Effects of Aging Treatment on the Microstructure and Mechanical Properties of Rene 41 Alloy and the Strengthening Mechanisms

Highlights

- An optimal strength–ductility balance with yield strength (823.5 MPa) with 15.8% elongation was achieved by aging at 760 °C for 16 h.

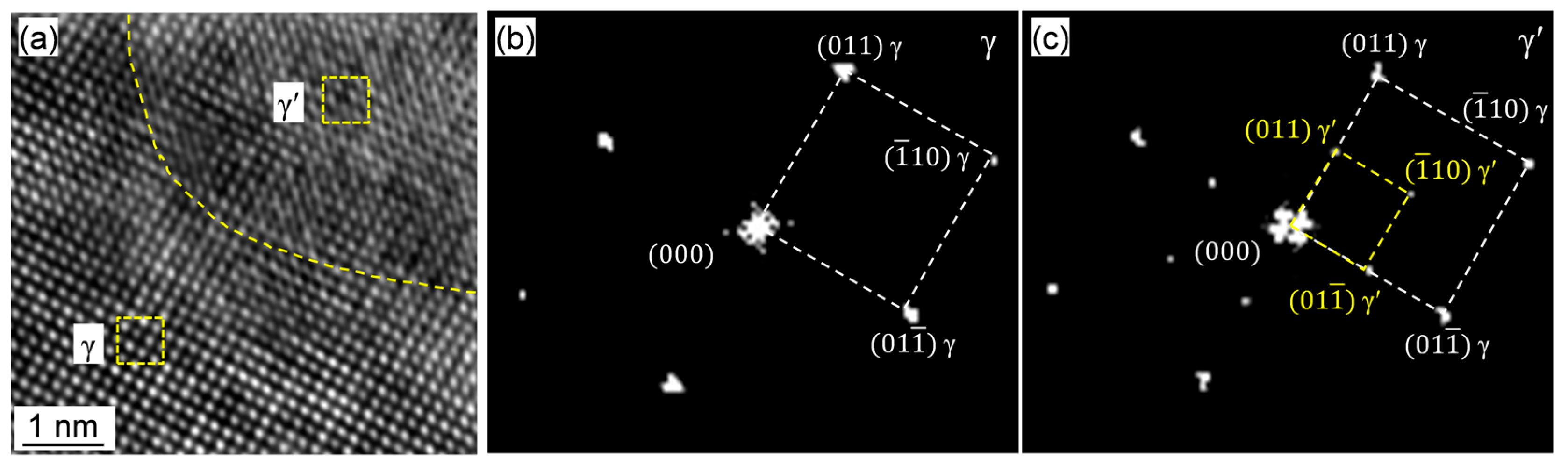

- γ′ maintained a coherent interface with the matrix even after high-temperature aging at 860 °C.

- The precipitation strengthening is mainly belong to the strong pair-coupling cutting mechanism rather than Orowan bypass mechanism.

Abstract

1. Introduction

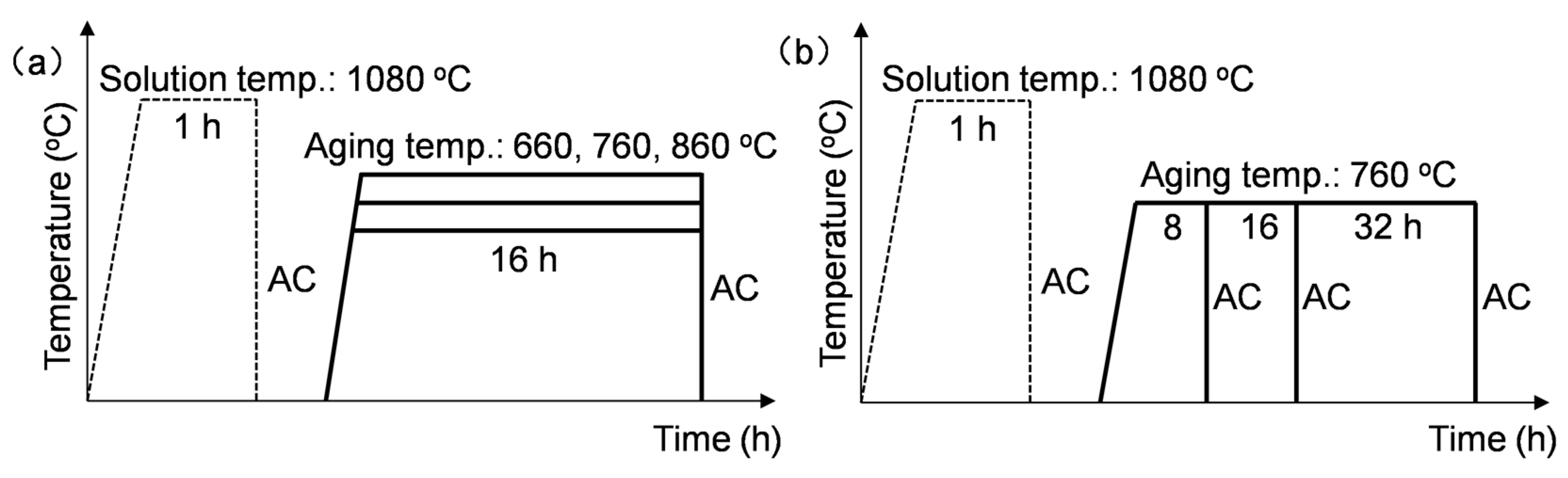

2. Experimental Procedures

3. Experimental Results and Discussion

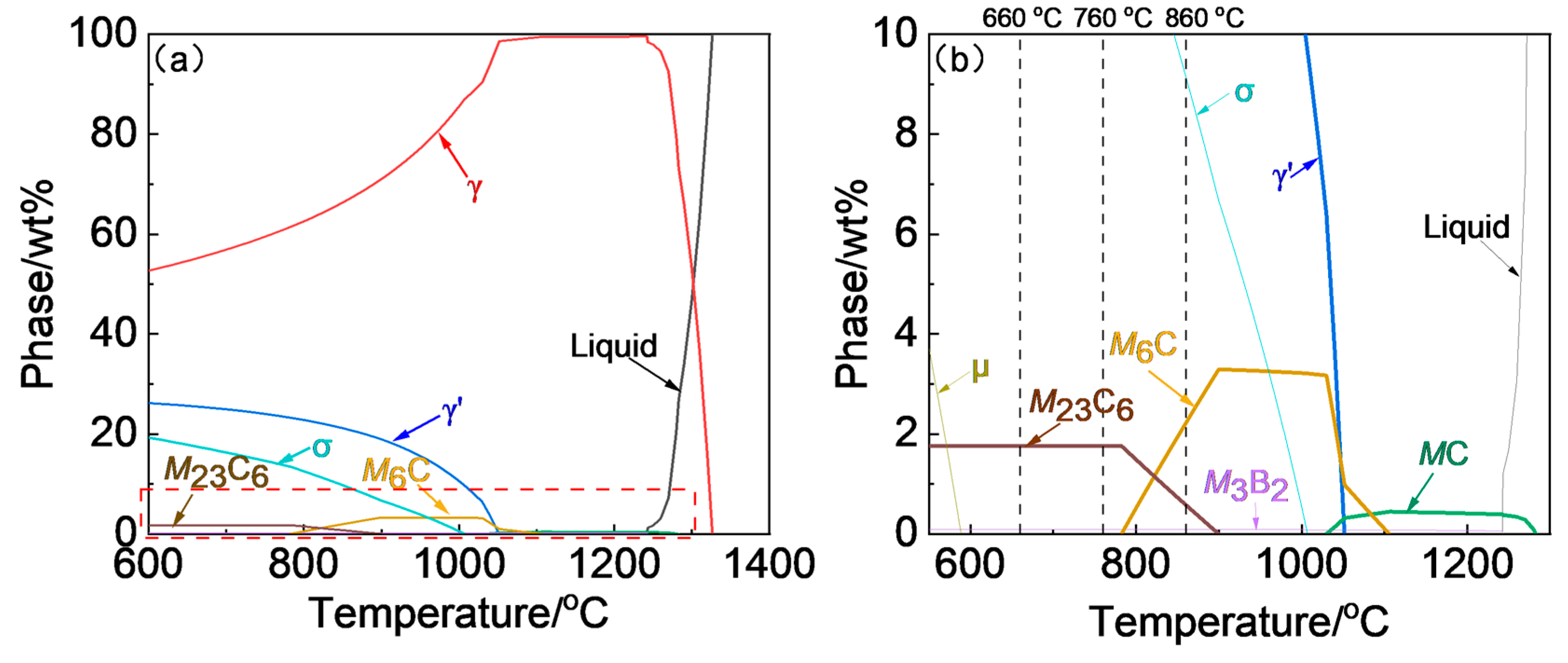

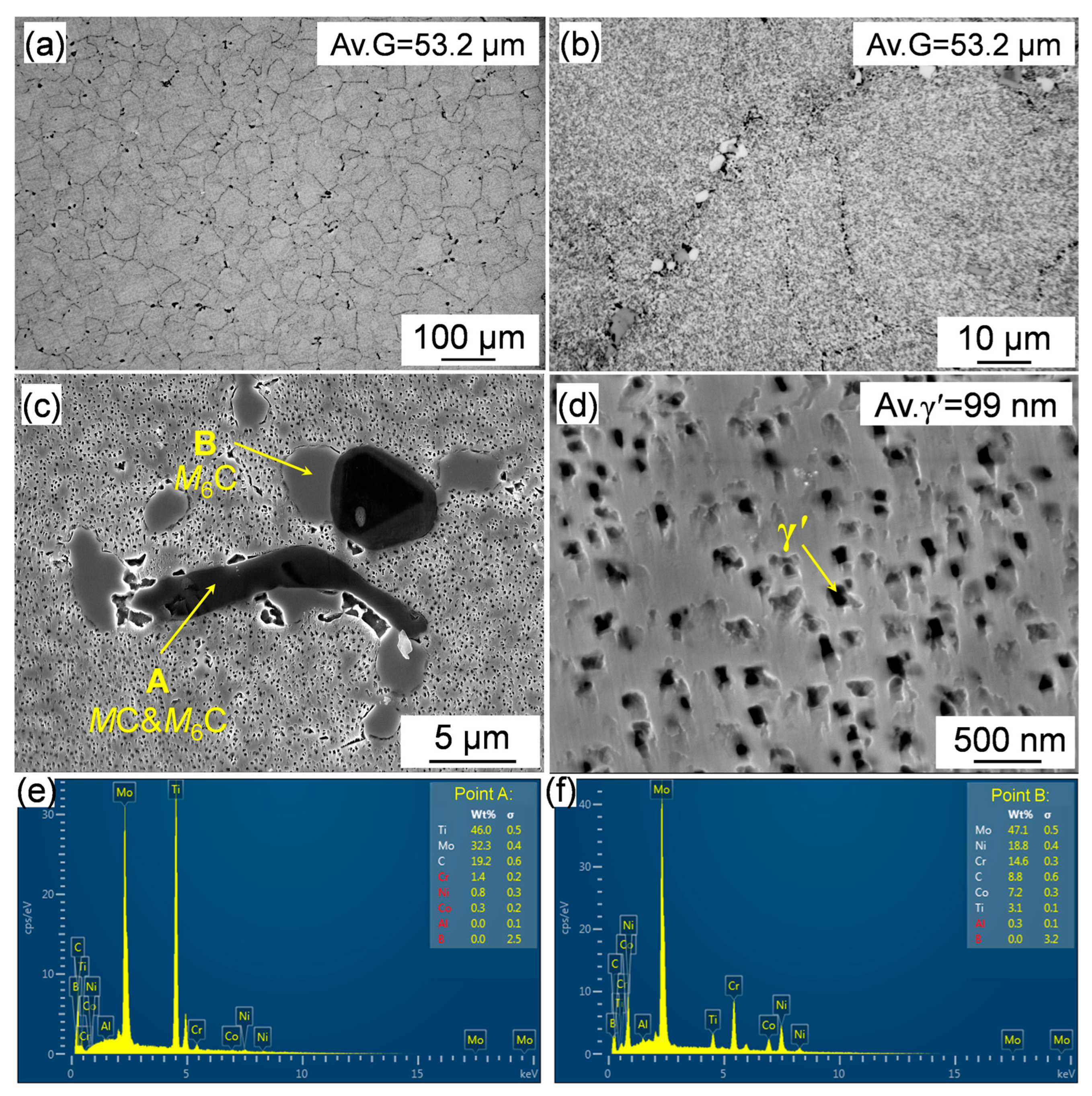

3.1. Initial Structure Characterization

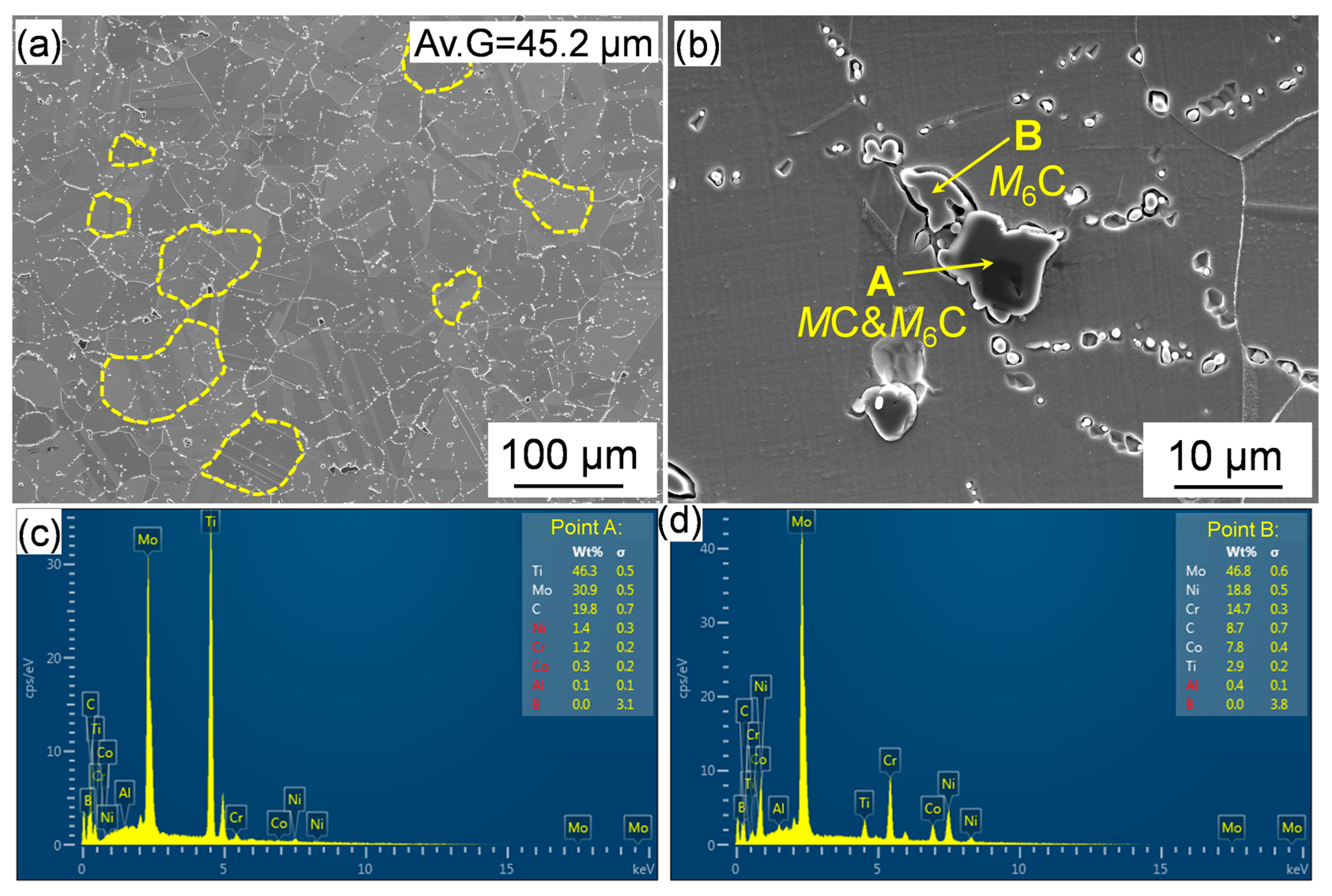

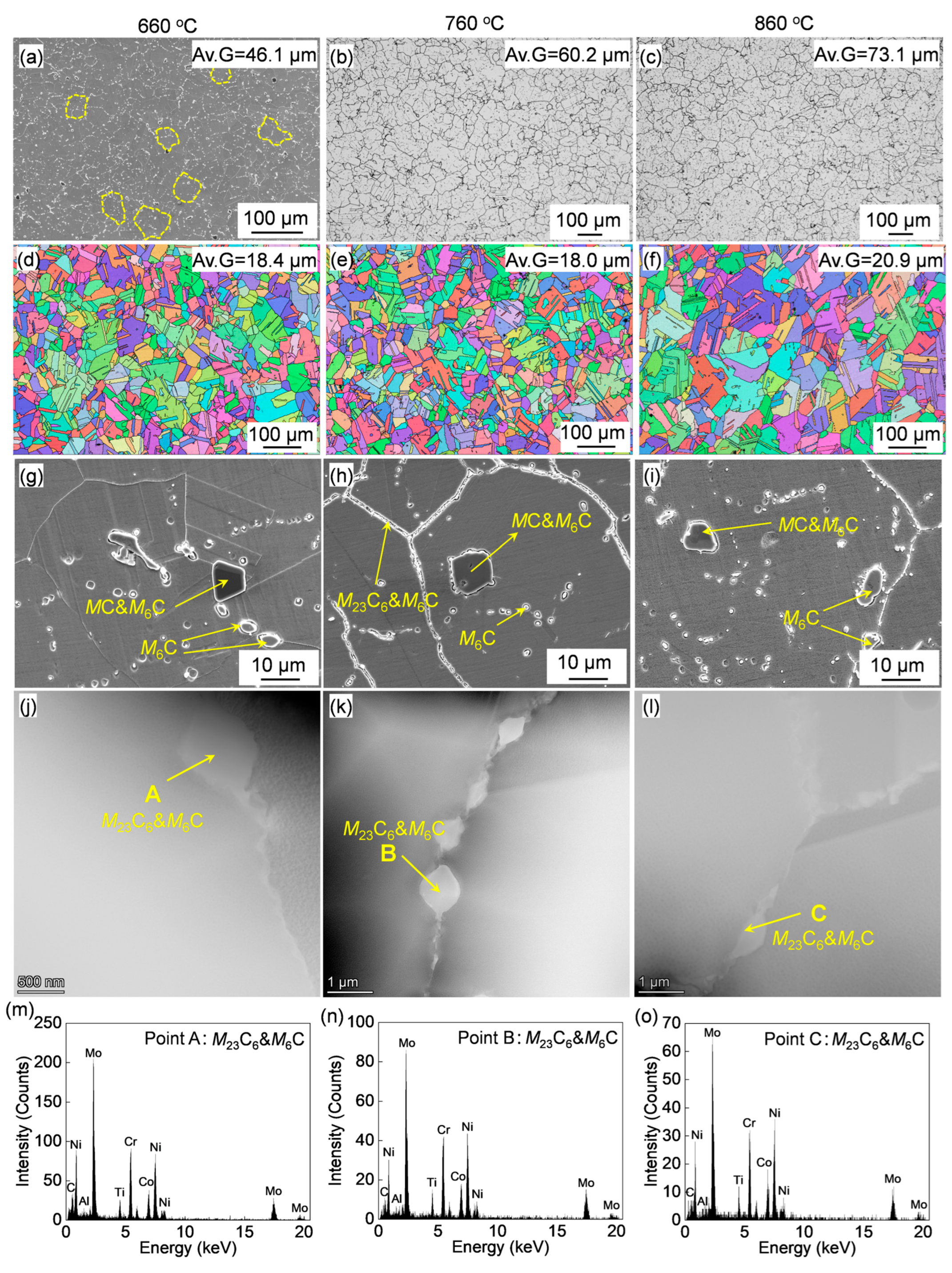

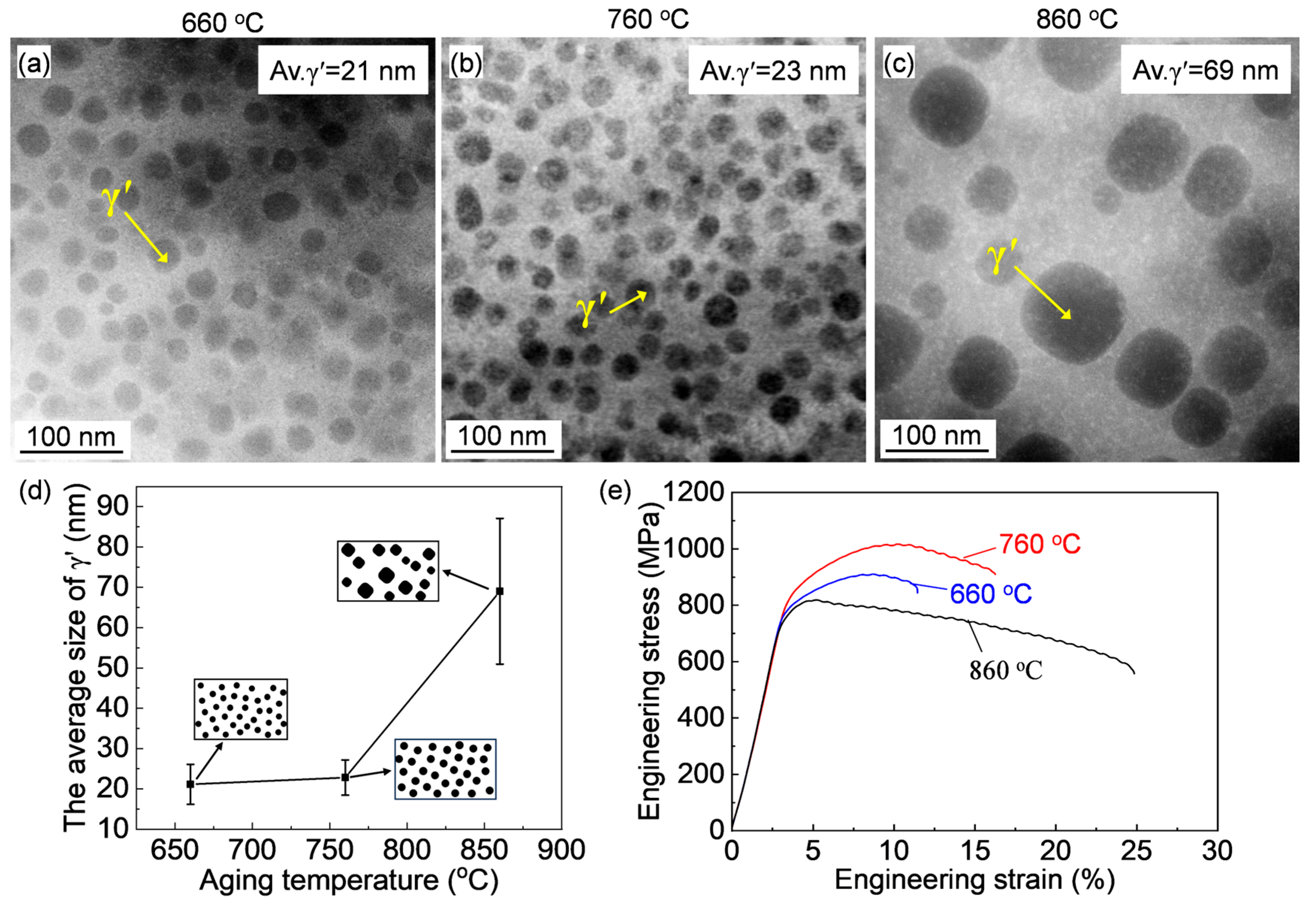

3.2. Influences of Aging Temperature

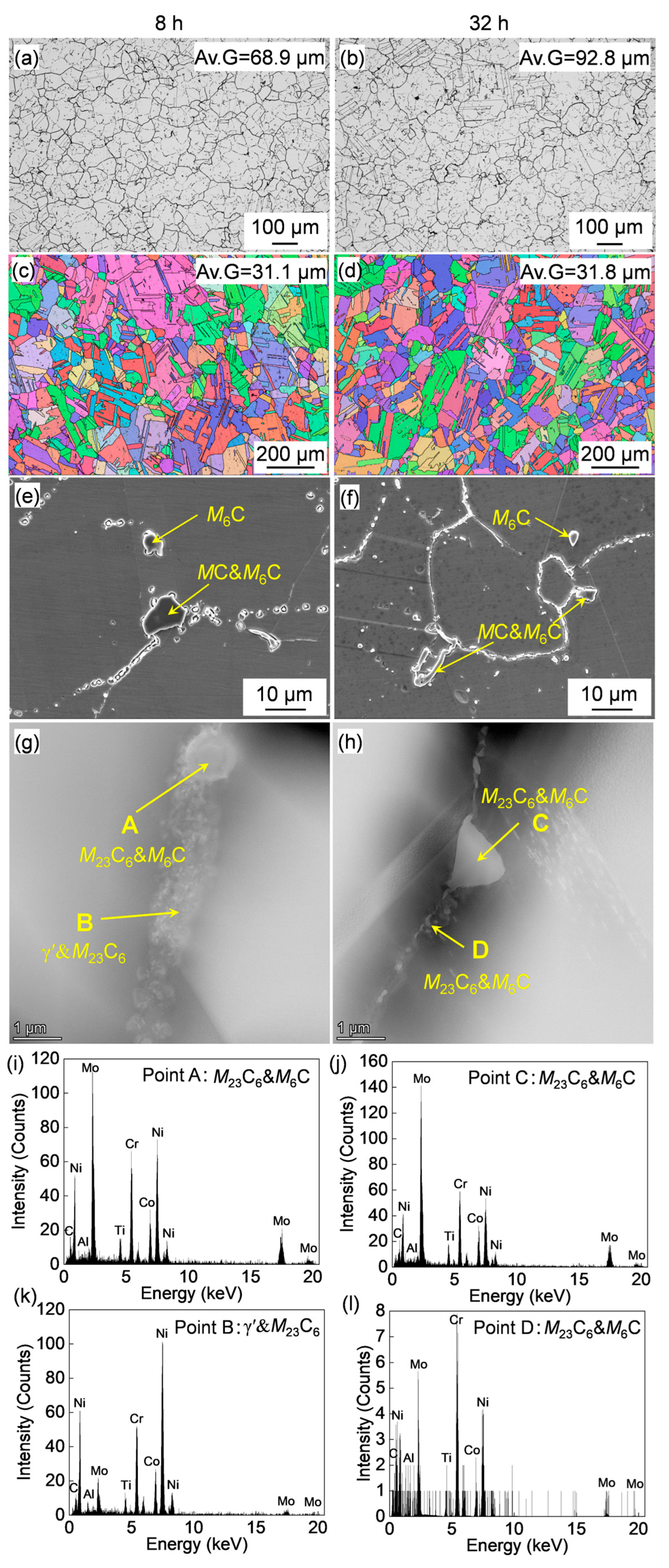

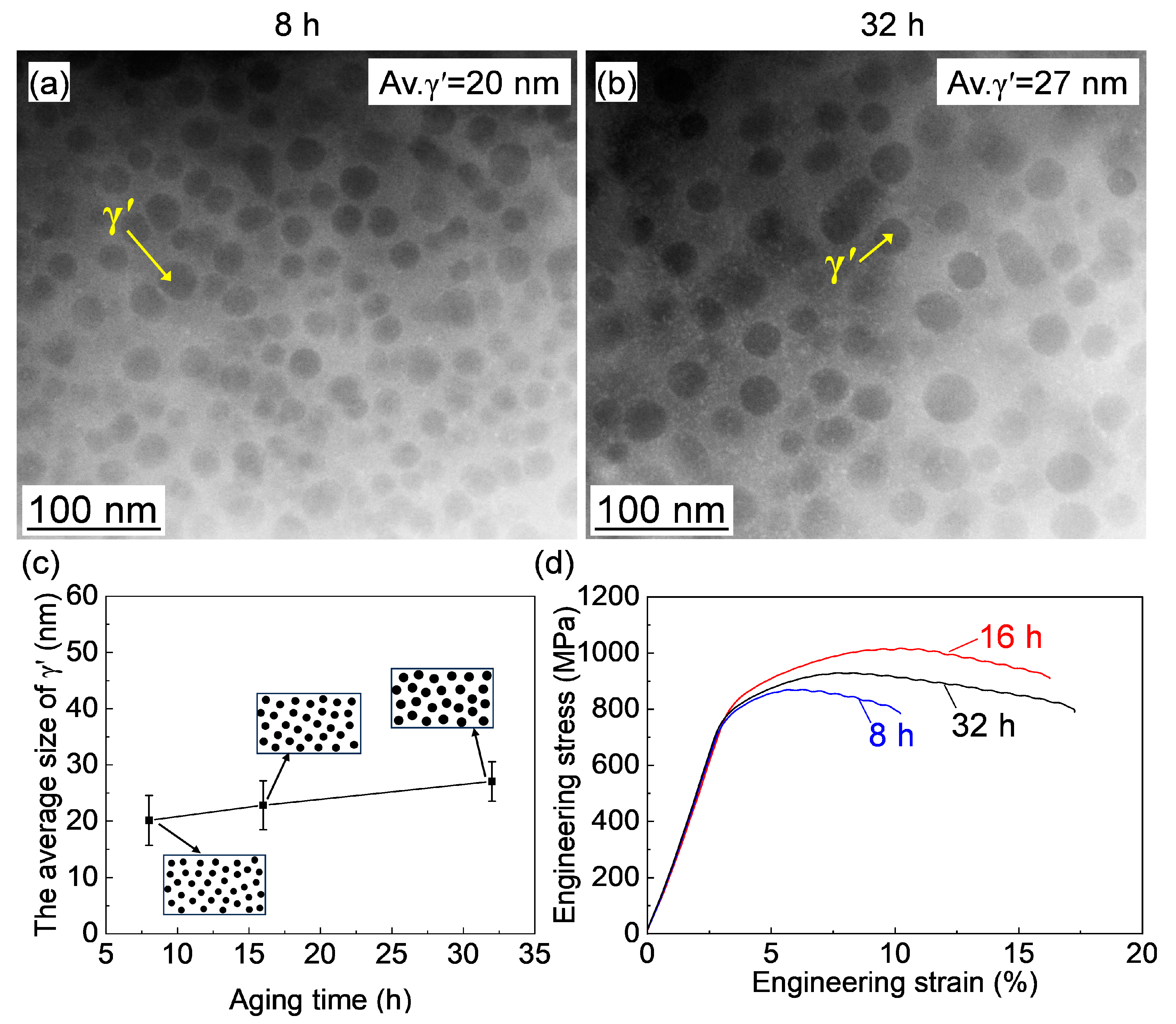

3.3. Influences of Aging Time

3.4. Strengthening Mechanisms

- (1)

- Intrinsic strength

- (2)

- Grain boundary strengthening

- (3)

- Solid solution strengthening

- (4)

- Dislocation strengthening

- (5)

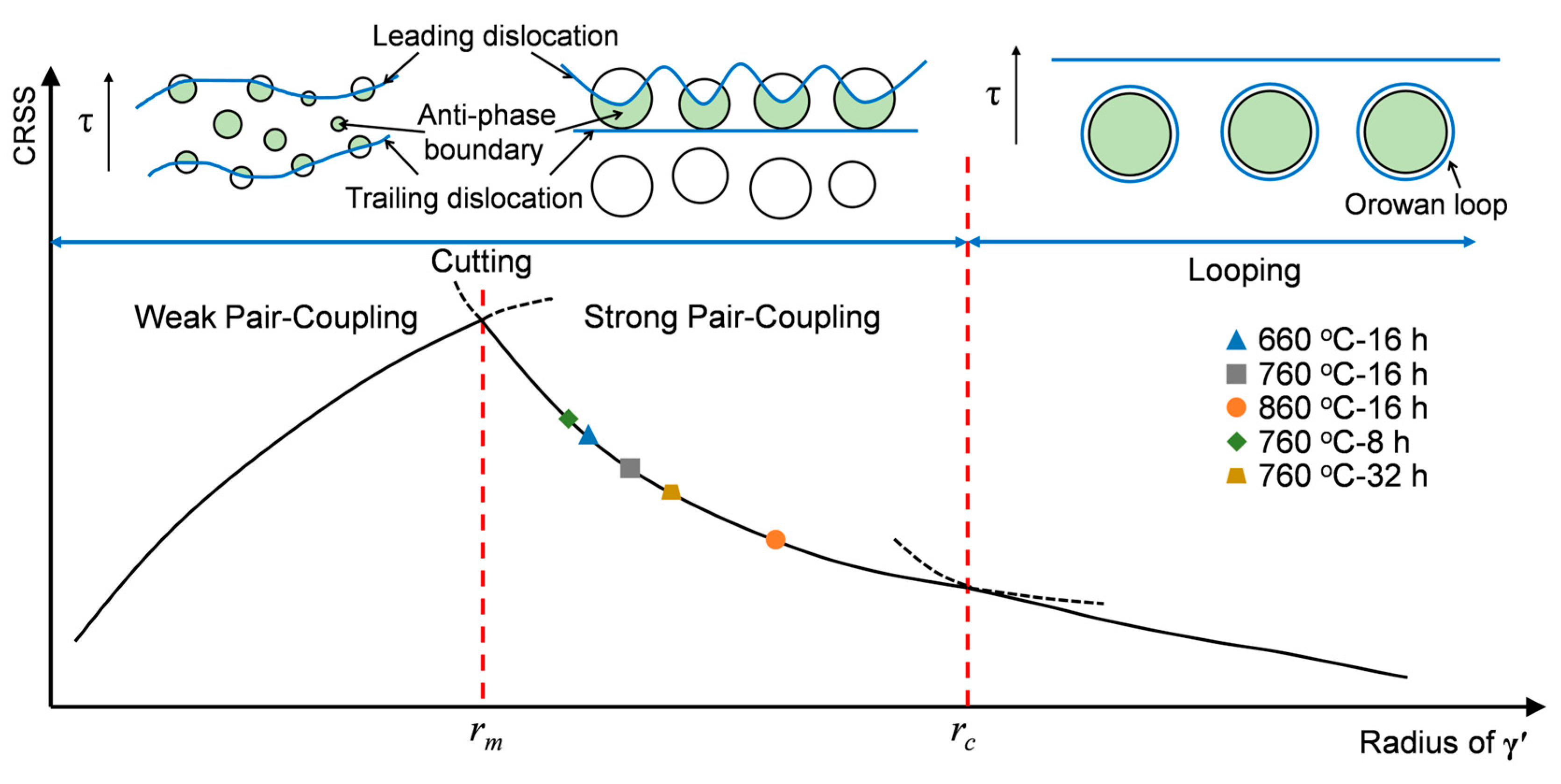

- Precipitation strengthening

4. Conclusions

- As the aging temperature increased from 660 °C to 860 °C, the grain size gradually increased from 46.1 µm to 73.1 µm, and carbide distribution shifted from intragranular to grain boundaries. Additionally, the secondary γ′ phase size increased from 21 nm to 69 nm, with morphology evolving from spherical to quasi-square. The γ′ maintained a coherent interface with the matrix even after high-temperature aging at 860 °C. The yield strength initially increased and then decreased, while elongation continuously improved. Aging at 760 °C for 16 h achieved an optimal balance between strength and ductility.

- At 760 °C, the grain size slightly increased when the aging time extended from 8 h to 16 h. However, significant grain coarsening occurred after 32 h, indicating excessive aging based on grain size evolution. The γ′ phase size marginally increased from 21 nm to 27 nm with a prolonged aging time, while maintaining a coherent interface with the matrix even after 860 °C aging for 16 h. The yield strength exhibited an initial rise followed by a decline, whereas elongation consistently improved.

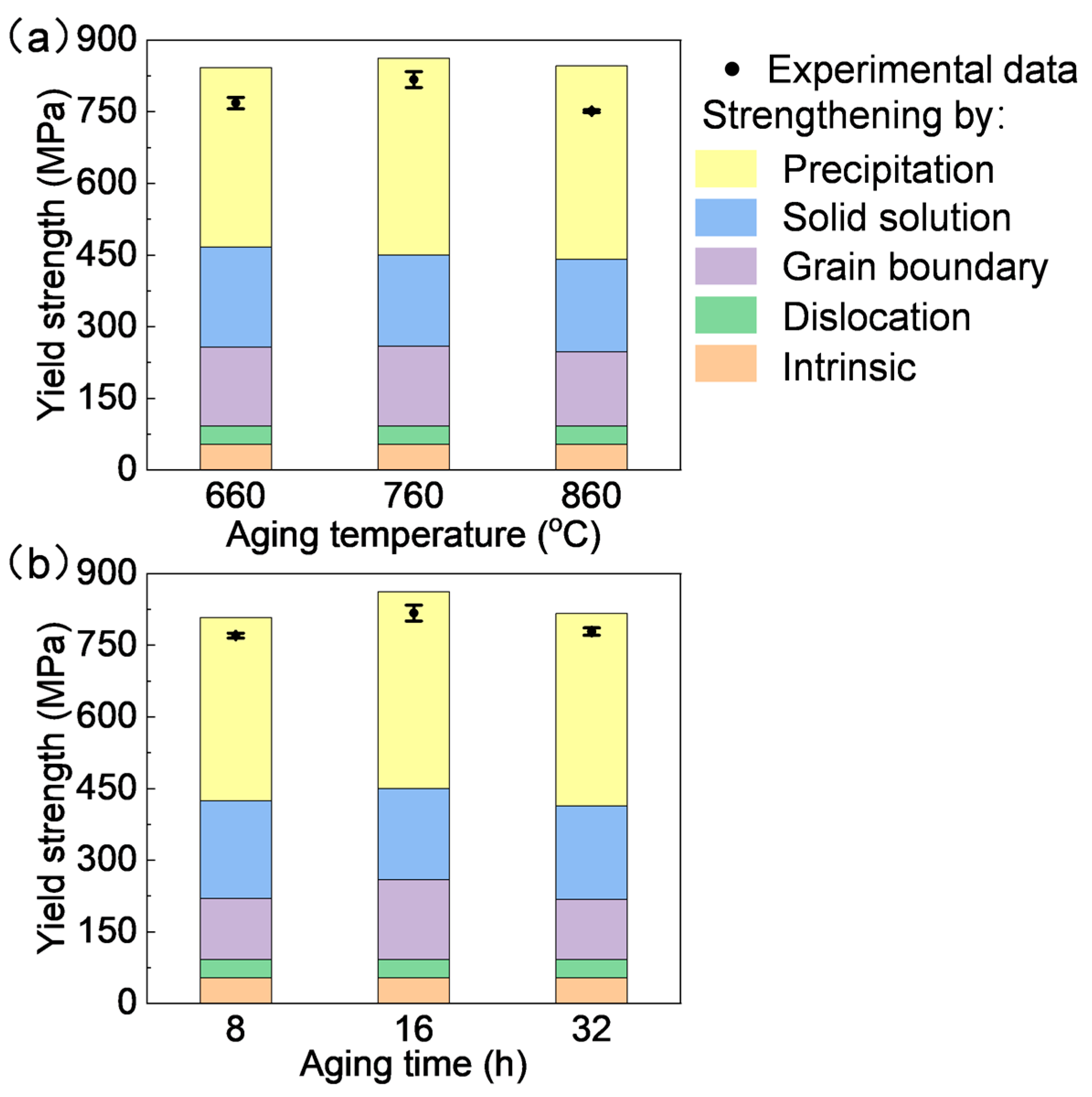

- Precipitation strengthening was identified as the dominant contributor to the overall yield strength (approximately 50%, 300–400 MPa), followed by solid solution strengthening (25%, 190–210 MPa) and grain boundary strengthening (20%, 125–170 MPa). Dislocation strengthening contributed minimally (<5%, ~38 MPa). The γ′ particle sizes ranged from 20 nm to 69 nm under the aging conditions of this study. Modeling confirmed that precipitation strengthening primarily arises from the strong pair-coupling cutting mechanism.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Chen, J.-J.; Zhou, Y.; Han, H.-R.; Zhang, X.-G.; Miyamoto, G.; Tang, P.-M.; Xiao, D.-P.; Fu, J.-H.; Shi, P.; Pei, Y.-W.; et al. Accelerating homogenization kinetics and enhancing hot-workability of as-cast nickel-based superalloy via prior hot-deformation. J. Iron Steel Res. Int. 2025, 32, 215–226. [Google Scholar]

- Zhang, X.G.; Pei, Y.W.; Zhou, Y.; Chen, J.J.; Xiao, D.P.; Tang, P.M.; Fu, J.H.; Yan, J.H.; Zhang, J. Hot-Deformation Behavior and Dynamic Recrystallization Rules of Hot-rolled GH4141 Superalloy. Rare Metal Mat. Eng. 2025, 54, 505–516. [Google Scholar]

- Yang, X.; Meng, T.; Chu, Q.; Su, Y.; Guo, Z.; Xu, R.; Fan, W.; Ma, T.; Li, W. A review of linear friction welding of Ni-based superalloys. Int. J. Miner. Metall. Mater. 2024, 31, 1382–1391. [Google Scholar]

- You, X.; Tan, Y.; Zhang, H.; Zhuang, X.; Zhao, L.; Li, P.; Wang, Y. Intermediate temperature creep and deformation behavior of a nickel-based superalloy prepared by electron beam layer solidification. Scr. Mater. 2020, 187, 395–401. [Google Scholar]

- Yang, W.-C.; Zhou, Y.; Zhang, J.; Liu, H.; Ren, Y.-J.; Chen, J.-J.; Zhang, X.-G. Role of radiative and convective heat transfer during heating of an ingot product in a tubular furnace: Experiment and simulation. J. Iron Steel Res. Int. 2022, 29, 1978–1985. [Google Scholar]

- Zhang, B.; Zhao, G.; Zhang, W.; Huang, S.; Chen, S. Investigation of high performance disc alloy GH4065 and associated advanced processing techniques. Acta Metall. Sin. 2015, 51, 1227–1234. [Google Scholar]

- Zhang, X.-G.; Yang, W.-C.; Zhou, Y.; Yan, J.-H.; Xiao, D.-P.; Shui, L.; Fu, J.-H.; Sun, F.; Shi, P.; Chen, J.-J.; et al. New model for predicting homogenization kinetics of typical wrought superalloy. Trans. Nonferrous Met. Soc. China 2024, 34, 1178–1190. [Google Scholar]

- Liu, X.; Fan, J.; Zhang, P.; Cao, K.; Wang, Z.; Chen, F.; Liu, D.; Tang, B.; Kou, H.; Li, J. Influence of heat treatment on Inconel 625 superalloy sheet: Carbides, γ′′, δ phase precipitation and tensile deformation behavior. J. Alloys Compd. 2023, 930, 167522. [Google Scholar]

- Gai, Y.; Zhang, R.; Yang, J.; Cui, C.; Qu, J. Effects of heat treatment on γ′ precipitates and tensile properties of a Ni-base superalloy. Mater. Sci. Eng. A 2022, 842, 143079. [Google Scholar]

- Chen, S.; Wang, T.; Fu, S.H.; Tian, J. Effect of aging treatment on microstructure and mechanical properties of GH6783. Mater. Sci. Technol. 2024; in press. [Google Scholar]

- Guo, C.; Zhang, P.; Zhou, Y.; Li, L.; Yin, H.; Yan, J.; Diao, W.; Li, P.; Yuan, Y. Microstructural evolution and yield strength of a novel precipitate-strengthened Fe-based superalloy during thermal aging at 700 °C. Intermetallics 2023, 163, 108077. [Google Scholar]

- Zhang, Y.; Wang, H.W.; Nian, J.; Li, C.C.; Jiang, M. Effect of aging treatment on the microstructure and hardness of GH105. New Technol. New Prod. China 2024, 12, 61–63. [Google Scholar]

- Li, K.; Wei, L.M.; Liang, Y.X.; Luo, A.B.; Li, J.C.; Zhang, S.Y. Effect of aging treatment on microstructure and hardness of Ni-based single crystal superalloy. Heat Treat. Met. 2023; 48, 21–28. [Google Scholar]

- Cheng, S.; Wang, J.; Wu, Y.; Qin, X.; Zhou, L. Microstructure, thermal stability and tensile properties of a Ni–Fe–Cr based superalloy with different Fe contents. Intermetallics 2023, 153, 107785. [Google Scholar]

- Liu, G.; Xiao, X.; Véron, M.; Birosca, S. The nucleation and growth of η phase in nickel-based superalloy during long-term thermal exposure. Acta Mater. 2020, 185, 493–506. [Google Scholar]

- Zhang, S.; Lin, X.; Wang, L.; Yu, X.; Hu, Y.; Yang, H.; Lei, L.; Huang, W. Strengthening mechanisms in selective laser-melted Inconel 718 superalloy. Mater. Sci. Eng. A 2021, 812, 141145. [Google Scholar]

- Wen, H.; Tang, X.; Jin, J.; Cai, C.; Yang, H.; Teng, Q.; Wei, Q.; Wang, X.; Zheng, C.; He, Y.; et al. Effect of extrusion ratios on microstructure evolution and strengthening mechanisms of a novel P/M nickel-based superalloy. Mater. Sci. Eng. A 2022, 847, 143356. [Google Scholar]

- Zhang, B.; Yan, F.; Zhao, M.; Tao, N.; Lu, K. Combined strengthening from nanotwins and nanoprecipitates in an iron-based superalloy. Acta Mater. 2018, 151, 310–320. [Google Scholar]

- Ding, Y.; Xia, Z.; Gao, Y.; Chen, J.; Zhang, B.; Ma, Y. Effect of ‘γ′ phase and Twin” Composite Structure on Strength and Plasticity of Superalloy. Rare Metal Mater. Eng. 2022, 51, 3732–3742. [Google Scholar]

- Jabło’nska, M.B.; Archie, F. Effect of the strain rate on the deformation mechanisms of TWIP-type steel. Mater. Sci. Eng. A 2024, 915, 147219. [Google Scholar]

- Sun, F.; Gu, Y.; Yan, J.; Zhong, Z.; Yuyama, M. Phenomenological and microstructural analysis of intermediate temperatures creep in a Ni-Fe-based alloy for advanced ultra-supercritical fossil power plants. Acta Mater. 2016, 102, 70–78. [Google Scholar]

- You, X.; Tan, Y.; Shi, S.; Yang, J.-M.; Wang, Y.; Li, J.; You, Q. Effect of solution heat treatment on the precipitation behavior and strengthening mechanisms of electron beam smelted Inconel 718 superalloy. Mater. Sci. Eng. A 2017, 689, 257–268. [Google Scholar]

- Zhang, X.; Han, H.; Zhou, Y.; Chen, J.; Feng, S.; Tang, P.; Xiao, D.; Fu, J.; Zhang, J. Effect of Solution Treatment on the Microstructure and Elevated Temperature Tensile Properties of Forged Rene 41 Superalloy. Materials 2024, 17, 6150. [Google Scholar] [CrossRef]

- ASTM E21-20; Standard Test Methods for Elevated Temperature Tension Tests of Metallic Materials. ASTM International: West Conshohocken, PA, USA, 2021.

- Zhang, X.G.; Chen, J.J.; Yang, W.C.; Zhou, Y.; Xiao, D.P.; Tang, P.M.; Fu, J.H.; Shi, P.; Pei, Y.W.; Yan, J.H.; et al. Identification of Precipitates in the As-cast Microstructure and Its Dissolution Behavior During Homogenization of Difficult-to-Deform GH4141 Superalloy. Rare Metal Mater. Eng. 2024, 53, 136–147. [Google Scholar]

- Shen, D.G. GH141 high strength superalloy. Aerosp. Mater. Technol. 1985, 6, 5–10. [Google Scholar]

- Theska, F.; Street, S.; Lison-Pick, M.; Primig, S. Grain boundary microstructure-property relationships in the cast & wrought Ni-based superalloy Rene 41 with boron and carbon additions. Acta Mater. 2023, 258, 119235. [Google Scholar]

- Collins, D.M.; Stone, H.J. A modelling approach to yield strength optimization in a nickel-base superalloy. Int. J. Plast. 2014, 54, 96–112. [Google Scholar]

- Sui, S.; Tan, H.; Chen, J.; Zhong, C.; Li, Z.; Fan, W.; Gasser, A.; Huang, W. The influence of Laves phases on the room temperature tensile properties of Inconel 718 fabricated by powder feeding laser additive manufacturing. Acta Mater. 2019, 164, 413–427. [Google Scholar]

- Fang, Q.; Li, L.; Li, J.; Wu, H.; Huang, Z.; Liu, B.; Liu, Y.; Liaw, P.K. A statistical theory of probability-dependent precipitation strengthening in metals and alloys. J. Mech. Phys. Solids 2019, 122, 177–189. [Google Scholar]

- Zhang, Z.; Yang, Z.; Lu, S.; Harte, A.; Morana, R.; Preuss, M. Strain localisation and failure at twin-boundary complexions in nickel-based superalloys. Nat. Commun. 2020, 11, 4890. [Google Scholar]

- Dunne, F.P.E.; Kiwanuka, R.; Wilkinson, A.J. Crystal plasticity analysis of micro-deformation, lattice rotation and geometrically necessary dislocation density. Proc. Math. Phys. Eng. Sci. 2012, 468, 2509–2531. [Google Scholar]

- Petch, N.J. The Cleavage Strength of Polycrystals. J. Iron Steel Inst. 1953, 174, 25–28. [Google Scholar]

- Kozar, R.; Suzuki, A.; Milligan, W.; Schirra, J.; Savage, M.; Pollock, T. Strengthening mechanisms in polycrystalline multimodal nickel-base superalloys. Metall. Mater. Trans. 2009, 40, 1588–1603. [Google Scholar]

- Li, X.; Ma, Q.; Liu, E.; Li, Z.; Bai, J.; Li, H.; Gao, Q. Order phase transition of HIP nickel-based powder superalloy during isothermal aging. J. Alloys Compd. 2025, 1010, 177269. [Google Scholar]

- Wang, Y.; Guo, W.; Li, H.; Xie, Y.; Shi, J.; Liang, Z.; Han, P.; Li, S.; Zhang, H. Nano-scale microstructural evolution and mechanical property enhancement mechanism during crack inhibition in nickel-based superalloys fabricated by laser powder bed fusion. Addit. Manuf. 2025, 100, 104685. [Google Scholar]

- Labusch, R. A statistical theory of solid solution hardening. Phys. Status Solidi B 1970, 41, 659–669. [Google Scholar] [CrossRef]

- Gypen, L.A. Multi-component solid solution hardening. J. Mater. Sci. 1977, 12, 1034–1038. [Google Scholar]

- Roth, H.A.; Davis, C.L.; Thomson, R.C. Modeling solid solution strengthening in nickel alloys. Metall. Mater. Trans. A 1997, 28, 1329–1335. [Google Scholar]

- Li, P.; Huang, H.; Du, W.; Fan, Y.; Yin, R.; Hou, S.; Sheng, L. Mechanical properties and fracture mechanism of high-strength FGH4097 superalloys prepared by hot oscillatory pressing. J. Mater. Res. Technol. 2025, 35, 3008–3020. [Google Scholar]

- Courtney, T.H. Mechanical Behavior of Materials; Long Grove Press: Waveland, MI, USA, 2005. [Google Scholar]

- Ma, K.; Wen, H.; Hu, T.; Topping, T.D.; Isheim, D.; Seidman, D.N.; Lavernia, E.J.; Schoenung, J.M. Mechanical behavior and strengthening mechanisms in ultrafine grain precipitation-strengthened aluminum alloy. Acta Mater. 2014, 62, 141–155. [Google Scholar] [CrossRef]

- Hu, Y.; Lin, X.; Zhang, S.; Jiang, Y.; Lu, X.; Yang, H.; Huang, W. Effect of solution heat treatment on the microstructure and mechanical properties of Inconel 625 superalloy fabricated by laser solid forming. J. Alloys Compd. 2018, 767, 330–344. [Google Scholar] [CrossRef]

- Hussein, A.M.; Rao, S.I.; Uchic, M.D.; Parthasarathy, T.A.; El-Awady, J.A. The strength and dislocation microstructure evolution in superalloy microcrystals. J. Mech. Phys. Solids 2017, 99, 146–162. [Google Scholar] [CrossRef]

- Prasad, K.; Obana, M.; Ito, A.; Torizuka, S. Synchrotron diffraction characterization of dislocation density in additively manufactured IN 718 superalloy. Mater. Charact. 2021, 179, 111379. [Google Scholar] [CrossRef]

- Whitmore, L.; Ahmadi, M.R.; Stockinger, M.; Povoden-Karadeniz, E.; Kozeschnik, E.; Leitner, H. Microstructural investigation of thermally aged nickel-based superalloy 718Plus. Mater. Sci. Eng. A 2014, 594, 253–259. [Google Scholar] [CrossRef]

- Chatterjee, S.; Li, Y.; Po, G. A discrete dislocation dynamics study of precipitate bypass mechanisms in nickel-based superalloys. Int. J. Plast. 2021, 145, 103062. [Google Scholar] [CrossRef]

- Hirsch, P.B. The interpretation of the slip pattern in terms of dislocation movements. J. Inst. Met. 1957, 86, 13. [Google Scholar]

- Orowan, E. Symposium on Internal Stresses in Metals and Alloys; Institute of Metals: London, UK, 1948. [Google Scholar]

- Mao, J.; Chang, K.-M.; Yang, W.; Furrer, D.U.; Ray, K.; Vaze, S.P. Cooling precipitation and strengthening study in powder metallurgy superalloy Rene88DT. Mater. Sci. Eng. A 2002, 332, 318–329. [Google Scholar] [CrossRef]

- Fan, L.; Li, J.; Sun, J.; Lv, M.; Wang, Q.; Dong, C. Effect of Cr/Mo/W on the Thermal Stability of γ/γ′ Coherent Microstructure in Ni-Based Superalloys. Acta Metall. Sin. 2024, 60, 453–463. [Google Scholar]

- Brown, L.M.; Ham, R.K. Dislocation-particle interactions. In Strengthening Methods in Crystals; Elsevier: Amsterdam, The Netherlands, 1971; pp. 9–135. [Google Scholar]

- Reed, R.C. The Superalloys Fundamentals and Applications; Cambridge University Press: Cambridge, UK, 2006; p. 141. [Google Scholar]

- Ardell, A.J. Precipitation hardening. Metall. Trans. A 1985, 16, 2131–2165. [Google Scholar] [CrossRef]

- Yashiro, K.; Kurose, F.; Nakashima, Y.; Kubo, K.; Tomita, Y.; Zbib, H. Discrete dislocation dynamics simulation of cutting of γ′ precipitate and interfacial dislocation network in Ni-based superalloys. Int. J. Plast. 2006, 22, 713–723. [Google Scholar] [CrossRef]

- Grant, B.M.; Francis, E.M.; da Fonseca, J.Q.; Daymond, M.R.; Preuss, M. Deformation behaviour of an advanced nickel-based superalloy studied by neutron diffraction and electron microscopy. Acta Mater. 2012, 60, 6829–6841. [Google Scholar] [CrossRef]

- Galindo-Nava, E.I.; Connor, L.D.; Rae, C.M.F. On the prediction of the yield stress of unimodal and multimodal γ′ Nickel-base superalloys. Acta Mater. 2015, 98, 377–390. [Google Scholar]

- Guo, J.T. Materials Science and Engineering for Superalloys; Science Press: Beijing, China, 2008; pp. 365–366. [Google Scholar]

- Zhou, H.; Wang, P.; Lu, S.P. Effect of Grain Boundary Morphology and MC on Plastic Deformation Behavior of NiCrFe Weld Metal: Crystal Plasticity Finite Element Analysis. Chin. J. Mater. Res. 2019, 33, 801–808. [Google Scholar]

- Wang, X.; Yang, Z.; Lv, P.; Liu, L. Effect of precipitation behaviour of μ phase and M23C6 carbide on microstructure and creep properties of DD5 single-crystal superalloy during long-term thermal exposure. Mater. High Temp. 2023, 40, 250–258. [Google Scholar]

- Décamps, B.; Raujol, S.; Coujou, A.; Pettinari-Sturmel, F.; Clément, N.; Locq, D.; Caron, P. On the shearing mechanism of γ′ precipitates by a single (a/6)<112> Shockley partial in Ni-based superalloys. Philos. Mag. 2004, 84, 91–107. [Google Scholar]

- Vorontsov, V.A.; Shen, C.; Wang, Y.; Dye, D.; Rae, C.M.F. Shearing of γ′ precipitates by a<112> dislocation ribbons in Ni-base superalloys: A phase field approach. Acta Mater. 2010, 58, 4110–4119. [Google Scholar]

- Zenk, C.H.; Feng, L.; McAllister, D.; Wang, Y.; Mills, M.J. Shearing mechanisms of co-precipitates in IN718. Acta Mater. 2021, 220, 117305. [Google Scholar]

| Cr | Co | Mo | Al | Ti | B | C | Ni |

|---|---|---|---|---|---|---|---|

| 19.58 | 11.35 | 10.40 | 1.4 | 3.1 | 0.007 | 0.09 | Bal. |

| YS/MPa | TS/MPa | EL/% | |

|---|---|---|---|

| 660 °C–16 h | 768.3 ± 12.1 | 884.6 ± 36.7 | 10.5 ± 1.3 |

| 760 °C–16 h | 817.6 ± 16.5 | 975.2 ± 59.3 | 15.2 ± 1.6 |

| 860 °C–16 h | 751.3 ± 2.8 | 802.3 ± 23.8 | 24.5 ± 0.4 |

| 760 °C–8 h | 770.4 ± 5.3 | 860.7 ± 13.2 | 10.5 ± 0.4 |

| 760 °C–32 h | 778.8 ± 7.8 | 907.3 ± 32.1 | 16.4 ± 1.2 |

| 660 °C–16 h | 760 °C–16 h | 860 °C–16 h | 760 °C–8 h | 760 °C–32 h | |

|---|---|---|---|---|---|

| Experiment YS | 768.3 ± 12.1 | 817.6 ± 16.5 | 751.3 ± 2.8 | 770.4 ± 5.3 | 778.8 ± 7.8 |

| σ0 | 53.6 | 53.6 | 53.6 | 53.6 | 53.6 |

| σGb | 165.5 | 167.4 | 155.1 | 127.3 | 126 |

| σSs | 209 | 190.7 | 194.6 | 205.4 | 195.8 |

| σDis | 38.4 | 38.4 | 38.4 | 38.4 | 38.4 |

| σ0 + σGb + σSs + σDis | 466.5 | 450.1 | 441.7 | 424.7 | 413.8 |

| Expected σp | 301.8 | 367.5 | 309.6 | 345.7 | 365 |

| Cr | Co | Mo |

|---|---|---|

| 337 | 39.4 | 1015 |

| 660 °C–16 h | 760 °C–16 h | 860 °C–16 h | 760 °C–8 h | 760 °C–32 h | |

|---|---|---|---|---|---|

| ƒ | 0.303 | 0.364 | 0.351 | 0.315 | 0.347 |

| 660 °C–16 h | 760 °C–16 h | 860 °C–16 h | 760 °C–8 h | 760 °C–32 h | |

|---|---|---|---|---|---|

| Expected σp | 301.8 | 367.5 | 309.6 | 345.7 | 365 |

| 66.3 | 63.3 | 316 | 55.4 | 96.5 | |

| 376.2 | 412.3 | 404.9 | 383.6 | 402.6 | |

| 1759 | 1760 | 576.3 | 1883 | 1464 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, X.; Han, H.; Tang, P.; Zhou, Y.; Xiao, D.; Fu, J.; Chen, J.; Feng, S.; Zhang, J. Effects of Aging Treatment on the Microstructure and Mechanical Properties of Rene 41 Alloy and the Strengthening Mechanisms. Materials 2025, 18, 1579. https://doi.org/10.3390/ma18071579

Zhang X, Han H, Tang P, Zhou Y, Xiao D, Fu J, Chen J, Feng S, Zhang J. Effects of Aging Treatment on the Microstructure and Mechanical Properties of Rene 41 Alloy and the Strengthening Mechanisms. Materials. 2025; 18(7):1579. https://doi.org/10.3390/ma18071579

Chicago/Turabian StyleZhang, Xianguang, Haoran Han, Pingmei Tang, Yang Zhou, Dongping Xiao, Jianhui Fu, Jiajun Chen, Shouli Feng, and Jian Zhang. 2025. "Effects of Aging Treatment on the Microstructure and Mechanical Properties of Rene 41 Alloy and the Strengthening Mechanisms" Materials 18, no. 7: 1579. https://doi.org/10.3390/ma18071579

APA StyleZhang, X., Han, H., Tang, P., Zhou, Y., Xiao, D., Fu, J., Chen, J., Feng, S., & Zhang, J. (2025). Effects of Aging Treatment on the Microstructure and Mechanical Properties of Rene 41 Alloy and the Strengthening Mechanisms. Materials, 18(7), 1579. https://doi.org/10.3390/ma18071579