Effect of Bio-Cementation Level and Rainfall Intensity on Surface Erosion Resistance of Biotreated Slope Using PEICP Method

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

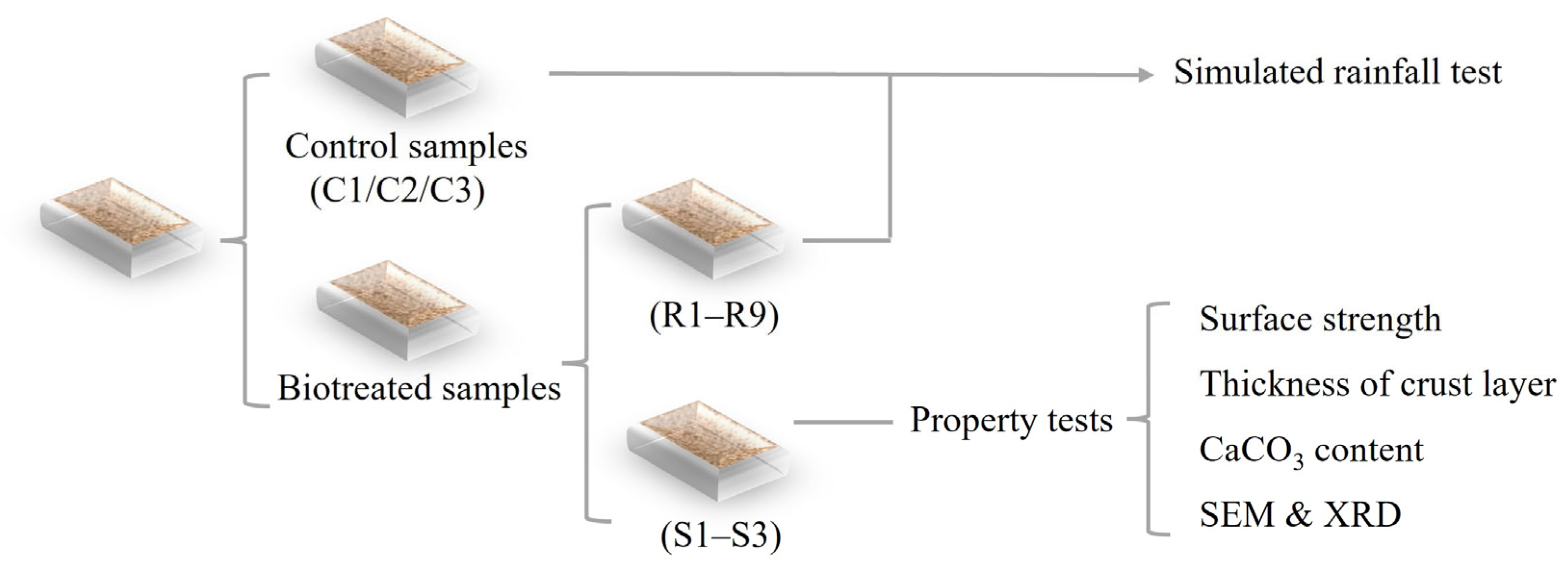

2.2. Test Arrangement

2.3. PEICP Biotreatment for the Small-Scale Slope Model

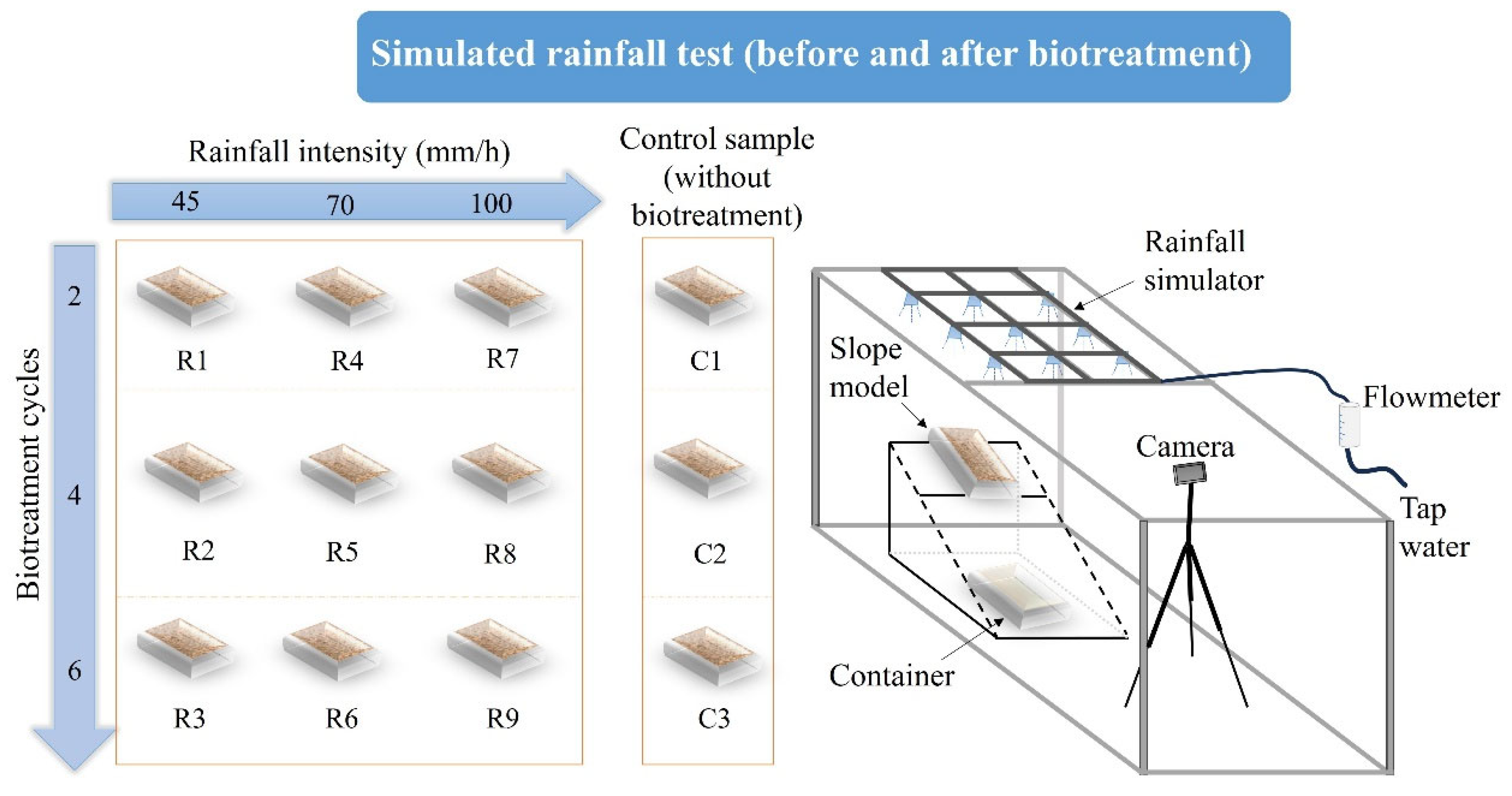

2.4. Simulated Rainfall Erosion Test

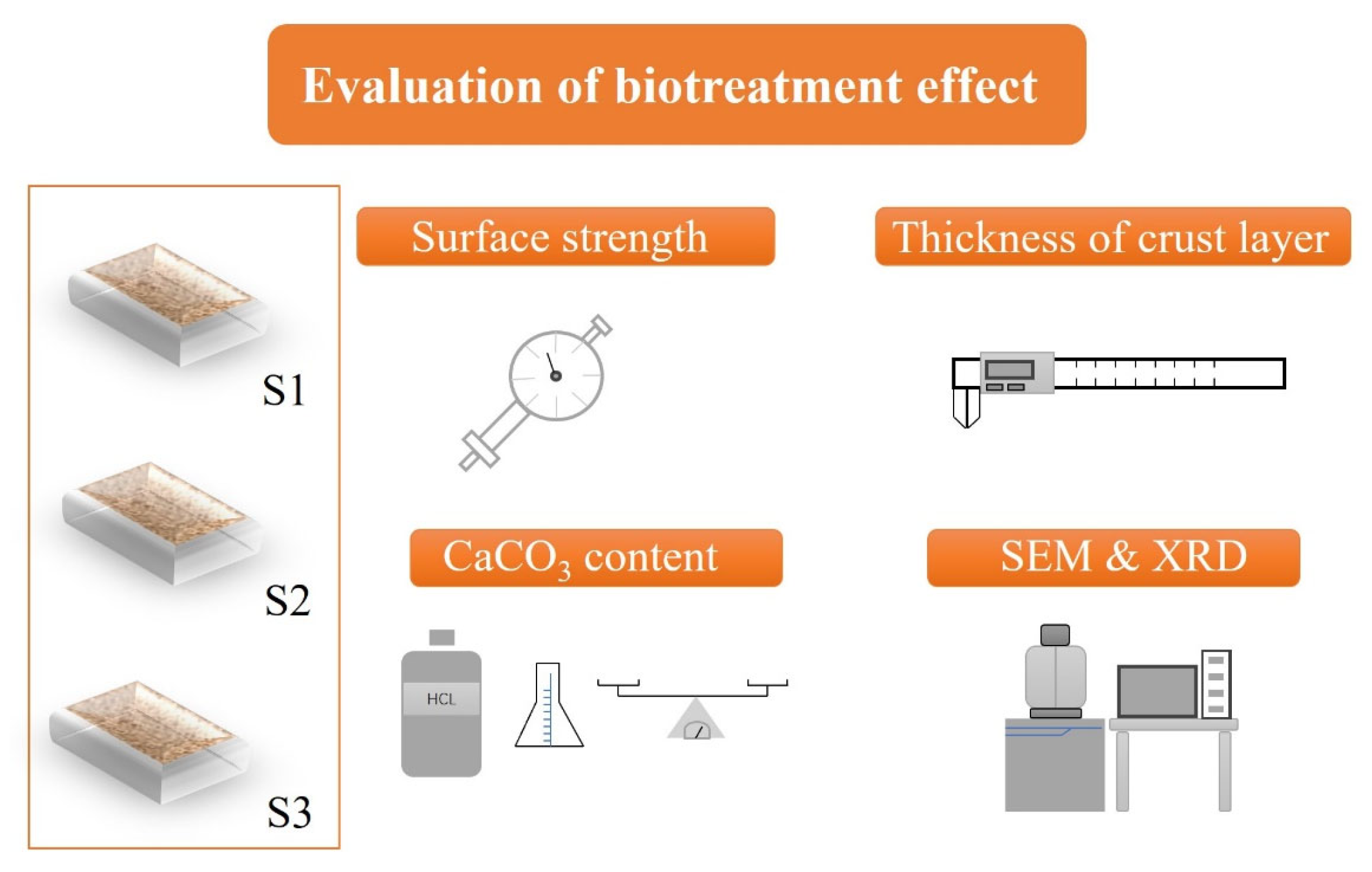

2.5. Properties Tests and Evaluation Method

3. Results and Discussion

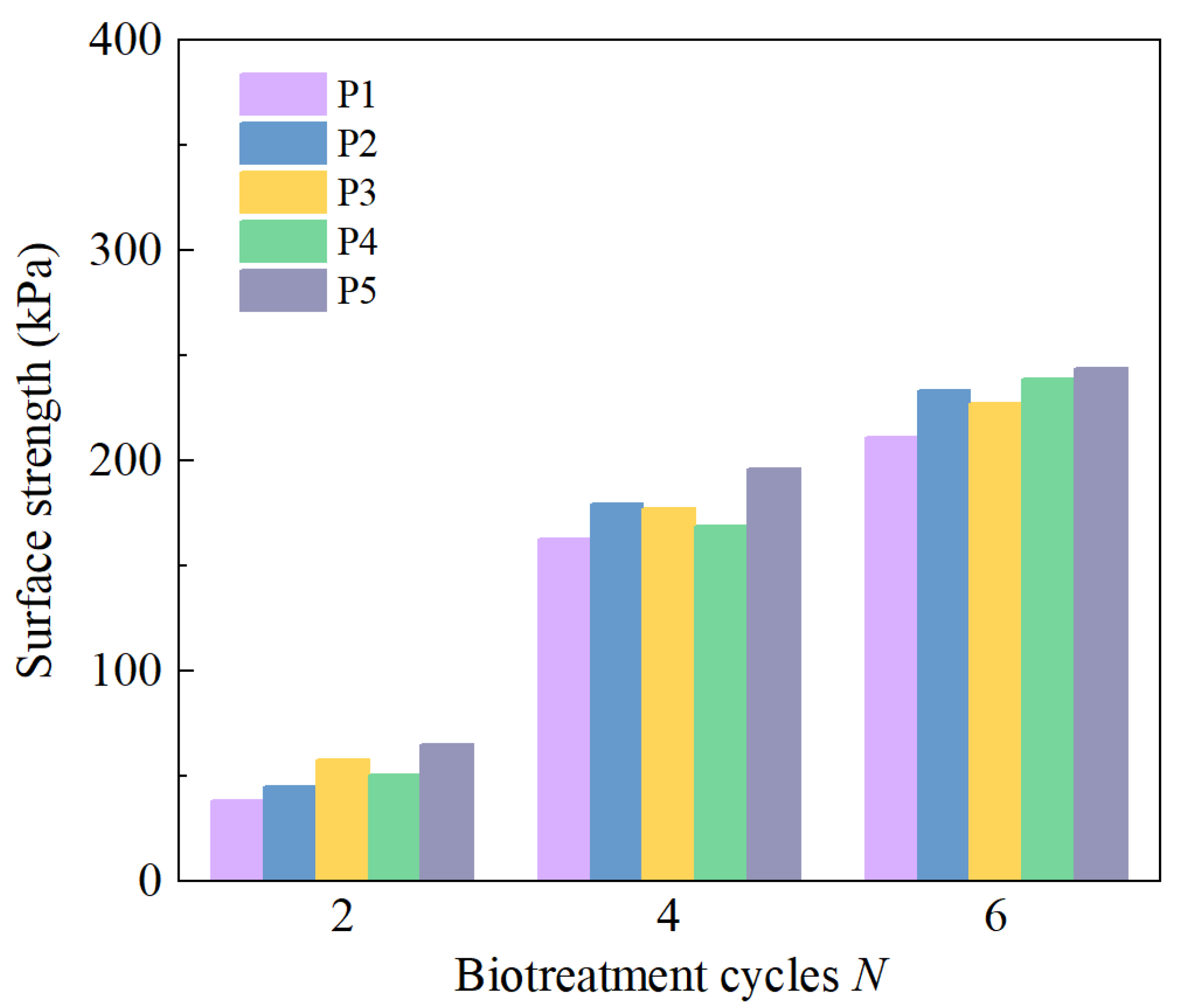

3.1. Surface Strength, Calcium Carbonate Content CCC, Thickness of Crust Layer

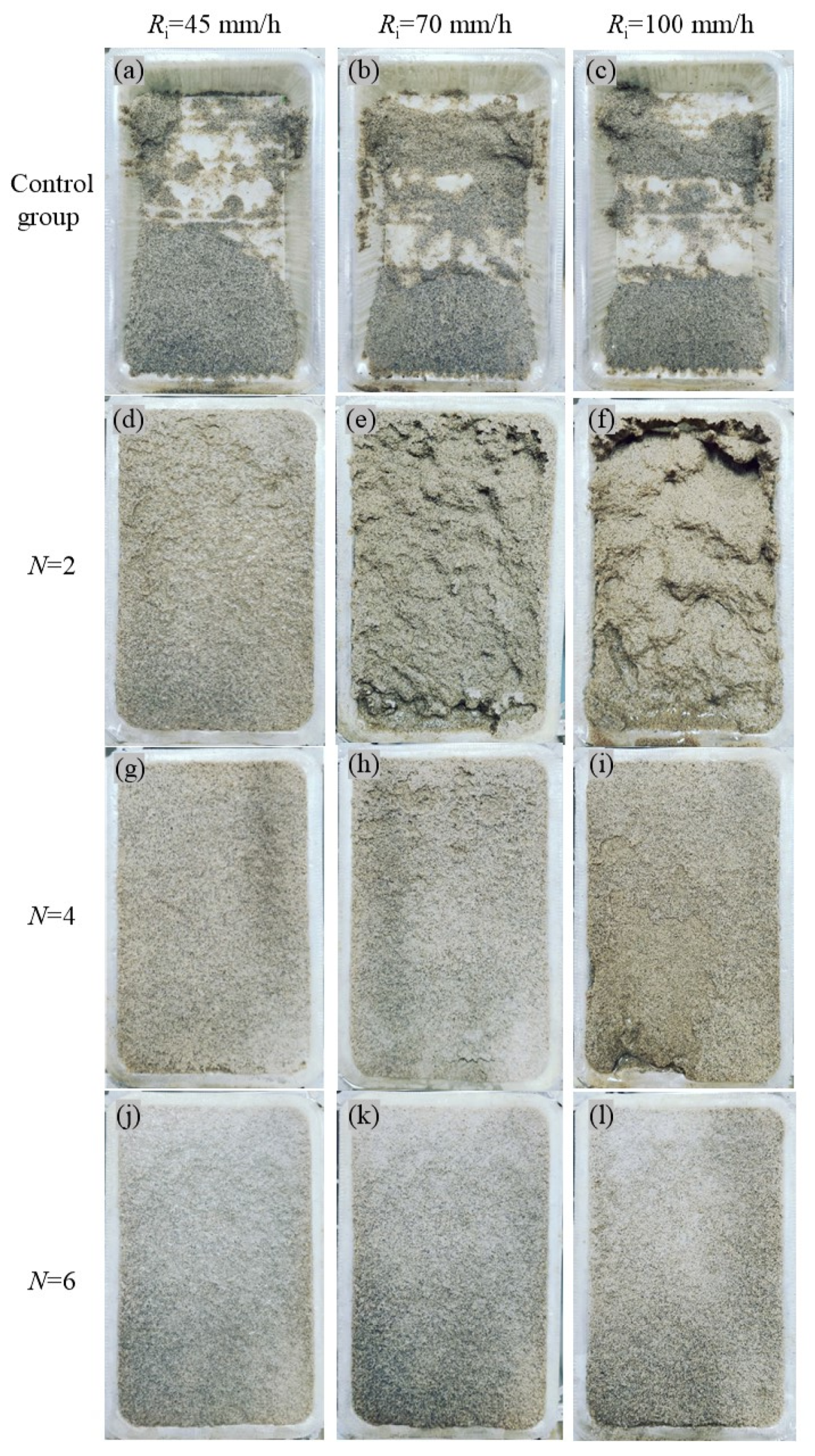

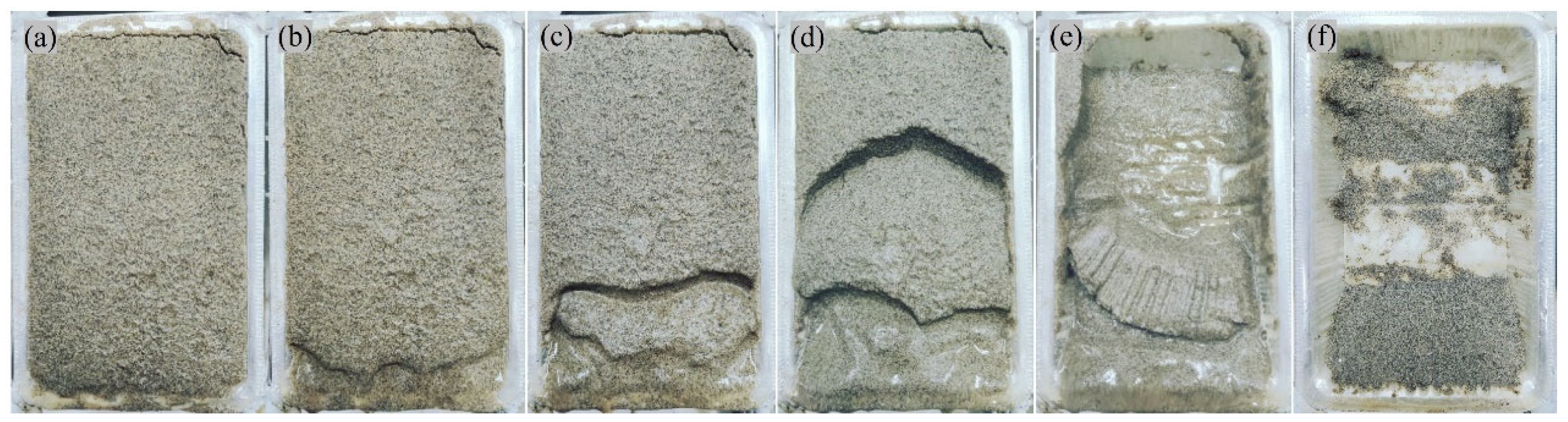

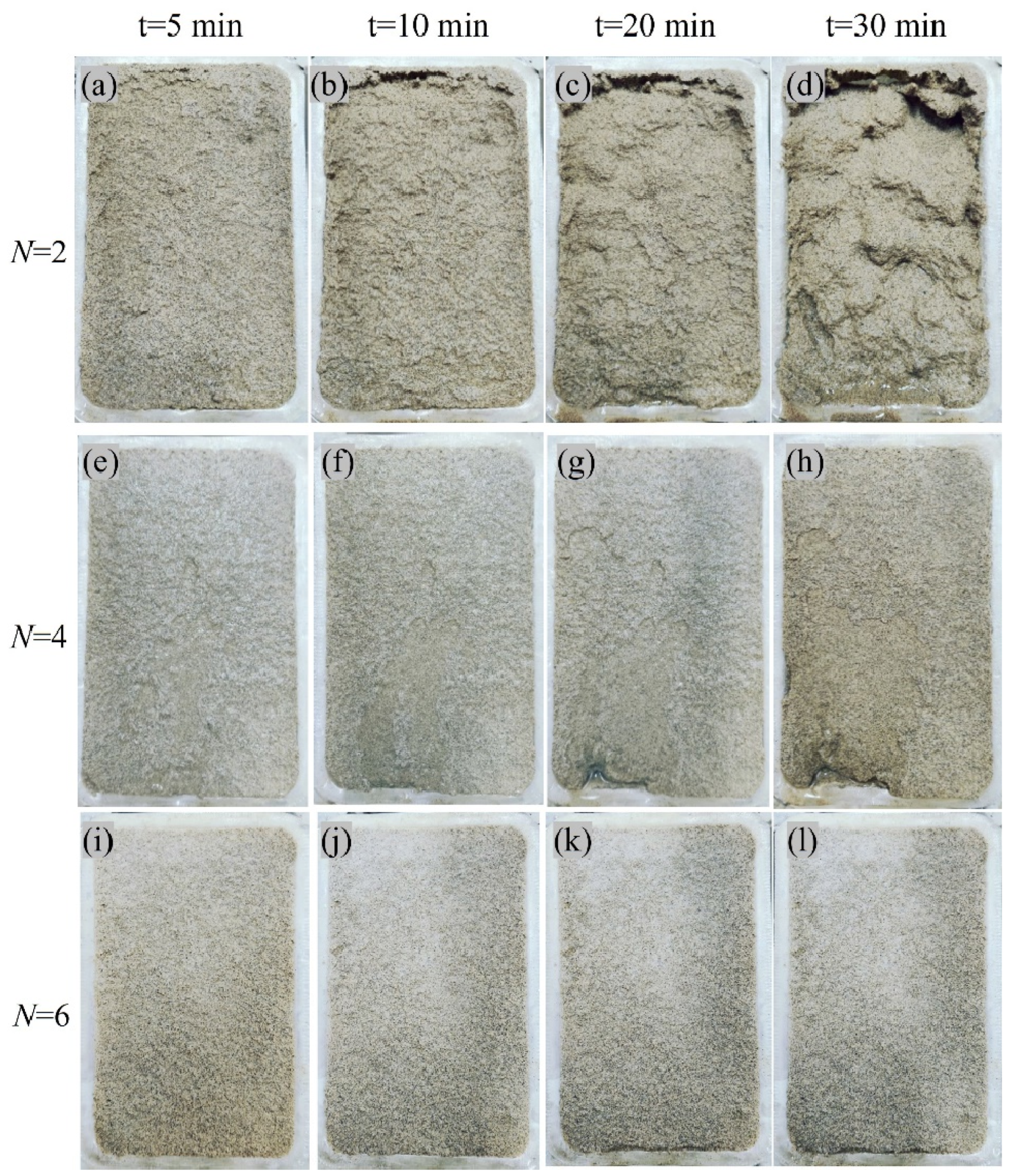

3.2. Visual Observation of Erosion Condition

3.3. Accumulative Soil Loss Weight and Erosion Rate

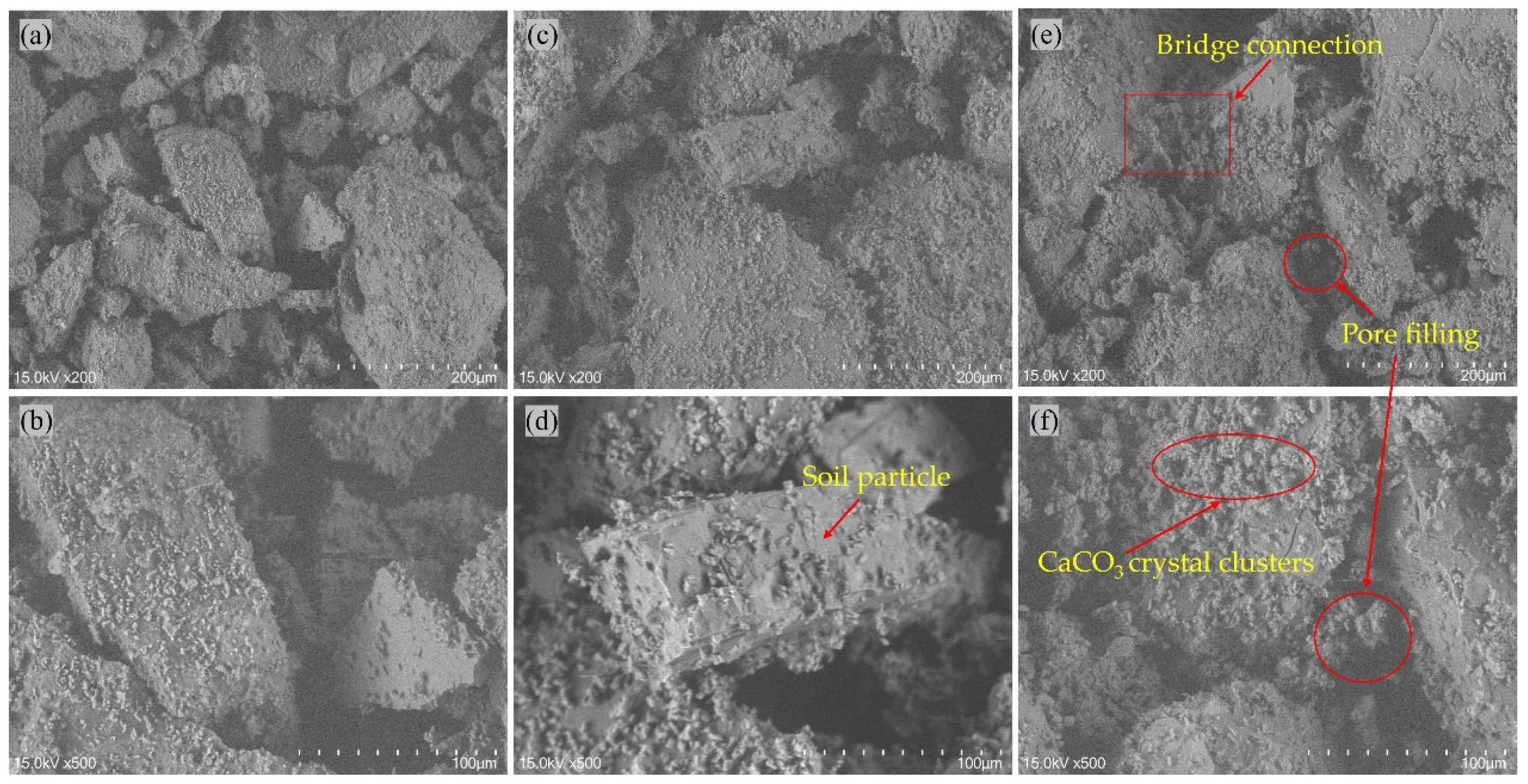

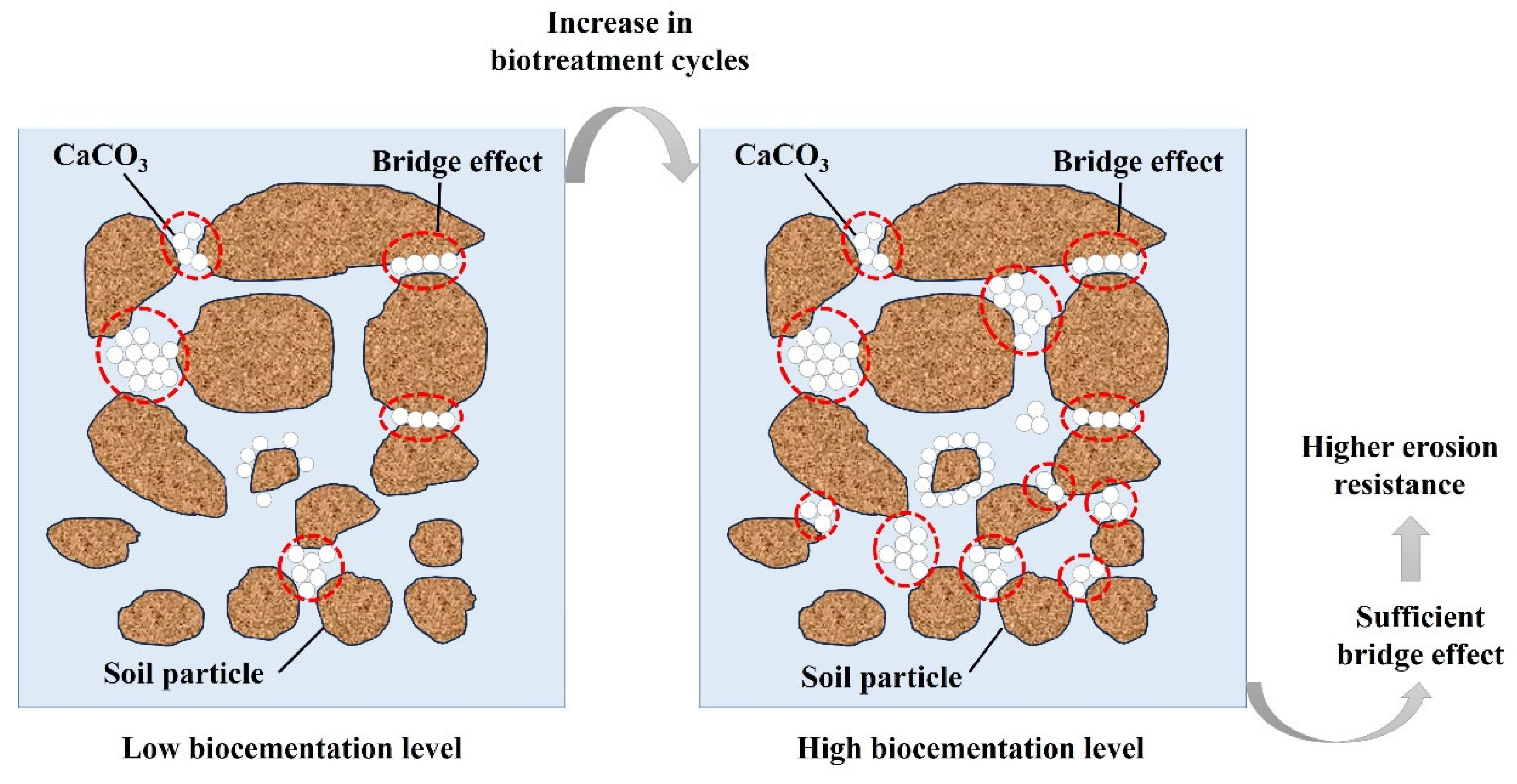

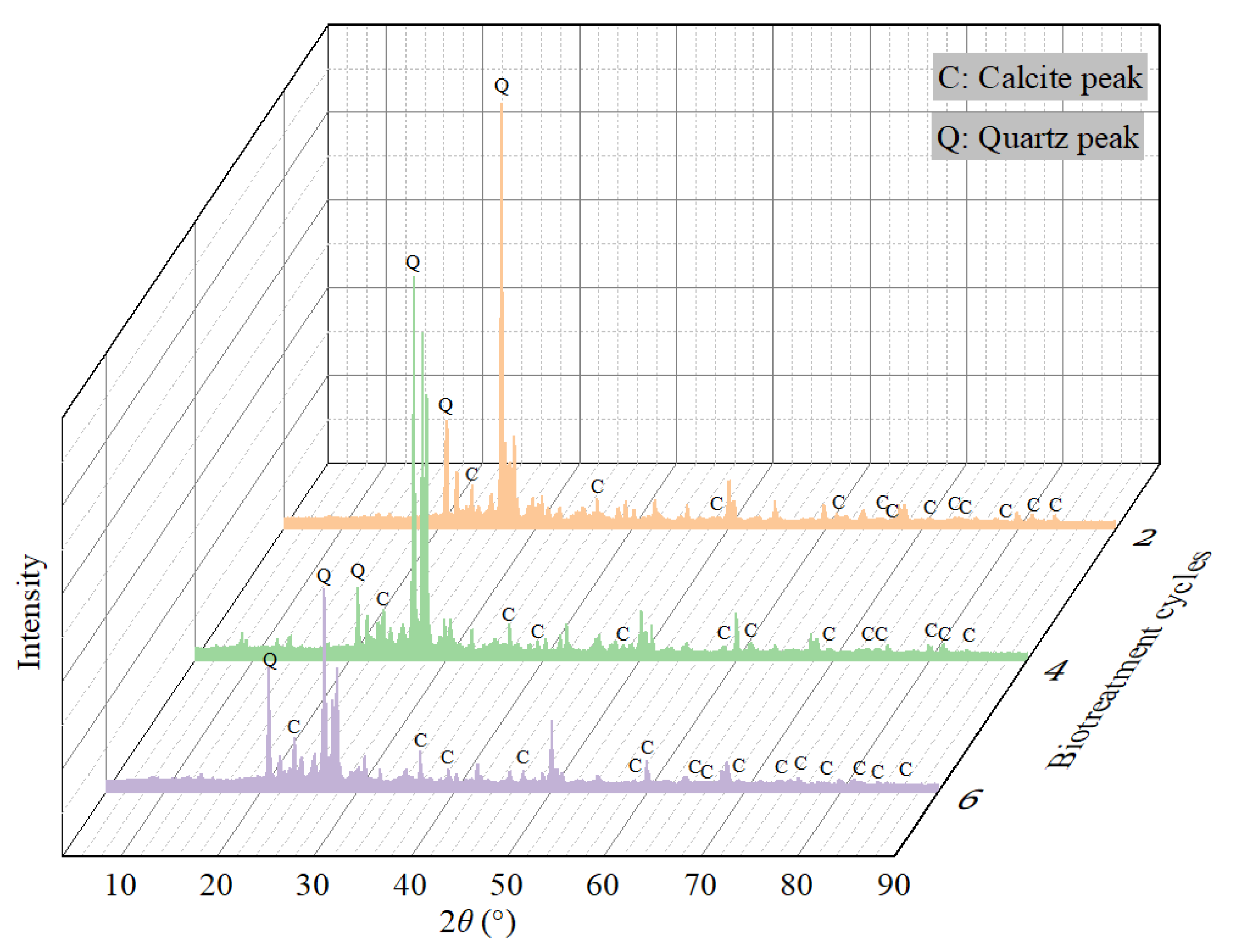

3.4. Analysis of Microscopic Mechanism

3.5. Shortcomings and Application Prospects

4. Conclusions

- By increasing biotreatment cycles, higher bio-cementation level and superior biological treatment effect can be achieved, contributing to the increase in surface strength, CCC and crust layer thickness, which is beneficial for rainfall erosion resistance. Specifically, surface strength increased from 38.3 kPa at a crust layer thickness of 5.2 mm (N = 2 cycles) to 244.3 kPa at a crust layer thickness of 15.7 mm (N = 6 cycles). Calcium carbonate content (CCC) increased from 1.09% at a crust layer thickness of 5.2 mm (N = 2 cycles) to 5.32% at a crust layer thickness of 15.7 mm (N = 6 cycles).

- Coupled effects of surface runoff erosion force and the internal seepage force triggered the surface erosion and internal soil particle loss of slope. For the untreated group and weakly bio-cemented slope (N = 2), the percentage of accumulative soil loss weight ranged from 58% to 86% by the end of the simulated rainfall tests. For the sample biotreated two times, its erosion resistance was still insufficient to cope with the simulated rainfall intensities of 75 mm/h and 100 mm/h, with cumulative soil particle losses reaching 27.23% and 41.32%, respectively. When crustal erosion occurs, the erosion rate accelerates. When the number of treatments was increased to four, the cumulative loss of soil particles was controlled within 10%. Finally, when the biotreatment cycles reached six cycles, the biotreated slope demonstrated optimal resistance to rainfall-induced erosion and remained intact.

- SEM images indicated that increasing the biotreatment cycle facilitated the crystal growth and formed larger size crystal clusters, which are more likely to bridge-connect adjacent soil particles. The bridge-connection effect induced by CaCO3 precipitation provided a strong bonding force that played a vital role in enhancing the erosion resistance to rainfall. Furthermore, the mineralogical composition of generated CaCO3 crystals was affirmed as calcite, which has better mechanical properties.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Chau, N.L.; Chu, L.M. Fern Cover and the importance of plant traits in reducing erosion on steep soil slopes. Catena 2017, 151, 98–106. [Google Scholar] [CrossRef]

- Guerra, A.J.T.; Fullen, M.A.; Jorge, M.D.C.O.; Bezerra, J.F.R.; Shokr, M.S. Slope processes, mass movement and soil erosion: A review. Pedosphere 2017, 27, 27–41. [Google Scholar] [CrossRef]

- Kobayashi, N.; Buck, M.; Payo, A.; Johnson, B.D. Berm and dune erosion during a storm. J. Waterw. Port Coast. Ocean Eng. 2009, 135, 1–10. [Google Scholar] [CrossRef]

- Jiang, N.J.; Tang, C.S.; Yin, L.Y.; Xie, Y.H.; Shi, B. Applicability of microbial calcification method for sandy-slope surface erosion control. J. Mater. Civ. Eng. 2019, 31, 4019250. [Google Scholar] [CrossRef]

- Tang, C.S.; Wang, D.Y.; Shi, B.; Li, J. Effect of wetting–drying cycles on profile mechanical behavior of soils with different initial conditions. Catena 2016, 139, 105–116. [Google Scholar] [CrossRef]

- Lei, X.Q.; Yang, Z.J.; He, S.M.; Liu, E.L.; Wong, H.; Li, X.P. Hydro-mechanical analysis of rainfall-induced fines migration process within unsaturated soils. J. Mt. Sci. 2017, 14, 2603–2619. [Google Scholar] [CrossRef]

- Qi, S.; Vanapalli, S.K. Simulating hydraulic and mechanical responses of unsaturated expansive soil slope to rainfall: Case study. Int. J. Geomech. 2018, 18, 5018002. [Google Scholar] [CrossRef]

- Hassanikhah, A.; Drumm, E.C. Stability and evolution of planar and concave slopes under unsaturated and rainfall conditions. Int. J. Geomech. 2020, 20, 4020099. [Google Scholar] [CrossRef]

- He, J.; Huang, A.; Ji, J.; Qu, S.; Hang, L. Enzyme induced carbonate precipitation with fibers for the improvement of clay soil slopes against rainfall and surface runoff erosions. Transp. Geotech. 2023, 42, 101074. [Google Scholar] [CrossRef]

- Broda, J.; Grzybowska-Pietras, J.; Gawłowski, A.; Rom, M.; Przybylo, S.; Laszczak, R. Application of wool geotextiles for the protection of steep slopes. Procedia Eng. 2017, 200, 112–119. [Google Scholar] [CrossRef]

- Song, G.; He, S.; Song, X.; Duan, Z.; Zhang, Y.; Kong, D.; Huang, M. The use of geocell as soil stabilization and soil erosion countermeasures. Geomat. Nat. Hazards Risk 2021, 12, 2155–2169. [Google Scholar] [CrossRef]

- Zhao, C.; Gao, J.E.; Huang, Y.; Wang, G.; Xu, Z. The contribution of Astragalus adsurgens roots and canopy to water erosion control in the water–wind crisscrossed erosion region of the Loess Plateau, China. Land Degrad. Dev. 2017, 28, 265–273. [Google Scholar] [CrossRef]

- Su, L.J.; Hu, B.L.; Xie, Q.J.; Yu, F.W.; Zhang, C.L. Experimental and theoretical study of mechanical properties of root-soil interface for slope protection. J. Mt. Sci. 2020, 17, 2784–2795. [Google Scholar] [CrossRef]

- Sun, X.; Miao, L.; Wang, H.; Chen, R.; Wu, L. Bio-cementation for the mitigation of surface erosion in loess slopes based on simulation experiment. J. Soils Sediments 2022, 22, 1804–1818. [Google Scholar] [CrossRef]

- Boluk, B.; Puppala, A.J.; Chakraborty, S.; Bhaskar, P. Forensic analyses and rehabilitation of a failed highway embankment slope in Texas. Transp. Res. Rec. 2021, 2675, 121–134. [Google Scholar] [CrossRef]

- Al Qabany, A.; Soga, K.; Santamarina, C. Factors affecting efficiency of microbially induced calcite precipitation. J. Geotech. Geoenviron. Eng. 2012, 138, 992–1001. [Google Scholar] [CrossRef]

- He, J.; Chu, J.; Gao, Y.; Liu, H. Research advances and challenges in biogeotechnologies. Geotech. Res. 2019, 6, 144–155. [Google Scholar] [CrossRef]

- Ahenkorah, I.; Rahman, M.M.; Karim, M.R.; Beecham, S.; Saint, C. A review of enzyme induced carbonate precipitation (EICP): The role of enzyme kinetics. Sustain. Chem. 2021, 2, 92–114. [Google Scholar] [CrossRef]

- Saif, A.; Cuccurullo, A.; Gallipoli, D.; Perlot, C.; Bruno, A.W. Advances in enzyme induced carbonate precipitation and application to soil improvement: A review. Materials 2022, 15, 950. [Google Scholar] [CrossRef]

- DeJong, J.T.; Mortensen, B.M.; Martinez, B.C.; Nelson, D.C. Bio-mediated soil improvement. Ecol. Eng. 2010, 36, 197–210. [Google Scholar] [CrossRef]

- Wang, Y.; Wang, Z.; Chen, Y.; Cao, T.; Yu, X.; Rui, P. Experimental study on bio-treatment effect of the dredged Yellow River silt based on soybean urease induced calcium carbonate precipitation. J. Build. Eng. 2023, 75, 106943. [Google Scholar] [CrossRef]

- Yasuhara, H.; Neupane, D.; Hayashi, K.; Okamura, M. Experiments and predictions of physical properties of sand cemented by enzymatically-induced carbonate precipitation. Soils Found. 2012, 52, 539–549. [Google Scholar] [CrossRef]

- Almajed, A.; Khodadadi Tirkolaei, H.; Kavazanjian, E., Jr. Baseline investigation on enzyme-induced calcium carbonate precipitation. J. Geotech. Geoenviron. Eng. 2018, 144, 4018081. [Google Scholar] [CrossRef]

- Almajed, A.; Tirkolaei, H.K.; Kavazanjian, E., Jr.; Hamdan, N. Enzyme induced biocementated sand with high strength at low carbonate content. Sci. Rep. 2019, 9, 1135. [Google Scholar] [CrossRef]

- Hoang, T.; Alleman, J.; Cetin, B.; Ikuma, K.; Choi, S.G. Sand and silty-sand soil stabilization using bacterial enzyme–induced calcite precipitation (BEICP). Can. Geotech. J. 2019, 56, 808–822. [Google Scholar] [CrossRef]

- Hoang, T.; Alleman, J.; Cetin, B.; Choi, S.G. Engineering properties of biocementation coarse-and fine-grained sand catalyzed by bacterial cells and bacterial enzyme. J. Mater. Civ. Eng. 2020, 32, 4020030. [Google Scholar] [CrossRef]

- Wu, C.; Chu, J.; Cheng, L.; Wu, S. Biogrouting of aggregates using premixed injection method with or without pH adjustment. J. Mater. Civ. Eng. 2019, 31, 6019008. [Google Scholar] [CrossRef]

- Pan, X.; Chu, J.; Yang, Y.; Cheng, L. A new biogrouting method for fine to coarse sand. Acta Geotech. 2020, 15, 1–16. [Google Scholar] [CrossRef]

- Cheng, L.; Shahin, M.A.; Cord-Ruwisch, R. Bio-cementation of sandy soil using microbially induced carbonate precipitation for marine environments. Géotechnique 2014, 64, 1010–1013. [Google Scholar] [CrossRef]

- Shanahan, C.; Montoya, B.M. Strengthening coastal sand dunes using microbial-induced calcite precipitation. In Proceedings of the Geo-Congress 2014: Geo-Characterization and Modeling for Sustainability, Atlanta, GA, USA, 23–26 February 2014; pp. 1683–1692. [Google Scholar] [CrossRef]

- Salifu, E.; MacLachlan, E.; Iyer, K.R.; Knapp, C.W.; Tarantino, A. Application of microbially induced calcite precipitation in erosion mitigation and stabilisation of sandy soil foreshore slopes: A preliminary investigation. Eng. Geol. 2016, 201, 96–105. [Google Scholar] [CrossRef]

- Wang, X.; Tao, J.; Bao, R.; Tran, T.; Tucker-Kulesza, S. Surficial soil stabilization against water-induced erosion using polymer-modified microbially induced carbonate precipitation. J. Mater. Civ. Eng. 2018, 30, 4018267. [Google Scholar] [CrossRef]

- Liu, K.W.; Jiang, N.J.; Qin, J.D.; Wang, Y.J.; Tang, C.S.; Han, X.L. An experimental study of mitigating coastal sand dune erosion by microbial-and enzymatic-induced carbonate precipitation. Acta Geotech. 2021, 16, 467–480. [Google Scholar] [CrossRef]

- Ghasemi, P.; Montoya, B.M. Field implementation of microbially induced calcium carbonate precipitation for surface erosion reduction of a coastal plain sandy slope. J. Geotech. Geoenviron. Eng. 2022, 148, 4022071. [Google Scholar] [CrossRef]

- Jiang, N.J.; Soga, K. The applicability of microbially induced calcite precipitation (MICP) for internal erosion control in gravel–sand mixtures. Géotechnique 2017, 67, 42–55. [Google Scholar] [CrossRef]

- Jiang, N.J.; Soga, K. Erosional behavior of gravel-sand mixtures stabilized by microbially induced calcite precipitation (MICP). Soils Found. 2019, 59, 699–709. [Google Scholar] [CrossRef]

- Jiang, N.J.; Soga, K.; Kuo, M. Microbially induced carbonate precipitation for seepage-induced internal erosion control in sand–clay mixtures. J. Geotech. Geoenviron. Eng. 2017, 143, 4016100. [Google Scholar] [CrossRef]

- Gao, Y.; Tang, X.; Chu, J.; He, J. Microbially induced calcite precipitation for seepage control in sandy soil. Geomicrobiol. J. 2019, 36, 366–375. [Google Scholar] [CrossRef]

- Shao, G.; Feng, J.; Zhao, Z.; Liu, P.; Li, Z.; Zhou, N. Influence factor analysis related to strength and anti-erosion stability of silt slope with microbial mortar protective covering. Trans. Chin. Soc. Agric. Eng. 2017, 33, 133–139. [Google Scholar] [CrossRef]

- Shih, D.S.; Lai, T.Y.; Hsu, Z.M. Applying biomineralization technology to study the effects of rainfall induced soil erosion. Water 2019, 11, 2555. [Google Scholar] [CrossRef]

- Sun, X.; Miao, L.; Chen, R.; Wang, H.; Xia, J. Surface rainfall erosion resistance and freeze-thaw durability of bio-cemented and polymer-modified loess slopes. J. Environ. Manag. 2022, 301, 113883. [Google Scholar] [CrossRef]

- Xiao, Y.; Ma, G.; Wu, H.; Lu, H.; Zaman, M. Rainfall-induced erosion of biocemented graded slopes. Int. J. Geomech. 2022, 22, 4021256. [Google Scholar] [CrossRef]

- Xiao, Y.; Zhou, W.; Shi, J.; Lu, H.; Zhang, Z. Erosion of biotreated field-scale slopes under rainfalls. J. Perform. Constr. Facil. 2022, 36, 4022030. [Google Scholar] [CrossRef]

- Liu, Y.; Gao, Y.; He, J.; Zhou, Y.; Geng, W. An experimental investigation of wind erosion resistance of desert sand cemented by soybean-urease induced carbonate precipitation. Geoderma 2023, 429, 116231. [Google Scholar] [CrossRef]

- Sun, X.; Miao, L.; Yuan, J.; Wang, H.; Wu, L. Application of enzymatic calcification for dust control and rainfall erosion resistance improvement. Sci. Total Environ. 2021, 759, 143468. [Google Scholar] [CrossRef]

- Sun, X.; Miao, L.; Wang, H.; Yuan, J.; Fan, G. Enhanced rainfall erosion durability of enzymatically induced carbonate precipitation for dust control. Sci. Total Environ. 2021, 791, 148369. [Google Scholar] [CrossRef]

- Song, W.; Yang, Y.; Qi, R.; Li, J.; Pan, X. Suppression of coal dust by microbially induced carbonate precipitation using Staphylococcus succinus. Environ. Sci. Pollut. Res. 2019, 26, 35968–35977. [Google Scholar] [CrossRef]

- Cui, M.J.; Lai, H.J.; Hoang, T.; Chu, J. One-phase-low-pH enzyme induced carbonate precipitation (EICP) method for soil improvement. Acta Geotech. 2021, 16, 481–489. [Google Scholar] [CrossRef]

- Dubey, A.A.; Devrani, R.; Ravi, K.; Dhami, N.K.; Mukherjee, A.; Sahoo, L. Experimental investigation to mitigate aeolian erosion via biocementation employed with a novel ureolytic soil isolate. Aeolian Res. 2021, 52, 100727. [Google Scholar] [CrossRef]

- Dubey, A.A.; Ravi, K.; Mukherjee, A.; Sahoo, L.; Abiala, M.A.; Dhami, N.K. Biocementation mediated by native microbes from Brahmaputra riverbank for mitigation of soil erodibility. Sci. Rep. 2021, 11, 15250. [Google Scholar] [CrossRef]

- Dubey, A.A.; Hooper-Lewis, J.; Ravi, K.; Dhami, N.K.; Mukherjee, A. Biopolymer-biocement composite treatment for stabilisation of soil against both current and wave erosion. Acta Geotech. 2022, 17, 5391–5410. [Google Scholar] [CrossRef]

- Meng, H.; Shu, S.; Gao, Y.; Yan, B.; He, J. Multiple-phase enzyme-induced carbonate precipitation (EICP) method for soil improvement. Eng. Geol. 2021, 294, 106374. [Google Scholar] [CrossRef]

- Hamdan, N.; Kavazanjian, E., Jr. Enzyme-induced carbonate mineral precipitation for fugitive dust control. Géotechnique 2016, 66, 546–555. [Google Scholar] [CrossRef]

- He, J.; Gao, Y.; Gu, Z.; Chu, J.; Wang, L. Characterization of crude bacterial urease for CaCO 3 precipitation and cementation of silty sand. J. Mater. Civ. Eng. 2020, 32, 4020071. [Google Scholar] [CrossRef]

- Sun, X.; Miao, L.; Wu, L. Applicability and theoretical calculation of enzymatic calcium carbonate precipitation for sand improvement. Geomicrobiol. J. 2020, 37, 389–399. [Google Scholar] [CrossRef]

- Ahenkorah, I.; Rahman, M.M.; Karim, M.R.; Beecham, S. Enzyme induced calcium carbonate precipitation and its engineering application: A systematic review and meta-analysis. Constr. Build. Mater. 2021, 308, 125000. [Google Scholar] [CrossRef]

- Gao, Y.; Hua, C.; Ke, T. Field test on soybean-urease induced calcite precipitation (SICP) for desert sand stabilization against the wind-induced erosion. Sustainability 2022, 14, 15474. [Google Scholar] [CrossRef]

- Wei, H.; Fan, Y.; Sun, L.; Du, H.; Liang, R. Experimental Study on High-Temperature Damage Repair of Concrete by Soybean Urease Induced Carbonate Precipitation. Materials 2022, 15, 2436. [Google Scholar] [CrossRef]

- Yu, X.; Pan, X. One-phase improvement of sandy soil using seawater-based soybean-induced carbonate precipitation. J. Sustain. Cem.-Based Mater. 2023, 12, 962–971. [Google Scholar] [CrossRef]

- Li, M.; Yang, Y.; Zhang, S.; Chen, X.; Yin, H.; Zhu, L. Effects of sorbitol and sucrose on soybean-urease induced calcium carbonate precipitate. Biogeotechnics 2023, 1, 100052. [Google Scholar] [CrossRef]

- Yan, B.; Zhou, Y.; Li, C.; Shu, S.; Gao, Y. Modified SICP method to mitigate the effect of bio-clogging by excess protein from soybean crude urease extracts for biocementation process. Acta Geotech. 2023, 18, 5047–5062. [Google Scholar] [CrossRef]

- Zhou, Y.; Zhang, Y.; Geng, W.; He, J.; Gao, Y. Evaluation of liquefaction resistance for single-and multi-phase SICP-treated sandy soil using shaking table test. Acta Geotech. 2023, 18, 6007–6025. [Google Scholar] [CrossRef]

- Wang, Y.; Chen, H.; Chen, Y.; Jiao, M.; Fan, Z. Experimental study on macro-micro effectiveness of Yellow River silt solidified by using soybean-induced carbonate precipitation (SICP) technology. Mar. Georesour. Geotechnol. 2025, 43, 112–122. [Google Scholar] [CrossRef]

- Gao, Y.; He, J.; Tang, X.; Chu, J. Calcium carbonate precipitation catalyzed by soybean urease as an improvement method for fine-grained soil. Soils Found. 2019, 59, 1631–1637. [Google Scholar] [CrossRef]

- Wang, Y.; Chen, Y.; Marchelina, N. Crack repairing performance by soybean urease induced calcium carbonate precipitation (SICP) combined with fibers and lightweight aggregates. Constr. Build. Mater. 2025, 458, 139678. [Google Scholar] [CrossRef]

- Liu, Y.; Hazarika, H.; Kanaya, H.; Takiguchi, O.; Rohit, D. Landslide prediction based on low-cost and sustainable early warning systems with IoT. Bull. Eng. Geol. Environ. 2023, 82, 177. [Google Scholar] [CrossRef]

- Xu, K.; Huang, M.; Cui, M.; Li, S. Retarding effect of cementation solution concentration on cementation ability of calcium carbonate crystal induced using crude soybean enzyme. Acta Geotech. 2023, 18, 6235–6251. [Google Scholar] [CrossRef]

- Miao, L.; Wu, L.; Sun, X.; Li, X.; Zhang, J. Method for solidifying desert sands with enzyme-catalysed mineralization. Land Degrad. Dev. 2020, 31, 1317–1324. [Google Scholar] [CrossRef]

- Wang, H.; Wang, J.; Sun, X.; Miao, L.; Shi, W.; WU, L.; Yuan, J. Erosion resistance of treated dust soils based on the combined enzymatically induced carbonate precipitation and polyacrylic acid. Biogeotechnics 2023, 1, 100050. [Google Scholar] [CrossRef]

- Putra, H.; Yasuhara, H.; Kinoshita, N.; Hirata, A. Optimization of enzyme-mediated calcite precipitation as a soil-improvement technique: The effect of aragonite and gypsum on the mechanical properties of treated sand. Crystals 2017, 7, 59. [Google Scholar] [CrossRef]

- Cheng, L.; Shahin, M.A.; Mujah, D. Influence of key environmental conditions on microbially induced cementation for soil stabilization. J. Geotech. Geoenviron. Eng. 2017, 143, 4016083. [Google Scholar] [CrossRef]

- Zhang, J.; Wang, X.; Shi, L.; Yin, Y. Enzyme-induced carbonate precipitation (EICP) combined with lignin to solidify silt in the Yellow River flood area. Constr. Build. Mater. 2022, 339, 127792. [Google Scholar] [CrossRef]

| Index | K-7 Sand |

|---|---|

| Specific Gravity of Soil Particles, Gs | 2.67 |

| Unit weight, γt (kN/m3) | 14.8 |

| Coefficient of uniformity, Cu | 4 |

| Coefficient of curvature, Cc | 1.21 |

| Maximum density, ρmax (g/cm3) | 1.63 |

| Minimum density, ρmin (g/cm3) | 1.27 |

| Maximum void ratio, emax | 1.202 |

| Minimum void ratio, emin | 0.641 |

| Model | Test Conditions | Test Category | |

|---|---|---|---|

| Biotreatment Cycles N | Rainfall Intensity Ri | ||

| S1 | 2 | —— | Property tests |

| S2 | 4 | —— | |

| S3 | 6 | —— | |

| C1 | 0 | 45 | Control group (without biotreatment) |

| C2 | 0 | 70 | |

| C3 | 0 | 100 | |

| R1 | 2 | 45 | Rainfall erosion analysis (after biotreatment) |

| R2 | 2 | 70 | |

| R3 | 2 | 100 | |

| R4 | 4 | 45 | |

| R5 | 4 | 70 | |

| R6 | 4 | 100 | |

| R7 | 6 | 45 | |

| R8 | 6 | 70 | |

| R9 | 6 | 100 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, Y.; Hazarika, H.; Marchelina, N. Effect of Bio-Cementation Level and Rainfall Intensity on Surface Erosion Resistance of Biotreated Slope Using PEICP Method. Materials 2025, 18, 1662. https://doi.org/10.3390/ma18071662

Chen Y, Hazarika H, Marchelina N. Effect of Bio-Cementation Level and Rainfall Intensity on Surface Erosion Resistance of Biotreated Slope Using PEICP Method. Materials. 2025; 18(7):1662. https://doi.org/10.3390/ma18071662

Chicago/Turabian StyleChen, Yuyuan, Hemanta Hazarika, and Nadella Marchelina. 2025. "Effect of Bio-Cementation Level and Rainfall Intensity on Surface Erosion Resistance of Biotreated Slope Using PEICP Method" Materials 18, no. 7: 1662. https://doi.org/10.3390/ma18071662

APA StyleChen, Y., Hazarika, H., & Marchelina, N. (2025). Effect of Bio-Cementation Level and Rainfall Intensity on Surface Erosion Resistance of Biotreated Slope Using PEICP Method. Materials, 18(7), 1662. https://doi.org/10.3390/ma18071662