Multiscale Investigation of Modified Recycled Aggregate Concrete on Sulfate Attack Resistance

Abstract

1. Introduction

2. Experimental Details

2.1. Materials

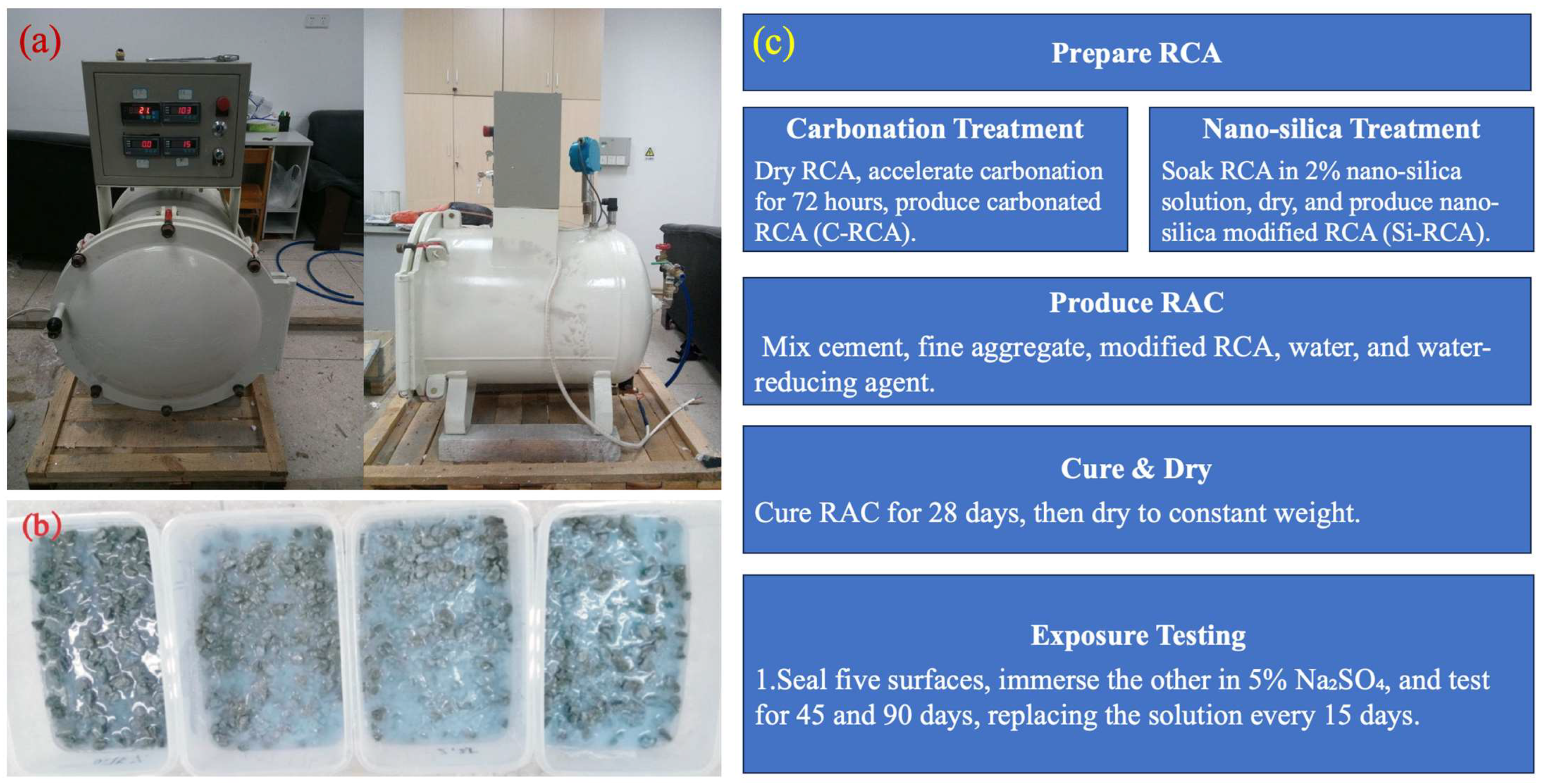

2.2. Sample Preparation and the Sulfate Attack

2.3. Testing

2.3.1. Morphological and Compositional Examination of RCA

2.3.2. Compressive Strength Evaluation and Sulfate Concentration Assessment of RAC

2.3.3. Micro-Mechanical Testing of RAC

- (1)

- Specimen Fabrication: A thin section with a thickness of 10 mm was precisely cut perpendicular to the erosion surface of the RAC using a concrete cutting machine. This thin section was then further divided into two specimens, each with dimensions of 100 mm × 50 mm × 10 mm, using a metallographic cutting machine. The specimens were subsequently dried to constant weight in an oven at 50 °C after replacing the free water with anhydrous ethanol. The specimens underwent grinding using a metallographic grinding machine, employing sandpaper with grit sizes ranging from 75 to 10 μm, while anhydrous ethanol served as a coolant and lubricant. Ultimately, the specimens were polished to produce samples suitable for microhardness testing.

- (2)

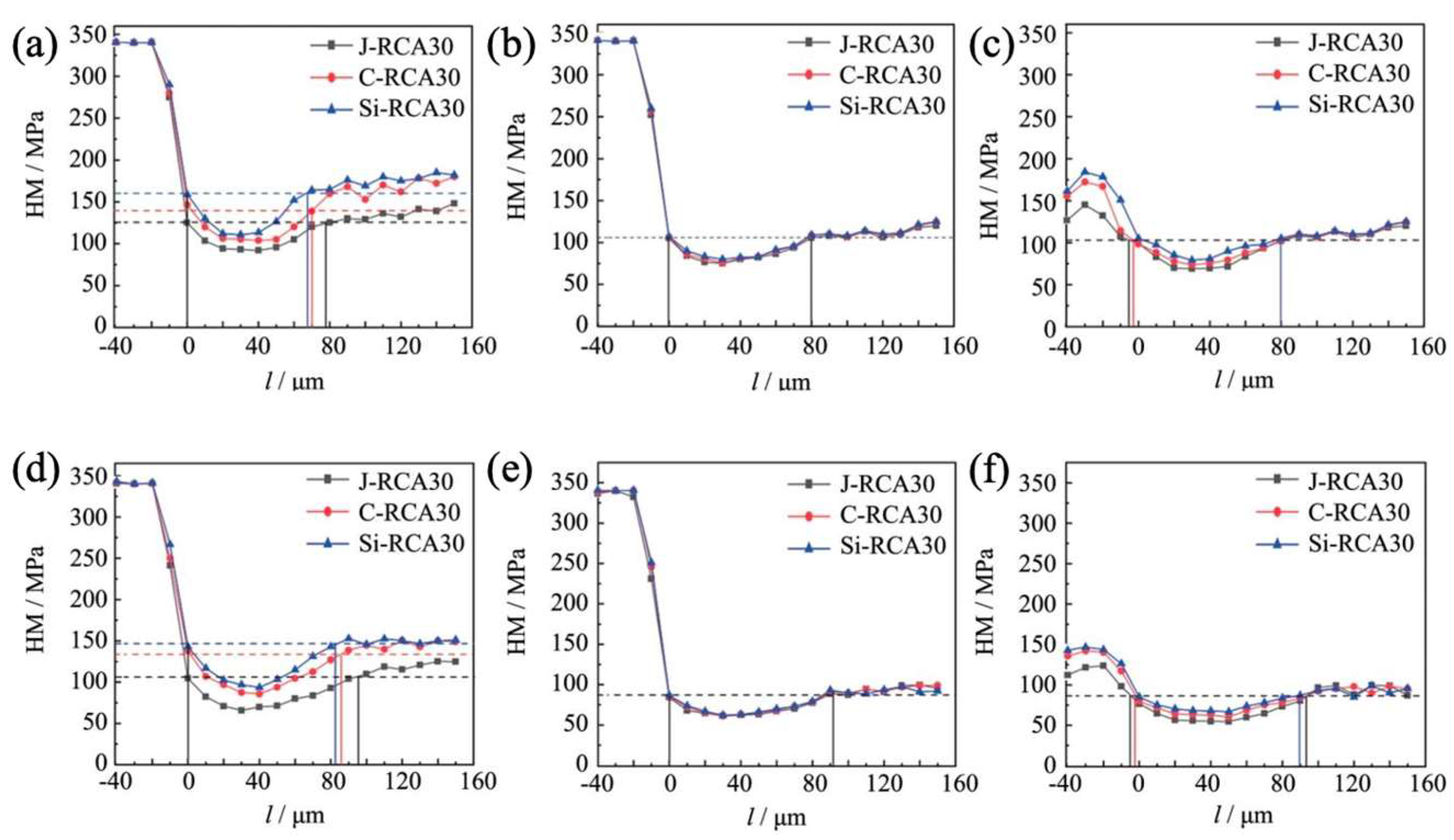

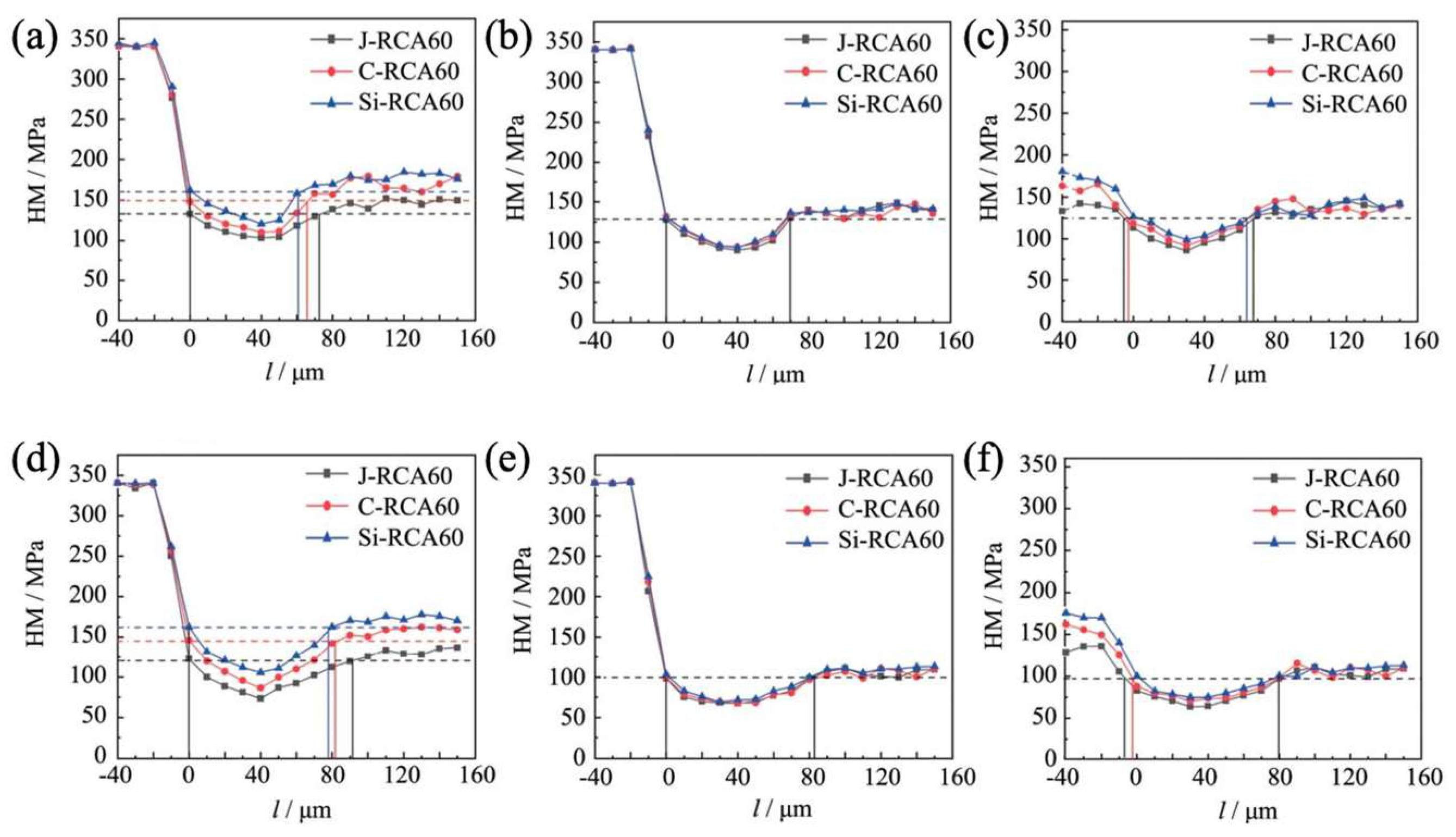

- Testing Protocol: Within the vicinity of a single aggregate, three types of ITZs were identified: old aggregate-old mortar (LG-LS), old aggregate-new mortar (LG-XS), and old mortar-new mortar (LS-XS). Nine lattices, each containing a 4 × 5 grid of measurement points, were tested within each ITZ. To prevent overlapping of adjacent indentations, the test load was carefully calibrated to 50 g. Also, the longitudinal distance (L1) and horizontal distance (L2) between adjacent indentations were both equivalent to the vertical height difference (h) of 10 μm between transversely adjacent indentations. Notably, the first indentation of each lattice, located at a distance of 0 μm from the ITZ boundary, was positioned directly on the interfacial boundary.

2.3.4. Thermogravimetric of RAC

3. Results and Discussion

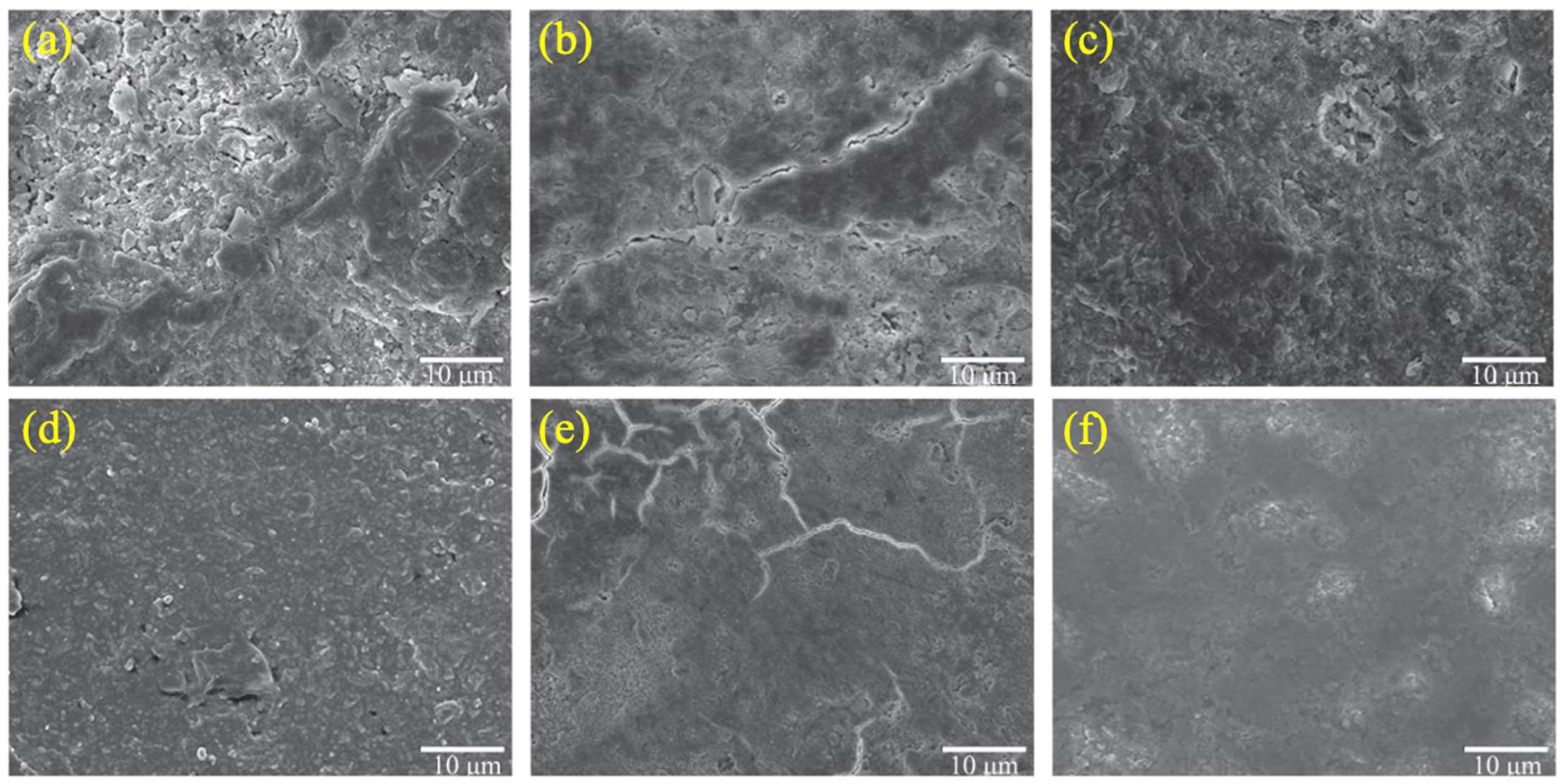

3.1. Morphological Graph and Composition of RCA

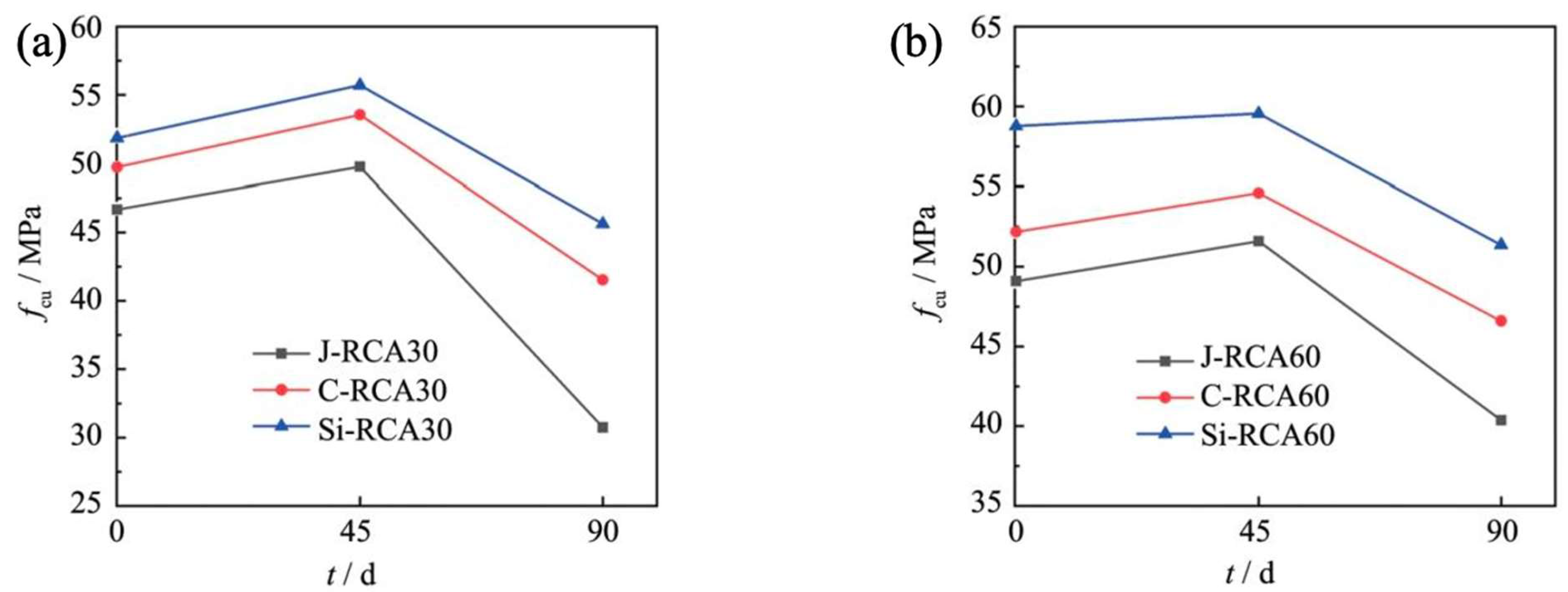

3.2. Compressive Strength and Sulfate Erosion Concentration Profiles in RAC

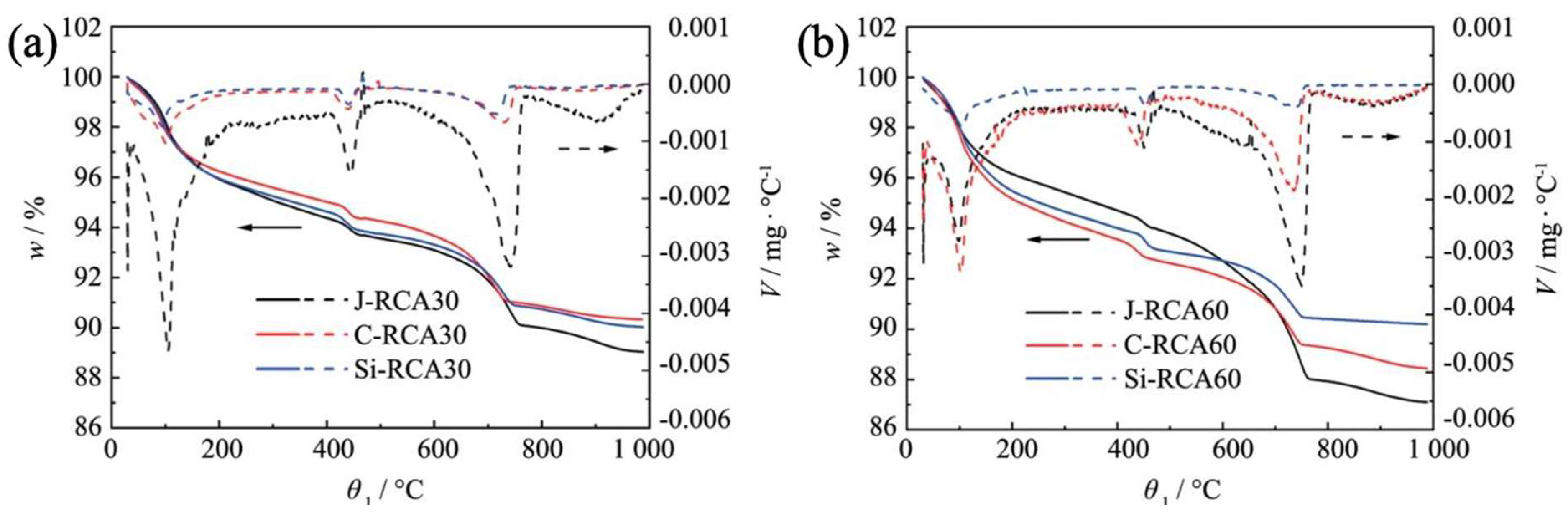

3.3. Thermogravimetric Analysis

3.4. Micro-Mechanical Characterization of RAC

3.5. Mechanism of the Modification Techniques Used to Strengthen RAC

4. Conclusions

- The porosity and crack density in the ITZ between the recycled aggregate and the cement paste in RAC are significant. Studies have shown that the porosity in the ITZ of RAC can be up to 30% higher than in virgin aggregate concrete. Sulfate ions readily penetrate through these pathways, leading to the formation of expansive ettringite, which causes deterioration in the mechanical properties of RAC. Under sulfate attack, RAC has been observed to lose up to 40% of its compressive strength.

- Carbonation treatment was found to be moderately effective in improving sulfate resistance. After carbonation, the sulfate penetration depth in RAC was reduced by approximately 15%. However, nano-silica incorporation demonstrated significantly greater efficacy. The incorporation of 2% nano-silica by weight of cement reduced the sulfate penetration depth by over 30% and the sulfate concentration by 25% compared to unmodified RAC. The compressive strength of nano-silica-modified RAC after 28 days of sulfate attack was increased by approximately 15% compared to the unmodified RAC.

- The sulfate ion mass equilibrium depth in nano-silica-modified RAC was reduced by approximately 30% compared to unmodified RAC. The sulfate concentration in the pore solution of nano-silica-modified RAC was also significantly lower, indicating improved sulfate resistance. After 56 days of sulfate attack, the compressive strength of nano-silica-modified RAC was maintained at 85% of its initial value, while that of unmodified RAC dropped to 70%.

- The quality of the recycled aggregate significantly influences the sulfate resistance of RAC. RCA derived from high-strength concrete (greater than 40 MPa) exhibited superior sulfate resistance compared to RCA from low-strength concrete (less than 20 MPa). The smoother and denser surface of high-strength RCA effectively mitigated sulfate ion ingress. Under sulfate attack, RAC made with high-strength RCA lost only 20% of its compressive strength, while RAC with low-strength RCA lost 40%.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Wang, D.; Lu, C.; Zhu, Z.; Zhang, Z.; Liu, S.; Ji, Y.; Xing, Z. Mechanical Performance of Recycled Aggregate Concrete in Green Civil Engineering: Review. Case Stud. Constr. Mater. 2023, 19, e02384. [Google Scholar] [CrossRef]

- Wang, D.; Shen, X.; Wang, Z.; Zhang, X.; Chen, X.-F. Effect of Quicklime Substitution for Cement on the Physical and Mechanical Properties of Autoclaved Fly Ash Aggregates via Hydrothermal Synthesis. Materials 2025, 18, 707. [Google Scholar] [CrossRef] [PubMed]

- Lu, C.-G.; Zhang, X.-C.; Chen, X.-F. Maximizing Nano-Silica Efficiency in Laboratory-Simulated Recycled Concrete Aggregate via Prior Accelerated Carbonation: An Effective Strategy to Up-Cycle Construction Wastes. Molecules 2024, 29, 5995. [Google Scholar] [CrossRef] [PubMed]

- Lu, C.-G.; Zhang, X.-C.; Chen, W.-Z.; Chen, X.-F. Quantitative Analysis of Crack Propagation Behavior in Recycled Concrete Subjected to Axial Compression Using Digital Image Correlation (DIC) Technology and Fractal Theory. Fractal Fract. 2024, 8, 686. [Google Scholar] [CrossRef]

- Wen, W.; Su, Y.; Tang, Y.; Zhang, X.; Hu, Y.; Ben, Y.; Qu, S. Evaluating Carbon Emissions Reduction Compliance Based on “dual Control” Policies of Energy Consumption and Carbon Emissions in China. J. Environ. Manag. 2024, 367, 121990. [Google Scholar] [CrossRef]

- Wang, B.; Yan, L.; Fu, Q.; Kasal, B. A Comprehensive Review on Recycled Aggregate and Recycled Aggregate Concrete. Resour. Conserv. Recycl. 2021, 171, 105565. [Google Scholar] [CrossRef]

- Tejas, S.; Pasla, D. Assessment of Mechanical and Durability Properties of Composite Cement-Based Recycled Aggregate Concrete. Constr. Build. Mater. 2023, 387, 131620. [Google Scholar] [CrossRef]

- Tang, Y.; Xiao, J.; Zhang, H.; Duan, Z.; Xia, B. Mechanical Properties and Uniaxial Compressive Stress-Strain Behavior of Fully Recycled Aggregate Concrete. Constr. Build. Mater. 2022, 323, 126546. [Google Scholar] [CrossRef]

- Adessina, A.; Ben Fraj, A.; Barthélémy, J.-F. Improvement of the Compressive Strength of Recycled Aggregate Concretes and Relative Effects on Durability Properties. Constr. Build. Mater. 2023, 384, 131447. [Google Scholar] [CrossRef]

- Chen, W.-Z.; Chen, X.-F. Experimental Study and Mathematical Modeling of Mechanical Properties of Basalt Fiber-Reinforced Recycled Concrete Containing a High Content of Construction Waste. Constr. Mater. 2023, 3, 462–473. [Google Scholar] [CrossRef]

- Jiao, C.-J.; Zhang, X.-C.; Chen, W.-Z.; Chen, X.-F. Mechanical Property and Dimensional Stability of Chopped Basalt Fiber-Reinforced Recycled Concrete and Modeling with Fuzzy Inference System. Buildings 2023, 13, 97. [Google Scholar] [CrossRef]

- Chen, X.-F.; Kou, S.-C.; Xing, F. Mechanical and Durable Properties of Chopped Basalt Fiber Reinforced Recycled Aggregate Concrete and the Mathematical Modeling. Constr. Build. Mater. 2021, 298, 123901. [Google Scholar] [CrossRef]

- Lin, Y.; Feng, X.; Zhang, Z. Microscopic Simulation of Thermo-Mechanical Behaviors in Recycled Concrete under Freeze–Thaw Action. Constr. Build. Mater. 2023, 409, 133892. [Google Scholar] [CrossRef]

- Hosseinzadeh, M.; Dehestani, M.; Alizadeh, E. Three-Dimensional Multiscale Simulations of Recycled Aggregate Concrete Employing Energy Homogenization and Finite Element Approaches. Constr. Build. Mater. 2022, 328, 127110. [Google Scholar] [CrossRef]

- Tanta, A.; Kanoungo, A.; Singh, S.; Kanoungo, S. The Effects of Surface Treatment Methods on Properties of Recycled Concrete Aggregates. Mater. Today Proc. 2022, 50, 1848–1852. [Google Scholar] [CrossRef]

- Makul, N. A Review on Methods to Improve the Quality of Recycled Concrete Aggregates. J. Sustain. Cem. Based Mater. 2021, 10, 65–91. [Google Scholar] [CrossRef]

- Arandara, K.P.; Paranavithana, G.N.; Priyadarshana, S.T.; Pitawala, H.M.T.G.A.; Dissanayake, R. Evaluation of Coconut Shell Biochar on Recycled Aggregate Concrete through Petrographic Studies. Constr. Build. Mater. 2024, 428, 136342. [Google Scholar] [CrossRef]

- Trivedi, S.S.; Sarangi, D.; Das, B.B.; Barbhuiya, S. Influence of Multi-Stage Processing and Mechano-Chemical Treatments on the Hydration and Microstructure Properties of Recycled Aggregate Concrete. Constr. Build. Mater. 2023, 409, 133993. [Google Scholar] [CrossRef]

- Al-Bayati, H.K.A.; Jadaa, W.; Tighe, S.L. Effect of Recycled Concrete Aggregate Addition on the Asphalt Mixtures Performance: ITZ Area, Microstructure, and Chemical Analysis Perspectives. Recycling 2024, 9, 41. [Google Scholar] [CrossRef]

- Jalilifar, H.; Sajedi, F. Micro-Structural Analysis of Recycled Concretes Made with Recycled Coarse Concrete Aggregates. Constr. Build. Mater. 2021, 267, 121041. [Google Scholar] [CrossRef]

- Wu, Y.; Wu, B. Residual Compressive Strength and Freeze–Thaw Resistance of Ordinary Concrete after High Temperature. Constr. Build. Mater. 2014, 54, 596–604. [Google Scholar] [CrossRef]

- Liu, K.; Yan, J.; Zou, C. A Pilot Experimental Study on Seismic Behavior of Recycled Aggregate Concrete Columns after Freeze-Thaw Cycles. Constr. Build. Mater. 2018, 164, 497–507. [Google Scholar] [CrossRef]

- Deng, X.; Gao, X.; Wang, R.; Gao, M.; Yan, X.; Cao, W.; Liu, J. Investigation of Microstructural Damage in Air-Entrained Recycled Concrete under a Freeze–Thaw Environment. Constr. Build. Mater. 2021, 268, 121219. [Google Scholar] [CrossRef]

- Hussein Bani-Hani, E.; El Haj Assad, M.; Al Mallahi, M.; Almuqahwi, Z.; Meraj, M.; Azhar, M. Overview of the Effect of Aggregates from Recycled Materials on Thermal and Physical Properties of Concrete. Clean. Mater. 2022, 4, 100087. [Google Scholar] [CrossRef]

- Verma, A.; Babu, V.S.; Arunachalam, S. Influence of Acetic Acid Soaking and Mechanical Grinding Treatment on the Properties of Treated Recycled Aggregate Concrete. J. Mater. Cycles Waste Manag. 2022, 24, 877–899. [Google Scholar] [CrossRef]

- Mi, T.; Peng, L.; Yu, K.; Zhao, Y. Enhancement Strategies for Recycled Brick Aggregate Concrete Using MICP and EICP Treatments. J. Build. Eng. 2023, 79, 107909. [Google Scholar] [CrossRef]

- Khushnood, R.A.; Qureshi, Z.A.; Shaheen, N.; Ali, S. Bio-Mineralized Self-Healing Recycled Aggregate Concrete for Sustainable Infrastructure. Sci. Total Environ. 2020, 703, 135007. [Google Scholar] [CrossRef]

- Zhao, P.; Tian, Y.; You, J.; Hu, X.; Liu, Y. Recent Advances of Calcium Carbonate Nanoparticles for Biomedical Applications. Bioengineering 2022, 9, 691. [Google Scholar] [CrossRef]

- Fadia, P.; Tyagi, S.; Bhagat, S.; Nair, A.; Panchal, P.; Dave, H.; Dang, S.; Singh, S. Calcium Carbonate Nano- and Microparticles: Synthesis Methods and Biological Applications. 3 Biotech 2021, 11, 457. [Google Scholar] [CrossRef]

- Feng, C.; Cui, B.; Ge, H.; Huang, Y.; Zhang, W.; Zhu, J. Reinforcement of Recycled Aggregate by Microbial-Induced Mineralization and Deposition of Calcium Carbonate—Influencing Factors, Mechanism and Effect of Reinforcement. Crystals 2021, 11, 887. [Google Scholar] [CrossRef]

- Kalinowska-Wichrowska, K.; Kosior-Kazberuk, M.; Pawluczuk, E. The Properties of Composites with Recycled Cement Mortar Used as a Supplementary Cementitious Material. Materials 2020, 13, 64. [Google Scholar] [CrossRef] [PubMed]

- Abellan-Garcia, J.; Fernández-Gómez, J.; Iqbal Khan, M.; Abbas, Y.M.; Pacheco-Bustos, C. ANN Approach to Evaluate the Effects of Supplementary Cementitious Materials on the Compressive Strength of Recycled Aggregate Concrete. Constr. Build. Mater. 2023, 402, 132992. [Google Scholar] [CrossRef]

- Chen, X.-F.; Quan, C.-Q.; Jiao, C.-J. Experimental Study of Chloride Resistance of Polypropylene Fiber Reinforced Concrete with Fly Ash and Modeling. Materials 2021, 14, 4417. [Google Scholar] [CrossRef] [PubMed]

- Shuvo, A.K.; Sarker, P.K.; Shaikh, F.U.A. Efficacy of Various Accelerated Carbonation Techniques to Improve Recycled Concrete Aggregates: A Comprehensive Review. J. Build. Eng. 2024, 95, 110257. [Google Scholar] [CrossRef]

- Zeng, P.; Abbas, M.A.A.M.; Ran, X.; Li, P. Impermeability, Strength and Microstructure of Concrete Modified by Nano-Silica and Expansive Agent. J. Compos. Sci. 2025, 9, 108. [Google Scholar] [CrossRef]

- Chen, W.-Z.; Jiao, C.-J.; Zhang, X.-C.; Yang, Y.; Chen, X.-F. Study on the Microstructure of Recycled Aggregate Concrete Strengthened by the Nano-SiO2 Soaking Method. Structures 2023, 58, 105388. [Google Scholar] [CrossRef]

- Chen, X.-F.; Jiao, C.-J. Microstructure and Physical Properties of Concrete Containing Recycled Aggregates Pre-Treated by a Nano-Silica Soaking Method. J. Build. Eng. 2022, 51, 104363. [Google Scholar] [CrossRef]

- Golewski, G.L. Determination of Fracture Mechanic Parameters of Concretes Based on Cement Matrix Enhanced by Fly Ash and Nano-Silica. Materials 2024, 17, 4230. [Google Scholar] [CrossRef]

- Bayraktar, O.Y.; Turhala, S.; Benlib, A.; Shi, J.; Kaplan, G. Application of Recycled Aggregates and Biomass Ash in Fibre-Reinforced Green Roller Compacted Concrete Pavement-Technical and Environmental Assessment. Int. J. Pavement Eng. 2025, 26, 2458140. [Google Scholar] [CrossRef]

- Bastos, D.; Brazão Farinha, C.; Maia Pederneiras, C.; Veiga, R.; Bogas, J.A.; Infante Gomes, R.; Santos Silva, A. Pathway to Carbon Neutrality in the Cement Industry: CO2 Uptake by Recycled Aggregates from Construction and Demolition Waste. Appl. Sci. 2024, 14, 5224. [Google Scholar] [CrossRef]

- Sereng, M.; Djerbi, A.; Metalssi, O.O.; Dangla, P.; Torrenti, J.-M. Improvement of Recycled Aggregates Properties by Means of CO2 Uptake. Appl. Sci. 2021, 11, 6571. [Google Scholar] [CrossRef]

- Infante Gomes, R.; Brazão Farinha, C.; Veiga, R.; de Brito, J.; Faria, P.; Bastos, D. CO2 Sequestration by Construction and Demolition Waste Aggregates and Effect on Mortars and Concrete Performance—An Overview. Renew. Sustain. Energy Rev. 2021, 152, 111668. [Google Scholar] [CrossRef]

- Li, L.; Xuan, D.; Sojobi, A.O.; Liu, S.; Chu, S.H.; Poon, C.S. Development of Nano-Silica Treatment Methods to Enhance Recycled Aggregate Concrete. Cem. Concr. Compos. 2021, 118, 103963. [Google Scholar] [CrossRef]

| Grade | Cement | FA | NCA | w/b | WR | f-28 d (MPa) |

|---|---|---|---|---|---|---|

| C30 | 300 | 800 | 1200 | 0.38 | 0.9 | 47.1 |

| C60 | 530 | 680 | 1000 | 0.32 | 1.2 | 64.7 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, X.-F.; Zhang, X.-C.; Yan, G.-H. Multiscale Investigation of Modified Recycled Aggregate Concrete on Sulfate Attack Resistance. Materials 2025, 18, 1450. https://doi.org/10.3390/ma18071450

Chen X-F, Zhang X-C, Yan G-H. Multiscale Investigation of Modified Recycled Aggregate Concrete on Sulfate Attack Resistance. Materials. 2025; 18(7):1450. https://doi.org/10.3390/ma18071450

Chicago/Turabian StyleChen, Xue-Fei, Xiu-Cheng Zhang, and Guo-Hui Yan. 2025. "Multiscale Investigation of Modified Recycled Aggregate Concrete on Sulfate Attack Resistance" Materials 18, no. 7: 1450. https://doi.org/10.3390/ma18071450

APA StyleChen, X.-F., Zhang, X.-C., & Yan, G.-H. (2025). Multiscale Investigation of Modified Recycled Aggregate Concrete on Sulfate Attack Resistance. Materials, 18(7), 1450. https://doi.org/10.3390/ma18071450