Effect of Curing Temperature on Crack Resistance of Low-Heat Portland Cement Hydraulic Lining Concrete

Abstract

1. Introduction

2. Experiment

2.1. Raw Materials and Mix Proportion

2.1.1. Raw Material

2.1.2. Mix Proportion

2.2. Test Scheme

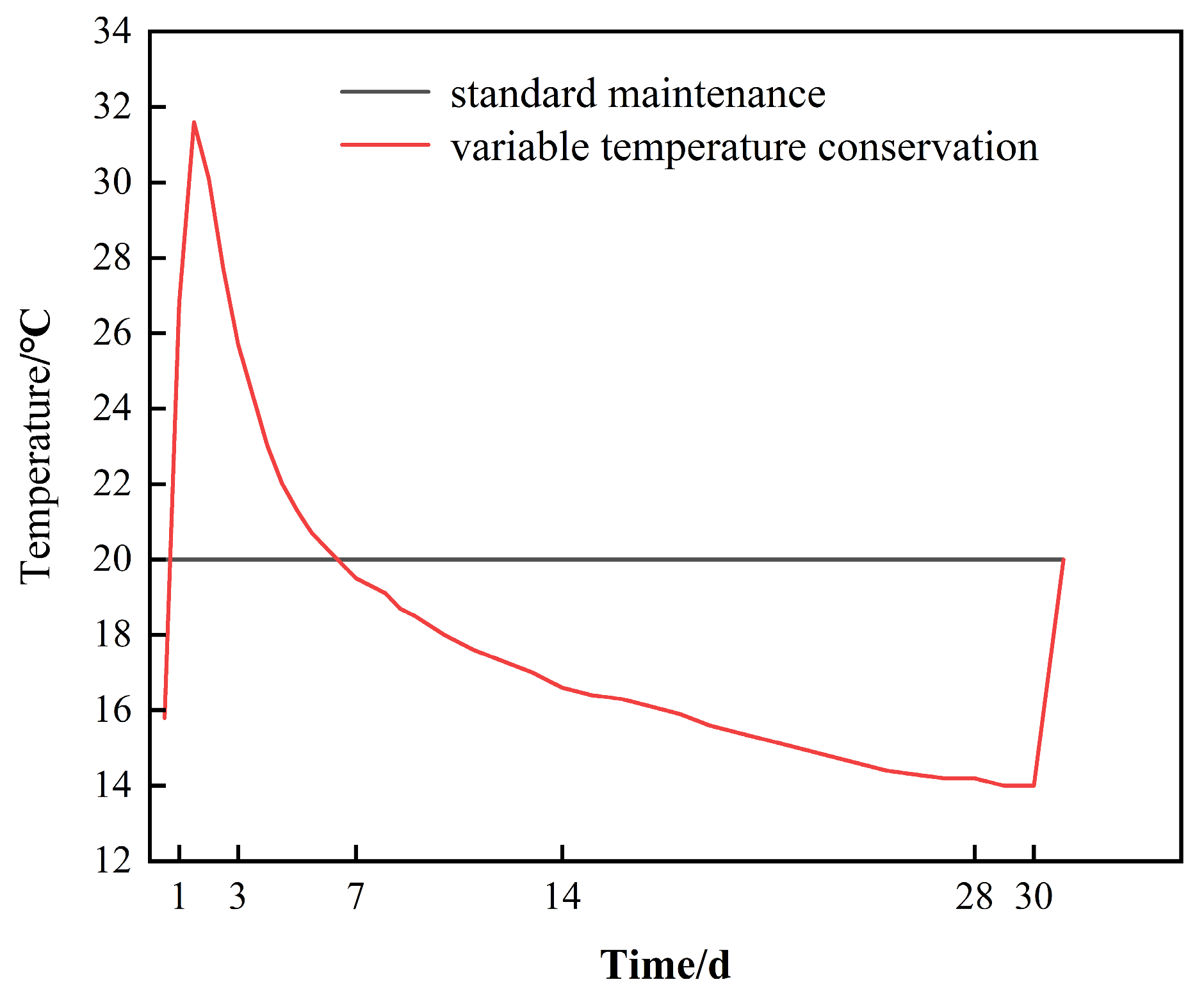

2.2.1. Variable Temperature Curing Test

2.2.2. Mechanical Performance Test

2.2.3. Maturity Calculation

2.2.4. Microscopic Tests

3. Experiment Results and Analysis

3.1. Mechanical Properties Analysis

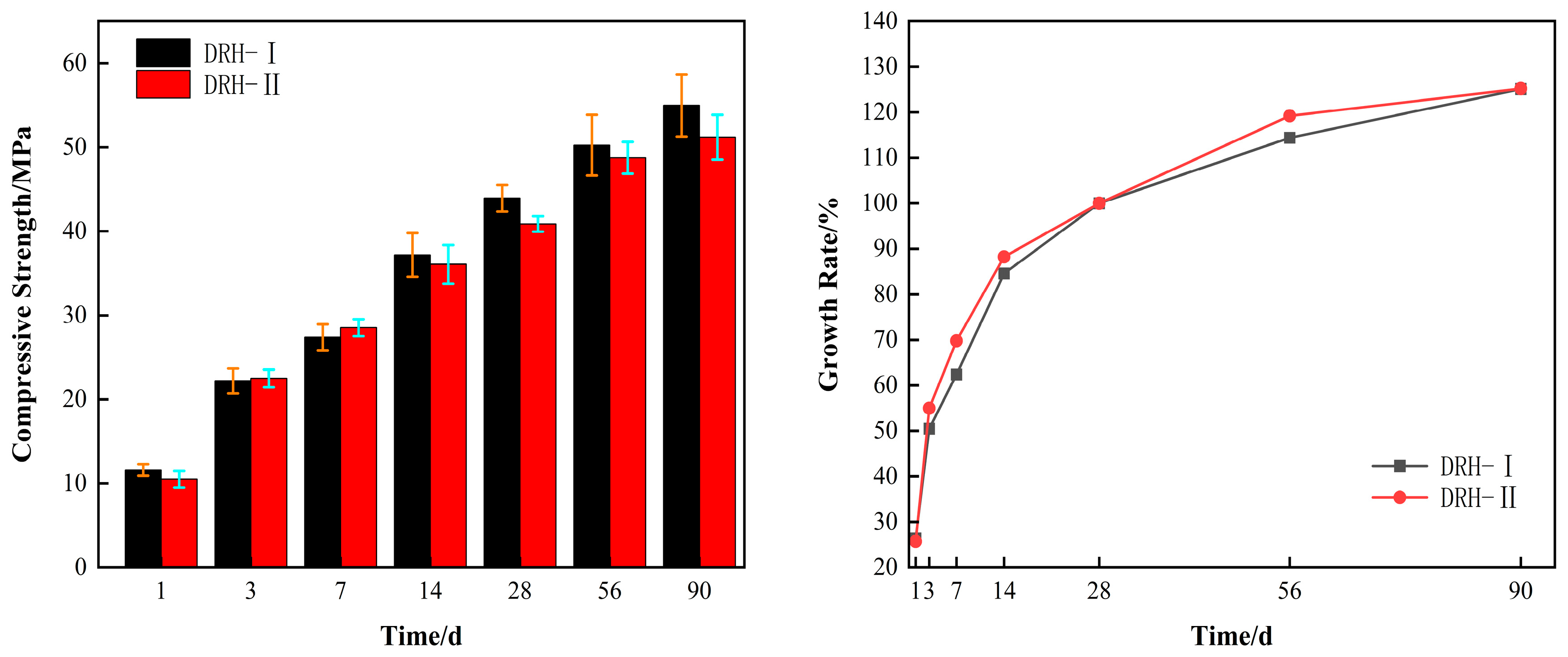

3.1.1. Compressive Strength

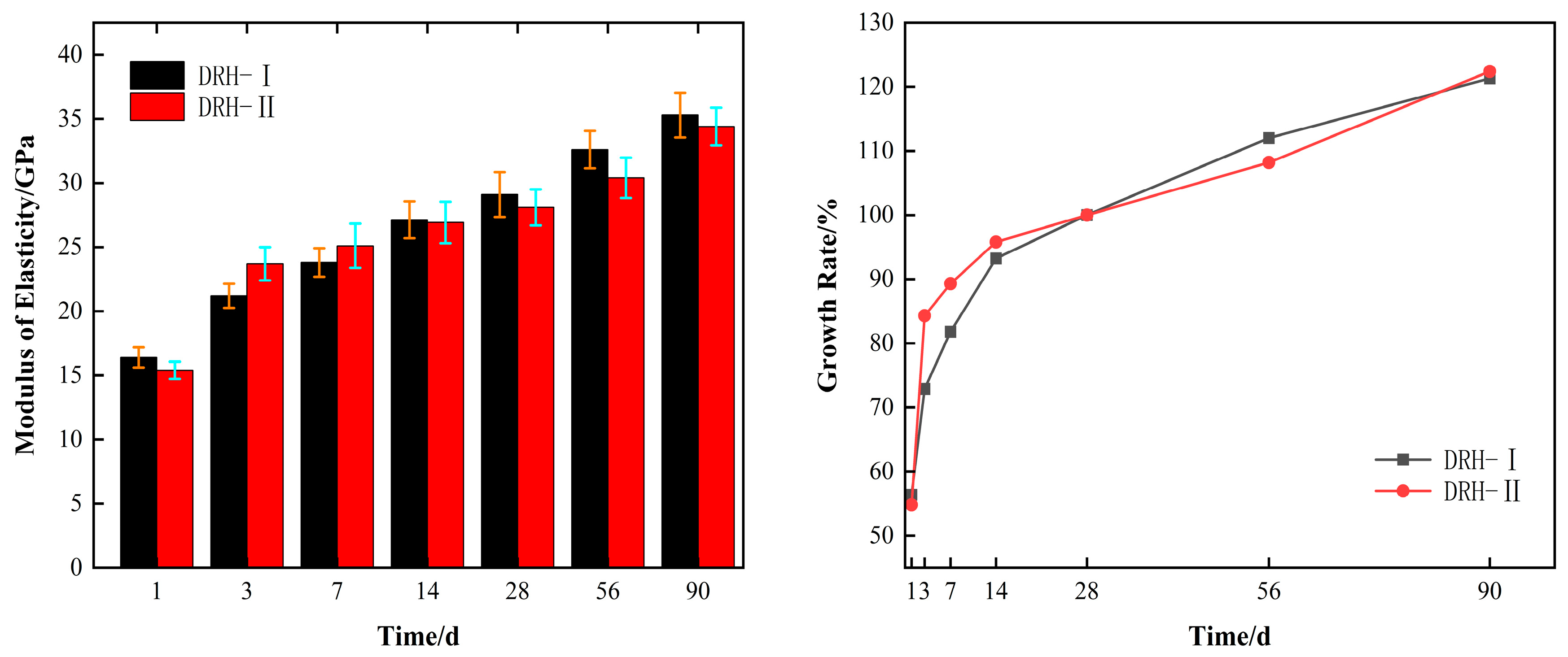

3.1.2. Elastic Modulus

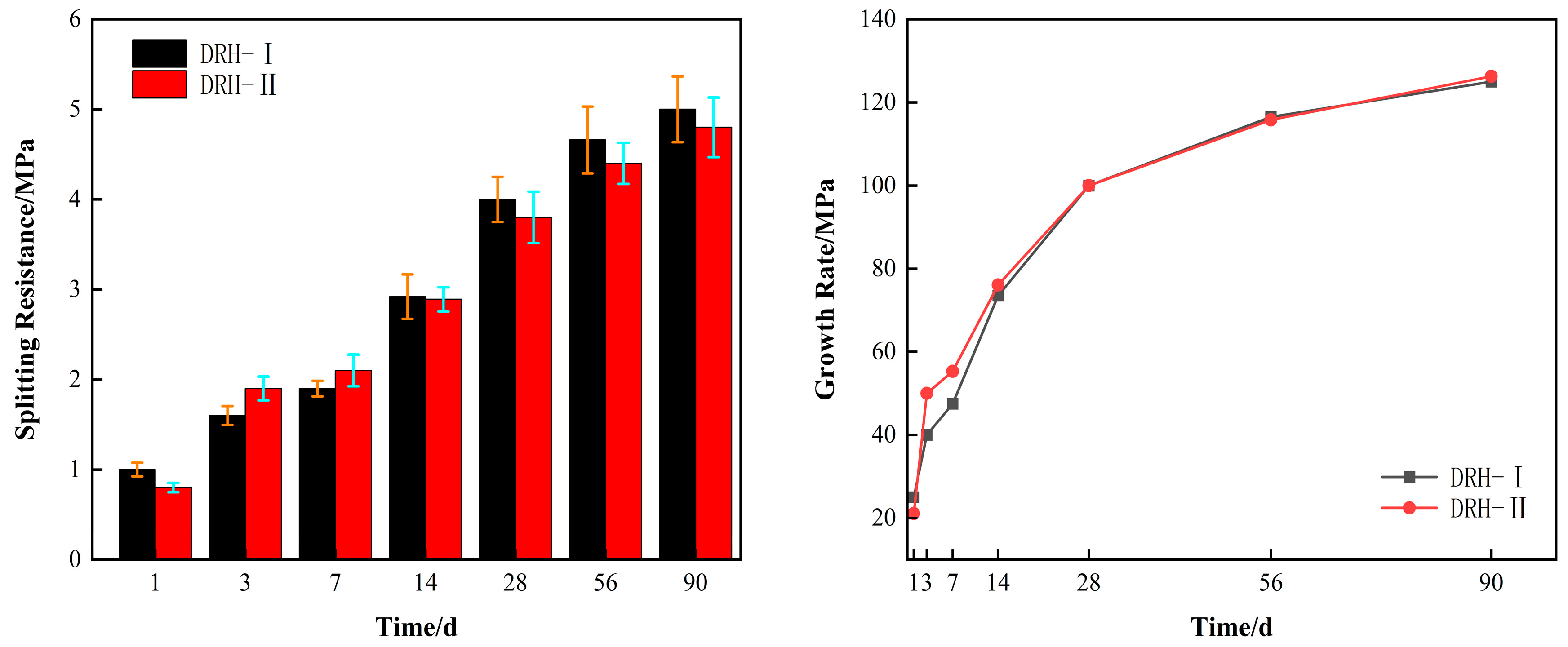

3.1.3. Splitting Tension

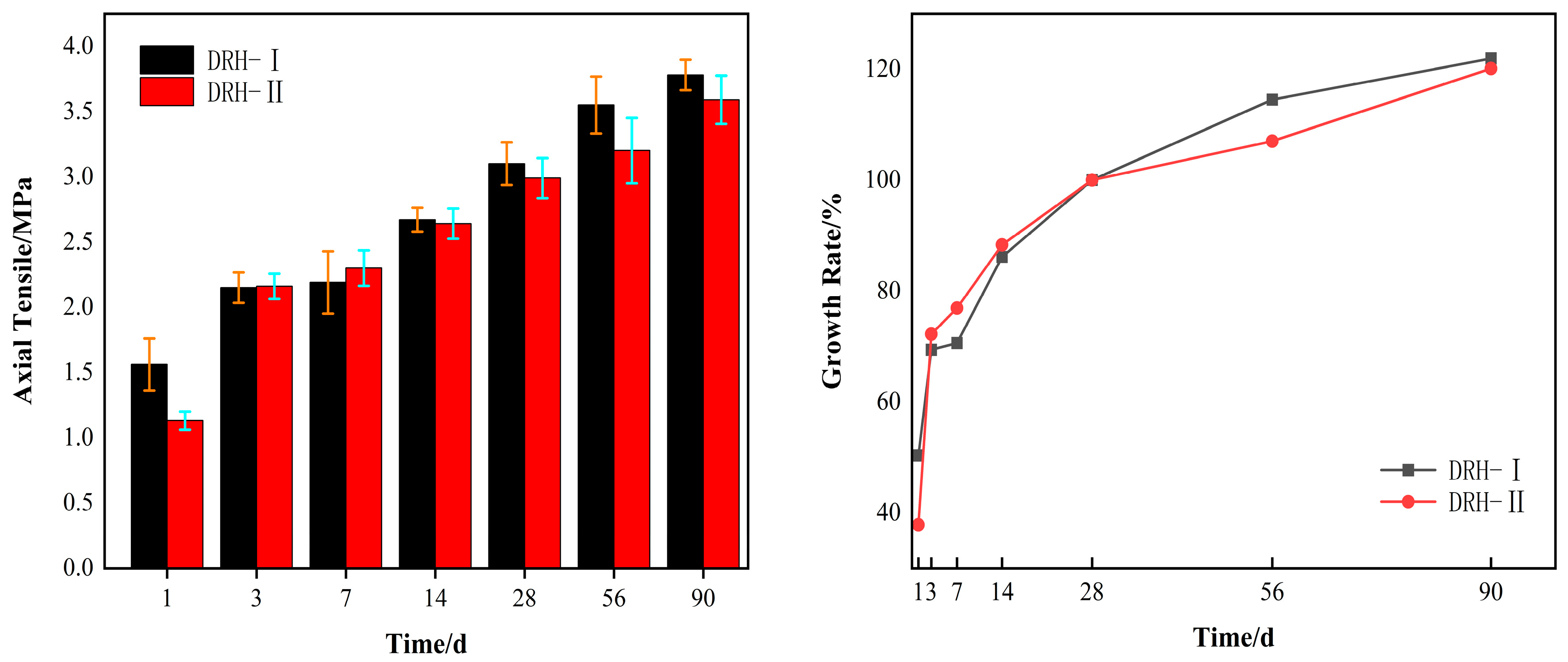

3.1.4. Axial Tensile Strength

3.2. Maturity Theoretical Analysis

3.2.1. Maturity Indicator

3.2.2. The Relationship Between Maturity and Strength

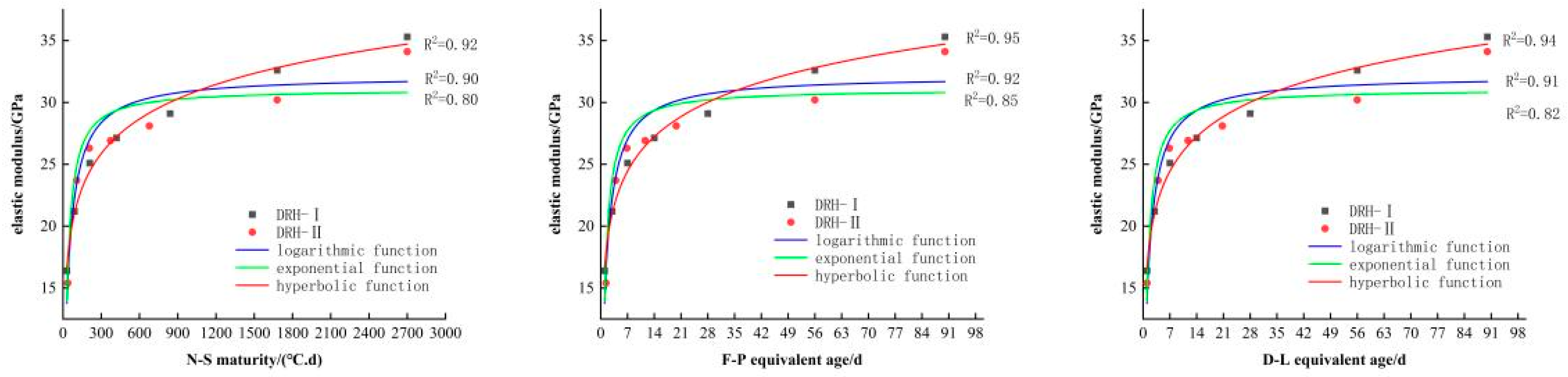

3.2.3. The Establishment and Analysis of Function Model

3.3. Microscopic Analysis

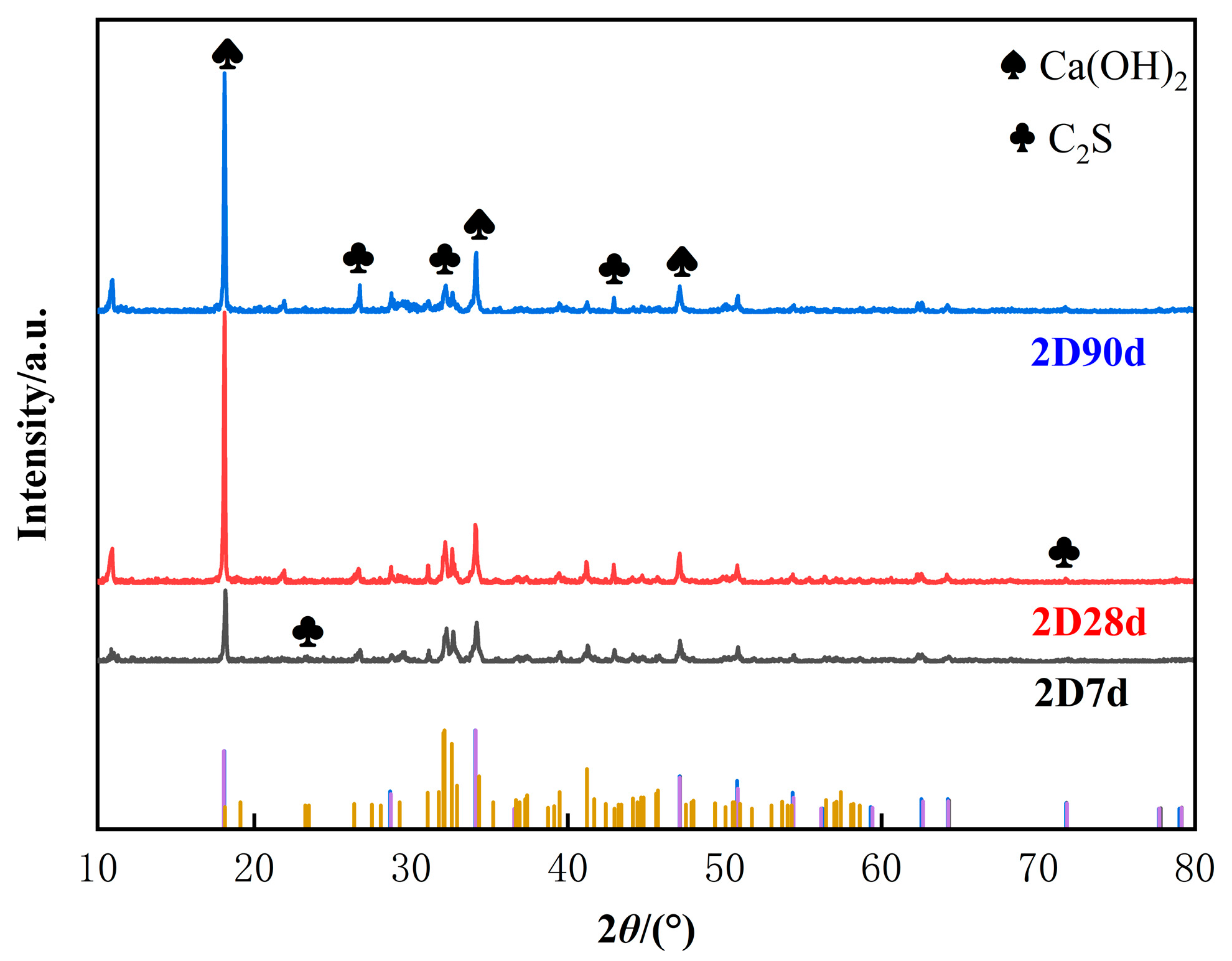

3.3.1. X-Ray Diffraction Analysis

3.3.2. Simultaneous Thermal Analysis

3.3.3. Pore Structure Analysis

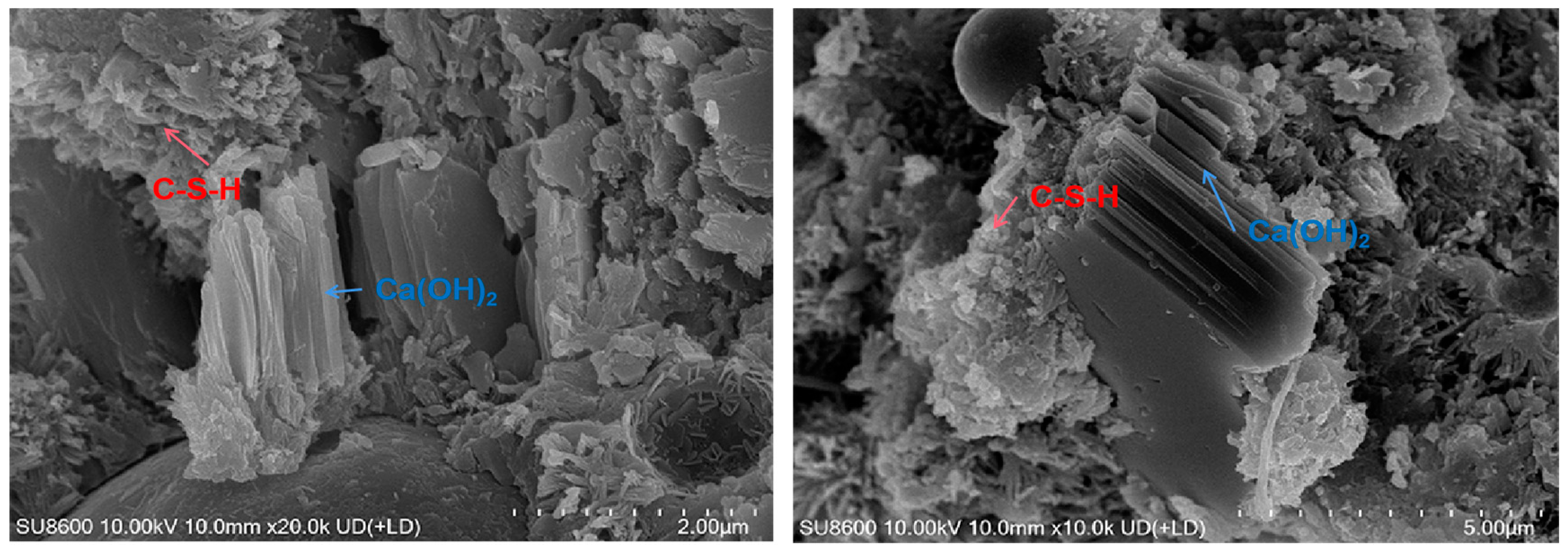

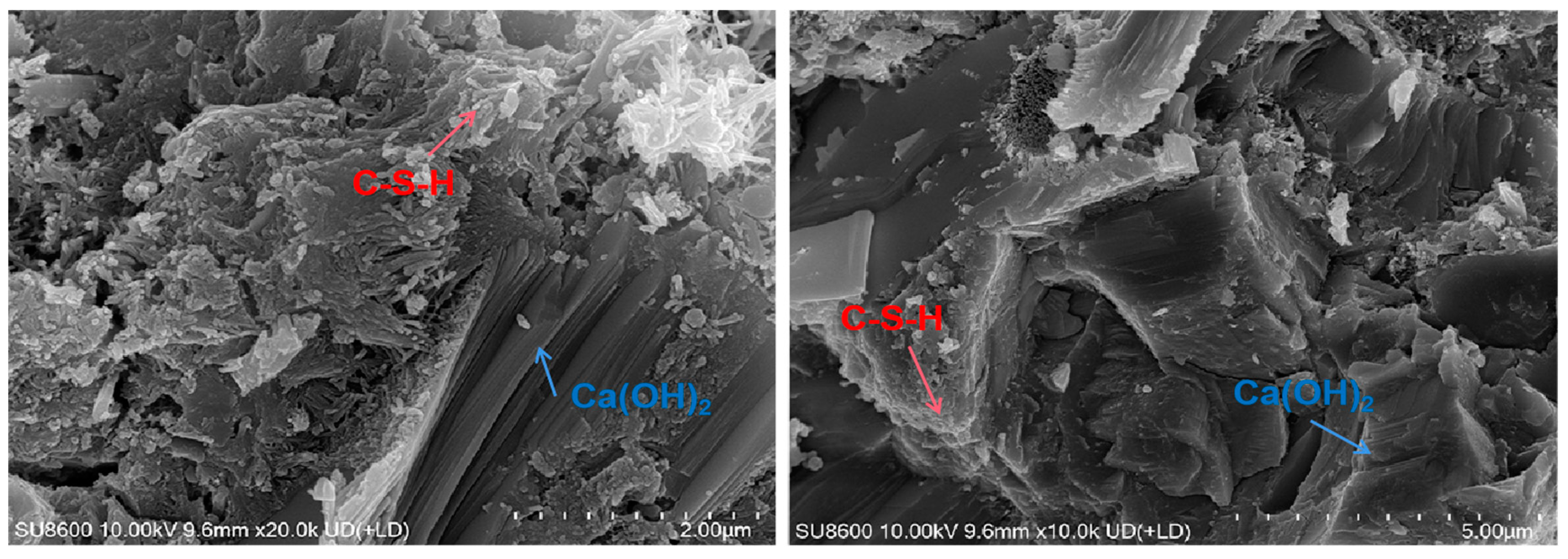

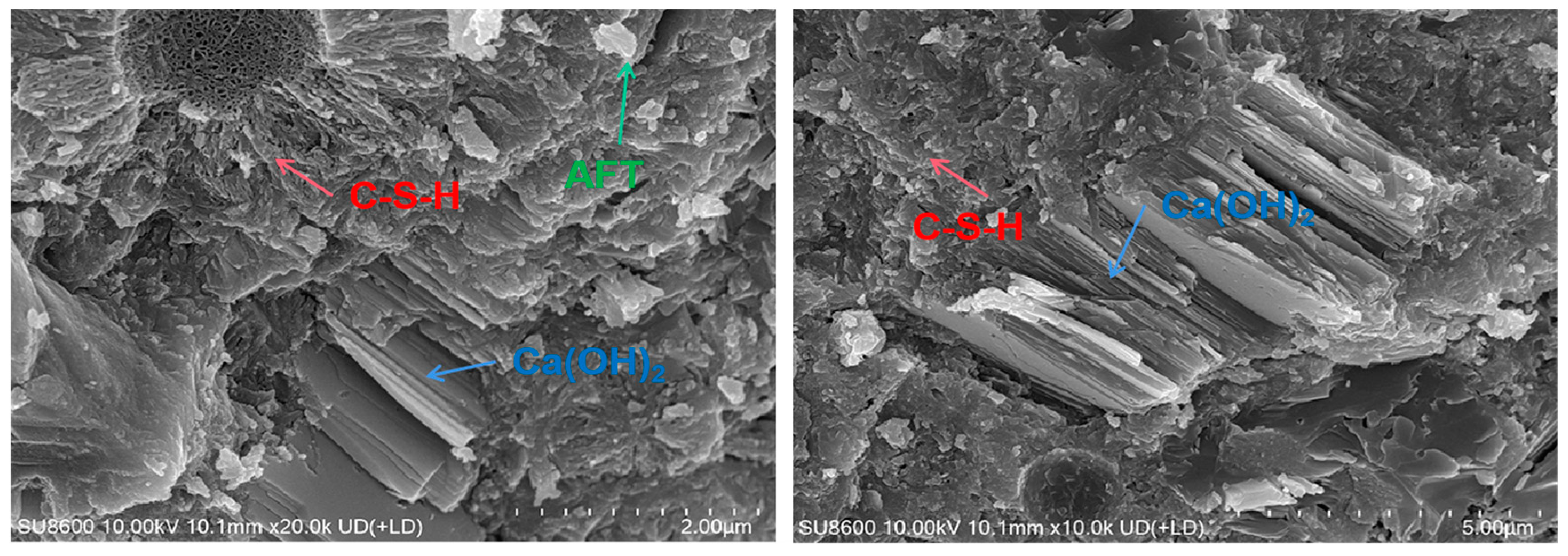

3.3.4. Scanning Electron Microscope

3.3.5. Energy Spectrum Analysis

4. Conclusions

- In this experiment, it was found that temperature has a significant effect on the early mechanical properties of concrete, more specifically, mechanical properties and their growth rates in terms of standard and proposed environmental curing. Mechanical properties increase with increasing temperature and decrease with decreasing temperature. Temperature changes have the greatest effect on the tensile aspect of concrete in terms of splitting resistance.

- In this experiment, it was found that the late mechanical properties of low-heat silicate hydraulic lining concrete under the two curing methods are considerable and can be applied to hydraulic tunnels.

- Based on the highest correlation coefficient of the double curve fitting function in the F-P equivalent age and D-L equivalent age, the maturity can be applied to the early-age-strength prediction of hydraulic lining concrete with low-heat silicate cement, which provides a reference scheme for the demolding of hydraulic tunnels.

- Microscopic tests show that low-heat cement generates a large number of C-S-H gels at a later stage, which makes the concrete structure dense and has a micro-expansive effect. Thus, an improvement in strength and crack resistance is imparted over time.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Li, F.; Jiang, H.; Xiang, P.; Wei, G. Study on temperature control and crack prevention of lining structure of high geothermal hydraulic tunnel based on concrete hydration heat effect. Tunn. Constr. 2024, 44, 1262–1273. [Google Scholar]

- Chen, G.; Liu, Y.; Ji, G.; Ji, T.; Liu, C. Study on the application of low heat Portland cement in hydraulic concrete. Water Conserv. Hydropower Technol. 2021, 52, 191–200. [Google Scholar]

- Pan, L.; Xu, W.; Liang, Z.; Wang, Y. Research on anti-cracking technology of mass concrete for main pier cap of Changtai Yangtze River Bridge. Bridge Constr. 2024, 54, 8–14. [Google Scholar]

- Wang, L.; Yang, H.Q.; Zhou, S.H.; Chen, E.; Tang, S.W. Mechanical properties, long-term hydration heat, shinkage behavior and crack resistance of dam concrete designed with low heat Portland (LHP) cement and fly ash. Constr. Build. Mater. 2018, 187, 1073–1091. [Google Scholar] [CrossRef]

- Li, X.; Huang, X.; Xu, F.; Li, C.; Wang, L. The correlation of basic mechanical indexes of C20~C120 concrete. China Civil Eng. J. 2024, 1–14. [Google Scholar] [CrossRef]

- Zhou, B.; Gu, L.; Wu, Y.R.; Yao, L.; Jie, S. A deformability-based mechanical model for predicting shear strength of FRP-strengthened RC beams failed in concrete cover separation. Eng. Fracture Mech. 2024, 311, 110537. [Google Scholar]

- Garba, M.J.; Tian, Y.; Shalaby, Y.; Chen, L.; Hu, C.; Yu, C.; Xie, Z.; Xu, Y.; Yuan, Q. Effects of liquid accelerators on long-term mechanical strength development and microstructural changes of wet-mixed shotcrete. J. Build. Eng. 2024, 97, 110926. [Google Scholar]

- Guan, B.; Lu, X.; Chen, B. Effect of curing temperature on thermal conductivity of low heat cement concrete at early age. Yangtze River 2023, 54, 222–229+251. [Google Scholar]

- Shen, X. Study on the Performance of Low Heat Portland Cement in Simulated Harsh Environment of Plateau. Ph.D. Thesis, China Research Institute of Building Materials Science, Beijing, China, 2023. [Google Scholar]

- Ai, D.; Chen, C.; Zhu, H. Monitoring of compressive strength gain in mass concrete using embedded piezoelectric transducers. Struct. Des. Tall Spec. Build. 2024, 33, e2162. [Google Scholar]

- Kim, S.; Jung, D.; Kim, J.Y.; Mun, J.H. Study on Early Age Concrete’s Compressive Strengths in UnmanagedCuring Condition Using IoT-Based Maturity Monitoring. Buildings 2024, 14, 798. [Google Scholar] [CrossRef]

- Sun, B.; Dominicus, R.; Dong, E.; Li, P.; Ye, Z.; Wang, W. Predicting the strength development of 3D printed concrete considering the synergistic effect of curing temperature and humidity: From perspective of modified maturity model. Constr. Build. Mater. 2024, 427, 136291. [Google Scholar]

- Tekle, B.H.; Al-Deen, S.; Anwar-Us-Saadat, M.; Willans, N.; Zhang, Y.X.; Lee, C.K.; Ribakov, Y. Maturity method to estimate early age concrete strength in cold weather: Alternative activation energy calibration. Aust. J. Civ. Eng. 2024, 22, 1–12. [Google Scholar]

- DL/T 5144–2015; National Energy Board. Code for Construction of Hydraulic Concrete: DL/T 5144–2015. China Electric Power Press: Beijing, China, 2015.

- Dai, J.P.; Wang, Q.C.; Qu, S.; Duan, Y.; Xie, Z.G. Strength prediction model of low temperature curing concrete based on maturity theory. J. Mater. Sci. Eng. 2018, 36, 263–267. [Google Scholar]

- Zhong, Y.; Wu, L.; Liu, C.; Li, K.; Gao, X. Early age strength test and maturity analysis of low heat cement concrete. Yangtze River 2021, 52, 186–192. [Google Scholar]

- ASTM 2018 ASTM C 150; Standard Specification for Portland Cement. ASTM International: West Conshohocken, PA, USA, 2018.

- SL/T 352-2020; Hydraulic Concrete Construction Specification. National Standards of the People’s Republic of China: Beijing, China, 2020.

- Zhou, S. Experimental study on long-term performance of dam concrete for Udonde high arch dam. J. Yangtze River Acad. Sci. 2021, 38, 156–160. [Google Scholar]

- Luo, Q.; Xing, F.; Han, N.; Wang, Y. Prediction of early strength of concrete by simplified weight maturity method. Concrete 2010, 247, 39–42. [Google Scholar]

- Liu, Z.; Hu, Y.; Wu, K.; Yang, N.; Tan, Y.; Gao, X. Study on the development characteristics of early age fracture properties of low heat cement concrete. Yangtze River 2022, 53, 175–181. [Google Scholar]

- Zhao, M. Prediction of Very Early Age Strength of Concrete Based on Maturity Method. Ph.D. Thesis, Hefei University of Technology, Hefei, China, 2021. [Google Scholar]

- Hetmanczyk, P.M. A Method to Evaluate the Maturity Level of Robotization of Production Processes in the Context of Digital Transformation—Polish Case Study. Appl. Sci. 2024, 14, 5401. [Google Scholar] [CrossRef]

- Choi, H.-B.; Kim, G.-H.; Kang, K.-I. Predicting the Strength of Recycled Aggregate Concrete-Predicting the strength of artificial neural networks and maturity method. J. Archit. Inst. Korea Struct. Constr. 2005, 21, 49–55. [Google Scholar]

- Kim, T.; Rens, L.K. Concrete Maturity Method Using Variable Temperature Curing for Normal and High-Strength Concrete. I: Experimental Study. J. Mater. Civ. Eng. 2008, 20, 727–734. [Google Scholar]

- Jiang, C.; An, S.; Li, S.; Chen, Y.; Liu, J. Comparative Study on the Calcium Leaching Resistance of Low-Heat Cement, Moderate-Heat Cement, and Ordinary Portland Cement Pastes. Materials 2025, 18, 212. [Google Scholar] [CrossRef]

| Specimen | CaO | SiO2 | Al2O3 | MgO | Fe2O3 | SO3 | F-CaO | Loss | K2O | Na2O | R2O |

|---|---|---|---|---|---|---|---|---|---|---|---|

| LHC | 59.8 | 23.04 | 4.42 | 3.2 | 4.30 | 2.52 | 0.84 | 1.09 | 0.56 | 0.26 | 0.63 |

| Fly ash | 13.18 | 50.05 | 16.1 | 4.5 | 5.5 | 1.11 | 0.71 | 2.16 | 3.64 | 1.4 | 4.56 |

| Cement | Specific Surface Area/m2·kg−1 | Density/g·cm−3 | Normal Consistency/% | Setting Time/min | Hydration Heat/KJ·kg−1 | Compressive Strength/MPa | Break off Strength/MPa | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Initial Set | Final Set | 3 d | 7 d | 3 d | 7 d | 28 d | 90 d | 3 d | 7 d | 28 d | 90 d | ||||

| LHC | 317.6 | 3.23 | 27.7 | 216 | 291 | 188 | 220 | 17.4 | 30.3 | 51.3 | 67.4 | 3.9 | 5.0 | 7.0 | 8.2 |

| Aggregate | Coarse Aggregate | Fine Aggregate | |

|---|---|---|---|

| Grain Size/mm | 20–40 | 5–20 | ≤5 |

| Dry apparent density of saturated surface/kg/m3 | 2680 | 2650 | 2630 |

| Water absorption at saturated surface–dry basis/kg/m3 | 0.42 | 0.63 | 0.80 |

| Soil content/% | 0.5 | 0.2 | 1.4 |

| Fineness modulus | - | - | 2.8 |

| Numbering | Water-Binder Ratio | Fly Ash/% | Admixture/% | Amount/kg·m−3 | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Water Reducing Admixture | Air Entraining Agent | Water | Cement | Fly Ash | Sand | Pebble | Nakaishi | |||

| DRH | 0.36 | 25 | 1 | 0.006 | 140 | 291.7 | 97.2 | 771.6 | 566.8 | 469 |

| DRH-I | DRH-II | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Time/d | 1 | 3 | 7 | 14 | 28 | 56 | 90 | 1 | 3 | 7 | 14 | 28 | 56 | 90 |

| Temperature/°C | 20 | 26.8 | 25.7 | 19.5 | 16.6 | 14.2 | 20 | 20 | ||||||

| N-S/(°C·d) | 30 | 90 | 210 | 420 | 840 | 1680 | 2700 | 31.3 | 108.9 | 233.7 | 428 | 780.4 | 1608 | 2628 |

| F-P/d | 1 | 3 | 7 | 14 | 28 | 56 | 90 | 1.078 | 4.074 | 8.314 | 14.54 | 25.134 | 52.5 | 86.5 |

| D-L/d | 1 | 3 | 7 | 14 | 28 | 56 | 90 | 1.089 | 4.097 | 8.356 | 14.62 | 25.5 | 53 | 87 |

| Mechanical Property | Compressive Strength | Split Tensile Strength | Axial Tensile Strength | Elastic Modulus | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Maturity Method | N-S | F-P | D-L | N-S | F-P | D-L | N-S | F-P | D-L | N-S | F-P | D-L |

| logarithmic function | 0.9 | 0.92 | 0.91 | 0.93 | 0.98 | 0.97 | 0.92 | 0.95 | 0.95 | 0.90 | 0.92 | 0.91 |

| exponential function | 0.82 | 0.85 | 0.84 | 0.85 | 0.90 | 0.88 | 0.71 | 0.77 | 0.73 | 0.80 | 0.85 | 0.82 |

| hyperbolic function | 0.93 | 0.95 | 0.94 | 0.96 | 0.99 | 0.98 | 0.92 | 0.97 | 0.95 | 0.92 | 0.95 | 0.94 |

| Number | Water-to-Cement Ratio | Fly Ash/% | Amount of Adhesive Material/g | ||

|---|---|---|---|---|---|

| Water | Cement | Fly Ash | |||

| 2D | 0.36 | 25 | 180 | 375 | 125 |

| Measurement Point | Time/d | Elemental Mass Percentage/% | Ca/Si | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| C | O | Mg | Al | Si | S | Ca | Fe | other | |||

| D1 | 7 | 9.45 | 37.35 | 0.36 | 1.07 | 11.34 | 0.83 | 37.95 | 1.42 | 0.23 | 2.35 |

| D2 | 28 | 12.35 | 41.07 | 0.85 | 1.4 | 11.3 | 1.05 | 29.45 | 2.02 | 0.51 | 1.83 |

| D3 | 90 | 11.23 | 41.3 | 0.52 | 2.73 | 12.19 | 1.12 | 29.14 | 1.77 | - | 1.67 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, S.; Kong, X.; Li, S.; Wei, B. Effect of Curing Temperature on Crack Resistance of Low-Heat Portland Cement Hydraulic Lining Concrete. Materials 2025, 18, 1618. https://doi.org/10.3390/ma18071618

Chen S, Kong X, Li S, Wei B. Effect of Curing Temperature on Crack Resistance of Low-Heat Portland Cement Hydraulic Lining Concrete. Materials. 2025; 18(7):1618. https://doi.org/10.3390/ma18071618

Chicago/Turabian StyleChen, Shujun, Xiangzhi Kong, Shuangxi Li, and Bo Wei. 2025. "Effect of Curing Temperature on Crack Resistance of Low-Heat Portland Cement Hydraulic Lining Concrete" Materials 18, no. 7: 1618. https://doi.org/10.3390/ma18071618

APA StyleChen, S., Kong, X., Li, S., & Wei, B. (2025). Effect of Curing Temperature on Crack Resistance of Low-Heat Portland Cement Hydraulic Lining Concrete. Materials, 18(7), 1618. https://doi.org/10.3390/ma18071618