Enhanced Strength of Al-10Ce-3Mg-5Zn Heat-Resistant Alloy by Combining Extrusion and Heat Treatment

Abstract

1. Introduction

2. Materials and Methods

3. Results

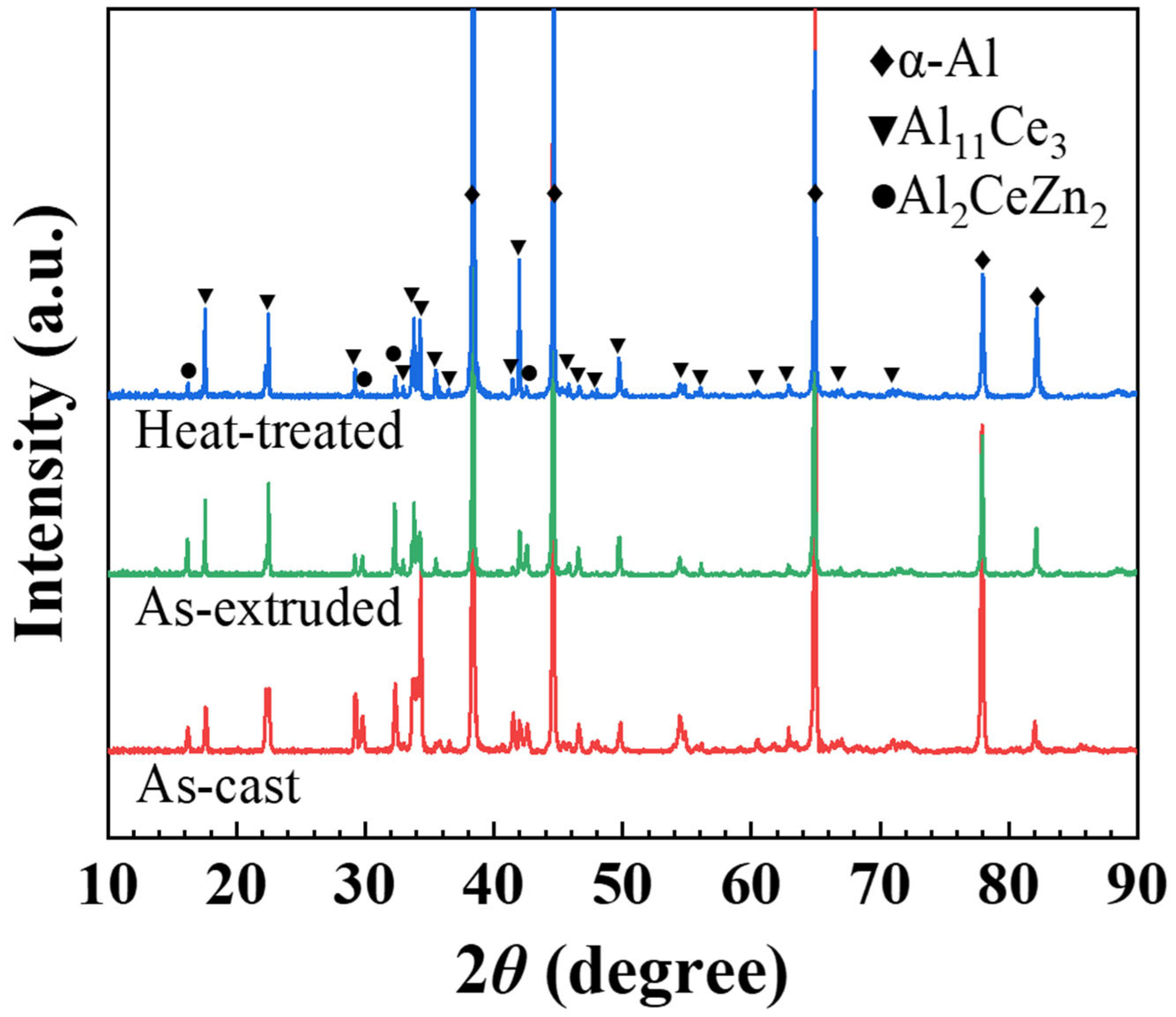

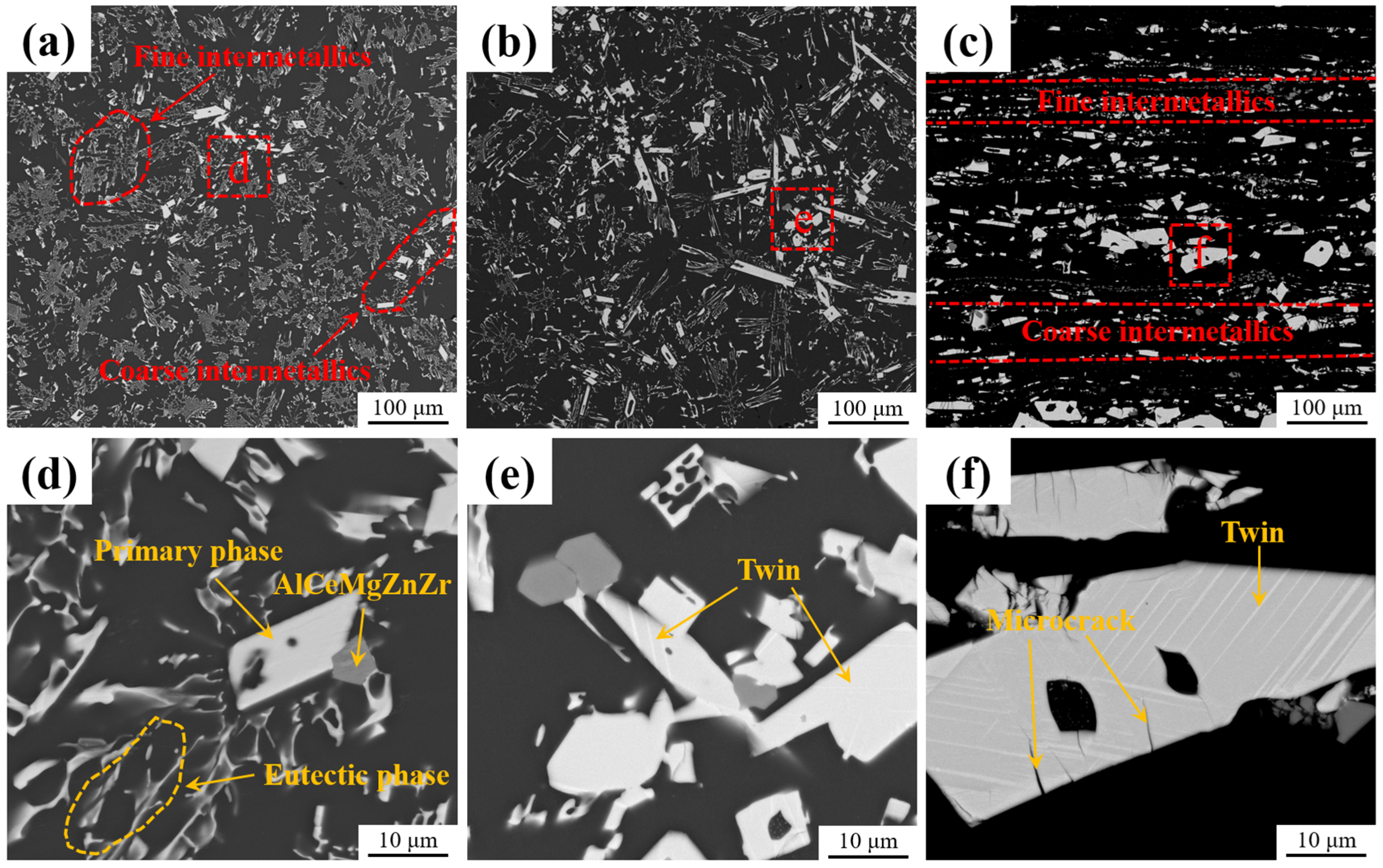

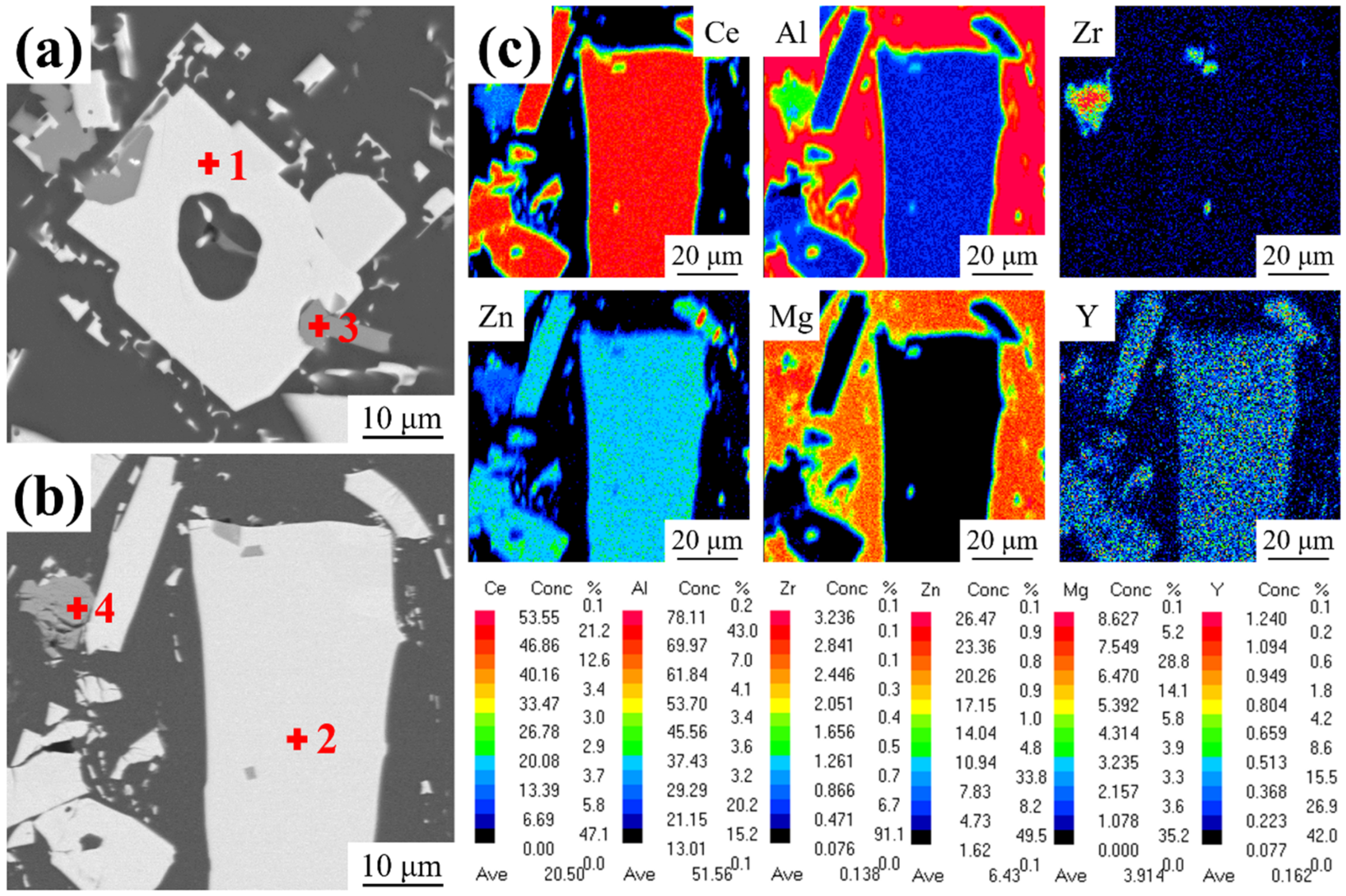

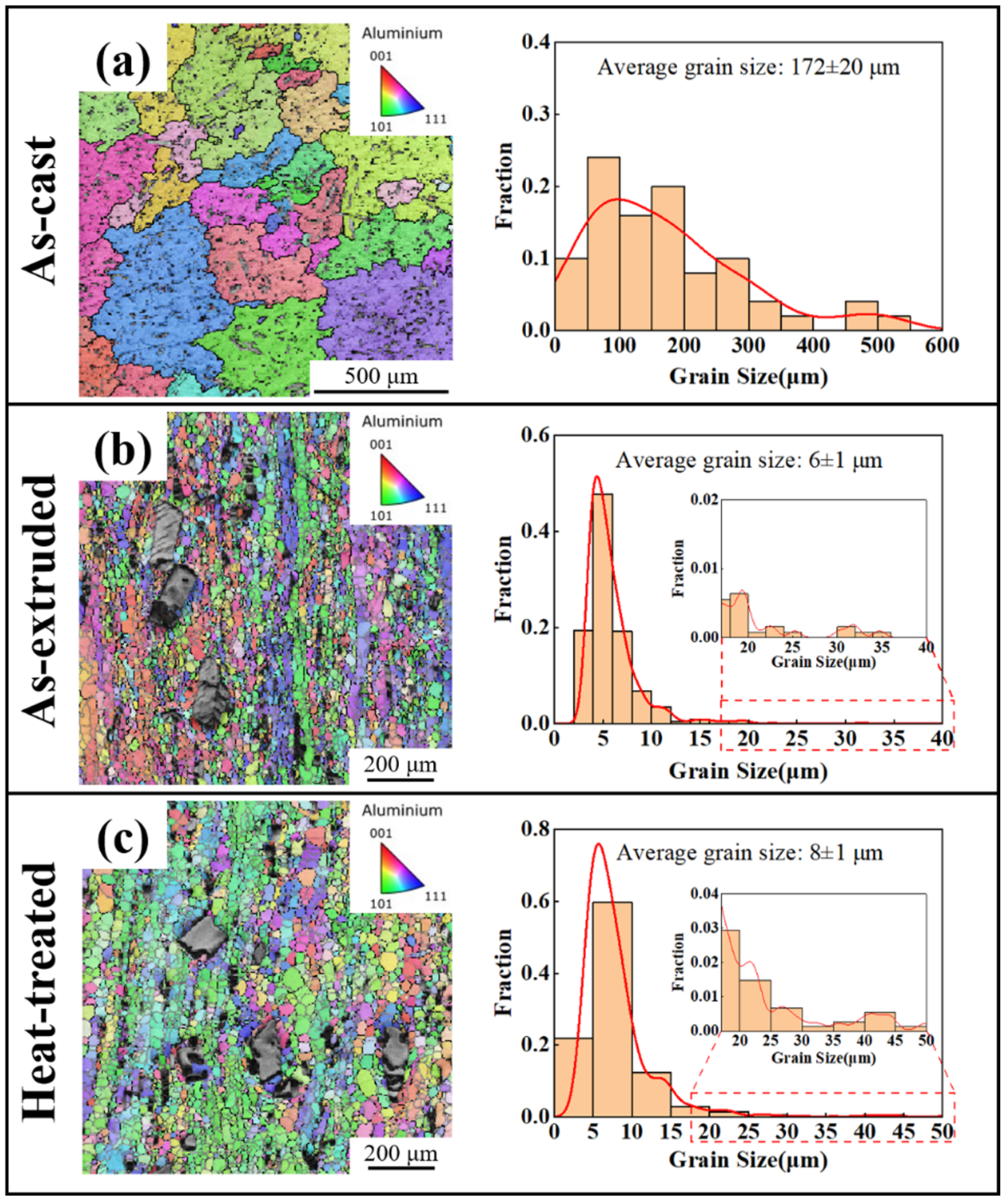

3.1. The Microstructures of the Al-10Ce-3Mg-5Zn Alloy

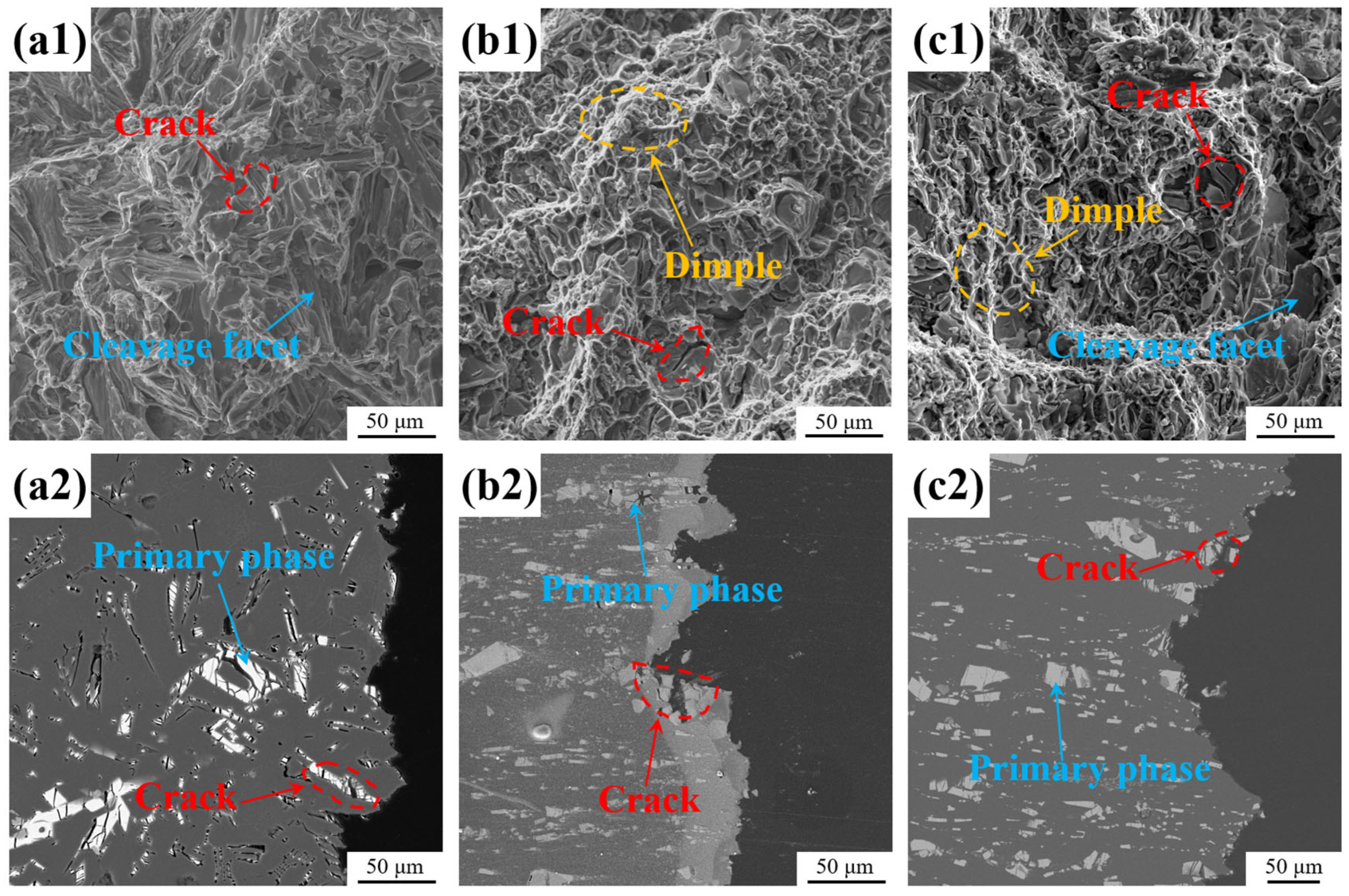

3.2. Mechanical Properties and Fracture Morphologies

4. Discussion

4.1. Intermetallic and Microstructure Evolutions

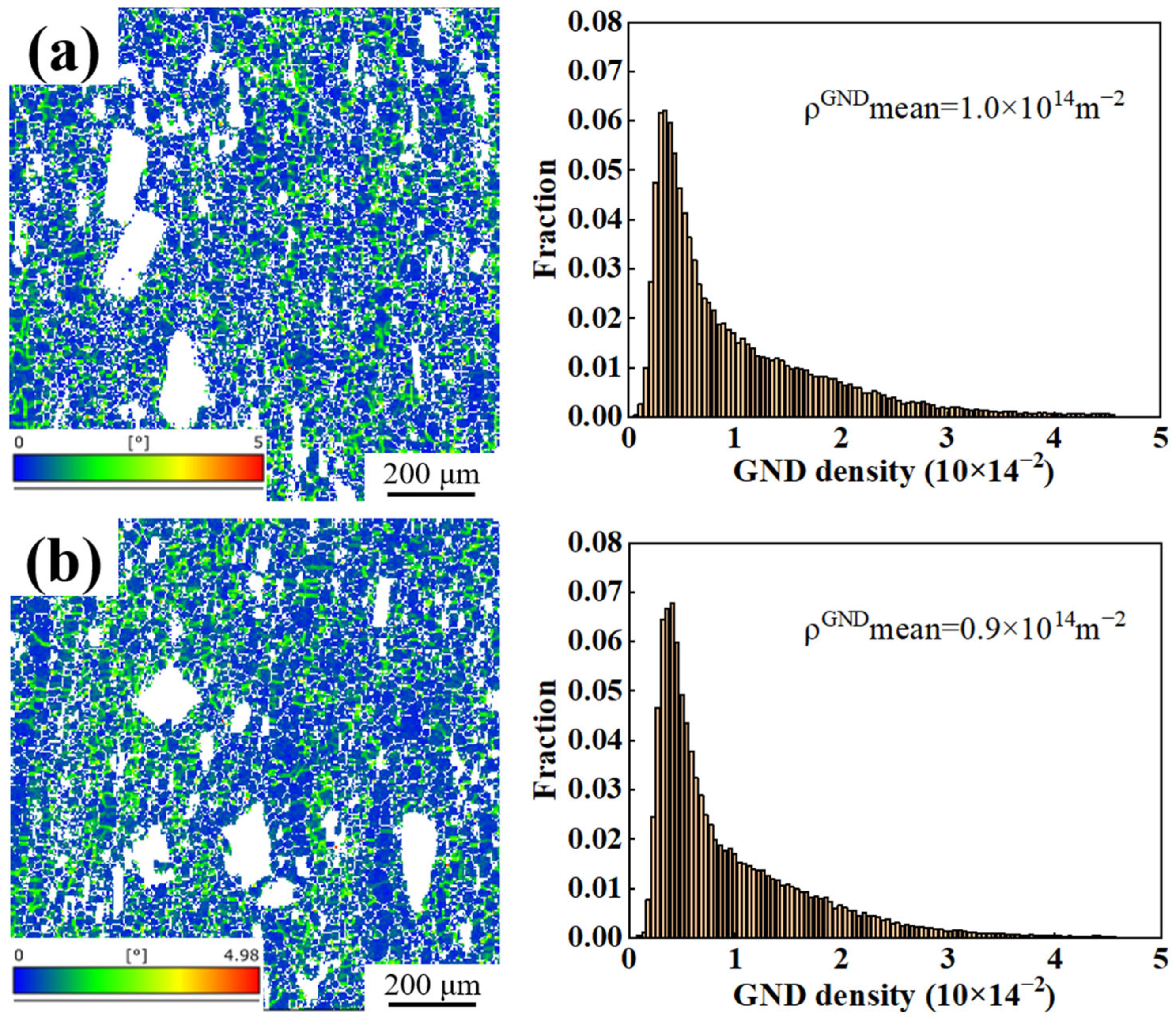

4.2. Strengthening Mechanism

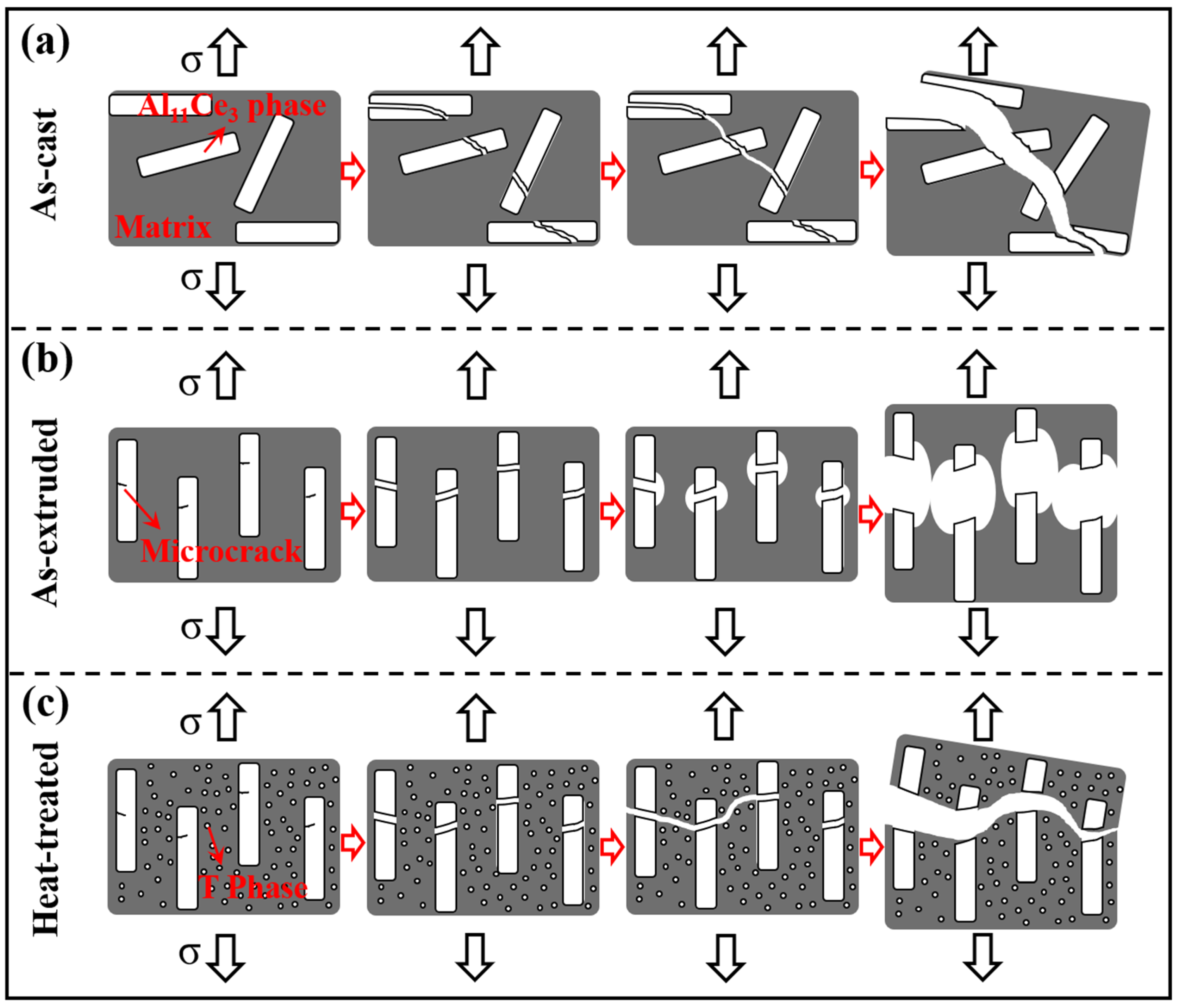

4.3. Ductility

5. Conclusions

- (1)

- The as-extruded alloy exhibits a bimodal intermetallic compound, and there are high-density microcracks and twins in the coarse intermetallic compound. Furthermore, the bimodal intermetallic compound structure gives rise to the bimodal distribution of α-Al grains. In addition to the formation of a substantial number of strengthened nano-scale T phases, there is no discernible alteration in the other microstructures of the heat-treated alloy.

- (2)

- Due to the combined effect of grain boundary strengthening and dislocation strengthening, the as-extruded alloy has higher UTS, which is 51% higher than that of the as-cast alloy at 210 MPa, reaching 318 MPa. After heat treatment, the strength of the alloy is further improved to 367 MPa, primarily due to the enhanced Orowan strengthening effect resulting from the precipitation of the nano-strengthened T phase.

- (3)

- The as-extruded alloy displays notable plasticity, which is primarily attributable to the bimodal structure of the alloy, the orientation relationship between the intermetallic phase and the load, the pre-existing microcrack propagation, and twin deformation. The plasticity of the heat-treated alloy is diminished, primarily due to the T phase strengthening of the matrix and the simultaneous reduction in its plastic deformation ability.

- (4)

- The heat-treated alloy exhibits a good strength retention rate at elevated temperatures. The UTS retention rate of the heat-treated alloy at room temperature was calculated to be 64% at 200 °C, 29% at 260 °C, and 21% at 300 °C. Moreover, the room- and elevated-temperature stress–strain curves of the studied alloys were serrated. The primary factors contributing to the serrated flow behavior are twinning deformation, the interaction between the obstacles (such as solute atoms and precipitated phases), and movable dislocations.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ye, K.; Cai, X.; Sun, B.; Zhou, L.; Ma, S.; Yue, Y.; Xu, F.; Zheng, D.; Fu, X. Effect of rare earth Ce on the microstructure and mechanical properties of cast Al–7Si alloys. J. Sci. Adv. Mater. Devices 2023, 8, 100634. [Google Scholar] [CrossRef]

- Wu, M.; Liu, W.; Xiao, D.; Huang, L. Influence of thermal exposure on the microstructure evolution and mechanical behaviors of an Al-Cu-Li alloy. Mater. Des. 2023, 227, 111767. [Google Scholar] [CrossRef]

- Hou, X.; Sun, S.; Bai, P.; Zhao, X.; Lang, F.; Li, B. Investigation of nanoscale strain fields induced by the L12–Al3Zr phase in Al–Zn–Mg–Cu alloys. Mater. Lett. 2024, 359, 135933. [Google Scholar] [CrossRef]

- Nakatsuka, S.; Ishihara, M.; Takata, N.; Suzuki, A.; Kobashi, M. Tensile Properties of a Heat-Resistant Aluminium Alloy Strengthened by T-Al6Mg11Zn11 Intermetallic Phase. MRS Adv. 2019, 4, 1485–1490. [Google Scholar] [CrossRef]

- Zhao, P.; Wu, X.; Gao, K.; Wen, S.; Rong, L.; Huang, H.; Wei, W.; Nie, Z. Effect of Zn/Mg ratio on microstructure and mechanical properties of Al-Zn-Mg alloys. Mater. Lett. 2022, 312, 131676. [Google Scholar] [CrossRef]

- Dastgiri, M.; Fuerth, Z.; Kiawi, L.; Green, D. Experimental study on high temperature tensile behaviour of aluminium alloy AA5083 with oscillating load. Sci. Rep. 2023, 13, 13307. [Google Scholar] [CrossRef]

- Czerwinski, F. Thermal stability of aluminum–cerium binary alloys containing the Al–Al11Ce3 eutectic. Mater. Sci. Eng. A 2021, 809, 140973. [Google Scholar] [CrossRef]

- Liu, Y.; Michi, R.; Dunand, D. Cast near-eutectic Al-12.5 wt.% Ce alloy with high coarsening and creep resistance. Mater. Sci. Eng. A 2019, 767, 138440. [Google Scholar] [CrossRef]

- Sims, Z.; Weiss, D.; McCall, S.; McGuire, M.; Ott, R.; Geer, T.; Rios, O.; Turchi, P. Intermetallic-Strengthened Aluminum Casting Alloy: High-Volume Co-product Development. JOM 2016, 68, 1940–1947. [Google Scholar] [CrossRef]

- Okamoto, H. Al-Ce (Aluminum-Cerium). J. Phase Equilibria Diffus. 2011, 32, 392–393. [Google Scholar] [CrossRef]

- Emery, R.; Rios, O.; Thompson, M.; Weiss, D.; Rack, P. Thin film combinatorial sputtering of Al-Ce alloys: Investigating the phase separation of as-deposited solid solutions and determining the coefficient of thermal expansion. J. Alloys Compd. 2022, 913, 165271. [Google Scholar] [CrossRef]

- Czerwinski, F.; Amirkhiz, B. On the Al–Al11Ce3 Eutectic Transformation in Aluminum–Cerium Binary Alloys. Materials 2020, 13, 4549. [Google Scholar] [CrossRef] [PubMed]

- Kozakevich, J.; Stroh, J.; Mallouhi, V.; Sediako, D.; Weiss, D. Interplay Between Cooling Rate, Microstructure, and Mechanical Properties of an Al–Ce–Ni–Mn Alloy, Light Metals 2022; Springer International Publishing: Berlin/Heidelberg, Germany, 2022; pp. 83–91. [Google Scholar]

- Czerwinski, F. Cerium in aluminum alloys. J. Mater. Sci. 2020, 55, 24–72. [Google Scholar] [CrossRef]

- Weiss, D. Castability and Characteristics of High Cerium Aluminum Alloys. In Advanced Casting Technologies; IntechOpen: Rijeka, Croatia, 2018; pp. 47–56. [Google Scholar]

- Zhang, H.; Wu, M.; Li, Z.; Xiao, D.; Huang, Y.; Huang, L.; Liu, W. Effect of Combined Addition of CeLa and GdY on Microstructure and Mechanical Properties of As-Cast Al-Cu-Mn Alloys. Materials 2023, 16, 7332. [Google Scholar] [CrossRef]

- Ye, J.; Dai, K.; Wang, Z.; Chen, J.; Gao, M.; Guan, R. Beneficial effects of Sc/Zr addition on hypereutectic Al–Ce alloys: Modification of primary phases and precipitation hardening. Mater. Sci. Eng. A 2022, 835, 142611. [Google Scholar] [CrossRef]

- Ng, D.; Dunand, D. Aging- and creep-resistance of a cast hypoeutectic Al-6.9Ce-9.3Mg (wt.%) alloy. Mater. Sci. Eng. A 2020, 786, 139398. [Google Scholar] [CrossRef]

- Wang, Y.; Hou, F.; Fu, Z.; Mao, H.; Xu, H. Microstructure and mechanical properties of novel heat-resistant Al-12Ce-xCu-yMg alloy under laser melting. J. Alloys Compd. 2022, 924, 166359. [Google Scholar] [CrossRef]

- Czerwinski, F.; Amirkhiz, B. Aluminum Cast Alloys Based on the Al–Ce–Si–Mg System: An Influence of Silicon on Crystallization, Phase Composition, and Tensile Properties. Metall. Mater. Trans. A 2022, 53, 4233–4246. [Google Scholar] [CrossRef]

- Wang, L.; Song, H.; Ye, B.; Zhao, B.; Bai, Y.; Ding, W. Microstructure and mechanical properties of high performance die cast Al-8Ce-3Y aluminum alloy containing Al4(Ce,Y) phase. Mater. Lett. 2021, 305, 130742. [Google Scholar] [CrossRef]

- Zhang, H.; Wu, M.; Li, Z.; Xiao, D.; Huang, Y.; Huang, L.; Liu, W. Microstructure and Mechanical Properties of As-Cast Al-10Ce-3Mg-xZn Alloys. Materials 2024, 17, 3999. [Google Scholar] [CrossRef]

- Weiss, D. Improved High-Temperature Aluminum Alloys Containing Cerium. J. Mater. Eng. Perform. 2019, 28, 1903–1908. [Google Scholar] [CrossRef]

- Murashkin, M.; Sabirov, I.; Medvedev, A.; Enikeev, N.; Lefebvre, W.; Valiev, R.; Sauvage, X. Sauvage, Mechanical and electrical properties of an ultrafine grained Al–8.5 wt. % RE (RE = 5.4 wt.% Ce, 3.1 wt.% La) alloy processed by severe plastic deformation. Mater. Des. 2016, 90, 433–442. [Google Scholar] [CrossRef]

- Sisco, K.; Plotkowski, A.; Yang, Y.; Leonard, D.; Stump, B.; Nandwana, P.; Dehoff, R.; Babu, S. Microstructure and properties of additively manufactured Al–Ce–Mg alloys. Sci. Rep. 2021, 11, 6953. [Google Scholar] [CrossRef] [PubMed]

- El-Hadad, S.; Moussa, M.; Waly, M. Effects of Solidification under Ultrasonic Vibrations on Al11Ce3 Phase Fragmentation and Mechanical Properties of Al-10 wt.% Ce Alloy. J. Mater. Eng. Perform. 2022, 31, 5393–5408. [Google Scholar] [CrossRef]

- Wang, L.; Qi, R.; Ye, B.; Bai, Y.; Huang, R.; Jiang, H.; Ding, W. Improved Tensile Strength of Al-5Ce Alloy by Permanent Magnet Stirring. Metall. Mater. Trans. A 2020, 51, 1972–1977. [Google Scholar] [CrossRef]

- El-Hadad, S.; Moussa, M.; Shoeib, M. Influence of Al11Ce3 Size and Distribution on the Electrochemical Properties of Sonoprocessed Al-10 wt.% Ce Alloy. Int. J. Met. 2022, 17, 1606–1614. [Google Scholar] [CrossRef]

- Ditta, A.; Wei, L.; Xu, Y.; Wu, S. Effect of hot extrusion and optimal solution treatment on microstructure and properties of spray-formed Al-11.3Zn-2.65Mg-1Cu alloy. J. Alloys Compd. 2019, 797, 558–565. [Google Scholar] [CrossRef]

- Yang, Z.; Chen, C.; Li, D.; Wu, Y.; Geng, Z.; Konakov, V.; Zhou, K. An additively manufactured heat-resistant Al-Ce-Sc-Zr alloy: Microstructure, mechanical properties and thermal stability. Mater. Sci. Eng. A 2023, 872, 144965. [Google Scholar] [CrossRef]

- Zhou, L.; Huynh, T.; Park, S.; Hyer, H.; Mehta, A.; Song, S.; Bai, Y.; McWilliams, B.; Cho, K.; Sohn, Y. Laser powder bed fusion of Al–10 wt% Ce alloys: Microstructure and tensile property. J. Mater. Sci. 2020, 55, 14611–14625. [Google Scholar] [CrossRef]

- Plotkowski, A.; Rios, O.; Sridharan, N.; Sims, Z.; Unocic, K.; Ott, R.; Dehoff, R.; Babu, S. Evaluation of an Al-Ce alloy for laser additive manufacturing. Acta Mater. 2017, 126, 507–519. [Google Scholar] [CrossRef]

- Lane, R.; Momen, A.; Kesler, M.; Brechtl, J.; Rios, O.; Nawaz, K.; Mirzaeifar, R. Developing an experimental-computational framework to investigate the deformation mechanisms and mechanical properties of Al-8Ce-10Mg alloys at micro and macroscales. Mater. Today Commun. 2021, 28, 102674. [Google Scholar] [CrossRef]

- Wan, S.; Su, H.; Shao, B.; Zong, Y.; Shan, D.; Guo, B. Changes in microstructure and mechanical properties of 2219 Al alloy during hot extrusion and post-extrusion aging. J. Mater. Res. Technol. 2023, 24, 3453–3463. [Google Scholar] [CrossRef]

- Zhang, C.; Wang, Y.; Lv, H.; Gao, H.; Wang, J.; Sun, B. Enhanced load transfer and ductility in Al–9Ce alloy through heterogeneous lamellar microstructure design by cold rolling and annealing. Mater. Sci. Eng. A 2021, 821, 141591. [Google Scholar] [CrossRef]

- Wu, M.; Xiao, D.; Yuan, S.; Tang, S.; Li, Z.; Yin, X.; Huang, L.; Liu, W. Development of bimodal grain-structured Al-Zn-Mg-Cu-Zr alloys for strength-ductility synergy via microalloying with Hf and Sc. Mater. Charact. 2023, 205, 113349. [Google Scholar] [CrossRef]

- Qiu, M.; Du, X.; Zhang, Z.; Chen, C.; Lei, X. Hot Deformation Combined with Heat Treatment on the Microstructure and Mechanical Behavior of (Ce + Yb)-Modified Al-Si-Mg-Cu-Cr Casting Alloy. J. Mater. Eng. Perform. 2022, 32, 3577–3589. [Google Scholar] [CrossRef]

- Yuan, S.; Wu, M.; Yin, X.; Li, Z.; Huang, Y.; Xiao, D.; Wang, J.; Huang, L.; Liu, W. Synchronous improvement of strength and corrosion resistance by an improved variable-rate non-isothermal aging process in Al-Zn-Mg-Cu alloy. Mater. Charact. 2023, 207, 113491. [Google Scholar] [CrossRef]

- Chu, J.; Lin, T.; Wang, G.; Fang, H.; Wang, D. Effect of Heat Treatment on Microstructure and Properties of Al-7.0Zn-1.5Cu-1.5Mg-0.1Zr-0.1Ce Alloy. Metallogr. Microstruct. Anal. 2020, 9, 312–322. [Google Scholar] [CrossRef]

- GB/T228.1-2010; Metallicmaterials—Tensiletesting—Part 1: Method of Testat Room Temperature. National Standard of the People’s Republic of China: Beijing, China, 2010.

- Zhang, X.; Li, L.; Wang, Z.; Chen, S.; Peng, H.; Gao, J.; Peng, Z. Bimodal microstructure evolution and strength-ductility co-enhancement of hot-extruded Al–La–Mg–Mn alloy. Mater. Sci. Eng. A 2022, 859, 144195. [Google Scholar] [CrossRef]

- Sims, Z.; Rios, O.; Weiss, D.; Turchi, P.; Perron, A.; Lee, J.; Li, T.; Hammons, J.; Bagge-Hansen, M.; Willey, T.; et al. High performance aluminum–cerium alloys for high-temperature applications. Mater. Horiz. 2017, 4, 1070–1078. [Google Scholar] [CrossRef]

- Michi, R.; Sisco, K.; Bahl, S.; Yang, Y.; Poplawsky, J.; Allard, L.; Dehoff, R.; Plotkowski, A.; Shyam, A. A creep-resistant additively manufactured Al-Ce-Ni-Mn alloy. Acta Mater. 2022, 227, 117699. [Google Scholar] [CrossRef]

- Wei, Q.; Wang, H.; Li, J.; Quan, X.; Li, W.; Wang, B. Microstructure and creep properties of cast hypereutectic Al-11Ce alloy with Si addition. J. Alloys Compd. 2023, 960, 170878. [Google Scholar] [CrossRef]

- Weiss, D. Composites and Alloys Based on the Al-Ce System. In Aluminium Alloys; IntechOpen: London, UK, 2019. [Google Scholar]

- Zhang, Y.; Liu, J.P.; Chen, S.Y.; Xie, X.; Liaw, P.K.; Dahmen, K.A.; Qiao, J.W.; Wang, Y.L. Serration and noise behaviors in materials. Prog. Mater. Sci. 2017, 90, 358–460. [Google Scholar] [CrossRef]

- Lan, P.; Zhang, J. Twinning and dynamic strain aging behavior during tensile deformation of Fe-Mn-C TWIP steel. Mater. Sci. Eng. A 2017, 700, 250–258. [Google Scholar] [CrossRef]

- Zhang, X.; Dong, R.; Zhao, Y.; Liu, D.; Yang, L.; Hou, H. Serrated flow behaviors in a Ni-based superalloy. Mater. Res. Express 2021, 8, 026515. [Google Scholar] [CrossRef]

- Yuan, L.; Hu, R.; Li, J.; Gao, X.; Zhang, X.; Yang, Y. New insights into serrated flow in Pt 2 Mo-type superlattice strengthened Ni–Cr–Mo alloy at room temperature. Mater. Lett. 2016, 163, 94–97. [Google Scholar] [CrossRef]

- Gopinath, K.; Gogia, A.; Kamat, S.; Ramamurty, U. Dynamic strain ageing in Ni-base superalloy 720Li. Acta Mater. 2009, 57, 1243–1253. [Google Scholar] [CrossRef]

- Qi, J.; Dunand, D. Substituting Ce with La and Nd in Al11Ce3: Effect on microstructure and mechanical properties. Acta Mater. 2023, 261, 119357. [Google Scholar] [CrossRef]

- Lv, H.; Peng, P.; Feng, T.; Gao, H.; Wang, Y.; Wang, J. Phase transformation and thermal stability of the laser powder bed fused high-strength and heat-resistant Al–Ce–Mg alloy. J. Mater. Res. Technol. 2024, 28, 4577–4584. [Google Scholar] [CrossRef]

- Tao, K.; Xu, J.; Zhang, D.; Zhang, A.; Su, G.; Zhang, J. Effect of Final Thermomechanical Treatment on the Mechanical Properties and Microstructure of T Phase Hardened Al-5.8Mg-4.5Zn-0.5Cu Alloy. Materials 2023, 16, 3062. [Google Scholar] [CrossRef]

- Zhang, D.; Wang, X.; Pan, Y.; Hou, S.; Zhang, J.; Zhuang, L.; Zhou, L. Friction stir welding of novel T-phase strengthened Zn-modified Al–Mg alloy. J. Mater. Sci. 2020, 56, 5283–5295. [Google Scholar] [CrossRef]

- Xu, H.; Li, Q. Effect of carbon nanofiber concentration on mechanical properties of porous magnesium composites: Experimental and theoretical analysis. Mater. Sci. Eng. A 2017, 706, 249–255. [Google Scholar] [CrossRef]

- Wu, G.; Zhang, Q.; Yang, X.; Huang, Z.; Sha, W. Effects of particle/matrix interface and strengthening mechanisms on the mechanical properties of metal matrix composites. Compos. Interfaces 2014, 21, 415–429. [Google Scholar] [CrossRef]

- Hansen, N. Hall–Petch relation and boundary strengthening. Scr. Mater. 2004, 51, 801–806. [Google Scholar] [CrossRef]

- Hall, E.O. The Deformation and Ageing of Mild Steel: III Discussion of Results. Proc. Phys. Soc. Sect. B 1951, 64, 747–753. [Google Scholar] [CrossRef]

- Petch, N. The cleavage strength of polycrystals. J. Iron Steel Inst. 1953, 174, 25–28. [Google Scholar]

- Hansen, N.; Huang, X. Microstructure and flow stress of polycrystals and single crystals. Acta Mater. 1998, 46, 1827–1836. [Google Scholar] [CrossRef]

- Zha, M.; Li, Y.; Mathiesen, R.; Bjørge, R.; Roven, H. Microstructure evolution and mechanical behavior of a binary Al–7Mg alloy processed by equal-channel angular pressing. Acta Mater. 2015, 84, 42–54. [Google Scholar] [CrossRef]

- Hu, B.; Quan, B.; Li, D.; Wang, X.; Li, Z.; Zeng, X. Solid solution strengthening mechanism in high pressure die casting Al–Ce–Mg alloys. Mater. Sci. Eng. A 2021, 812, 141109. [Google Scholar] [CrossRef]

- Sanaty-Zadeh, A. Comparison between current models for the strength of particulate-reinforced metal matrix nanocomposites with emphasis on consideration of Hall–Petch effect. Mater. Sci. Eng. A 2012, 531, 112–118. [Google Scholar] [CrossRef]

- Yan, S.; Wang, R.; Peng, C.; Cai, Z.; Peng, J. Enhancing mechanical properties of 7055 Al alloy by adding 1 wt.% Mg and tailoring the precipitations. J. Alloys Compd. 2023, 947, 169536. [Google Scholar] [CrossRef]

- Zhang, Z.; Yu, J.; He, D. Effects of contact body temperature and holding time on the microstructure and mechanical properties of 7075 aluminum alloy in contact solid solution treatment. J. Alloys Compd. 2020, 823, 153919. [Google Scholar] [CrossRef]

- Wu, M.; Yao, T.; Xiao, D.; Yuan, S.; Li, Z.; Wang, J.; Huang, L.; Liu, W. Precipitation behavior and properties of an Al-8.26Zn-1.95Mg-1.89Cu-0.08Sc-0.17Zr alloy with different dislocation morphologies via pre-treatment. J. Mater. Res. Technol. 2024, 29, 4714–4727. [Google Scholar] [CrossRef]

- Sun, X.; Guo, Y.; Wei, Q.; Li, Y.; Zhang, S. A comparative study on the microstructure and mechanical behavior of titanium: Ultrafine grain vs. coarse grain. Mater. Sci. Eng. A 2016, 669, 226–245. [Google Scholar] [CrossRef]

- Nakano, T.; Kawanaka, T.; Yasuda, H.; Umakoshi, Y. Effect of lamellar structure on fracture behavior of TiAl polysynthetically twinned crystals. Mater. Sci. Eng. A 1995, 194, 43–51. [Google Scholar] [CrossRef]

| Point | Al | Ce | Mg | Zn | Zr | Y | Phase |

|---|---|---|---|---|---|---|---|

| 1 | 69.64 | 20.07 | 0.15 | 9.79 | 0.01 | 0.34 | AlCeZn |

| 2 | 70.68 | 20.93 | 0.05 | 8.06 | 0.01 | 0.27 | AlCeZn |

| 3 | 84.42 | 4.53 | 5.37 | 4.31 | 1.36 | 0.01 | AlCeMgZn |

| 4 | 83.30 | 4.31 | 6.64 | 4.34 | 1.37 | 0.04 | AlCeMgZn |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, H.; Li, Z.; Xiao, D.; Wu, M.; Huang, Y.; Liu, W. Enhanced Strength of Al-10Ce-3Mg-5Zn Heat-Resistant Alloy by Combining Extrusion and Heat Treatment. Materials 2025, 18, 1706. https://doi.org/10.3390/ma18081706

Zhang H, Li Z, Xiao D, Wu M, Huang Y, Liu W. Enhanced Strength of Al-10Ce-3Mg-5Zn Heat-Resistant Alloy by Combining Extrusion and Heat Treatment. Materials. 2025; 18(8):1706. https://doi.org/10.3390/ma18081706

Chicago/Turabian StyleZhang, Haiyang, Zeyu Li, Daihong Xiao, Mingdong Wu, Yang Huang, and Wensheng Liu. 2025. "Enhanced Strength of Al-10Ce-3Mg-5Zn Heat-Resistant Alloy by Combining Extrusion and Heat Treatment" Materials 18, no. 8: 1706. https://doi.org/10.3390/ma18081706

APA StyleZhang, H., Li, Z., Xiao, D., Wu, M., Huang, Y., & Liu, W. (2025). Enhanced Strength of Al-10Ce-3Mg-5Zn Heat-Resistant Alloy by Combining Extrusion and Heat Treatment. Materials, 18(8), 1706. https://doi.org/10.3390/ma18081706