Biochars from Cotton Seed, Camelia Seed Shell, and Coffee Ground in Modification of Asphalt: Fundamental Properties, Rheological Performance, and Inhibition of VOC Emissions

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Asphalt Modification

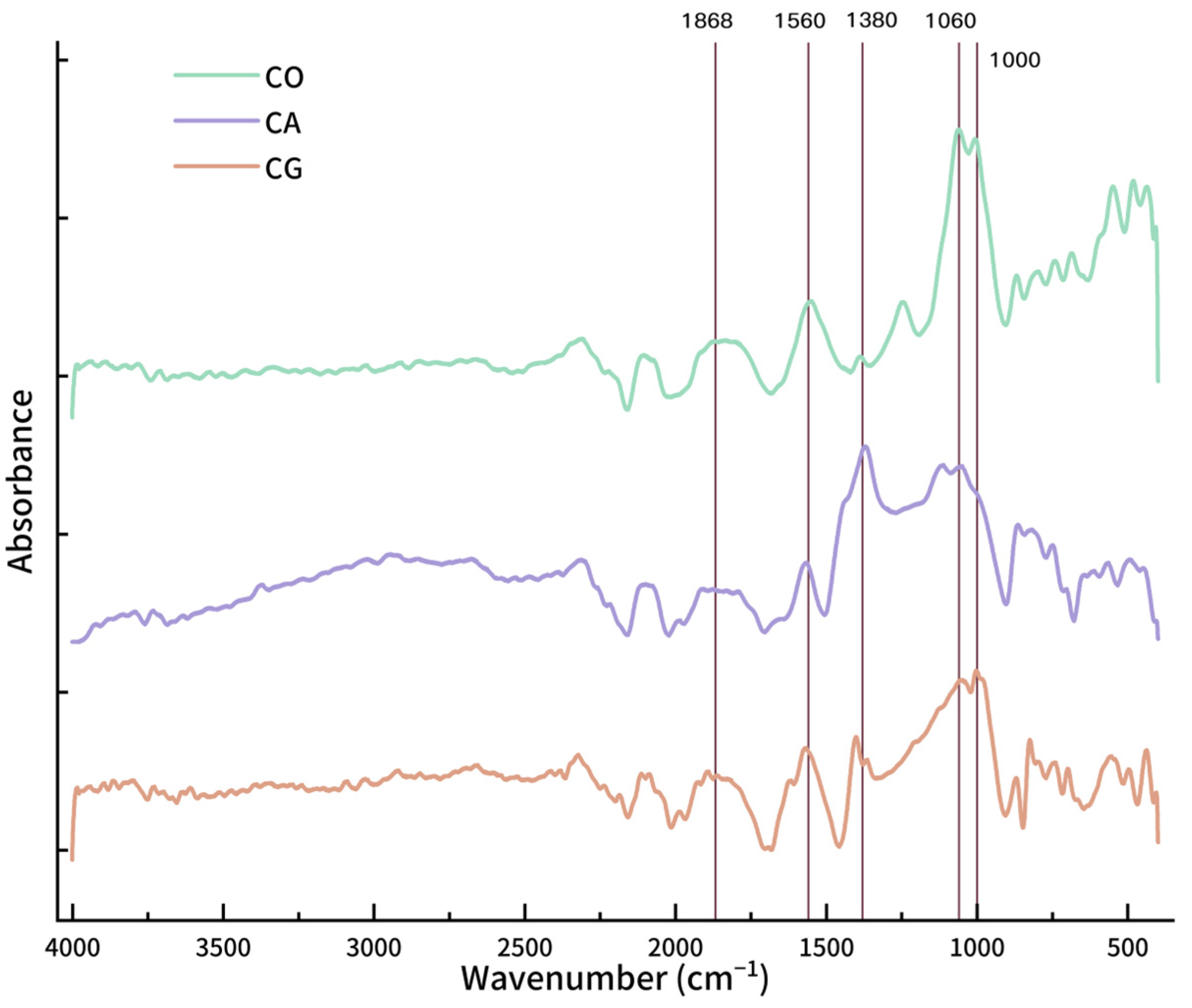

2.3. Characterization of Biochar

2.3.1. Elemental Analysis

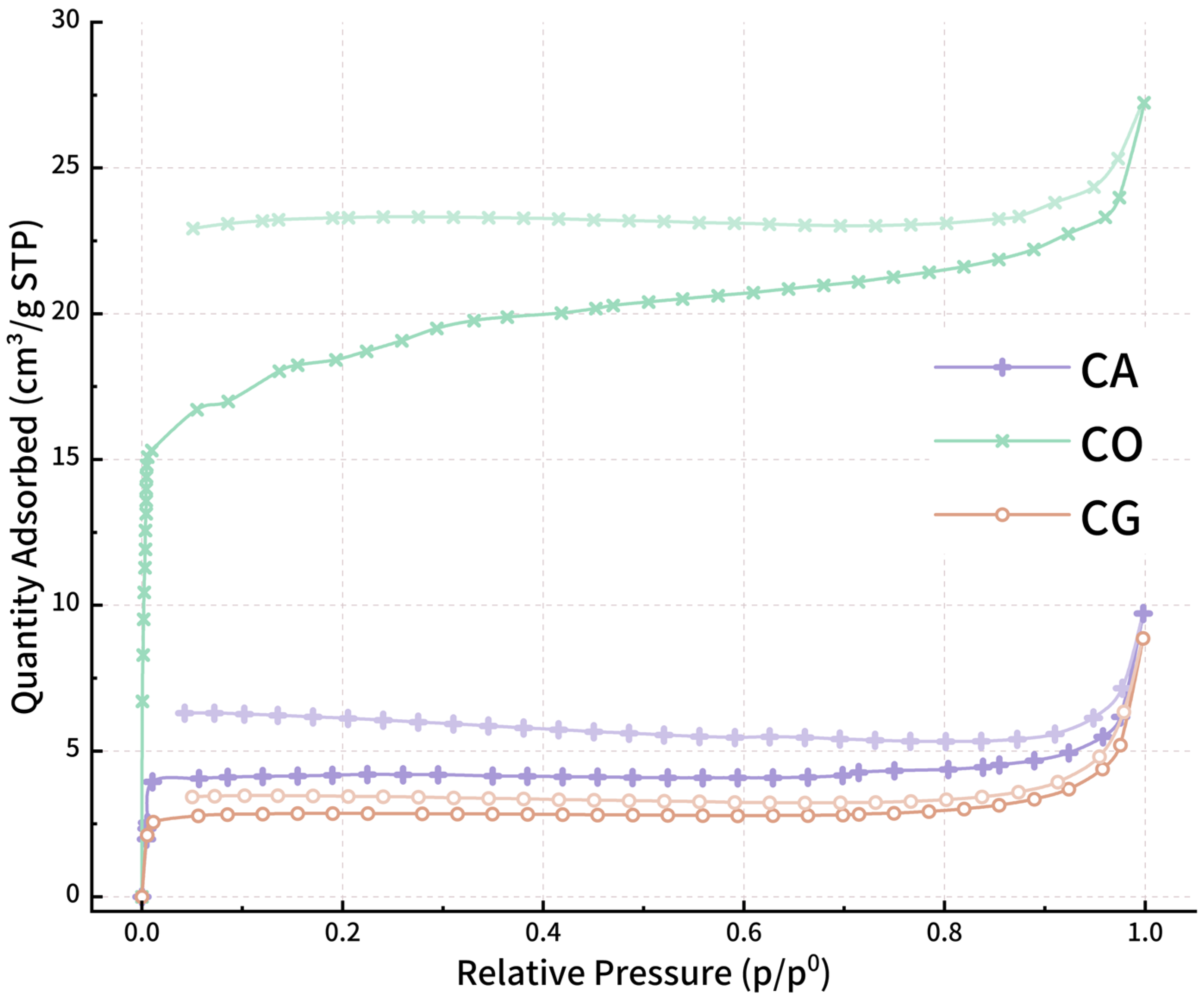

2.3.2. BET

2.3.3. FTIR

2.4. Evaluation of Biochar-Modified Asphalt Properties

2.4.1. Conventional Properties

2.4.2. Segregation Test

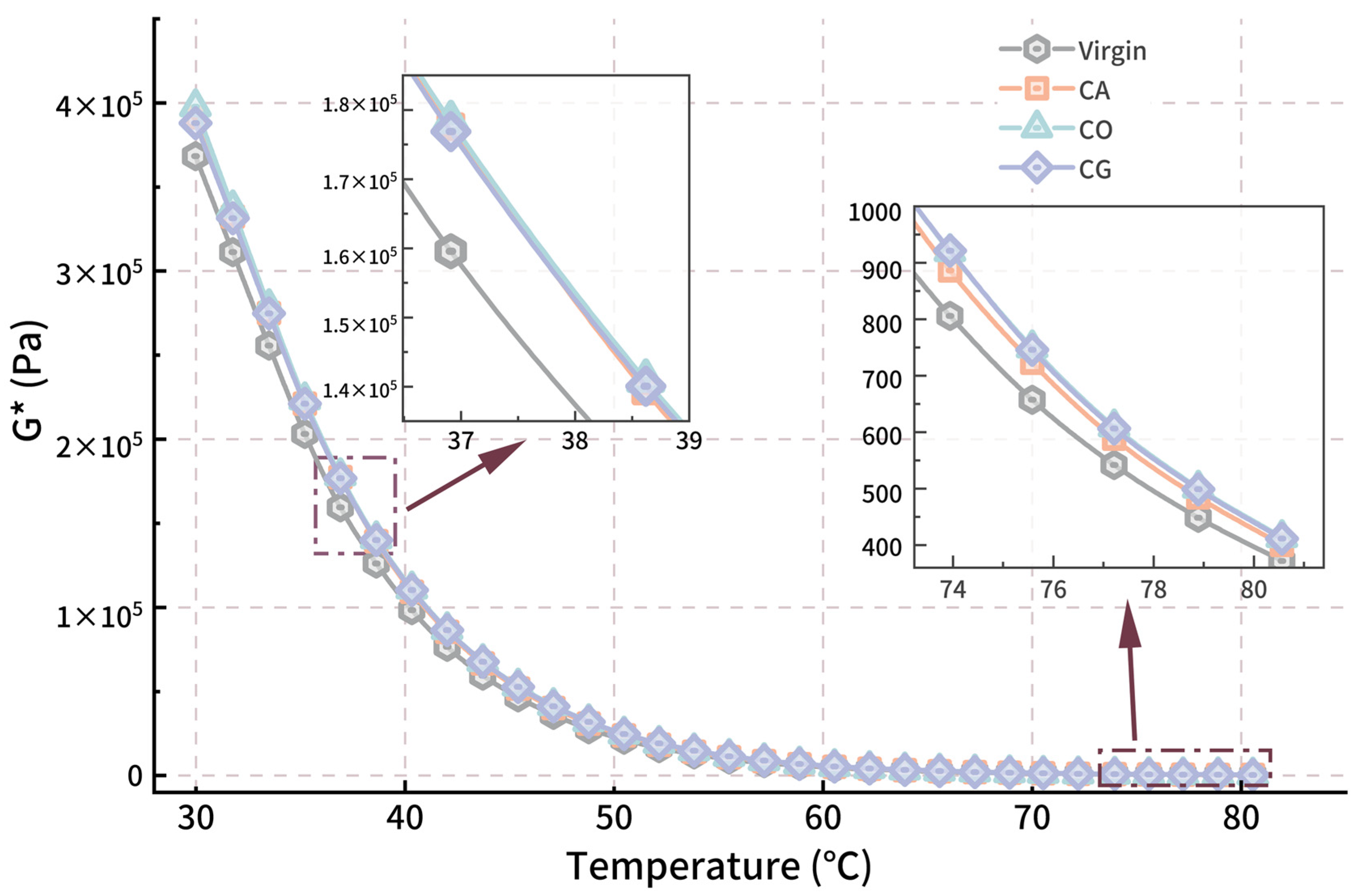

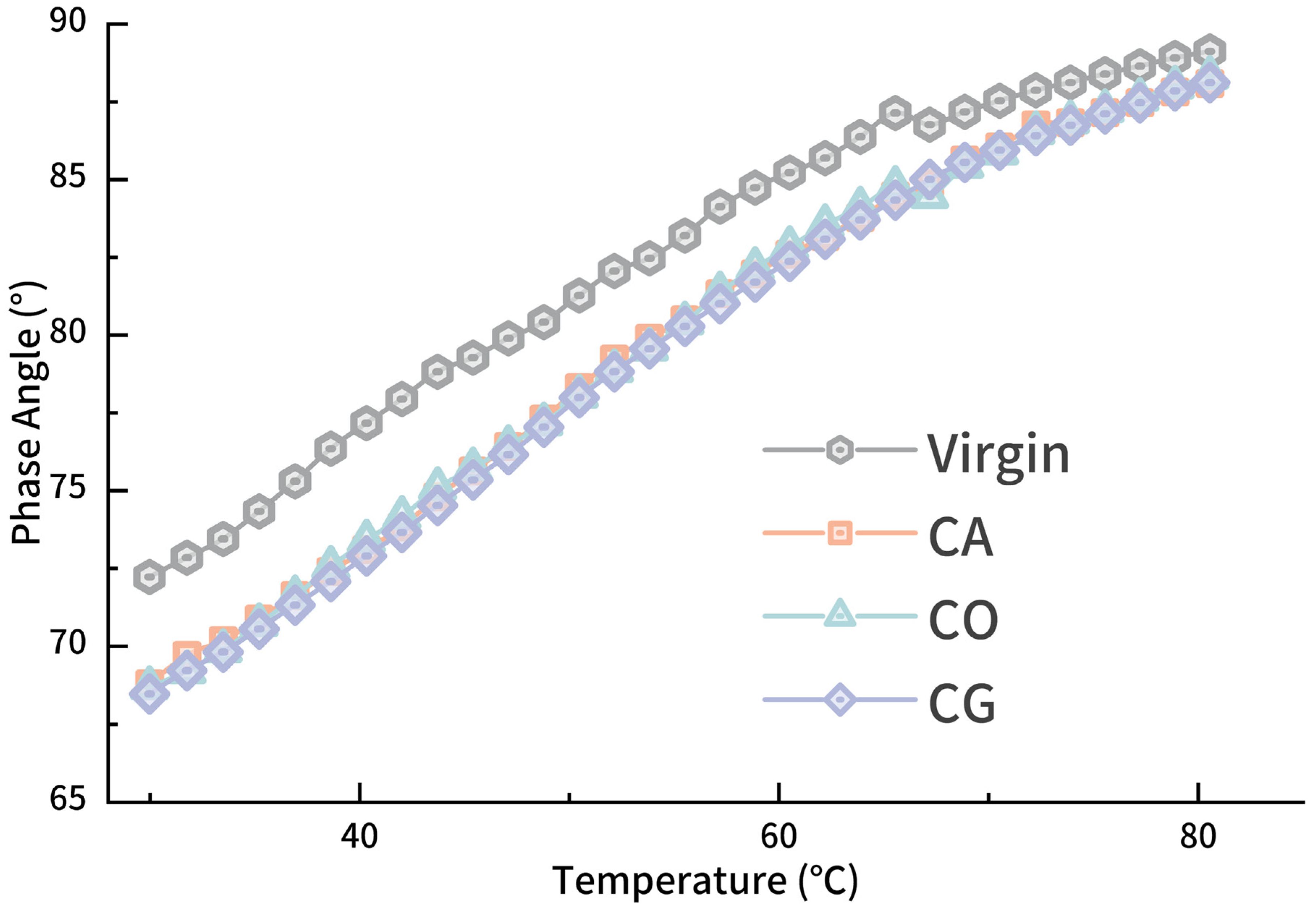

2.4.3. Temperature Sweep

2.4.4. Frequency Sweep

2.4.5. Bending Beam Rheometer Test

2.5. Asphalt VOC Emission Evaluation

3. Results and Discussion

3.1. Biochar Characterization

3.2. Performance of Modified Asphalt

3.2.1. Selection of Biochar Content Based on Conventional Properties

3.2.2. Storage Stability

3.2.3. Temperature Sweep Analysis

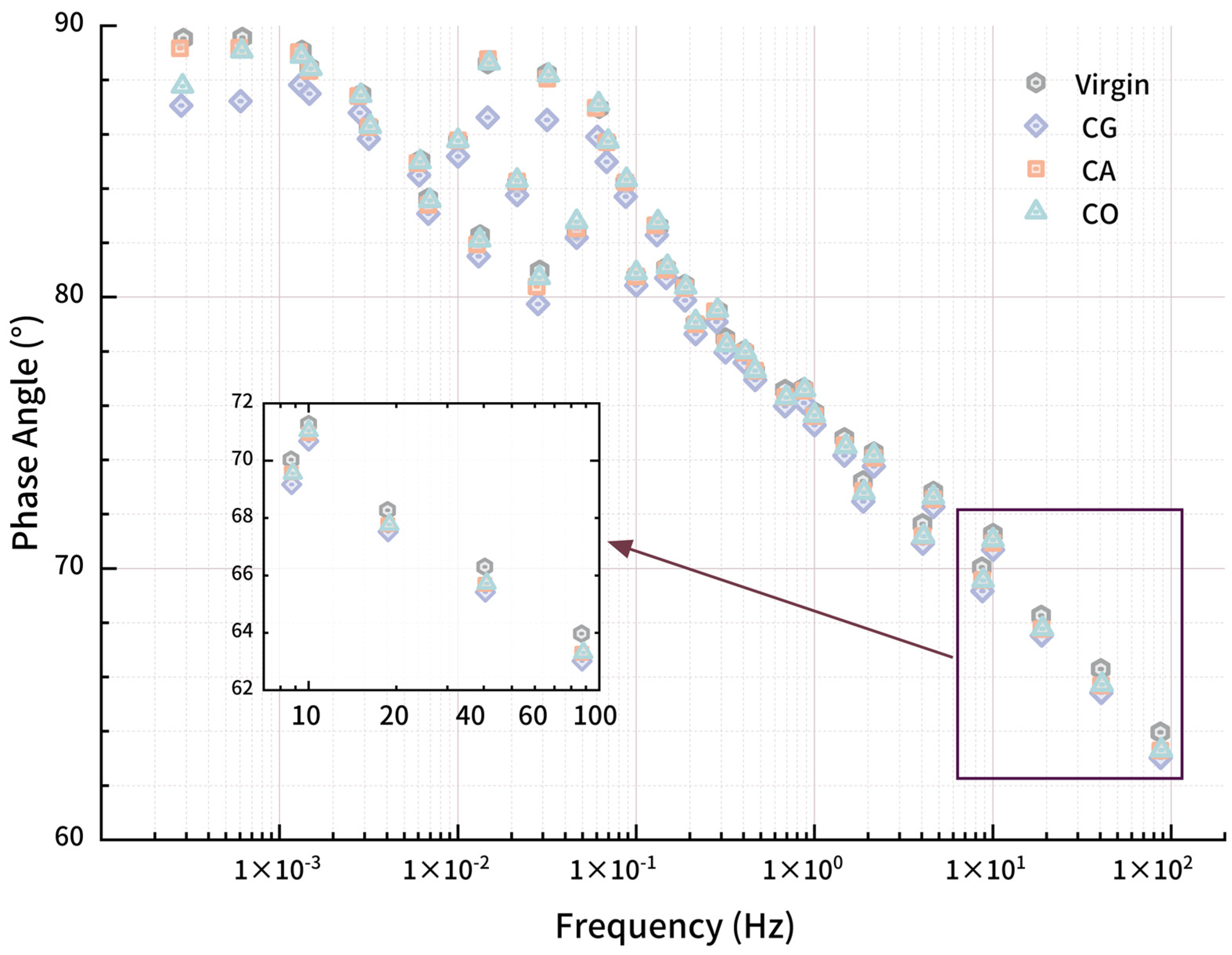

3.2.4. Master Curve

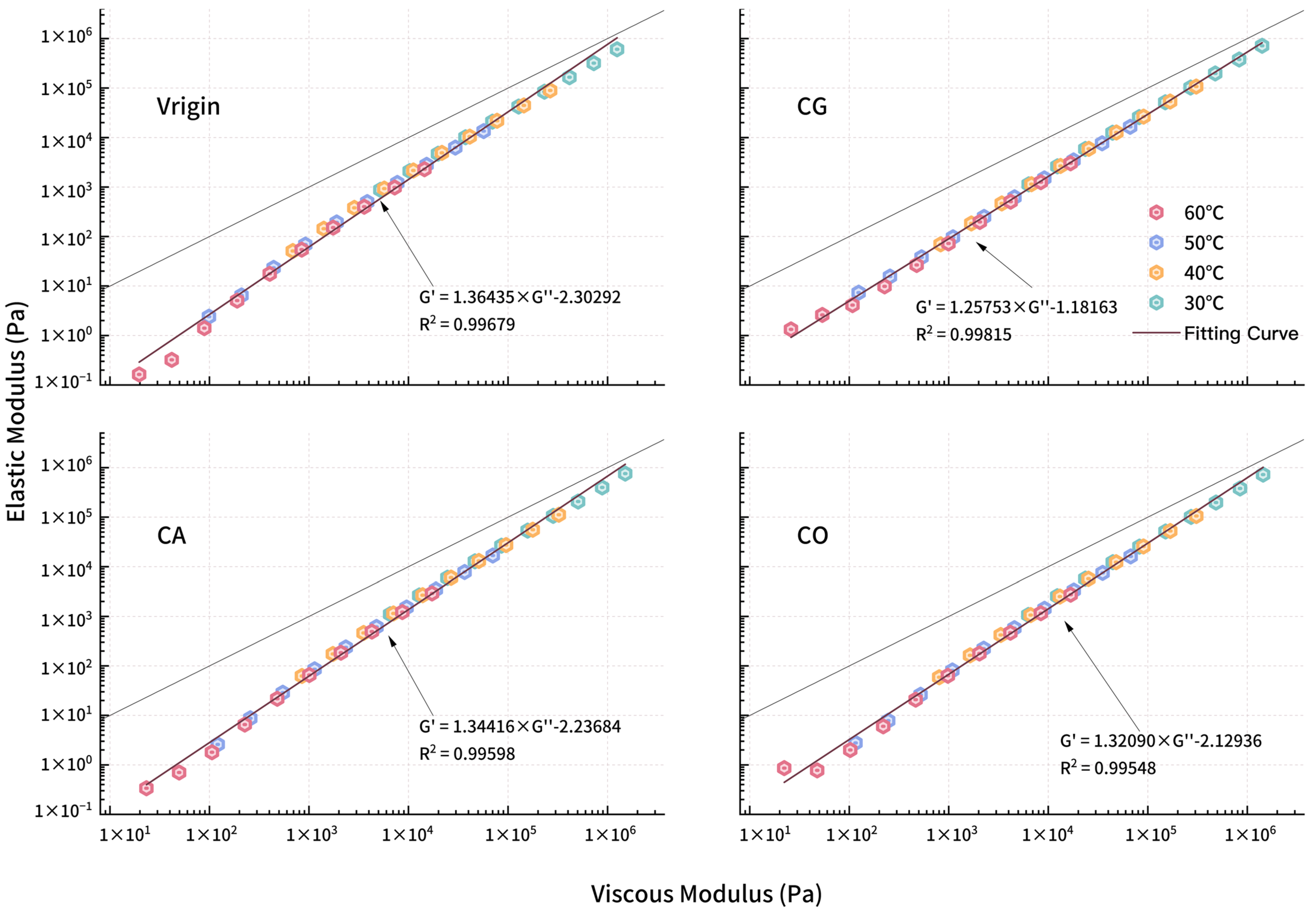

3.2.5. Han Curve

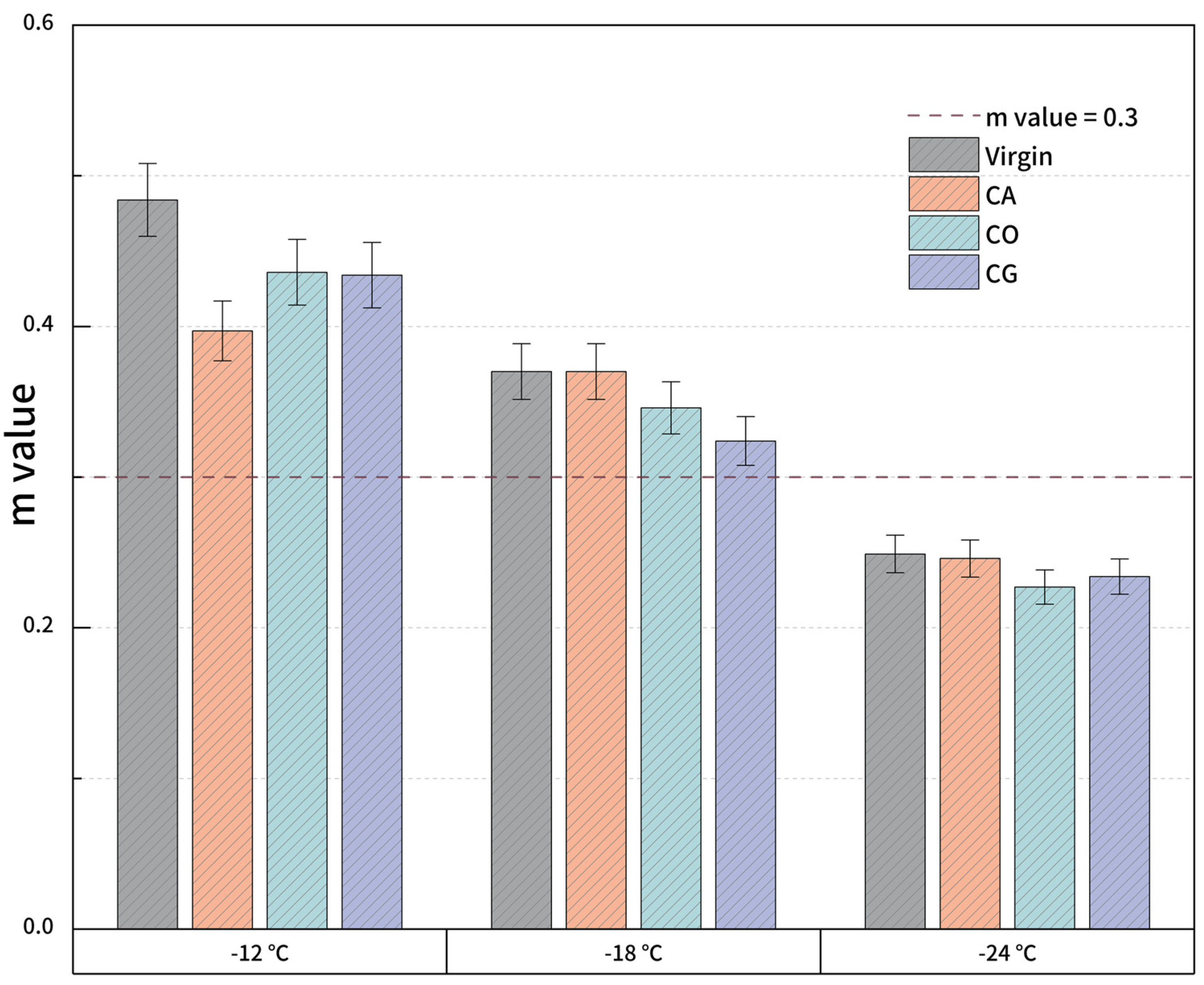

3.2.6. Low-Temperature Properties

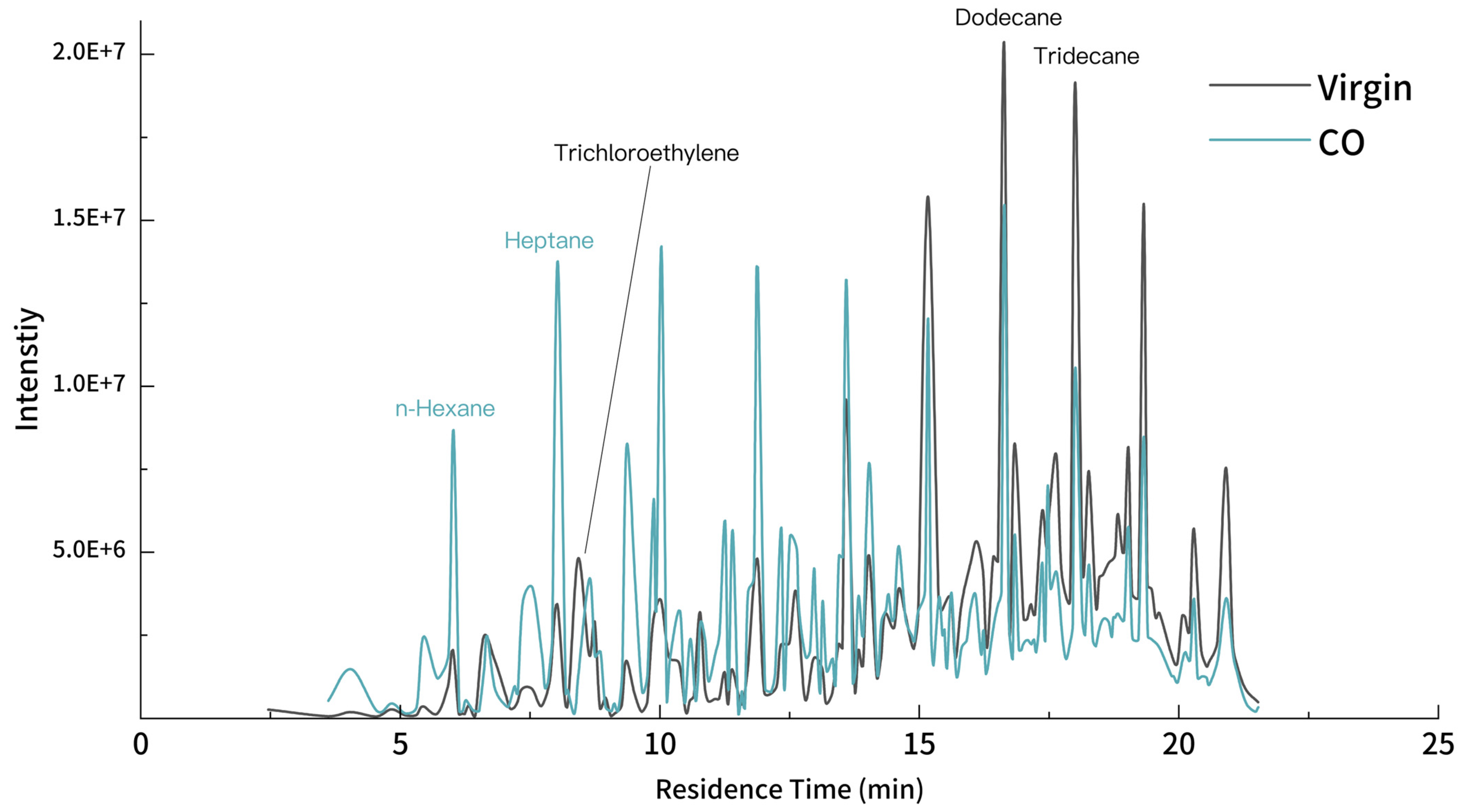

3.3. Asphalt VOC Emission Behavior Analysis

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| CO | Cotton seed |

| CA | Camelia seed shell |

| CG | Coffee ground |

| DSR | Dynamic shear rheometer |

| BBR | Bending beam rheometer |

| VOCs | Volatile organic compounds |

| GC-MS | Gas chromatography–mass spectrometry |

| SBS | Styrene–butadiene–styrene block copolymer |

| SBR | Styrene butadiene rubber |

| PE | Polyethylene |

| DSC | Differential scanning calorimetry |

| TD | Thermal desorption |

| TTS | Time–temperature superposition |

| WLF | Williams–Landel–Ferry |

References

- Dong, F.; Yang, P.; Yu, X.; Jiang, M.; Wang, S.; Zu, Y.; Chen, B.; Wang, J. Morphology, chemical reaction mechanism, and cross-linking degree of asphalt binder modified by SBS block co-polymer. Constr. Build. Mater. 2023, 378, 131204. [Google Scholar]

- Li, H.; Cui, C.; Temitope, A.A.; Feng, Z.; Zhao, G.; Guo, P. Effect of SBS and crumb rubber on asphalt modification: A review of the properties and practical application. J. Traffic Transp. Eng. (Engl. Ed.) 2022, 9, 836–863. [Google Scholar]

- Yuan, D.; Xing, C.; Jiang, W.; Xiao, J.; Wu, W.; Li, P.; Li, Y. Viscoelastic Behavior and Phase Structure of High-Content SBS-Modified Asphalt. Polymers 2022, 14, 2476. [Google Scholar] [CrossRef] [PubMed]

- Zhang, F.; Yu, J. The research for high-performance SBR compound modified asphalt. Constr. Build. Mater. 2010, 24, 410–418. [Google Scholar]

- Vargas, M.A.; Vargas, M.A.; Sánchez-Sólis, A.; Manero, O. Asphalt/polyethylene blends: Rheological properties, microstructure and viscosity modeling. Constr. Build. Mater. 2013, 45, 243–250. [Google Scholar]

- Davoodi, A.; Aboutalebi Esfahani, M.; Bayat, M.; Mohammadyan-Yasouj, S.E.; Rahman, A. Influence of nano-silica modified rubber mortar and EVA modified porous asphalt on the performance improvement of modified semi-flexible pavement. Constr. Build. Mater. 2022, 337, 127573. [Google Scholar]

- Yan, K.; Chen, J.; You, L.; Tian, S. Characteristics of compound asphalt modified by waste tire rubber (WTR) and ethylene vinyl acetate (EVA): Conventional, rheological, and microstructural properties. J. Clean. Prod. 2020, 258, 120732. [Google Scholar]

- Liu, G.; Zhang, W.; Yang, X.; Ning, Z. Study on the Conventional Performance and Microscopic Properties of PPA/SBS-Modified Bio-Mixed Asphalt. Materials 2022, 15, 4101. [Google Scholar] [CrossRef]

- Babagoli, R.; Rezaei, M. Development of prediction models for moisture susceptibility of asphalt mixture containing combined SBR, waste CR and ASA using support vector regression and artificial neural network methods. Constr. Build. Mater. 2022, 322, 126430. [Google Scholar]

- Hemmati, N.; Yun, J.; Mazumder, M.; Lee, M.-S.; Lee, S.-J. Laboratory Characterization of Asphalt Binders Modified with Styrene Butadiene Rubber (SBR). Materials 2021, 14, 7666. [Google Scholar] [CrossRef]

- Santero, N.J.; Masanet, E.; Horvath, A. Life-cycle assessment of pavements. Part I: Critical review. Resour. Conserv. Recycl. 2011, 55, 801–809. [Google Scholar]

- Wang, T.; Xiao, F.; Zhu, X.; Huang, B.; Wang, J.; Amirkhanian, S. Energy consumption and environmental impact of rubberized asphalt pavement. J. Clean. Prod. 2018, 180, 139–158. [Google Scholar]

- Rondón-Quintana, H.A.; Reyes-Lizcano, F.A.; Chaves-Pabón, S.B.; Bastidas-Martínez, J.G.; Zafra-Mejía, C.A. Use of Biochar in Asphalts: Review. Sustainability 2022, 14, 4745. [Google Scholar] [CrossRef]

- Li, D.; Li, C.; Fan, M.; Shao, Y.; Sun, Y.; Zhang, L.; Zhang, S.; Huang, Y.; Li, B.; Wang, S.; et al. Investigation of property of biochar in staged pyrolysis of cellulose. J. Anal. Appl. Pyrolysis 2023, 172, 105999. [Google Scholar]

- Calixto, G.Q.; Melo, D.M.A.; Melo, M.A.F.; Braga, R.M. Analytical pyrolysis (Py–GC/MS) of corn stover, bean pod, sugarcane bagasse, and pineapple crown leaves for biorefining. Braz. J. Chem. Eng. 2022, 39, 137–146. [Google Scholar]

- Raček, J.; Chorazy, T.; Miino, M.C.; Vršanská, M.; Brtnický, M.; Mravcová, L.; Kučerík, J.; Hlavínek, P. Biochar production from the pyrolysis of food waste: Characterization and implications for its use. Sustain. Chem. Pharm. 2023, 37, 101387. [Google Scholar]

- Kumar, A.; Choudhary, R.; Narzari, R.; Kataki, R.; Shukla, S.K.; Chailleux, E. Evaluation of bio-asphalt binders modified with biochar: A pyrolysis by-product of Mesua ferrea seed cover waste. Cogent Eng. 2018, 5, 1548534. [Google Scholar] [CrossRef]

- Zhang, R.; Dai, Q.; You, Z.; Wang, H.; Peng, C. Rheological Performance of Bio-Char Modified Asphalt with Different Particle Sizes. Appl. Sci. 2018, 8, 1665. [Google Scholar] [CrossRef]

- Ma, F.; Dai, J.; Fu, Z.; Li, C.; Wen, Y.; Jia, M.; Wang, Y.; Shi, K. Biochar for asphalt modification: A case of high-temperature properties improvement. Sci. Total Environ. 2022, 804, 150194. [Google Scholar]

- Hu, C.; Feng, J.; Zhou, N.; Zhu, J.; Zhang, S. Hydrochar from corn stalk used as bio-asphalt modifier: High-temperature performance improvement. Environ. Res. 2021, 193, 110157. [Google Scholar]

- Zhao, S.; Huang, B.; Shu, X.; Ye, P. Laboratory Investigation of Biochar-Modified Asphalt Mixture. Transp. Res. Rec. J. Transp. Res. Board 2014, 2445, 56–63. [Google Scholar]

- Zhou, X.; Moghaddam, T.B.; Chen, M.; Wu, S.; Adhikari, S. Biochar removes volatile organic compounds generated from asphalt. Sci. Total Environ. 2020, 745, 141096. [Google Scholar]

- Li, N.; Jiang, Q.; Wang, F.; Xie, J.; Li, Y.; Li, J.; Wu, S. Emission behavior, environmental impact and priority-controlled pollutants assessment of volatile organic compounds (VOCs) during asphalt pavement construction based on laboratory experiment. J. Hazard. Mater. 2020, 398, 122904. [Google Scholar] [PubMed]

- Zhou, Y.; Shen, C.; Wang, T.; Xue, Y. Inhibition effect of three types of biochar on volatile organic compounds from asphalt: Revealing chemical adsorption as the primary mechanism. Constr. Build. Mater. 2023, 411, 134322. [Google Scholar] [CrossRef]

- Xia, Y.; Zhu, C.; Ouyang, S.; Yang, Y.; Xie, Y.; Deng, T.; Li, L.; Yang, K.; Xiao, Y.; Tsang, C.-W. Thermogravimetric characteristics and evaluation of products during pyrolysis of Camellia oleifera seed residues. Biomass Convers. Biorefin. 2024, 15, 4677–4693. [Google Scholar] [CrossRef]

- Ostadi Moghadam, M.; Moeenfard, M. How does particle size of spent coffee ground affect the physicochemical properties of isolated cellulose nanosphere? Results Chem. 2024, 10, 101683. [Google Scholar]

- Deb Dutta, S.; Patel, D.K.; Ganguly, K.; Lim, K.-T. Isolation and characterization of cellulose nanocrystals from coffee grounds for tissue engineering. Mater. Lett. 2021, 287, 129311. [Google Scholar]

- ASTM D5; Standard Test Method for Penetration of Bituminous Materials. ASTM International: West Conshohocken, PA, USA, 2020.

- ASTM D36; Standard Test Method for Softening Point of Bitumen (Ring-and-Ball Apparatus). ASTM International: West Conshohocken, PA, USA, 2014.

- ASTM D113-17; Standard Test Method for Ductility of Asphalt Materials. ASTM International: West Conshohocken, PA, USA, 2017.

- Zhou, X.; Adhikari, S. Flow-induced crystallization of biochar in bio-asphalt under various aging conditions. Sci. Total Environ. 2019, 695, 133943. [Google Scholar] [CrossRef]

- Yang, S.; Zhu, H.; Tan, Q.; Yang, X.; Chen, Y.; Lei, L. Application of TOR as a secondary modifier for the preparation of crumb rubber modified asphalt with excellent storage stability. Constr. Build. Mater. 2024, 428, 135863. [Google Scholar] [CrossRef]

- Li, Y.; Ma, R.; Wang, X.; Cheng, P.; Chen, Y. Improvement effect of different modifiers on storage stability of high content SBS modified asphalt. Case Stud. Constr. Mater. 2024, 20, e02820. [Google Scholar]

- Al-Abdul Wahhab, H.I.; Dalhat, M.A.; Habib, M.A. Storage stability and high-temperature performance of asphalt binder modified with recycled plastic. Road Mater. Pavement Des. 2016, 18, 1117–1134. [Google Scholar]

- ASTM D7173-14; Standard Practice for Determining the Separation Tendency of Polymer from Polymer Modified Asphalt. ASTM International: West Conshohocken, PA, USA, 2014.

- Han, C.D.; Kim, J.; Kim, J.K. Determination of the Order-Disorder Transition Temperature of Block Copolymers. Macromolecules 1989, 22, 383–394. [Google Scholar] [CrossRef]

- Han, C.D.; Baek, D.M.; Kim, J.K.; Ogawa, T.; Sakamoto, N.; Hashimoto, T. Effect of Volume Fraction on the Order Disorder Transition in Low Molecular Weight Polystyrene-block-Polyisoprene Copolymers. Marcomolecules 1995, 28, 5043–5062. [Google Scholar]

- Yang, Z.; Han, C.D. Rheology of Miscible Polymer Blends with Hydrogen Bonding. Macromolecules 2008, 3, 15. [Google Scholar] [CrossRef]

- ASTM D6648-16; Standard Test Method for Determining the Flexural Creep Stiffness of Asphalt Binder Using the Bending Beam Rheometer (BBR). ASTM International: West Conshohocken, PA, USA, 2016.

- Ren, H.; Qian, Z.; Huang, W.; Li, H.; Liu, Y. Low-temperature thermal cracking performance of waterborne epoxy asphalt emulsion mastic based on bending beam rheometer (BBR). Constr. Build. Mater. 2022, 334, 127461. [Google Scholar]

- Ministry of Commerce, People’s Republic of China. Stationary Source Emission-Determination of Volatile Organic Compounds-Sorbent Adsorption and Thermal Desorption Gas Chromatography Mass Spectrometry Method; China Environment Publish Group: Beijing, China, 2014; Volume HJ 734-2014.

- Ariyanti, D.; Purbasari, A.; Sugianto, D.N.; Lesdantina, D.; Widiyanti, M. Rice husk-based magnetic biochar produced via hydrothermal route for petroleum spills adsorption: Characterization, adsorption kinetics, and isotherms. Adsorption 2024, 30, 2175–2186. [Google Scholar]

- Gao, W.; Lin, Z.; Yan, S.; Gao, Y.; Zhang, H.; Hu, X.; Sun, H.; Zhang, S. Preparation of N-, O-, and S-Tri-Doped Biochar through One-Pot Pyrolysis of Poplar and Urea Formaldehyde and Its Enhanced Removal of Tetracycline from Wastewater. Energies 2022, 15, 8081. [Google Scholar] [CrossRef]

- Mastalerz, M.; Drobniak, A.; Briggs, D.; Bradburn, J. Variations in microscopic properties of biomass char: Implications for biochar characterization. Int. J. Coal Geol. 2023, 271, 104235. [Google Scholar]

- Zhang, S.; Cui, Y.; Wei, W. Low-temperature characteristics and microstructure of asphalt under complex aging conditions. Constr. Build. Mater. 2021, 303, 124408. [Google Scholar] [CrossRef]

- Yu, S.; Zhou, J.; Ren, Y.; Yang, Z.; Zhong, M.; Feng, X.; Su, B.; Lei, Z. Excellent adsorptive-photocatalytic performance of zinc oxide and biomass derived N, O-contained biochar nanocomposites for dyes and antibiotic removal. Chem. Eng. J. 2022, 451, 138959. [Google Scholar]

- El-Nemr, M.A.; Ismail, I.M.A.; Abdelmonem, N.M.; El Nemr, A.; Ragab, S. Amination of biochar surface from watermelon peel for toxic chromium removal enhancement. Chin. J. Chem. Eng. 2021, 36, 199–222. [Google Scholar] [CrossRef]

- Gan, X.; Zhang, W. Application of biochar from crop straw in asphalt modification. PLoS ONE 2021, 16, e0247390. [Google Scholar] [CrossRef]

- Mohan, V.B.; Jayaraman, K.; Bhattacharyya, D. Brunauer–Emmett–Teller (BET) specific surface area analysis of different graphene materials: A comparison to their structural regularity and electrical properties. Solid State Commun. 2020, 320, 114004. [Google Scholar] [CrossRef]

- Maziarka, P.; Wurzer, C.; Arauzo, P.J.; Dieguez-Alonso, A.; Mašek, O.; Ronsse, F. Do you BET on routine? The reliability of N2 physisorption for the quantitative assessment of biochar’s surface area. Chem. Eng. J. 2021, 418, 129234. [Google Scholar] [CrossRef]

- Al-Ghouti, M.A.; Da’ana, D.A. Guidelines for the use and interpretation of adsorption isotherm models: A review. J. Hazard. Mater. 2020, 393, 122383. [Google Scholar] [CrossRef] [PubMed]

- Thommes, M.; Kaneko, K.; Neimark, A.V.; Olivier, J.P.; Rodriguez-Reinoso, F.; Rouquerol, J.; Sing, K.S.W. Physisorption of gases, with special reference to the evaluation of surface area and pore size distribution (IUPAC Technical Report). Pure Appl. Chem. 2015, 87, 1051–1069. [Google Scholar] [CrossRef]

- Svidrytski, A.; Hlushkou, D.; Thommes, M.; Monson, P.A.; Tallarek, U. Modeling the Impact of Mesoporous Silica Microstructures on the Adsorption Hysteresis Loop. J. Phys. Chem. C 2020, 124, 21646–21655. [Google Scholar] [CrossRef]

- Zhang, H.; Li, J.; Gong, M. Studying the anti-ageing performance of road asphalt based on penetration and ductility. Proc. Inst. Civ. Eng.—Eng. Sustain. 2021, 174, 199–210. [Google Scholar] [CrossRef]

- Yang, S.; Zhu, H.; Li, R.; Yang, X.; Tan, Q.; Chen, Y.; Lei, L. Application of functionalized graphene oxide in the preparation of crumb rubber modified asphalt with excellent storage stability. Constr. Build. Mater. 2024, 450, 138488. [Google Scholar] [CrossRef]

- Iftikhar, S.; Shah, P.M.; Mir, M.S. Potential Application of Various Nanomaterials on the Performance of Asphalt Binders and Mixtures: A Comprehensive Review. Int. J. Pavement Res. Technol. 2022, 16, 1439–1467. [Google Scholar] [CrossRef]

- Ding, Z.; Zhang, J.; Li, P.; Yue, X.; Bing, H. Analysis of viscous flow properties of styrene–butadiene–styrene-modified asphalt. Constr. Build. Mater. 2019, 229, 116881. [Google Scholar] [CrossRef]

- Li, P.; Ding, Z.; Ma, L.X.; Feng, Z.G. Analysis of viscous flow properties of asphalt in aging process. Constr. Build. Mater. 2016, 124, 631–638. [Google Scholar]

- Lu, Q.; Sha, A.; Jiao, W.; Shi, K.; Li, Z.; Chen, Y.; Du, P.; Peng, Z.; Song, R. Waste coffee biochar and bi-oil composite modified rejuvenated asphalt: Preparation, characterization, and performance evaluation. Constr. Build. Mater. 2024, 450, 138588. [Google Scholar] [CrossRef]

- Rosińska, A. Impact of biochar on sorption of polycyclic aromatic hydrocarbons in water. Desalination Water Treat. 2023, 305, 103–113. [Google Scholar]

- Jia, H.; Ye, J.; Wu, Y.; Zhang, M.; Peng, W.; Wang, H.; Tang, D. Evaluation and characterization of biochar on the biogeochemical behavior of polycyclic aromatic hydrocarbons in mangrove wetlands. Sci. Total Environ. 2022, 864, 161039. [Google Scholar]

- Azman, N.A.; Fuzi, S.F.Z.M.; Manas, N.H.A.; Azelee, N.I.W.; Masngut, N. Improved heterocyclic aromatic hydrocarbon compound adsorption using functionalised rice husk biochar. Bioresour. Technol. Rep. 2023, 25, 101704. [Google Scholar]

- Ge, L.; Yao, Y.; Xu, L.; Zhou, Z.; Li, J.; Zhang, X.; Liu, C.; Lv, H. Mitigation of asphalt volatile organic compounds emissions and health hazards using a TiO2-doped biochar composite: Microscopic and physiological insights. Environ. Technol. Innov. 2024, 36, 103763. [Google Scholar]

| Technical Indexes | Units | Results | Requirements | Standards |

|---|---|---|---|---|

| Penetration (25 °C) | 0.1 mm | 69 | 60–80 | ASTM D5 [28] |

| Softening Point | °C | 48 | ≥46 | ASTM D36 [29] |

| Ductility (15 °C) | cm | >100 | >100 | ASTM D113-17 [30] |

| Variety | CO | CG | CA |

|---|---|---|---|

| Surface area (m2/g) | 66.4172 | 11.3879 | 15.7413 |

| Pore volume (cm3/g) | 0.0421 | 0.0137 | 0.0150 |

| t-Plot micropore area (m2/g) | 41.1906 | 9.4560 | 14.7117 |

| t-Plot micropore volume (cm3/g) | 0.0176 | 0.0037 | 0.0060 |

| BJH mesopore area (m2/g) | 27.2051 | 1.0192 | 1.2887 |

| BJH mesopore volume (cm3/g) | 0.0256 | 0.0098 | 0.0092 |

| Sample | Content (%) | Penetration (dmm) | Penetration Index | Softening Point (°C) | Ductility (cm) | ||

|---|---|---|---|---|---|---|---|

| 15 °C | 25 °C | 30 °C | |||||

| Virgin | 0 | 29.17 | 77.62 | 124.27 | −0.32726 | 49.42 | >100 |

| CG | 1 | 28.31 | 73.30 | 115.92 | −0.14617 | 49.78 | 75 |

| 6 | 23.44 | 69.82 | 110.00 | −0.78907 | 51.11 | 30 | |

| 9 | 18.68 | 57.23 | 100.18 | −1.25747 | 51.98 | <20 | |

| CA | 1 | 25.81 | 72.11 | 120.54 | −0.71495 | 50.41 | 78 |

| 6 | 23.00 | 64.27 | 107.43 | −0.71639 | 51.45 | 25 | |

| 9 | 22.68 | 63.97 | 108.43 | −0.80601 | 52.06 | <20 | |

| CO | 1 | 28.83 | 76.64 | 124.94 | −0.39385 | 50.01 | 82 |

| 6 | 24.22 | 67.87 | 113.61 | −0.73359 | 50.55 | 27 | |

| 9 | 23.11 | 62.69 | 103.25 | −0.52731 | 51.72 | <20 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, X.; Zhou, Y.; Xue, Y. Biochars from Cotton Seed, Camelia Seed Shell, and Coffee Ground in Modification of Asphalt: Fundamental Properties, Rheological Performance, and Inhibition of VOC Emissions. Materials 2025, 18, 1504. https://doi.org/10.3390/ma18071504

Zhang X, Zhou Y, Xue Y. Biochars from Cotton Seed, Camelia Seed Shell, and Coffee Ground in Modification of Asphalt: Fundamental Properties, Rheological Performance, and Inhibition of VOC Emissions. Materials. 2025; 18(7):1504. https://doi.org/10.3390/ma18071504

Chicago/Turabian StyleZhang, Xiao, Yi Zhou, and Yongjie Xue. 2025. "Biochars from Cotton Seed, Camelia Seed Shell, and Coffee Ground in Modification of Asphalt: Fundamental Properties, Rheological Performance, and Inhibition of VOC Emissions" Materials 18, no. 7: 1504. https://doi.org/10.3390/ma18071504

APA StyleZhang, X., Zhou, Y., & Xue, Y. (2025). Biochars from Cotton Seed, Camelia Seed Shell, and Coffee Ground in Modification of Asphalt: Fundamental Properties, Rheological Performance, and Inhibition of VOC Emissions. Materials, 18(7), 1504. https://doi.org/10.3390/ma18071504