Comparison of Mechanical and Optical Properties of Multilayer Zirconia After High-Speed and Repeated Sintering

Abstract

1. Introduction

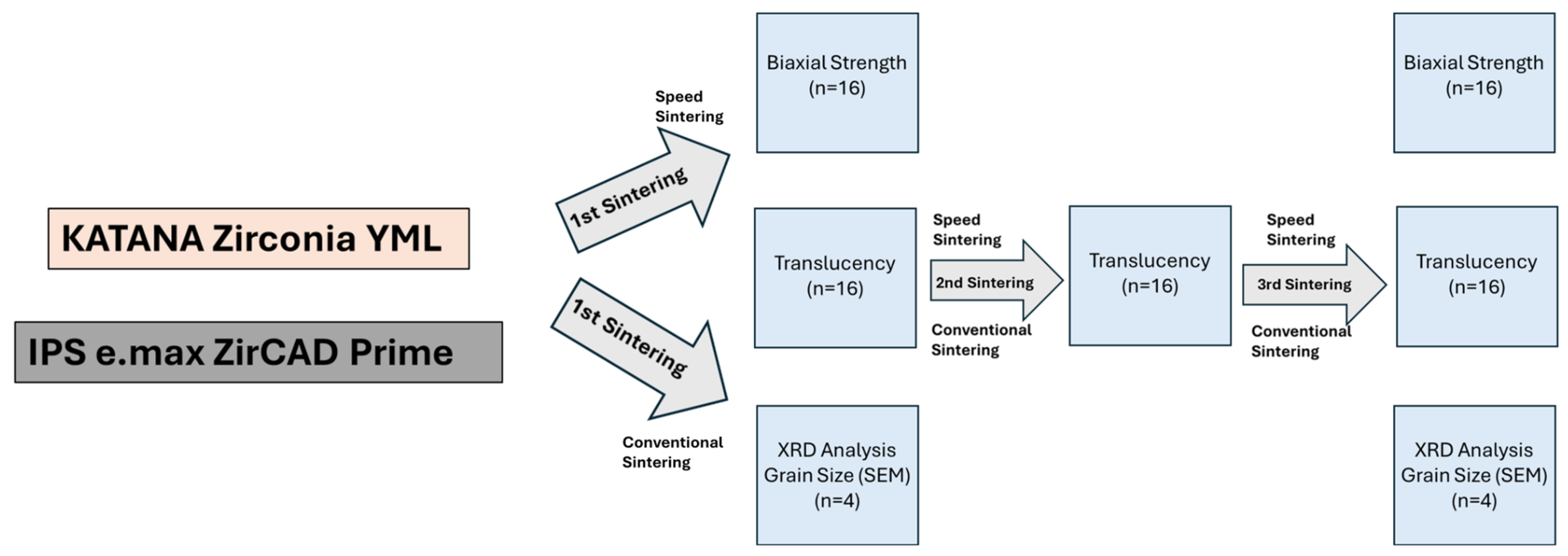

2. Materials and Methods

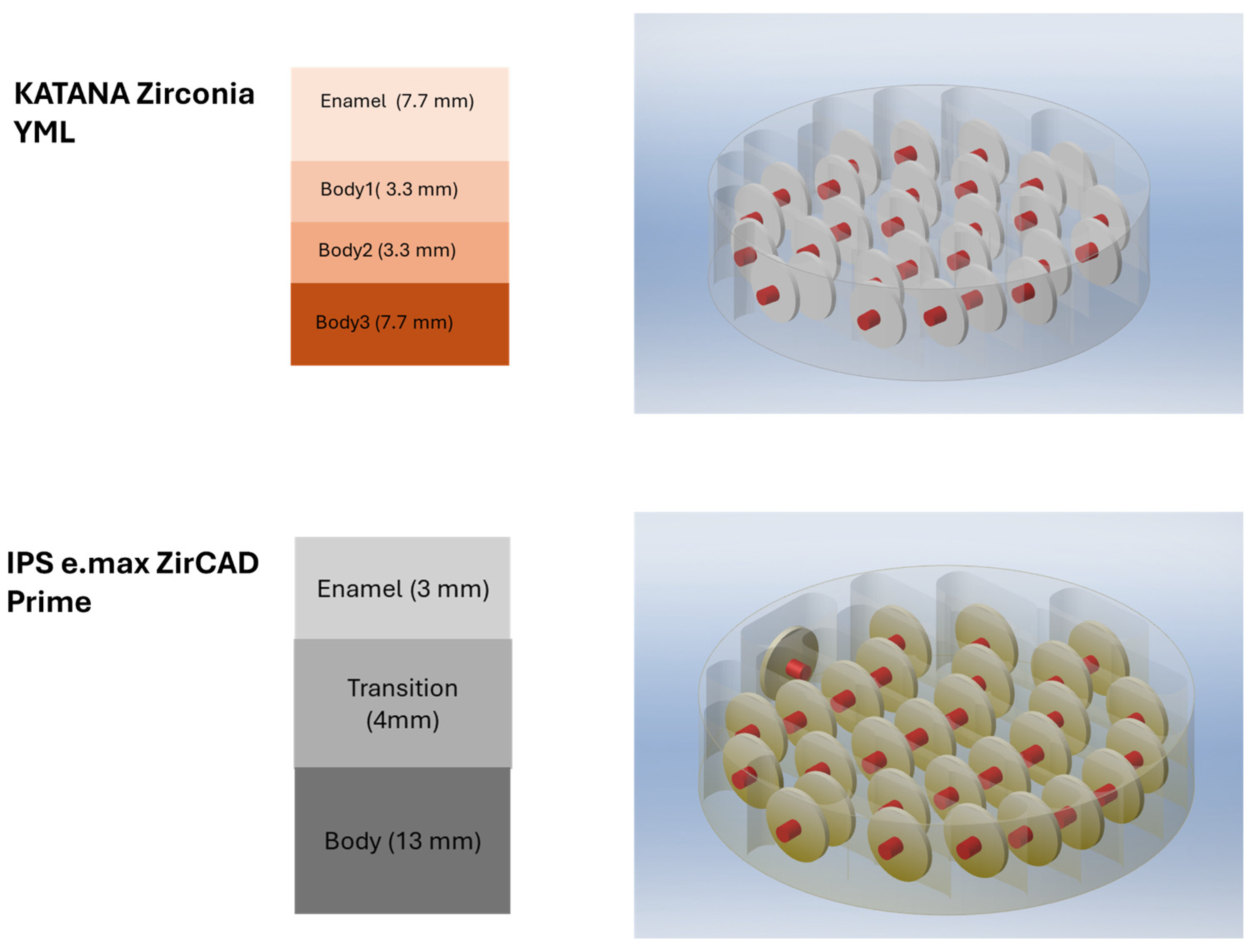

2.1. Specimen Preparation

2.2. Biaxial Flexural Strength

2.3. SEM Microstructural Analysis

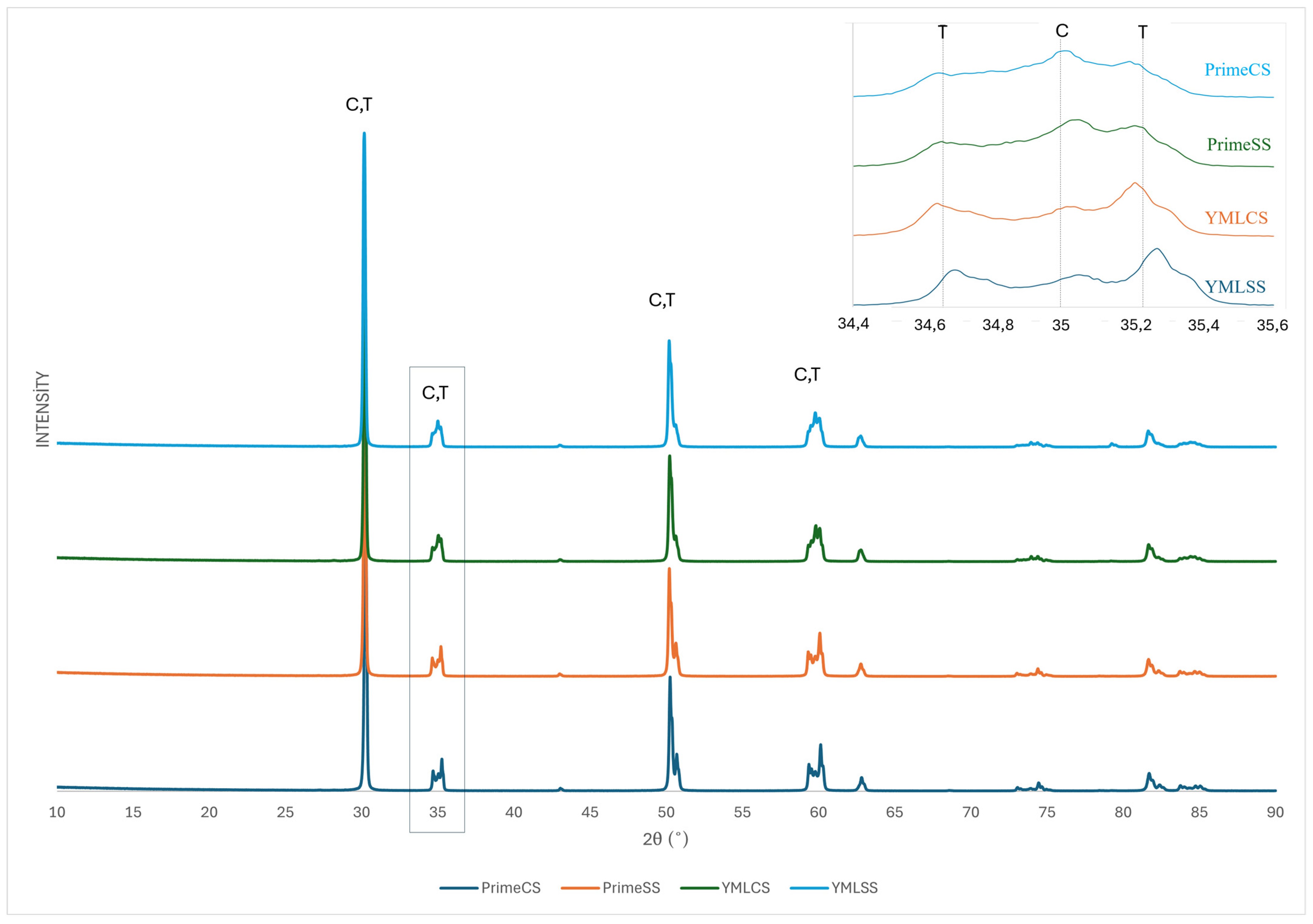

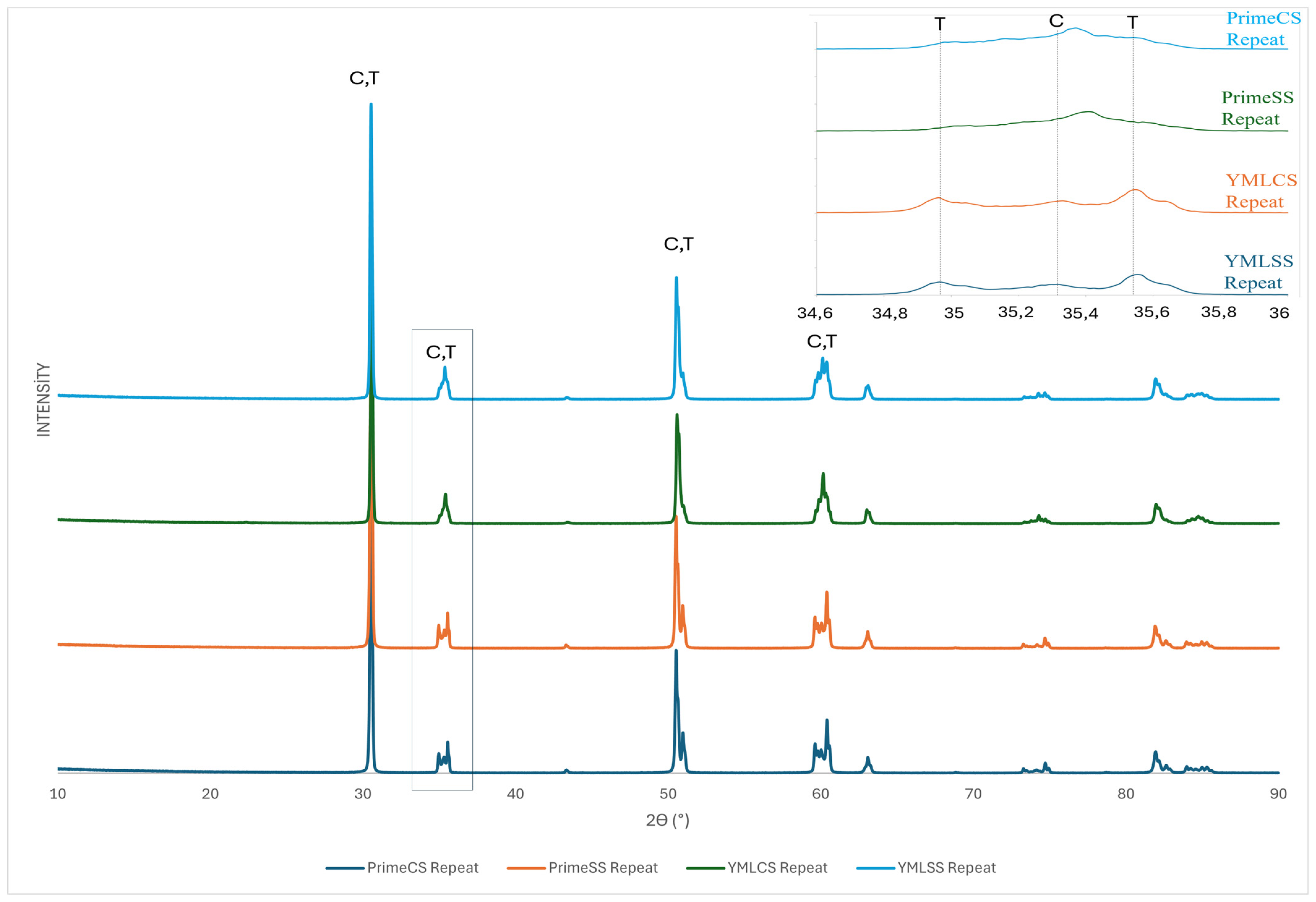

2.4. XRD Phase Analysis

2.5. Translucency

2.6. Statistical Analysis

3. Results

3.1. Biaxial Flexural Strength

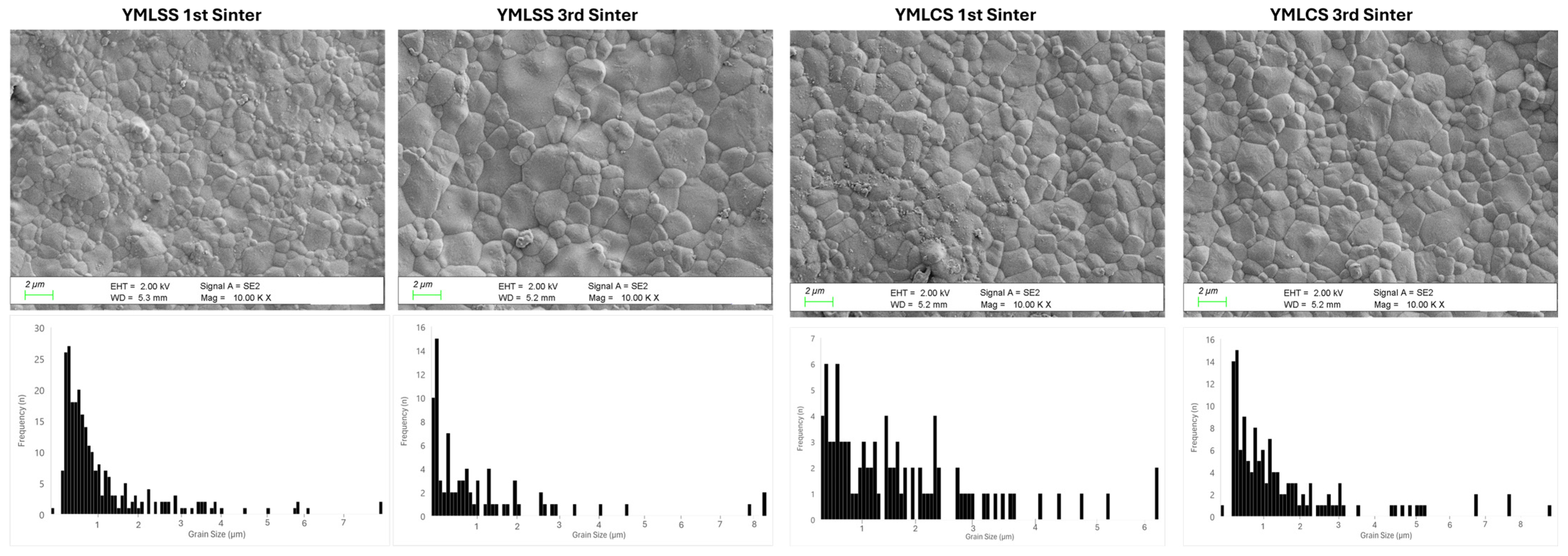

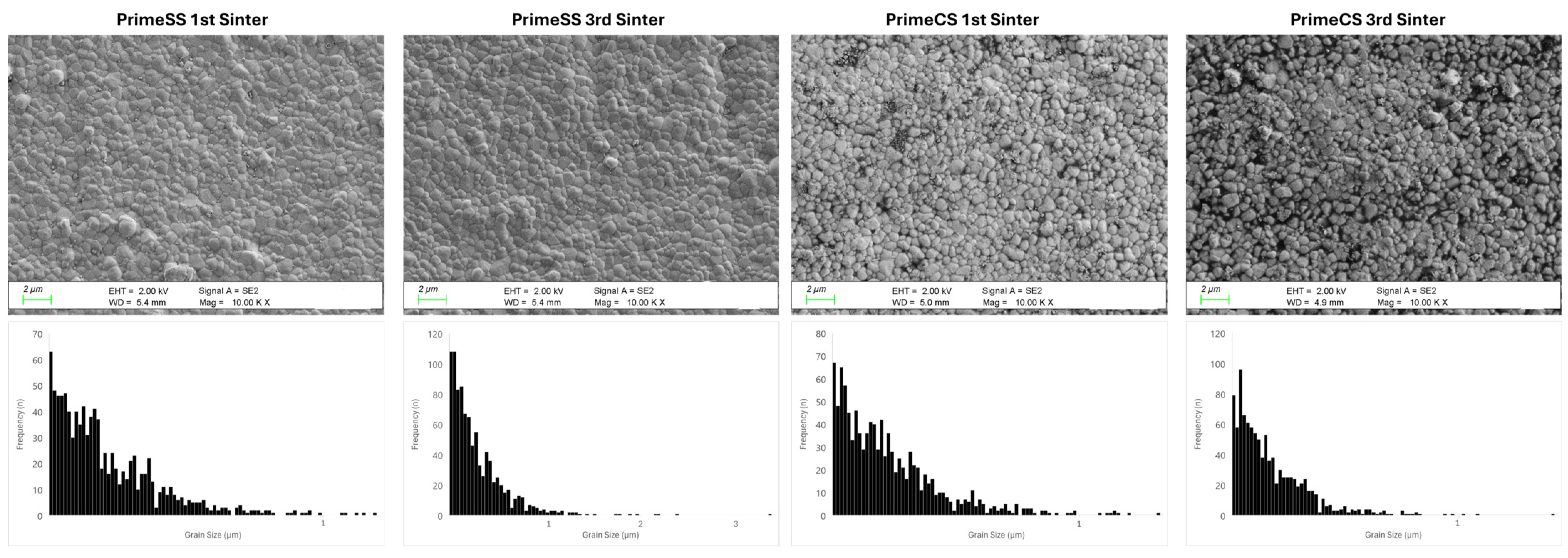

3.2. SEM Microstructural Analysis

3.3. XRD Phase Analysis

3.4. Translucency

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Sen, N.; Sermet, I.B.; Cinar, S. Effect of Coloring and Sintering on the Translucency and Biaxial Strength of Monolithic Zirconia. J. Prosthet. Dent. 2018, 119, 308.e1–308.e7. [Google Scholar] [CrossRef] [PubMed]

- Bakitian, F. Flexural Strength of Translucent Zirconia Materials Produced with Different Multilayer Technologies: An in Vitro Study. Int. J. Dent. 2024, 2024, 8410101. [Google Scholar] [CrossRef] [PubMed]

- Pekkan, G.; Pekkan, K.; Bayindir, B.Ç.; Özcan, M.; Karasu, B. Factors Affecting the Translucency of Monolithic Zirconia Ceramics: A Review from Materials Science Perspective. Dent. Mater. J. 2020, 39, 1–8. [Google Scholar]

- Maharishi, A.; McLaren, E.A.; White, S.N. Color- and Strength-Graded Zirconia: Strength, Light Transmission, and Composition. J. Prosthet. Dent. 2024, 131, 1236.e1–1236.e9. [Google Scholar] [CrossRef] [PubMed]

- Kanpalta, B.; Burduro, D.; Kara, Ö. Effect of Artificial Aging on the Translucency of Monolithic Zirconia Materials Sintered at Different Temperatures. J. Prosthet. Dent. 2022, 128, 91.e1–91.e6. [Google Scholar]

- Madruga, C.F.L.; Dal Piva, A.M.d.O.; Pereira, G.K.R.; Caneppele, T.M.F.; Valandro, L.F.; Bottino, M.A. Sintering Mode of a Translucent Y-TZP: Effects on Its Biaxial Flexure Fatigue Strength, Surface Morphology and Translucency. J. Esthet. Restor. Dent. 2022, 34, 1197–1205. [Google Scholar] [CrossRef]

- Munoz, A.; Zhao, Z.; Paolone, G.; Louca, C.; Vichi, A. Flexural Strength of CAD/CAM Lithium-Based Silicate Glass–Ceramics: A Narrative Review. Materials 2023, 16, 4398. [Google Scholar] [CrossRef]

- Melc, T.; Attin, T.; Eyüboğlu, T.F.; Özcan, M. Flexural Strength of Modern CAD/CAM Restoratives After Artificial Aging. Materials 2024, 17, 5178. [Google Scholar] [CrossRef]

- Ban, S. Classification and Properties of Dental Zirconia as Implant Fixtures and Superstructures. Materials 2021, 14, 4879. [Google Scholar] [CrossRef]

- Strasser, T.; Wertz, M.; Koenig, A.; Koetzsch, T.; Rosentritt, M. Microstructure, Composition, and Flexural Strength of Different Layers within Zirconia Materials with Strength Gradient. Dent. Mater. 2023, 39, 463–468. [Google Scholar] [CrossRef]

- Silmeoglu Yagli, O.; Talay Cevlik, E.; Kurklu Arpacay, D. The Impact of Aging and Thickness on Flexural Strength of Various Zirconia Ceramics. BMC Oral Health 2024, 24, 967. [Google Scholar] [CrossRef] [PubMed]

- Labetić, A.; Klaser, T.; Skoko, Ž.; Jakovac, M.; Žic, M. Flexural Strength and Morphological Study of Different Multilayer Zirconia Dental Materials. Materials 2024, 17, 1143. [Google Scholar] [CrossRef]

- Michailova, M.; Elsayed, A.; Fabel, G.; Edelhoff, D.; Zylla, I.M.; Stawarczyk, B. Comparison between Novel Strength-Gradient and Color-Gradient Multilayered Zirconia Using Conventional and High-Speed Sintering. J. Mech. Behav. Biomed. Mater. 2020, 111, 103977. [Google Scholar] [CrossRef] [PubMed]

- Yang, S.; Li, Q.; Chen, S.-Y.; Yu, H. Effect of Multiple Firings on the Marginal Fit of Monolithic Zirconia Crowns: An in Vitro Study. J. Prosthet. Dent. 2023, 130, 897–901. [Google Scholar] [CrossRef]

- Altan, B.; Cinar, S. Effect of Repeated Firings and Thickness on Optical Properties of Variable Preshaded and Shaded Novel Translucent Zirconia Blocks. BioMed Res. Int. 2022, 2022, 8572782. [Google Scholar] [CrossRef]

- Durkan, R.; Deste Gökay, G.; Şimşek, H.; Yilmaz, B. Biaxial Flexural Strength and Phase Transformation Characteristics of Dental Monolithic Zirconia Ceramics with Different Sintering Durations: An in Vitro Study. J. Prosthet. Dent. 2022, 128, 498–504. [Google Scholar] [CrossRef]

- Inokoshi, M.; Liu, H.; Yoshihara, K.; Yamamoto, M.; Tonprasong, W.; Benino, Y.; Minakuchi, S.; Vleugels, J.; Van Meerbeek, B.; Zhang, F. Layer Characteristics in Strength-Gradient Multilayered Yttria-Stabilized Zirconia. Dent. Mater. 2023, 39, 430–441. [Google Scholar] [CrossRef] [PubMed]

- Sharma, G.; Wu, W.; Dalal, E.N. The CIEDE2000 Color-Difference Formula: Implementation Notes, Supplementary Test Data, and Mathematical Observations. Col. Res. Appl. 2005, 30, 21–30. [Google Scholar] [CrossRef]

- Winter, A.; Schurig, A.; Odenthal, A.L.; Schmitter, M. Impact of Different Layers within a Blank on Mechanical Properties of Multi-Layered Zirconia Ceramics before and after Thermal Aging. Dent. Mater. 2022, 38, e147–e154. [Google Scholar] [CrossRef]

- Stawarczyk, B.; Keul, C.; Eichberger, M.; Figge, D.; Edelhoff, D.; Lümkemann, N. Three Generations of Zirconia: From Veneered to Monolithic. Part I. Quintessence Int. 2017, 48, 369–380. [Google Scholar] [CrossRef]

- Katada, H.; Inokoshi, M.; Kamijo, S.; Liu, H.; Xu, K.; Kawashita, M.; Yokoi, T.; Shimabukuro, M.; Minakuchi, S. Effects of Multiple Firings on the Translucency, Crystalline Phase, and Mechanical Strength of Highly Translucent Zirconia. Dent. Mater. J. 2024, 43, 294–302. [Google Scholar] [CrossRef] [PubMed]

- Gülce, M.; Subaşı, S.; Çakmak, G.; Sert, M.; Yilmaz, B. Effect of Multiple Firings on Surface Roughness and Flexural Strength of CAD-CAM Ceramics. J. Prosthet. Dent. 2022, 128, 216.e1–216.e8. [Google Scholar]

- Di Cho Too, T.; Inokoshi, M.; Nozaki, K.; Shimizubata, M.; Nakai, H.; Liu, H.; Minakuchi, S. Influence of Sintering Conditions on Translucency, Biaxial Flexural Strength, Microstructure, and Low-Temperature Degradation of Highly Translucent Dental Zirconia. Dent. Mater. J. 2021, 40, 1320–1328. [Google Scholar] [CrossRef]

- Cokic, S.M.; Vleugels, J.; Van Meerbeek, B.; Camargo, B.; Willems, E.; Li, M.; Zhang, F. Mechanical Properties, Aging Stability and Translucency of Speed-Sintered Zirconia for Chairside Restorations. Dent. Mater. 2020, 36, 959–972. [Google Scholar] [CrossRef]

- Shin, H.J.; Kwon, Y.H.; Seol, H.J. Effect of Superspeed Sintering on Translucency, Opalescence, Microstructure, and Phase Fraction of Multilayered 4 Mol% Yttria-Stabilized Tetragonal Zirconia Polycrystal and 6 Mol% Yttria-Stabilized Partially Stabilized Zirconia Ceramics. J. Prosthet. Dent. 2023, 130, 254.e1–254.e10. [Google Scholar] [CrossRef] [PubMed]

- Jansen, J.U.; Lümkemann, N.; Letz, I.; Pfefferle, R.; Sener, B.; Stawarczyk, B. Impact of High-Speed Sintering on Translucency, Phase Content, Grain Sizes, and Flexural Strength of 3Y-TZP and 4Y-TZP Zirconia Materials. J. Prosthet. Dent. 2019, 122, 396–403. [Google Scholar] [CrossRef]

- Tuncel, I.; Turp, I.; Üsümez, A. Evaluation of Translucency of Monolithic Zirconia and Framework Zirconia Materials. J. Adv. Prosthodont. 2016, 8, 181–186. [Google Scholar] [CrossRef]

- Salas, M.; Lucena, C.; Herrera, L.J.; Yebra, A.; Della Bona, A.; Pérez, M.M. Translucency Thresholds for Dental Materials. Dent. Mater. 2018, 34, 1168–1174. [Google Scholar] [CrossRef]

| YMLSS | YMLCS | PrimeSS | PrimeCS | |

|---|---|---|---|---|

| Heating Rate (°C/min) | 50 °C/min (1400 °C) 4 °C/min (1500 °C) 10 °C/min (1560 °C) | 10 °C/min (1550 °C) | 60 °C/min (1000 °C) 3 °C/min (1530 °C) | 10 °C/min (900 °C) 3.3 °C/min (1500 °C) |

| Sintering | 1560 °C for 16 min | 1550 °C for120 min | 1000 °C for 10 min 1530 °C for 60 min | 900 °C for 30 min 1500 °C for 120 min |

| Cooling Rate (°C/min) | 50 °C/min (800 °C) | 10 °C/min (37 °C) | 50 °C/min (1100 °C) 60 °C/min (100 °C) | 10 °C/min (900 °C) 8.3 °C/min (300 °C) |

| Sintering Mode | Repeated Sintering | Brand | Mean | |

|---|---|---|---|---|

| Prime | YML | |||

| SS | 1st sintering | 631.47 ± 8.72 | 835.29 ± 9.06 | 733.38 ± 104.01 |

| 3rd sintering | 629.86 ± 26.12 | 866.95 ± 24.85 | 748.41 ± 123.15 | |

| Mean | 630.67 ± 19.15 C | 851.12 ± 24.43 A | 740.89 ± 113.27 | |

| CS | 1st sintering | 625.10 ± 5.8 | 817.46 ± 10.86 | 721.28 ± 98.2 |

| 3rd sintering | 624.11 ± 10.38 | 843.67 ± 33.85 | 733.89 ± 114.33 | |

| Mean | 624.61 ± 8.28 C | 830.56 ± 28.06 B | 727.59 ± 105.85 | |

| Mean | 1st sintering | 628.29 ± 7.97 C | 826.37 ± 13.36 B | 727.33 ± 100.47 |

| 3rd sintering | 626.98 ± 19.74 C | 855.31 ± 31.49 A | 741.15 ± 118.03 | |

| Mean | 627.64 ± 14.94 | 840.84 ± 28.07 | 734.24 ± 109.37 | |

| t-ZrO2 (wt%) | m-ZrO2 (wt%) | c-ZrO2 (wt%) | |

|---|---|---|---|

| YMLCC | 68.5 | 0.4 | 31.1 |

| YMLSC | 66 | 34 | |

| PrimeCS | 71 | 29 | |

| PrimeSS | 68.6 | 31.4 | |

| YMLCC 3rd | 62.5 | 37.5 | |

| YMLSC 3rd | 60.2 | 39.8 | |

| PrimeCS 3rd | 67.3 | 32.7 | |

| PrimeSS 3rd | 60.8 | 33.1 |

| Repeated Sintering | Mode | Brand | Mean | |

|---|---|---|---|---|

| YML | Prime | |||

| 1st sintering | SS | 7.34 ± 0.12 A | 7.51 ± 0.08 AB | 7.46 ± 0.05 |

| CS | 7.66 ± 0.13 ABC | 7.98 ± 0.61 ABC | 7.58 ± 0.08 | |

| Mean | 7.52 ± 0.08 | 7.49 ± 0.06 | 7.51 ± 0.04 | |

| 2nd sintering | SS | 7.6 ± 0.16 ABC | 7.7 ± 0.04 ABC | 7.69 ± 0.05 |

| CS | 7.75 ± 0.12 ABC | 8.04 ± 0.11 C | 7.92 ± 0.07 | |

| Mean | 7.72 ± 0.08 | 7.88 ± 0.06 | 7.81 ± 0.05 | |

| 3rd sintering | SS | 7.5 ± 0.14 ABC | 7.83 ± 0.08 BC | 7.71 ± 0.05 |

| CS | 7.77 ± 0.13 ABC | 7.55 ± 0.11 ABC | 7.68 ± 0.08 | |

| Mean | 7.67 ± 0.08 | 7.7 ± 0.06 | 7.7 ± 0.05 | |

| Mean | SS | 7.52 ± 0.07 | 7.68 ± 0.04 | 7.62 ± 0.03 |

| CS | 7.75 ± 0.07 | 7.7 ± 0.07 | 7.73 ± 0.05 | |

| Mean | 7.64 ± 0.05 | 7.69 ± 0.04 | ||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Güntekin, N.; Kızılırmak, B.; Tunçdemir, A.R. Comparison of Mechanical and Optical Properties of Multilayer Zirconia After High-Speed and Repeated Sintering. Materials 2025, 18, 1493. https://doi.org/10.3390/ma18071493

Güntekin N, Kızılırmak B, Tunçdemir AR. Comparison of Mechanical and Optical Properties of Multilayer Zirconia After High-Speed and Repeated Sintering. Materials. 2025; 18(7):1493. https://doi.org/10.3390/ma18071493

Chicago/Turabian StyleGüntekin, Neslihan, Burcu Kızılırmak, and Ali Rıza Tunçdemir. 2025. "Comparison of Mechanical and Optical Properties of Multilayer Zirconia After High-Speed and Repeated Sintering" Materials 18, no. 7: 1493. https://doi.org/10.3390/ma18071493

APA StyleGüntekin, N., Kızılırmak, B., & Tunçdemir, A. R. (2025). Comparison of Mechanical and Optical Properties of Multilayer Zirconia After High-Speed and Repeated Sintering. Materials, 18(7), 1493. https://doi.org/10.3390/ma18071493