Advanced Pore Structure Characterization of High-Volume Mineral Admixture Steam-Cured Mortar Using X-Ray Computed Tomography

Abstract

1. Introduction

2. Methods

2.1. Materials

2.2. Specimen Preparation and Curing Regimes

2.3. Experimental Setup and Testing

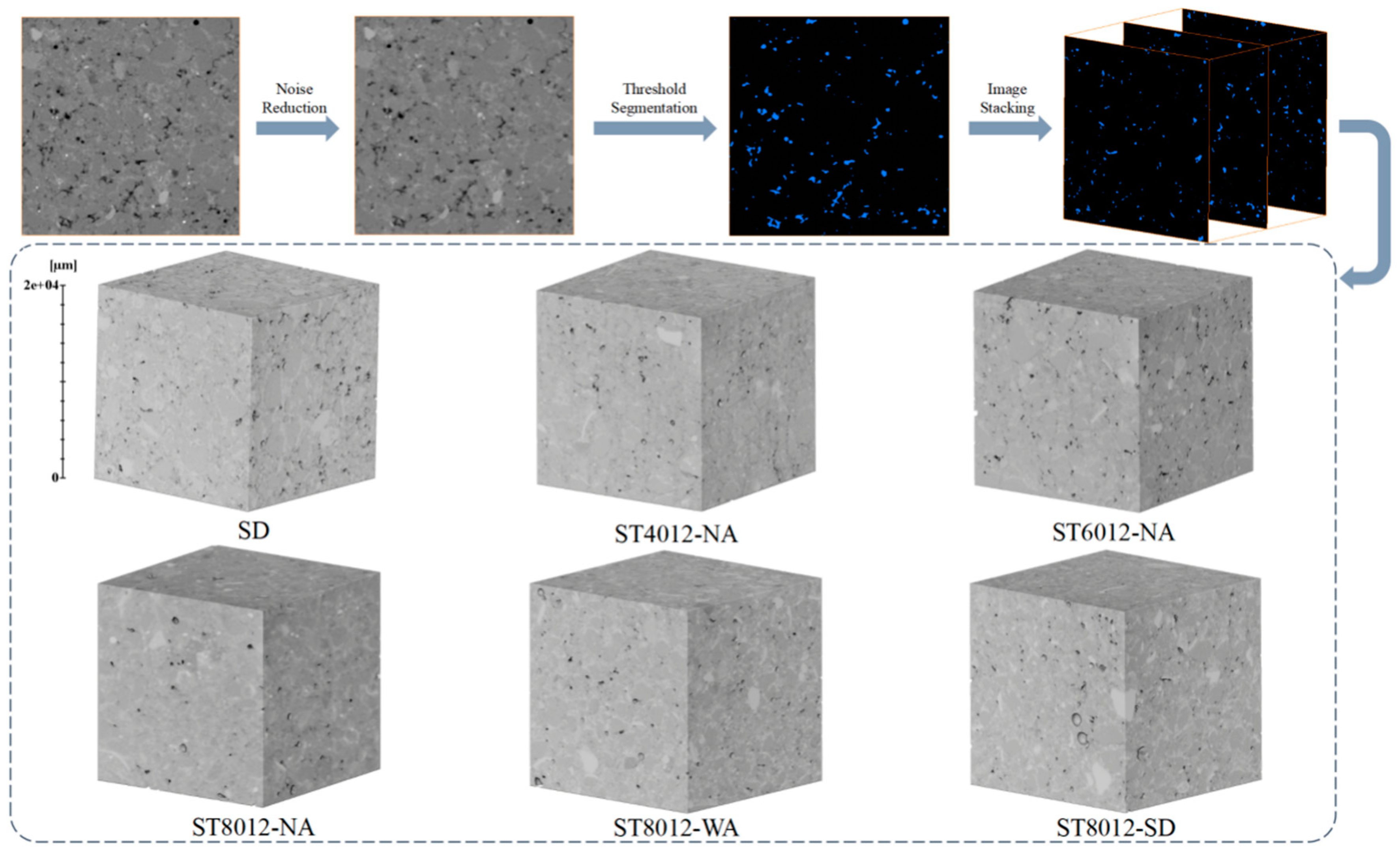

2.4. CT Imaging

2.4.1. CT Imaging Principle

2.4.2. CT Image Processing Method

3. Results and Discussion

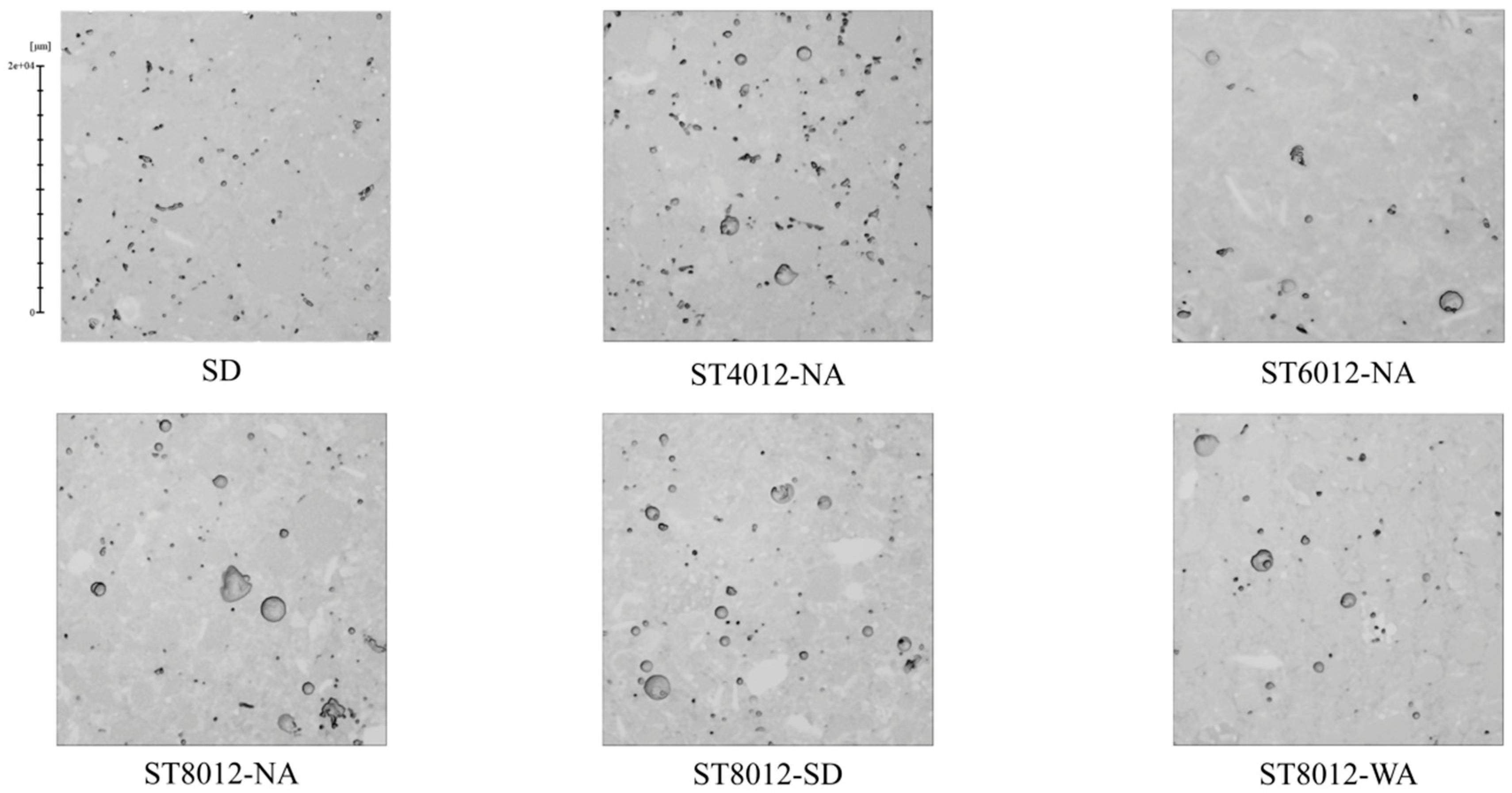

3.1. Pore Size Distribution Analysis

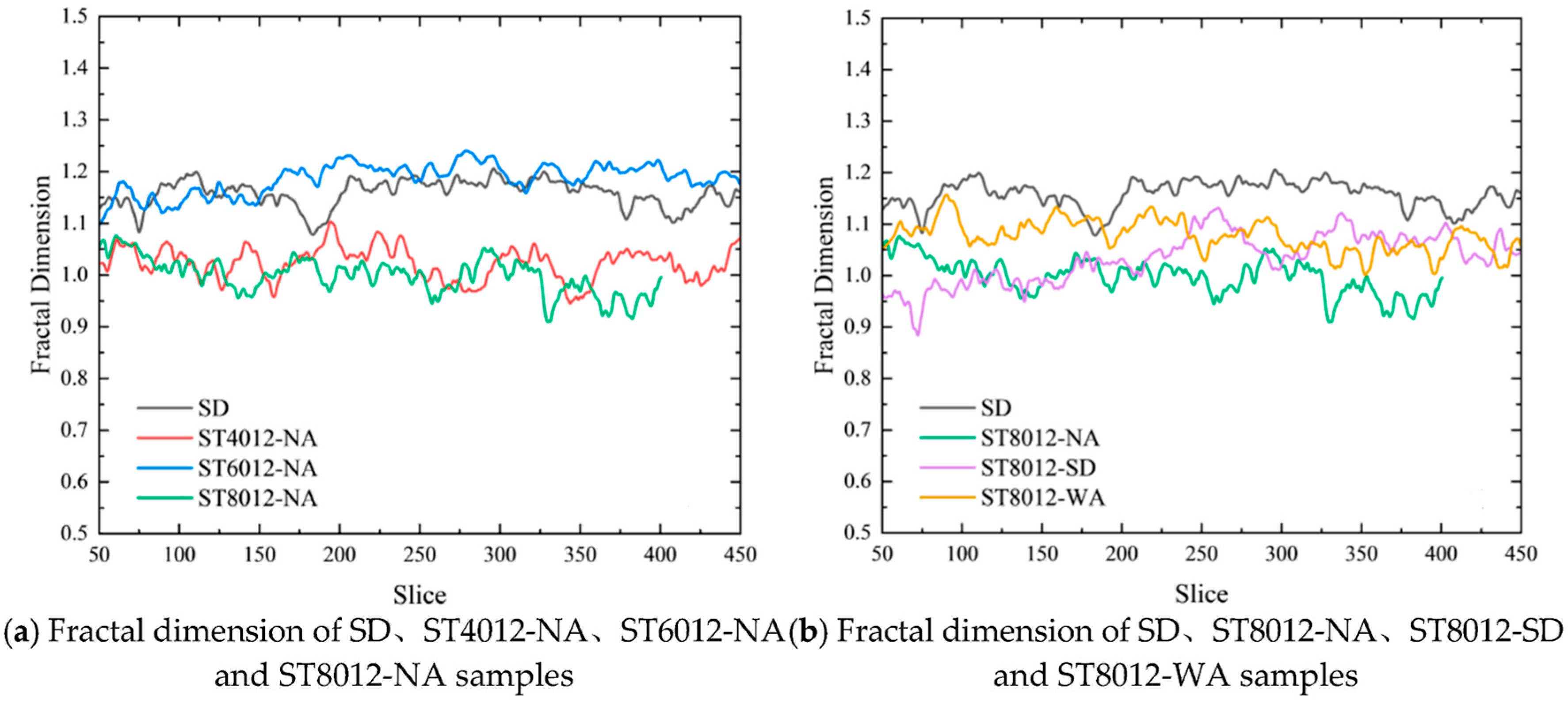

3.2. Fractal Analysis

3.3. Morphology Analysis

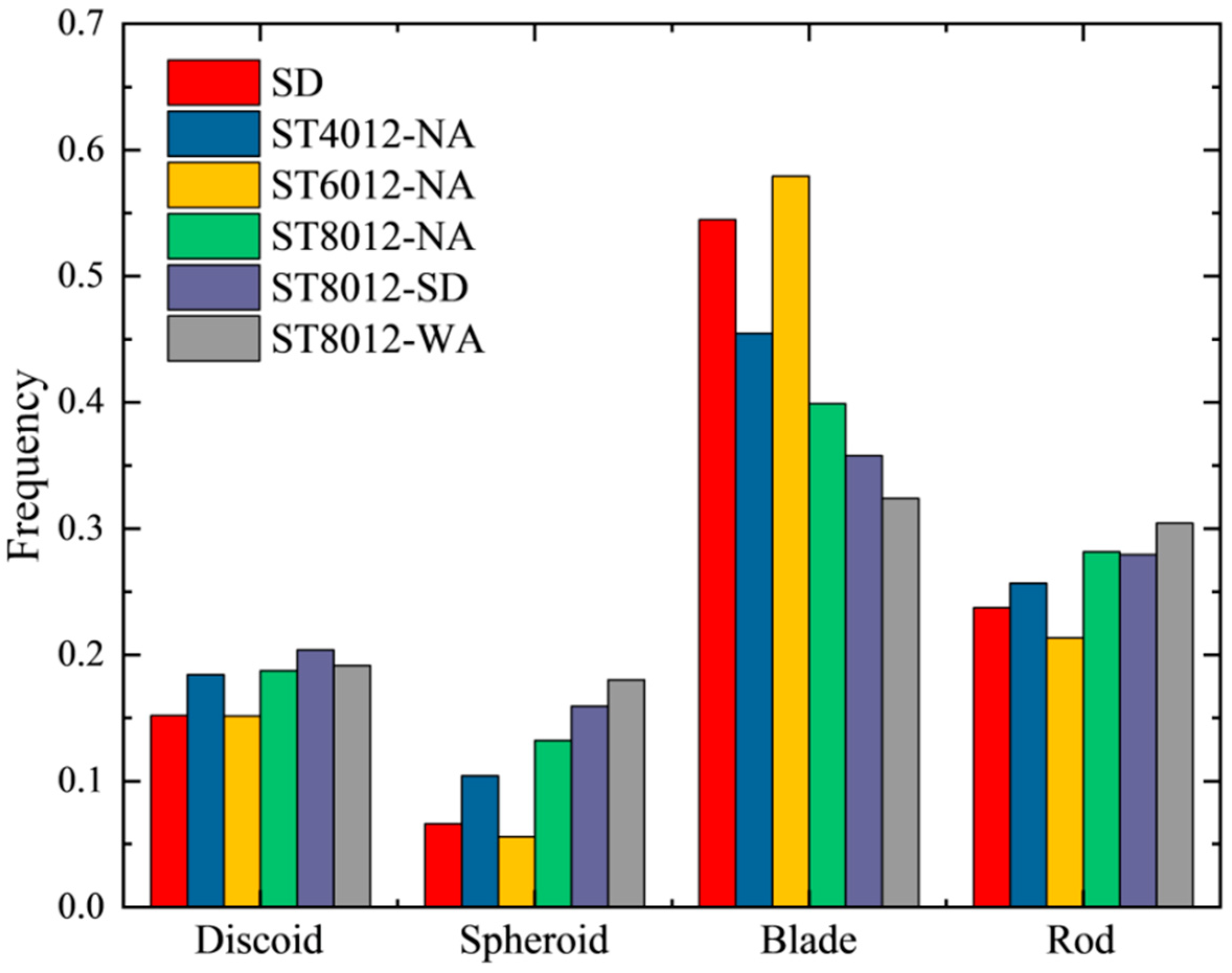

3.3.1. Shape Factor Analysis

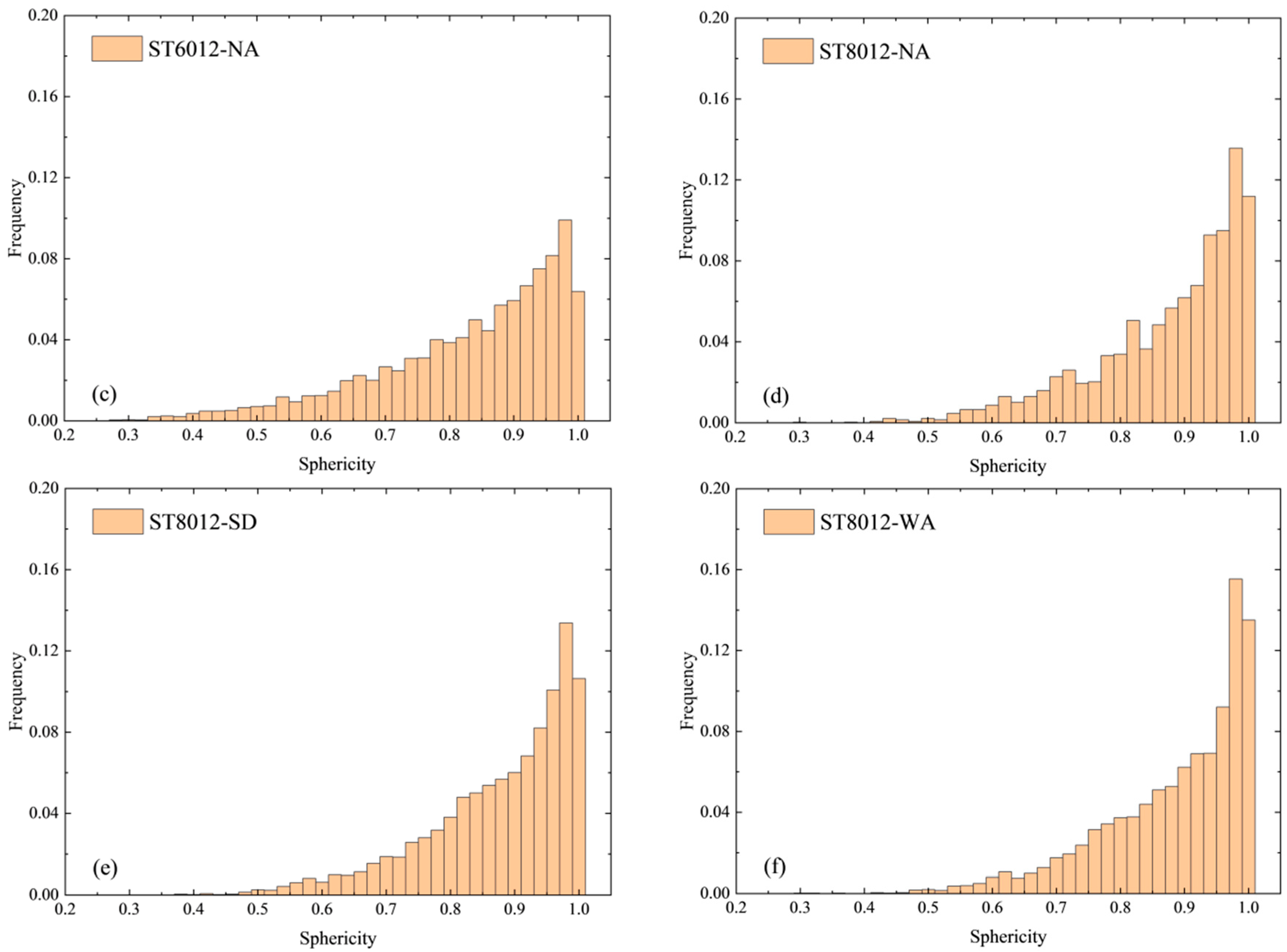

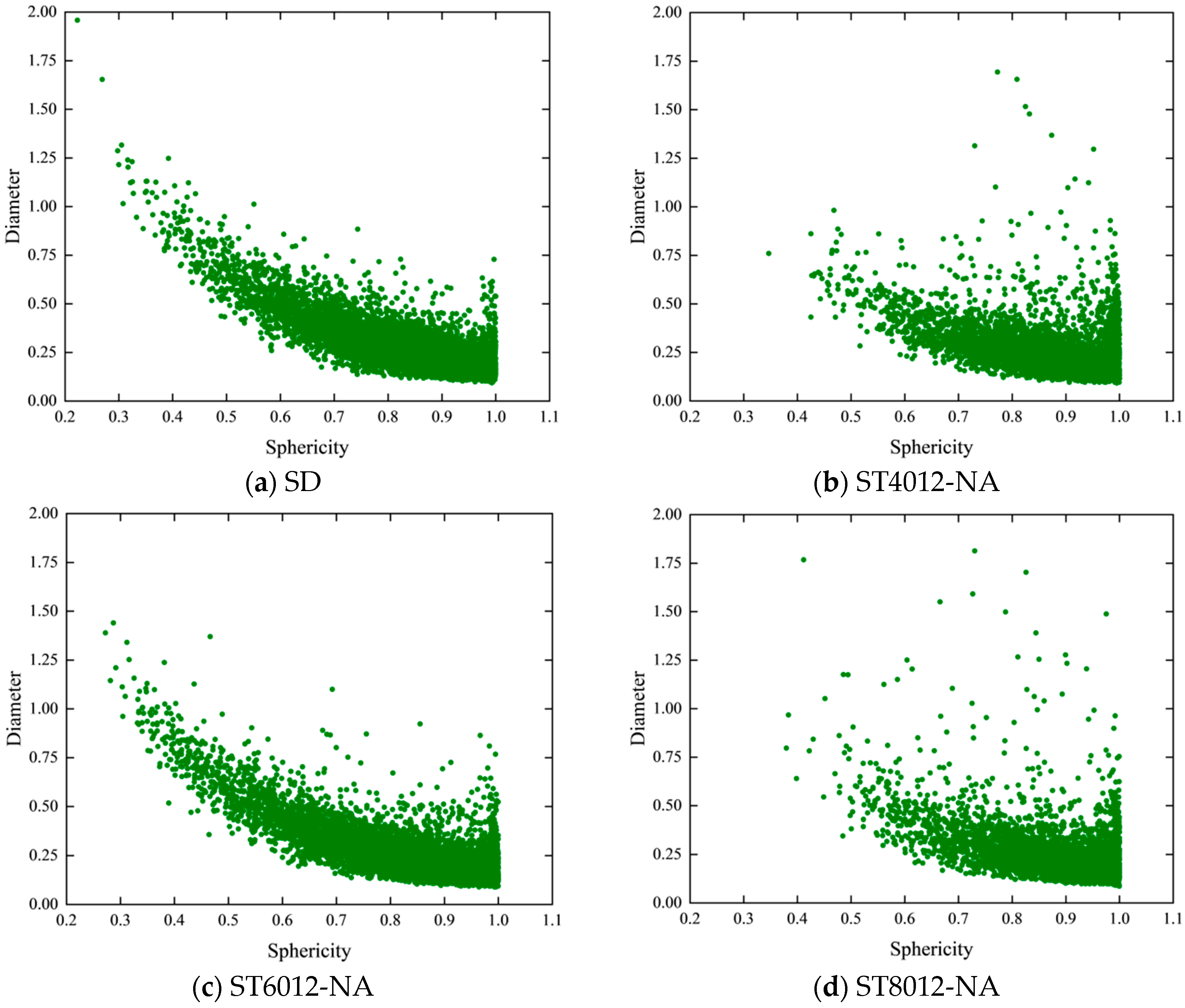

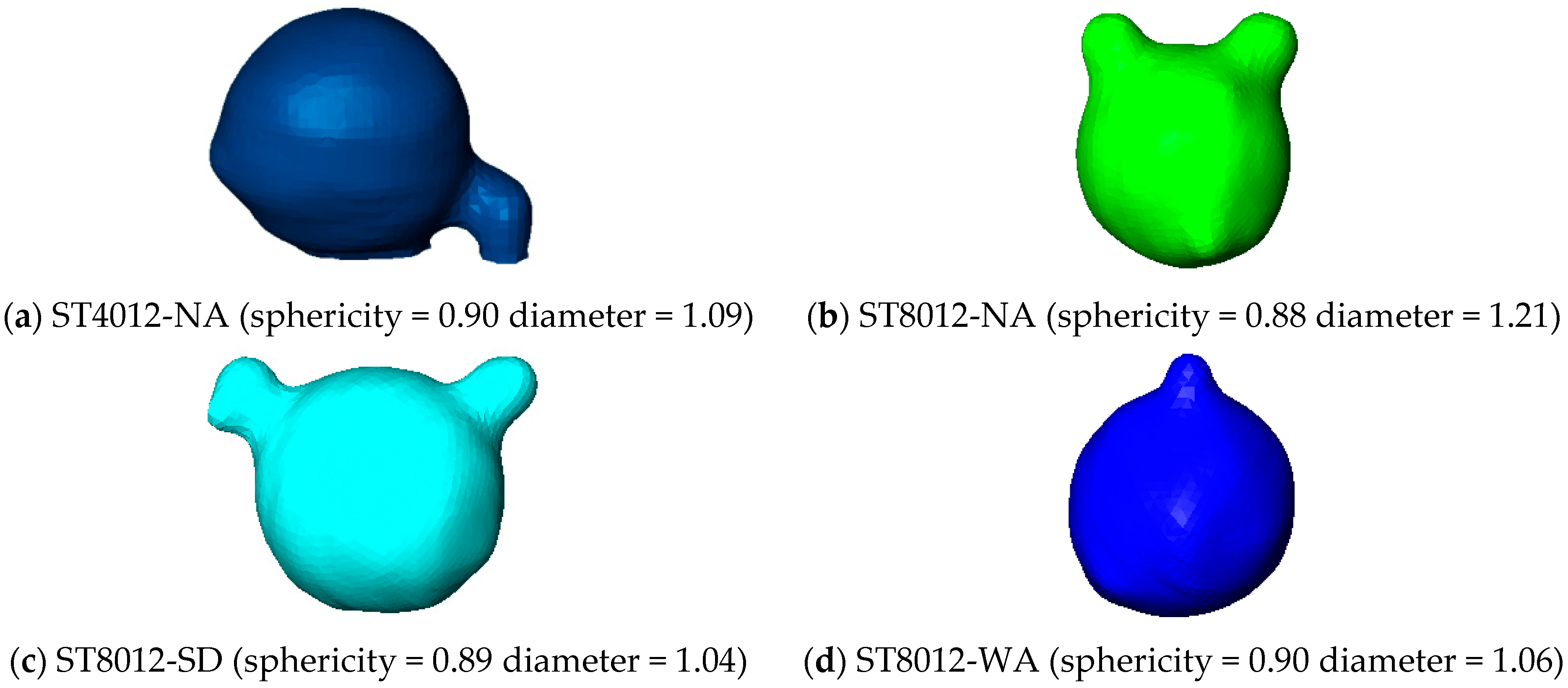

3.3.2. Sphericity Analysis

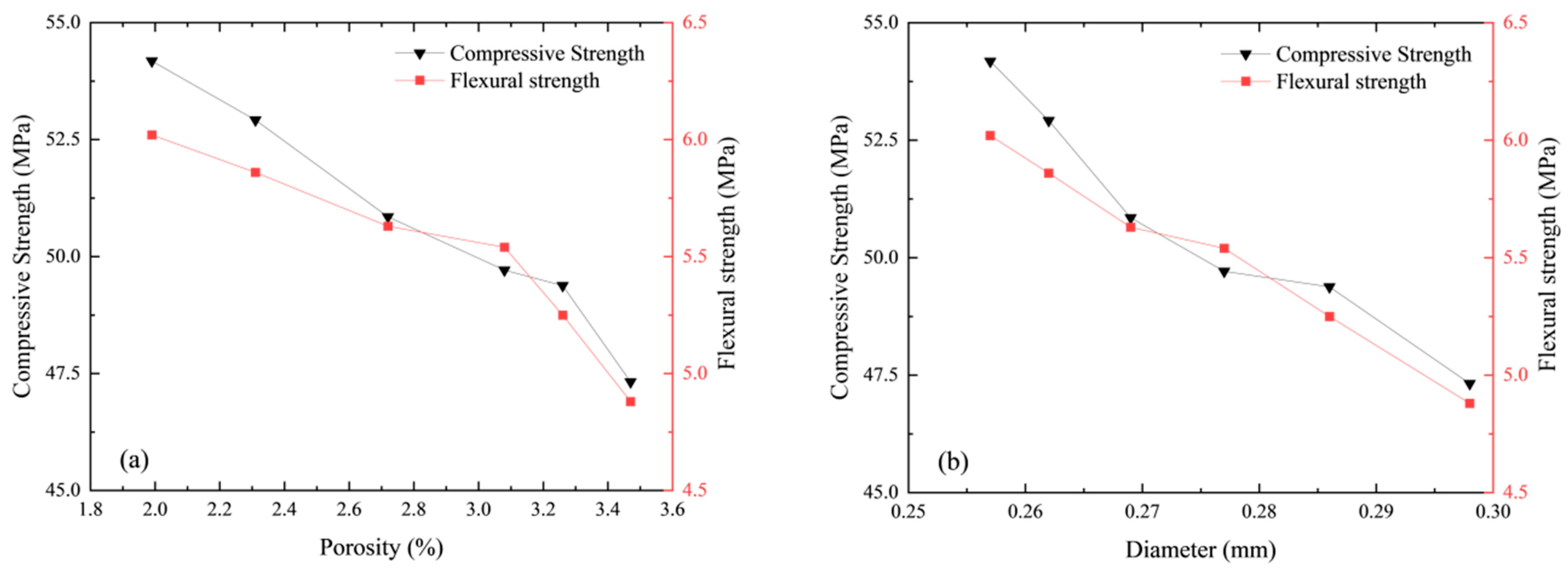

3.4. Correlation Between Pore Characteristics and Mechanical Properties

3.5. Field Implication

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviation

| 2D | Two-dimensional |

| CT | CT imaging principle computed tomography |

| MIP | Mercury intrusion porosimetry |

| NA | Natural curing |

| SCM | Supplementary cementitious material |

| SD | Standard curing |

| SEM | Scanning electron microscopy |

| ST | Steam curing |

| ST-NA | Steam curing group—natural curing |

| ST-SD | Steam curing group—standard curing |

| ST-WA | Steam curing group—water curing |

| UHPC | Ultrahigh performance concrete |

| WA | Water curing |

| X-CT | X-trray computed tomography |

| Eint | Internal energy |

| Eext | External energy |

| Etot | Total energy |

| s | Normalized arc length |

| v | Discrete control point on the active contour curve |

| α | Elasticity coefficient. |

| β | Stiffness coefficient. |

| φ | Sphericity |

| V | Volume |

| A | Area |

References

- John, E.; Lothenbach, B. Cement hydration mechanisms through time—A review. J. Mater. Sci. 2023, 58, 9805–9833. [Google Scholar] [CrossRef]

- Fu, Q.; Bu, M.; Xu, W.; Chen, L.; Li, D.; He, J.; Kou, H.; Li, H. Comparative analysis of dynamic constitutive response of hybrid fibre-reinforced concrete with different matrix strengths. Int. J. Impact Eng. 2021, 148, 103763. [Google Scholar] [CrossRef]

- Yuan, X.; Xu, W.; AlAteah, A.H.; Mostafa, S.A. Evaluation of the performance of high-strength geopolymer concrete prepared with recycled coarse aggregate containing eggshell powder and rice husk ash cured at different curing regimes. Constr. Build. Mater. 2024, 434, 136722. [Google Scholar] [CrossRef]

- Liu, B.; Jiang, J.; Shen, S.; Zhou, F.; Shi, J.; He, Z. Effects of curing methods of concrete after steam curing on mechanical strength and permeability. Constr. Build. Mater. 2020, 256, 119441. [Google Scholar] [CrossRef]

- Zeyad, A.M.; Tayeh, B.A.; Adesina, A.; de Azevedo, A.R.; Amin, M.; Hadzima-Nyarko, M.; Agwa, I.S. Review on effect of steam curing on behavior of concrete. Clean. Mater. 2022, 3, 100042. [Google Scholar] [CrossRef]

- Wang, L.; Wei, W.; Zhang, J.; Hu, Y.; Zhang, L. Effect of curing regime on the mechanical properties and durability of steam cured-concrete. Buildings 2023, 13, 1697. [Google Scholar] [CrossRef]

- Yang, J.; Hu, H.; He, X.; Su, Y.; Wang, Y.; Tan, H.; Pan, H. Effect of steam curing on compressive strength and microstructure of high volume ultrafine fly ash cement mortar. Constr. Build. Mater. 2021, 266, 120894. [Google Scholar] [CrossRef]

- Duan, Y.; Wang, Q.; Yang, Z.; Cui, X.; Liu, F.; Chen, H. Research on the effect of steam curing temperature and duration on the strength of manufactured sand concrete and strength estimation model considering thermal damage. Constr. Build. Mater. 2022, 315, 125531. [Google Scholar] [CrossRef]

- Assaggaf, R.A.; Adekunle, S.K.; Ahmad, S.; Maslehuddin, M.; Al-Amoudi, O.S.B.; Ali, S. Mechanical properties, durability characteristics and shrinkage of plain cement and fly ash concretes subjected to accelerated carbonation curing. J. S. Afr. Inst. Civ. Eng. 2019, 61, 73–81. [Google Scholar] [CrossRef]

- Xie, Y.; Wang, X.; Long, G.; Ma, C. Quantitative analysis of the influence of subfreezing temperature on the mechanical properties of steam-cured concrete. Constr. Build. Mater. 2019, 206, 504–511. [Google Scholar] [CrossRef]

- Zhu, X.; Lei, P.; Chen, X.; Bu, J. Influence of steam curing on cyclic triaxial characteristics of recycled aggregate concrete: Experimental analysis and DEM simulation. Eng. Fract. Mech. 2024, 312, 110643. [Google Scholar] [CrossRef]

- He, Y.M.C. Hydration heat evolution of Portland cement paste during unsteady steam curing process: Modelling and optimization. Thermochim. Acta 2020, 694, 178784. [Google Scholar]

- Han, X.; Wang, B.; Feng, J. Relationship between fractal feature and compressive strength of concrete based on MIP. Constr. Build. Mater. 2022, 322, 126504. [Google Scholar]

- Zhang, Y.; Xu, S.; Gao, Y.; Guo, J.; Cao, Y.; Zhang, J. Correlation of chloride diffusion coefficient and microstructure parameters in concrete: A comparative analysis using NMR, MIP, and X-CT. Front. Struct. Civ. Eng. 2020, 14, 1509–1519. [Google Scholar]

- He, J.; Lei, D.; Di Luzio, G.; Zhu, F.; Bai, P. Mechanical properties measurement and micro-damage characterization of ITZ in concrete by SEM-DIC method. Opt. Lasers Eng. 2022, 155, 107064. [Google Scholar]

- Fan, S.; Ren, H.; Hong, S.; Xing, F.; Hou, D.; Dong, B. Interfacial mechanical bond characterization between cement pastes and porous aggregates through a coupled XCT and DVC technique. Cem. Concr. Compos. 2023, 142, 105158. [Google Scholar] [CrossRef]

- Deresse, N.E.; Van Steen, C.; Soete, J.; Sarem, M.; Vanhulst, J.; Wevers, M.; François, S.; Verstrynge, E. Fracture mode analysis of cementitious mortars by simultaneous application of 4D-XCT and acoustic emission technique. Constr. Build. Mater. 2024, 419, 135486. [Google Scholar] [CrossRef]

- Leite, M.B.; Monteiro, P.J.M. Microstructural analysis of recycled concrete using X-ray microtomography. Cem. Concr. Res. 2016, 81, 38–48. [Google Scholar]

- Olawuyi, B.J.; Boshoff, W.P. Influence of SAP content and curing age on air void distribution of high performance concrete using 3D volume analysis. Constr. Build. Mater. 2017, 135, 580–589. [Google Scholar]

- Pilehvar, S.; Cao, V.D.; Szczotok, A.M.; Valentini, L.; Salvioni, D.; Magistri, M.; Pamies, R.; Kjøniksen, A.-L. Mechanical properties and microscale changes of geopolymer concrete and Portland cement concrete containing micro-encapsulated phase change materials. Cem. Concr. Res. 2017, 100, 341–349. [Google Scholar]

- Schock, J.; Liebl, S.; Achterhold, K.; Pfeiffer, F. Obtaining the spacing factor of microporous concrete using high-resolution Dual Energy X-ray Micro CT. Cem. Concr. Res. 2016, 89, 200–205. [Google Scholar]

- GB/T 14684-2022; Sand for Construction. China Building Materials Federation: Beijing, China, 2022.

- GB/T 17671-2021; Test Method of Cement Mortar Strength (ISO Method). China Building Materials Federation: Beijing, China, 2021.

- Brisard, S.; Serdar, M.; Monteiro, P.J.M. Multiscale X-ray tomography of cementitious materials: A review. Cem. Concr. Res. 2020, 128, 105824. [Google Scholar]

- Wang, R.; Wu, H.; Zhao, M.; Liu, Y.; Chen, C. The classification and mechanism of microcrack homogenization research in cement concrete based on X-ray CT. Buildings 2022, 12, 1011. [Google Scholar] [CrossRef]

- Wang, P.; Qiao, H.; Zhang, Y.; Li, Y.; Chen, K.; Feng, Q. Three-dimensional characteristics of steel corrosion and corrosion-induced cracks in magnesium oxychloride cement concrete monitored by X-ray computed tomography. Constr. Build. Mater. 2020, 246, 118504. [Google Scholar] [CrossRef]

- Kaur, I.; Kaur, A. Modified active contour snake model for image segmentation using anisotropic filtering. Int. Res. J. Eng. Technol 2016, 3, 2151–2157. [Google Scholar]

- Friesen, W.I.; Laidlaw, W.G. Porosimetry of fractal surfaces. J. Colloid Interface Sci. 1993, 160, 226–235. [Google Scholar]

- Agboola, O.; Onyango, M.S.; Popoola, P.; Oyewo, O.A. Fractal geometry and porosity. In Fractal Analysis: Applications in Physics, Engineering and Technology; Intech Open: London, UK, 2017. [Google Scholar]

- Schmitt, M.; Halisch, M.; Müller, C.; Fernandes, C.P. Classification and quantification of pore shapes in sandstone reservoir rocks with 3-D X-ray micro-computed tomography. Solid Earth 2016, 7, 285–300. [Google Scholar]

- Kong, L.; Ostadhassan, M.; Li, C.; Tamimi, N. Pore characterization of 3D-printed gypsum rocks: A comprehensive approach. J. Mater. Sci. 2018, 53, 5063–5078. [Google Scholar]

- Guo, Y.; Chen, X.; Chen, B.; Wen, R.; Wu, P. Analysis of foamed concrete pore structure of railway roadbed based on X-ray computed tomography. Constr. Build. Mater. 2021, 273, 121773. [Google Scholar] [CrossRef]

- Chen, K.Y.; Xia, J.; Wu, R.J.; Shen, X.-Y.; Chen, J.-J.; Zhao, Y.-X.; Jin, W.-L. An overview on the influence of various parameters on the fabrication and engineering properties of CO2-cured cement-based composites. J. Clean. Prod. 2022, 366, 132968. [Google Scholar]

- Junaid, M.F.; ur Rehman, Z.; Kuruc, M.; Medveď, I.; Bačinskas, D.; Čurpek, J.; Čekon, M.; Ijaz, N.; Ansari, W.S. Lightweight concrete from a perspective of sustainable reuse of waste byproducts. Constr. Build. Mater. 2022, 319, 126061. [Google Scholar]

- Liu, K.; Yu, R.; Shui, Z.; Li, X.; Guo, C.; Yu, B.; Wu, S. Optimization of autogenous shrinkage and microstructure for Ultra-High Performance Concrete (UHPC) based on appropriate application of porous pumice. Constr. Build. Mater. 2019, 214, 369–381. [Google Scholar]

- Sattar, O.; Khalid, U.; Rehman, Z.U.; Kayani, W.I.; Haider, A. Impact of crushing shape and geopolymerization on reclaimed concrete aggregate for recycling in the flexible pavement: An enhanced circular economy solution. Road Mater. Pavement Des. 2024, 25, 1910–1932. [Google Scholar]

- Al-Maharma, A.Y.; Patil, S.P.; Markert, B. Effects of porosity on the mechanical properties of additively manufactured components: A critical review. Mater. Res. Express 2020, 7, 122001. [Google Scholar]

| Material | CaO | MgO | SiO2 | Fe2O3 | P2O5 | Al2O3 | SO3 |

|---|---|---|---|---|---|---|---|

| Cement | 54.65 | 2.58 | 22.07 | 4.32 | 1.03 | 6.30 | 2.59 |

| Slag | 45.09 | 6.99 | 27.33 | 0.45 | 0.13 | 13.66 | 4.03 |

| Fly ash | 8.18 | 0.30 | 41.11 | 6.28 | 1.15 | 38.62 | 0.42 |

| Specimen | Steam Curing Temperature | Steam Curing Age | Scanning System | X-Ray Source Power/W | Voxel Size/mL |

|---|---|---|---|---|---|

| ST4012-NA | 40 °C | 12 h | German Vtomexs micro-focus X-ray CT system | 18 | 38.8 |

| ST6012-NA | 60 °C | 12 h | |||

| ST8012-NA | 80 °C | 12 h | |||

| ST8012-WA | 80 °C | 12 h | |||

| ST8012-SD | 80 °C | 12 h |

| Shape | Elongation Index (I/L) | Flatness Index (S/I) | Class |

|---|---|---|---|

| Discoid | >0.67 | <0.67 | Class I |

| Spheroid | >0.67 | >0.67 | Class II |

| Blade | <0.67 | <0.67 | Class III |

| Rod | <0.67 | >0.67 | Class IV |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Y.; Xie, S.; Li, Y.; Yang, M.; Chen, Q.; Huang, L.; Hu, D.; Li, S. Advanced Pore Structure Characterization of High-Volume Mineral Admixture Steam-Cured Mortar Using X-Ray Computed Tomography. Materials 2025, 18, 1575. https://doi.org/10.3390/ma18071575

Wang Y, Xie S, Li Y, Yang M, Chen Q, Huang L, Hu D, Li S. Advanced Pore Structure Characterization of High-Volume Mineral Admixture Steam-Cured Mortar Using X-Ray Computed Tomography. Materials. 2025; 18(7):1575. https://doi.org/10.3390/ma18071575

Chicago/Turabian StyleWang, Yuntian, Songlin Xie, Yushu Li, Min Yang, Qiuling Chen, Lijuan Huang, Danping Hu, and Sheng Li. 2025. "Advanced Pore Structure Characterization of High-Volume Mineral Admixture Steam-Cured Mortar Using X-Ray Computed Tomography" Materials 18, no. 7: 1575. https://doi.org/10.3390/ma18071575

APA StyleWang, Y., Xie, S., Li, Y., Yang, M., Chen, Q., Huang, L., Hu, D., & Li, S. (2025). Advanced Pore Structure Characterization of High-Volume Mineral Admixture Steam-Cured Mortar Using X-Ray Computed Tomography. Materials, 18(7), 1575. https://doi.org/10.3390/ma18071575