. [Google Scholar] [CrossRef]

- Rizwan, S.A.; Bier, T.A. Blends of limestone powder and fly-ash enhance the response of self-compacting mortars. Constr. Build. Mater. 2012, 27, 398–403. [Google Scholar] [CrossRef]

- Xu, H.; Chen, F.J.; Tao, H.Y.; He, Y.F.; Zhai, W.Q.; Zhang, J.P.; He, Z.H. Effect of limestone powder on properties of self-leveling mortar. Mater. Express 2023, 13, 1790–1798. [Google Scholar] [CrossRef]

- Schönlein, M.; Plank, J. Influence of PCE kind and dosage on ettringite crystallization performed under terrestrial and microgravity conditions. J. Am. Ceram. Soc. 2018, 101, 3575–3584. [Google Scholar] [CrossRef]

- Zhang, L.; Miao, X.; Kong, X.; Zhou, S. Retardation effect of PCE superplasticizers with different architectures and their impacts on early strength of cement mortar. Cem. Concr. Compos. 2019, 104, 103369. [Google Scholar] [CrossRef]

- Yoshioka, K.; Tazawa, E.-i.; Kawai, K.; Enohata, T. Adsorption characteristics of superplasticizers on cement component minerals. Cem. Concr. Res. 2002, 32, 1507–1513. [Google Scholar] [CrossRef]

- Uchikawa, H.; Hanehara, S.; Sawaki, D. The role of steric repulsive force in the dispersion of cement particles in fresh paste prepared with organic admixture. Cem. Concr. Res. 1997, 27, 37–50. [Google Scholar] [CrossRef]

- Flatt, R.J.; Houst, Y.F. A simplified view on chemical effects perturbing the action of superplasticizers. Cem. Concr. Res. 2001, 31, 1169–1176. [Google Scholar] [CrossRef]

- Dalas, F.; Nonat, A.; Pourchet, S.; Mosquet, M.; Rinaldi, D.; Sabio, S. Tailoring the anionic function and the side chains of comb-like superplasticizers to improve their adsorption. Cem. Concr. Res. 2015, 67, 21–30. [Google Scholar] [CrossRef]

- Chuang, P.-H.; Tseng, Y.-H.; Fang, Y.; Gui, M.; Ma, X.; Luo, J. Effect of Side Chain Length on Polycarboxylate Superplasticizer in Aqueous Solution: A Computational Study. Polymers 2019, 11, 346. [Google Scholar] [CrossRef] [PubMed]

- Liu, M.; Gao, Y.; Zhang, L.; Jiang, G.; Zeng, C.; Wang, P. The application of thermal analysis to study the hydration behavior of tricalcium aluminate-gypsum in the presence of polycarboxylate-based superplasticizers. Thermochim. Acta 2021, 696, 178821. [Google Scholar] [CrossRef]

- Li, J.; Wang, R.; Li, L. Influence of cellulose ethers structure on mechanical strength of calcium sulphoaluminate cement mortar. Constr. Build. Mater. 2021, 303, 124514. [Google Scholar] [CrossRef]

- Li, Q.; Wang, B.; Wei, Z.; Zhong, Y. Experiment and numerical simulation study of polycarboxylate superplasticizer modified cemented ultrafine tailings filling slurry: Rheology, fluidity, and flow properties in pipeline. Constr. Build. Mater. 2024, 438, 137041. [Google Scholar] [CrossRef]

- Basha, S.I.; Aziz, M.A.; Ahmad, S.; Al-Zahrani, M.M.; Shameem, M.; Maslehuddin, M. Improvement of concrete durability using nanocomposite coating prepared by mixing epoxy coating with Submicron/Nano-carbon obtained from heavy fuel oil ash. Constr. Build. Mater. 2022, 325, 126812. [Google Scholar] [CrossRef]

- Miao, J.; Lu, L.; Jiang, J. Reinforcement of ultra-low dosage of polycarboxylate ether (PCE) grafted nano-silica sol to the mechanical and durable properties of cement mortar. J. Mater. Res. Technol. 2022, 19, 3646–3657. [Google Scholar] [CrossRef]

- Peng, J.; Qu, J.; Zhang, J.; Chen, M.; Wan, T. Adsorption characteristics of water-reducing agents on gypsum surface and its effect on the rheology of gypsum plaster. Cem. Concr. Res. 2005, 35, 527–531. [Google Scholar] [CrossRef]

- Qian, S.; Yao, Y.; Wang, Z.; Cui, S.; Liu, X.; Jiang, H.; Guo, Z.; Lai, G.; Xu, Q.; Guan, J. Synthesis, characterization and working mechanism of a novel polycarboxylate superplasticizer for concrete possessing reduced viscosity. Constr. Build. Mater. 2018, 169, 452–461. [Google Scholar] [CrossRef]

- Uchikawa, H.; Hanehara, S.; Shirasaka, T.; Sawaki, D. Effect of admixture on hydration of cement, adsorptive behavior of admixture and fluidity and setting of fresh cement paste. Cem. Concr. Res. 1992, 22, 1115–1129. [Google Scholar] [CrossRef]

- Jansen, D.; Neubauer, J.; Goetz-Neunhoeffer, F.; Haerzschel, R.; Hergeth, W.D. Change in reaction kinetics of a Portland cement caused by a superplasticizer—Calculation of heat flow curves from XRD data. Cem. Concr. Res. 2012, 42, 327–332. [Google Scholar] [CrossRef]

- Zhang, Y.-R.; Kong, X.-M.; Lu, Z.-B.; Lu, Z.-C.; Hou, S.-S. Effects of the charge characteristics of polycarboxylate superplasticizers on the adsorption and the retardation in cement pastes. Cem. Concr. Res. 2015, 67, 184–196. [Google Scholar] [CrossRef]

- Cheung, J.; Jeknavorian, A.; Roberts, L.; Silva, D. Impact of admixtures on the hydration kinetics of Portland cement. Cem. Concr. Res. 2011, 41, 1289–1309. [Google Scholar] [CrossRef]

- Pourchez, J.; Peschard, A.; Grosseau, P.; Guyonnet, R.; Guilhot, B.; Vallée, F. HPMC and HEMC influence on cement hydration. Cem. Concr. Res. 2006, 36, 288–294. [Google Scholar] [CrossRef]

- Nguyen, D.D.; Devlin, L.P.; Koshy, P.; Sorrell, C.C. Impact of water-soluble cellulose ethers on polymer-modified mortars. J. Mater. Sci. 2013, 49, 923–951. [Google Scholar] [CrossRef]

- Pourchez, J.; Ruot, B.; Debayle, J.; Pourchez, E.; Grosseau, P. Some aspects of cellulose ethers influence on water transport and porous structure of cement-based materials. Cem. Concr. Res. 2010, 40, 242–252. [Google Scholar] [CrossRef]

- Li, J.; Wang, R.; Xu, Y. Influence of cellulose ethers chemistry and substitution degree on the setting and early-stage hydration of calcium sulphoaluminate cement. Constr. Build. Mater. 2022, 344, 128266. [Google Scholar] [CrossRef]

- Bülichen, D.; Kainz, J.; Plank, J. Working mechanism of methyl hydroxyethyl cellulose (MHEC) as water retention agent. Cem. Concr. Res. 2012, 42, 953–959. [Google Scholar] [CrossRef]

- Brumaud, C.; Bessaies-Bey, H.; Mohler, C.; Baumann, R.; Schmitz, M.; Radler, M.; Roussel, N. Cellulose ethers and water retention. Cem. Concr. Res. 2013, 53, 176–184. [Google Scholar] [CrossRef]

- Bülichen, D.; Plank, J. Mechanistic study on carboxymethyl hydroxyethyl cellulose as fluid loss control additive in oil well cement. J. Appl. Polym. Sci. 2012, 124, 2340–2347. [Google Scholar] [CrossRef]

- Chen, N.; Wang, P.; Zhao, L.; Zhang, G. Water Retention Mechanism of HPMC in Cement Mortar. Materials 2020, 13, 2918. [Google Scholar] [CrossRef]

- Xu, L.; Ou, Y.; Hecker, A.; Rößler, C.; Ludwig, H.M.; Yang, Z.; Wu, K. State of water in calcium sulfoaluminate cement paste modified by hydroxyethyl methyl cellulose ether. J. Build. Eng. 2021, 43, 102894. [Google Scholar] [CrossRef]

- Zhou, S.-C.; Lv, H.-L.; Li, N.; Zhang, J. Effects of Chemical Admixtures on the Working and Mechanical Properties of Ordinary Dry-Mixed Mortar. Adv. Mater. Sci. Eng. 2019, 2019, 5978089. [Google Scholar] [CrossRef]

- You Seok, K.; Ho-Jong, K. Effect of Cellulose Based Water Retention Additives on Mechanical Properties of Cement Based Mortar. Polymer 2015, 39, 820–826. [Google Scholar] [CrossRef]

- Pourchez, J.; Grosseau, P.; Ruot, B. Changes in C3S hydration in the presence of cellulose ethers. Cem. Concr. Res. 2010, 40, 179–188. [Google Scholar] [CrossRef]

- Ou, Z.H.; Ma, B.G.; Jian, S.W. Influence of cellulose ethers molecular parameters on hydration kinetics of Portland cement at early ages. Constr. Build. Mater. 2012, 33, 78–83. [Google Scholar] [CrossRef]

- Knapen, E.; Van Gemert, D. Cement hydration and microstructure formation in the presence of water-soluble polymers. Cem. Concr. Res. 2009, 39, 6–13. [Google Scholar] [CrossRef]

- Huang, G.; Zhao, J.; Gupta, R.; Liu, W.V. Influence of tartaric acid dosage on the early-age and long-term properties of calcium sulfoaluminate belite cement composites. Constr. Build. Mater. 2022, 356, 129257. [Google Scholar] [CrossRef]

- Sun, F.; Pang, X.; Kawashima, S.; Cheng, G.; Guo, S.; Bu, Y. Effect of tartaric acid on the hydration of oil well cement at elevated temperatures between 60 °C and 89 °C. Cem. Concr. Res. 2022, 161, 106952. [Google Scholar] [CrossRef]

- Guan, B.; Tian, H.; Ding, D.; Wu, J.; Xiong, R.; Xu, A.; Chen, H. Effect of Citric Acid on the Time-Dependent Rheological Properties of Magnesium Oxychloride Cement. J. Mater. Civ. Eng. 2018, 30, 04018275. [Google Scholar] [CrossRef]

- Coppola, L.; Coffetti, D.; Crotti, E. Use of tartaric acid for the production of sustainable Portland-free CSA-based mortars. Constr. Build. Mater. 2018, 171, 243–249. [Google Scholar] [CrossRef]

- Telesca, A.; Marroccoli, M.; Coppola, L.; Coffetti, D.; Candamano, S. Tartaric acid effects on hydration development and physico-mechanical properties of blended calcium sulphoaluminate cements. Cem. Concr. Compos. 2021, 124, 104275. [Google Scholar] [CrossRef]

- Zou, D.; Zhang, Z.; Wang, D. Influence of citric acid and sodium gluconate on hydration of calcium sulfoaluminate cement at various temperatures. Constr. Build. Mater. 2020, 263, 120247. [Google Scholar] [CrossRef]

- Burris, L.E.; Kurtis, K.E. Influence of set retarding admixtures on calcium sulfoaluminate cement hydration and property development. Cem. Concr. Res. 2018, 104, 105–113. [Google Scholar] [CrossRef]

- Belhadi, R.; Govin, A.; Grosseau, P. Influence of polycarboxylate superplasticizer, citric acid and their combination on the hydration and workability of calcium sulfoaluminate cement. Cem. Concr. Res. 2021, 147, 106513. [Google Scholar] [CrossRef]

- Lim, H.M.; Yang, H.C.; Chun, B.S.; Lee, S.H. The Effect of Sodium Tripolyphosphate on Sodium Silicate-Cement Grout. Mater. Sci. Forum 2005, 486–487, 391–394. [Google Scholar] [CrossRef]

- Rashad, A.M.; Gharieb, M. Impact of long-term natural weathering on the properties of alkali-activated fly ash mortars modified with silica fume and sodium tripolyphosphate. Constr. Build. Mater. 2023, 405, 133354. [Google Scholar] [CrossRef]

- Kastiukas, G.; Zhou, X.; Castro-Gomes, J.; Huang, S.; Saafi, M. Effects of lactic and citric acid on early-age engineering properties of Portland/calcium aluminate blended cements. Constr. Build. Mater. 2015, 101, 389–395. [Google Scholar] [CrossRef]

- Ding, X.; Huang, W.; Li, Y.; Hu, Z.; Shan, Z. Study on retarding feature and retardation mechanism of various retarding materials on gypsum as a construction material: A review. J. Build. Eng. 2023, 72, 106569. [Google Scholar] [CrossRef]

- Ding, X.; Wei, B.; Deng, M.; Chen, H.; Shan, Z. Effect of protein peptides with different molecular weights on the setting and hydration process of gypsum. Constr. Build. Mater. 2022, 318, 126185. [Google Scholar] [CrossRef]

- Ding, X.; Ye, B.; Dai, R.; Chen, H.; Shan, Z. A graft copolymer of collagen hydrolysate obtained from chrome leather scraps for retardation in Portland cement. J. Clean. Prod. 2021, 284, 125408. [Google Scholar] [CrossRef]

- Yalcin, D.; Ozcalik, O.; Altiok, E.; Bayraktar, O. Characterization and recovery of tartaric acid from wastes of wine and grape juice industries. J. Therm. Anal. Calorim. 2008, 94, 767–771. [Google Scholar] [CrossRef]

- Nurgel, C.; Canbas, A. Production of Tartaric Acid From Pomace of Some Anatolian Grape Cultivars. Am. J. Enol. Vitic. 1998, 49, 95–99. [Google Scholar] [CrossRef]

- Bishop, M.; Barron, A.R. Cement Hydration Inhibition with Sucrose, Tartaric Acid, and Lignosulfonate: Analytical and Spectroscopic Study. Ind. Eng. Chem. Res. 2006, 45, 7042–7049. [Google Scholar] [CrossRef]

- Plank, J.; Winter, C. Competitive adsorption between superplasticizer and retarder molecules on mineral binder surface. Cem. Concr. Res. 2008, 38, 599–605. [Google Scholar] [CrossRef]

- Ltifi, M.; Guefrech, A.; Mounanga, P. Effects of sodium tripolyphosphate on the rheology and hydration rate of Portland cement pastes. Adv. Cem. Res. 2012, 24, 325–335. [Google Scholar] [CrossRef]

- Cheng, B.; Feng, H.; Armia, E.; Guo, H.; Zhang, S.; Zhang, H. Effects of Sodium Tripolyphosphate Addition on the Dispersion and Hydration of Pure Calcium Aluminate Cement. Materials 2023, 16, 3141. [Google Scholar] [CrossRef]

- Liu, C.; Jia, Y.M. Effect of Redispersible Latex Powder and Fly Ash on Properties of Mortar. Coatings 2022, 12, 1930. [Google Scholar] [CrossRef]

- Wang, S.; Zhang, G.; Wang, Z.; Huang, T.; Wang, P. Effect of defoaming agent on the properties of cement mortars with hydroxyethyl methyl cellulose through adjusting air content gradient. Cem. Concr. Compos. 2023, 139, 105024. [Google Scholar] [CrossRef]

- Ping, Z.; Ming, L.; Chi, Z.; Xiujian, X.; Yongjin, Y.; Fengzhong, Q.; Yuanpeng, W. Ultra-high temperature suspending stabilizer and cement slurry interface interaction law and mechanism study for ultra-deep well cementing. Constr. Build. Mater. 2023, 409, 133979. [Google Scholar] [CrossRef]

- Oliveira, T.V.; Cordeiro, L.D.P.; Bessa, S.A.L. Experimental study of self-leveling mortars produced with recycled concrete aggregates. Case Stud. Constr. Mater. 2022, 17, e01294. [Google Scholar] [CrossRef]

- Yu, Z.Y.; Zhao, Y.D.; Ba, H.J.; Liu, M.H. Synergistic effects of ettringite-based expansive agent and polypropylene fiber on early-age anti-shrinkage and anti-cracking properties of mortars. J. Build. Eng. 2021, 39, 102275. [Google Scholar] [CrossRef]

- Zhao, W.H.; Ji, X.P.; Jiang, Y.Q.; Pan, T.H. Effect of C-S-H Nucleating Agent on Cement Hydration. Appl. Sci. 2021, 11, 6638. [Google Scholar] [CrossRef]

- Manh Do, T.; Kang, G.-O.; Kim, Y.-S. Development of a new cementless binder for controlled low strength material (CLSM) using entirely by-products. Constr. Build. Mater. 2019, 206, 576–589. [Google Scholar] [CrossRef]

- Zhi, Z.; Ma, B.; Tan, H.; Guo, Y.; Jin, Z.; Yu, H.; Jian, S. Effect of Competitive Adsorption between Polycarboxylate Superplasticizer and Hydroxypropylmethyl Cellulose on Rheology of Gypsum Paste. J. Mater. Civ. Eng. 2018, 30, 04018141. [Google Scholar] [CrossRef]

- Zha, F.; Qiao, B.; Kang, B.; Xu, L.; Chu, C.; Yang, C. Engineering properties of expansive soil stabilized by physically amended titanium gypsum. Constr. Build. Mater. 2021, 303, 124456. [Google Scholar] [CrossRef]

- Yuan, H.; Chen, S. Effects of titanium gypsum on high calcium fly ash system: Physical and microscopic properties, hydration, and Fe transformation. J. Build. Eng. 2023, 78, 107653. [Google Scholar] [CrossRef]

- Li, X.-Y.; Yang, J.-Y. Production, characterisation, and application of titanium gypsum: A review. Process Saf. Environ. Prot. 2024, 181, 64–74. [Google Scholar] [CrossRef]

- Du, J.; Tian, L.; Qi, M.; Zhang, C.; Di, H.; Zhi, X.; Zhu, J. Revealing maleic acid role in the preparation of α-hemihydrate gypsum from titanium gypsum through experiments and DFT calculations. Sci. Total Environ. 2023, 897, 166405. [Google Scholar] [CrossRef]

- Huang, K.; Cai, G.; Yan, C.; Yu, J.; Tang, L.; Zhang, J. Strength and microstructure characteristics of red-bed weathered residual soil stabilized by Titanium Gypsum-Cement. Constr. Build. Mater. 2023, 403, 133071. [Google Scholar] [CrossRef]

- Pereira, V.M.; Camarini, G. Fresh and Hardened Properties of Self-Leveling Mortars with Porcelain and Red Ceramic Wastes. Adv. Civ. Eng. 2018, 2018, 6378643. [Google Scholar] [CrossRef]

- Wang, Q.; Jia, R.Q. A novel gypsum-based self-leveling mortar produced by phosphorus building gypsum. Constr. Build. Mater. 2019, 226, 11–20. [Google Scholar] [CrossRef]

- Anjos, M.A.S.; Araújo, T.R.; Ferreira, R.L.S.; Farias, E.C.; Martinelli, A.E. Properties of self-leveling mortars incorporating a high-volume of sugar cane bagasse ash as partial Portland cement replacement. J. Build. Eng. 2020, 32, 101694. [Google Scholar] [CrossRef]

- Barluenga, G.; Hernández-Olivares, F. Self-levelling cement mortar containing grounded slate from quarrying waste. Constr. Build. Mater. 2010, 24, 1601–1607. [Google Scholar] [CrossRef]

- Schiefer, C.; Plank, J. Mechanochemical syngenite as hydration accelerator for anhydrite-based self-levelling floor screeds. Constr. Build. Mater. 2021, 308, 124982. [Google Scholar] [CrossRef]

- Mendes, G.A.; Effting, C.; Schackow, A. Argamassa autonivelante com adição de resíduos de mármorese granitos: Propriedades físicase mecânicas. Ambiente Construído 2020, 20, 403–418. [Google Scholar] [CrossRef]

- Li, B.; Wang, C.-Q.; Huang, H.-S. Red mud modified phosphogypsum based self-leveling mortar: Hydration mechanism, heavy metal migration law and spatial distribution characteristics. Constr. Build. Mater. 2024, 426, 136071. [Google Scholar] [CrossRef]

| CSL Property | Standard Test | Description | Requirement (JC/T 985-2017) [1] |

|---|---|---|---|

| Appearance | JC/T 985-2017 [1] | Cementitious self-leveling compound for floor | Uniform, no lumps, no other objects |

| Initial fluidity/mm | ISO 9597:2008 [28] | Cement—Test methods—Determination of setting time and soundness | ≥130 |

| 20 min fluidity/mm | ≥130 | ||

| 24 h flexural strength/MPa | ISO 679:2009 [29] | Cement—Test methods—Determination of strength | ≥2.0 |

| 24 h compressive strength/MPa | ≥6.0 | ||

| 28 d flexural strength/MPa | ≥6.0 | ||

| 28 d compressive strength/MPa | ≥25.0 | ||

| 28 d tensile bond strength/MPa | ISO 13007-2:2013 [30] | Ceramic tiles—Grouts and adhesives—Part 2: Test methods for adhesives | ≥1.5 |

| Shrinkage/% | JGJ/T 70-2009 [32] | Standard for test method of performance on building mortar | −0.10~+0.10 |

| Impact resistance | JC/T 985-2017 [1] | Cementitious self-leveling compound for floor | No cracking or detachment from the base plate |

| Wear resistance/mm3 | ISO 10545-6:2010 [31] | Ceramic tiles-Part 6: Determination of resistance to deep abrasion for unglazed tiles | ≤400 |

| Organic Acid Retarder | Structural Structure | Functional Group | Molecular Weight |

|---|---|---|---|

| Citric acid (CA) |  | —COOH —OH | 192 |

| Tartaric acid (TA) |  | —COOH —OH | 150 |

| Sodium tripolyphosphate (STPP) |  | — | 368 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zong, M.; Ma, H.; Yan, X.; Zhu, P.; Wang, W.; Liu, H.; Dong, F.; Hua, M. Advances in the Application and Mechanism of Admixtures and Industrial By-Products in Cement-Based Self-Leveling Mortar: A Comprehensive Review. Materials 2025, 18, 1709. https://doi.org/10.3390/ma18081709

Zong M, Ma H, Yan X, Zhu P, Wang W, Liu H, Dong F, Hua M. Advances in the Application and Mechanism of Admixtures and Industrial By-Products in Cement-Based Self-Leveling Mortar: A Comprehensive Review. Materials. 2025; 18(8):1709. https://doi.org/10.3390/ma18081709

Chicago/Turabian StyleZong, Meirong, Haozhe Ma, Xiancui Yan, Pinghua Zhu, Wenhao Wang, Hui Liu, Faqin Dong, and Minqi Hua. 2025. "Advances in the Application and Mechanism of Admixtures and Industrial By-Products in Cement-Based Self-Leveling Mortar: A Comprehensive Review" Materials 18, no. 8: 1709. https://doi.org/10.3390/ma18081709

APA StyleZong, M., Ma, H., Yan, X., Zhu, P., Wang, W., Liu, H., Dong, F., & Hua, M. (2025). Advances in the Application and Mechanism of Admixtures and Industrial By-Products in Cement-Based Self-Leveling Mortar: A Comprehensive Review. Materials, 18(8), 1709. https://doi.org/10.3390/ma18081709