Effect of Stirring Needle Length on the Microstructures and Properties of A380/6061 Dissimilar Aluminium Alloy FSW Joints

Abstract

1. Introduction

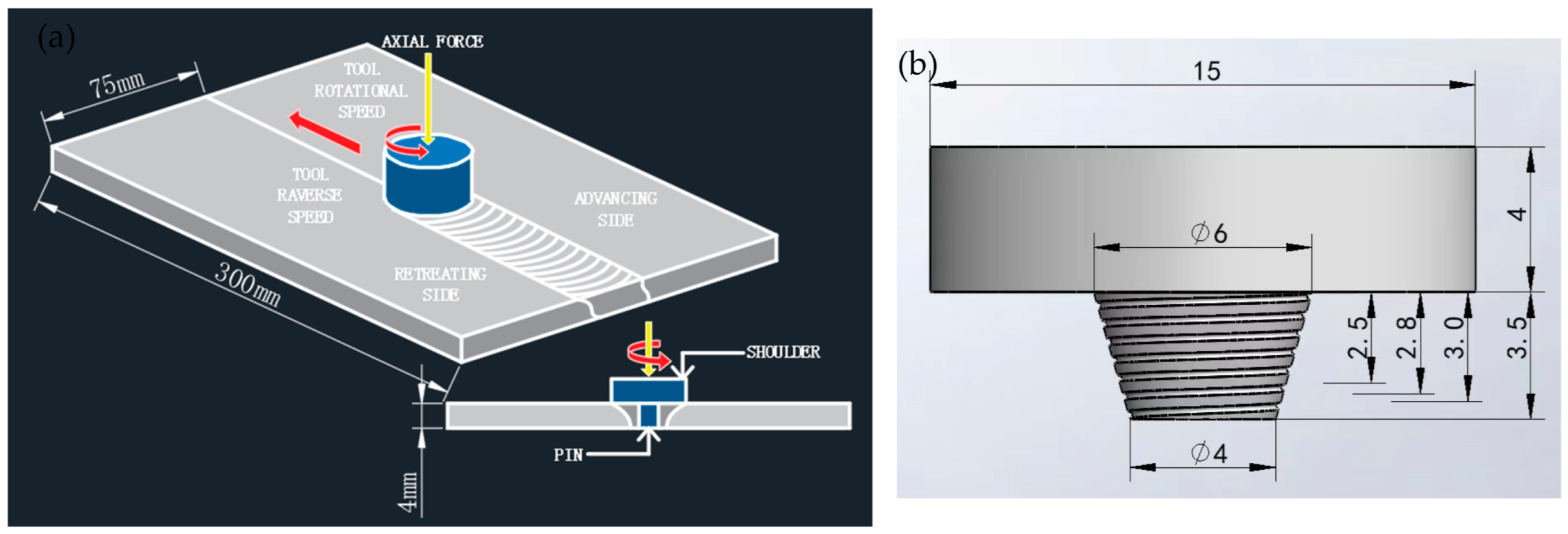

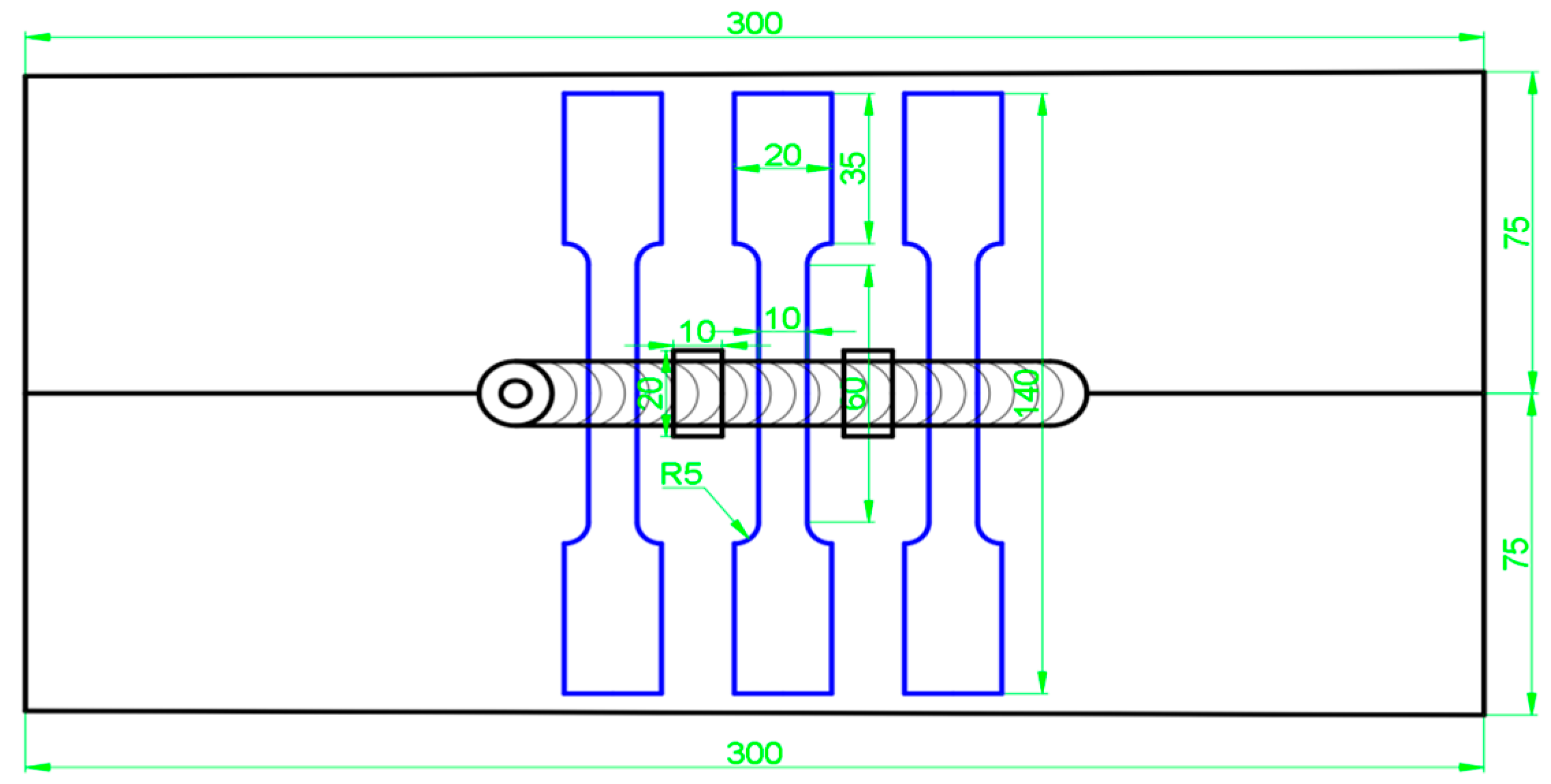

2. Materials and Methods

2.1. Materials

2.2. Experimental Procedure

3. Results and Discussion

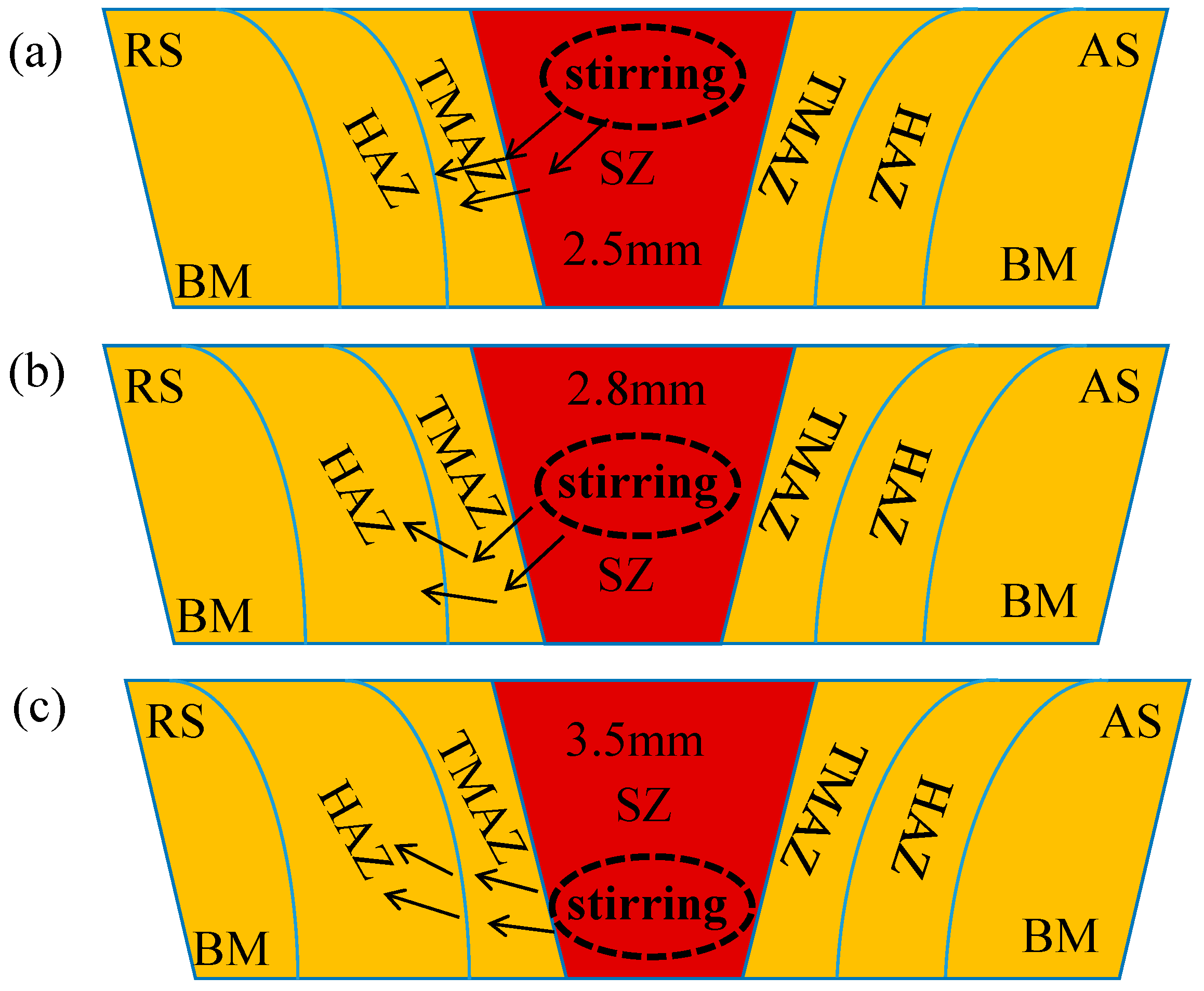

3.1. Macro-Discussion of Joint Morphology

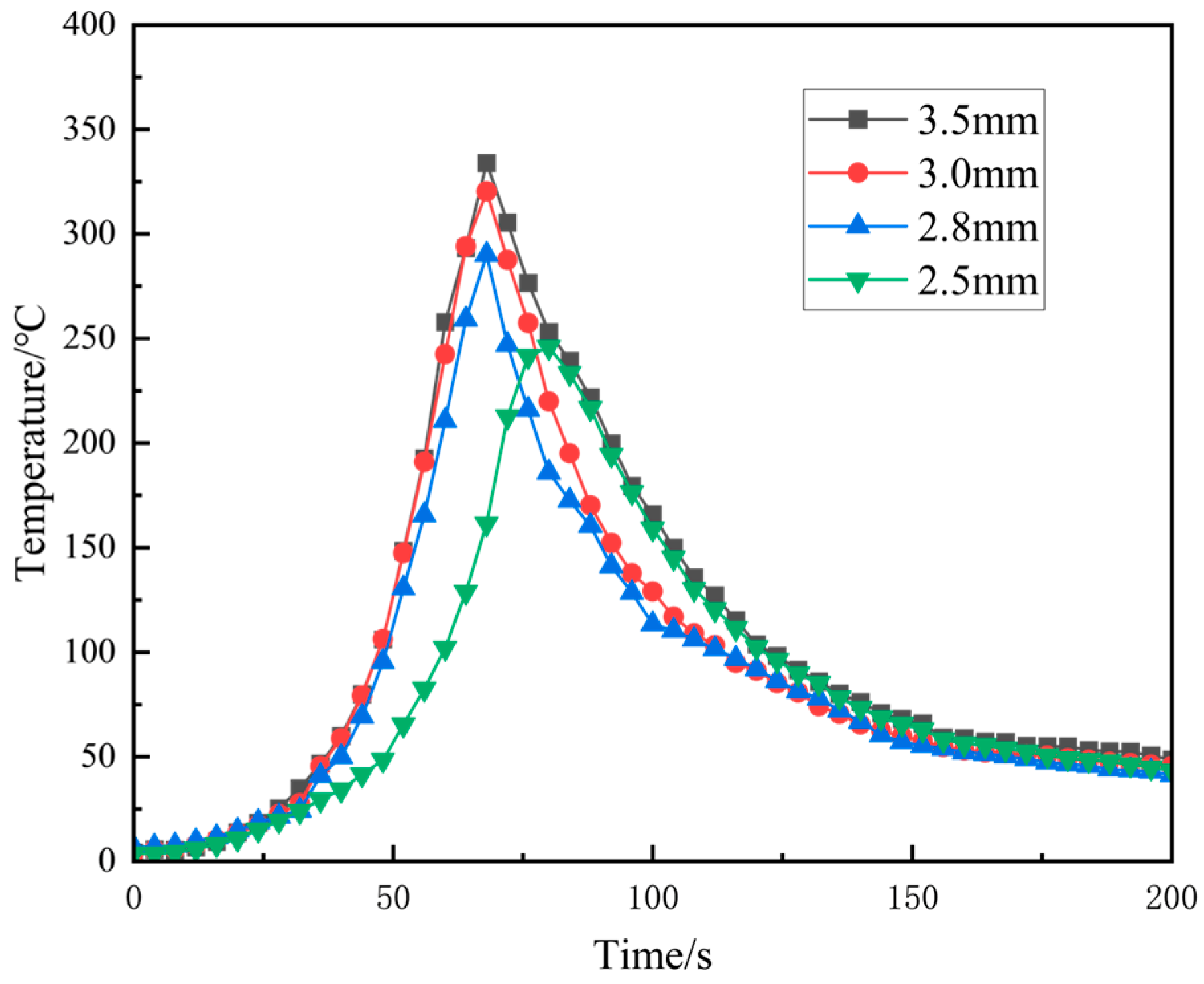

3.2. Effect of Welding Temperature

3.3. Mechanical Properties of Joints

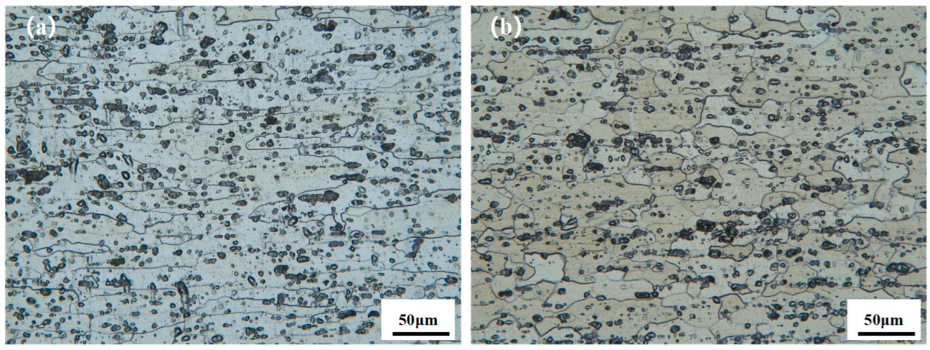

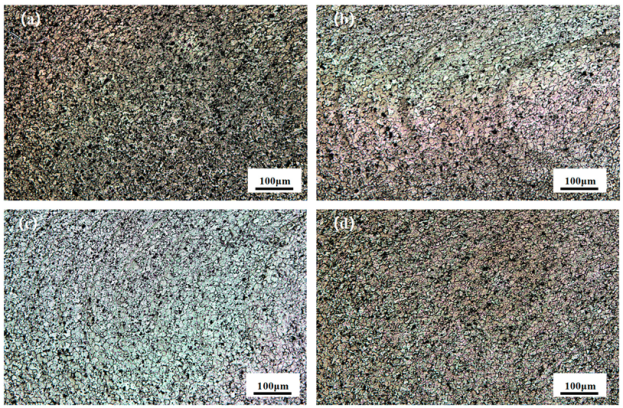

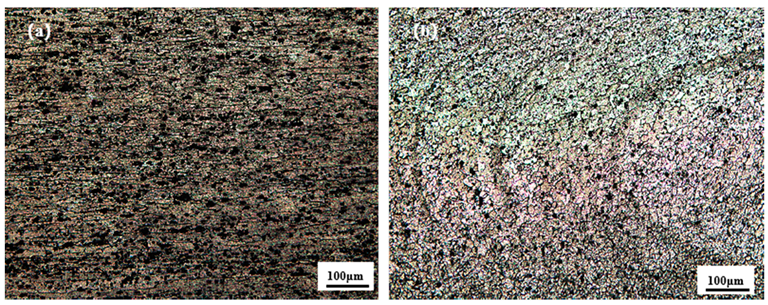

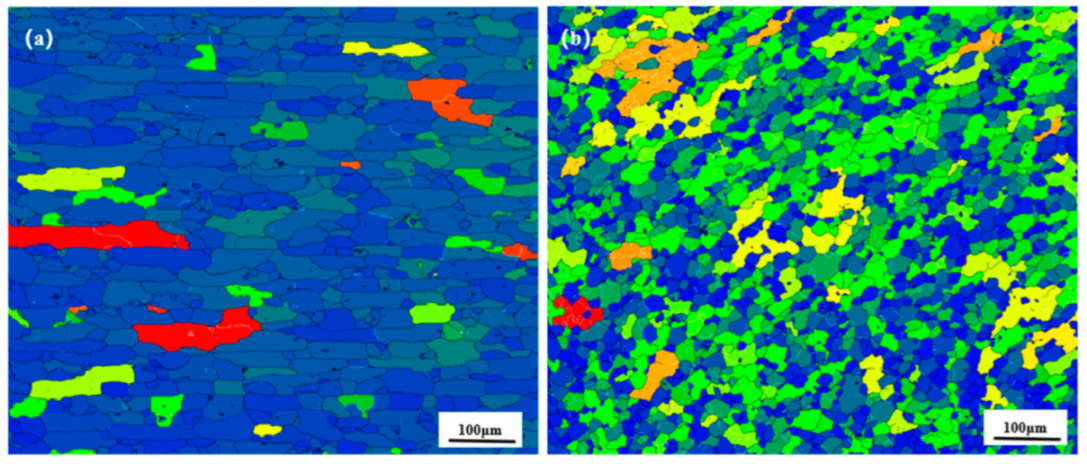

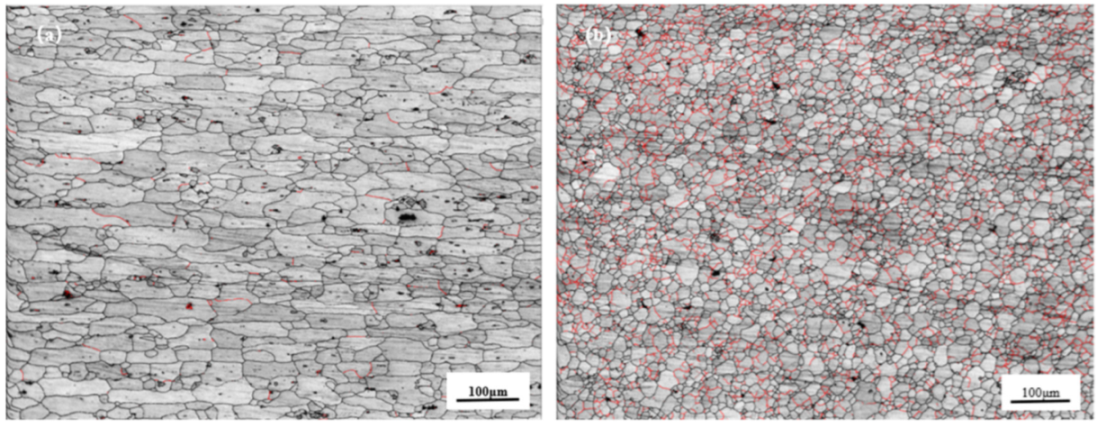

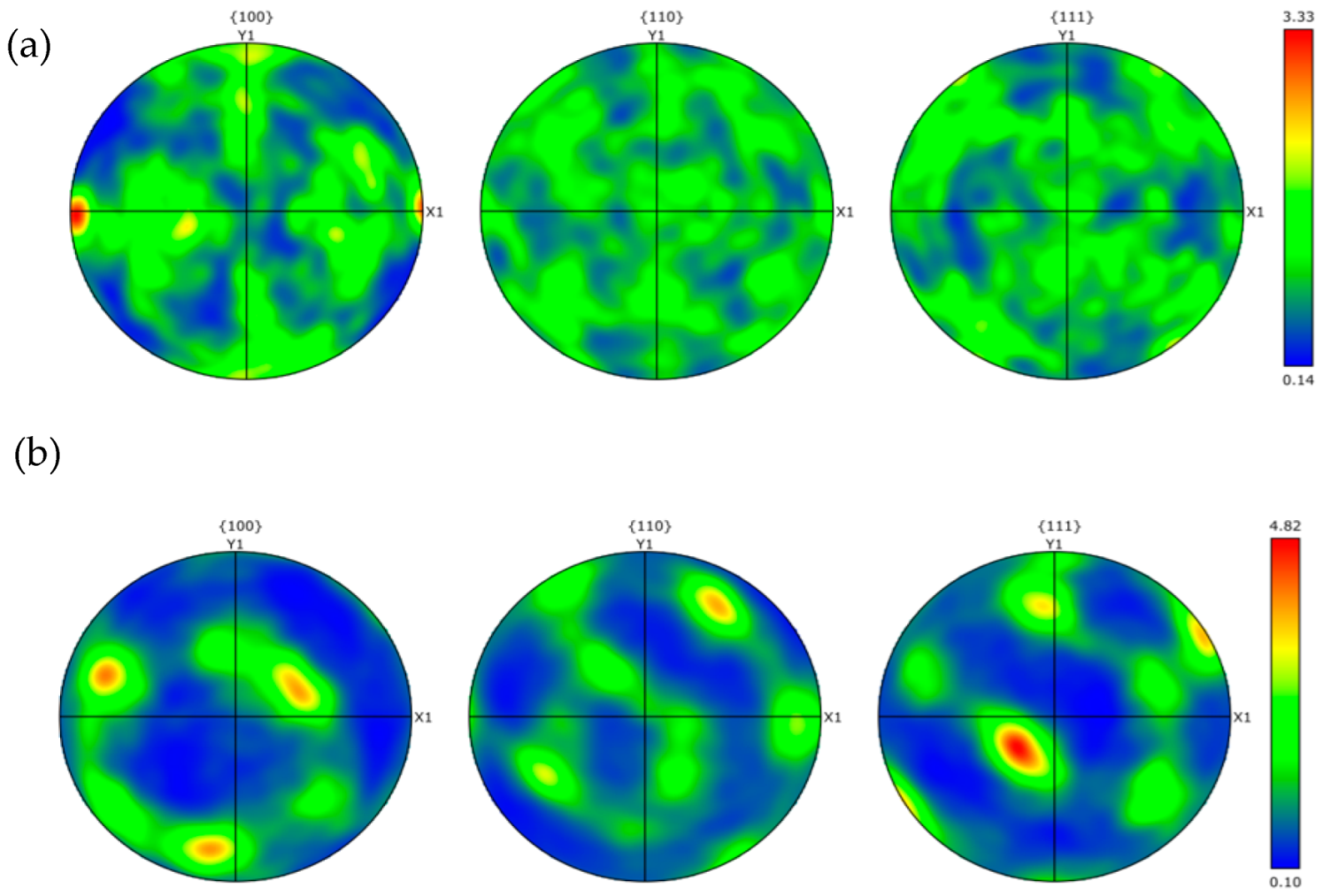

3.4. Joint Microstructure

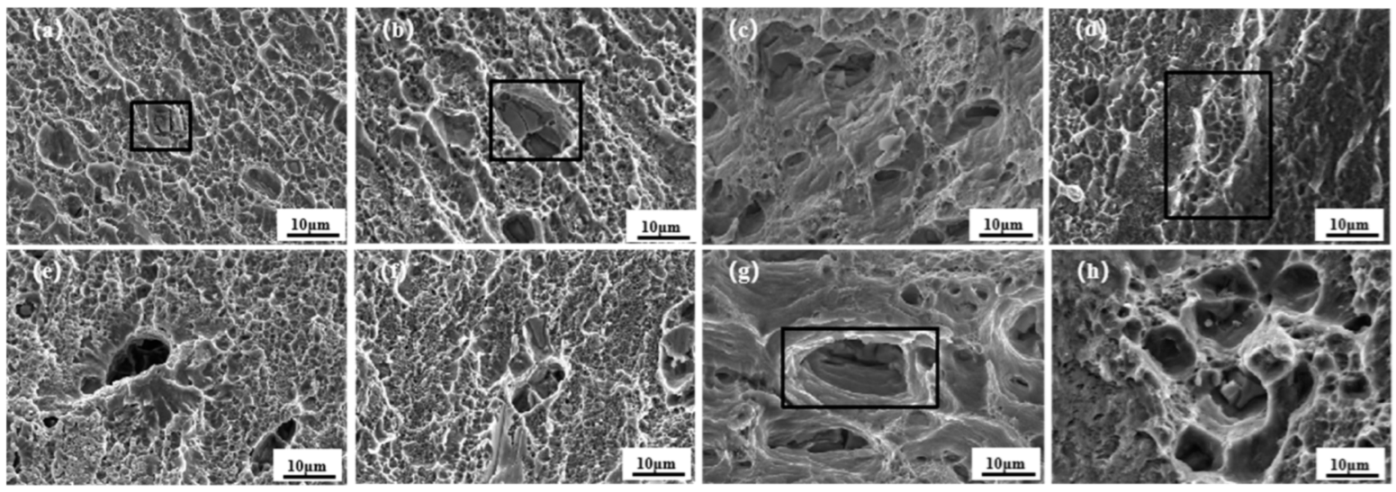

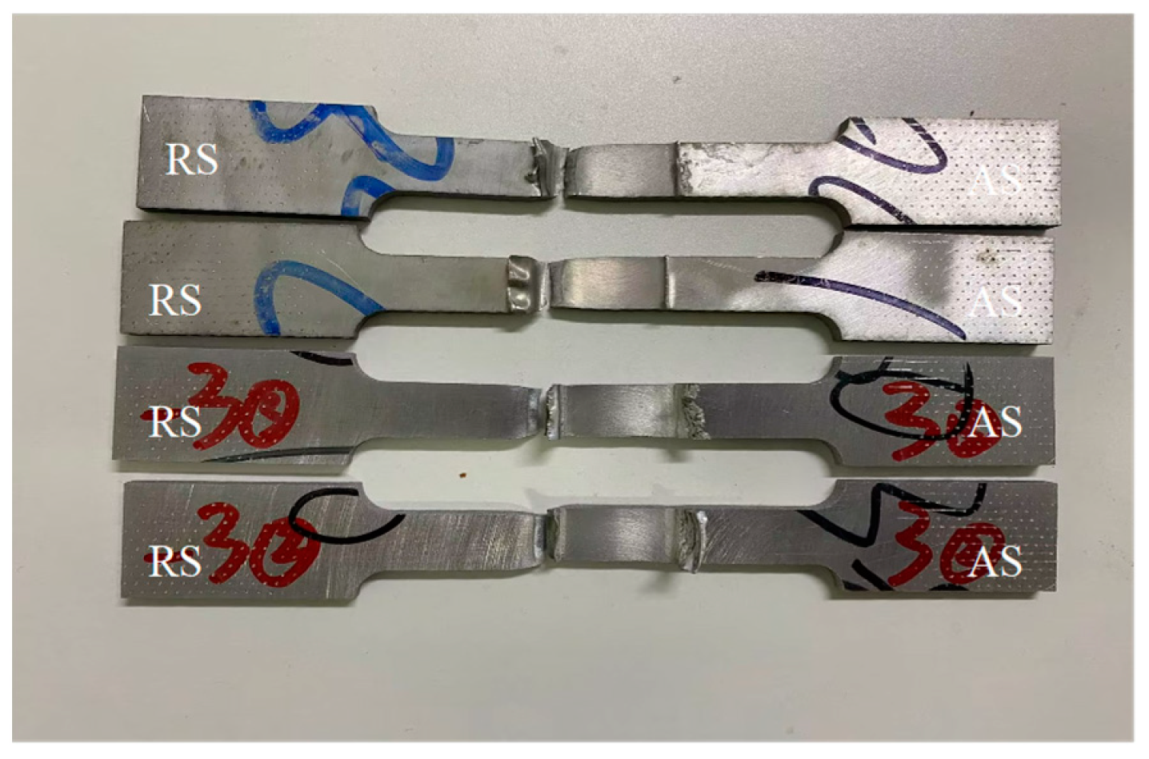

3.5. Fracture Discussion

4. Conclusions

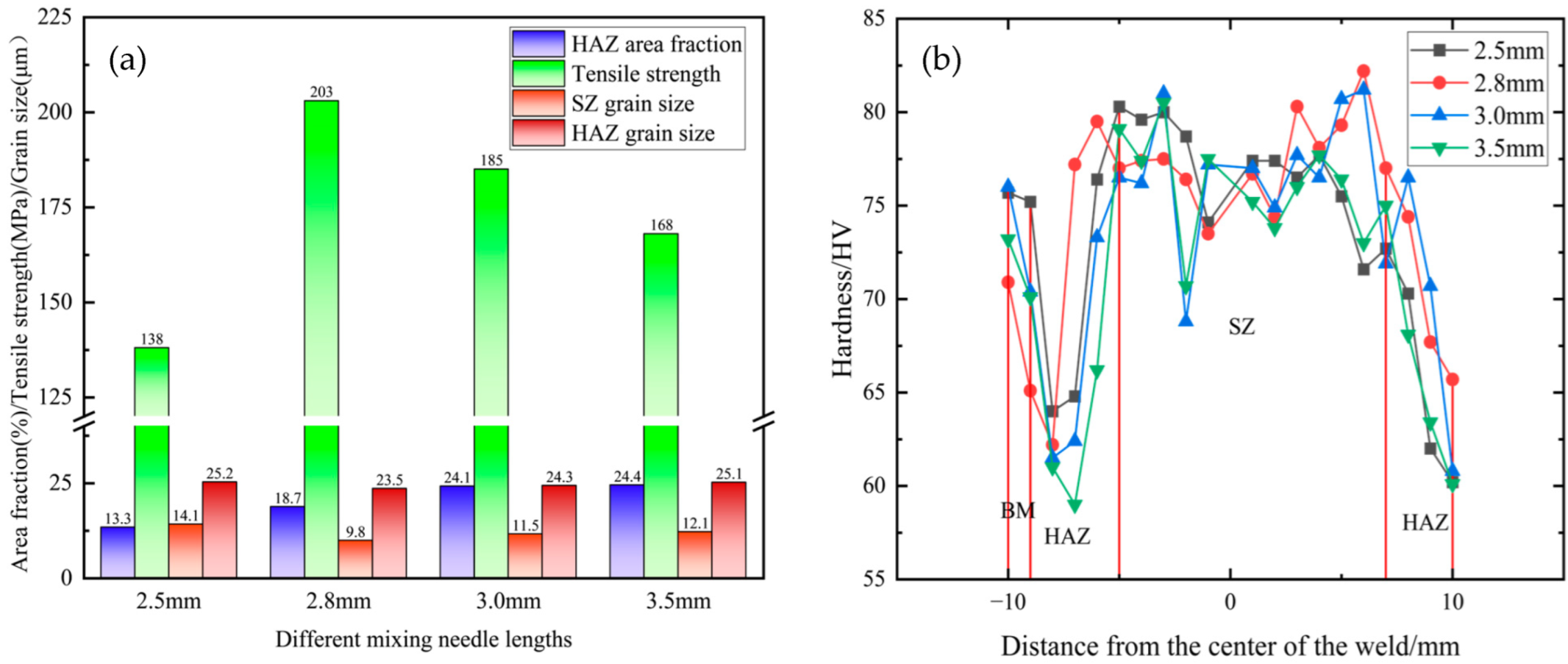

- When the spindle speed is 1000 rpm, and the welding speed is 120 mm/min, a 2.8 mm needle length for welding can obtain great fluidity of the weld, with the highest tensile strength. The joint strength coefficient is 85.3%, and the weld core area has a lot of Mg2Si. The average grain size in the weld core area is 9.8 μm, and the fracture mode of the tensile specimens is mixed fracture.

- Under the mechanical action of the stirring needle, grain refinement occurs in the weld core zone, with a large number of low-angle grain boundaries; grain regrowth occurs in the RS-HAZ, with a large number of high-angle grain boundaries. The hardness of the RS-HAZ is also the lowest, and most of the tensile specimens are fractured here. There is no significant difference in the hardness values of the RS-HAZ at different needle lengths.

- Under the same welding parameters, the length of the stirring needle affects the plastic flow at the bottom. When the length of the stirring needle is increased, the stirring area at the bottom of the material increases, resulting in poorer fluidity in the weld core area. When the stirring needle length decreases, the stirring needle cannot reach the bottom, and the heat generated is insufficient, which also makes the flowability of the weld core area worse. Therefore, a reasonable range of stirring needle lengths has a significant influence on the welding performance of the A380/6061 FSW joints.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Chaitanya, S.; Vikas, U. Friction stir welding of dissimilar aluminum alloys AA5086 and AA7039. J. Hysics Conf. Series. 2010, 1240, 012160. [Google Scholar] [CrossRef]

- Karakizis, P.N.; Pantelis, D.I.; Dragatogiannis, D.A.; Bougiouri, V.D.; Charitidis, C.A. Study of friction stir butt welding between thin plates of AA5754 and mild steel for automotive applications. Int. J. Adv. Manuf. Technol. 2019, 102, 3065–3076. [Google Scholar] [CrossRef]

- Sen, D.; Katiyar, B.S.; Panda, S.K.; Pal, S.K. Crushing performance of cost-effective tubular components of AA 5083-O fabricated through friction stir welding process for automotive application. Arch. Civ. Mech. Eng. 2024, 24, 237. [Google Scholar] [CrossRef]

- Hassan, A.S.; Mahmoud, T.S.; Mahmoud, F.H.; Khalifa, T.A. Friction stir welding of dissimilar A319 and A356 aluminium cast alloys. Sci. Technol. Weld. Join. 2010, 15, 414–422. [Google Scholar] [CrossRef]

- Zhang, Z.; Zhang, J.; Ji, S.; Gong, P.; Sun, Y.; Liu, H.; Ma, L. Microstructure, mechanical property and bonding mechanism of the repaired mechanical hole out of dimension tolerance of 2024 aluminum alloy by radial-additive friction stir repairing. J. Mater. Res. Technol. 2024, 29, 1565–1578. [Google Scholar] [CrossRef]

- Saboktakin, M.R.; Hossein, A.K. Microstructure evolution and microhardness of friction stir welded cast aluminum bronze. J. Mater. Process. Tech. 2014, 214, 1524–1529. [Google Scholar] [CrossRef]

- Fallu, J.; Izadi, H.; Gerlich, A.P. Friction stir welding of co-cast aluminium clad sheet. Sci. Technol. Weld. Join. 2014, 19, 9–14. [Google Scholar] [CrossRef]

- Thakur, L.; Aravindan, S. Effect of defects in lap joints between AZ31B and Ti-6Al-4V alloys processed using gas tungsten arc welding. JOM 2024, 76, 4526–4541. [Google Scholar] [CrossRef]

- Zhang, T.; Chen, J.; Gong, H.; Li, H. Study on residual stresses of 2219 aluminum alloy with TIG Welding and Its Reduction by Shot Peening. Metals 2023, 13, 1581. [Google Scholar] [CrossRef]

- Duan, C.; Hao, X.; Luo, X.; Cao, X.; Xu, H.; Zhu, Z. Microstructure and fatigue properties of laser-MIG hybrid welding of medium-thickness 6005A aluminum alloy. Eng. Fail. Anal. 2024, 165, 165108753. [Google Scholar] [CrossRef]

- Nie, F.; Dong, H.; Chen, S.; Li, P.; Wang, L.; Zhao, Z.; Xintao, L.; Zhang, H. Microstructure and mechanical properties of pulse MIG welded 6061/A356 aluminum alloy dissimilar butt joints. J. Mater. Sci. Technol. 2018, 34, 551–560. [Google Scholar] [CrossRef]

- Jeon, J.; Kim, H.; Lee, I.; Cho, J. Basic research of directed energy deposition for aluminum 4043 alloys using pulsed variable polarity gas metal arc welding. Int. J. Precis. Eng. Manuf. 2024, 25, 1475–1487. [Google Scholar] [CrossRef]

- Bikash, K.; Bag, S.; Mahadevan, S.; Paul, C.P.; Das, C.R.; Bindra, K.S. On the interaction of microstructural morphology with residual stress in fiber laser welding of austenitic stainless steel. CIRP J. Manuf. Sci. Technol. 2021, 33, 158–175. [Google Scholar]

- Sadasivan, N.; Balasubramanian, M. Equal channel angular pressing of gas tungsten arc welded AA6061 alloy. Weld. World. 2020, 64, 1–12. [Google Scholar] [CrossRef]

- Qiao, Y.; Zhang, H.; Zhao, L.; Feng, Q. Fatigue crack growth properties of AA 5754 aluminum alloy gas tungsten arc welding and friction stir welding joints. J. Mater. Eng. Perform. 2020, 29, 2113–2124. [Google Scholar] [CrossRef]

- Pan, Y.; Lados, A.D. Friction stir welding in wrought and cast aluminum alloys: Weld quality evaluation and effects of processing parameters on microstructure and mechanical properties. Metall. Mater. Trans. A. 2017, 48, 1708–1726. [Google Scholar] [CrossRef]

- Majid, F.; Mohammadreza, F. Experimental Correlation Between Microstructure, Residual Stresses and Mechanical Properties of Friction Stir Welded 2024-T6 Aluminum Alloys. Int. J. Adv. Des. Manuf. Technol. 2022, 15. [Google Scholar]

- Huang, Z.; Sun, S.; Wang, J.; Zhou, L.; Guo, N.; Meng, Q.; Dong, J.; Zhao, H. Formation and fracture characteristics of friction stir lap joint of Alclad 2A12-T42 aluminum alloy at different tilt angles. Weld. World 2023, 67, 1901–1910. [Google Scholar]

- Pandav, N.A.; Patil, A.R.; Pandipati, S. Process parameters settings of friction stir welding using multi-response optimization for aluminum alloys. Eng. Res. Express. 2024, 6, 025525. [Google Scholar] [CrossRef]

- Dehabadi, V.M.; Ghorbanpour, S.; Azimi, G. Application of artificial neural network to predict Vickers micro-hardness of AA6061 friction stir welded sheets. J. Cent. South Univ. 2016, 23, 2146–2155. [Google Scholar] [CrossRef]

- Delijaicov, S.; Silva PA, D.O.; Resende, H.B.; Batalha MH, F. Effect of weld parameters on residual stress hardness and microstructure of dissimilar AA2024-T3 and AA7475-T761 friction stir welded joints. Mater. Res. 2018, 21, 246–258. [Google Scholar] [CrossRef]

- Salloomi, K.N.; Ahmed, A.Z.S.S.H. Evaluation of FSW process parameters of dissimilar aluminium alloys. Innov. Syst. Des. Engineering 2016, 7, 55–69. [Google Scholar]

- Zhao, Z.M.; Huang, Y.; Wang, S.J. Fatigue properties of friction stir welded joints of 6082-T6/7075-T6 dissimilar aluminum alloys. Mater. Prot. 2021, 54, 19–23. [Google Scholar]

- Khajeh, R. Microstructure, mechanical and electrical properties of dissimilar friction stir welded 2024 aluminum alloy and copper joints. J. Mater. Res. Technol. 2021, 14, 1945–1957. [Google Scholar] [CrossRef]

- Xiaoyan, W.; Wei, L.; Haitao, J. Effect of probe length on microstructure and mechanical properties of friction stir lap-welded aluminum alloy and steel. Rare Met. Mater. Eng. 2022, 51, 3197–3203. [Google Scholar]

- Ehiasarian, A.; Purandare, Y.; Sugumaran, A.; Hovsepian, P.; Hatto, P.; De Backer, J. Improving the quality of friction stir welds in aluminium alloys. Coatings 2021, 11, 539. [Google Scholar] [CrossRef]

- Ren, D.; Zeng, F.; Liu, Y.; Liu, L.; He, Z. Friction stir welding of 5754 aluminum alloy with cover sheet. Materials 2019, 12, 1765. [Google Scholar] [CrossRef] [PubMed]

- Verma, S.; Gupta, M.; Misra, P.J. Effect of pin-profiles on thermal cycle, mechanical and metallurgical properties of friction stir–welded aviation-grade aluminum alloy. Proc. Inst. Mech. Eng. B J. Eng. Manuf. 2019, 233, 2183–2195. [Google Scholar] [CrossRef]

- Yi, D.; Onuma, T.; Mironov, S.; Sato, Y.S.; Kokawa, H. Evaluation of heat input during friction stir welding of aluminium alloys. Sci. Technol. Weld. Join. 2017, 22, 41–46. [Google Scholar] [CrossRef]

- Hosseini, M.M.; Tabrizi, B.H.; Jalili, N. Thermal optimization of friction stir welding with simultaneous cooling using inverse approach. Appl. Therm. Eng. 2016, 108, 751–763. [Google Scholar] [CrossRef]

- Cabibbo, M.; Paoletti, C.; Simoncini, M.; Forcellese, A. Formability and grained structure refinement of cold-rolled friction stir welded AA5754 sheet. In IOP Conference Series Materials Science and Engineering; IOP Publishing: Bristol, UK, 2019; Volume 611, p. 012001. [Google Scholar] [CrossRef]

- Yi, D.; Mironov, S.; Sato, Y.S.; Kokawa, H. Effect of cooling rate on microstructure of friction-stir welded AA1100 aluminum alloy. Philos. Mag. 2016, 96, 1965–1977. [Google Scholar] [CrossRef]

- Kalinenko, A.; Mishin, V.; Shishov, I.; Malopheyev, S.; Zuiko, I.; Novikov, V.; Mironov, S.; Kaibyshev, R.; Semiatin, S.L. Mechanisms of abnormal grain growth in friction-stir-welded aluminum alloy 6061-T6. Mater. Charact. 2022, 194, 112473. [Google Scholar] [CrossRef]

- Chunliang, Y.; ChuanSong, W.; Lei, S. Phase-field modelling of dynamic recrystallization process during friction stir welding of aluminium alloys. Sci. Technol. Weld. Join. 2020, 25, 345–358. [Google Scholar] [CrossRef]

- Haghdadi, N.; Zarei Hanzaki, A.; Roostaei Ali, A.; Hemmati, A.R. Evaluating the mechanical properties of a thermomechanically processed unmodified A356 Al alloy employing shear punch testing method. Mater Des. 2012, 43, 419–425. [Google Scholar] [CrossRef]

- Kalinenko, A.; Vysotskiy, I.; Malopheyev, S.; Mironov, S.; Kaibyshev, R. New insight into the phenomenon of the abnormal grain growth in friction-stir welded aluminum. Mater Lett. 2021, 302, 130407. [Google Scholar] [CrossRef]

| Alloys | Fe | Cr | Mn | Zn | Ti | Si | Cu | Sn | Mg | Al |

|---|---|---|---|---|---|---|---|---|---|---|

| A380 | 2.00 | - | 0.50 | 3.00 | - | 8.00 | 3.00 | 0.35 | 0.10 | Bal |

| 6061 | 0.20 | 0.05 | 0.10 | 0.10 | 0.10 | 0.40 | 0.10 | - | 0.40 | Bal |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hu, X.; Luo, Z.; Liu, S.; Ren, Y.; Long, W. Effect of Stirring Needle Length on the Microstructures and Properties of A380/6061 Dissimilar Aluminium Alloy FSW Joints. Materials 2025, 18, 1621. https://doi.org/10.3390/ma18071621

Hu X, Luo Z, Liu S, Ren Y, Long W. Effect of Stirring Needle Length on the Microstructures and Properties of A380/6061 Dissimilar Aluminium Alloy FSW Joints. Materials. 2025; 18(7):1621. https://doi.org/10.3390/ma18071621

Chicago/Turabian StyleHu, Xinbin, Zhongxu Luo, Sheng Liu, Yongjun Ren, and Wei Long. 2025. "Effect of Stirring Needle Length on the Microstructures and Properties of A380/6061 Dissimilar Aluminium Alloy FSW Joints" Materials 18, no. 7: 1621. https://doi.org/10.3390/ma18071621

APA StyleHu, X., Luo, Z., Liu, S., Ren, Y., & Long, W. (2025). Effect of Stirring Needle Length on the Microstructures and Properties of A380/6061 Dissimilar Aluminium Alloy FSW Joints. Materials, 18(7), 1621. https://doi.org/10.3390/ma18071621