Thermal and Optical Characterization of Polycarbonate Reflectors Doped with Titanium Dioxide Using Thermography

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Methods

2.2.1. Determination of the Thermal Stability of the Materials

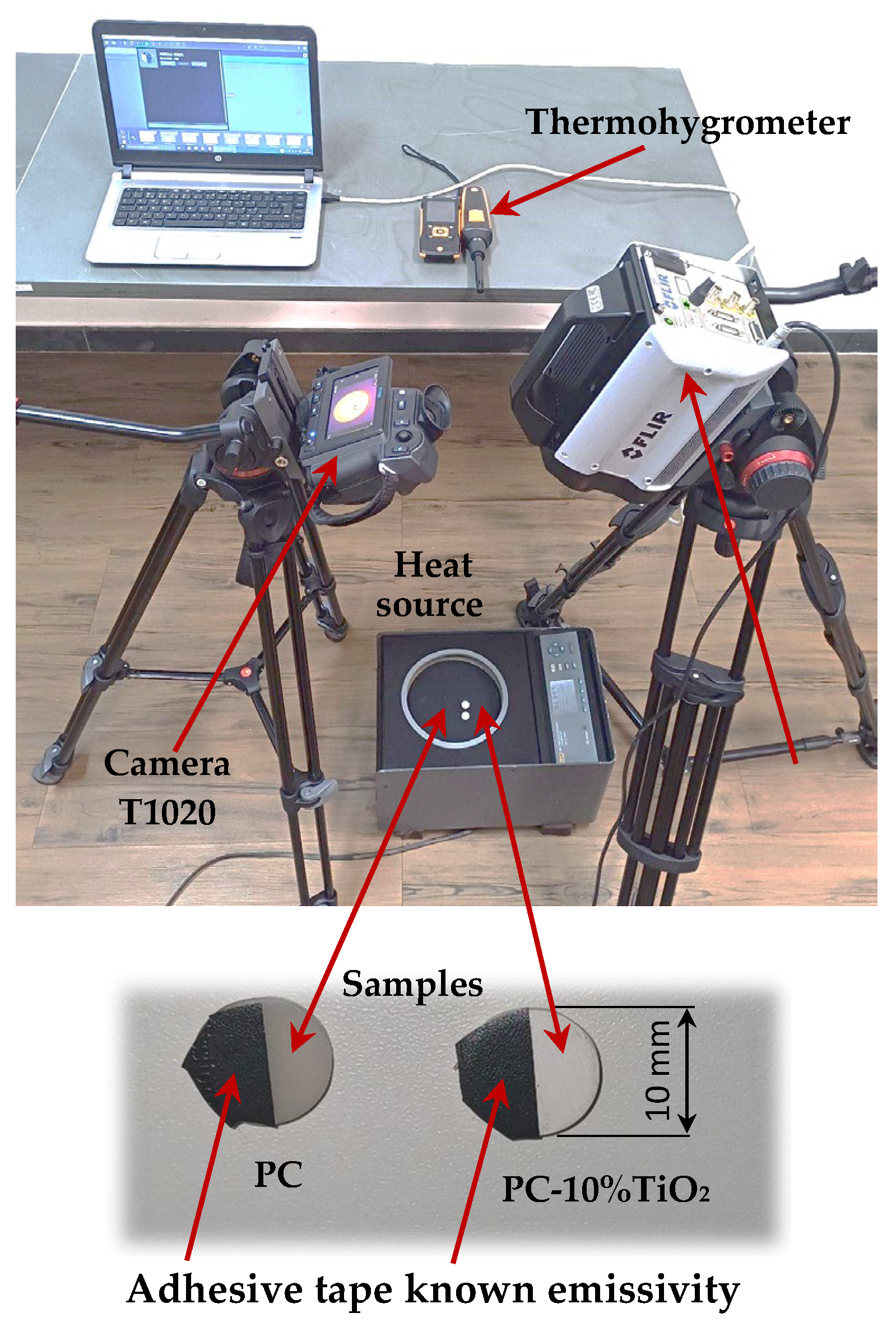

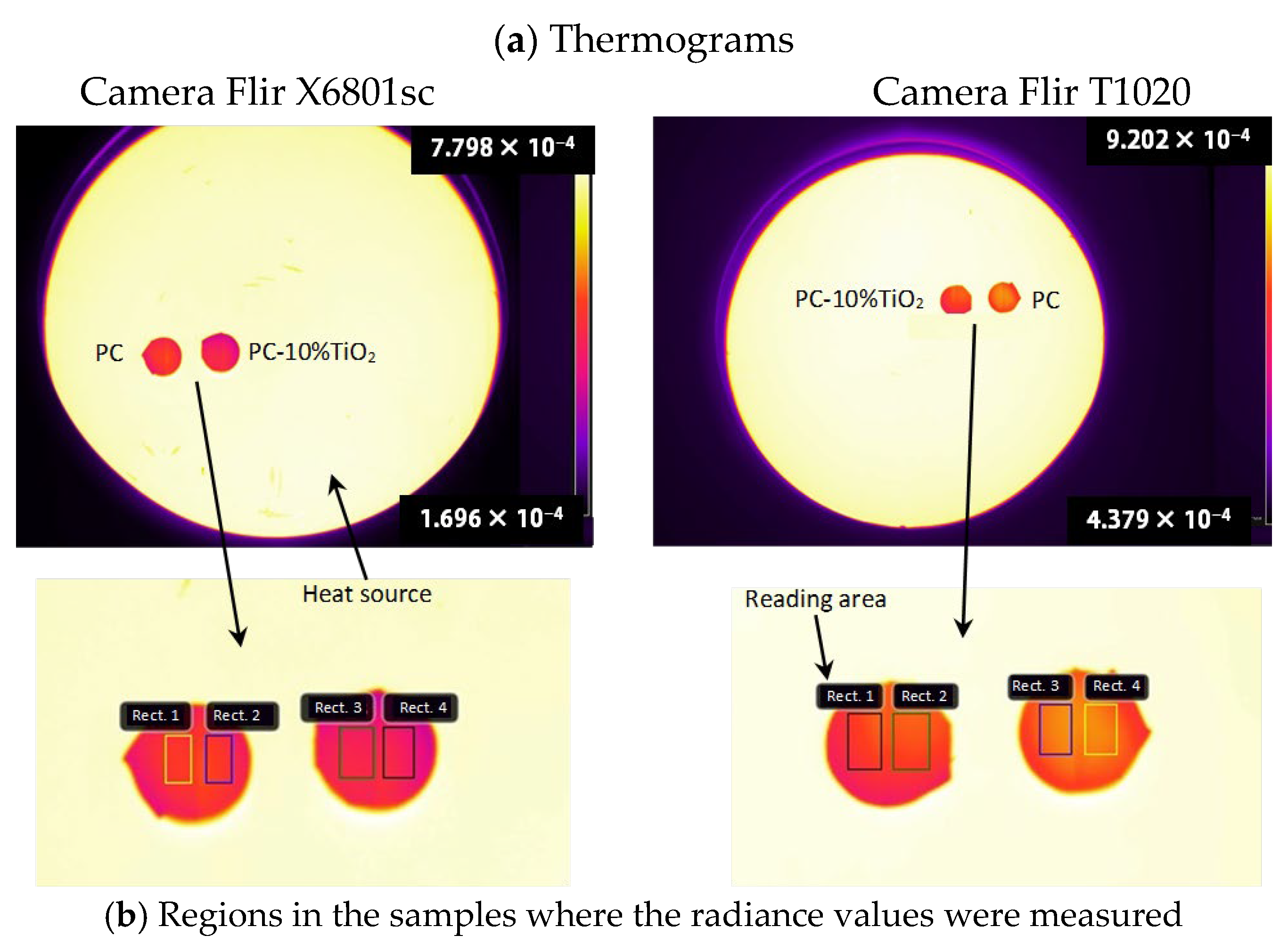

2.2.2. Determination of the Emissivity of the Materials

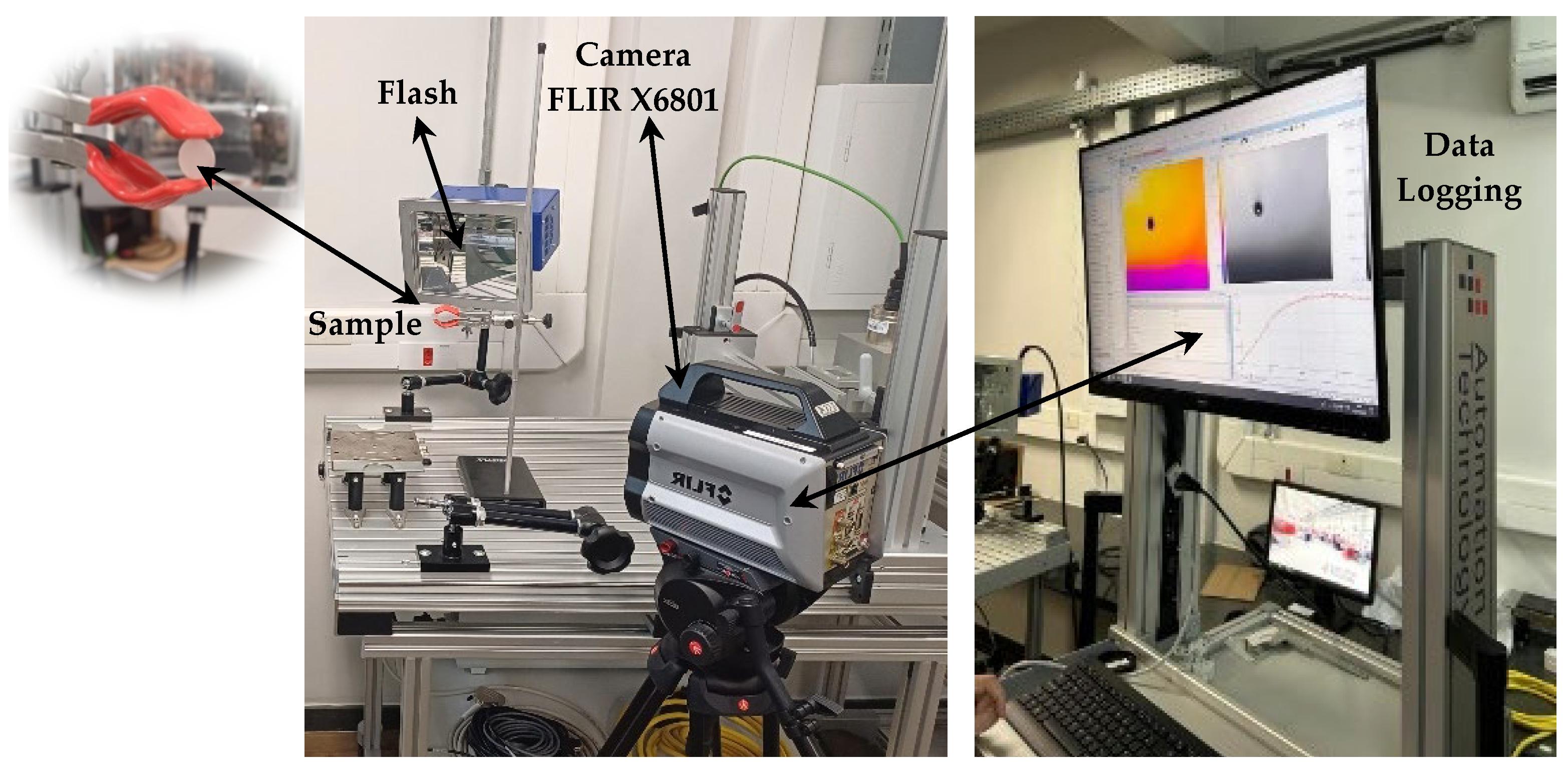

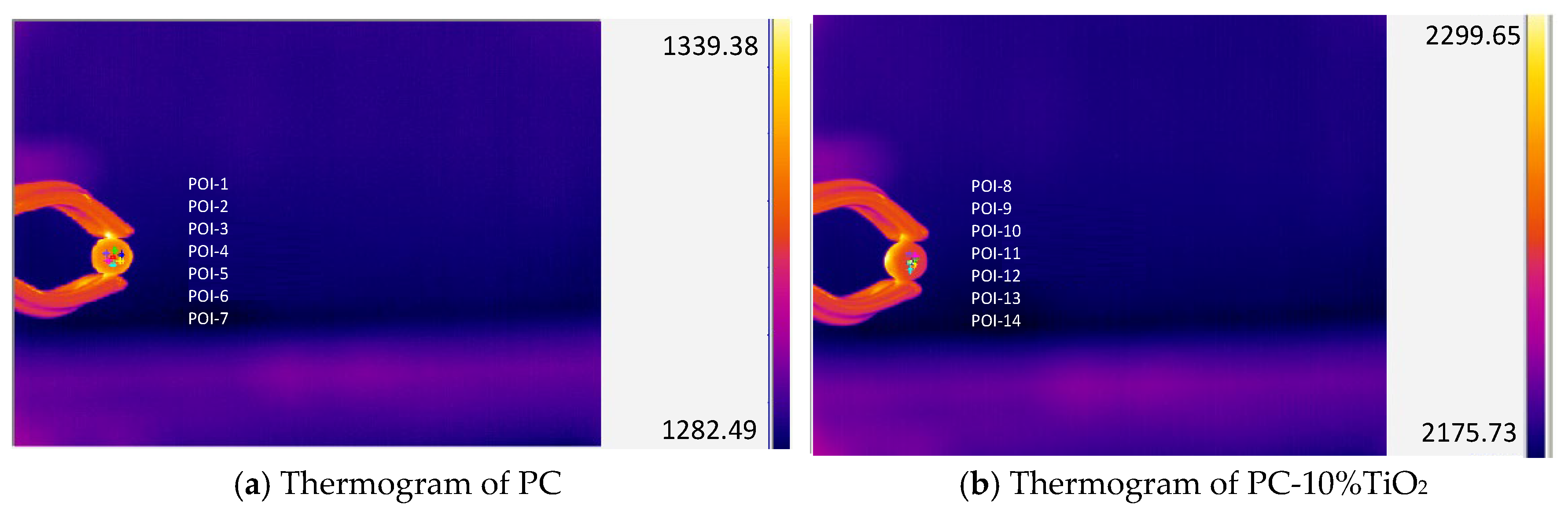

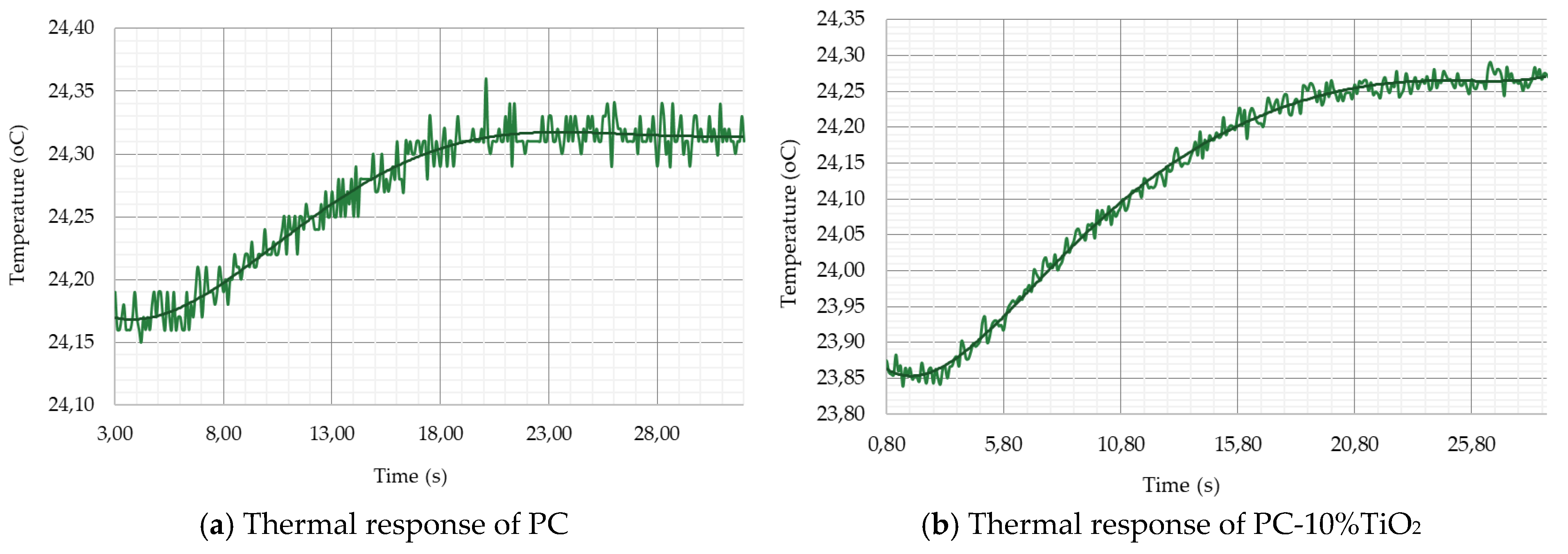

2.2.3. Determination of the Thermal Diffusivity of the Material

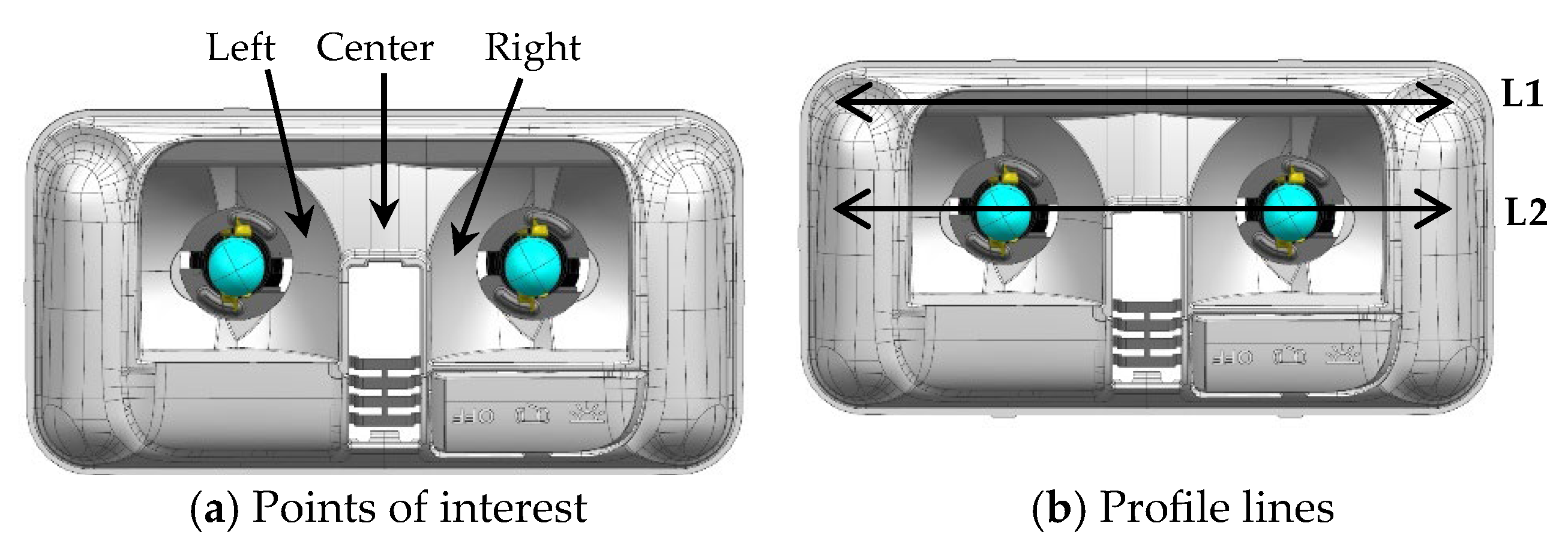

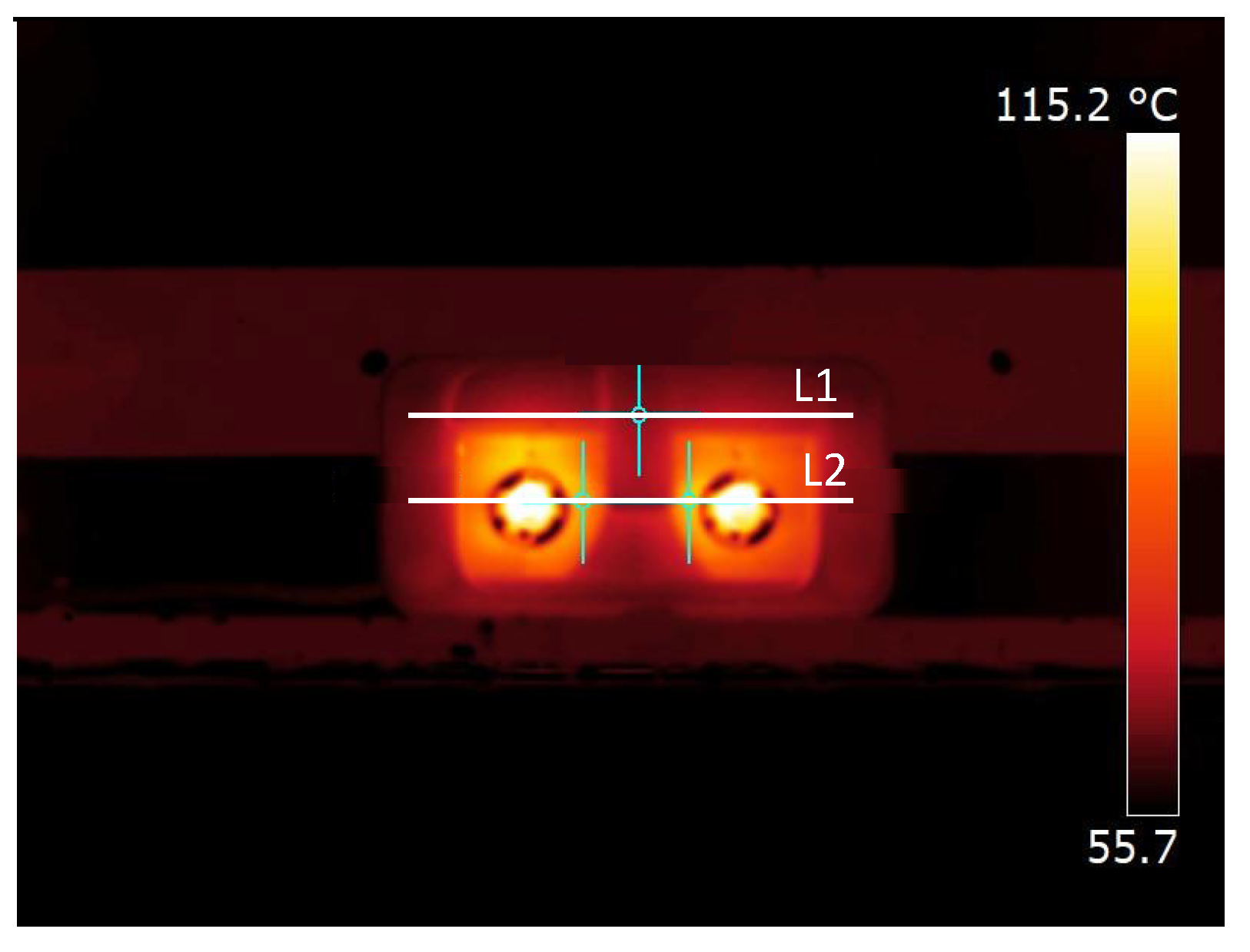

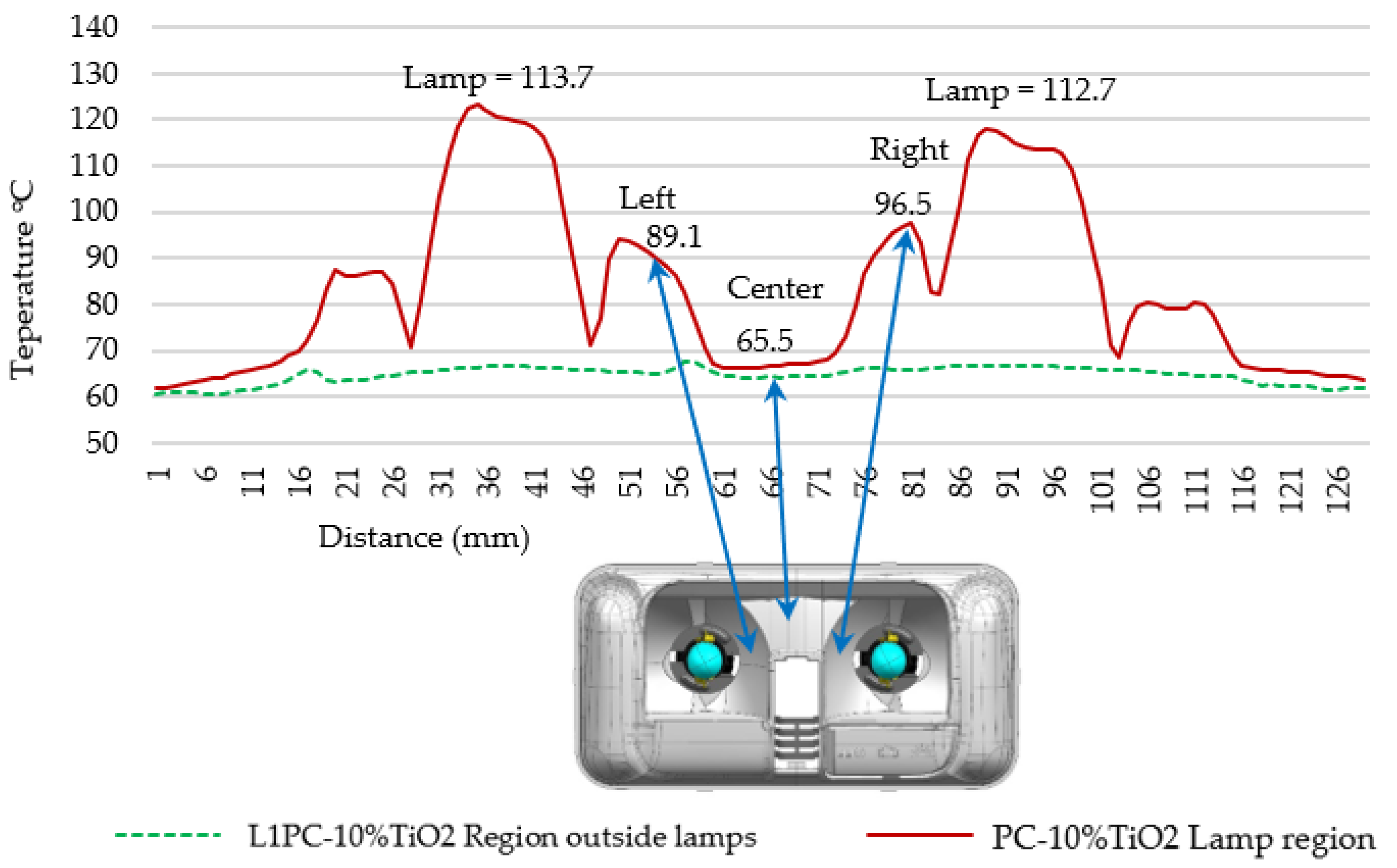

2.2.4. Determination of the Thermal Performance of the Reflector

2.2.5. Determination of the Lighting Performance

3. Results and Discussion

3.1. Thermal Stability of Materials

3.2. Emissivity of the Materials

3.3. Thermal Diffusivity of the Material

3.4. Thermal Performance of the Reflector

3.5. Lighting Performance

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Gupta, P.; Toksha, B.; Patel, B.; Rushiya, Y.; Das, P.; Rahaman, M. Recent Developments and Research Avenues for Polymers in Electric Vehicles. Chem. Rec. 2022, 22, e202200186. [Google Scholar] [CrossRef] [PubMed]

- Jaleh, B.; Shahbazi, N.; Jabbari, A. Optical and Thermal Properties of Polycarbonate–TiO2 Nanocomposite Film. Synth. React. Inorg. Met.-Org. Nano-Met. Chem. 2016, 46, 602–607. [Google Scholar] [CrossRef]

- Malnati, P. Enlightening Possibilities: Plastics Expand Role in Vehicle Lighting Applications. Plast. Eng. 2018, 74, 38–45. [Google Scholar] [CrossRef]

- Zhang, J.; Feng, J.; Jia, L.; Zhang, H.; Zhang, G.; Sun, S.; Zhou, T. Laser-Induced Selective Metallization on Polymer Substrates Using Organocopper for Portable Electronics. ACS Appl. Mater. Interfaces 2019, 11, 13714–13723. [Google Scholar] [CrossRef] [PubMed]

- Filonov, D.; Kolen, S.; Shmidt, A.; Shacham-Diamand, Y.; Boag, A.; Ginzburg, P. Volumetric 3D-Printed Antennas, Manufactured via Selective Polymer Metallization. Phys. Status Solidi (RRL)—Rapid Res. Lett. 2019, 13, 13. [Google Scholar] [CrossRef]

- Petrova, M.; Georgieva, M.; Lazarova, D.; Dobrev, D.; Pavlov, T. Electroless metallisation of ABS polymer samples produced by different technologies. Trans. IMF 2021, 99, 188–193. [Google Scholar] [CrossRef]

- Diniță, A.; Ripeanu, R.G.; Ilincă, C.N.; Cursaru, D.; Matei, D.; Naim, R.I.; Tănase, M.; Portoacă, A.I. Advancements in Fiber-Reinforced Polymer Composites: A Comprehensive Analysis. Polymers 2023, 16, 2. [Google Scholar] [CrossRef]

- Afshar, A.; Mihut, D. Enhancing durability of 3D printed polymer structures by metallization. J. Mater. Sci. Technol. 2020, 53, 185–191. [Google Scholar] [CrossRef]

- Lage-Rivera, S.; Ares-Pernas, A.; Abad, M. Last developments in polymers for wearable energy storage devices. Int. J. Energy Res. 2022, 46, 10475–10498. [Google Scholar] [CrossRef]

- Akhouri, D.; Banerjee, D.; Mishra, S.B. A review report on the plating process of fused deposition modelling (FDM) built parts. Mater. Today Proc. 2020, 26, 2140–2142. [Google Scholar] [CrossRef]

- Melentiev, R.; Yu, N.; Lubineau, G. Polymer metallization via cold spray additive manufacturing: A review of process control, coating qualities, and prospective applications. Addit. Manuf. 2021, 48, 102459. [Google Scholar] [CrossRef]

- Melentiev, R.; Yudhanto, A.; Tao, R.; Vuchkov, T.; Lubineau, G. Metallization of polymers and composites: State-of-the-art approaches. Mater. Des. 2022, 221, 110958. [Google Scholar] [CrossRef]

- Jaleh, B.; Shahidzadeh, E.S.; Azizian, S. Effects of UV irradiation treated polycarbonate substrates for nanocrystalline deposition of 10TiO2 thin films. J. Interfaces 2018, 2, 73–79. [Google Scholar]

- Vidakis, N.; Petousis, M.; Grammatikos, S.; Papadakis, V.; Korlos, A.; Mountakis, N. High Performance Polycarbonate Nanocomposites Mechanically Boosted with Titanium Carbide in Material Extrusion Additive Manufacturing. Nanomaterials 2022, 12, 1068. [Google Scholar] [CrossRef]

- Thatcher, J.E.; Crump, D.A.; Devivier, C.; Bailey, P.B.S.; Dulieu-Barton, J.M. Low cost infrared thermography for automated crack monitoring in fatigue testing. Opt. Lasers Eng. 2020, 126, 105914. [Google Scholar] [CrossRef]

- Zhu, C.; Hobbs, M.J.; Willmott, J.R. An accurate instrument for emissivity measurements by direct and indirect methods. Meas. Sci. Technol. 2020, 31, 044007. [Google Scholar] [CrossRef]

- Jahantigh, F.; Nazirzadeh, M. Synthesis and Characterization of TiO2 Nanoparticles with Polycarbonate and Investigation of Its Mechanical Properties. Int. J. Nanosci. 2017, 16, 1750012. [Google Scholar] [CrossRef]

- Saad, N.A.; Jwad, E.R. Investigation of Addition Titanium Dioxide on General Properties of Polycarbonate. OAlib 2018, 05, 1–11. [Google Scholar] [CrossRef]

- da Silva, D.J.; Escote, M.T.; Cruz, S.A.; Simião, D.F.; Zenatti, A.; Curvello, M.S. Polycarbonate/TiO2 nanofibers nanocomposite: Preparation and properties. Polym. Compos. 2018, 39, E780–E790. [Google Scholar] [CrossRef]

- Li, C.; Yu, H.; Song, Y.; Liang, H.; Yan, X. Preparation and characterization of PMMA/TiO2 hybrid shell microencapsulated PCMs for thermal energy storage. Energy 2019, 167, 1031–1039. [Google Scholar] [CrossRef]

- Pavličević, J.; Špírková, M.; Aroguz, A.; Jovičić, M.; Kojić, D.; Govedarica, D.; Ikonić, B. The effect of TiO2 particles on thermal properties of polycarbonate-based polyurethane nanocomposite films. J. Therm. Anal. Calorim. 2019, 138, 2043–2055. [Google Scholar] [CrossRef]

- Ghazaryan, L.; Handa, S.; Schmitt, P.; Beladiya, V.; Roddatis, V.; Tünnermann, A.; Szeghalmi, A. Structural, optical, and mechanical properties of TiO2 nanolaminates. Nanotechnology 2021, 32, 095709. [Google Scholar] [CrossRef] [PubMed]

- Ferreira, R.A.M.; Pottie, D.L.F.; Dias, L.H.C.; Filho, B.J.C.; Porto, M.P. A directional-spectral approach to estimate temperature of outdoor PV panels. Sol. Energy 2019, 183, 782–790. [Google Scholar] [CrossRef]

- Oliveira, A.H.P.; Moura, J.A.S.; Oliveira, H.P. Preparação e Caracterização de Microfibras de Poli(Álcool Vinílico)/Dióxido de Titânio. Polímeros 2013, 23, 196–200. [Google Scholar]

- Jawad, A.; Ahmed, S. Studying the influence of the addition of nano-titanium dioxide on the rheological, mechanical, thermal, and electrical properties of polycarbonate/wood flour. J. Thermoplast. Compos. Mater. 2023, 36, 4874–4904. [Google Scholar] [CrossRef]

- Eskandari, M.; Liavali, M.N.; Malekfar, R.; Taboada, P. Investigation of Optical Properties of Polycarbonate/TiO2/ZnO Nanocomposite: Experimental and DFT Calculations. J. Inorg. Organomet. Polym. Mater. 2020, 30, 5283–5292. [Google Scholar] [CrossRef]

- Bergman, T.L.; Lavine, A.S.; Incropera, F.P.; DeWitt, D.P. Fundamentals of Heat and Mass Transfer, 8th ed.; John Wiley & Sons: Hoboken, NJ, USA, 2020. [Google Scholar]

- Gohil, M.; Joshi, G. Perspective of polycarbonate composites and blends properties, applications, and future development: A review. In Green Sustainable Process for Chemical and Environmental Engineering and Science; Elsevier: Amsterdam, The Netherlands, 2022; pp. 393–424. [Google Scholar] [CrossRef]

- Parrino, F.; Palmisano, L. Titanium Dioxide (TiO₂) and Its Applications, 1st ed.; Elsevier: Amsterdam, The Netherlands, 2020. [Google Scholar]

- Haider, A.J.; Jameel, Z.N.; Al-Hussaini, I.H.M. Review on: Titanium Dioxide Applications. Energy Procedia 2019, 157, 17–29. [Google Scholar] [CrossRef]

- Pandey, A.K.; Tiwari, A.K.; Paliwal, H.K. Enhancement of mechanical, thermal and optical properties of TiO2 thin films using glancing angle deposition technique. Opt. Mater. 2022, 134, 113054. [Google Scholar] [CrossRef]

- Santoro, L.; Quercio, M.; Canova, A.; Sesana, R. Measuring thermal and electrical performances of additively manufactured magnetic shielding material: An active thermography approach. Nondestruct. Test. Eval. 2024, 39, 2692–2715. [Google Scholar] [CrossRef]

- Bison, P.; Cernuschi, F.; Muscio, A. Ermanno Grinzato: A survey on thermophysical properties assessment. Quant. Infrared Thermogr. J. 2024, 21, 438–450. [Google Scholar] [CrossRef]

- Bedoya, A.; Salazar, A.; Mendioroz, A.; Marín, E. Measuring the in-plane thermal diffusivity of anisotropic solids by lock-in infrared thermography: Laser-spot vs laser-line heating. J. Appl. Phys. 2024, 135, 135102. [Google Scholar] [CrossRef]

- Santos, T.; Amaral, J.S.; Amaral, V.S.; Costa, V.A.F. In-plane thermal anisotropy of natural cork and its variability. Measurement 2025, 242, 116062. [Google Scholar] [CrossRef]

- Zhang, Y.; Xu, R.; Zhang, T.; Yang, J.; Liu, Y.; Liu, Y.; Wang, J. Planar distribution measurement of cross-plane thermal diffusivity for microscale films using laser spot periodic heating technique. Int. J. Therm. Sci. 2025, 211, 109692. [Google Scholar] [CrossRef]

- Barreira, E.; Almeida, R.M.S.F.; Simões, M.L. Emissivity of Building Materials for Infrared Measurements. Sensors 2021, 21, 1961. [Google Scholar] [CrossRef]

- Savino, L.; De Cesare, M.; Musto, M.; Rotondo, G.; De Filippis, F.; Del Vecchio, A.; Russo, F. Free emissivity temperature investigations by dual color applied physics methodology in the mid- and long-infrared ranges. Int. J. Therm. Sci. 2017, 117, 328–341. [Google Scholar] [CrossRef]

- Moreira, M.D.O.; Abrão, A.M.; Ferreira, R.A.; Porto, M.P. Temperature monitoring of milling processes using a directional-spectral thermal radiation heat transfer formulation and thermography. Int. J. Heat Mass Transf. 2021, 171, 121051. [Google Scholar] [CrossRef]

- Ishikawa, M.; Emoto, A.; Suto, Y.; Nishino, H. Active Thermography Inspection of Surface-whitened Mortars—Measurement of Surface Spectral Absorptivity for Investigation of Efficient Heating Light Wavelengths. J. Nondestruct. Eval. 2024, 43, 7. [Google Scholar] [CrossRef]

- ASTM E1461-13; Standard Test Method for Thermal Diffusivity by the Flash Method. ASTM International: West Conshohocken, PA, USA, 2022.

- Bonjour, O.; Liblikas, I.; Pehk, T.; Khai-Nghi, T.; Rissanen, K.; Vares, L.; Jannasch, P. Rigid biobased polycarbonates with good processability based on a spirocyclic diol derived from citric acid. Green Chem. 2020, 22, 3940–3951. [Google Scholar] [CrossRef]

- Al-Hakami, Y.M.N.; Wahab, M.A.; Yildirir, E.; Ates, F. Thermal degradation kinetics, thermodynamics and pyrolysis behaviour of polycarbonate by TGA and Py-GC/MS. J. Energy Inst. 2024, 113, 101499. [Google Scholar] [CrossRef]

- Apaydin-Varol, E.; Polat, S.; Putun, A. Pyrolysis kinetics and thermal decomposition behavior of polycarbonate—A TGA-FTIR study. Therm. Sci. 2014, 18, 833–842. [Google Scholar] [CrossRef]

- Wu, X.; Wang, X.; Qin, Z.; Zhang, W. Polycarbonate composites with high light transmittance, haze, and flame retardancy based on a series of incomplete-cage oligomeric silsesquioxanes. J. Mater. Sci. 2021, 56, 428–441. [Google Scholar] [CrossRef]

- Li, C.; Yu, H.; Song, Y.; Wang, M.; Liu, Z. A n-octadecane/hierarchically porous TiO2 form-stable PCM for thermal energy storage. Renew. Energy 2020, 145, 1465–1473. [Google Scholar] [CrossRef]

- Gamarra, F.; Medina, J.; Lanchipa, W.; Tamayo, R.; Sacari, E. Structural, Optical, and Arsenic Removal Properties of Sol–Gel Synthesized Fe-Doped TiO2 Nanoparticles. Nanomaterials 2022, 12, 3402. [Google Scholar] [CrossRef]

- Svora, P.; Pawełkowicz, S.S.; Ecorchard, P.; Plocek, J.; Schieberová, A.; Prošek, Z.; Ptáček, P.; Pošta, J.; Targowski, P.; Kuklík, P.; et al. Study of Interactions Between Titanium Dioxide Coating and Wood Cell Wall Ultrastructure. Nanomaterials 2022, 12, 2678. [Google Scholar] [CrossRef]

- Howell, J.R.; Mengüc, M.P.; Daun, K.; Siegel, R. Thermal Radiation Heat Transfer, 7th ed.; CRC Press: Boca Raton, FL, USA, 2021; Volume 1. [Google Scholar]

- Kang, K.; Byeon, I.; Kim, Y.G.; Choi, J.; Kim, D. Nanostructures in Organic Light-Emitting Diodes: Principles and Recent Advances in the Light Extraction Strategy. Laser Photon Rev. 2024, 18, 2400547. [Google Scholar] [CrossRef]

- Chen, J.; Zhao, Q.; Yu, B.; Lemmer, U. A Review on Quantum Dot-Based Color Conversion Layers for Mini/Micro-LED Displays: Packaging, Light Management, and Pixelation. Adv. Opt. Mater. 2024, 12, 2300873. [Google Scholar] [CrossRef]

| Sample | Target | Atmosphere | Thermal Camera Image (Filters, Lenses, and Sensors) | Full Simulation | |||

|---|---|---|---|---|---|---|---|

| |||||||

|  | ||||||

|  | ||||||

|  | ||||||

|  |  | |||||

| Environmental Component | Target | Atmosphere | |||||

| Location by Region | Points Inside the Vehicle | Measured Points | Manufacturer’s Reflection Range (lux) |

|---|---|---|---|

|  | 1 | ˃4 ˂40 |

| 2–3–4 6–7–8 | ˃15 ˂40 | |

| 5–9 | ˃4 ˂40 |

| Sample | Calculated Temperature (°C) | Emissivity | ||

|---|---|---|---|---|

| Camera X6801sc | Camera T1020 | Camera X6801sc | Camera T1020 | |

| PC | 62.30 | 67.80 | 0.96 | 0.95 |

| PC-10%TiO2 | 59.60 | 65.20 | 0.93 | 0.92 |

| Material | Curve Points | kx | Temperature | Thermal Diffusivity (mm2/s) | kr | Corrected Mean Thermal Diffusivity (mm2/s) |

|---|---|---|---|---|---|---|

| PC | 25% | 0.09272 | 24.20 | 0.28 | 0.14 | 0.28 |

| 50% | 0.13879 | 24.24 | 0.29 | |||

| 75% | 0.21049 | 24.27 | 0.29 | |||

| PC-10%TiO2 | 25% | 0.09272 | 23.96 | 0.18 | 0.15 | 0.20 |

| 50% | 0.13879 | 24.06 | 0.26 | |||

| 75% | 0.21049 | 24.16 | 0.23 |

| Sample | Output | Temperature (°C) | ||

|---|---|---|---|---|

| Left | Center | Right | ||

| PC-10%TiO2 | Apparent temperature | 89.1 | 65.5 | 96.5 |

| Actual temperature | 78.1 (ε = 0.8, Τrefl = 113.7 °C) | 67.2 (ε = 0.9, Τrefl = 30 °C) | 90.9 (ε = 0.2, Τrefl = 112.7 °C) | |

| Measured Points | Manufacturer’s Lighting Limits Min/Max. (lux) | Reflector PC + Met (lux) | Reflector PC-10%TiO2 (lux) | Variation (%) |

|---|---|---|---|---|

| 1 | >4 <40 | 21.1 | 19.6 | −7.1 |

| 2 | >15 <40 | 21.1 | 20.6 | −2.4 |

| 3 | >15 <40 | 21.0 | 19.9 | −5.2 |

| 4 | >15 <40 | 17.6 | 16.7 | −5.1 |

| 5 | >4 <40 | 19.2 | 18.5 | −3.6 |

| 6 | >15 <40 | 17.2 | 16.7 | −2.9 |

| 7 | >15 <40 | 21.0 | 19.6 | −6.7 |

| 8 | >15 <40 | 21.1 | 20.9 | −0.9 |

| 9 | >4 <40 | 19.3 | 18.6 | −3.6 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cassimiro, I.L.V.A.; Tomsich, J.I.; Porto, M.P.; Sales, R.d.B.C.; Rezende, I.H.W.S.; Rezende, N.F.d.; Paulino Aguilar, M.T. Thermal and Optical Characterization of Polycarbonate Reflectors Doped with Titanium Dioxide Using Thermography. Materials 2025, 18, 1628. https://doi.org/10.3390/ma18071628

Cassimiro ILVA, Tomsich JI, Porto MP, Sales RdBC, Rezende IHWS, Rezende NFd, Paulino Aguilar MT. Thermal and Optical Characterization of Polycarbonate Reflectors Doped with Titanium Dioxide Using Thermography. Materials. 2025; 18(7):1628. https://doi.org/10.3390/ma18071628

Chicago/Turabian StyleCassimiro, Isabella Luísa Vieira Aquino, Juan Ignacio Tomsich, Matheus Pereira Porto, Rosemary do Bom Conselho Sales, Izabella Helena Werneck Soares Rezende, Nathan Funchal de Rezende, and Maria Teresa Paulino Aguilar. 2025. "Thermal and Optical Characterization of Polycarbonate Reflectors Doped with Titanium Dioxide Using Thermography" Materials 18, no. 7: 1628. https://doi.org/10.3390/ma18071628

APA StyleCassimiro, I. L. V. A., Tomsich, J. I., Porto, M. P., Sales, R. d. B. C., Rezende, I. H. W. S., Rezende, N. F. d., & Paulino Aguilar, M. T. (2025). Thermal and Optical Characterization of Polycarbonate Reflectors Doped with Titanium Dioxide Using Thermography. Materials, 18(7), 1628. https://doi.org/10.3390/ma18071628