Response of Bare and CFRP-Retrofitted Multi-Column Piers Under Post-Fire-Coupled Vehicle Collision and Air Blast

Abstract

1. Introduction

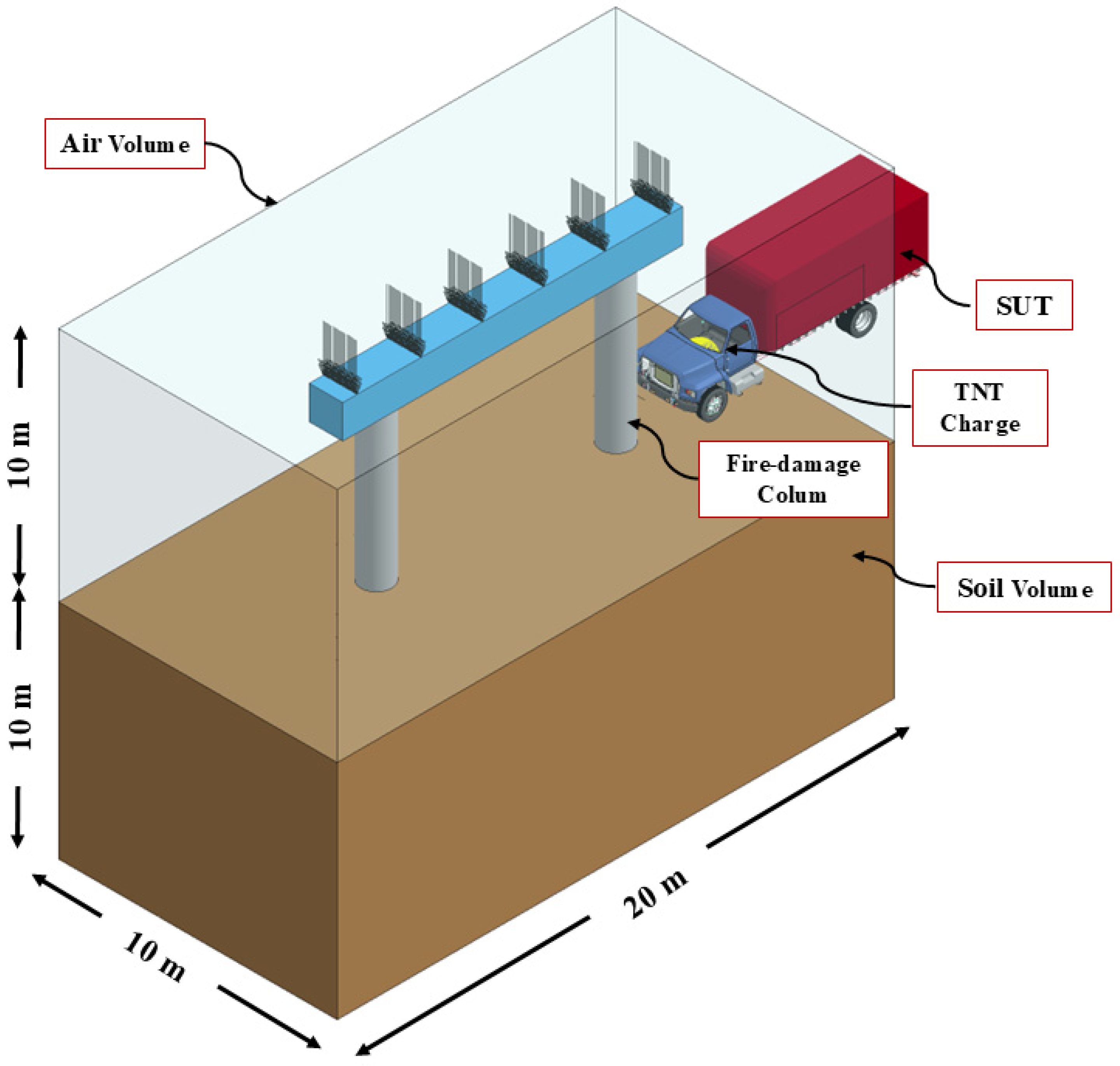

2. Numerical Modeling

2.1. Element Formulation

2.2. Material Models

2.2.1. Concrete and Steel Reinforcement

2.2.2. Soil, Air, and Explosive

2.2.3. CFRP

2.3. Fire, Vehicle Collision, and Air Blast Modeling

2.3.1. Fire

2.3.2. Vehicle Collision

2.3.3. Air Blast

2.4. Model Coupling and Contacts

2.5. Loading Sequence

2.6. Model Validation

3. Numerical Studies

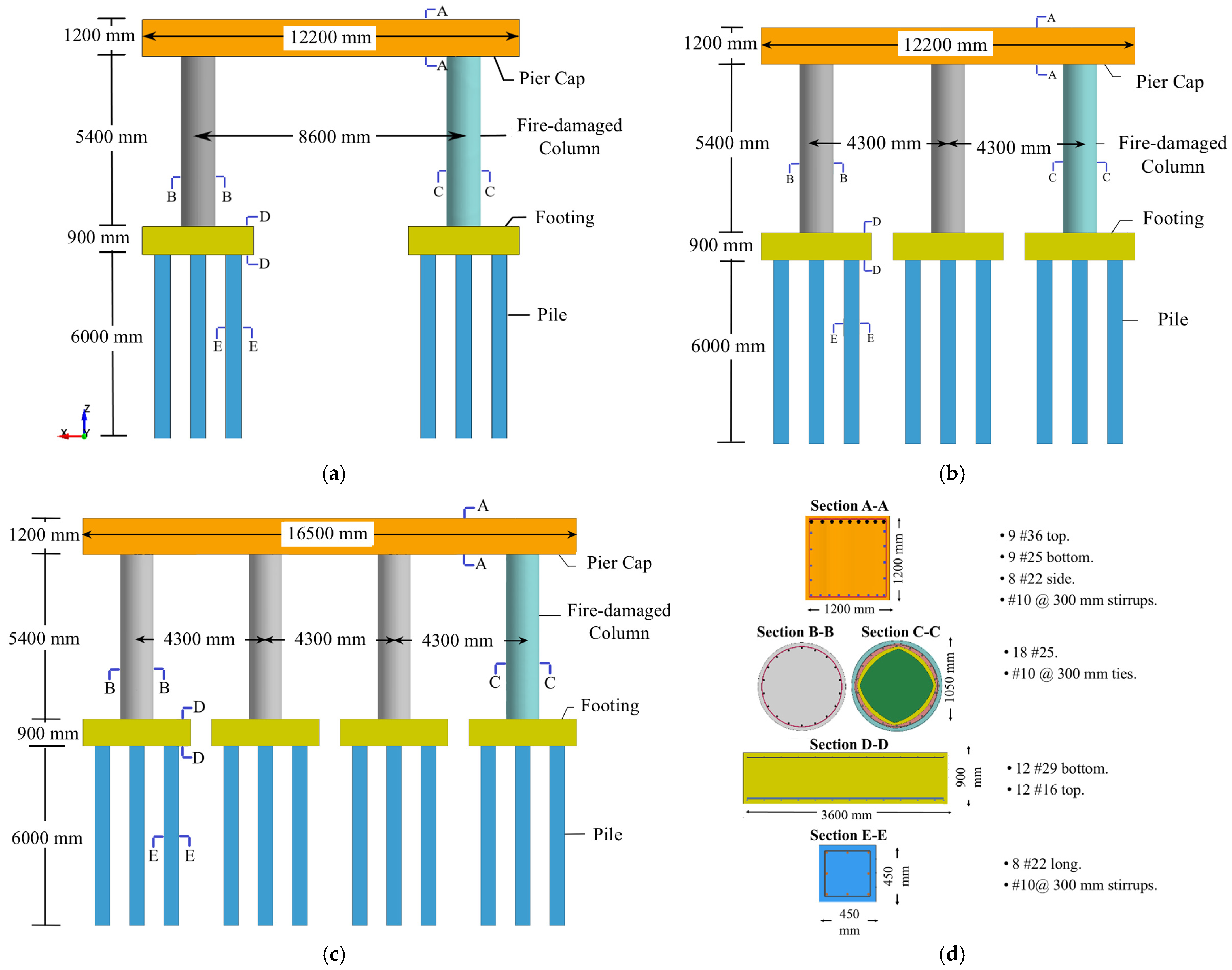

3.1. Prototype Multi-Column Pier

3.2. Response of Bare Multi-Column Pier

3.2.1. Structural-Fire Response

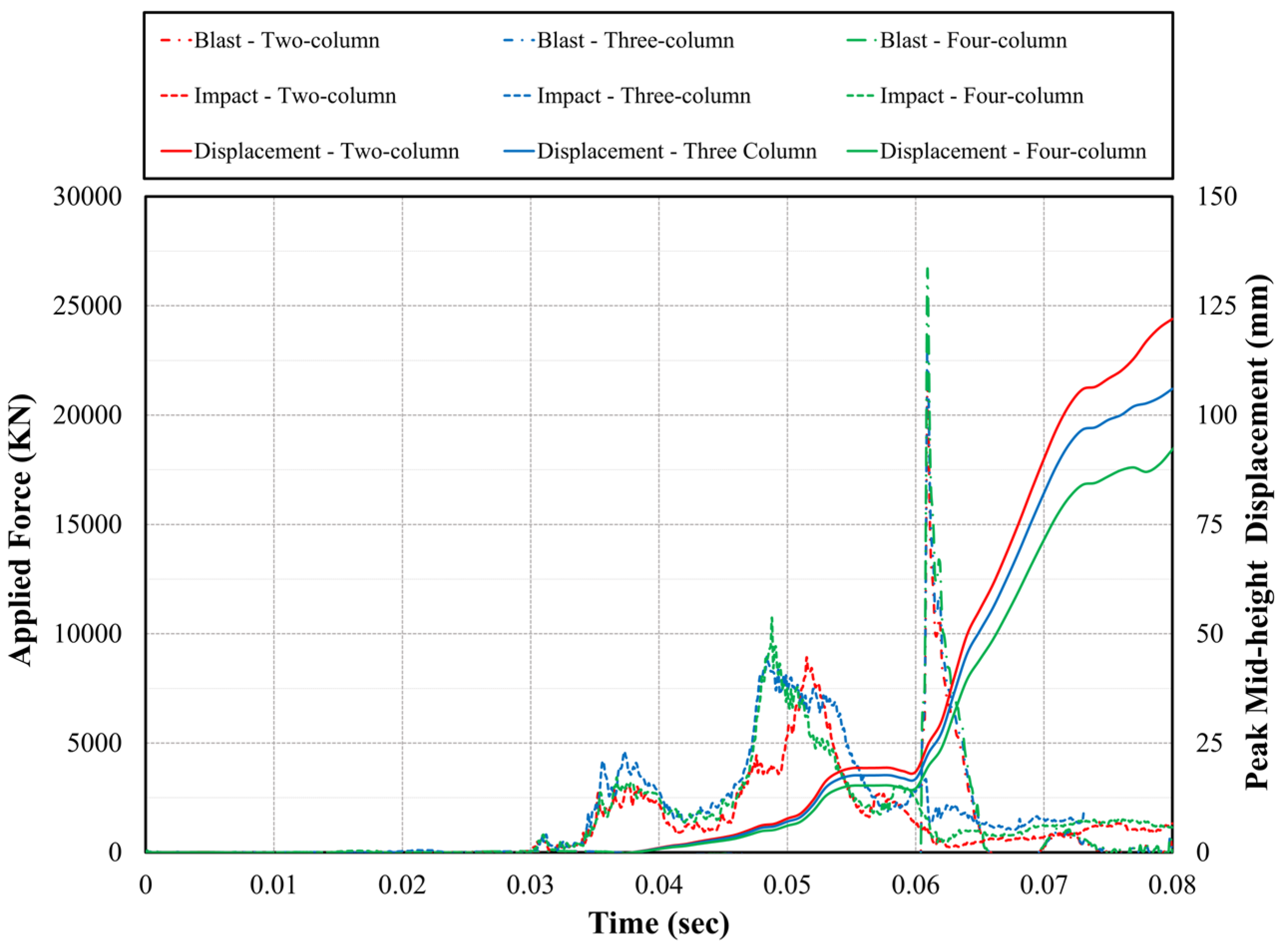

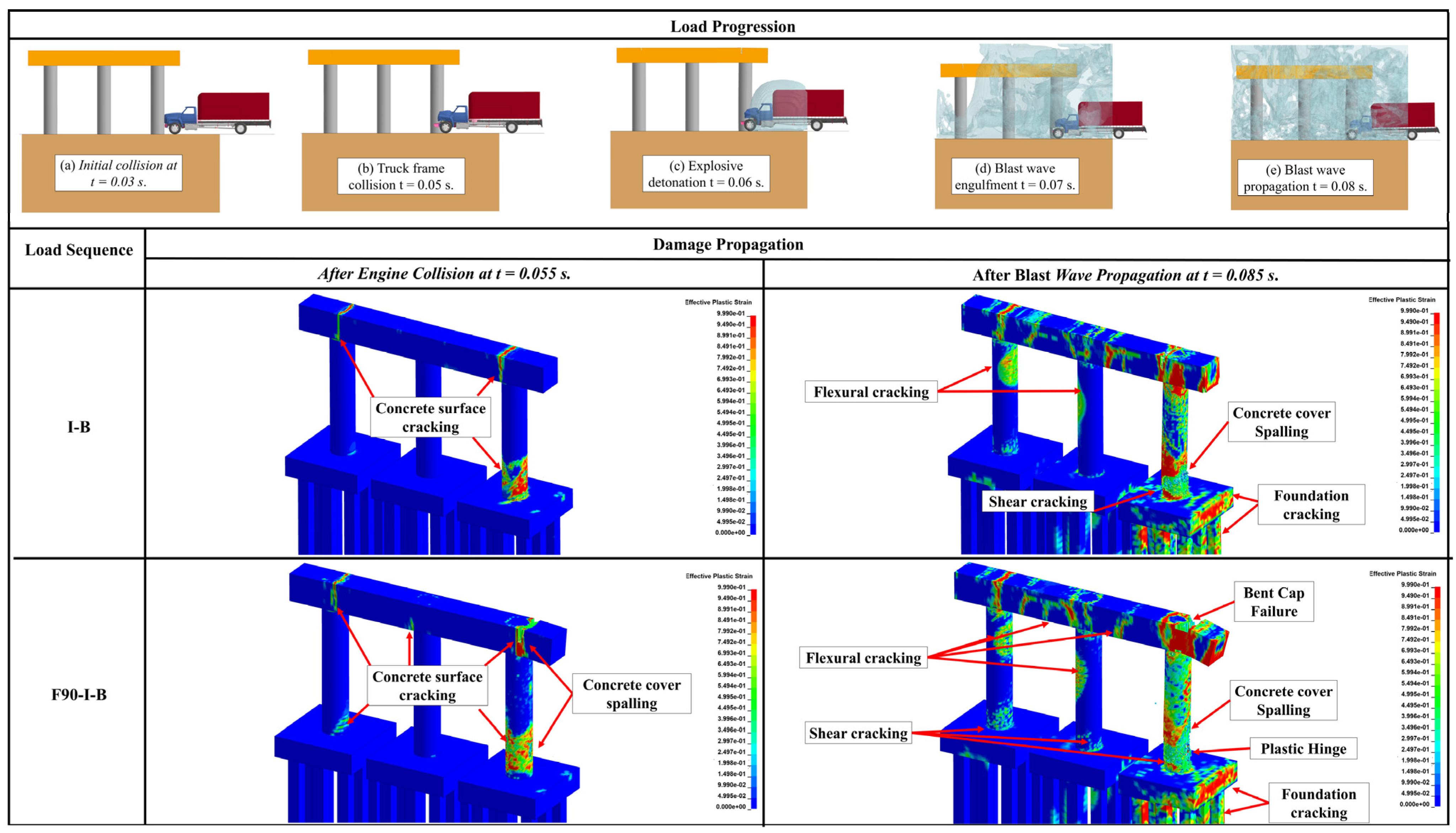

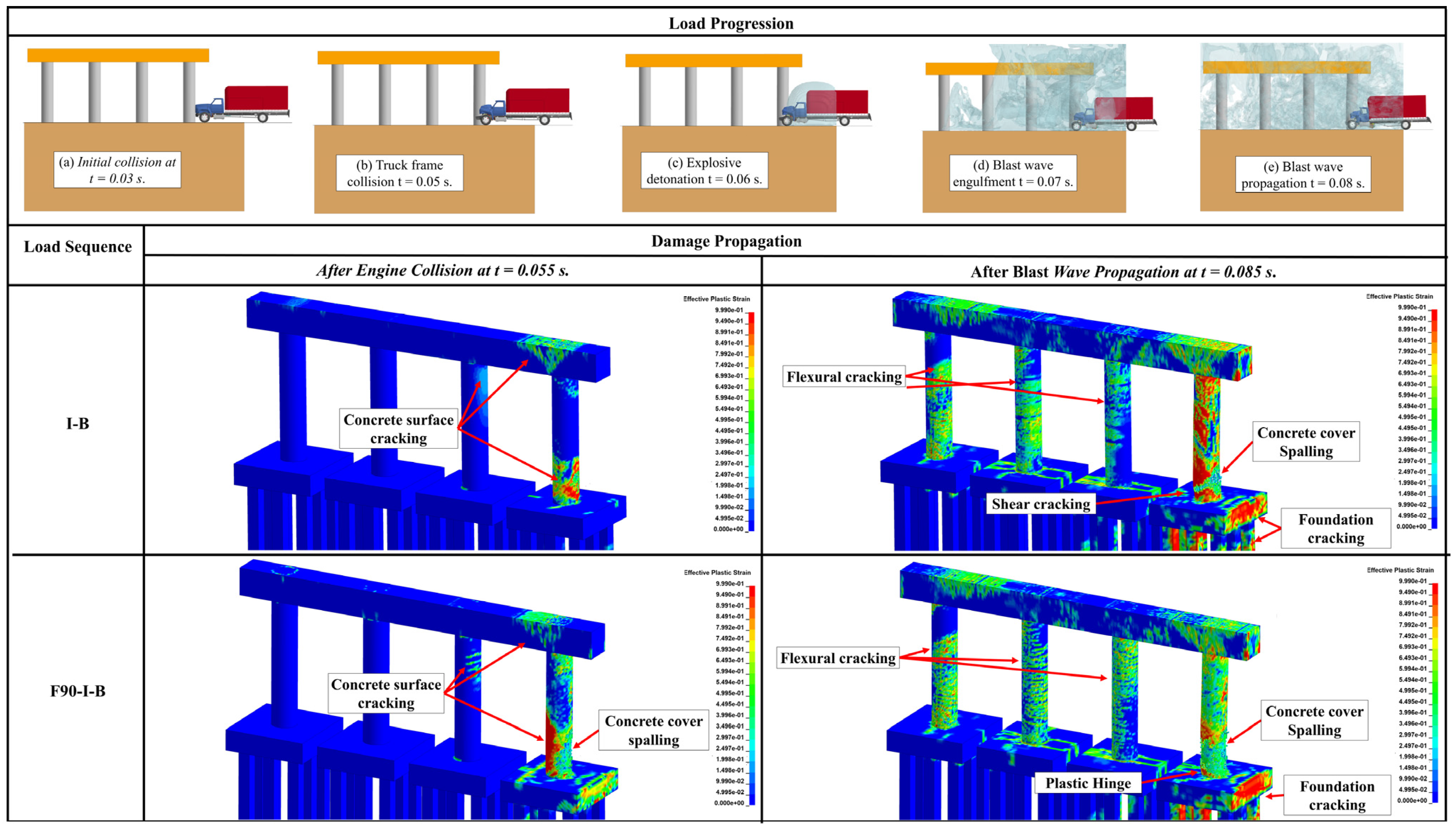

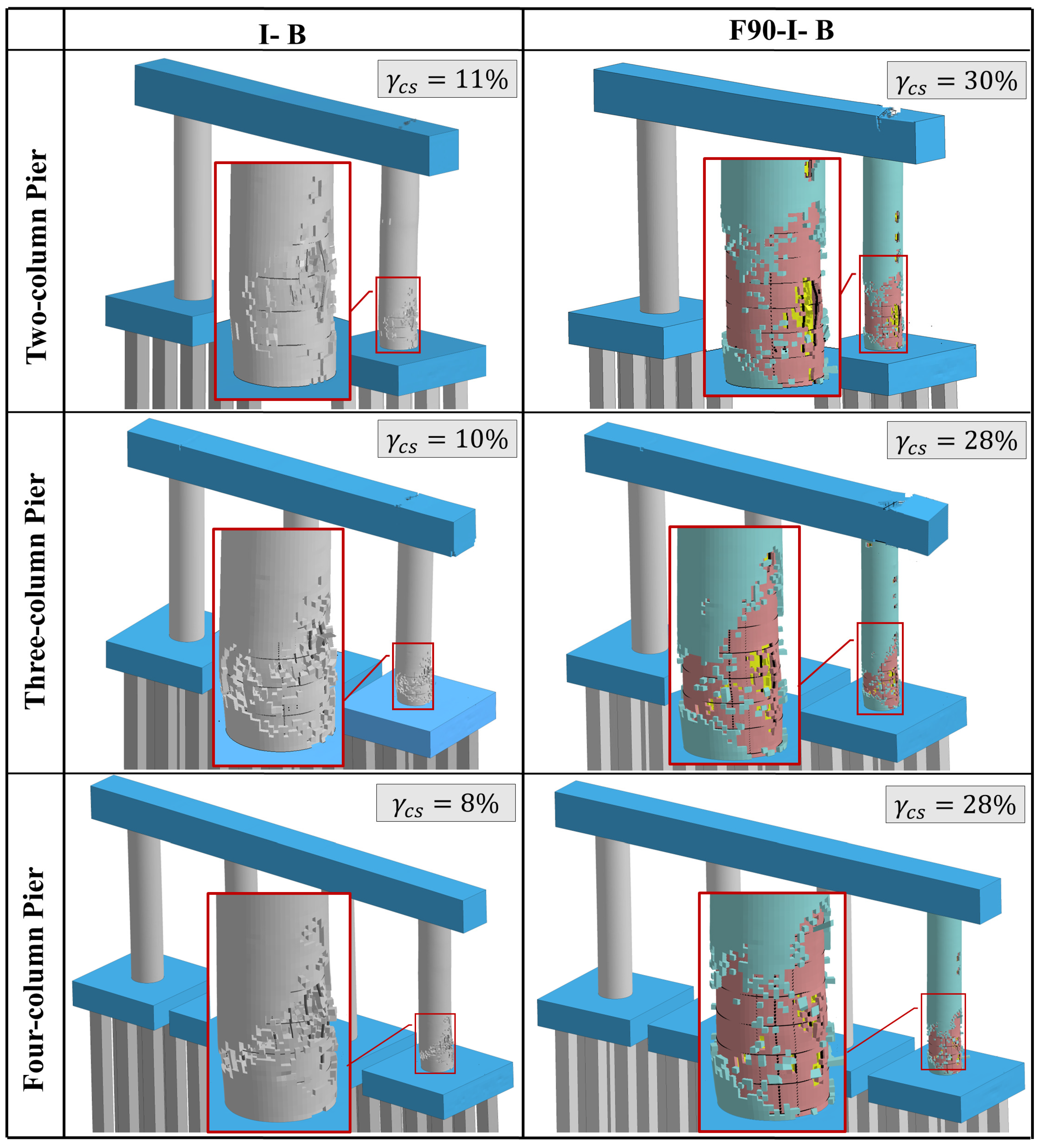

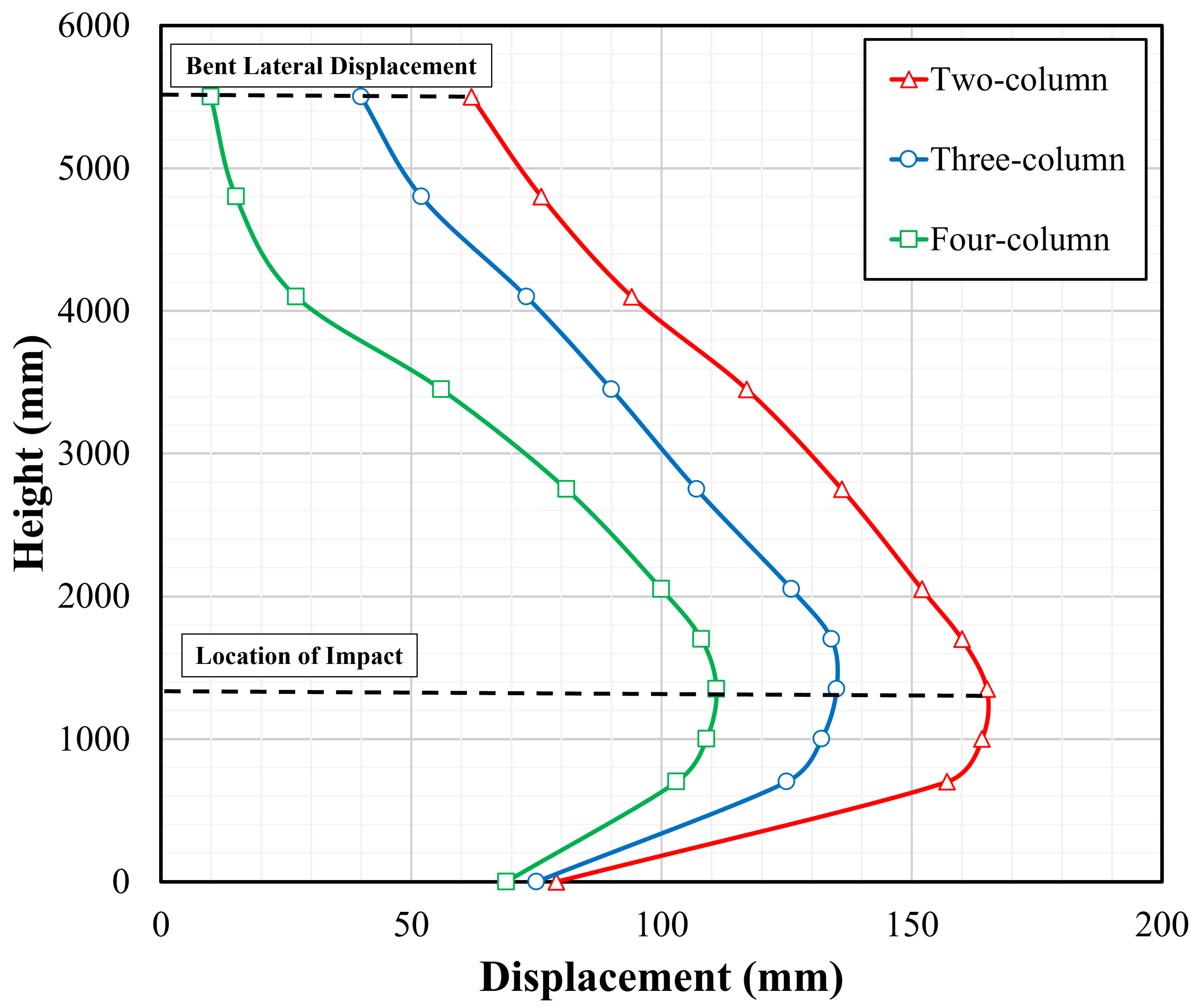

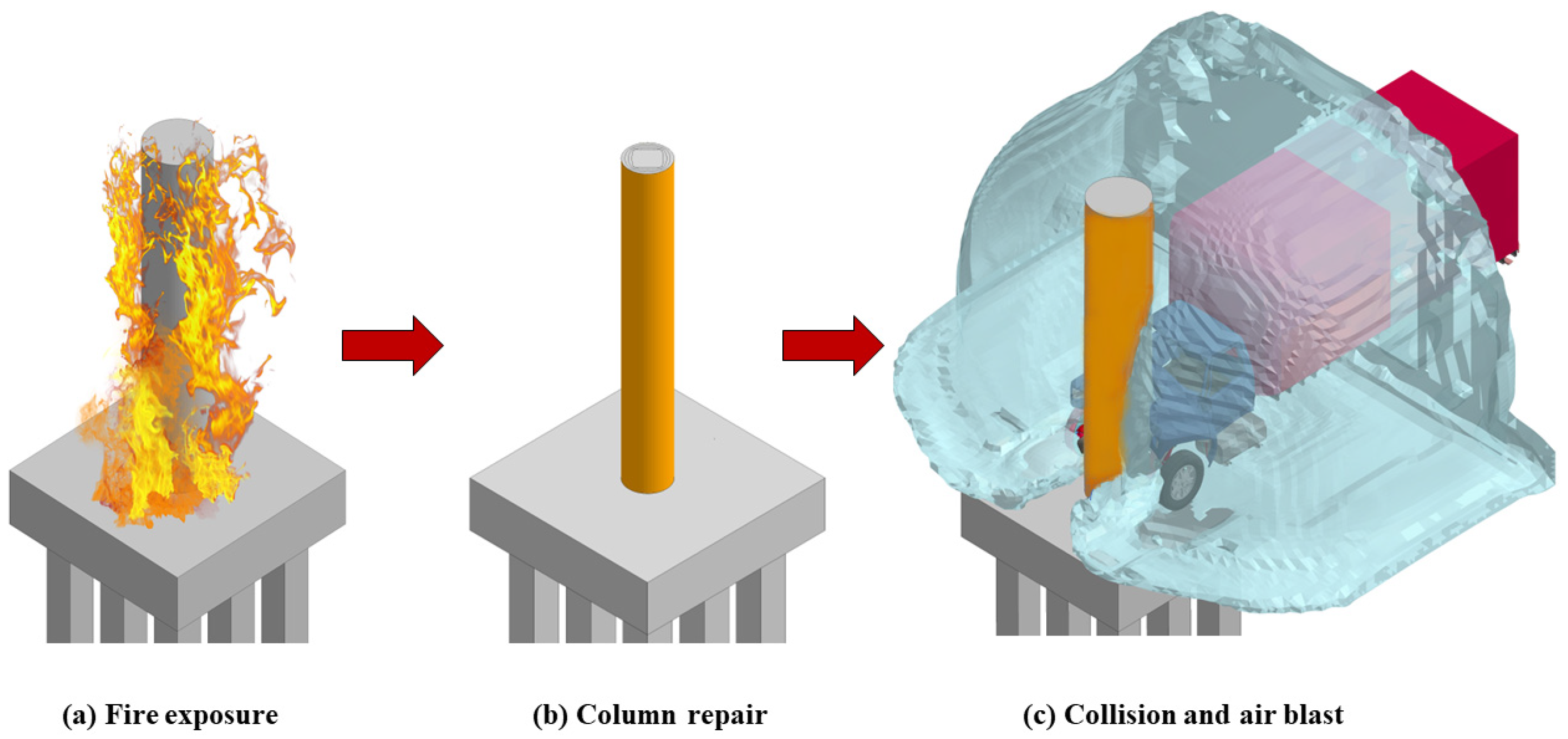

3.2.2. Response Under Impact and Blast

3.3. Response of CFRP-Repaired Two-Column Pier

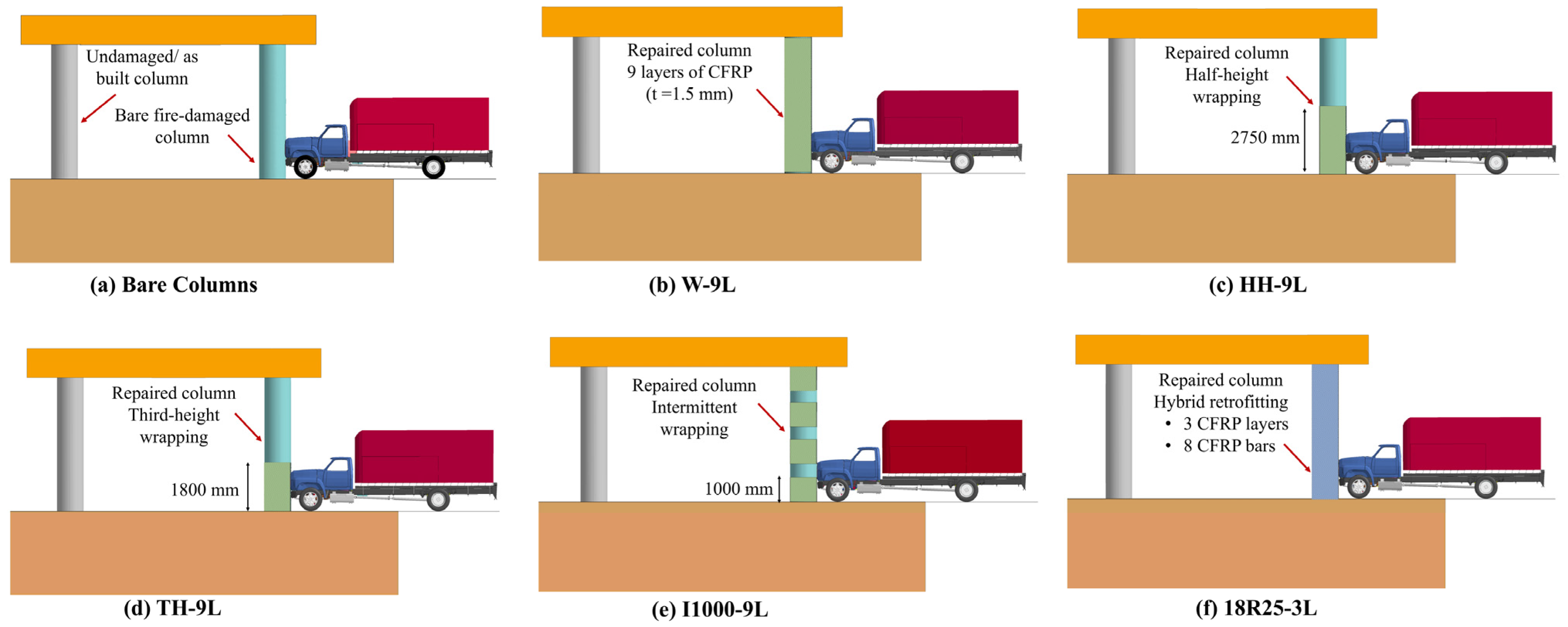

3.3.1. Retrofit Design

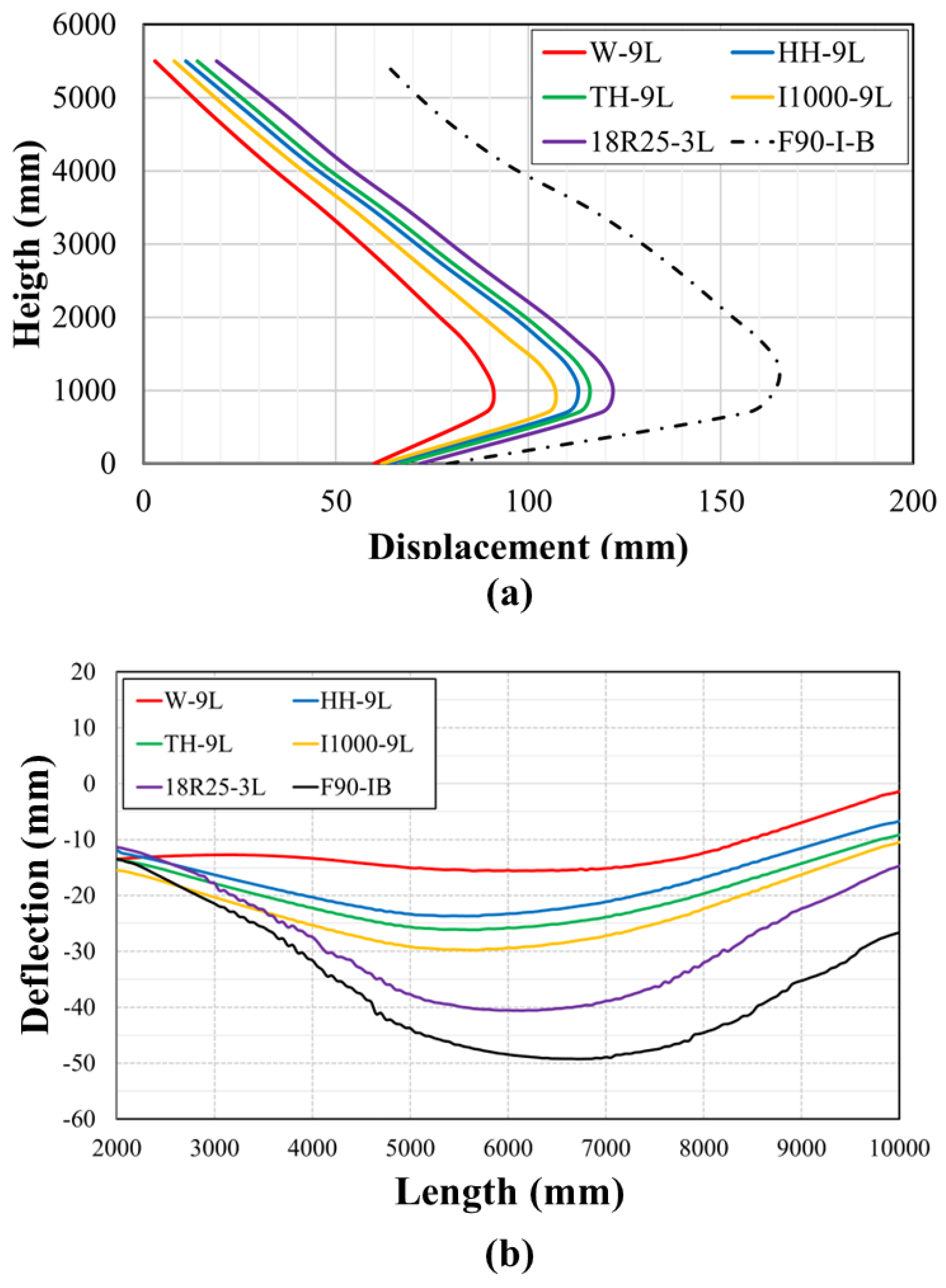

3.3.2. Structural Response

4. Summary and Conclusions

- Exposing one column to fire caused substantial damage in the impacted and non-impacted columns irrespective of the number of pier columns.

- The two-column pier was susceptible to the imposed demands withstanding sever damage and complete replacement deemed to be necessary.

- While the three-column pier sustained less critical damage than the two-column pier, extensive repairs are still needed to restore its design capacity and integrity. On the other hand, the four-column pier could potentially continue in service while being repaired given the localized damage.

- Generally, all proposed CFRP retrofit schemes effectively reduced the damage intensity. However, wrapping the full column height was the optimal scheme compared to all other cases.

- The hybrid retrofit scheme, which included NSM CFRP bars with EB wrapping, was the least effective technique. Given that a 0.5 mm thick CFRP sheet was used in this scheme, this finding highlight that the thickness of CFRP composites has more influence on performance enhancement compared to the reinforcement ratio of CFRP bars.

- From a practical perspective, wrapping the bottom half or third of column height was shown to be more economically justified given the adequate level of damage mitigation they offer.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Liu, Q.; Guo, Z.; Wu, X.; Lu, K.; Ren, X.; Xiao, J. Energy Dissipation Enhanced by Multiple Hinges in Bridge Piers with CFST Y-Shaped Fuses. Symmetry 2022, 14, 2371. [Google Scholar] [CrossRef]

- Lee, G.C.; Mohan, S.B.; Huang, C.; Fard, B.N. Technical Report MCEER-13-008: A Study of US Bridge Failures (1980–2012); Univercity at Buffalo (SUNY): Buffalo, NY, USA, 2013. [Google Scholar]

- Wardhana, K.; Hadipriono, F.C. Analysis of recent bridge failures in the United States. J. Perform. Constr. Facil. 2003, 17, 144–150. [Google Scholar] [CrossRef]

- Zimmerman, R. Transport, the Environment and Security: Making the Connection; Edward Elgar Publishing: Cheltenham, UK, 2012. [Google Scholar]

- Tebor, C.; Sottile, Z. Section of Major I-95 Highway in Philadelphia that Collapsed After Tanker Truck Caught Fire Underneath Could Take Months to Repair, Officials Say; CNN: Atlanta, GA, USA, 2023. [Google Scholar]

- Kodur, V.; Bhatt, B. Strategies for mitigating fire hazard in tunnel structures. In The 6th International Workshop on Structural Life Management of Power Structures; KEPCO-RI: Daejeon, Republic of Korea, 2016. [Google Scholar]

- Kodur, V.; Naser, M.Z. Fire hazard in transportation infrastructure: Review, assessment, and mitigation strategies. Front. Struct. Civ. Eng. 2021, 15, 46–60. [Google Scholar] [CrossRef]

- Peris-Sayol, G.; Paya-Zaforteza, I.; Balasch-Parisi, S.; Alós-Moya, J. Detailed analysis of the causes of bridge fires and their associated damage levels. J. Perform. Constr. Facil. 2017, 31, 04016108. [Google Scholar]

- Michael, W.; William, W.; Brian, L. Fire risks for highway bridges: A statistical investigation. In Structures Congress 2013: Bridging Your Passion with Your Profession, Proceedings of the 2013 Structures Congress, Pittsburgh, PA, USA, 2–4 May 2013; ASCE Library: Reston, VA, USA, 2013; pp. 744–757. [Google Scholar]

- AASHTO LRFD. Bridge Design Specifications, 9th ed.; American Association of State Highway and Transportation Officials (AASHTO): Washington, DC, USA, 2020. [Google Scholar]

- Garlock, M.; Paya-Zaforteza, I.; Kodur, V.; Gu, L. Fire hazard in bridges: Review, assessment and repair strategies. Eng. Struct. 2012, 35, 89–98. [Google Scholar]

- Woodworth, M.A. Fire Hazard Assessment for Highway Bridges with Thermal Mechanical Modeling. Ph.D. Thesis, Virginia Polytechnic Institute and State University, Blacksburg, VA, USA, 2013. [Google Scholar]

- Alomari, Q.; Linzell, D.G.; Fang, C. Performance investigation of highway bridge pier columns under the sequential effects of fire followed by vehicle collision and subsequent air blast: A numerical investigation. Adv. Struct. Eng. 2024, 27, 13694332241242987. [Google Scholar] [CrossRef]

- Alomari, Q.A.; Linzell, D.G. Bridge Pier Column Multi-Hazard Response—Fire, Impact and Blast. In Bridge Safety, Maintenance, Management, Life-Cycle, Resilience and Sustainability, Proceedings of the Eleventh International Conference on Bridge Maintenance, Safety and Management (IABMAS 2022), Barcelona, Spain, 11–15 July 2022; CRC Press: Boca Raton, FL, USA, 2022. [Google Scholar]

- Alomari, Q.A.; Linzell, D.G. Reinforced Concrete Bridge Column Multihazard Performance: A Computational Tool to Assess Response to Vehicle Impact, Air Blast, and Fire. J. Perform. Constr. Facil. 2024, 38, 04023061. [Google Scholar] [CrossRef]

- Alomari, Q.A.; Linzell, D.G. Advanced analysis of intact, fire-damaged, and CFRP retrofitted bridge pier columns under vehicle collisions: Empirical equivalent static force equation and framework. Eng. Struct. 2024, 314, 118250. [Google Scholar]

- Guo, Z.; Chen, W.; Zhang, Y.; Zou, H. Post fire blast-resistances of RPC-FST columns using improved Grigorian model. Int. J. Impact Eng. 2017, 107, 80–95. [Google Scholar] [CrossRef]

- Chen, L.; Fang, Q.; Jiang, X.; Ruan, Z.; Hong, J. Combined effects of high temperature and high strain rate on normal weight concrete. Int. J. Impact Eng. 2015, 86, 40–56. [Google Scholar] [CrossRef]

- Ruta, D. Numerical and Experimental Study of Concrete Structures Exposed to Impact and Fire; IAEA: Vienna, Austria, 2018. [Google Scholar]

- Chen, W.; Guo, Z.; Zhang, T.; Zou, H.; Gu, J. Near-field blast test on reactive powder concrete-filled steel tubular columns after exposure to fire. Int. J. Prot. Struct. 2016, 7, 193–212. [Google Scholar] [CrossRef]

- Jin, L.; Bai, J.; Zhang, R.; Li, L.; Du, X. Effect of elevated temperature on thelow-velocity impact performances of reinforced concrete slabs. Int. J. Impact Eng. 2021, 149, 103797. [Google Scholar] [CrossRef]

- Kakogiannis, D.; Pascualena, F.; Reymen, B.; Pyl, L.; Ndambi, J.M.; Segers, E.; Lecompte, D.; Vantomme, J.; Krauthammer, T. Blast performance of reinforced concrete hollow core slabs in combination with fire: Numerical and experimental assessment. Fire Saf. J. 2013, 57, 69–82. [Google Scholar]

- Zhai, C.; Chen, L.; Xiang, H.; Fang, Q. Experimental and numerical investigation into RC beams subjected to blast after exposure to fire. Int. J. Impact Eng. 2016, 97, 29–45. [Google Scholar] [CrossRef]

- Hollaway, L.C.; Teng, J.-G. Strengthening and Rehabilitation of Civil Infrastructures Using Fibre-Reinforced Polymer (FRP) Composites; Elsevier: Amsterdam, The Netherlands, 2008. [Google Scholar]

- ACI 440.2R-17; Guide for the Design and Construction of Externally Bonded FRP Systems for Strengthening Concrete Structures. ACI Farmington: Hills, MI, USA, 2017.

- John, S.K.; Cascardi, A.; Verre, S.; Nadir, Y. RC-columns subjected to lateral cyclic force with different FRCM-strengthening schemes: Experimental and numerical investigation. Bull Earthquake Eng. 2025, 23, 1561–1590. [Google Scholar] [CrossRef]

- Bank, L.C. Composites for Construction: Structural Design with FRP Materials; John Wiley & Sons: Hoboken, NJ, USA, 2006. [Google Scholar]

- Baylot, J.T.; Bullock, B.; Slawson, T.R.; Woodson, S.C. Blast response of lightly attached concrete masonry unit walls. J. Struct. Eng. 2005, 131, 1186–1193. [Google Scholar]

- Muszynski, L.C.; Purcell, M.R. Use of composite reinforcement to strengthen concrete and air-entrained concrete masonry walls against air blast. J. Compos. Constr. 2003, 7, 98–108. [Google Scholar]

- Kadhom, B. Blast Performance of Reinforced Concrete Columns Protected by FRP Laminates. Ph.D. Thesis, Université d’Ottawa/University of Ottawa, Ottawa, ON, Canada, 2016. [Google Scholar]

- Xu, J.J.; Demartino, C.; Shan, B.; Heo, Y.A.; Xiao, Y. Experimental investigation on performance of cantilever CFRP-wrapped circular RC columns under lateral low-velocity impact. Compos. Struct. 2020, 242, 112143. [Google Scholar] [CrossRef]

- Pham, T.M.; Zhang, X.; Elchalakani, M.; Karrech, A.; Hao, H.; Ryan, A. Dynamic response of rubberized concrete columns with and without FRP confinement subjected to lateral impact. Constr. Build. Mater. 2018, 186, 207–218. [Google Scholar] [CrossRef]

- Sha, Y.; Hao, H. Laboratory tests and numerical simulations of CFRP strengthened RC pier subjected to barge impact load. Int. J. Struct. Stab. Dyn. 2015, 15, 1450037. [Google Scholar]

- Al-Nimry, H.S.; Ghanem, A.M. FRP confinement of heat-damaged circular RC columns. Int. J. Concr. Struct. Mater. 2017, 11, 115–133. [Google Scholar] [CrossRef]

- Al-Nimry, H.; Haddad, R.; Afram, S.; Abdel-Halim, M. Effectiveness of advanced composites in repairing heat-damaged RC columns. Mater. Struct. 2013, 46, 1843–1860. [Google Scholar] [CrossRef]

- Ashteyat, A.M.; Obaidat, Y.T.; Al-Btoush, A.Y.; Hanandeh, S. Experimental and numerical study of strengthening and repairing heat-damaged RC circular column using hybrid system of CFRP. Case Stud. Constr. Mater. 2021, 15, e00742. [Google Scholar]

- Yaqub, M.; Bailey, C.G. Repair of fire damaged circular reinforced concrete columns with FRP composites. Constr. Build. Mater. 2011, 25, 359–370. [Google Scholar] [CrossRef]

- Al-Kamaki, Y.S.; Al-Mahaidi, R.; Bennetts, I. Experimental and numerical study of the behaviour of heat-damaged RC circular columns confined with CFRP fabric. Compos. Struct. 2015, 133, 679–690. [Google Scholar] [CrossRef]

- Chinthapalli, H.K.; Chellapandian, M.; Agarwal, A.; Prakash, S.S. Emergency repair of severely damaged reinforced concrete column under fire: An experimental study. Constr. Build. Mater. 2019, 155, 751–761. [Google Scholar]

- Fang, C.; Yosef, T.Y.; Linzell, D.G.; Rasmussen, J.D. Computational modeling and dynamic response of highway bridge columns subjected to combined vehicle collision and air blast. Eng. Fail. Anal. 2021, 125, 105389. [Google Scholar] [CrossRef]

- Ruan, Z.; Chen, L.; Fang, Q. Numerical investigation into dynamic responses of RC columns subjected for fire and blast. J. Loss Prev. Process Ind. 2015, 34, 10–21. [Google Scholar] [CrossRef]

- Sharma, H.; Hurlebaus, S.; Gardoni, P. Performance-based response evaluation of reinforced concrete columns subject to vehicle impact. Int. J. Impact Eng. 2012, 43, 52–62. [Google Scholar] [CrossRef]

- Hallquist, J.O. LS-DYNA® Keyword User’s Manual: Volumes, I., II, and III LSDYNA R7. 1; Livermore Software Technology Corporation, Livermore (LSTC): Livermore, CA, USA, 2014; No. 1265. [Google Scholar]

- Group L-DAW. Modeling Guidelines Document Version 13-1; US Department of Transportation, National Highway Traffic Safety Administration: Washington, DC, USA, 2013. [Google Scholar]

- Murray, Y.D. Users manual for LS-DYNA Concrete Material Model 159; U.S. Department of Transportation: Washington, DC, USA, 2007. [Google Scholar]

- Murray, Y.D. Theory and Evaluation of Concrete Material Model 159; NASA: Washington, DC, USA, 2004. [Google Scholar]

- Coughlin, A.M.; Musselman, E.S.; Schokker, A.J.; Linzell, D.G. Behavior of portable fiber reinforced concrete vehicle barriers subject to blasts from contact charges. Int. J. Impact Eng. 2010, 37, 521–529. [Google Scholar] [CrossRef]

- Murray, Y.D.; Abu-Odeh, A.Y.; Bligh, R.P. Evaluation of LS-DYNA Concrete Material Model 159; Federal Highway Administration, Office of Research: Washington, DC, USA, 2007. [Google Scholar]

- AuYeung, S.; Alipour, A. Evaluation of AASHTO suggested design values for reinforced concrete bridge piers under vehicle collisions. Transp. Res. Rec. 2016, 2592, 1–8. [Google Scholar] [CrossRef]

- O’Hare, E.V. Computational Assessment of Steel-Jacketed Bridge Pier Column Performance Under Blast Loads. Master’s Thesis, The University Libraries, Tokyo, Japan, 2011. [Google Scholar]

- Fang, C.; Yosef, T.Y.; Linzell, D.G. Multi-Hazard-Resistant Behavior of CFRP-and Polyurea-Retrofitted Reinforced Concrete Two-Column Piers under Combined Collision–Blast Loading. Materials 2023, 16, 3784. [Google Scholar] [CrossRef] [PubMed]

- Reid, J.D.; Coon, B.A.; Lewis, B.A.; Sutherland, S.H.; Murray, Y.D. Evaluation of LS-DYNA Soil Material Model 147; Federal Highway Administration: Washington, DC, USA, 2004. [Google Scholar]

- Lewis, B.A. Manual for LS-DYNA Soil Material Model 147; United States; Federal Highway Administration: Washington, DC, USA, 2004. [Google Scholar]

- Yosef, T.Y.; Fang, C.; Faller, R.K.; Kim, S. A multi-material ALE model for investigating impact dynamics of pile-soil systems. Soil Dyn. Earthq. Eng. 2023, 164, 107648. [Google Scholar] [CrossRef]

- Jayasinghe, L.B.; Thambiratnam, D.P.; Perera, N.; Jayasooriya, J. Computer simulation of underground blast response of pile in saturated soil. Comput. Struct. 2013, 120, 86–95. [Google Scholar] [CrossRef]

- Chen, W.; Pan, J.; Guo, Z.; Zou, H. Damage evaluations of fire-damaged RPC-FST columns under blast loading. Thin-Walled Struct. 2019, 134, 319–332. [Google Scholar] [CrossRef]

- Mutalib, A.A.; Hao, H. Numerical analysis of FRP-composite-strengthened RC panels with anchorages against blast loads. J. Perform. Constr. Facil. 2011, 25, 360–372. [Google Scholar] [CrossRef]

- Fang, C.; Alomari, Q.A.; Linzell, D.G. Assessment of bridge pier response to fire, vehicleimpact, and air blast. In Proceedings of the International Conference on Protective Structures (ICPS 2023), Auburn, AL, USA, 14–17 May 2023. [Google Scholar]

- Fang, C.; Linzell, D.G.; Yosef, T.Y.; Rasmussen, J.D. Numerical Modeling and Performance Assessment of Bridge Column Strengthened by FRP and Polyurea under Combined Collision and Blast Loading. J. Compos. Constr. 2022, 26, 04022002. [Google Scholar] [CrossRef]

- Liu, L.; Feng, H.; Tang, H.; Guan, Z. Impact resistance of Nomex honeycomb sandwich structures with thin fibre reinforced polymer facesheets. J. Sandw. Struct. Mater. 2018, 20, 531–552. [Google Scholar]

- TxDOT. Bent (Pier) Protection Guide; Texas Department of Transportation, Bridge Devision: Austin, TX, USA, 2022. [Google Scholar]

- Šelešovský, J.; Krupka, M. The using of LS-DYNA for the simulation of heat transfer in explosives. J Comput. Aided Mater Des 2007, 14, 317–325. [Google Scholar] [CrossRef]

- Rackauskaite, E.; Kotsovinos, P.; Rein, G. Model parameter sensitivity and benchmarking of the explicit dynamic solver of LS-DYNA for structural analysis in case of fire. Fire Saf. J. 2017, 90, 123–138. [Google Scholar] [CrossRef]

- Rackauskaite, E.; Flint, G.; Maani, A.; Temple, A.; Kotsovinos, P. Use of LS-DYNA for Structural Fire Engineering. In Proceedings of the 12th European LS-DYNA Users Conference, Koblenz, Germany, 14–16 May 2019; Volume 8. [Google Scholar]

- ISO 834-1:1999; Fire Resistance Tests-Elements of Building Construction. International Organization for Standardization: Geneva, Switzerland, 1999.

- Kodur, V.R.; Raut, N. Performance of concrete structures under fire hazard: Emerging trends. Indian Concr. J. 2010, 84, 23–31. [Google Scholar]

- Kodur, V.; Hibner, D.; Agrawal, A. Residual response of reinforced concrete columns exposed to design fires. Procedia Eng. 2017, 210, 574–581. [Google Scholar]

- Wu, X.; Huang, T.; Au, F.T.K.; Li, J. A localized fire model for predicting the surface temperature of box girder bridges subjected to tanker truck fire. Fire Technol. 2020, 56, 2059–2087. [Google Scholar]

- Hurley, M.J.; Gottuk, D.T.; Hall, J.R., Jr.; Harada, K.; Kuligowski, E.D.; Puchovsky, M.; Torero, J.; Watts, J.M.; Wieczorek, C. SFPE Handbook of Fire Protection Engineering; Springer: Berlin/Heidelberg, Germany, 2015. [Google Scholar]

- EN 1992-1-2; Eurocode 2: Design of Concrete Structures—Part 1–2: General Rules—Structural Fire Design. The European Union: Brussels, Belgium, 2004.

- Alomari, Q.A. Structural Performance and Resiliency of Reinforced Concrete Bridge Pier Columns, Multi-Column Piers, and Bridge Systems Subjected to Multiple Hazards–Fire, Collision, and Air Blast. Ph.D. Thesis, The University of Nebraska-Lincoln, Lincoln, NE, USA, 2023. [Google Scholar]

- Mohan, P.; Marzougui, D.; Kan, C.D. Validation of a single unit truck model for roadside hardware impact. Int. J. Veh. Syst. Model. Test. 2007, 2, 1–15. [Google Scholar]

- Williamson, E.B. Blast-Resistant Highway Bridges: Design and Detailing Guidelines; Transportation Research Board: Washington, DC, USA, 2010; Volume 645. [Google Scholar]

- Chipley, M. Reference Manual to Mitigate Potential Terrorist Attacks Against Buildings: Providing Protection to People and Building; Federal Emergency Management Agency: Washington, DC, USA, 2003. [Google Scholar]

- Nam, J.-W.; Kim, H.-J.; Kim, S.-B.; Yi, N.-H.; Kim, J.-H.J. Numerical evaluation of the retrofit effectiveness for GFRP retrofitted concrete slab subjected to blast pressure. Compos. Struct. 2010, 92, 1212–1222. [Google Scholar]

- Sayed-Ahmed, E.Y. Numerical investigation into strengthening steel I-section beams using CFRP strips. In Proceedings of the Structures Congress 2006: Structural Engineering and Public Safety, St. Louis, MI, USA, 18–21 May 2006; pp. 1–8. [Google Scholar]

- Choi, S.-J.; Lee, S.-W.; Kim, J.-H.J. Impact or blast induced fire simulation of bi-directional PSC panel considering concrete confinement and spalling effect. Eng. Struct. 2017, 149, 113–130. [Google Scholar]

- Kim, J.H.; Kim, C.K.; Islam, M.S.; Park, S.I.; Paik, J.K. A study on methods for fire load application with passive fire protection effects. Ocean Eng. 2013, 70, 177–187. [Google Scholar]

- Auyeung, S.; Alipour, A.; Saini, D. Performance-based design of bridge piers under vehicle collision. Eng. Struct. 2019, 191, 752–765. [Google Scholar]

- Fujikake, K.; Li, B.; Soeun, S. Impact response of reinforced concrete beam and its analytical evaluation. J. Struct. Eng. 2009, 135, 938–950. [Google Scholar]

- Razaqpur, A.G.; Tolba, A.; Contestabile, E. Blast loading response of reinforced concrete panels reinforced with externally bonded GFRP laminates. Compos. Part B Eng. 2007, 38, 535–546. [Google Scholar]

- Fang, C. Structural Resilience and Hardening of Bridge Piers and Pier Columns Against Vehicle Collision and Blast Loads; The University of Nebraska–Lincoln: Lincoln, NE, USA, 2020. [Google Scholar]

- Linzell, D.G.; Fang, C.; Alomari, Q.A. Protecting Critical Civil Infrastructure Against Impact from Commercial Vehicles—Phase II; Mid-America Transportation Center, UNL: Lincoln, NE, USA, 2020. [Google Scholar]

- Wassef, W.G.; Smith, C.; Clancy, C.M.; Smith, M.J. Comprehensive Design Example for Prestressed Concrete (PSC) Girder Superstructure Bridge with Commentary (in SI Units); Federal Highway Administration: Washington, DC, USA, 2003. [Google Scholar]

- AASHTO. Manual for Condition Evaluation and Load and Resistance Factor Rating (LRFR) of Highway Bridges; American Association of State Highway and Transportation Officials: Washington, DC, USA, 2003. [Google Scholar]

- Fhwa, F.H. Recording and Coding Guide for the Structure Inventory and Appraisal of the Nation’s Bridges; Rep No FHWA-PD-96-001; Federal Highway Administration: Washington, DC, USA, 1995. [Google Scholar]

| Material | Parameters | |||

|---|---|---|---|---|

| Concrete | Mass Density | Compressive Strength | Max. Aggregate Size | |

| Steel | Mass Density | Elastic Modulus | Poisson’s Ratio | Yield Strength |

| 0.3 | ||||

| Parameter | Specific Gravity | Bulk Modulus | Shear Modulus | Friction Angle | Cohesion Coefficient |

|---|---|---|---|---|---|

| Value | 2.65 |

| Material | Air | Linear Polynomial EOS Parameter | ||

|---|---|---|---|---|

| Parameter | Mass Density | Eo. air | ||

| Value | 0 | |||

| Material | TNT Explosive | JWL EOS Parameter | |||||||

|---|---|---|---|---|---|---|---|---|---|

| Parameter | Mass Density | Detonation Velocity | Chapman–Jouget Pressure | ||||||

| Value | 371.2 | ||||||||

| Parameter | Mass Density | Poisson’s Ratio | Sheet Thickness | Long. Elastic Modulus | Trans. Elastic Modulus |

|---|---|---|---|---|---|

| Value | 0.021 | ||||

| Parameter | Long. Tensile Strength | Trans. Tensile Strength | Ultimate Tensile Strain | ||

| Value | |||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alomari, Q.A.; Linzell, D.G.; Abu Zouriq, M.F. Response of Bare and CFRP-Retrofitted Multi-Column Piers Under Post-Fire-Coupled Vehicle Collision and Air Blast. Materials 2025, 18, 1449. https://doi.org/10.3390/ma18071449

Alomari QA, Linzell DG, Abu Zouriq MF. Response of Bare and CFRP-Retrofitted Multi-Column Piers Under Post-Fire-Coupled Vehicle Collision and Air Blast. Materials. 2025; 18(7):1449. https://doi.org/10.3390/ma18071449

Chicago/Turabian StyleAlomari, Qusai A., Daniel G. Linzell, and Mubarak F. Abu Zouriq. 2025. "Response of Bare and CFRP-Retrofitted Multi-Column Piers Under Post-Fire-Coupled Vehicle Collision and Air Blast" Materials 18, no. 7: 1449. https://doi.org/10.3390/ma18071449

APA StyleAlomari, Q. A., Linzell, D. G., & Abu Zouriq, M. F. (2025). Response of Bare and CFRP-Retrofitted Multi-Column Piers Under Post-Fire-Coupled Vehicle Collision and Air Blast. Materials, 18(7), 1449. https://doi.org/10.3390/ma18071449